Rethinking Efficiency: How Increased Electricity Use Can Reduce Environmental Impacts in Controlled Hemp Cultivation—A Life Cycle Assessment (LCA) Study

Abstract

1. Introduction

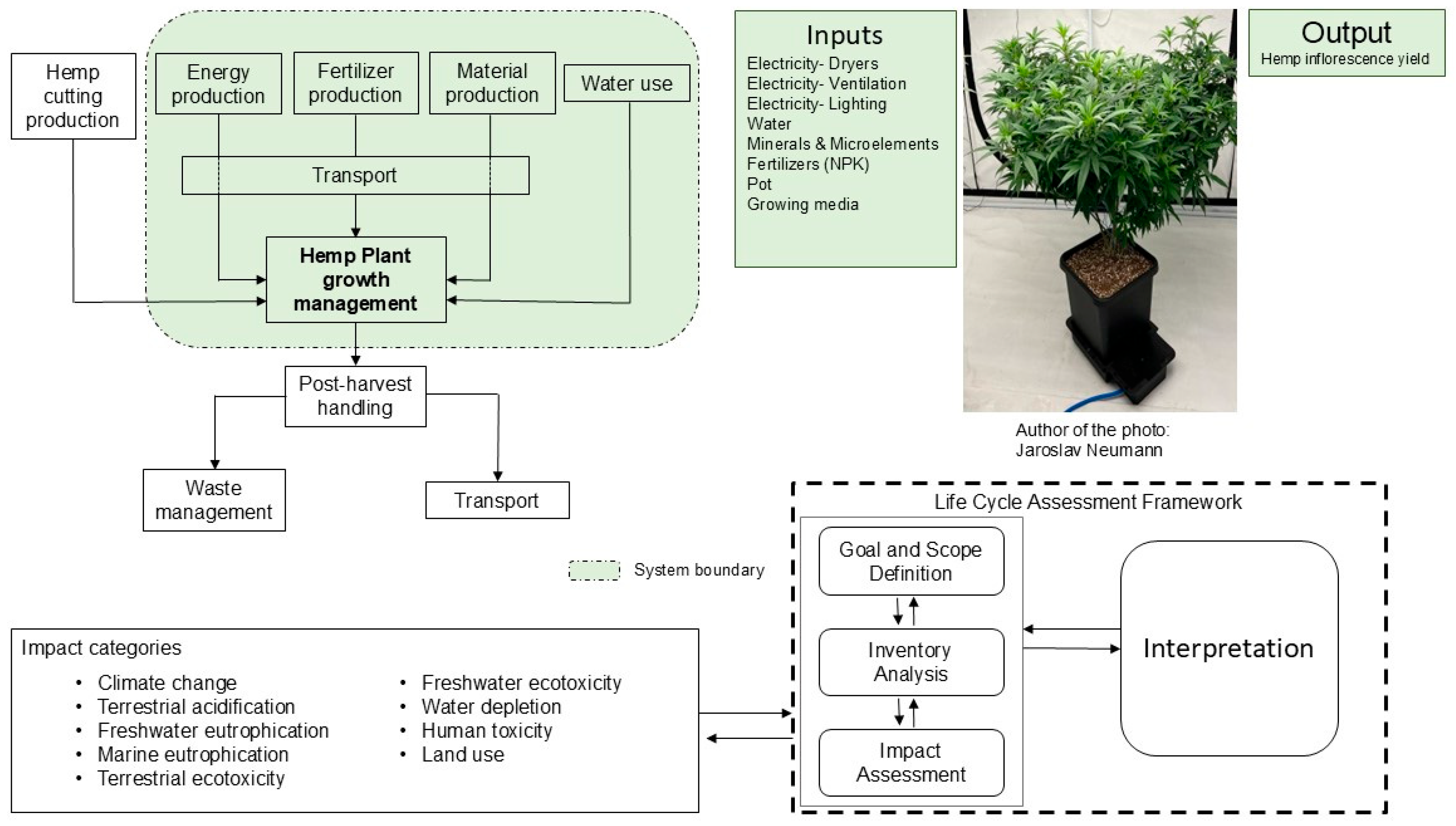

2. Materials and Methods

2.1. Goal and Scope Definition

2.2. Primary Data Collection (Hemp Cultivation)

- 360 W (≈300 µmol m−2 s−1 PPFD) under the first intensity setting (L1)

- 540 W (≈500 µmol m−2 s−1 PPFD) under the second, higher intensity setting (L2)

- 540 W (≈900 µmol m−2 s−1 PPFD) under the lower intensity setting (L1)

- 900 W (≈1300 µmol m−2 s−1 PPFD) under the higher intensity setting (L2)

- S1-L1

- S1-L2

- S2-L1

- S2-L2

2.3. Secondary Data

2.4. Impact Categories and Impact Assessment Method

3. Results

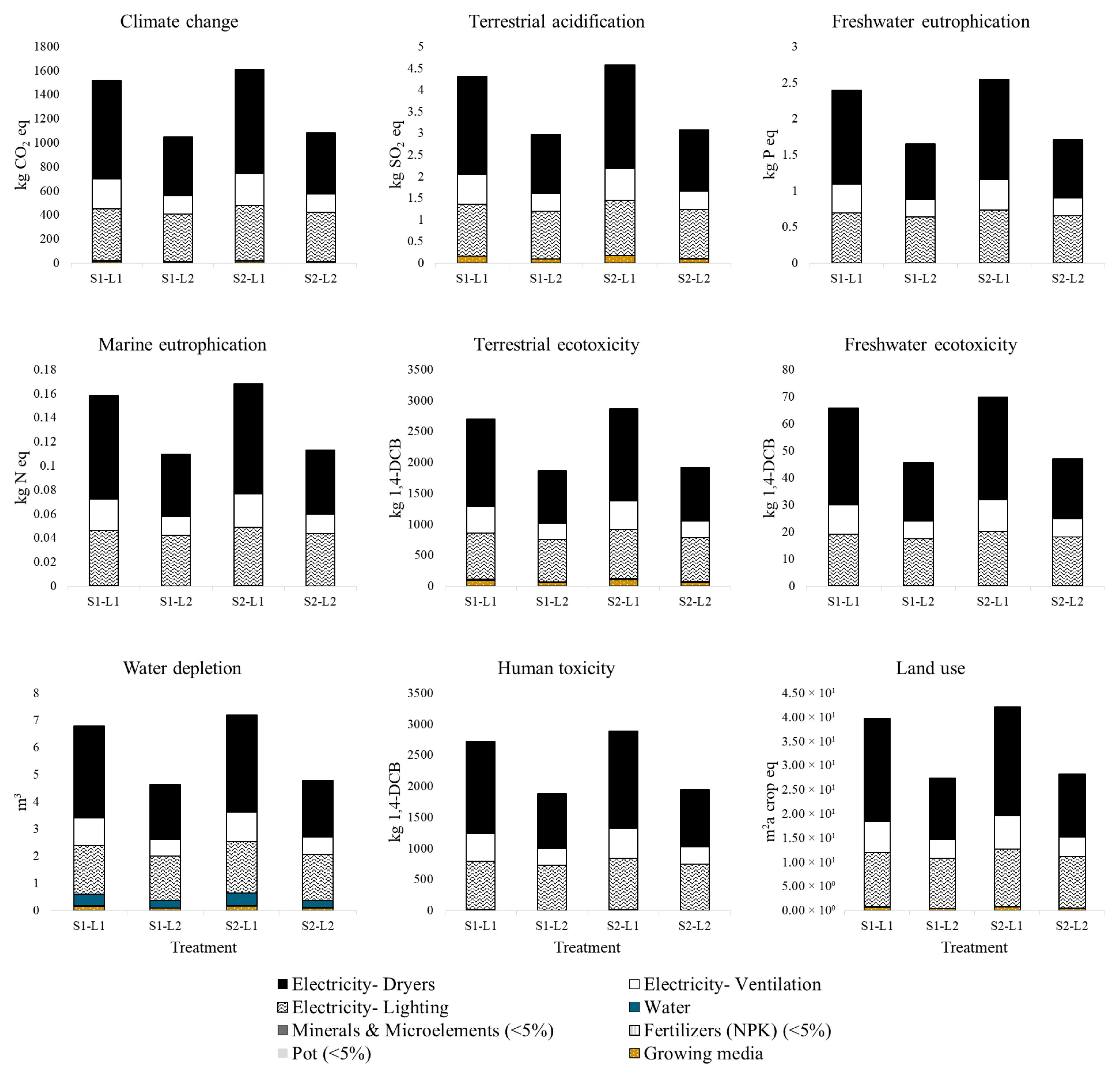

3.1. Environmental Impact per Cultivation Scenario

3.2. Contribution Analysis

3.2.1. Full System Aggregated Input Analysis

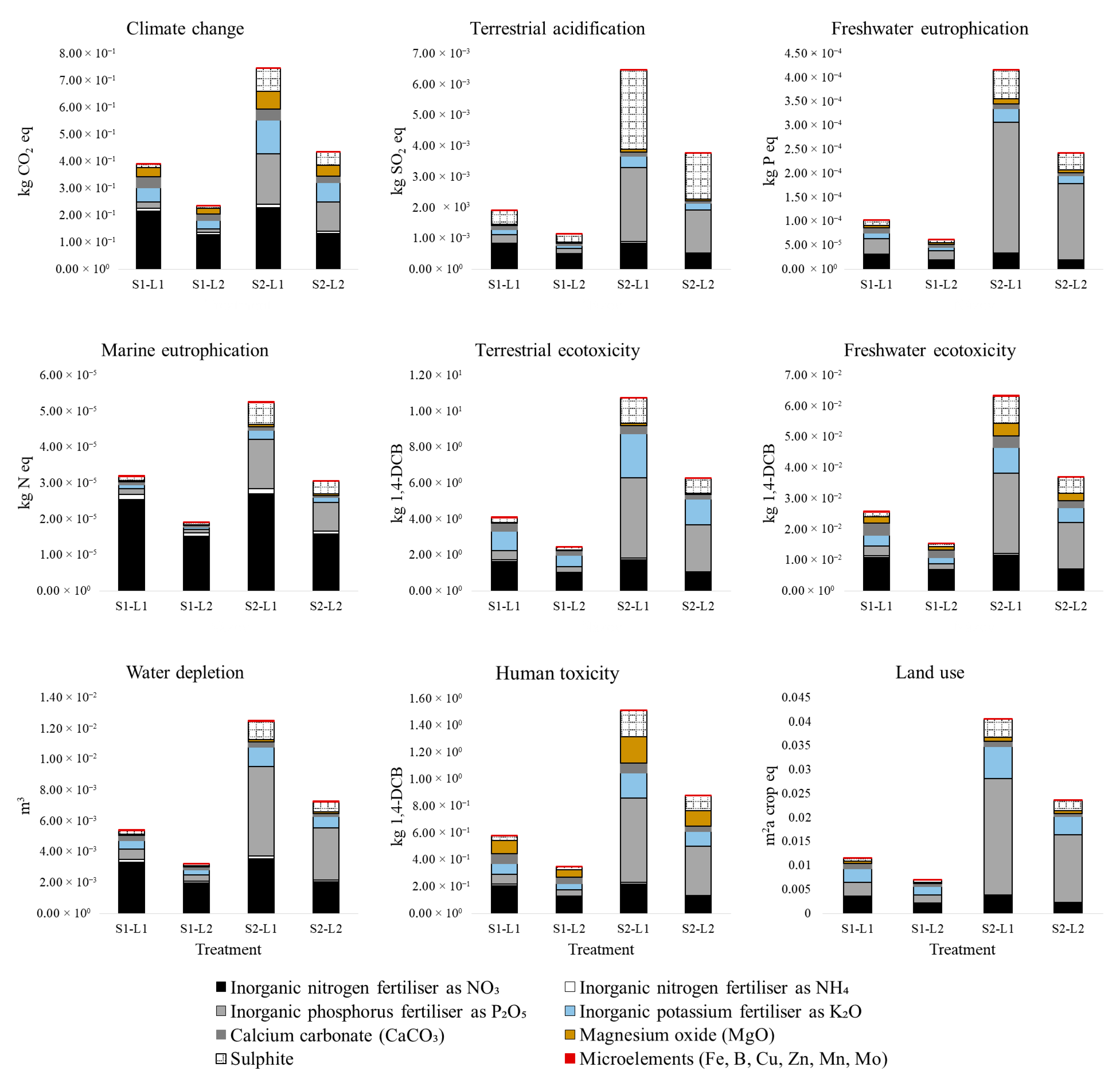

3.2.2. Fertilizer-Focused Contribution Analysis

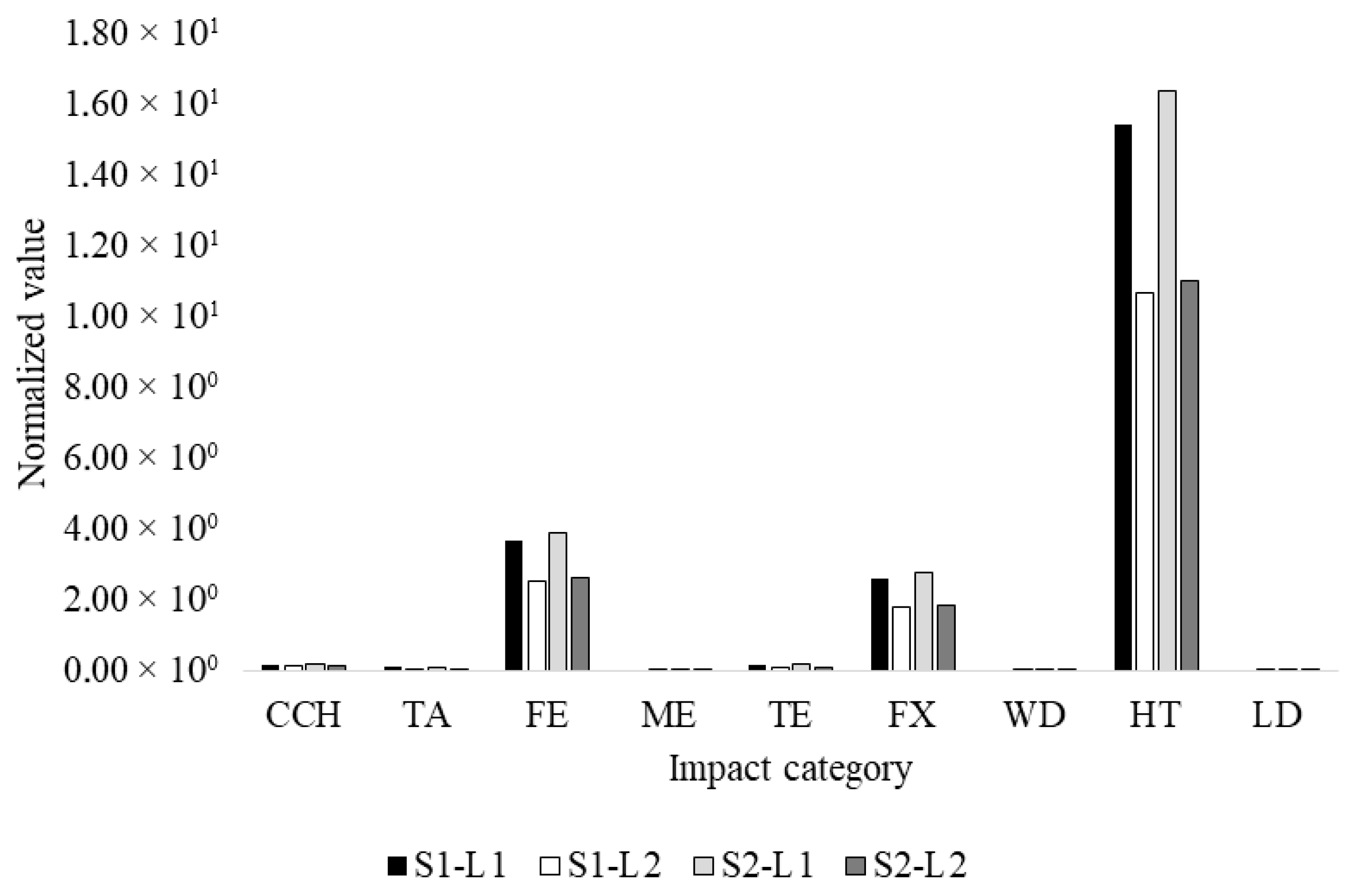

3.3. Normalization

3.4. Sensitivity Analysis

4. Discussion

4.1. Selection of the Functional Unit and Allocation Approach

4.2. Comparison with Previous Studies on the Environmental Impacts of Indoor Hemp Cultivation

4.3. Strategies for Sustainable Indoor Cultivation of Hemp

4.4. Environmental Implications of Fertilization Intensity and Nutrient Management

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| LCA | Life Cycle Assessment |

| FU | Functional unit |

| GHG | Greenhouse gas |

| NPK | Nitrogen (N), Phosphorus (P), and Potassium (K) fertilizers |

Appendix A

| Treatment | Mean | Median | SD | CV | 2.5% | 97.5% | SEM | |

|---|---|---|---|---|---|---|---|---|

| CCH | S1-L1 | 1.51 × 103 | 1.51 × 103 | 1.12 × 102 | 7.44 × 100 | 1.30 × 103 | 1.74 × 103 | 3.55 × 100 |

| S1-L2 | 1.05 × 103 | 1.05 × 103 | 8.20 × 101 | 7.80 × 100 | 9.06 × 102 | 1.23 × 103 | 2.59 × 100 | |

| S2-L1 | 1.61 × 103 | 1.60 × 103 | 1.17 × 102 | 7.32 × 100 | 1.39 × 103 | 1.86 × 103 | 3.71 × 100 | |

| S2-L2 | 1.09 × 103 | 1.09 × 103 | 8.18 × 101 | 7.53 × 100 | 9.27 × 102 | 1.25 × 103 | 2.59 × 100 | |

| TA | S1-L1 | 4.31 × 100 | 4.30 × 100 | 2.77 × 10−1 | 6.42 × 100 | 3.80 × 100 | 4.92 × 100 | 8.75 × 10−3 |

| S1-L2 | 2.97 × 100 | 2.96 × 100 | 1.93 × 10−1 | 6.48 × 100 | 2.63 × 100 | 3.38 × 100 | 6.09 × 10−3 | |

| S2-L1 | 4.58 × 100 | 4.57 × 100 | 2.95 × 10−1 | 6.44 × 100 | 4.02 × 100 | 5.19 × 100 | 9.33 × 10−3 | |

| S2-L2 | 3.07 × 100 | 3.06 × 100 | 1.98 × 10−1 | 6.45 × 100 | 2.70 × 100 | 3.47 × 100 | 6.26 × 10−3 | |

| FE | S1-L1 | 2.43 × 100 | 1.89 × 100 | 1.90 × 100 | 7.84 × 101 | 5.78 × 10−1 | 7.33 × 100 | 6.01 × 10−2 |

| S1-L2 | 1.70 × 100 | 1.32 × 100 | 1.48 × 100 | 8.70 × 101 | 4.14 × 10−1 | 5.43 × 100 | 4.67 × 10−2 | |

| S2-L1 | 2.52 × 100 | 1.92 × 100 | 2.17 × 100 | 8.62 × 101 | 6.07 × 10−1 | 8.49 × 100 | 6.86 × 10−2 | |

| S2-L2 | 1.72 × 100 | 1.33 × 100 | 1.51 × 100 | 8.76 × 101 | 4.08 × 10−1 | 5.49 × 100 | 4.76 × 10−2 | |

| ME | S1-L1 | 1.57 × 10−1 | 1.53 × 10−1 | 3.43 × 10−2 | 2.18 × 101 | 1.01 × 10−1 | 2.34 × 10−1 | 1.08 × 10−3 |

| S1-L2 | 1.10 × 10−1 | 1.07 × 10−1 | 2.46 × 10−2 | 2.23 × 101 | 7.19 × 10−2 | 1.66 × 10−1 | 7.78 × 10−4 | |

| S2-L1 | 1.69 × 10−1 | 1.64 × 10−1 | 3.77 × 10−2 | 2.23 × 101 | 1.10 × 10−1 | 2.62 × 10−1 | 1.19 × 10−3 | |

| S2-L2 | 1.13 × 10−1 | 1.11 × 10−1 | 2.40 × 10−2 | 2.13 × 101 | 7.17 × 10−2 | 1.62 × 10−1 | 7.58 × 10−4 | |

| TE | S1-L1 | 2.80 × 103 | 2.43 × 103 | 1.45 × 103 | 5.17 × 101 | 1.29 × 103 | 6.34 × 103 | 4.58 × 101 |

| S1-L2 | 1.85 × 103 | 1.62 × 103 | 8.78 × 102 | 4.74 × 101 | 8.77 × 102 | 4.09 × 103 | 2.78 × 101 | |

| S2-L1 | 2.97 × 103 | 2.63 × 103 | 1.48 × 103 | 5.00 × 101 | 1.37 × 103 | 6.84 × 103 | 4.69 × 101 | |

| S2-L2 | 1.90 × 103 | 1.69 × 103 | 8.52 × 102 | 4.49 × 101 | 9.18 × 102 | 4.44 × 103 | 2.69 × 101 | |

| FX | S1-L1 | 6.74 × 101 | 4.83 × 101 | 7.28 × 101 | 1.08 × 102 | 2.30 × 101 | 2.30 × 102 | 2.30 × 100 |

| S1-L2 | 4.77 × 101 | 3.51 × 101 | 5.25 × 101 | 1.10 × 102 | 1.55 × 101 | 1.60 × 102 | 1.66 × 100 | |

| S2-L1 | 7.24 × 101 | 5.27 × 101 | 7.71 × 101 | 1.07 × 102 | 2.49 × 101 | 2.57 × 102 | 2.44 × 100 | |

| S2-L2 | 4.80 × 101 | 3.53 × 101 | 4.12 × 101 | 8.57 × 101 | 1.73 × 101 | 1.65 × 102 | 1.30 × 100 | |

| WD | S1-L1 | 4.12 × 101 | 1.50 × 102 | 1.31 × 103 | 3.18 × 103 | −2.91 × 103 | 2.33 × 103 | 4.14 × 101 |

| S1-L2 | −1.21 × 101 | 7.65 × 101 | 9.44 × 102 | −7.81 × 103 | −2.02 × 103 | 1.58 × 103 | 2.98 × 101 | |

| S2-L1 | 7.67 × 101 | 1.72 × 102 | 1.30 × 103 | 1.70 × 103 | −2.81 × 103 | 2.42 × 103 | 4.11 × 101 | |

| S2-L2 | −2.83 × 100 | 1.70 × 102 | 9.88 × 102 | −3.49 × 104 | −2.51 × 103 | 1.62 × 103 | 3.12 × 101 | |

| HT | S1-L1 | 1.39 × 103 | 9.94 × 102 | 2.60 × 103 | 1.86 × 102 | 1.28 × 103 | 1.51 × 103 | 5.81 × 101 |

| S1-L2 | 9.78 × 102 | 7.11 × 102 | 1.83 × 103 | 1.88 × 102 | 8.98 × 102 | 1.06 × 103 | 4.10 × 101 | |

| S2-L1 | 1.52 × 103 | 1.09 × 103 | 2.91 × 103 | 1.91 × 102 | 1.39 × 103 | 1.65 × 103 | 6.50 × 101 | |

| S2-L2 | 9.80 × 102 | 7.14 × 102 | 1.64 × 103 | 1.67 × 102 | 9.08 × 102 | 1.05 × 103 | 3.66 × 101 | |

| LD | S1-L1 | 3.86 × 101 | 3.88 × 101 | 2.04 × 101 | 5.29 × 101 | −5.51 × 100 | 7.97 × 101 | 6.46 × 10−1 |

| S1-L2 | 2.68 × 101 | 2.67 × 101 | 1.43 × 101 | 5.35 × 101 | −3.08 × 100 | 5.55 × 101 | 4.53 × 10−1 | |

| S2-L1 | 4.20 × 101 | 4.25 × 101 | 2.07 × 101 | 4.94 × 101 | −2.63 × 100 | 8.26 × 101 | 6.56 × 10−1 | |

| S2-L2 | 2.75 × 101 | 2.73 × 101 | 1.50 × 101 | 5.45 × 101 | −2.49 × 100 | 5.57 × 101 | 4.75 × 10−1 |

| Impact Category | Treatment | Growing Media | Flowerpot-1 Year Amortization | Fertilizers (NPK) | Minerals & Microelements | Tap Water | Electricity-Lighting | Electricity-Ventilation | Electricity-Dryers |

|---|---|---|---|---|---|---|---|---|---|

| CCH | S1-L1 | 1.6 × 101 | 1.1 × 100 | 3.0 × 10−1 | 8.9 × 10−2 | 1.3 × 10−1 | 4.3 × 102 | 2.5 × 102 | 8.2 × 102 |

| S1-L2 | 9.9 × 100 | 6.3 × 10−1 | 1.8 × 10−1 | 5.3 × 10−2 | 7.9 × 10−2 | 4.0 × 102 | 1.5 × 102 | 4.9 × 102 | |

| S2-L1 | 1.8 × 101 | 1.1 × 100 | 5.5 × 10−1 | 1.9 × 10−1 | 1.4 × 10−1 | 4.6 × 102 | 2.7 × 102 | 8.7 × 102 | |

| S2-L2 | 1.0 × 101 | 6.5 × 10−1 | 3.2 × 10−1 | 1.1 × 10−1 | 8.2 × 10−2 | 4.1 × 102 | 1.5 × 102 | 5.1 × 102 | |

| TA | S1-L1 | 1.6 × 10−1 | 3.2 × 10−3 | 1.3 × 10−3 | 6.3 × 10−4 | 4.7 × 10−4 | 1.2 × 100 | 6.9 × 10−1 | 2.3 × 100 |

| S1-L2 | 9.6 × 10−2 | 1.9 × 10−3 | 7.7 × 10−4 | 3.8 × 10−4 | 2.8 × 10−4 | 1.1 × 100 | 4.2 × 10−1 | 1.4 × 100 | |

| S2-L1 | 1.7 × 10−1 | 3.3 × 10−3 | 3.7 × 10−3 | 2.8 × 10−3 | 5.0 × 10−4 | 1.3 × 100 | 7.4 × 10−1 | 2.4 × 100 | |

| S2-L2 | 9.9 × 10−2 | 2.0 × 10−3 | 2.1 × 10−3 | 1.6 × 10−3 | 2.9 × 10−4 | 1.1 × 100 | 4.3 × 10−1 | 1.4 × 100 | |

| FE | S1-L1 | 2.7 × 10−3 | 2.7 × 10−4 | 7.6 × 10−5 | 2.6 × 10−5 | 8.8 × 10−5 | 6.9 × 10−1 | 4.0 × 10−1 | 1.3 × 100 |

| S1-L2 | 2.1 × 10−4 | 1.6 × 10−4 | 4.6 × 10−5 | 1.6 × 10−5 | 5.3 × 10−5 | 6.4 × 10−1 | 2.4 × 10−1 | 7.8 × 10−1 | |

| S2-L1 | 2.8 × 10−3 | 2.9 × 10−4 | 3.3 × 10−4 | 8.1 × 10−5 | 9.3 × 10−5 | 7.3 × 10−1 | 4.2 × 10−1 | 1.4 × 100 | |

| S2-L2 | 1.7 × 10−3 | 1.7 × 10−4 | 2.0 × 10−4 | 4.7 × 10−5 | 5.4 × 10−5 | 6.6 × 10−1 | 2.5 × 10−1 | 8.1 × 10−1 | |

| ME | S1-L1 | 3.5 × 10−4 | 2.3 × 10−5 | 3.0 × 10−5 | 2.5 × 10−6 | 8.6 × 10−6 | 4.6 × 10−2 | 2.6 × 10−2 | 8.6 × 10−2 |

| S1-L2 | 2.1 × 10−4 | 1.4 × 10−5 | 1.8 × 10−5 | 1.5 × 10−6 | 5.2 × 10−6 | 4.2 × 10−2 | 1.6 × 10−2 | 5.2 × 10−2 | |

| S2-L1 | 3.7 × 10−4 | 2.4 × 10−5 | 4.5 × 10−5 | 7.9 × 10−6 | 9.1 × 10−6 | 4.8 × 10−2 | 2.8 × 10−2 | 9.1 × 10−2 | |

| S2-L2 | 2.2 × 10−4 | 1.4 × 10−5 | 2.6 × 10−5 | 4.6 × 10−6 | 5.3 × 10−6 | 4.3 × 10−2 | 1.6 × 10−2 | 5.3 × 10−2 | |

| TE | S1-L1 | 9.7 × 101 | 7.7 × 10−1 | 3.3 × 100 | 8.0 × 10−1 | 9.4 × 100 | 7.5 × 102 | 4.3 × 102 | 1.4 × 103 |

| S1-L2 | 5.8 × 101 | 4.6 × 10−1 | 2.0 × 100 | 4.8 × 10−1 | 5.6 × 100 | 6.9 × 102 | 2.6 × 102 | 8.5 × 102 | |

| S2-L1 | 1.0 × 102 | 8.2 × 10−1 | 8.8 × 100 | 2.0 × 100 | 9.9 × 100 | 7.9 × 102 | 4.6 × 102 | 1.5 × 103 | |

| S2-L2 | 6.0 × 101 | 4.8 × 10−1 | 5.1 × 100 | 1.2 × 100 | 5.8 × 100 | 7.1 × 102 | 2.7 × 102 | 8.7 × 102 | |

| FX | S1-L1 | 2.6 × 10−1 | 1.2 × 10−2 | 1.8 × 10−2 | 7.7 × 10−3 | 1.1 × 10−2 | 1.9 × 101 | 1.1 × 101 | 3.6 × 101 |

| S1-L2 | 1.5 × 10−1 | 6.7 × 10−3 | 1.1 × 10−2 | 4.6 × 10−3 | 6.5 × 10−3 | 1.7 × 101 | 6.6 × 100 | 2.1 × 101 | |

| S2-L1 | 2.7 × 10−1 | 1.3 × 10−2 | 4.7 × 10−2 | 1.7 × 10−2 | 1.2 × 10−2 | 2.0 × 101 | 1.2 × 101 | 3.8 × 101 | |

| S2-L2 | 1.6 × 10−1 | 7.4 × 10−3 | 2.7 × 10−2 | 9.9 × 10−3 | 6.7 × 10−3 | 1.8 × 101 | 6.8 × 100 | 2.2 × 101 | |

| WD | S1-L1 | 1.5 × 10−1 | 1.1 × 10−2 | 4.7 × 10−3 | 7.1 × 10−4 | 4.3 × 10−1 | 1.8 × 100 | 1.0 × 100 | 3.4 × 100 |

| S1-L2 | 9.2 × 10−2 | 6.5 × 10−3 | 2.8 × 10−3 | 4.2 × 10−4 | 2.6 × 10−1 | 1.6 × 100 | 6.2 × 10−1 | 2.0 × 100 | |

| S2-L1 | 1.6 × 10−1 | 1.1 × 10−2 | 1.1 × 10−2 | 1.7 × 10−3 | 4.6 × 10−1 | 1.9 × 100 | 1.1 × 100 | 3.6 × 100 | |

| S2-L2 | 9.5 × 10−2 | 6.7 × 10−3 | 6.3 × 10−3 | 1.0 × 10−3 | 2.7 × 10−1 | 1.7 × 100 | 6.4 × 10−1 | 2.1 × 100 | |

| HT | S1-L1 | 6.8 × 100 | 4.4 × 10−1 | 3.7 × 10−1 | 2.1 × 10−1 | 5.8 × 10−1 | 7.8 × 102 | 4.5 × 102 | 1.5 × 103 |

| S1-L2 | 4.1 × 100 | 2.6 × 10−1 | 2.2 × 10−1 | 1.3 × 10−1 | 3.5 × 10−1 | 7.2 × 102 | 2.7 × 102 | 8.9 × 102 | |

| S2-L1 | 7.2 × 100 | 4.6 × 10−1 | 1.0 × 100 | 4.7 × 10−1 | 6.2 × 10−1 | 8.3 × 102 | 4.8 × 102 | 1.6 × 103 | |

| S2-L2 | 4.2 × 100 | 2.7 × 10−1 | 6.1 × 10−1 | 2.7 × 10−1 | 3.6 × 10−1 | 7.4 × 102 | 2.8 × 102 | 9.1 × 102 | |

| LD | S1-L1 | 6.8 × 10−1 | 3.0 × 10−2 | 9.4 × 10−3 | 2.2 × 10−3 | 4.7 × 10−3 | 1.1 × 101 | 6.5 × 100 | 2.1 × 101 |

| S1-L2 | 4.1 × 10−1 | 1.8 × 10−2 | 5.6 × 10−3 | 1.3 × 10−3 | 2.8 × 10−3 | 1.0 × 101 | 3.9 × 100 | 1.3 × 101 | |

| S2-L1 | 7.3 × 10−1 | 3.2 × 10−2 | 3.5 × 10−2 | 5.8 × 10−3 | 5.0 × 10−3 | 1.2 × 101 | 6.9 × 100 | 2.2 × 101 | |

| S2-L2 | 4.2 × 10−1 | 1.9 × 10−2 | 2.0 × 10−2 | 3.4 × 10−3 | 2.9 × 10−3 | 1.1 × 101 | 4.0 × 100 | 1.3 × 101 |

| Impact Category | Treatment | Total | Inorganic Nitrogen Fertilizer as NO3 | Inorganic Nitrogen Fertilizer as NH4 | Inorganic Phosphorus Fertilizer as P2O5 | Inorganic Potassium Fertilizer as K2O | Calcium Carbonate (CaCO3) | Magnesium Oxide (MgO) | Sulphite | Microelements (Fe, B, Cu, Zn, Mn, Mo) |

|---|---|---|---|---|---|---|---|---|---|---|

| CCH | S1-L1 | 3.92 × 10−1 | 2.15 × 10−1 | 1.15 × 10−2 | 2.22 × 10−2 | 5.43 × 10−2 | 4.00 × 10−2 | 3.26 × 10−2 | 1.46 × 10−2 | 1.43 × 10−3 |

| S1-L2 | 2.35 × 10−1 | 1.29 × 10−1 | 6.90 × 10−3 | 1.33 × 10−2 | 3.25 × 10−2 | 2.39 × 10−2 | 1.95 × 10−2 | 8.75 × 10−3 | 8.55 × 10−4 | |

| S2-L1 | 7.46 × 10−1 | 2.29 × 10−1 | 1.22 × 10−2 | 1.87 × 10−1 | 1.26 × 10−1 | 3.98 × 10−2 | 6.69 × 10−2 | 8.41 × 10−2 | 1.31 × 10−3 | |

| S2-L2 | 4.35 × 10−1 | 1.33 × 10−1 | 7.12 × 10−3 | 1.09 × 10−1 | 7.31 × 10−2 | 2.32 × 10−2 | 3.90 × 10−2 | 4.90 × 10−2 | 7.65 × 10−4 | |

| TA | S1-L1 | 1.92 × 10−3 | 7.96 × 10−4 | 4.26 × 10−5 | 2.84 × 10−4 | 1.63 × 10−4 | 1.32 × 10−4 | 4.55 × 10−5 | 4.46 × 10−4 | 7.80 × 10−6 |

| S1-L2 | 2.97 × 100 | 4.77 × 10−4 | 2.55 × 10−5 | 1.70 × 10−4 | 9.78 × 10−5 | 7.89 × 10−5 | 2.73 × 10−5 | 2.67 × 10−4 | 4.67 × 10−6 | |

| S2-L1 | 6.46 × 10−3 | 8.45 × 10−4 | 4.52 × 10−5 | 2.40 × 10−3 | 3.77 × 10−4 | 1.31 × 10−4 | 9.35 × 10−5 | 2.56 × 10−3 | 7.18 × 10−6 | |

| S2-L2 | 3.77 × 10−3 | 4.92 × 10−4 | 2.63 × 10−5 | 1.40 × 10−3 | 2.20 × 10−4 | 7.65 × 10−5 | 5.45 × 10−5 | 1.49 × 10−3 | 4.18 × 10−6 | |

| FE | S1-L1 | 1.02 × 10−4 | 2.99 × 10−5 | 1.60 × 10−6 | 3.24 × 10−5 | 1.21 × 10−5 | 1.04 × 10−5 | 4.97 × 10−6 | 1.04 × 10−5 | 5.31 × 10−7 |

| S1-L2 | 1.66 × 100 | 1.79 × 10−5 | 9.57 × 10−7 | 1.94 × 10−5 | 7.27 × 10−6 | 6.25 × 10−6 | 2.98 × 10−6 | 6.20 × 10−6 | 3.18 × 10−7 | |

| S2-L1 | 4.15 × 10−4 | 3.17 × 10−5 | 1.69 × 10−6 | 2.73 × 10−4 | 2.80 × 10−5 | 1.04 × 10−5 | 1.02 × 10−5 | 5.96 × 10−5 | 4.89 × 10−7 | |

| S2-L2 | 2.42 × 10−4 | 1.85 × 10−5 | 9.87 × 10−7 | 1.59 × 10−4 | 1.63 × 10−5 | 6.06 × 10−6 | 5.95 × 10−6 | 3.47 × 10−5 | 2.85 × 10−7 | |

| ME | S1-L1 | 3.21 × 10−5 | 2.55 × 10−5 | 1.36 × 10−6 | 1.63 × 10−6 | 1.11 × 10−6 | 8.36 × 10−7 | 3.11 × 10−7 | 1.06 × 10−6 | 3.33 × 10−7 |

| S1-L2 | 1.10 × 10−1 | 1.53 × 10−5 | 8.16 × 10−7 | 9.75 × 10−7 | 6.65 × 10−7 | 5.01 × 10−7 | 1.87 × 10−7 | 6.32 × 10−7 | 2.00 × 10−7 | |

| S2-L1 | 5.26 × 10−5 | 2.70 × 10−5 | 1.45 × 10−6 | 1.37 × 10−5 | 2.56 × 10−6 | 8.33 × 10−7 | 6.39 × 10−7 | 6.07 × 10−6 | 3.07 × 10−7 | |

| S2-L2 | 3.07 × 10−5 | 1.58 × 10−5 | 8.43 × 10−7 | 8.00 × 10−6 | 1.49 × 10−6 | 4.85 × 10−7 | 3.73 × 10−7 | 3.54 × 10−6 | 1.79 × 10−7 | |

| TE | S1-L1 | 4.12 × 100 | 1.63 × 100 | 8.74 × 10−2 | 5.30 × 10−1 | 1.07 × 100 | 4.44 × 10−1 | 5.31 × 10−2 | 2.44 × 10−1 | 5.82 × 10−2 |

| S1-L2 | 1.86 × 103 | 9.78 × 10−1 | 5.23 × 10−2 | 3.17 × 10−1 | 6.40 × 10−1 | 2.66 × 10−1 | 3.18 × 10−2 | 1.46 × 10−1 | 3.49 × 10−2 | |

| S2-L1 | 1.08 × 101 | 1.73 × 100 | 9.27 × 10−2 | 4.47 × 100 | 2.47 × 100 | 4.42 × 10−1 | 1.09 × 10−1 | 1.40 × 100 | 5.36 × 10−2 | |

| S2-L2 | 6.28 × 100 | 1.01 × 100 | 5.40 × 10−2 | 2.61 × 100 | 1.44 × 100 | 2.58 × 10−1 | 6.35 × 10−2 | 8.19 × 10−1 | 3.12 × 10−2 | |

| FX | S1-L1 | 259 × 10−2 | 1.09 × 10−2 | 5.83 × 10−4 | 3.08 × 10−3 | 3.62 × 10−3 | 3.86 × 10−3 | 1.96 × 10−3 | 1.53 × 10−3 | 3.27 × 10−4 |

| S1-L2 | 4.55 × 101 | 6.53 × 10−3 | 3.49 × 10−4 | 1.84 × 10−3 | 2.17 × 10−3 | 2.31 × 10−3 | 1.18 × 10−3 | 9.14 × 10−4 | 1.96 × 10−4 | |

| S2-L1 | 6.35 × 10−2 | 1.16 × 10−2 | 6.19 × 10−4 | 2.60 × 10−2 | 8.36 × 10−3 | 3.85 × 10−3 | 4.03 × 10−3 | 8.78 × 10−3 | 3.01 × 10−4 | |

| S2-L2 | 3.70 × 10−2 | 6.74 × 10−3 | 3.60 × 10−4 | 1.51 × 10−2 | 4.87 × 10−3 | 2.24 × 10−3 | 2.35 × 10−3 | 5.12 × 10−3 | 1.75 × 10−4 | |

| WD | S1-L1 | 5.44 × 10−3 | 3.32 × 10−3 | 1.78 × 10−4 | 6.89 × 10−4 | 5.44 × 10−4 | 3.38 × 10−4 | 8.60 × 10−5 | 1.96 × 10−4 | 8.85 × 10−5 |

| S1-L2 | 4.64 × 100 | 1.99 × 10−3 | 1.06 × 10−4 | 4.13 × 10−4 | 3.26 × 10−4 | 2.02 × 10−4 | 5.15 × 10−5 | 1.17 × 10−4 | 5.30 × 10−5 | |

| S2-L1 | 1.25 × 10−2 | 3.53 × 10−3 | 1.89 × 10−4 | 5.81 × 10−3 | 1.26 × 10−3 | 3.36 × 10−4 | 1.77 × 10−4 | 1.13 × 10−3 | 8.15 × 10−5 | |

| S2-L2 | 7.29 × 10−3 | 2.06 × 10−3 | 1.10 × 10−4 | 3.39 × 10−3 | 7.32 × 10−4 | 1.96 × 10−4 | 1.03 × 10−4 | 6.56 × 10−4 | 4.75 × 10−5 | |

| HT | S1-L1 | 5.84 × 10−1 | 2.07 × 10−1 | 1.11 × 10−2 | 7.43 × 10−2 | 8.16 × 10−2 | 7.30 × 10−2 | 9.55 × 10−2 | 3.36 × 10−2 | 7.73 × 10−3 |

| S1-L2 | 1.88 × 103 | 1.24 × 10−1 | 6.64 × 10−3 | 4.45 × 10−2 | 4.89 × 10−2 | 4.37 × 10−2 | 5.72 × 10−2 | 2.01 × 10−2 | 4.63 × 10−3 | |

| S2-L1 | 1.52 × 100 | 2.20 × 10−1 | 1.18 × 10−2 | 6.27 × 10−1 | 1.89 × 10−1 | 7.27 × 10−2 | 1.96 × 10−1 | 1.93 × 10−1 | 7.11 × 10−3 | |

| S2-L2 | 8.83 × 10−1 | 1.28 × 10−1 | 6.86 × 10−3 | 3.65 × 10−1 | 1.10 × 10−1 | 4.24 × 10−2 | 1.14 × 10−1 | 1.13 × 10−1 | 4.14 × 10−3 | |

| LD | S1-L1 | 3.43 × 10−3 | 1.83 × 10−4 | 2.88 × 10−3 | 2.90 × 10−3 | 1.06 × 10−3 | 4.35 × 10−4 | 6.54 × 10−4 | 3.13 × 10−5 | 3.43 × 10−3 |

| S1-L2 | 2.05 × 10−3 | 1.10 × 10−4 | 1.72 × 10−3 | 1.74 × 10−3 | 6.37 × 10−4 | 2.61 × 10−4 | 3.92 × 10−4 | 1.88 × 10−5 | 2.05 × 10−3 | |

| S2-L1 | 3.64 × 10−3 | 1.94 × 10−4 | 2.43 × 10−2 | 6.70 × 10−3 | 1.06 × 10−3 | 8.94 × 10−4 | 3.76 × 10−3 | 2.88 × 10−5 | 3.64 × 10−3 | |

| S2-L2 | 2.12 × 10−3 | 1.13 × 10−4 | 1.41 × 10−2 | 3.90 × 10−3 | 6.17 × 10−4 | 5.21 × 10−4 | 2.19 × 10−3 | 1.68 × 10−5 | 2.12 × 10−3 |

| Impact Category | S1-L1 | S1-L2 | S2-L1 | S2-L2 |

|---|---|---|---|---|

| CCH | 1.90 × 10−1 | 1.31 × 10−1 | 2.01 × 10−1 | 1.35 × 10−1 |

| TA | 1.05 × 10−1 | 7.25 × 10−2 | 1.12 × 10−1 | 7.49 × 10−2 |

| FE | 3.69 × 100 | 2.55 × 100 | 3.92 × 100 | 2.64 × 100 |

| ME | 3.44 × 10−2 | 2.38 × 10−2 | 3.65 × 10−2 | 2.46 × 10−2 |

| TE | 1.78 × 10−1 | 1.22 × 10−1 | 1.89 × 10−1 | 1.27 × 10−1 |

| FX | 2.61 × 100 | 1.81 × 100 | 2.77 × 100 | 1.86 × 100 |

| WD | 2.54 × 10−2 | 1.74 × 10−2 | 2.70 × 10−2 | 1.80 × 10−2 |

| HT | 1.54 × 101 | 1.07 × 101 | 1.64 × 101 | 1.10 × 101 |

| LD | 6.44 × 10−3 | 4.44 × 10−3 | 6.83 × 10−3 | 4.59 × 10−3 |

| Treatment | Baseline (CZ 2022) | Lignite | Nuclear | Renewables |

|---|---|---|---|---|

| S1-L1 | 4.17 × 101 | 8.87 × 101 | 2.96 × 101 | 3.46 × 101 |

| S1-L2 | 2.88 × 101 | 6.13 × 101 | 2.04 × 101 | 2.39 × 101 |

| S2-L1 | 4.43 × 101 | 9.42 × 101 | 3.14 × 101 | 3.68 × 101 |

| S2-L2 | 2.97 × 101 | 6.33 × 101 | 2.10 × 101 | 2.47 × 101 |

References

- Jami, T.; Rawtani, D.; Agrawal, Y.K. Hemp Concrete: Carbon-Negative Construction. Emerg. Mater. Res. 2016, 5, 240–247. [Google Scholar] [CrossRef]

- Crini, G.; Lichtfouse, E.; Chanet, G.; Morin-Crini, N. Applications of Hemp in Textiles, Paper Industry, Insulation and Building Materials, Horticulture, Animal Nutrition, Food and Beverages, Nutraceuticals, Cosmetics and Hygiene, Medicine, Agrochemistry, Energy Production and Environment: A Review. Environ. Chem. Lett. 2020, 18, 1451–1476. [Google Scholar] [CrossRef]

- Yano, H.; Fu, W. Hemp: A Sustainable Plant with High Industrial Value in Food Processing. Foods 2023, 12, 651. [Google Scholar] [CrossRef] [PubMed]

- Zimniewska, M. Hemp Fibre Properties and Processing Target Textile: A Review. Materials 2022, 15, 1901. [Google Scholar] [CrossRef]

- European Commission Hemp—Crop Production and Plant-Based Products 2025. Available online: https://agriculture.ec.europa.eu/farming/crop-productions-and-plant-based-products/hemp_en (accessed on 16 July 2025).

- Fischer, B.; Hall, W. Germany’s Evolving Framework for Cannabis Legalization and Regulation: Select Comments Based on Science and Policy Experiences for Public Health. Lancet Reg. Health Eur. 2022, 23, 100546. [Google Scholar] [CrossRef]

- Mirpoor, S.F.; Ibáñez-Ibáñez, P.F.; Giosafatto, C.V.L.; Del Castillo-Santaella, T.; Rodríguez-Valverde, M.A.; Maldonado-Valderrama, J. Surface Activity of Protein Extracts from Seed Oil By-Products and Wettability of Developed Bioplastics. Food Hydrocoll. 2023, 145, 109091. [Google Scholar] [CrossRef]

- Rheay, H.T.; Omondi, E.C.; Brewer, C.E. Potential of Hemp (Cannabis sativa L.) for Paired Phytoremediation and Bioenergy Production. GCB Bioenergy 2021, 13, 525–536. [Google Scholar] [CrossRef]

- Milan, J.; Michalska, A.; Jurowski, K. The Comprehensive Review about Elements Accumulation in Industrial Hemp (Cannabis sativa L.). Food Chem. Toxicol. 2024, 184, 114344. [Google Scholar] [CrossRef]

- Padmavathiamma, P.K.; Li, L.Y. Phytoremediation Technology: Hyper-Accumulation Metals in Plants. Water Air Soil Pollut. 2007, 184, 105–126. [Google Scholar] [CrossRef]

- Burczyk, H.; Grabowska, L.; Kołodziej, J.; Strybe, M. Industrial Hemp as a Raw Material for Energy Production. J. Ind. Hemp 2008, 13, 37–48. [Google Scholar] [CrossRef]

- Amaducci, S.; Scordia, D.; Liu, F.H.; Zhang, Q.; Guo, H.; Testa, G.; Cosentino, S.L. Key Cultivation Techniques for Hemp in Europe and China. Ind. Crops Prod. 2015, 68, 2–16. [Google Scholar] [CrossRef]

- Jin, D.; Jin, S.; Chen, J. Cannabis Indoor Growing Conditions, Management Practices, and Post-Harvest Treatment: A Review. Am. J. Plant Sci. 2019, 10, 925–946. [Google Scholar] [CrossRef]

- Ampim, P.A.Y.; Obeng, E.; Olvera-Gonzalez, E. Indoor Vegetable Production: An Alternative Approach to Increasing Cultivation. Plants 2022, 11, 2843. [Google Scholar] [CrossRef] [PubMed]

- Choi, H.G.; Moon, B.Y.; Kang, N.J. Effects of LED Light on the Production of Strawberry during Cultivation in a Plastic Greenhouse and in a Growth Chamber. Sci. Hortic. 2015, 189, 22–31. [Google Scholar] [CrossRef]

- Engler, N.; Krarti, M. Review of Energy Efficiency in Controlled Environment Agriculture. Renew. Sustain. Energy Rev. 2021, 141, 110786. [Google Scholar] [CrossRef]

- Moosavi-Nezhad, M.; Salehi, R.; Aliniaeifard, S.; Winans, K.S.; Nabavi-Pelesaraei, A. An Analysis of Energy Use and Economic and Environmental Impacts in Conventional Tunnel and LED-Equipped Vertical Systems in Healing and Acclimatization of Grafted Watermelon Seedlings. J. Clean. Prod. 2022, 361, 132069. [Google Scholar] [CrossRef]

- Pinstrup-Andersen, P. Is It Time to Take Vertical Indoor Farming Seriously? Glob. Food Secur. 2018, 17, 233–235. [Google Scholar] [CrossRef]

- Llewellyn, D.; Golem, S.; Foley, E.; Dinka, S.; Jones, A.M.P.; Zheng, Y. Indoor Grown Cannabis Yield Increased Proportionally with Light Intensity, but Ultraviolet Radiation Did Not Affect Yield or Cannabinoid Content. Front. Plant Sci. 2022, 13, 974018. [Google Scholar] [CrossRef]

- Pedrazzi, S.; Santunione, G.; Mustone, M.; Cannazza, G.; Citti, C.; Francia, E.; Allesina, G. Techno-Economic Study of a Small Scale Gasifier Applied to an Indoor Hemp Farm: From Energy Savings to Biochar Effects on Productivity. Energy Convers. Manag. 2021, 228, 113645. [Google Scholar] [CrossRef]

- Ely, K.; Podder, S.; Reiss, M.; Fike, J. Industrial Hemp as a Crop for a Sustainable Agriculture. In Cannabis/Hemp for Sustainable Agriculture and Materials; Agrawal, D.C., Kumar, R., Dhanasekaran, M., Eds.; Springer: Singapore, 2022; pp. 1–28. ISBN 978-981-16-8777-8. [Google Scholar]

- Bernas, J.; Bernasová, T.; Nedbal, V.; Neugschwandtner, R.W. Agricultural LCA for Food Oil of Winter Rapeseed, Sunflower, and Hemp, Based on Czech Standard Cultivation Practices. Agronomy 2021, 11, 2301. [Google Scholar] [CrossRef]

- Ruviaro, C.F.; Gianezini, M.; Brandão, F.S.; Winck, C.A.; Dewes, H. Life Cycle Assessment in Brazilian Agriculture Facing Worldwide Trends. J. Clean. Prod. 2012, 28, 9–24. [Google Scholar] [CrossRef]

- Desaulniers Brousseau, V.; Goldstein, B.P.; Lachapelle, M.; Tazi, I.; Lefsrud, M. Greener Green: The Environmental Impacts of the Canadian Cannabis Industry. Resour. Conserv. Recycl. 2024, 208, 107737. [Google Scholar] [CrossRef]

- Mills, E. Energy-Intensive Indoor Cultivation Drives the Cannabis Industry’s Expanding Carbon Footprint. One Earth 2025, 8, 101179. [Google Scholar] [CrossRef]

- Mills, E. The Carbon Footprint of Indoor Cannabis Production. Energy Policy 2012, 46, 58–67. [Google Scholar] [CrossRef]

- Summers, H.M.; Sproul, E.; Quinn, J.C. The Greenhouse Gas Emissions of Indoor Cannabis Production in the United States. Nat. Sustain. 2021, 4, 644–650. [Google Scholar] [CrossRef]

- Ahamed, M.S.; Sultan, M.; Monfet, D.; Rahman, M.S.; Zhang, Y.; Zahid, A.; Bilal, M.; Ahsan, T.M.A.; Achour, Y. A Critical Review on Efficient Thermal Environment Controls in Indoor Vertical Farming. J. Clean. Prod. 2023, 425, 138923. [Google Scholar] [CrossRef]

- Dillis, C.; Butsic, V.; Georgakakos, P.; Portugal, E.; Grantham, T.E. Water Demands of Permitted and Unpermitted Cannabis Cultivation in Northern California. Environ. Res. Commun. 2023, 5, 025005. [Google Scholar] [CrossRef]

- ISO 14040; Environmental Management–Life Cycle Assessment–Principles and Framework. International Organization for Standardization: Geneva, Switzerland, 2006.

- ISO 14044; Environmental Management–Life Cycle Assessment–Requirements and Guidelines. International Organization for Standardization: Geneva, Switzerland, 2006.

- Steubing, B.; Wernet, G.; Reinhard, J.; Bauer, C.; Moreno-Ruiz, E. The Ecoinvent Database Version 3 (Part II): Analyzing LCA Results and Comparison to Version 2. Int. J. Life Cycle Assess. 2016, 21, 1269–1281. [Google Scholar] [CrossRef]

- Konvalina, P.; Neumann, J.; Hoang, T.N.; Bernas, J.; Trojan, V.; Kuchař, M.; Lošák, T.; Varga, L. Effect of Light Intensity and Two Different Nutrient Solutions on the Yield of Flowers and Cannabinoids in Cannabis sativa L. Grown in Controlled Environment. Agronomy 2024, 14, 2960. [Google Scholar] [CrossRef]

- European Commission; Joint Research Centre; Institute for Environment and Sustainability. International Reference Life Cycle Data System (ILCD) Handbook: General Guide for Life Cycle Assessment: Detailed Guidance; Publications Office: Luxembourg, 2010. [Google Scholar]

- Koch, P.; Salou, T. AGRIBALYSE®: Methodology, version 1.3; ADEME: Angers, France, 2013. [Google Scholar]

- Tyszler, H.B.M.; van der Voet, E.; van Paassen, M.; Braconi, N.; Kuling, L.; Durlinger, B.; Gual, P. Agri-Footprint 6: Methodology Report; Parts 1–2; Blonk Sustainability: Gouda, The Netherlands, 2022. [Google Scholar]

- Wernet, G.; Bauer, C.; Steubing, B.; Reinhard, J.; Moreno-Ruiz, E.; Weidema, B. The Ecoinvent Database Version 3 (Part I): Overview and Methodology. Int. J. Life Cycle Assess. 2016, 21, 1218–1230. [Google Scholar] [CrossRef]

- Nemecek, T.; Bengoa, X.; Lansche, J.; Roesch, A.; Faist-Emmenegger, M.; Rossi, V.; Humbert, S. Methodological Guidelines for the Life Cycle Inventory of Agricultural Products; Version 3.5; World Food LCA Database (WFLDB); Quantis and Agroscope: Lausanne/Zurich, Switzerland, 2019. [Google Scholar]

- Ministry of Industry and Trade of the Czech Republic. Renewable Energy Sources 2022–2023. Available online: https://mpo.gov.cz/assets/cz/energetika/statistika/obnovitelne-zdroje-energie/2024/12/Obnovitelne-zdroje-energie-2022-2023_web.pdf (accessed on 10 July 2025).

- Oenergetice.cz. EnergoStat. Available online: https://oenergetice.cz/energostat (accessed on 10 July 2025).

- Dijkman, T.J.; Basset-Mens, C.; Antón, A.; Núñez, M. LCA of Food and Agriculture. In Life Cycle Assessment; Hauschild, M.Z., Rosenbaum, R.K., Olsen, S.I., Eds.; Springer International Publishing: Cham, Switzerland, 2018; pp. 723–754. ISBN 978-3-319-56474-6. [Google Scholar]

- Bernas, J.; Bernasová, T.; Gerstberger, P.; Moudrý, J.; Konvalina, P.; Moudrý, J. Cup Plant, an Alternative to Conventional Silage from a LCA Perspective. Int. J. Life Cycle Assess. 2021, 26, 311–326. [Google Scholar] [CrossRef]

- Hauschild, M.Z.; Rosenbaum, R.K.; Olsen, S.I. (Eds.) Life Cycle Assessment: Theory and Practice; Springer International Publishing: Cham, Switzerland, 2018; ISBN 978-3-319-56474-6. [Google Scholar]

- Hayashi, K.; Gaillard, G.; Nemecek, T. Life Cycle Assessment of Agricultural Production Systems: Current Issues and Future Perspectives. In Good Agricultural Practice (GAP) in Asia and Oceania; Food and Fertilizer Technology Center: Taipei, Taiwan, 2005. [Google Scholar]

- Pérez, R.; Argüelles, F.; Laca, A.; Laca, A. Evidencing the Importance of the Functional Unit in Comparative Life Cycle Assessment of Organic Berry Crops. Environ. Sci. Pollut. Res. 2024, 31, 22055–22072. [Google Scholar] [CrossRef]

- Meffo Kemda, M.; Marchi, M.; Neri, E.; Marchettini, N.; Niccolucci, V. Environmental Impact Assessment of Hemp Cultivation and Its Seed-Based Food Products. Front. Environ. Sci. 2024, 12, 1342330. [Google Scholar] [CrossRef]

- Reichel, P.; Munz, S.; Hartung, J.; Präger, A.; Kotiranta, S.; Burgel, L.; Graeff-Hönninger, S. Impact of Three Different Light Spectra on the Yield, Morphology and Growth Trajectory of Three Different Cannabis sativa L. Strains. Plants 2021, 10, 1866. [Google Scholar] [CrossRef] [PubMed]

- Zheng, Z.; Fiddes, K.; Yang, L. A Narrative Review on Environmental Impacts of Cannabis Cultivation. J. Cannabis Res. 2021, 3, 35. [Google Scholar] [CrossRef] [PubMed]

- Holzapfel, P.; Bach, V.; Finkbeiner, M. Electricity Accounting in Life Cycle Assessment: The Challenge of Double Counting. Int. J. Life Cycle Assess. 2023, 28, 771–787. [Google Scholar] [CrossRef]

- Šerešová, M.; Štefanica, J.; Vitvarová, M.; Zakuciová, K.; Wolf, P.; Kočí, V. Life Cycle Performance of Various Energy Sources Used in the Czech Republic. Energies 2020, 13, 5833. [Google Scholar] [CrossRef]

- Barros, M.V.; Salvador, R.; Piekarski, C.M.; De Francisco, A.C.; Freire, F.M.C.S. Correction to: Life Cycle Assessment of Electricity Generation: A Review of the Characteristics of Existing Literature. Int. J. Life Cycle Assess. 2020, 25, 55–56. [Google Scholar] [CrossRef]

- Bauer, S.; Olson, J.; Cockrill, A.; Van Hattem, M.; Miller, L.; Tauzer, M.; Leppig, G. Impacts of Surface Water Diversions for Marijuana Cultivation on Aquatic Habitat in Four Northwestern California Watersheds. PLoS ONE 2015, 10, e0120016. [Google Scholar] [CrossRef]

- Butsic, V.; Brenner, J.C. Cannabis (Cannabis sativa or C. Indica) Agriculture and the Environment: A Systematic, Spatially-Explicit Survey and Potential Impacts. Environ. Res. Lett. 2016, 11, 044023. [Google Scholar] [CrossRef]

- Hassanien, R.H.E.; Li, M.; Dong Lin, W. Advanced Applications of Solar Energy in Agricultural Greenhouses. Renew. Sustain. Energy Rev. 2016, 54, 989–1001. [Google Scholar] [CrossRef]

- Liantas, G.; Chatzigeorgiou, I.; Ravani, M.; Koukounaras, A.; Ntinas, G.K. Energy Use Efficiency and Carbon Footprint of Greenhouse Hydroponic Cultivation Using Public Grid and PVs as Energy Providers. Sustainability 2023, 15, 1024. [Google Scholar] [CrossRef]

- Parkes, M.G.; Azevedo, D.L.; Cavallo, A.C.; Domingos, T.; Teixeira, R.F.M. Life Cycle Assessment of Microgreen Production: Effects of Indoor Vertical Farm Management on Yield and Environmental Performance. Sci. Rep. 2023, 13, 11324. [Google Scholar] [CrossRef] [PubMed]

- Poore, J.; Nemecek, T. Reducing Food’s Environmental Impacts through Producers and Consumers. Science 2018, 360, 987–992. [Google Scholar] [CrossRef]

- Jwaideh, M.A.A.; Sutanudjaja, E.H.; Dalin, C. Global Impacts of Nitrogen and Phosphorus Fertiliser Use for Major Crops on Aquatic Biodiversity. Int. J. Life Cycle Assess. 2022, 27, 1058–1080. [Google Scholar] [CrossRef]

- Bartzas, G.; Zaharaki, D.; Komnitsas, K. Life Cycle Assessment of Open Field and Greenhouse Cultivation of Lettuce and Barley. Inf. Process. Agric. 2015, 2, 191–207. [Google Scholar] [CrossRef]

| Unit | S1-L1 | S1-L2 | S2-L1 | S2-L2 | |

|---|---|---|---|---|---|

| Output | |||||

| Yield (⌀) | g | 365 | 609 | 344 | 590 |

| Input from Technosphere | |||||

| Tap water | l | 156 | 156 | 156 | 156 |

| Stone wool | g | 20 | 20 | 20 | 20 |

| Coconut fiber | kg | 19 | 19 | 19 | 19 |

| Perlite | kg | 3.53 | 3.53 | 3.53 | 3.53 |

| Flowerpot–1 year amortization | p | 1 | 1 | 1 | 1 |

| Inorganic nitrogen fertilizer as NO3 | g | 16.1 | 16.1 | 16.1 | 16.1 |

| Inorganic nitrogen fertilizer as NH4 | g | 0.86 | 0.86 | 0.86 | 0.86 |

| Inorganic phosphorus fertilizer as P2O5 | g | 4.36 | 4.36 | 34.7 | 34.7 |

| Inorganic potassium fertilizer as K2O | g | 16.5 | 16.5 | 36 | 36 |

| Calcium carbonate (CaCO3) | g | 39.4 | 39.4 | 37 | 37 |

| Magnesium oxide (MgO) | g | 6.5 | 6.5 | 12.6 | 12.6 |

| Sulphite | g | 5.01 | 5.01 | 27.2 | 27.2 |

| Microelements (Fe, B, Cu, Zn, Mn, Mo) | g | 0.58 | 0.58 | 0.51 | 0.51 |

| Electricity production (Regional mix)–Lighting | kWh | 272 | 419 | 272 | 419 |

| Electricity production (Regional mix)–Fan, ventilation | kWh | 158 | 158 | 158 | 158 |

| Electricity production (Regional mix)–Dryers | kWh | 515 | 515 | 515 | 515 |

| Impact Category | Unit | S1-L1 | S1-L2 | S2-L1 | S2-L2 |

|---|---|---|---|---|---|

| CCH | kg CO2 eq | 1.52 × 103 | 1.05 × 103 | 1.61 × 103 | 1.08 × 103 |

| TA | kg SO2 eq | 4.31 × 100 | 2.97 × 100 | 4.58 × 100 | 3.07 × 100 |

| FE | kg P eq | 2.40 × 100 | 1.66 × 100 | 2.54 × 100 | 1.71 × 100 |

| ME | kg N eq | 1.59 × 10−1 | 1.10 × 10−1 | 1.68 × 10−1 | 1.13 × 10−1 |

| TE | kg 1.4-DCB | 2.70 × 103 | 1.86 × 103 | 2.87 × 103 | 1.92 × 103 |

| FX | kg 1.4-DCB | 6.58 × 101 | 4.55 × 101 | 6.98 × 101 | 4.70 × 101 |

| WD | m3 | 6.78 × 100 | 4.64 × 100 | 7.21 × 100 | 4.79 × 100 |

| HT | kg 1.4-DCB | 2.72 × 103 | 1.88 × 103 | 2.89 × 103 | 1.94 × 103 |

| LD | m2a crop eq | 3.97 × 101 | 2.74 × 101 | 4.22 × 101 | 2.83 × 101 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kalkušová, A.; Neumann, J.; Veselovská, N.; Kůrková, E.; Konvalina, P.; Neugschwandtner, R.W.; Bernas, J. Rethinking Efficiency: How Increased Electricity Use Can Reduce Environmental Impacts in Controlled Hemp Cultivation—A Life Cycle Assessment (LCA) Study. Agronomy 2025, 15, 2400. https://doi.org/10.3390/agronomy15102400

Kalkušová A, Neumann J, Veselovská N, Kůrková E, Konvalina P, Neugschwandtner RW, Bernas J. Rethinking Efficiency: How Increased Electricity Use Can Reduce Environmental Impacts in Controlled Hemp Cultivation—A Life Cycle Assessment (LCA) Study. Agronomy. 2025; 15(10):2400. https://doi.org/10.3390/agronomy15102400

Chicago/Turabian StyleKalkušová, Adéla, Jaroslav Neumann, Nina Veselovská, Eliška Kůrková, Petr Konvalina, Reinhard W. Neugschwandtner, and Jaroslav Bernas. 2025. "Rethinking Efficiency: How Increased Electricity Use Can Reduce Environmental Impacts in Controlled Hemp Cultivation—A Life Cycle Assessment (LCA) Study" Agronomy 15, no. 10: 2400. https://doi.org/10.3390/agronomy15102400

APA StyleKalkušová, A., Neumann, J., Veselovská, N., Kůrková, E., Konvalina, P., Neugschwandtner, R. W., & Bernas, J. (2025). Rethinking Efficiency: How Increased Electricity Use Can Reduce Environmental Impacts in Controlled Hemp Cultivation—A Life Cycle Assessment (LCA) Study. Agronomy, 15(10), 2400. https://doi.org/10.3390/agronomy15102400