Optimizing Vents Opening Configurations and Orientations for Effective Natural Ventilation in Sustainable Greenhouses: A Case Study

Abstract

1. Introduction

2. Materials and Methods

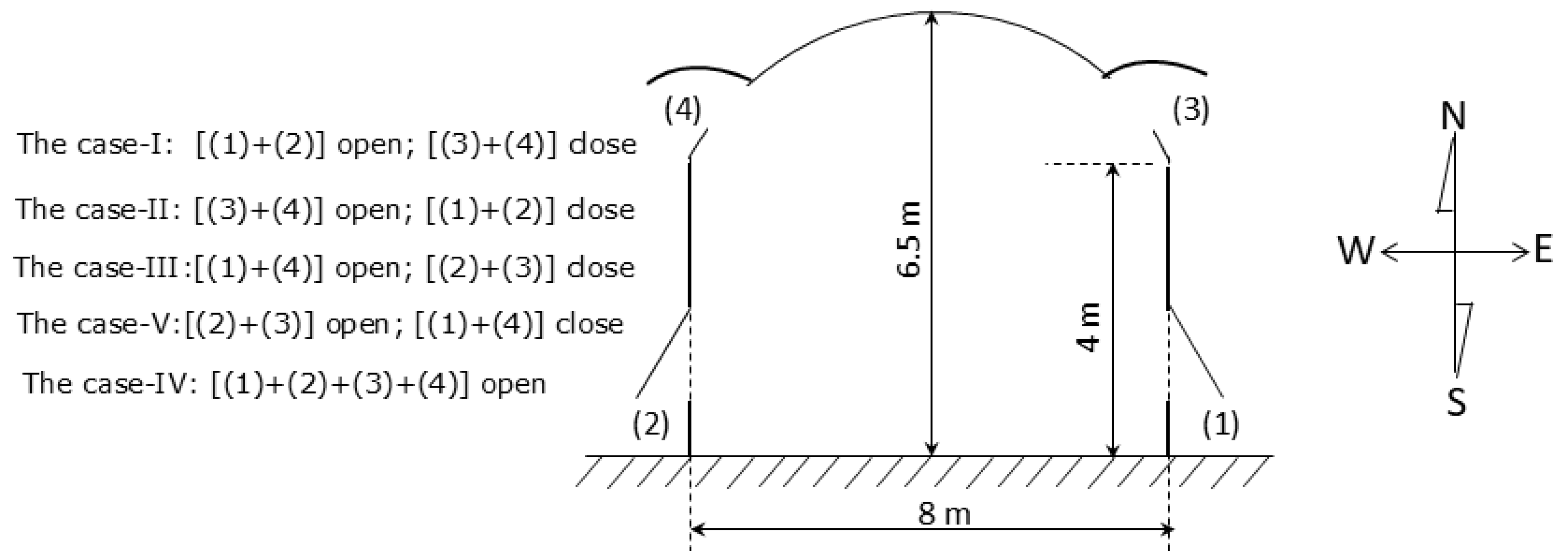

2.1. Experimental Set-Up and Vents Opening Configurations

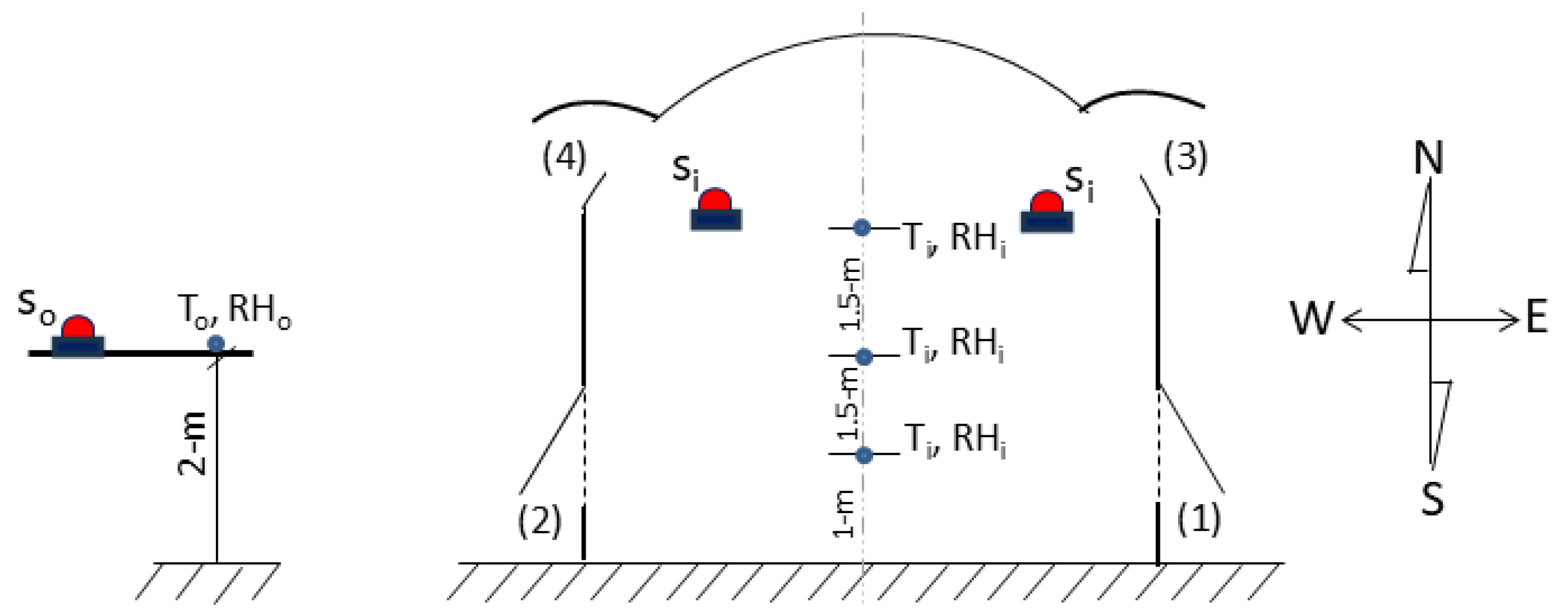

2.2. Measuring the Required Parameters

2.3. Determination of the Ventilation Rate

3. Results and Discussion

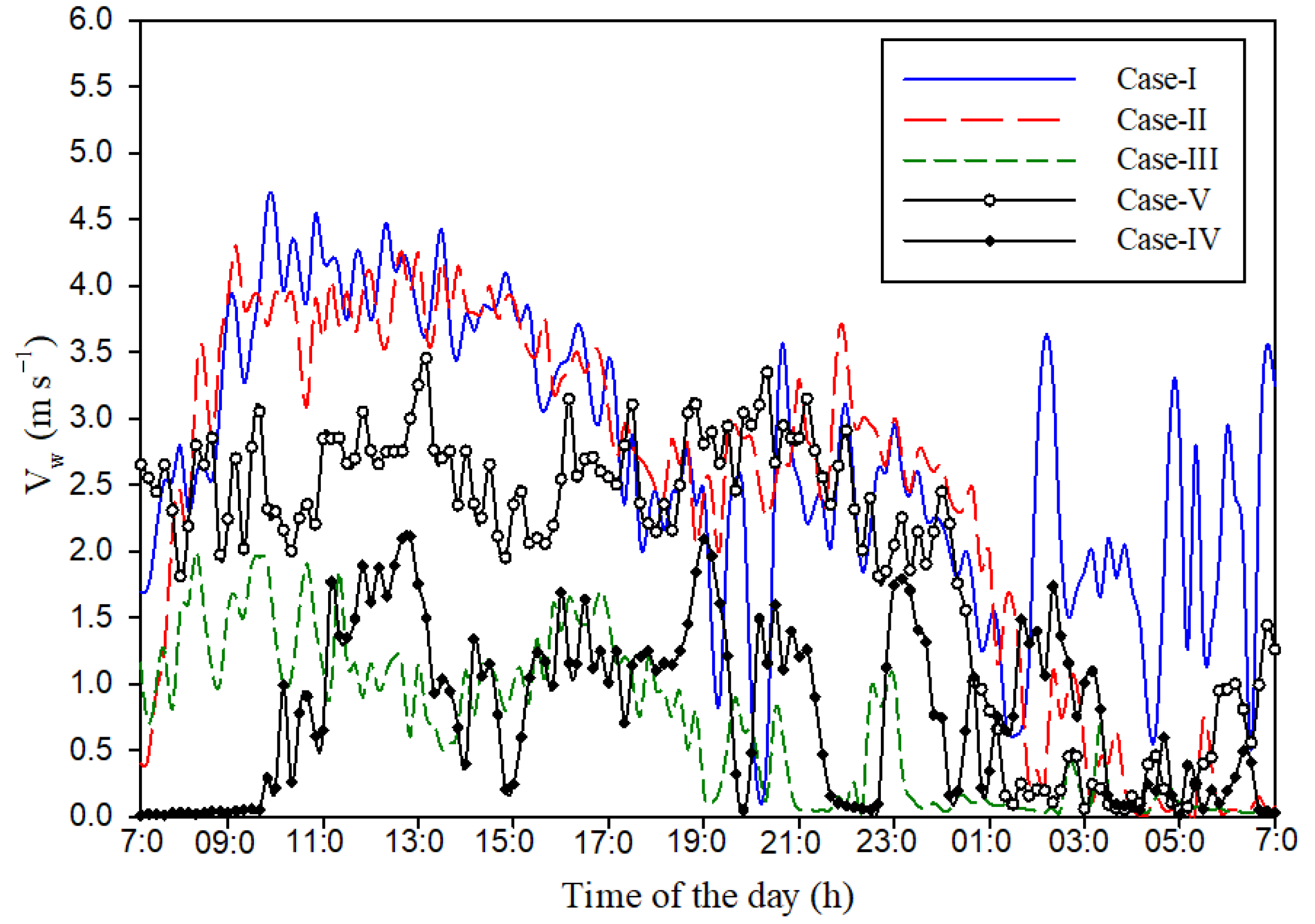

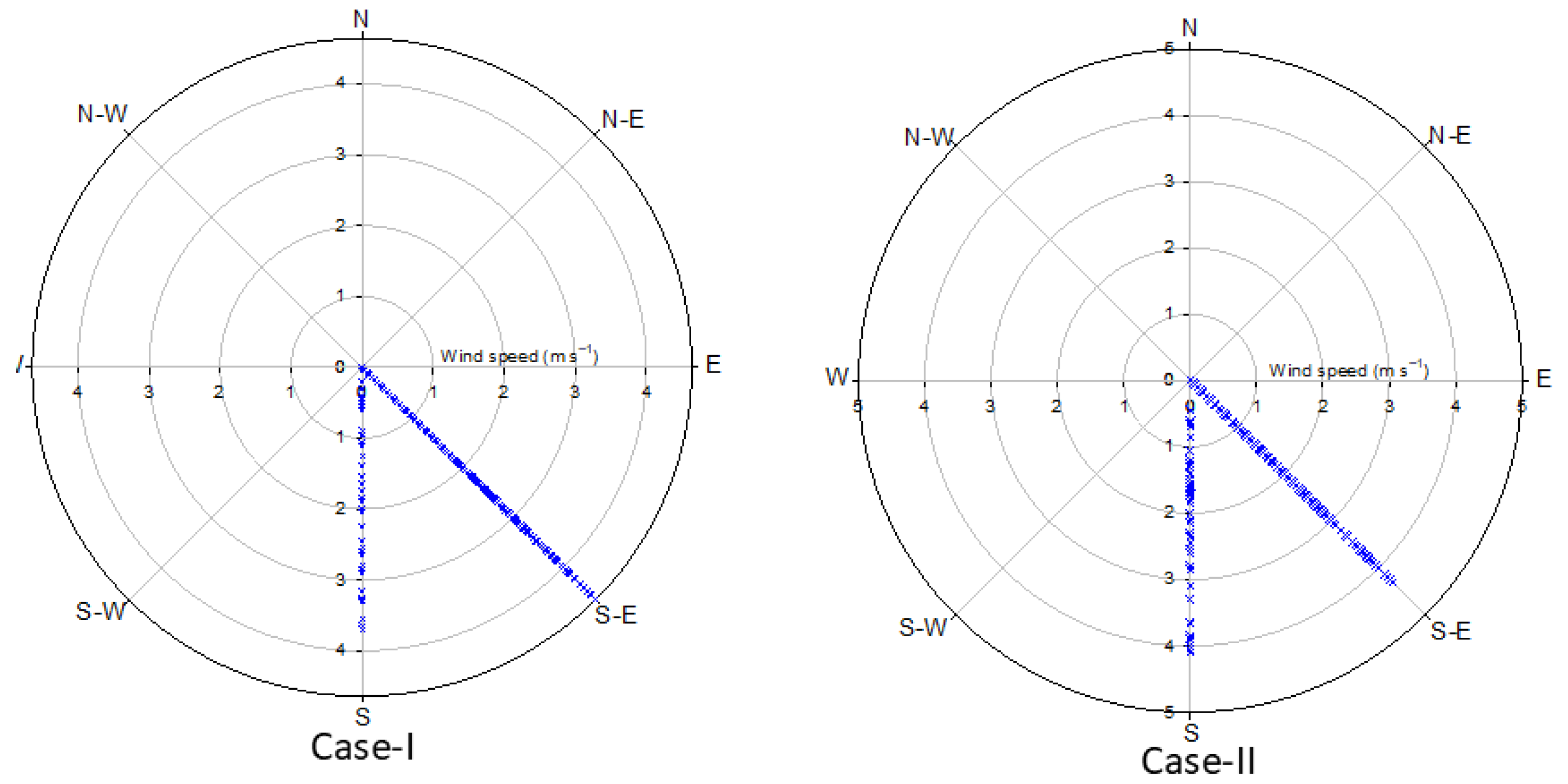

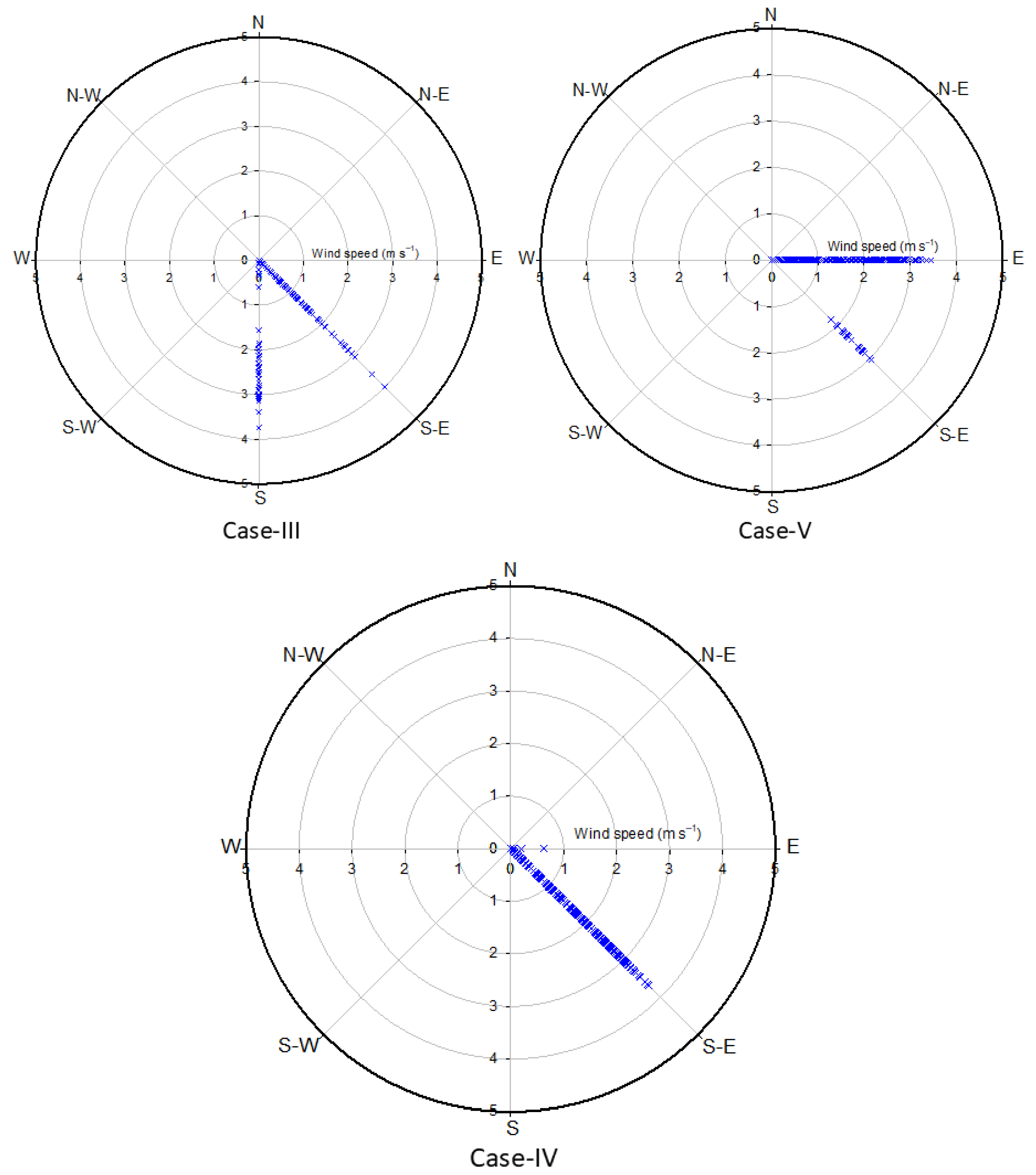

3.1. Wind Characterization

3.2. Parameters Controlling Ventilation

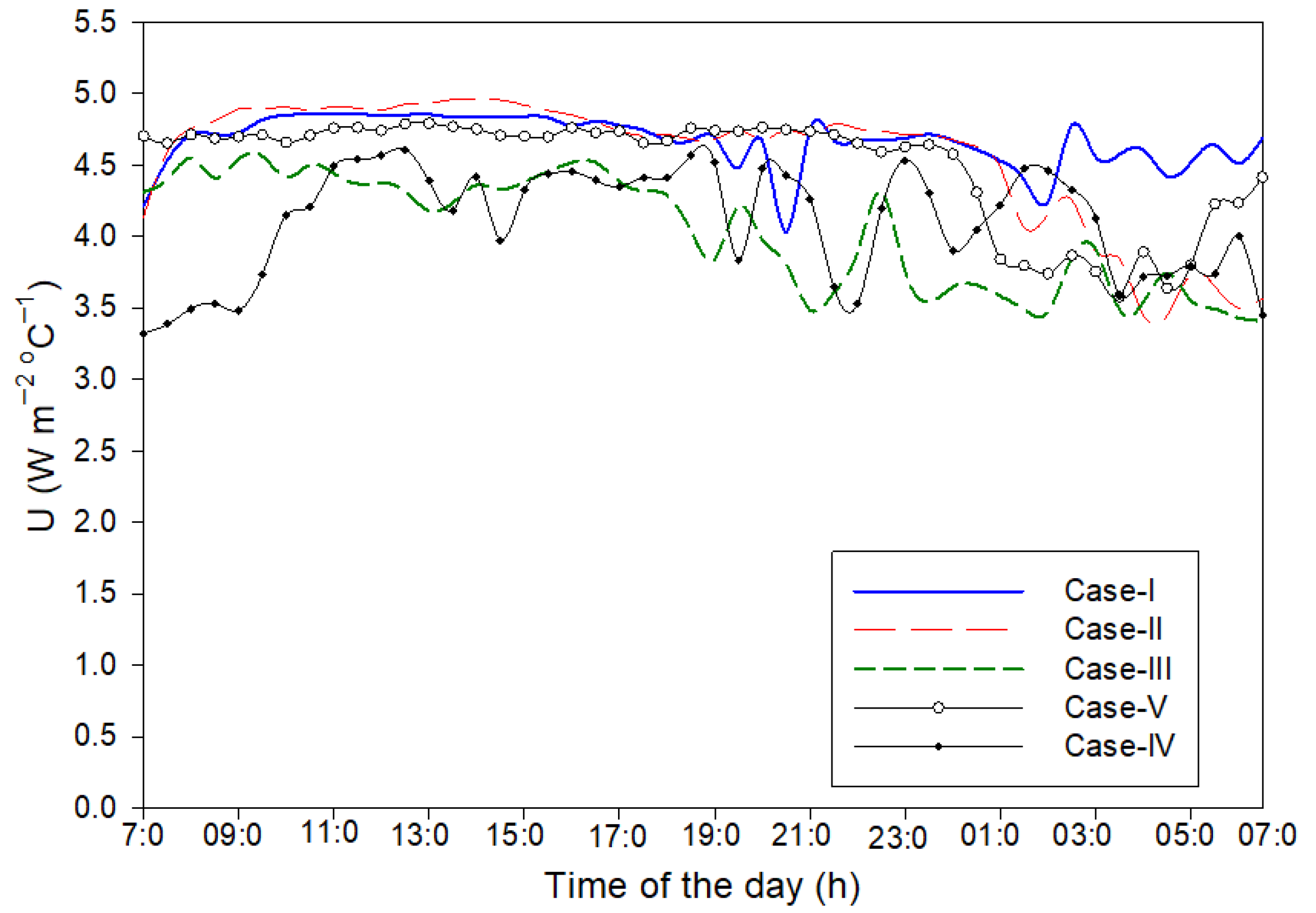

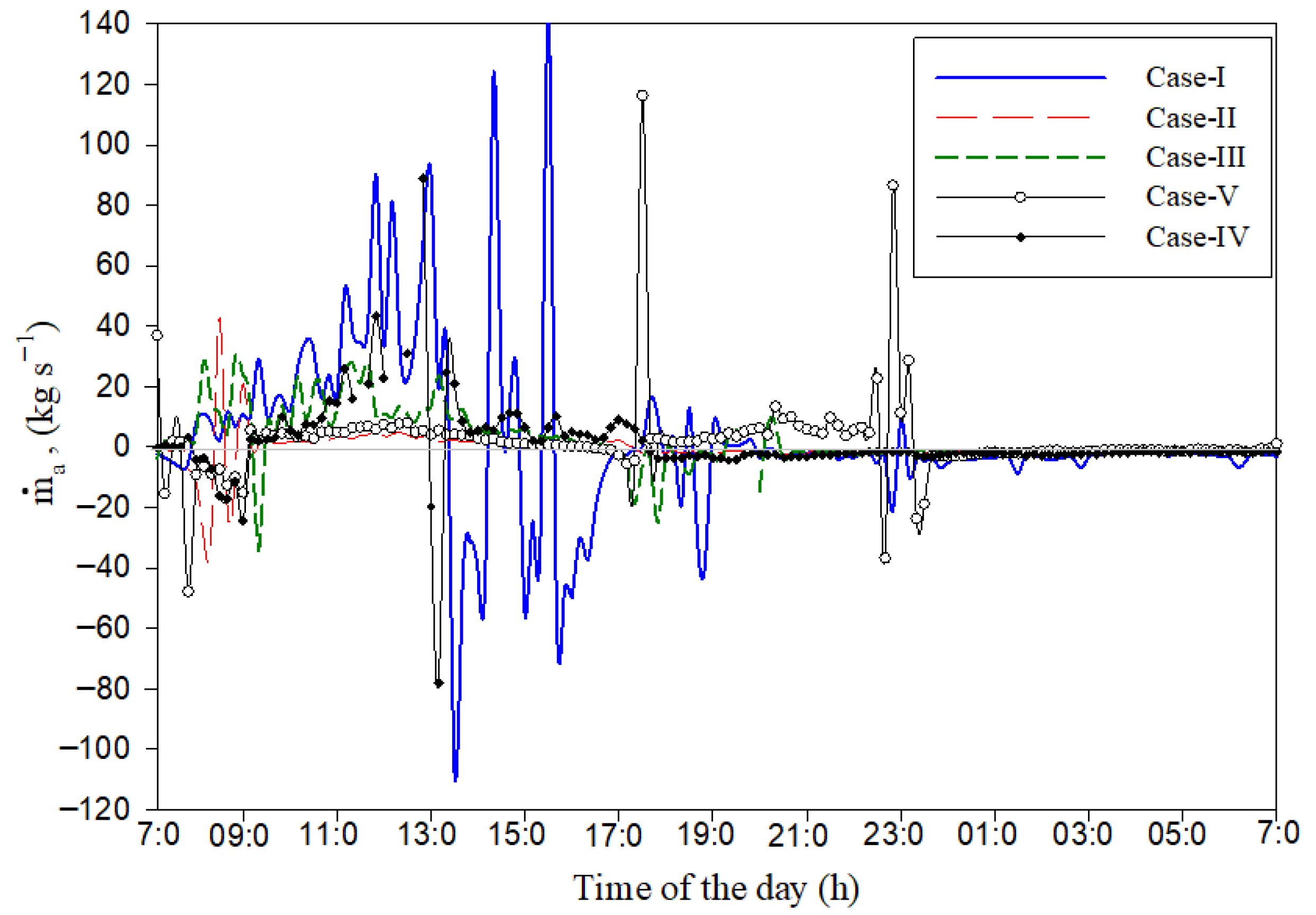

3.3. The Estimated Ventilation Rate

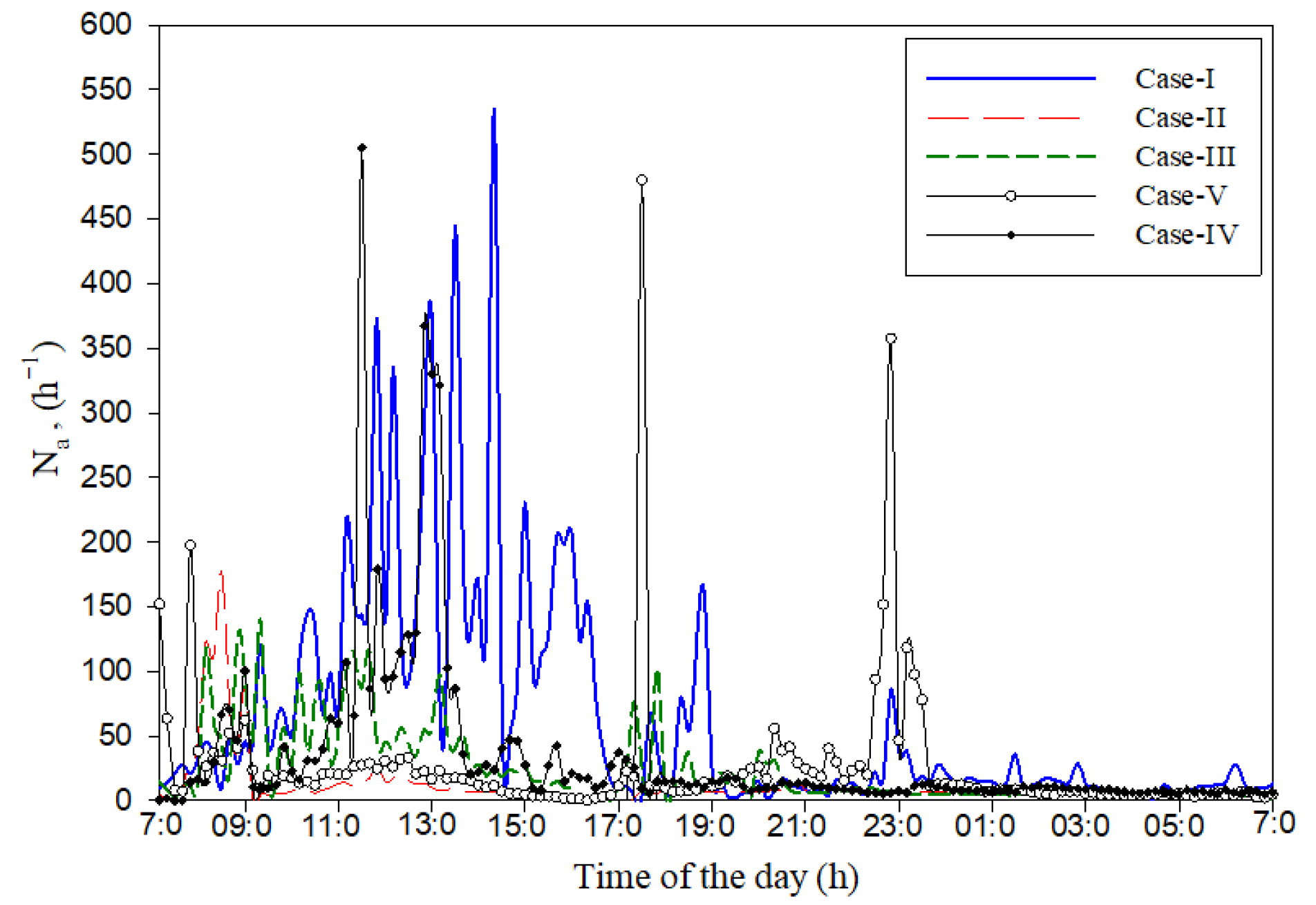

3.4. Quantification of Ventilation Regime

4. Conclusions and Recommendation

- Opening the side-wall vents is essential, exhibiting the highest ventilation rate; however, opening the roof vents alone is not recommended for greenhouse ventilation.

- Opening the roof and side-wall vents (in opposite directions) is effective if the greenhouse is properly oriented to make the vent opening perpendicular to the wind direction.

- According to the common wind direction in the central region of Saudi Arabia, the greenhouse should be oriented in the E-W or in the NE-SW directions.

- In winter seasons, natural ventilation for greenhouses is sufficient and can effectively replace the energy-consuming mechanical ventilation. However, in the summer, shading and evaporative cooling is required because ventilation replaces the inside greenhouse air with the outside hot air.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| Ac | Surface area of the greenhouse cover, m2 |

| Af | Surface area of the greenhouse floor, m2 |

| hi | Enthalpy of the inside greenhouse air, kJ·kg−1 |

| ho | enthalpy of the outside greenhouse air, kJ·kg−1 |

| Ventilation mass flow rate, kg·s−1 | |

| Na | Number of air exchange rate, h−1 |

| Mean value of Na | |

| Si | Solar radiation flux in the greenhouse, W·m−2 |

| So | Solar radiation flux outside the greenhouse, W·m−2 |

| Ti | Temperature of air in the greenhouse, °C |

| To | Temperature of air outside the greenhouse, °C |

| U | Overall heat transmission coefficient, W·m−2·°C−1 |

| Vg | Volume of air in the greenhouse, m3 |

| Vw | Wind speed, m·s−1 |

| Daily average of wind speed, m·s−1 | |

| ρa | Density of air, kg·m−3 |

| ψ | Cover to floor area ratio, |

| ω | Absolute humidity of air, kg of water vapor/kg dry air |

References

- Alsadon, A.A.; Al-Helal, I.M.; Ibrahim, A.; Abdel-Ghany, A.M.; Al-Zaharani, S.; Ashour, T. The effects of plastic greenhouse covering on cucumber (Cucumis sativus L.) growth. Ecol. Eng. 2016, 87, 305–312. [Google Scholar] [CrossRef]

- Al-Helal, I.M.; Waheeb, S.A.; Shady, M.R.; Abdel-Ghany, A.M. Modified thermal model to predict the natural ventilation of greenhouses. Energy Build. 2015, 99, 1–8. [Google Scholar] [CrossRef]

- Al-Ajlouni, M. Natural ventilation in greenhouses: Principles, design, and applications. J. Agric. Eng. 2020, 13, 58–72. [Google Scholar]

- Raji, B.A.; Lal, S. Natural ventilation and its application in hot climates. Renew. Energy Rev. 2019, 8, 120–132. [Google Scholar]

- Jafari, A.; Tavakol, A. Design and optimization of natural ventilation systems for greenhouses. Energy Build. 2018, 166, 71–82. [Google Scholar]

- Pereira, L.S.; Rivas, R. Greenhouse climate control in hot regions. Agric. Sys. 2017, 152, 58–75. [Google Scholar]

- Boulard, T.; Baille, A. Modelling and measurement of greenhouse ventilation. Agric. For. Meteorol. 1995, 75, 33–51. [Google Scholar]

- Abdel-Ghany, A.M.; Picuno, P.; Al-Helal, I.M.; Alsadon, A.A.; Ibrahim, A.; Shady, M.R. Radiometric characterization, solar and thermal radiation in a greenhouse as affected by shading configuration in an arid climate. Energies 2015, 8, 13928–13937. [Google Scholar] [CrossRef]

- Parra, J.P.; Baeza, E.; Montero, J.I.; Bailey, B.J. Natural ventilation of Parral greenhouses. Boisyst. Eng. 2004, 87, 355–366. [Google Scholar] [CrossRef]

- Katsoulas, N.; Bartzanas, T.; Boulard, T.; Mermier, M.; Kittas, C. Effect of vent openings and insect screens on greenhouse ventilation. Biosyst. Eng. 2006, 93, 427–436. [Google Scholar] [CrossRef]

- Samer, M.; Ammon, C.; Loebsin, C.; Fiedler, M.; Berg, W.; Sanftleben, P.; Brunsch, R. Moisture balance and tracer gas technique for ventilation rates measurements and greenhouse gases and ammonia emissions quantification in naturally ventilated buildings. Build Environ. 2012, 50, 10–20. [Google Scholar] [CrossRef]

- Cui, S.; Cohen, M.; Stabat, P.; Marchio, D. CO2 tracer gas concentration decay method for measuring air change rate. Build. Environ. 2015, 84, 162–169. [Google Scholar] [CrossRef]

- Kittas, C.; Bartzanas, T. Greenhouse microclimate and dehumidification effectiveness under different ventilator configurations. Build Environ. 2007, 42, 3774–3784. [Google Scholar] [CrossRef]

- Montero, J.I.; Anton, A.; Muñoz, P. Discharge coefficients of greenhouse windows with insect-proof screens. Biosyst. Eng. 2001, 81, 399–407. [Google Scholar] [CrossRef]

- Fatnassi, H.; Boulard, T.; Poncet, C. Optimization of greenhouse insect-proof screens with computational fluid dynamics. Biosyst. Eng. 2006, 93, 301–312. [Google Scholar] [CrossRef]

- Teitel, M. Greenhouse ventilation: Theory and practice. Acta Hortic. 2017, 1170, 243–248. [Google Scholar]

- Seginer, I. Alternative design formulae for the ventilation rate of greenhouses. J. Agric. Eng. Res. 1997, 68, 355–365. [Google Scholar] [CrossRef]

- Mihara, Y. Fundamental and Practice of Greenhouse Design, 1st ed.; Yokendo Inc.: Tokyo, Japan, 1983; pp. 160–169. (In Japanese) [Google Scholar]

- Abdel-Ghany, A.M. Energy balance equation for natural ventilation of greenhouses under unsteady–state conditions. Middle-East J. Sci. Res. 2011, 10, 286–293. [Google Scholar]

- Al-Helal, I.M.; Abdel-Ghany, A.M. Energy Partition and conversion of solar and thermal radiation into sensible and latent heat in a greenhouse under arid conditions. Energy Build. 2011, 43, 1740–1747. [Google Scholar] [CrossRef]

- Abdel-Ghany, A.M.; Kozai, T. On the determination of the overall heat transmission coefficient and soil heat flux for a fog-cooled, naturally ventilated greenhouse: Analysis of radiation and convection heat transfer. Energy Conver. Manag. 2006, 47, 2612–2628. [Google Scholar] [CrossRef]

- Abdel-Ghany, A.M.; Goto, E.; Kozai, T. Evaporation characteristics in a naturally ventilated, fog-cooled greenhouse. Renew. Energy 2006, 31, 2207–2226. [Google Scholar] [CrossRef]

- Georgios, K.S. Temperature control and energy conservation in a plastic greenhouse. J. Agric. Eng. Res. 2001, 80, 251–259. [Google Scholar]

- Swinkels, G.L.A.M.; Sonneveld, P.J.; Bot, G.P.A. Improvement of greenhouse insulation with restricted transmission loss through zigzag covering material. J. Agric. Eng. Res. 2001, 79, 91–97. [Google Scholar] [CrossRef]

- Nijskens, J.; Deltour, J.; Coutisse, S.; Nisen, A. Heat transfer through covering materials of greenhouses. Agric. For. Meteorol. 1984, 33, 193–214. [Google Scholar] [CrossRef]

- Zhang, Y.; Gauthier, L.; de Halleux, D.; Dansereau, B.; Gosselin, A. Effect of covering materials on energy consumption and greenhouse microclimate. Agric. For. Meteorol. 1996, 82, 227–244. [Google Scholar] [CrossRef]

- Ahemd, H.A.; Al-Faraj, A.A.; Abdel-Ghany, A.M. Shading greenhouses to improve the microclimate, energy and water saving in hot regions: A review. Sci. Hortic. 2016, 201, 36–45. [Google Scholar] [CrossRef]

- Baytorun, A.N.; Üstün, S.; Akyüz, A.; Önder, D. Determination of ventilation openings ratio in greenhouses under mediterranean climate conditions. Turkish J. Agric. Food Sci. Tech. 2017, 5, 409–415. [Google Scholar] [CrossRef][Green Version]

- Li, Y.; Zhao, S.; Dai, A.; Zhang, J.; Fan, Z.; Ding, T. Study on the natural ventilation model of a single-span plastic greenhouse in a high-altitude area. Agronomy 2024, 14, 2166. [Google Scholar] [CrossRef]

- Kim, H.-K. Evaluating the ventilation performance of single-span plastic greenhouses with continuous screened side openings. Agronomy 2024, 14, 1447. [Google Scholar] [CrossRef]

| Case-I | Case-II | Case-III | Case-V | Case-IV | |

|---|---|---|---|---|---|

| (m·s−1) | 2.7 | 2.4 | 0.69 | 1.96 | 0.8 |

| STD | 1.04 | 1.37 | 0.58 | 1.01 | 0.623 |

| STE | 0.087 | 0.11 | 0.049 | 0.084 | 0.052 |

| Case-I | Case-II | Case-III | Case-V | Case-IV | |

|---|---|---|---|---|---|

| (h−1) | 63.7 | 11.2 | 23.8 | 26.2 | 33.2 |

| STD | 90.15 | 21.7 | 30.2 | 55.5 | 67.2 |

| STE | 7.5 | 1.8 | 2.5 | 4.6 | 5.6 |

| Opening Cases | Buoyancy-Driven, % (Vw ≤ 1 m·s−1) | Combined Regime, % (1 < Vw ≤ 2 m·s−1) | Wind-Driven, % (Vw > 2 m·s−1) | (m·s−1) |

|---|---|---|---|---|

| Case-I | 18 | 14.5 | 67.5 | 2.7 |

| Case-II | 23.7 | 19.5 | 56.8 | 2.4 |

| Case-III | 24.7 | 7.6 | 67.6 | 0.69 |

| Case-V | 43.3 | 28.8 | 28.5 | 1.96 |

| Case-IV | 3.8 | 36 | 60 | 0.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al-Helal, I.M.; Alsadon, A.A.; Ibrahim, A.A.; Shady, M.R. Optimizing Vents Opening Configurations and Orientations for Effective Natural Ventilation in Sustainable Greenhouses: A Case Study. Agronomy 2025, 15, 2454. https://doi.org/10.3390/agronomy15112454

Al-Helal IM, Alsadon AA, Ibrahim AA, Shady MR. Optimizing Vents Opening Configurations and Orientations for Effective Natural Ventilation in Sustainable Greenhouses: A Case Study. Agronomy. 2025; 15(11):2454. https://doi.org/10.3390/agronomy15112454

Chicago/Turabian StyleAl-Helal, Ibrahim M., Abdullah A. Alsadon, Abdullah A. Ibrahim, and Mohamed R. Shady. 2025. "Optimizing Vents Opening Configurations and Orientations for Effective Natural Ventilation in Sustainable Greenhouses: A Case Study" Agronomy 15, no. 11: 2454. https://doi.org/10.3390/agronomy15112454

APA StyleAl-Helal, I. M., Alsadon, A. A., Ibrahim, A. A., & Shady, M. R. (2025). Optimizing Vents Opening Configurations and Orientations for Effective Natural Ventilation in Sustainable Greenhouses: A Case Study. Agronomy, 15(11), 2454. https://doi.org/10.3390/agronomy15112454