Influence of Air-Jet Configuration on Spray Deposit and Drift in a Blackcurrant Plantation

Abstract

1. Introduction

2. Materials and Methods

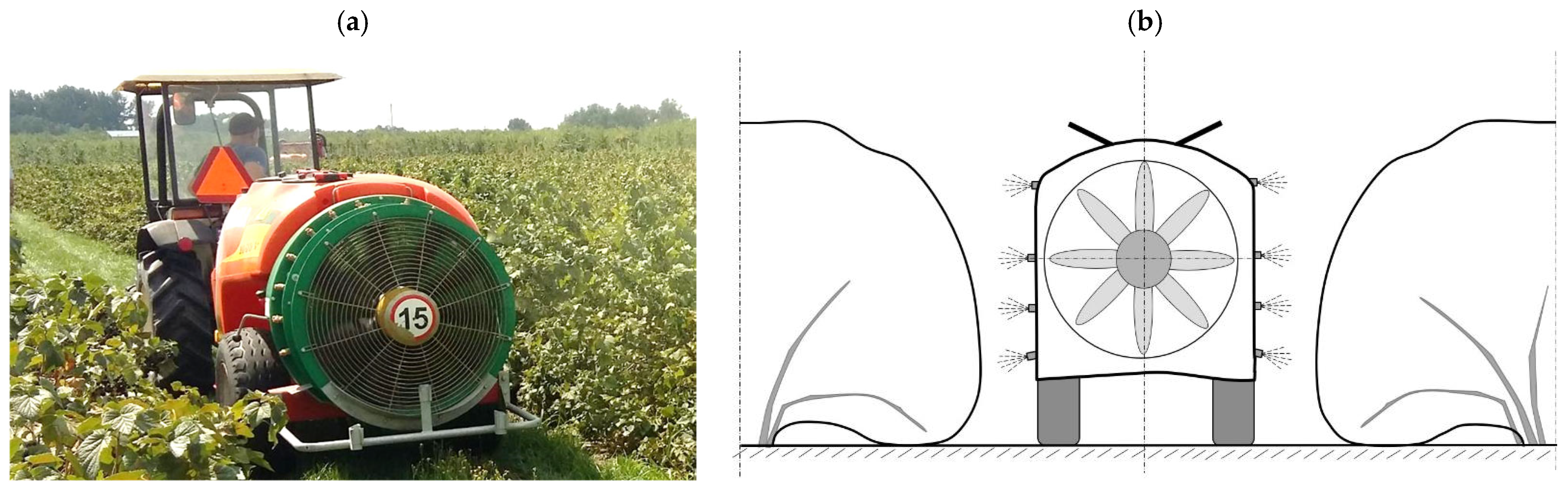

2.1. Experimental Two-Row Directed Air-Jet Sprayer

2.2. Conventional Axial Fan Sprayer

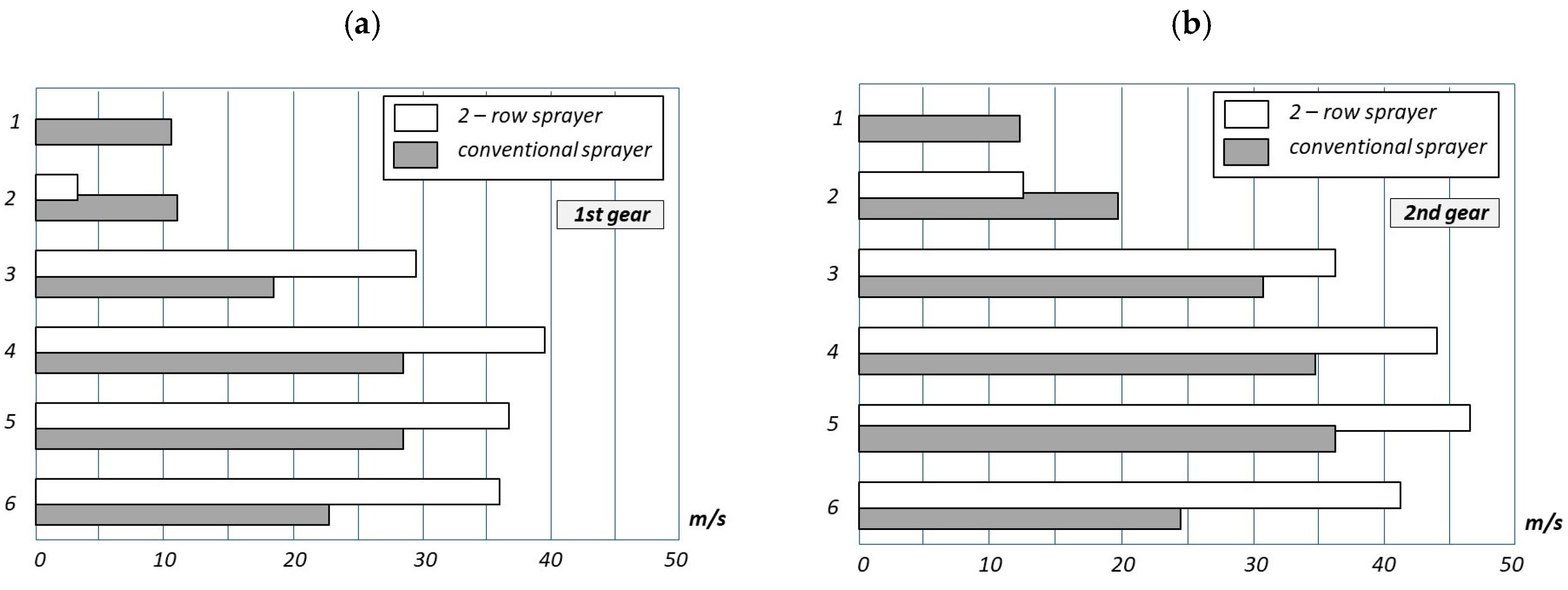

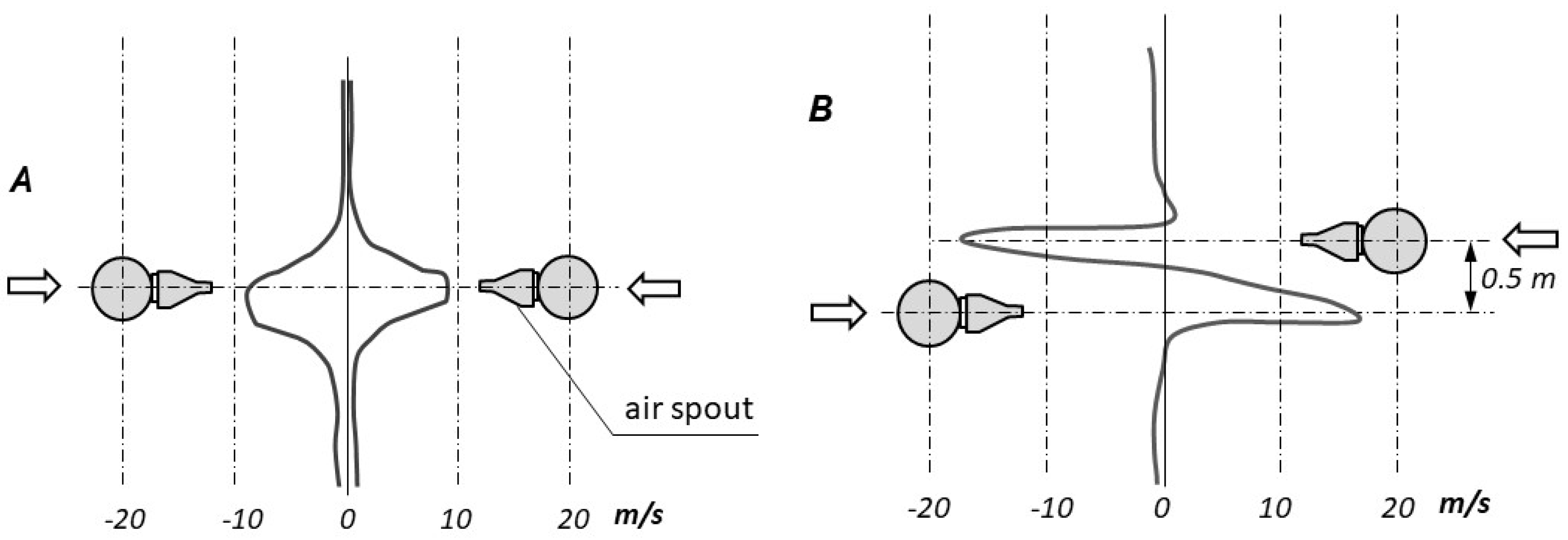

2.3. Air Velocity Measurements

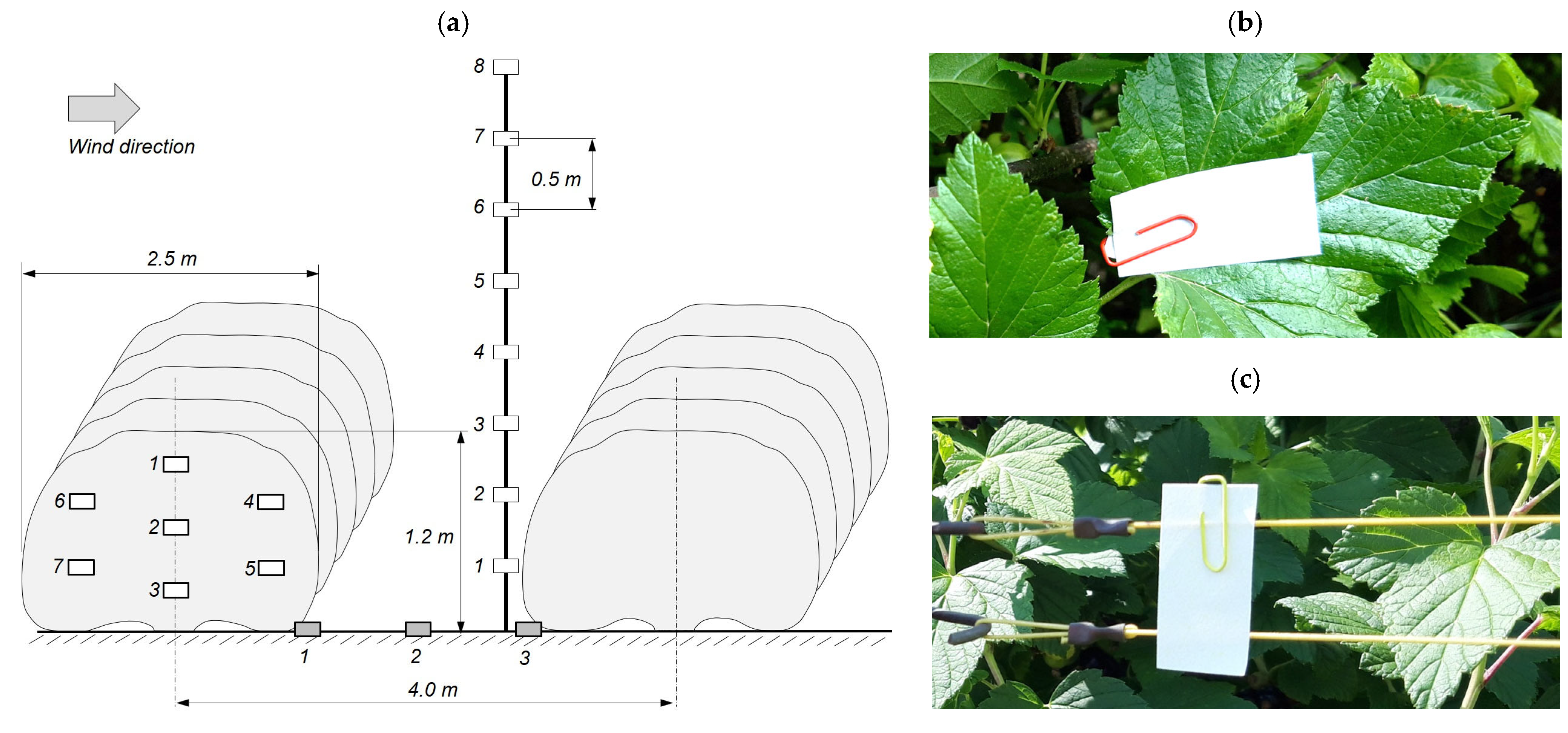

2.4. Field Experiment

2.5. Laboratory Measurements

2.6. Statistical Analysis

3. Results and Discussion

3.1. Air Distribution Measurements—Indoor Tests

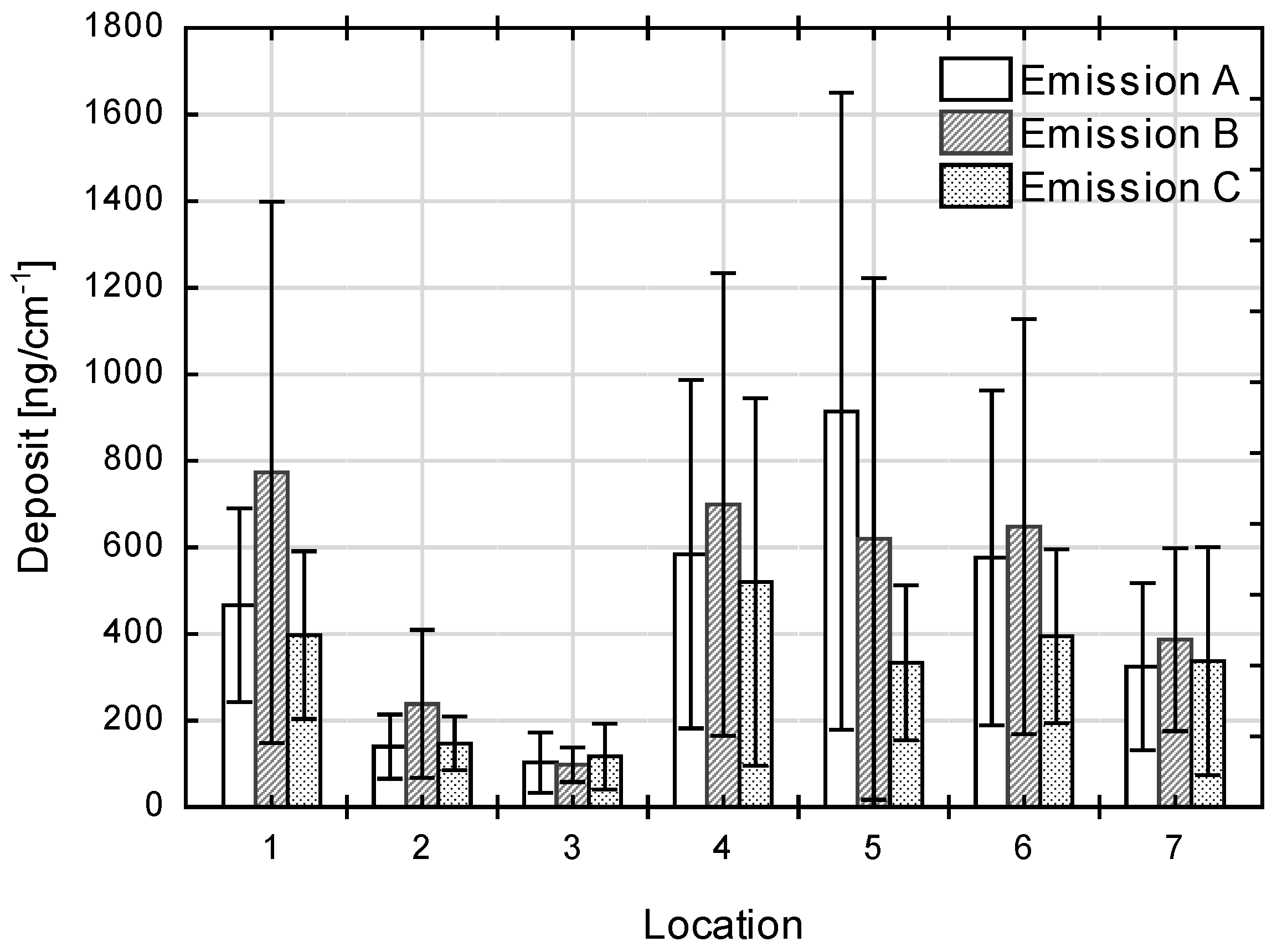

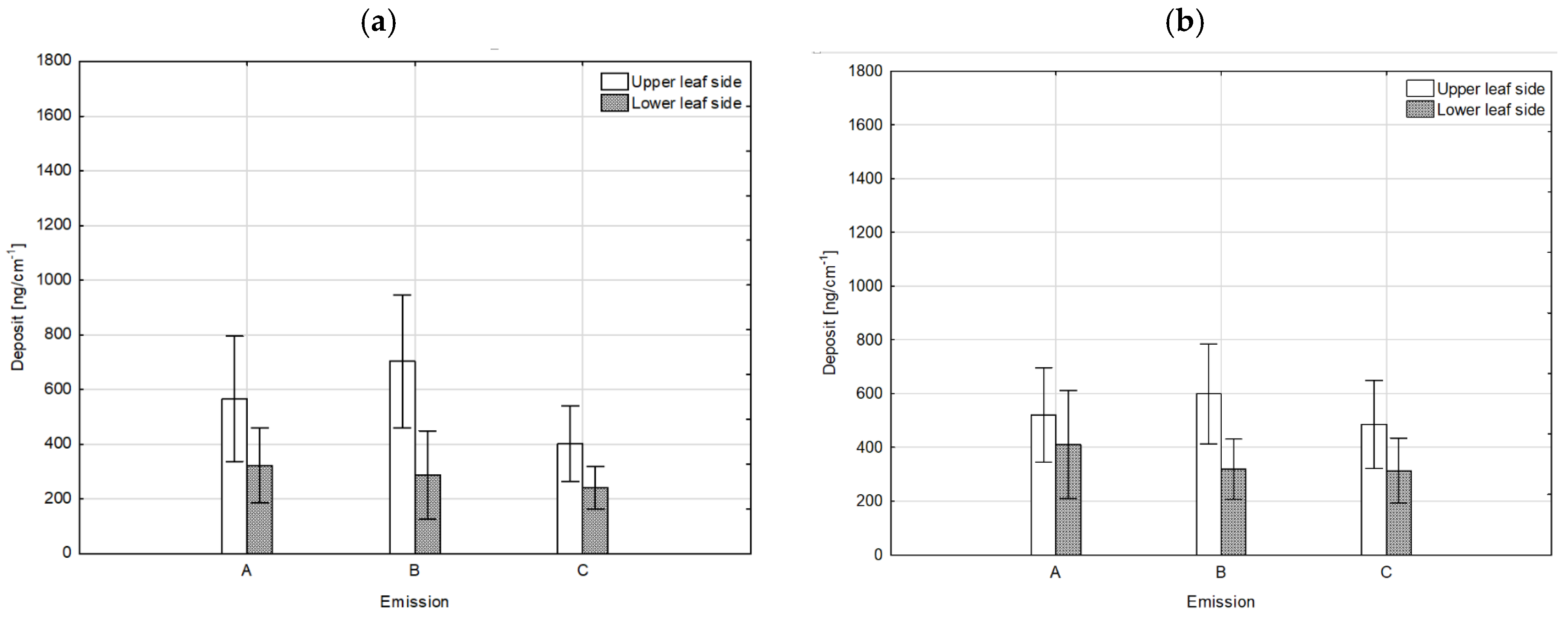

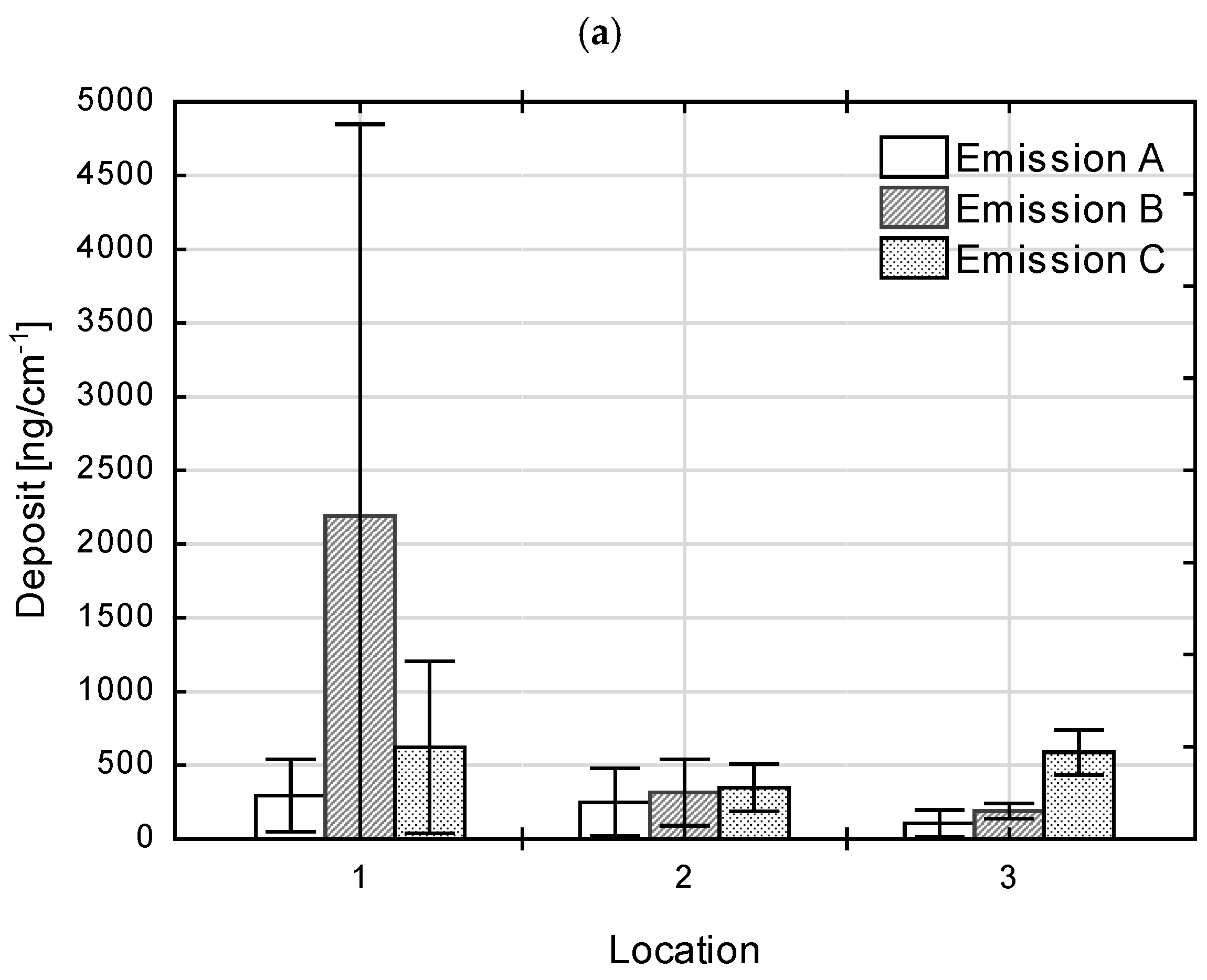

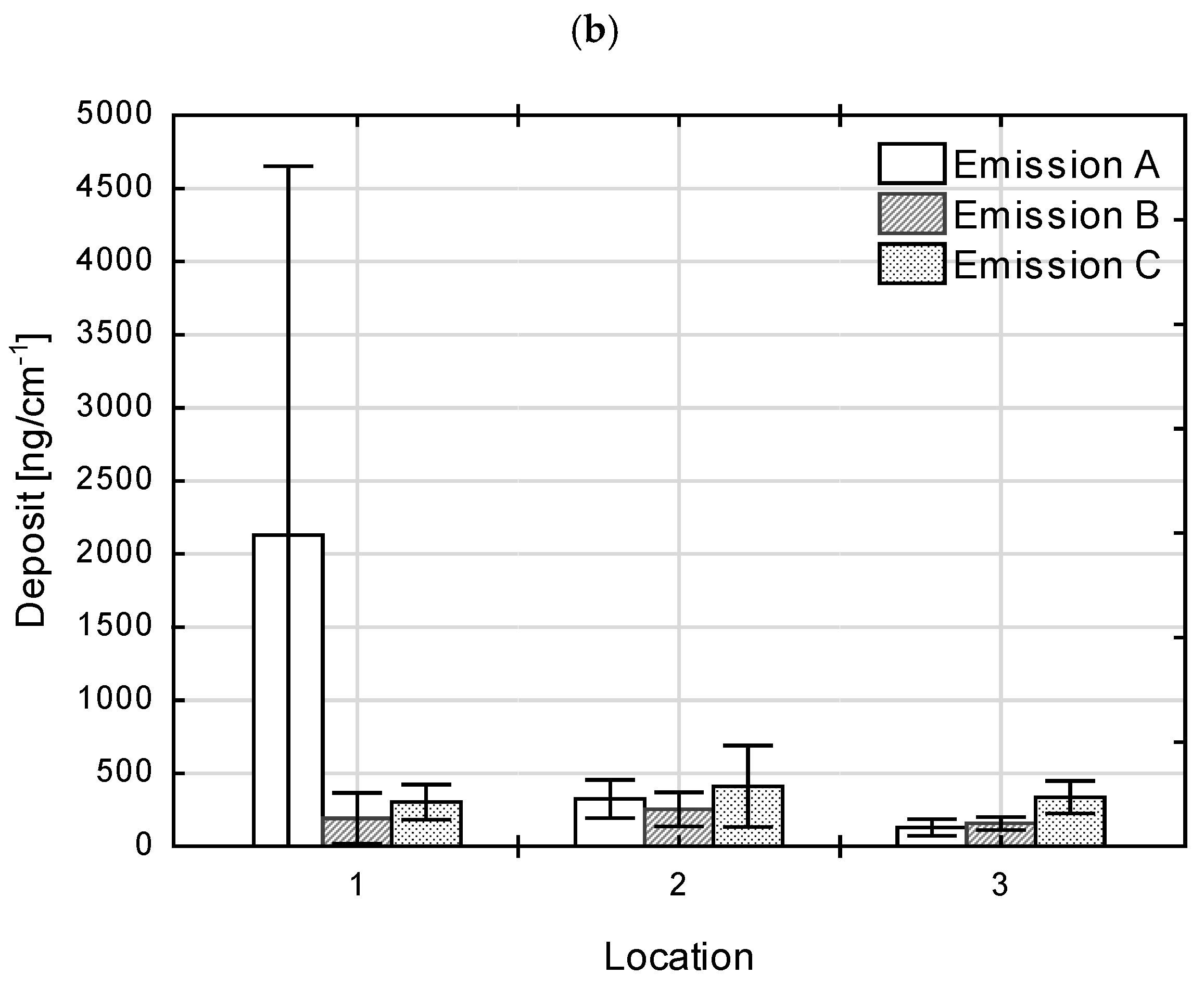

3.2. Spray Deposit

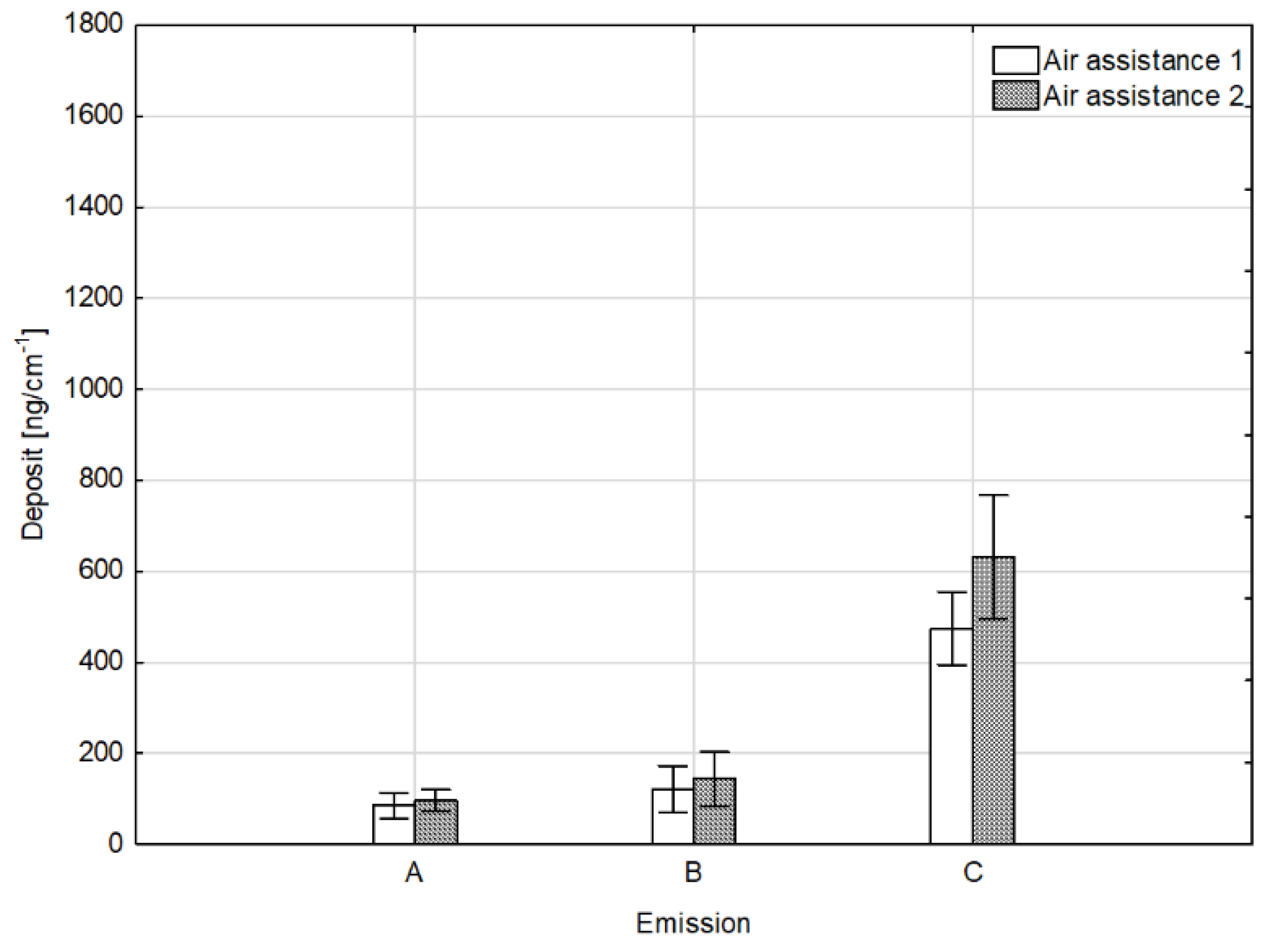

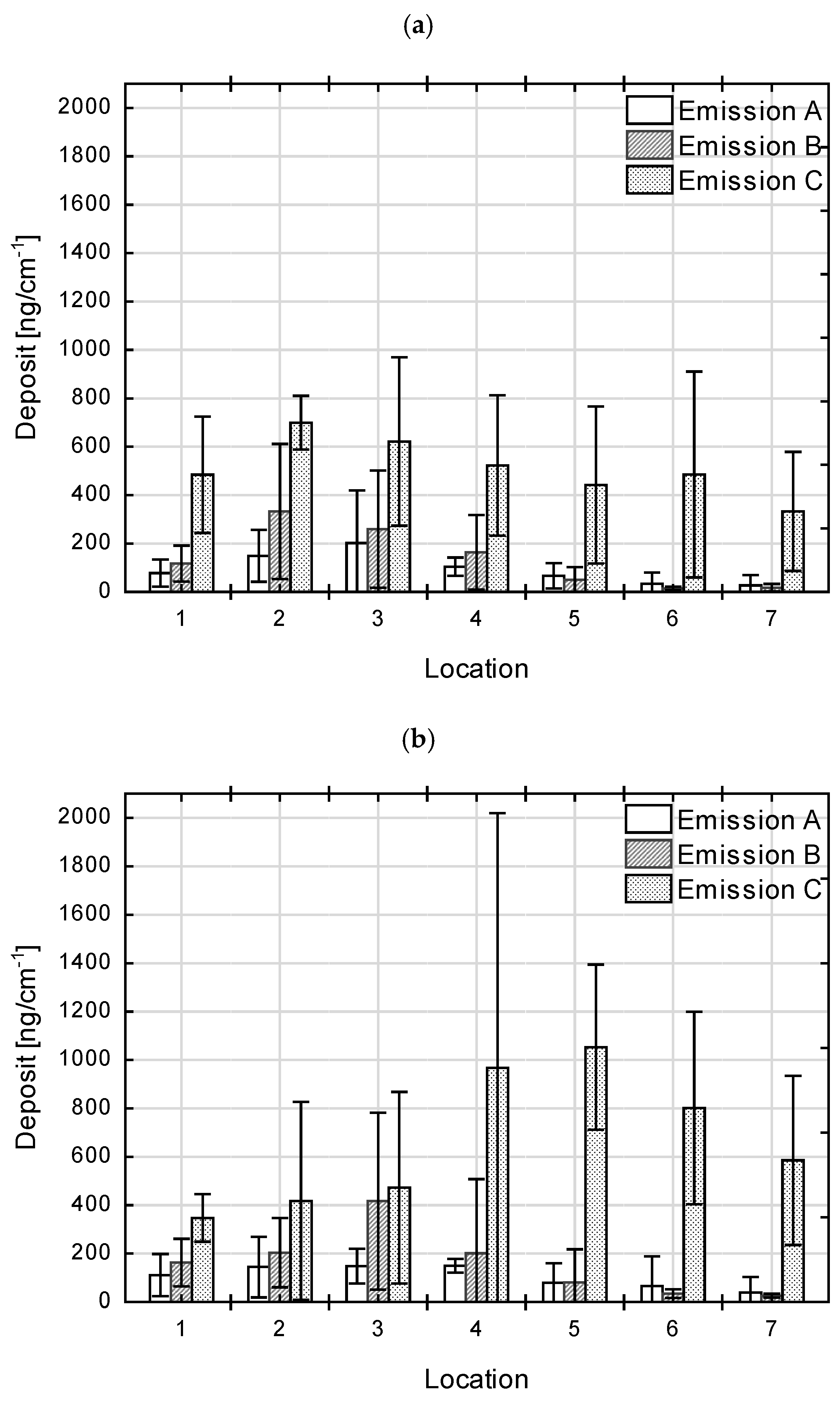

3.3. Spray Drift

4. Conclusions

- −

- verification of the obtained results in biological efficacy tests,

- −

- the use of spray recycling techniques.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Document 52019DC0640: Communication from the Commission to the European Parliment, The European Green Deal, COM/2019/640 Final; European Commission: Brussels, Belgium, 2019.

- Document 52020DC0381: Communication from the Commission, A Farm to Fork Strategy, COM/2020/381 Final; European Commission: Brussels, Belgium, 2020.

- Derksen, R.C.; Gray, R.L. Deposition and air speed patterns of air-carrier apple orchard sprayers. Trans. ASAE 1995, 38, 5–11. [Google Scholar] [CrossRef]

- Doruchowski, G.; Labanowska, B.; Goszczynski, W.; Godyn, A.; Holownicki, R. Spray deposit, spray loss and biological efficacy of chemicals applied with different spraying techniques in black currants. Electron. J. Pol. Agric. Univ. 2002, 5, 1. [Google Scholar]

- ISO/FDIS 22866; Equipment for Crop Protection. Methods for the Field Measurement of Spray Drift. International Standards Organization: Geneva, Switzerland, 2005.

- Balsari, P.; Marucco, P. Influence of canopy parameters on spray drift in vineyard. Asp. Appl. Biol. 2004, 71, 157–164. [Google Scholar]

- Cerruto, E. Influence of airflow rate and forward speed on the spray deposit in vineyards. J. Agric. Eng. 2007, 1, 7–14. [Google Scholar] [CrossRef]

- Grella, M.; Gallart, M.; Marucco, P.; Balsari, P.; Gil, E. Ground deposition and airborne spray drift assessment in vineyard and orchard: The influence of environmental variables and sprayer settings. Sustainability 2017, 9, 728. [Google Scholar] [CrossRef]

- Pergher, G.; Petris, R. The effect of air flow rate on spray deposition in a Guyot-trained vineyard. CIGR E. J. 2008, 10, 1–14. [Google Scholar]

- Walklate, P.J.; Weiner, K.L.; Parkin, C.S. Analysis of and experimental measurements made on a moving air-assisted sprayer with two-dimensional air-jets penetrating a uniform crop canopy. J. Agric. Engng. Res. 1996, 63, 365–378. [Google Scholar] [CrossRef]

- Grella, M.; Miranda-Fuentes, A.; Marucco, P.; Balsari, P.; Gioelli, F. Development of drift-reducing spouts for vineyard pneumatic sprayers: Measurement of droplet size spectra generated and their classification. Appl. Sci. 2020, 10, 7826. [Google Scholar] [CrossRef]

- Grella, M.; Miranda-Fuentes, A.; Marucco, P.; Balsari, P. Field assessment of a newly-designed pneumatic spout to contain spray drift in vineyards: Evaluation of canopy distribution and off-target losses. Pest Manag. Sci. 2020, 76, 4173–4191. [Google Scholar] [CrossRef]

- Panneton, B.; Lacasse, B.; Piché, M. Effect of air-jet configuration on spray coverage in vineyards. Biosyst. Eng. 2005, 90, 173–184. [Google Scholar] [CrossRef]

- Panneton, B.; Lacasse, B.; Thériault, R. Penetration of spray in apple trees as a function of airspeed, airflow, and power for tower sprayers. Can. Biosyst. Eng. 2005, 47, 13–20. [Google Scholar]

- Salcedo, R.; Pons, P.; Llop, J.; Zaragoza, T.; Campos, J.; Ortega, P.; Gallart, M.; Gil, E. Dynamic evaluation of airflow stream generated by a reverse system of an axial fan sprayer using 3D-ultrasonic anemometers. Effect of canopy structure. Comput. Electron. Agric. 2019, 163, 104851. [Google Scholar] [CrossRef]

- Gil, Y.; Sinfort, C. Emission of pesticides to the air during sprayer application: A bibliographic review. Atm. Environ. 2005, 39, 5183–5193. [Google Scholar] [CrossRef]

- Landers, A.J. Improving spraying efficiency. In National Wine and Grape Industry Centre; National Wine and Grape Industry Center: NWGIC Workshop. 2008. Available online: http://www.nysaes.cornell.edu/ent/faculty/landers/pestapp (accessed on 24 September 2025).

- Garcerá, C.; Moltó, E.; Chueca, P. Spray pesticide applications in Mediterranean citrus orchards: Canopy deposition and off-target losses. Total Environ. Sci. 2017, 599, 1344–1362. [Google Scholar] [CrossRef]

- Fornasiero, D.; Mori, N.; Tirello, P.; Pozzebon, A.; Duso, C.; Tescari, E.; Bradascio, R.; Otto, S. Effect of spray drift reduction techniques on pests and predatory mites in orchards and vineyards. Crop Prot. 2017, 98, 283–292. [Google Scholar] [CrossRef]

- Zhang, F.; Sun, H.; Qiu, W.; Lv, X.; Chen, Y.; Zhao, G. Model construction and validation of airflow velocity attenuation through pear tree canopies. Front. Plant Sci. 2022, 13, 1026503. [Google Scholar] [CrossRef]

- García-Ramos, F.J.; Vidal, M.; Boné, A.; Malón, H.; Aguirre, J. Analysis of the air flow generated by an air-assisted sprayer equipped with two axial fans using a 3D sonic anemometer. Sensors 2012, 12, 7598–7613. [Google Scholar] [CrossRef] [PubMed]

- García-Ramos, F.J.; Serreta, A.; Boné, A.; Vidal, M. Applicability of a 3D laser scanner for characterizing the spray distribution pattern of an air-assisted sprayer. J. Sens. 2018, 5231810, 1–7. [Google Scholar] [CrossRef]

- Foque, D.; Dekeyser, D.; Zwertvaegher, I.; Nuyttens, D. Accuracy of a multiple mineral tracer methodology for measuring spray deposition. Asp. Appl. Biol. 2014, 122, 203–212. [Google Scholar]

- Foque, D.; Nuyttens, D. Effects of nozzle type and spray angle on spray deposition in ivy pot plants. Pest Manag. Sci. 2011, 67, 199–208. [Google Scholar] [CrossRef] [PubMed]

- Nuyttens, D.; Windey, S.; Sonck, B. Optimisation of a vertical spray boom for greenhouse spray applications. Biosyst. Eng. 2004, 89, 417–423. [Google Scholar] [CrossRef]

- Pergher, G. Recovery rate of tracer dyes used for deposit assessment. ASAE Pap. 2001, 44, 787. [Google Scholar] [CrossRef]

- Stallinga, H.; Michielsen, J.M.; Snoussi, M.; van Steenbergen, G. Recovery and Stability of Fluorescent Tracer Acid Yellow 250; Wageningen University&Research: Wageningen, The Netherlands, 2024; Volume 7. [Google Scholar] [CrossRef]

- Szarka, Z.A.; Kruger, G.R.; Golus, J.; Rodgers, C.; Perkins, D.; Brain, R.A. Spray drift deposition comparison of fluorimetry and analytical confirmation techniques. Pest Manag. Sci. 2021, 77, 4192–4199. [Google Scholar] [CrossRef]

- Van de Zande, J.; Barendregt, A.; Michielsen, J.; Stallinga, H. Effect of sprayer settings on spray distribution and drift potential when spraying dwarf apple trees. In Proceedings of the ASAE Annual International Meeting, Chicago, IL, USA, 28–31 July 2002; p. 021036. Available online: https://edepot.wur.nl/660098 (accessed on 24 September 2025).

- Dekeyser, D.; Duga, A.T.; Verboven, P.; Endalew, A.M.; Hendrickx, N.; Nuyttens, D. Assessment of orchard sprayers using laboratory experiments and computational fluid dynamics modelling. Biosyst. Eng. 2013, 114, 157–169. [Google Scholar] [CrossRef]

- Łabanowska, B. Methodology of Integrated Currant Protection; IO-PIB: Skierniewice, Poland, 2021; pp. 1–46. ISBN 978-83-89800-31-2. (In Polish) [Google Scholar]

- Dekeyser, D.; Foque, D.; Duga, A.T.; Verboven, P.; Hendrickx, N.; Nuyttens, D. Spray deposition assessment using different application techniques in artificial orchard trees. Crop Prot. 2014, 64, 187–197. [Google Scholar] [CrossRef]

- Ou, M.; Zhang, Y.; Wu, M.; Wang, C.; Dai, S.; Wang, M.; Dong, X.; Jiang, L. Development and Experiment of an Air-Assisted Sprayer for Vineyard Pesticide Application. Agriculture 2024, 14, 2279. [Google Scholar] [CrossRef]

| Air-Jet Emission System | Gear | Air Volume m3 h−1 | Air Velocity m∙s−1 | Number of Nozzles | Pressure MPa |

|---|---|---|---|---|---|

| Directed air-jet (“offset”) | 1 | 12.000 | 38 | 2 × 4 | 1.05 |

| 2 | 16.000 | 44 | 2 × 4 | 1.05 | |

| Directed air-jet (“face-to face”) | 1 | 12.000 | 38 | 2 × 4 | 1.05 |

| 2 | 16.000 | 44 | 2 × 4 | 1.05 | |

| Conventional (axial fan) | 1 | 22.000 | 28 | 2 × 4 | 1.05 |

| 2 | 31.000 | 34 | 2 × 4 | 1.05 |

| Source of Variation | df | Sum of Squares | Percent of Total | df | Sum of Squares | Percent of Total |

|---|---|---|---|---|---|---|

| Lower Air Volume | Higher Air Volume | |||||

| Spray deposit—spray emission | ||||||

| Main effects: | ||||||

| L—Location | 6 | * 8,022,574 | 21.67 | 6 | * 5,842,392 | 14.29 |

| ET—Emission type | 2 | 1,117,983 | 3.02 | 2 | 183,108 | 0.45 |

| L × ET | 12 | 1,963,325 | 5.30 | 12 | 3,063,051 | 7.49 |

| ERROR | 189 | 46,888,898 | 189.00 | 39,347,307 | ||

| Spray deposit—leaf side | ||||||

| Main effects: | ||||||

| LS—Leaf side | 1 | * 3,929,106 | 10.61 | 1 | * 1,854,968 | 4.54 |

| ET—Emission type | 2 | 1,117,983 | 3.02 | 2 | 183,108 | 0.45 |

| ET × LS | 2 | 591,103 | 1.60 | 2 | 259,745 | 0.64 |

| Error | 204 | 52,354,587 | 204 | 46,138,037 | ||

| Source of Variation | df | Sum of Squares | Percent of Total |

|---|---|---|---|

| Spray drift (on the frame) | |||

| Main effects: | |||

| ET—Emission type | 2 | * 8,364,527 | 65.24 |

| EA—Air assistance | 1 | * 192,611 | 1.50 |

| ET × EA | 2 | 210,781 | 1.64 |

| Error | 186 | 7,692,981 |

| Source of Variation | df | Sum of Squares | Percent of Total | df | Sum of Squares | Percent of Total |

|---|---|---|---|---|---|---|

| Lower Air Volume | Higher Air Volume | |||||

| Spray drift (on the frame)—8 location | ||||||

| Main effects: | ||||||

| L—Location | 7 | * 998,304 | 20.23 | 7 | * 860,112 | 10.65 |

| ET—Emission type | 2 | * 2,959,888 | 59.97 | 2 | * 5,615,420 | 69.51 |

| L × ET | 14 | 207,428 | 4.20 | 14 | * 1,817,849 | 22.50 |

| ERROR | 72 | 1,140,656 | 72 | 2,668,631 | ||

| Spray drift (ground)—3 location | ||||||

| Main effects: | ||||||

| L—Location | 2 | * 4,340,018 | 40.69 | 2 | * 3,026,197 | 37.84 |

| ET—Emission type | 2 | * 2,800,331 | 26.26 | 2 | * 2,874,222 | 35.94 |

| L × ET | 4 | * 5,959,663 | 55.88 | 4 | * 6,747,215 | 84.37 |

| Error | 27 | 9,041,522 | 27 | 7,743,132 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hołownicki, R.; Doruchowski, G.; Świechowski, W.; Bartosik, A.; Konopacki, P.; Godyń, A. Influence of Air-Jet Configuration on Spray Deposit and Drift in a Blackcurrant Plantation. Agronomy 2025, 15, 2360. https://doi.org/10.3390/agronomy15102360

Hołownicki R, Doruchowski G, Świechowski W, Bartosik A, Konopacki P, Godyń A. Influence of Air-Jet Configuration on Spray Deposit and Drift in a Blackcurrant Plantation. Agronomy. 2025; 15(10):2360. https://doi.org/10.3390/agronomy15102360

Chicago/Turabian StyleHołownicki, Ryszard, Grzegorz Doruchowski, Waldemar Świechowski, Andrzej Bartosik, Paweł Konopacki, and Artur Godyń. 2025. "Influence of Air-Jet Configuration on Spray Deposit and Drift in a Blackcurrant Plantation" Agronomy 15, no. 10: 2360. https://doi.org/10.3390/agronomy15102360

APA StyleHołownicki, R., Doruchowski, G., Świechowski, W., Bartosik, A., Konopacki, P., & Godyń, A. (2025). Influence of Air-Jet Configuration on Spray Deposit and Drift in a Blackcurrant Plantation. Agronomy, 15(10), 2360. https://doi.org/10.3390/agronomy15102360