Effects of Tray-Drying on the Physicochemical, Microbiological, Proximate, and Sensory Properties of White- and Red-Fleshed Loquat (Eriobotrya Japonica Lindl.) Fruit

Abstract

1. Introduction

2. Materials and Methods

2.1. Vegetal Material

2.2. Experimental Design

- Thesis 1: dehydration at 50 °C for 12 h;

- Thesis 2: dehydration at 70 °C for 12 h.

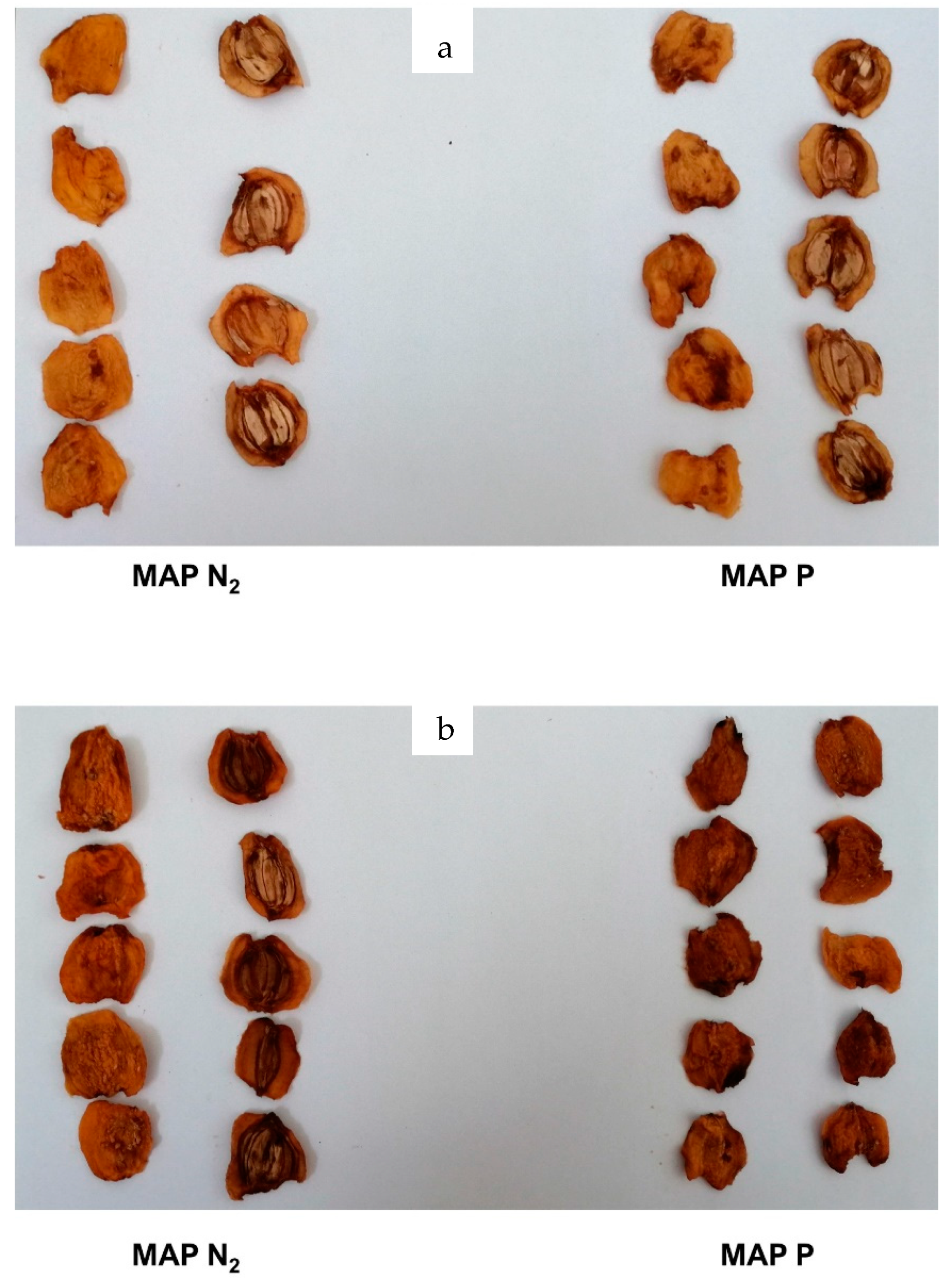

- MAPN2 white-flesh cultivar;

- MAPN2 red-fleshed cultivar;

- MAPP white-fleshed cultivar;

- MAPP red-fleshed cultivar.

2.3. Physico-Chemical Analysis

- Color;

- Firmness (N);

- Longitudinal Diameter;

- Transverse Diameter.

2.4. Microbial Analysis

2.5. Proximate Composition

2.6. Sensory Evaluation

Statistical Analysis

3. Results and Discussion

3.1. Fresh Fruit

3.2. Preliminary Test

3.3. Longitudinal and Transverse Diameter and Dry Residue (DR%)

3.4. Firmness

3.5. Color Characteristics

3.6. Microbial Analysis

3.7. Proximate Compounds

3.8. Sensory Analysis

4. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Monastra, F.; Insero, O. The Present Situation of Some Underutilized Fruit Crops in Italy. Cah. Options Méditerranéennes 1995, 13, 39–46. [Google Scholar]

- Llácer, G.; Badenes, M.; Calvo, J.M. Plant Material of Loquat in Mediterranean Countries; CIHEAM: Zaragoza, Spain, 2003; Volume 58, pp. 45–52. [Google Scholar]

- Testa, R.; Migliore, G.; Schifani, G.; Tinebra, I.; Farina, V. Chemical–Physical, Sensory Analyses and Consumers’ Quality Perception of Local vs. Imported Loquat Fruits: A Sustainable Development Perspective. Agronomy 2020, 10, 870. [Google Scholar] [CrossRef]

- Farina, V.; Gianguzzi, G.; Mazzaglia, A. Fruit Quality Evaluation of Affirmed and Local Loquat (Eriobotrya japonica Lindl) Cultivars Using Instrumental and Sensory Analyses. Fruits 2016, 71, 105–113. [Google Scholar] [CrossRef]

- Planeta, D.; Farina, V.; Bambina, P.; Tinebra, I.; Passafiume, R.; Cinquanta, L.; Corona, O. Analysis of Aroma Compounds of Nine Autochthonous and Non-Autochthonous Loquat Cultivars Grown in Sicily. Ital. J. Food Sci. 2021, 33, 33–42. [Google Scholar] [CrossRef]

- Gentile, C.; Reig, C.; Corona, O.; Todaro, A.; Mazzaglia, A.; Perrone, A.; Gianguzzi, G.; Agusti, M.; Farina, V. Pomological Traits, Sensory Profile and Nutraceutical Properties of Nine Cultivars of Loquat (Eriobotrya japonica Lindl.) Fruits Grown in Mediterranean Area. Plant Foods Hum. Nutr. 2016, 71, 330–338. [Google Scholar] [CrossRef]

- Hou, Y.; Li, Z.; Zheng, Y.; Jin, P. Effects of CaCl2 Treatment Alleviates Chilling Injury of Loquat Fruit (Eribotrya japonica) by Modulating ROS Homeostasis. Foods 2021, 10, 1662. [Google Scholar] [CrossRef]

- Fahim Abbas, M.; Batool, S.; Khaliq, S.; Mubeen, S.; Ullah, N.; Zafar, K.; Rafiq, M.; Al-Sadi, A.M.; Alotaibi, S.S.; El-Shehawi, A.M. Diversity of Fungal Pathogens Associated with Loquat and Development of Novel Virulence Scales. PLoS ONE 2021, 16, e0257951. [Google Scholar] [CrossRef]

- Gonzalez-Dominguez, E.; Rossi, V.; Farina, V.; Gianguzzi, G.; Berbegal, M.; Armengol, J. Validation of a Mechanistic Model for Predicting Fruit Scab Infection on Different Loquat Cultivars. Phytopathol. Mediterr. 2017, 56, 400–408. [Google Scholar]

- Gariglio, N.; Castillo, A.; Alós, E.; Juan, M.; Almela, V.; Agustı, M. The Influences of Environmental Factors on the Development of Purple Spot of Loquat Fruit (Eriobotrya japonica Lindl.). Sci. Hortic. 2003, 98, 17–23. [Google Scholar] [CrossRef]

- Avidan, B.; Klein, I. Physiological Disorders in Loquat (Eriobotrya japonica Lindl.). I. Russeting. Adv. Hortic. Sci. 1998, 12, 190–195. [Google Scholar]

- Dhiman, A.; Suhag, R.; Thakur, D.; Gupta, V.; Prabhakar, P.K. Current Status of Loquat (Eriobotrya japonica Lindl.): Bioactive Functions, Preservation Approaches, and Processed Products. Food Rev. Int. 2021, 1–31. [Google Scholar] [CrossRef]

- Pant, S.; Chinwan, D. Value Addition of Food Products. Int. J. Eng. Sci. Res. 2014, 4, 946–949. [Google Scholar]

- Lewicki, P.P. Design of Hot Air Drying for Better Foods. Trends Food Sci. Technol. 2006, 17, 153–163. [Google Scholar] [CrossRef]

- Mohite, A.; Mishra, A.; Sharma, N. Equilibrium Moisture Content and Drying Behaviour of Tamarind Seed under Thin Layer Condition. Int. J. Seed Spices 2016, 6, 18–22. [Google Scholar]

- Macedo, L.L.; Vimercati, W.C.; da Silva Araújo, C.; Saraiva, S.H.; Teixeira, L.J.Q. Effect of Drying Air Temperature on Drying Kinetics and Physicochemical Characteristics of Dried Banana. J. Food Process Eng. 2020, 43, e13451. [Google Scholar] [CrossRef]

- Caparino, O.; Tang, J.; Nindo, C.; Sablani, S.; Powers, J.; Fellman, J. Effect of Drying Methods on the Physical Properties and Microstructures of Mango (Philippine ‘Carabao’ Var.) Powder. J. Food Eng. 2012, 111, 135–148. [Google Scholar] [CrossRef]

- Reis, R.C.; de Souza Viana, E.; Da Silva, S.C.S.; de Oliveira Mamede, M.E.; da Silva Araújo, Í.M. Stability and Sensory Quality of Dried Papaya. Food Nutr. Sci. 2018, 9, 489. [Google Scholar] [CrossRef][Green Version]

- Vidinamo, F.; Fawzia, S.; Karim, M. Investigation of the Effect of Drying Conditions on Phytochemical Content and Antioxidant Activity in Pineapple (Ananas comosus). Food Bioprocess Technol. 2021, 15, 72–81. [Google Scholar] [CrossRef]

- Ullah, F.; Min, K.; Khattak, M.K.; Wahab, S.; Wahab, N.; Ameen, M.; Memon, M.S.; Wang, X.; Soomro, S.A.; Yousaf, K. Effects of Different Drying Methods on Some Physical and Chemical Properties of Loquat (Eriobotrya japonica) Fruits. Int. J. Fruit Sci. 2018, 18, 345–354. [Google Scholar] [CrossRef]

- Mishra, A.; Upadhyay, A.; Jaiswal, P.; Sharma, N. Effect of Different Drying Method on the Chemical and Microstructural Properties of Loquat Slices. J. Food Process. Preserv. 2021, 45, e15105. [Google Scholar] [CrossRef]

- Farina, V.; Cinquanta, L.; Vella, F.; Niro, S.; Panfili, G.; Metallo, A.; Cuccurullo, G.; Corona, O. Evolution of Carotenoids, Sensory Profiles and Volatile Compounds in Microwave-Dried Fruits of Three Different Loquat Cultivars (Eriobotrya japonica Lindl.). Plant Foods Hum. Nutr. 2020, 75, 200–207. [Google Scholar] [CrossRef]

- Lahbari, M.; Fahloul, D. Experimental Study and Mathematical Modelling of Loquat Drying: Effect of the Drying Method on Quality. Int. Rev. Mech. Eng. IREME 2020, 14, 208. [Google Scholar] [CrossRef]

- Mishra, A.; Sharma, N. Mathematical Modelling and Tray Drying Kinetics of Loquat (Eriobotrya japonica). J. Dairy Food Sci. 2014, 9, 272–284. [Google Scholar] [CrossRef]

- Dias, C.; Fonseca, A.; Amaro, A.L.; Vilas-Boas, A.A.; Oliveira, A.; Santos, S.A.; Silvestre, A.J.; Rocha, S.M.; Isidoro, N.; Pintado, M. Natural-Based Antioxidant Extracts as Potential Mitigators of Fruit Browning. Antioxidants 2020, 9, 715. [Google Scholar] [CrossRef] [PubMed]

- Suttirak, W.; Manurakchinakorn, S. Potential Application of Ascorbic Acid, Citric Acid and Oxalic Acid for Browning Inhibition in Fresh-Cut Fruits and Vegetables. Walailak J. Sci. Technol. WJST 2010, 7, 5–14. [Google Scholar]

- Sadler, M.J.; Gibson, S.; Whelan, K.; Ha, M.-A.; Lovegrove, J.; Higgs, J. Dried Fruit and Public Health–What Does the Evidence Tell Us? Int. J. Food Sci. Nutr. 2019, 70, 675–687. [Google Scholar] [CrossRef] [PubMed]

- Mossine, V.V.; Mawhinney, T.P.; Giovannucci, E.L. Dried Fruit Intake and Cancer: A Systematic Review of Observational Studies. Adv. Nutr. 2020, 11, 237–250. [Google Scholar] [CrossRef]

- Martínez-Calvo, J.; Badenes, M.L.; Llácer, G.; Bleiholder, H.; Hack, H.; Meier, U. Phenological Growth Stages of Loquat Tree (Eriobotrya japonica (Thunb.) Lindl.). Ann. Appl. Biol. 1999, 134, 353–357. [Google Scholar] [CrossRef]

- Caballero, P.; Fernández, M.A. Loquat, Production and Market. Options Mediterraéens Ser. Semin. Mediterr. 2003, 58, 11–20. [Google Scholar]

- Cisneros-Zevallos, L.; Krochta, J.M. Dependence of Coating Thickness on Viscosity of Coating Solution Applied to Fruits and Vegetables by Dipping Method. J. Food Sci. 2003, 68, 503–510. [Google Scholar] [CrossRef]

- Fu, X.; Xing, S.; Xiong, H.; Min, H.; Zhu, X.; He, J.; Feng, J.; Mu, H. Effects of Packaging Materials on Storage Quality of Peanut Kernels. PLoS ONE 2018, 13, e0190377. [Google Scholar] [CrossRef] [PubMed]

- Polenta, G.; Budde, C.; Murray, R. Effects of Different Pre-Storage Anoxic Treatments on Ethanol and Acetaldehyde Content in Peaches. Postharvest Biol. Technol. 2005, 38, 247–253. [Google Scholar] [CrossRef]

- Metodo Per la Deterimanzione del Residuo Secco o Sostanza Secca-Gazzetta Ufficiale.Pdf. Available online: https://www.gazzettaufficiale.it/do/atto/serie_generale/caricaPdf?cdimg=12A0671700200010110001&dgu=2012–06-14&art.dataPubblicazioneGazzetta=2012–06-14&art.codiceRedazionale=12A06717&art.num=1&art.tiposerie=SG (accessed on 1 January 2022).

- Passafiume, R.; Gugliuzza, G.; Gaglio, R.; Busetta, G.; Tinebra, I.; Sortino, G.; Farina, V. Aloe-Based Edible Coating to Maintain Quality of Fresh-Cut Italian Pears (Pyrus communis L.) during Cold Storage. Horticulturae 2021, 7, 581. [Google Scholar] [CrossRef]

- Passafiume, R.; Gaglio, R.; Sortino, G.; Farina, V. Effect of Three Different Aloe Vera Gel-Based Edible Coatings on the Quality of Fresh-Cut “Hayward” Kiwifruits. Foods 2020, 9, 939. [Google Scholar] [CrossRef]

- Barros, L.; Baptista, P.; Ferreira, I.C. Effect of Lactarius Piperatus Fruiting Body Maturity Stage on Antioxidant Activity Measured by Several Biochemical Assays. Food Chem. Toxicol. 2007, 45, 1731–1737. [Google Scholar] [CrossRef]

- Morand, C.-A. Les Recommendations, Les Resolutions et Les Avis Du Droit Communautaire. Cah. Dr Euro 1970, 6, 623. [Google Scholar]

- Tinebra, I.; Scuderi, D.; Sortino, G.; Inglese, P.; Farina, V. Effects of Argon-Based and Nitrogen-Based Modified Atmosphere Packaging Technology on the Quality of Pomegranate (Punica granatum L. Cv. Wonderful) Arils. Foods 2021, 10, 370. [Google Scholar] [CrossRef]

- Mazzaglia, A.; Lanza, C.; Farina, V.; Barone, F. Evaluation of Fruit Quality in Loquat Using Both Chemical and Sensory Analyses. In Proceedings of the III International Symposium on Loquat 887, Antakya-Hatay, Turkey, 3–6 May 2010; pp. 345–349. [Google Scholar]

- Stellfeldt, A.; Martín, J.J.H. Dinámica de Crecimiento del Fruto en Níspero Japonés ‘Algerie’ bajo Tratamiento de Riego Deficitario Precosecha. Available online: http://www.sech.info/ACTAS/Acta%20n%C2%BA%2054.%20VI%20Congreso%20Ib%C3%A9rico%20de%20Ciencias%20Hort%C3%ADcolas.%20XII%20Congreso%20Nacional%20de%20Ciencias%20Hort%C3%ADcolas/Comunicaciones/Din%C3%A1mica%20de%20crecimiento%20del%20fruto%20en%20n%C3%ADspero%20japon%C3%A9s%20%E2%80%98Algerie%E2%80%99%20bajo%20tratamiento%20de%20riego%20deficitario%20precosecha.pdf (accessed on 1 January 2022).

- Zhou, C.-H.; Xu, C.-J.; Sun, C.-D.; Li, X.; Chen, K.-S. Carotenoids in White-and Red-Fleshed Loquat Fruits. J Agric. Food Chem. 2007, 55, 7822–7830. [Google Scholar] [CrossRef]

- McGuire, R.G. Reporting of Objective Color Measurements. HortScience 1992, 27, 1254–1255. [Google Scholar] [CrossRef]

- Insero, O.; Monastra, F.; Barone, F.; Calabrese, F.; D’Ascanio, R.; Martelli, S.; Ondradu, G. Loquat Tree (Eriobotrya japonica Lindl.). Inf. Agrar. 1993, 12, 64–66. (In Italian) [Google Scholar]

- Xu, H.; Chen, J. Commercial Quality, Major Bioactive Compound Content and Antioxidant Capacity of 12 Cultivars of Loquat (Eriobotrya japonica Lindl.) Fruits. J. Sci. Food Agric. 2011, 91, 1057–1063. [Google Scholar] [CrossRef] [PubMed]

- Hasegawa, P.N.; Faria, A.F.d.; Mercadante, A.Z.; Chagas, E.A.; Pio, R.; Lajolo, F.M.; Cordenunsi, B.R.; Purgatto, E. Chemical Composition of Five Loquat Cultivars Planted in Brazil. Ciênc. E Tecnol. Aliment. 2010, 30, 552–559. [Google Scholar] [CrossRef]

- Jayaraman, K.; Das Gupta, D. Dehydration of Fruits and Vegetables-Recent Developments in Principles and Techniques. Dry. Technol. 1992, 10, 1–50. [Google Scholar] [CrossRef]

- Tarancón, P.; Fernández-Serrano, P.; Besada, C. Consumer Perception of Situational Appropriateness for Fresh, Dehydrated and Fresh-Cut Fruits. Food Res. Int. 2021, 140, 110000. [Google Scholar] [CrossRef] [PubMed]

- Rocculi, P.; Romani, S.; Dalla Rosa, M. Effect of MAP with Argon and Nitrous Oxide on Quality Maintenance of Minimally Processed Kiwifruit. Postharvest Biol. Technol. 2005, 35, 319–328. [Google Scholar] [CrossRef]

- Soltani, M.; Alimardani, R.; Mobli, H.; Mohtasebi, S.S. Modified Atmosphere Packaging: A Progressive Technology for Shelf-Life Extension of Fruits and Vegetables. J. Appl. Packag. Res. 2015, 7, 2. [Google Scholar]

- Alzamora, S.M.; Lopez Malo, A.; Tapia, M.S. Minimally Processed Fruits and Vegetables, 1st ed.; CRC Press: Boca Raton, FL, USA, 2000. [Google Scholar]

- Sagar, V.R.; Suresh Kumar, P. Recent Advances in Drying and Dehydration of Fruits and Vegetables: A Review. J. Food Sci. Technol. 2010, 47, 15–26. [Google Scholar] [CrossRef]

- Moreno, J.; Chiralt, A.; Escriche, I.; Serra, J.A. Effect of Blanching/Osmotic Dehydration Combined Methods on Quality and Stability of Minimally Processed Strawberries. Food Res. Int. 2000, 33, 609–616. [Google Scholar] [CrossRef]

- Bolin, H.R.; Huxsoll, C.C. Storage stability of minimally processed fruit. J. Food Process. Preserv. 1989, 13, 281–292. [Google Scholar] [CrossRef]

- Rodrigues, A.C.C.; Pereira, L.M.; Sarantópoulos, C.I.G.L.; Bolini, H.M.A.; Cunha, R.L.; Junqueira, V.C.A.; Hubinger, M.D. Impact of Modified Atmosphere Packaging on the Osmodehydrated Papaya Stability. J. Food Process. Preserv. 2006, 30, 563–581. [Google Scholar] [CrossRef]

- Moggia, C.; Lobos, G.A.; Retamales, J.B. Modified Atmosphere Packaging in Blueberries: Effect of Harvest Time and Moment of Bag Sealing. Acta Hortic. 2014, 153–158. [Google Scholar] [CrossRef]

- Nielsen, T.; Leufvén, A. The Effect of Modified Atmosphere Packaging on the Quality of Honeoye and Korona Strawberries. Food Chem. 2008, 107, 1053–1063. [Google Scholar] [CrossRef]

- Pareek, S.; Benkeblia, N.; Janick, J.; Cao, S.; Yahia, E.M. Postharvest Physiology and Technology of Loquat (Eriobotrya japonica Lindl.) Fruit. J. Sci. Food Agric. 2014, 94, 1495–1504. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Shao, X. Characterisation of Polyphenol Oxidase and Peroxidase and the Role in Browning of Loquat Fruit. Czech J. Food Sci. 2016, 33, 109–117. [Google Scholar] [CrossRef]

- Tian, S.; Li, B.; Ding, Z. Physiological Properties and Storage Technologies of Loquat Fruit. Fresh Prod. 2007, 1, 76–81. [Google Scholar]

- Ding, C.-K.; Chachin, K.; Ueda, Y.; Imahori, Y.; Wang, C.Y. Modified Atmosphere Packaging Maintains Postharvest Quality of Loquat Fruit. Postharvest Biol. Technol. 2002, 24, 341–348. [Google Scholar] [CrossRef]

- Sortino, G.; Allegra, A.; Farina, V.; De Chiara, M.L.V.; Inglese, P. Genotype Influence on Shelf Life Behaviour of Minimal Processed Loquat (Eriobotrya japonica (Thunb.) Lindl.) Fruit: The Role of Sugar, Acid Organics and Phenolic Compounds. Chem. Biol. Technol. Agric. 2022, 9, 8. [Google Scholar] [CrossRef]

- Koca, N.; Burdurlu, H.S.; Karadeniz, F. Kinetics of Colour Changes in Dehydrated Carrots. J. Food Eng. 2007, 78, 449–455. [Google Scholar] [CrossRef]

- Baloch, A.; Buckle, K.; Edwards, R. Measurement of Non-enzymic Browning of Dehydrated Carrot. J. Sci. Food Agric. 1973, 24, 389–398. [Google Scholar] [CrossRef]

- Abano, E.E. Kinetics and Quality of Microwave-Assisted Drying of Mango (Mangifera Indica). Int. J. Food Sci. 2016, 2016, 2037029. [Google Scholar] [CrossRef]

- Barth, M.; Hankinson, T.R.; Zhuang, H.; Breidt, F. Microbiological Spoilage of Fruits and Vegetables. In Compendium of the Microbiological Spoilage of Foods and Beverages; Springer: Berlin/Heidelberg, Germany, 2009; pp. 135–183. [Google Scholar]

- Leff, J.W.; Fierer, N. Bacterial Communities Associated with the Surfaces of Fresh Fruits and Vegetables. PLoS ONE 2013, 8, e59310. [Google Scholar] [CrossRef] [PubMed]

- Paswan, R.; Park, Y.W. Survivability of Salmonella and Escherichia Coli O157: H7 Pathogens and Food Safety Concerns on Commercial Powder Milk Products. Dairy 2020, 1, 189–201. [Google Scholar] [CrossRef]

- Bintsis, T. Foodborne Pathogens. AIMS Microbiol. 2017, 3, 529. [Google Scholar] [CrossRef] [PubMed]

- Witthuhn, R.; Engelbrecht, S.; Joubert, E.; Britz, T. Microbial Content of Commercial South African High-moisture Dried Fruits. J. Appl. Microbiol. 2005, 98, 722–726. [Google Scholar] [CrossRef]

- Liu, Z.; Liao, C.; Golson, K.; Phillips, S.; Wang, L. Survival of Common Foodborne Pathogens on Dried Apricots Made with and without Sulfur Dioxide Treatment. Food Control 2021, 121, 107569. [Google Scholar] [CrossRef]

- Radojčin, M.; Pavkov, I.; Bursać Kovačević, D.; Putnik, P.; Wiktor, A.; Stamenković, Z.; Kešelj, K.; Gere, A. Effect of Selected Drying Methods and Emerging Drying Intensification Technologies on the Quality of Dried Fruit: A Review. Processes 2021, 9, 132. [Google Scholar] [CrossRef]

- Seymour, G.B.; Taylor, J.E.; Tucker, G.A. Biochemistry of Fruit Ripening; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2012; ISBN 94–011-1584–2. [Google Scholar]

- Sun, Y.; Liang, C. Factors Determining Consumers’ Purchase Intentions Towards Dried Fruits. Int. J. Fruit Sci. 2020, 20, S1072–S1096. [Google Scholar] [CrossRef]

- Farina, V.; Passafiume, R.; Tinebra, I.; Palazzolo, E.; Sortino, G. Use of Aloe Vera Gel-Based Edible Coating with Natural Anti-Browning and Anti-Oxidant Additives to Improve Post-Harvest Quality of Fresh-Cut ‘Fuji’Apple. Agronomy 2020, 10, 515. [Google Scholar] [CrossRef]

| Cultivars | L* | a* | b* | C* | h° |

|---|---|---|---|---|---|

| Claudia | 66.01 ± 0.19 | 11.20 ± 0.21 | 24.49 ± 0.23 | 26.75 ± 0.33 | 77.20 ± 4.62 |

| Peluche | 60.00 ± 0.17 | 24.60 ± 0.09 | 35.00 ± 0.29 | 42.78 ± 0.61 | 70.85 ± 3.18 |

| Cultivars | TSSC | TA | TSSC/TA | FF |

|---|---|---|---|---|

| Claudia | 9.11 ± 0.16 | 0.69 ± 0.07 | 13.20 | 30.90 ± 0.18 |

| Peluche | 12.33 ± 0.21 | 0.82 ± 0.09 | 15.04 | 25.00 ± 0.22 |

| Time-Temperature Combination | L* | a* | b* | C* | h° | ΔE | DR% |

|---|---|---|---|---|---|---|---|

| 50 °C for 12 h | 46.04 ± 0.22 | 12.95 ± 0.19 | 39 ± 0.24 | 40.90 ± 0.10 | 1.24 ± 0.21 | 14 ± 0.03 | 39.07 ± 0.15 |

| Peluche Cv.—Mineral Composition (mg/100 g) | |||||

| MAP P | |||||

| K | Na | Ca | Mg | P | |

| Fresh | 228.66 ± 2.79 a | 10.66 ± 1.51 b | 15.00 ± 1.00 c | 11.66 ± 1.08 d | 23.00 ± 1.36 a |

| T0 | 205.00 ± 2.50 b | 12.00 ± 1.00 ab | 15.66 ± 1.15 c | 12.00 ± 2.00 c | 11.66 ± 1.00 b |

| T10 | 201.00 ± 2.06 b * | 13.66 ± 2.00 a | 20.67 ± 1.00 bc | 13.66 ± 1.06 bc | 11.66 ± 1.06 b |

| T20 | 196.66 ± 2.00 b | 13.75 ± 2.00 a | 20.70 ± 1.31 b | 14.66 ± 1.06 b | 11.33 ± 1.15 b |

| T30 | 190.00 ± 2.00 c | 14.00 ± 2.00 a | 21.25 ± 2.00 b | 14.66 ± 1.00 b | 10.66 ± 1.53 bc |

| T40 | 162.27 ± 2.00 d * | 14.00 ± 2.31 a | 21.50 ± 1.00 ab | 16.66 ± 1.00 a | 10.66 ± 1.53 bc |

| T50 | 143.33 ± 2.90 e * | 14.00 ± 2.00 a | 22.00 ± 1.00 a | 16.66 ± 1.08 a | 9.66 ± 1.50 c |

| MAP N2 | |||||

| K | Na | Ca | Mg | P | |

| Fresh | 228.66 ± 2.79 a | 10.66 ± 1.51 e | 15.00 ± 1.00 e | 11.66 ± 2.08 d | 23.00 ± 4.36 a |

| T0 | 205.00 ± 2.50 b | 12.00 ± 1.00 d | 15.66 ± 1.15 de | 12.00 ± 2.00 c | 11.66 ± 1.00 b |

| T10 | 196.67 ± 2.88 bc * | 13.66 ± 1.30 cd | 16.00 ± 3.05 d | 13.66 ± 1.57 b | 11.67 ± 3.04 b |

| T20 | 195.00 ± 2.00 c | 14.00 ± 2.00 c | 16.00 ± 2.00 d | 13.66 ± 1.52 b | 11.00 ± 1.00 c |

| T30 | 191.33 ± 2.30 cd | 14.00 ± 2.00 c | 18.00 ± 2.08 c | 14.67 ± 3.05 ab | 10.66 ± 1.52 c |

| T40 | 190.00 ± 2.00 d * | 15.00 ± 1.08 b | 20.00 ± 1.00 b | 14.66 ± 2.08 ab | 10.66 ± 1.27 c |

| T50 | 173.33 ± 2.00 e * | 17.00 ± 2.01 a | 22.00 ± 3.60 a | 15.00 ± 1.52 a | 9.00 ± 1.53 d |

| Claudia Cv.—Mineral Composition (mg/100 g) | |||||

| MAP P | |||||

| K | Na | Ca | Mg | P | |

| Fresh | 128.66 ± 2.79 a | 24.00 ± 2.64 e | 15.00 ± 1.00 d | 11.66 ± 2.08 e | 11.00 ± 1.00 a |

| T0 | 110.00 ± 2.00 b | 28.00 ± 2.00 de | 15.00 ± 1.00 d | 11.00 ± 1.03 e | 11.66 ± 1.51 ab |

| T10 | 105.00 ± 2.00 c | 29.00 ± 2.00 d | 15.66 ± 1.15 d * | 13.66 ± 0.57 d | 11.66 ± 1.52 ab |

| T20 | 103.33 ± 2.72 d | 31.00 ± 1.60 c | 17.00 ± 2.00 c * | 14.00 ± 0.11 cd | 11.66 ± 1.52 ab |

| T30 | 101.33 ± 2.00 e | 33.66 ± 2.30 bc | 22.00 ± 2.00 b | 14.66 ± 1.05 c | 11.66 ± 1.52 ab |

| T40 | 101.00 ± 2.93 e | 34.00 ± 1.63 b * | 25.00 ± 1.00 a | 21.00 ± 1.08 b * | 9.00 ± 1.00 b |

| T50 | 100.00 ± 1.90 f | 41.00 ± 1.00 a | 25.00 ± 1.00 a | 23.00 ± 0.57 a * | 9.66 ± 1.53 b |

| MAP N2 | |||||

| K | Na | Ca | Mg | P | |

| Fresh | 128.66 ± 2.79 a | 24.00 ± 2.64 e | 15.00 ± 1.00 d | 11.66 ± 1.08 de | 11.00 ± 1.00 a |

| T0 | 110.00 ± 1.62 b | 28.00 ± 2.00 d | 15.00 ± 1.00 d | 11.00 ± 1.03 e | 11.66 ± 1.51 ab |

| T10 | 106.00 ± 2.00 c | 29.00 ± 2.00 cd | 22.00 ± 2.00 c * | 11.66 ± 1.5 de | 11.33 ± 1.52 b |

| T20 | 105.00 ± 2.00 cd | 31.00 ± 1.00 c | 22.66 ± 1.30 bc * | 12.00 ± 1.05 d | 10.66 ± 1.15 c |

| T30 | 103.33 ± 2.72 d | 31.00 ± 1.00 c | 23.00 ± 2.00 b | 13.66 ± 0.50 c | 10.66 ± 1.52 c |

| T40 | 103.33 ± 2.58 d | 41.00 ± 1.00 b * | 25.00 ± 1.00 a | 14.66 ± 0.57 b * | 9.66 ± 1.53 d |

| T50 | 101.33 ± 2.93 e | 44.00 ± 2.45 a | 25.00 ± 1.00 a | 16.66 ± 1.27 a * | 9.00 ± 1.06 d |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tinebra, I.; Passafiume, R.; Scuderi, D.; Pirrone, A.; Gaglio, R.; Palazzolo, E.; Farina, V. Effects of Tray-Drying on the Physicochemical, Microbiological, Proximate, and Sensory Properties of White- and Red-Fleshed Loquat (Eriobotrya Japonica Lindl.) Fruit. Agronomy 2022, 12, 540. https://doi.org/10.3390/agronomy12020540

Tinebra I, Passafiume R, Scuderi D, Pirrone A, Gaglio R, Palazzolo E, Farina V. Effects of Tray-Drying on the Physicochemical, Microbiological, Proximate, and Sensory Properties of White- and Red-Fleshed Loquat (Eriobotrya Japonica Lindl.) Fruit. Agronomy. 2022; 12(2):540. https://doi.org/10.3390/agronomy12020540

Chicago/Turabian StyleTinebra, Ilenia, Roberta Passafiume, Dario Scuderi, Antonino Pirrone, Raimondo Gaglio, Eristanna Palazzolo, and Vittorio Farina. 2022. "Effects of Tray-Drying on the Physicochemical, Microbiological, Proximate, and Sensory Properties of White- and Red-Fleshed Loquat (Eriobotrya Japonica Lindl.) Fruit" Agronomy 12, no. 2: 540. https://doi.org/10.3390/agronomy12020540

APA StyleTinebra, I., Passafiume, R., Scuderi, D., Pirrone, A., Gaglio, R., Palazzolo, E., & Farina, V. (2022). Effects of Tray-Drying on the Physicochemical, Microbiological, Proximate, and Sensory Properties of White- and Red-Fleshed Loquat (Eriobotrya Japonica Lindl.) Fruit. Agronomy, 12(2), 540. https://doi.org/10.3390/agronomy12020540