1. Introduction

Humans have made use of growing plant material to create ash and charcoal through combustion for centuries. The oldest related evidence dates from about 1 million years ago. The earliest deliberately used by-products of biomass combustion include ash and charcoal [

1,

2,

3,

4,

5,

6]. From early historical times, ash was also used in farming, as a soil fertilizer [

7,

8]. Until the 19th century, biomass was mainly utilised in the production of heat energy by direct combustion [

6]. In recent years, biomass has been more and more appreciated all over the world as a valuable energy source. The growing interest in biomass is mainly associated with the climate change resulting from increased greenhouse gas emissions into the atmosphere, and it is linked with the search for alternative energy sources [

1]. Biomass of perennial energy plants, such as basket willow, poplar or giant miscanthus, can be an attractive source for conversion to charcoal or use as bioenergy. Furthermore, biomass as a resource is widely available worldwide [

9].

Different biomass sources are wood and its residues, as well as wooden by-products (i.e., wood chips and sawdust), agricultural waste and by-products (e.g., corncobs, rice husk and manure), as well as paper waste, household wastes and sewage sludge [

2,

10]. Perennial crops grown specifically as an energy source are becoming increasingly popular. Scientific research conducted in Poland on energy crops in recent years has focused predominantly on basket willow (

Salix viminalis L.), giant miscanthus (

Miscanthus x giganteus) and Virginia mallow (

Sida hermaphrodita R.), mainly due to their significant yield potential [

11,

12,

13]. Biomass is an indispensable element for the development of sustainable energy, since it is one of the renewable sources of energy which may replace fossil fuels as a source of conventional energy [

14]. The use of biomass in the production of thermal energy does not contribute to the accumulation of CO

2 in the atmosphere. However, the harvesting methods and transporting different biomass types generates some greenhouse gas (GHG) emissions. The amount of carbon emitted by biomass during its conversion is similar to that taken up by growing plants; consequently the greenhouse gas emissions are reduced. Furthermore, the extensive research and technological progress related to crop production and biomass conversion have resulted in a greater efficiency of biomass utilisation at a lower cost [

1].

Thermochemical processing plays an important role in the development of novel concepts and technologies of biomass transformation [

6]. During biochemical or thermochemical conversion, biomass displays the characteristics of both a raw material for the direct production of energy, and a source of valuable chemical substances, in the form of biochar. Methods of thermal conversion of biomass include pyrolysis, i.e., the thermochemical transformation of biomass occurring in the absence of oxygen or with access to a small amount of oxygen, insufficient for combustion. The process of biomass pyrolysis is widely used in industry. Its products include: biochar, which is a highly carbonised solid material; bio-oil, also known as pyrolytic oil; and syngas [

15,

16,

17,

18,

19]. Depending on the process parameters applied, it is possible to distinguish slow pyrolysis (biocarbonisation), as well as moderate and fast pyrolysis [

20,

21]. Higher biochar yield may be obtained from raw materials with higher concentrations of lignin and lower contents of hemicelluloses [

16,

22,

23]. The type and temperature of the pyrolysis process affects the physical properties and quality characteristics of the resulting biochar, i.e., surface areas and sorption ability, elemental composition, pH value, as well as the number and type of functional groups [

24,

25,

26,

27]. Extensive scientific research focusing on the feasibility of using biochar as a natural fertilizer has led to the increased use of this material in agriculture [

28,

29,

30,

31,

32]. The possible application of biochar in agriculture increases the significance of the biomass pyrolysis process. Additionally, in view of the results and relatively low costs of applying them, biochar compounds are increasingly used in the remediation process of soils. [

33].

Biochar can be used in agricultural soils to increase plant growth and development, which leads to improved yields. According to the scientific literature, the use of biochar as a fertilizer ensures many benefits by improving the physical, chemical and biological properties of soil, which in turn contributes to increased crop yield. Ash a by-product of biomass combustion, it may affect the physical and chemical properties of soils to a comparable or even to a greater extent than mineral fertilizer [

34,

35]. Energy crops, such as basket willow and giant miscanthus, can be grown sustainability and converted into pyrolysates that can be applied to the soil with no risk of heavy metal contamination.

The study was designed to investigate the effects of fertilizing soil, using biochar and ash from plant biomass, on the selected properties of the pyrolysates obtained from basket willow (Salix viminalis L.) and giant miscanthus (Miscanthus x giganteus). Our goal was to use biochar and biomass ash to produce high-quality pyrolysates with fertilizing potential.

2. Materials and Methods

2.1. Site Description

Two-year field trials in four replications were conducted from 2015 to 2017 in Krasne (Podkarpackie Region, Poland, 50°04′16.1″ N 22°04′37.6″ E). The area covered by the study was an agricultural set-aside left without any treatment for more than 10 years. Field trials were located on arable land of the IVb land quality class (soil suitable for a limited selection of arable crops; too dry or too moist; exposed to water erosion; gives average yields despite the use of good agricultural technology; yields vary widely and are very dependent on weather conditions) in a split-block system in four repetitions. Each experimental plot was 35 m2 (7 m length × 5 m width), but the harvest area was only 24 m2 (6 m length × 4 m width), leaving a 1 m buffer on all sides to avoid edge effects. According to agricultural suitability, soil corresponded to the defective wheat complex. These are soils with a concise granulometric composition and smaller humus level.

2.2. Experimental Design

We took 20 soil samples from the area where the experiment was planned, in order to prepare a general (average) sample. Soil samples were taken from the topsoil (0–20 cm). Calculations of fertilizer doses were selected on the basis of nutritional requirements of plants and content of macroelements in soil and fertilizers. The findings of the tests conducted show the basic parameters of the soil and the natural fertilizers applied in this study. The ash samples were found to have a high pH level. The total carbon concentration in the biochar was very high. In all analyzed cases the nitrogen content was low; below 1%. Biochar and biomass ash contributed high levels of phosphate, potassium, and magnesium as compared to the soil (

Table 1).

The levels of the specific macro- and micro-elements in the fertilizers investigated in the study are presented in

Table 2. Higher concentrations of all the elements were identified in the ash from the biomass of the energy crops. In view of the fact that toxic metals in soil fertilizers pose a hazard, the samples in the present study were also examined specifically for the contents of heavy metal. The tests showed no aluminium, arsenic, cadmium or lead in the biochar or the biomass ash. Further, molybdenum, sodium and strontium in the biochar and the biomass ash were below detection limits (0.01 mg kg

−1).

As a result of the soil analyses, the experimental plots were fertilised with biochar alone at a rate of 11.5 t ha−1, or biomass ash alone at a rate of 1.5 t ha−1, or with biochar and biomass ash in a combination. The samples of biomass pyrolysates subjected to further analyses are referred to with names, to reflect the type of the fertilizer used in the biomass cultivation: Control; Ash; Biochar; and Biochar + Ash. In April 2015, the fertilizers were distributed manually on the respective experimental plots, and then mixed with the surface layer of the soil (to a depth of about 20 cm) by means of a tiller. The giant miscanthus and basket willow planting material was acquired from a private supplier (Lublin Region, Poland). The giant miscanthus seedlings obtained from a perennial plantation were grown under standard nursery conditions. Seedlings of Salix viminalis L. clone 082 were planted in the form of sticks. On 16 April 2015, the seedlings were manually planted on the plots, respectively for basket willow and giant miscanthus: planting depth—18 cm and 10–15 cm; spacing of seedlings—0.33 and 1 m; spacing of rows—0.7 and 0.8 m; density—40,000 and 13,000 plants ha−1. The biomass was harvested in February 2016 and 2017 using a brushcutter, equipped with a cutting disc and set to disregard the buffer rows, and to perform the cut 10 cm above the soil surface. The soil treatments were not re-applied in the second year of the experiment.

2.3. Fertilizer Material

A high-speed CM−1000 Cutting Mill from Laarmann was used to grind the biochar. The latter process was carried out using a sieve with a mesh size of 10 mm. The ash generated by biomass combustion did not require additional treatment before the application. The biochar, in the form of coal scales, was obtained by the processing of biomass from basket willow (commercially available in Poland). The ash applied as a fertilizer was produced by combustion of plant biomass from agricultural crops and biomass from energy crops; the material was acquired from Elektrownia Stalowa Wola-Tauron Wytwarzanie S.A. (Stalowa Wola, Poland).

2.4. Pyrolysis

The plant biomass was subjected to the process of pyrolysis in a LECO TGA 701 thermogravimetric analyser. To achieve this, 5 g samples of the crushed material (granulation up to 10 mm) were placed in 18 crucibles. The process of thermal conversion of the biomass was conducted at 500 °C, with a residence time of 10 min, in a nitrogen atmosphere (purity level of 99.99%). Gas flow of 10 L/min was applied and the temperature was increased at a rate of 30 °C/min. The parameters of the pyrolysis process were determined based on an earlier study by these authors [

36]. The above procedure of the pyrolysis process was replicated four times for each type of the biomass. After the carbonisation processes were completed, the material from the crucibles was combined and mixed in order to prepare an overall sample. All the products of pyrolysis were filtered through a mesh with 1 mm openings, and then contaminants were washed out with demineralised water. Subsequently the samples were dried for 12 h, at a temperature of 80 °C, and finally they were closed in containers, to await further analyses (i.e., pH value, content of carbon, and macro- and micro-elements).

2.5. Samples Analysis

The samples of commercially available biochar and biomass ash, as well as the pyrolysates prepared from the above-ground parts of basket willow and giant miscanthus, were analyzed in a laboratory in compliance with the applicable analytical standards [

37,

38,

39,

40,

41].

The pH values of the samples investigated in the study were determined using the potentiometric method, i.e., by measuring the concentrations of hydrogen ions (H+), or their activity. The process was carried out using potassium chloride (KCl) solution with a concentration of 1 mol dm−3, and a 1:2.5 ratio of the sample weight to the solution volume. The measurements were carried out using the Nahita pH meter, model 907 (AUXILAB, Beriáin, Spain). Total carbon and nitrogen contents were tested using the TrueSpec CHN analyser, manufactured by LECO (LECO Corporation, Saint Joseph, MI, USA).

The mineralisation of the materials examined was carried out in three replications. The concentrations of the elements in the samples were identified using inductively coupled plasma atomic emission spectroscopy (ICP-OES), performed with iCAP Dual 6500 analyser (Thermo Fisher Scientific, Schaumburg, IL, USA). The samples were mineralised in Teflon containers, with a mixture of acids (7 mL HNO

3 65% and 1 mL H

2O

2 30%—biochar and produced pyrolysates; 7 mL HNO 65%, 1 mL H

2O

2 30% and 1.5 HF 40%—biomass ash and soil). Biochar as fertilizer and produced pyrolysates mineralization was carried out under defined conditions: temperature increase to 200 °C and 15 min duration; residence at 200 °C and 15 min duration. Biomass ash and soil mineralization was carried out in a higher temperature (220 °C) and longer duration time in first step (20 min). A power of 1500 W was used in this process [

42].

A 0.2 g sample was subjected to mineralisation in each case. Deionized water was added to the samples produced this way, up to the volume of 50 mL. The calibration step involved preparation of a standard solution for each element; for this, the spectroscopic grade reagent (Thermo) and a 3-step curve were applied. The curve fit factor of more than 0.99 was identified for all the elements. The method of standard additions was used to validate the choice of a measuring line of appropriate length. The recovery on the selected lines exceeded 98.5% for each element. In each case, Certified Reference Material (CRM 1515) was used, and the standard addition method was applied, to select the appropriate lines. Furthermore, internal standards for matrix curve correction were applied in each case; these were Yttrium (Y) and Ytterbium (Yb), i.e., two elements which were undetected in the samples. The detection limit identified in the case of the analytical method applied to determine the relevant elements was not lower than 0.01 mg kg−1. The content of Al, As, Ca, Cd, Cr, Cu, Fe, K, Mg, Mn, Mo, Na, NI, P, Pb, S, Sr and Zn was determined.

2.6. Statistical Analysis

The effects of the experimental factors reflected by the relevant parameters, and the relationships between these, were examined using Analysis of Variance (ANOVA) by means of the Bonferroni post-hoc test. Statistica 12 software was applied to compute the statistical analyses. A significance threshold of α ≤ 0.05 was set for all analyses. The data were analyzed separately for each year.

3. Results

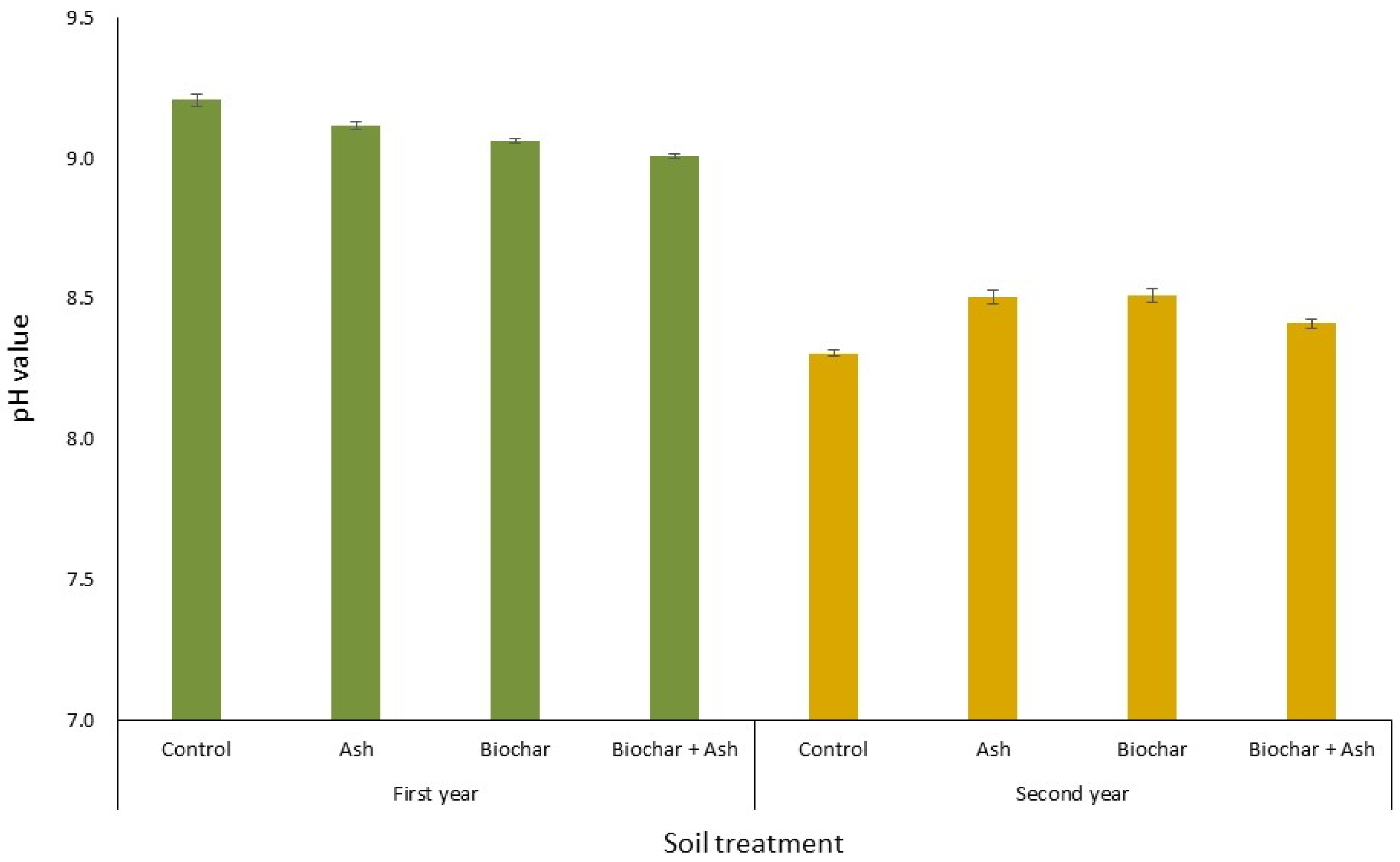

The basket willow pyrolysates’ pH was not significantly different among the three soil treatments and the control (

Figure 1). The pH values identified in the pyrolysates obtained from the control sample of biomass (no fertilisation applied) in the first and second year of the experiment amounted to 9.21 and 8.31, respectively. The pyrolysates produced in the first and second year of the experiment were found with pH values in the range of 9.01–9.21 and 8.31–8.51, respectively. The value of the pH decreased on average by 0.66 in the pyrolysate produced in 2017, compared to the pyrolysate obtained the previous year.

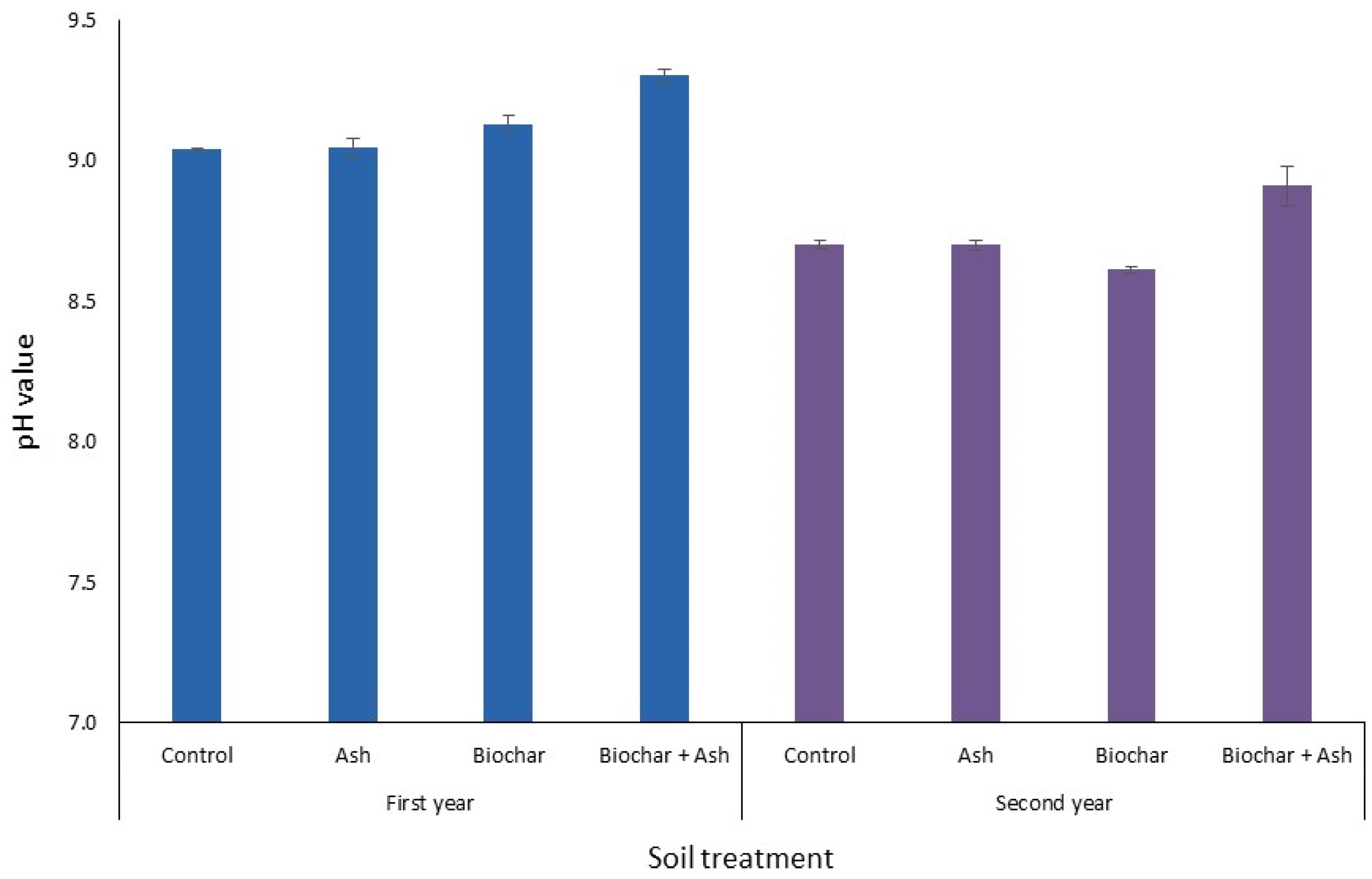

The giant miscanthus pyrolysates’ pH was not significantly different among the three soil treatments and the control (

Figure 2). The pH values identified in the pyrolysates obtained from the control sample biomass (no fertilisation applied) in the first and second year of the experiment amounted to 9.04 and 8.70, respectively. The pyrolysates produced in the first and second year of the experiment were found with pH values in the range of 9.04–9.30 and 8.61–8.91. The value of the pH decreased on average by 0.40 in the pyrolysate produced in 2017, compared to the pyrolysate obtained the previous year.

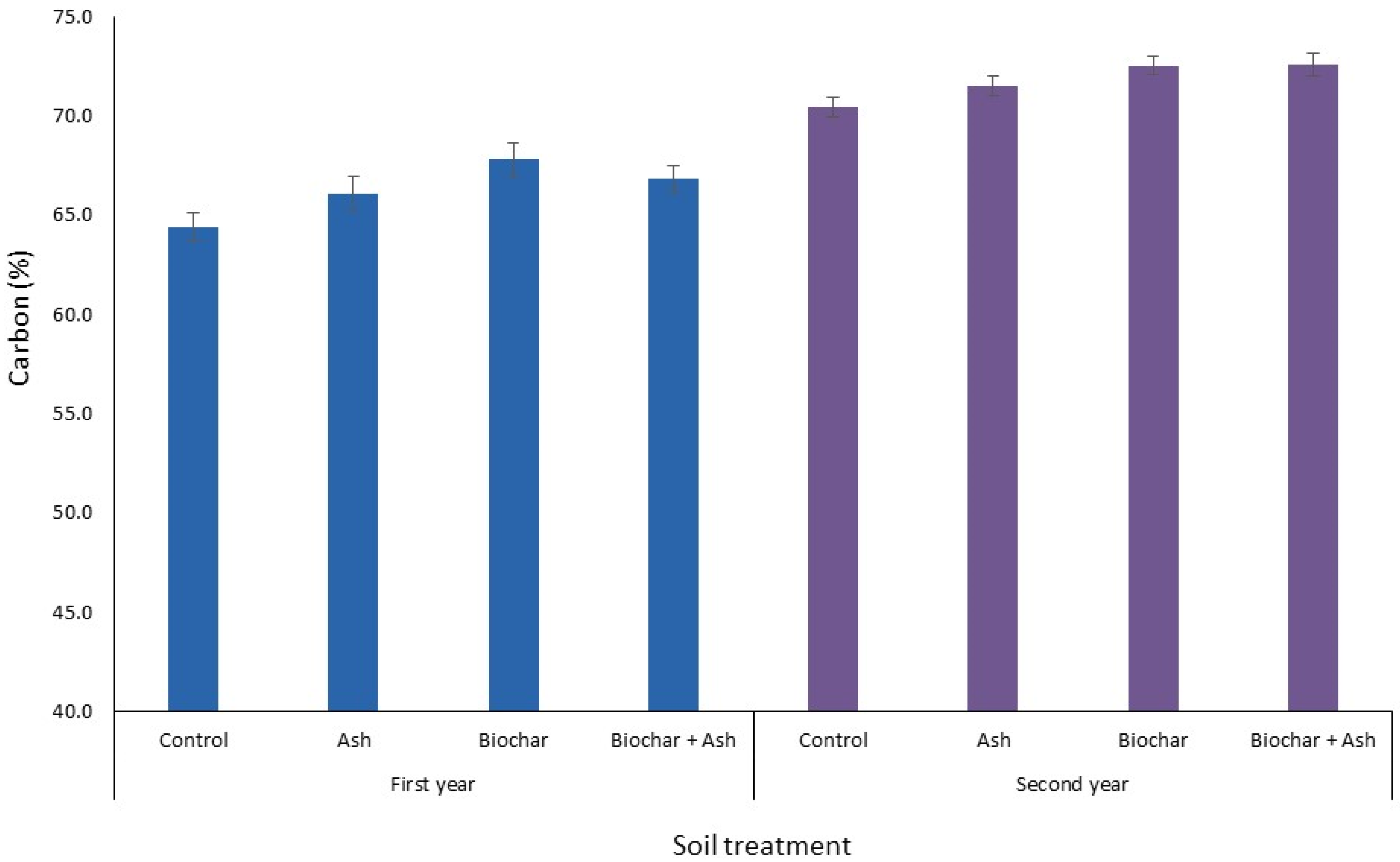

The basket willow pyrolysates’ total carbon contents were not significantly different among the three soil treatments and the control (

Figure 3). The respective analyses showed carbon contents in the range of 76.00–80.61% and 75.75–77.40% one and two years after planting, respectively. Differences of total carbon contents were not significantly different, but the general trend was for higher levels of C in the pyrolysates from the biochar + ash soil treatment.

The giant miscanthus pyrolysates’ total carbon contents were not significantly different among the three soil treatments and the control (

Figure 4). The respective analyses showed carbon contents in the range of 64.43–66.83% and 70.47–72.60% in one and two years after planting, respectively. Differences of total carbon contents were not significantly different, but the general trend was for higher levels of C in the pyrolysates from the biochar in the first, and biochar + ash in the second, year of soil treatment.

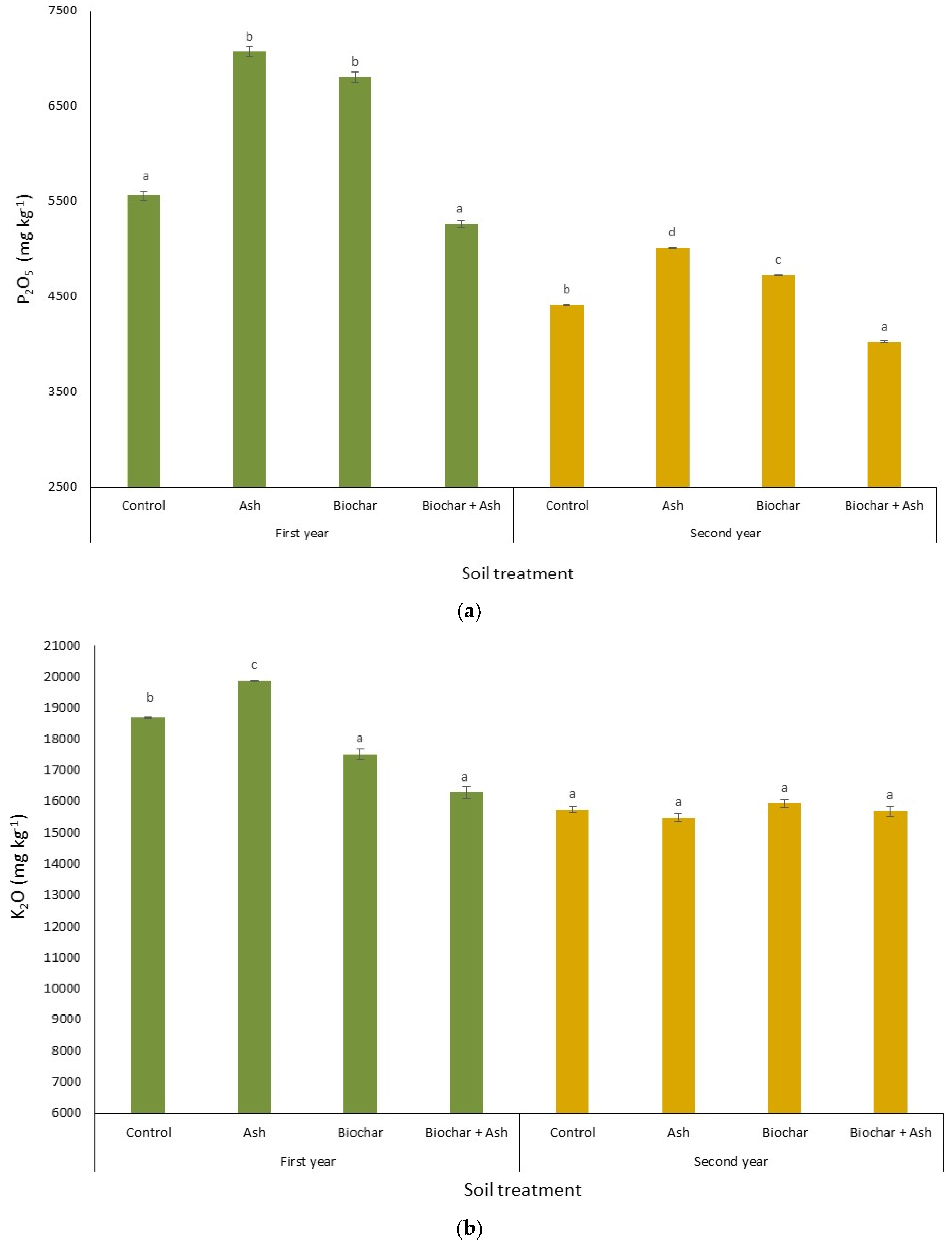

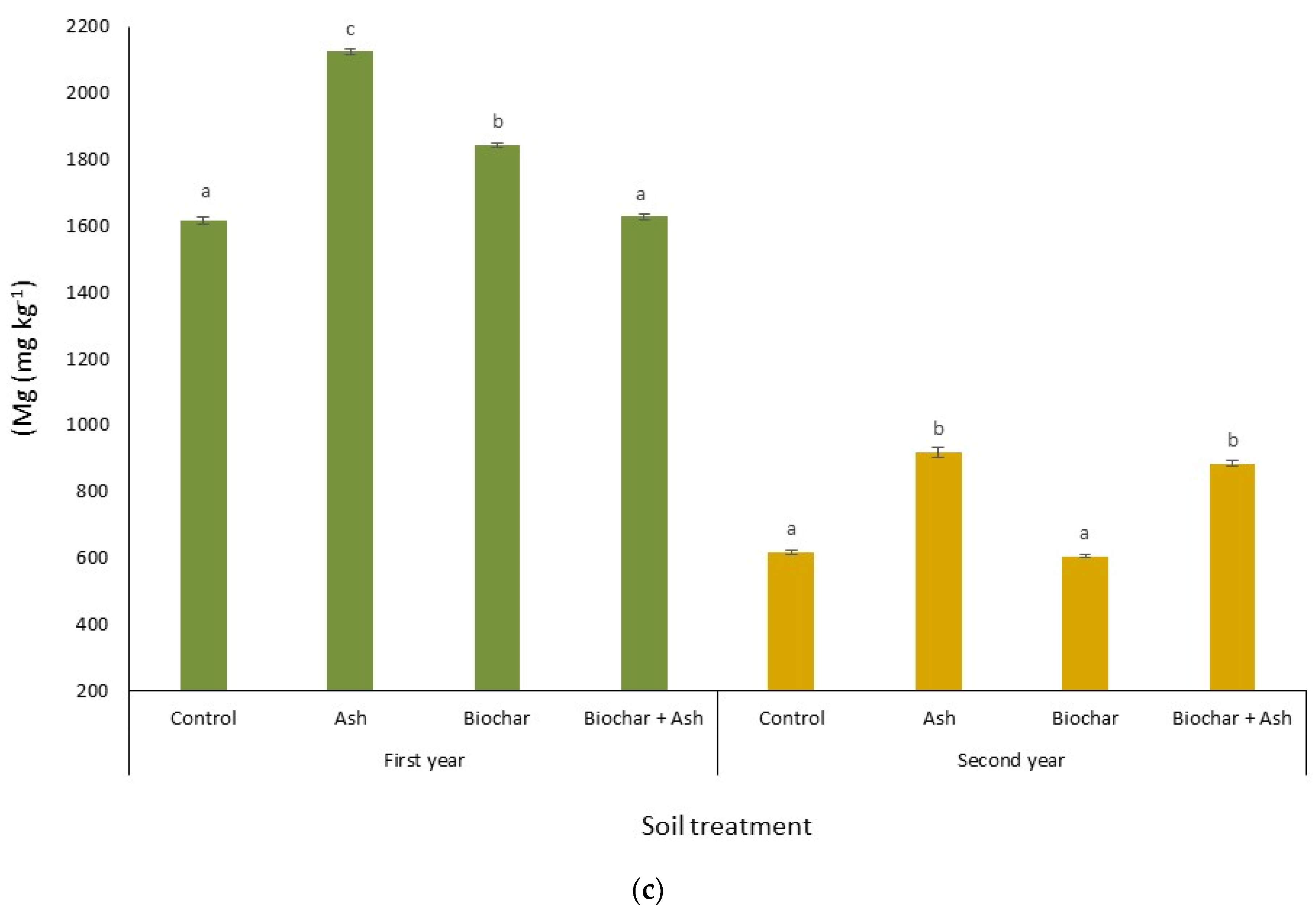

Analysis of the basket willow pyrolysates produced in the first year of the experiment showed contents of phosphoric acid in the control sample amounting to 5557 mg kg

−1. In the case of the treatment based on the use of ash or biochar alone, compared to the control condition, there was a statistically significant increase of phosphoric acid, the values of which reached the levels of 7068 and 6804 mg kg

−1, respectively. The contents of this element in the pyrolysates produced from the biomass obtained in the second year of the experiment were significantly lower than in the first year (

Figure 5a).

In the case of the treatments involving the use of ash or biochar alone, compared to the control condition, there was an increase in the concentrations of potash to 5011 and 4723 mg kg

−1, respectively. On the other hand, treatment with a combination of biochar and ash resulted in a decrease of the parameter, to the value of 4026 mg kg

−1. The basket willow pyrolysates’ potash content in the first year was significantly different among the three soil treatments and the control. These pyrolysates were characterised by contents of potash amounting to 18695, 19883, 17513 and 16288 mg kg

−1, respectively, in the control sample, and the samples fertilised with ash at a rate of 1.5 t ha

−1, biochar, or their combination. The contents of potassium in the pyrolysates produced from the biomass obtained in the second year of the experiment were far lower than in the previous year. The concentrations of absorbable forms of potassium in the pyrolysates were in the range of 15480–15933 mg kg

−1, and were not significantly different among soil treatments and the control (

Figure 5b).

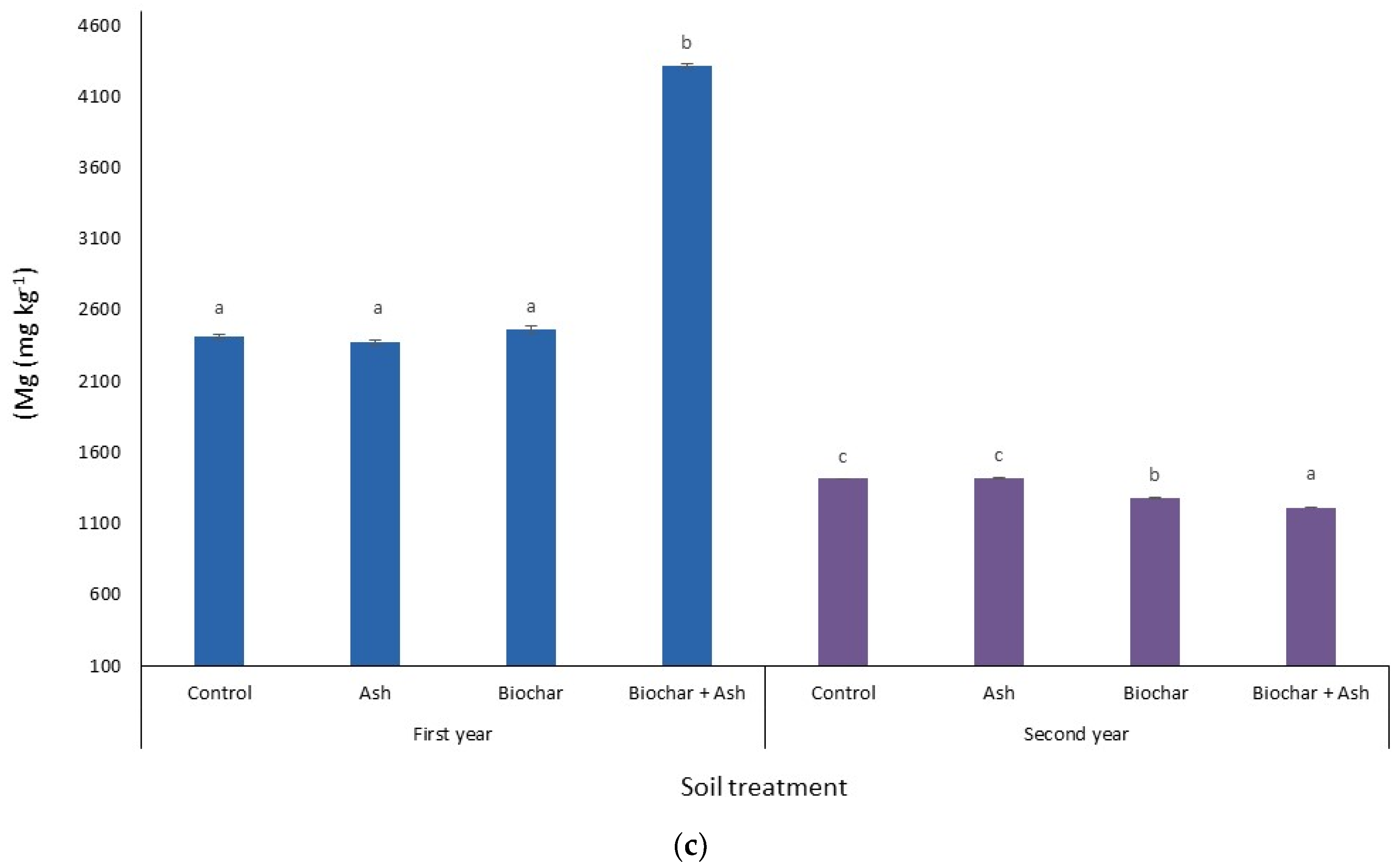

Analyses carried out in the first year of the experiment showed that the contents of absorbable forms of magnesium in the pyrolysates ranged from 1618 to 2125 mg kg

−1. The greatest increase in the contents of this element was identified in the case of the treatment involving the use of ash at a rate of 1.5 t ha

−1; compared to the control sample there was an increase of 31%, which was a statistically significant difference. There was a decrease of over 200% in the contents of magnesium in the pyrolysates produced from the biomass obtained in the second year compared to the first year. The identified contents of absorbable forms of magnesium were in the range of 605–918 mg kg

−1. The greatest statistically significant increase in the contents of this element was again identified in the case of the treatment involving the use of ash at a rate of 1.5 t ha

−1 (

Figure 5c).

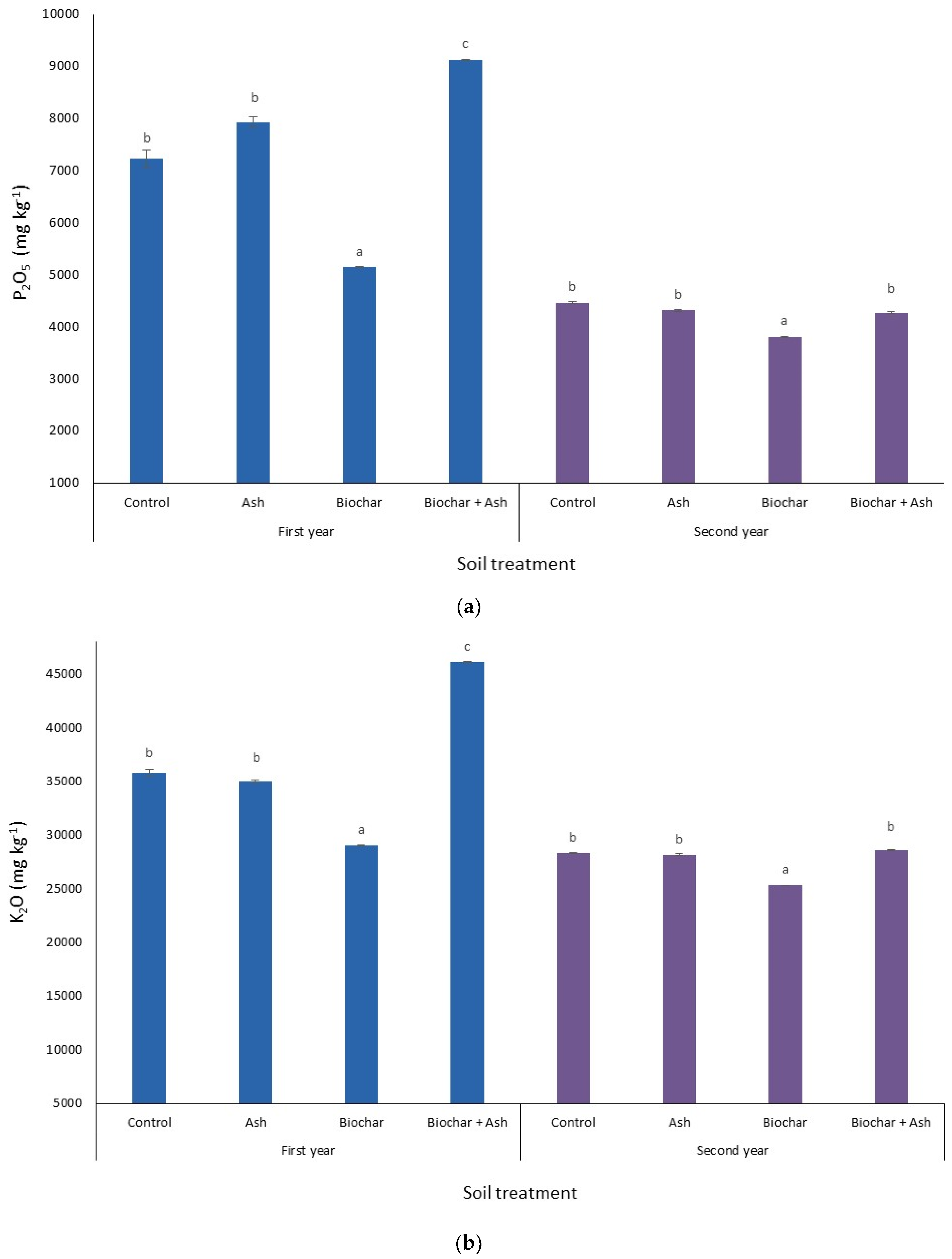

Analysis of giant miscanthus pyrolystates produced in the first year of the experiment showed the contents of phosphoric acid in the control sample amounting to 7237 mg kg

−1. In the case of the treatment based on the use of ash or biochar alone, or their combination, compared to the control condition, there was a statistically significant decrease in this parameter, whose values amounted to 7934, 5141 and 9121 mg kg

−1, respectively. The contents of this element in the pyrolysates produced from the biomass obtained in the second year of the experiment were significantly lower than in the first year. There was a statistically significant decrease in the concentrations of phosphoric acid, relative to the control sample, down to the level of 3798 mg kg

−1 for treatment involving the use of biochar alone (

Figure 6a).

In the case of the treatments involving the use of the biochar and ash combination, compared to the control condition, there was a significant increase in the concentrations of potash to 46077 mg kg

−1 in the first year of the experiment. The contents of potash in the pyrolysates produced from the biomass obtained in the second year of the experiment were far lower than in the previous year. The concentrations of absorbable forms of potassium in the pyrolysates were in the range of 25316–28559 mg kg

−1, and were significantly different among biochar soil treatments and the control (

Figure 6b).

Analyses carried out in the first year of the experiment showed that the contents of absorbable forms of magnesium in the pyrolysates ranged from 2378 to 4318 mg kg

−1. The only statistically significant change was identified for the combined application of biochar and ash; compared to the control sample, there was an increase of 79% in the contents of this element. There was a decrease of over 200% in the contents of magnesium in the pyrolysates produced from the biomass obtained in the second year compared to the first year. The contents of absorbable forms of magnesium were identified to be in the range 1215–1420 mg kg

−1. A statistically significant decrease in the contents of this element was identified in the case of the treatment involving the use of biochar or its combination with ash, relative to the control condition (

Figure 6c).

The highest concentrations of the selected macro-elements in the basket willow pyrolysates obtained in the two years of the study were identified when the aboveground parts of the plants from the control plots, and those fertilised with biochar alone, were used. The lowest overall contents of macro-elements in the pyrolysates produced both in 2016 and in 2017 were identified in the case of the treatment involving the combined use of biochar and ash at the lowest rate applied. For all the macro-elements, the highest and the lowest concentrations of calcium and sodium, respectively, were identified in the pyrolysates from basket willow biomass, after both the first and the second year of the experiment. Additionally, a decrease in the overall contents of the macro-elements examined was identified in the pyrolysates produced in 2017, when compared with those from the previous years in all of the treatments applied (

Table 3).

The findings showed the highest concentrations of the selected micro-elements in the pyrolysates produced in 2016 and 2017 from the aboveground parts of the plants from the plots fertilised with biochar alone and from the control plots, respectively. Like in the case of the previous group of ions, the lowest overall contents of micro-elements in the pyrolysates from 2016 and 2017 were identified in the case of the treatment involving the combined use of biochar and ash at the lowest rate. The pyrolysates obtained were found to contain no arsenic, cadmium, chromium, molybdenum, nickel or lead, in both the first and the second year of the experiment – the values were below the detection limit (0.01 mg kg

−1) defined for the analytical method used (

Table 3).

The highest concentrations of the selected macro-elements in the giant miscanthus pyrolysates obtained in the two years of the study were identified when these were made from the aboveground parts of the plants from the plots fertilised with biochar applied in combination with ash at the lowest rate, and with ash alone. The lowest overall contents of macro-elements in the pyrolysates were identified in the case of the treatment involving the use of ash, and in the control sample (2016 and 2017). For all the macro-elements, the highest and the lowest concentrations of calcium and sodium, respectively, were identified in the pyrolysates from giant miscanthus biomass, in both the first and the second year of the experiment. Additionally, a decrease in the overall contents of the macro-elements was identified in the pyrolysates produced in 2017, compared to those from the previous year in all of the treatments applied (

Table 4).

The findings showed the highest concentrations of the selected micro-elements in the pyrolysates produced in 2016 and 2017 from the aboveground parts of the plants from the control plots, and those fertilised with ash (1.5 t ha

−1), respectively. The lowest overall contents of micro-elements in the pyrolysates from 2016 and 2017 were identified in the case of the treatment involving the combined use of biochar and ash at the lowest rate, and in the control plots, respectively. The pyrolysates were found to contain no arsenic, cadmium, chromium, molybdenum, nickel or lead, in both the first and the second year of the experiment—the values were below the detection limit (0.01 mg kg

−1) defined for the analytical method used. Moreover, in 2017 the findings showed no contents of copper in the pyrolysates (

Table 4).

4. Discussion

According to numerous studies, a significant portion of fallow land may be used for the production of biomass for energy purposes. Hence, it seems important to create favourable conditions for the development of energy crop plantations [

43,

44,

45]. Crop cultivation is becoming more and more effective as a result of the use of numerous media, including a variety of soil fertilizers. The media most commonly applied in contemporary agriculture include chemical fertilizers containing minerals easily available to plants. Notably, however, the use of such soil fertilizers may pose a considerable hazard for the natural environment. If applied incorrectly, they may adversely affect the soil environment, and consequently the plants, and they may pollute groundwater [

46]. In recent years, there have been rapid advancements in research investigating unconventional materials to be used as soil fertilizers in crop cultivation and land remediation. The studies focus on the use of, for example, sludge, ash from biomass, lignite and biochar. Their purpose is to assess these materials for their potential to improve crop yield, or enhance soil fertility and characteristics [

47].

The present study was designed to assess the effectiveness of soil treatments based on biochar and ash from biomass, applied in the cultivation of basket willow and giant miscanthus, as reflected by selected properties of the pyrolysates obtained from these plants. Pyrolysates were tested for the content of selected macro and microelements due to the overwhelming significance of these elements in soil fertilization.

The soil reaction to the use of unconventional materials as plant fertilizers plays an important role in many processes in the soil environment. This is significant in the uptake of nutrients by plants and influences the mobility of heavy metals, for example cadmium, lead or nickel [

48]. The alkalizing effect related to the application of biochar as fertilizer refers to the alkaline compound concentration and doses of application. The most significant changes can be perceived in relation to heavily acidified soils, where a significant decrease is visible in the content of H

+ and Al

3+ [

49]. Many studies conducted so far suggest that the use of biochar as a fertilizer causes an increase in soil pH [

50,

51,

52]. Numerous authors report that significant effects on the soil pH, following the application of ashes, can be achieved by the use of doses at the level of 10–20 t ha

−1. However, the application of such high doses of biomass ash may result in the insertion of too large an amount of nutrients or heavy metals into the soil. The high potential of biochars for exchangeable ion sorption affects the increase in the concentration of macro- and microelements in the soil profile, which is why it modulates their effective uptake by plants. According to many authors, plant biomass ash is typified by a high concentration of the biogenic elements necessary for the proper growth of plants [

35,

53].

The biomass of basket willow and giant miscanthus obtained in the first and the second year of the experiment was transformed using the method of pyrolysis. The findings show that the pyrolysates produced as a result of the various experimental schemes were characterised by high levels of the tested parameters. A notably high pH value, ranging from 9.0 to 9.3, was identified in all the products obtained from the samples in the first year of the experiment. In general, the pH dropped in the second year but was still at a high level. This seems to be very promising in view of the possible alkalizing effect after introducing pyrolysates into the soil as a fertilizer. The specific parameters of the pyrolysis process made it possible to obtain high contents of total carbon, at a level of 76–81% (pyrolysates from basket willow produced in the first year of the study) and 64–68% (pyrolysates from giant miscanthus produced in the first year of the study). There was also an increase in carbon content in giant miscanthus pyrolystates produced in the second year of the study. Such high content may indicate even better fertilizing properties of this material. It should also be emphasised that stable forms of carbon are characterised by high resistance to biological decomposition, which is why biochar can be treated as an effective agent for carbon sequestration in the soil. Liu et al. (2010) reported that, by subjecting pinewood to pyrolysis, it is possible to obtain biochar with a pH of 6.6 [

54]. Pyrolysates obtained from poplar wood processed at a temperature of 525 °C were characterised by a pH of 8.7, and carbon content amounting to 77.90% [

55]. Lee et al. (2013) subjected wood bark to pyrolysis at 500 °C and obtained pyrolysates with a pH value of 9.6, and with 85% carbon content [

56]. According to Schmidt et al. (2015), the concentration of carbon increases with a higher temperature applied during a pyrolysis process (from 300 to 800 °C); this is accompanied with a decrease in the contents of nitrogen and oxygen [

57]. As reported by Mohan et al. (2011), the pyrolysates obtained from oak wood, in a process carried out at a temperature of 400–450 °C, were found on average to have total carbon and nitrogen amounting to 82.83% and 0.31%, respectively [

58]. Wang et al. (2015) reported 85.7% carbon concentration in the pyrolysates from pinewood processed at 700 °C [

26]. Pyrolysates produced from pinewood sawdust at 500 °C and 600 °C in a study by Keiluweit et al. (2010) were found with carbon contents of 81.90% and 89.00%, respectively [

59]. Notably, in the current study, the specific treatments applied (i.e., biochar, ash and their combination) did not significantly affect the above parameters in the pyrolysates from basket willow and giant miscanthus.

In the present study, the pyrolysates were found with very high contents of absorbable forms of phosphorus, potassium and magnesium, which shows the products have good soil-enhancing potential. The findings showed statistically significant effects of the soil treatments applied on the concentrations of absorbable forms of the elements in the pyrolysates produced in the first year of the experiment. In the case of the pyrolysates from basket willow, the greatest increase in the contents of absorbable forms of phosphorus, potassium and magnesium was observed when ash alone was applied as a fertilizer, compared to the control condition. A similar effect was observed in the case of the pyrolysates from giant miscanthus when biochar and ash were used in combination. This tendency, however, was not confirmed in the second year of the study, which may be linked to the fact that the soil enhancement was not applied a second time. This observation may reflect only the short-term effect of the soil treatment with respect to the relevant parameters. The mean concentrations of the above elements identified in the pyrolysates from basket willow and giant miscanthus (2016 and 2017) are expressed by the following decreasing sequence: K

2O > P

2O

5 > Mg. Notably, the biochars obtained from giant miscanthus biomass were characterised by higher mean contents of phosphorus, potassium and magnesium. Another study by these authors, investigating the impact of various parameters of the pyrolysis process on the quality of the biochars obtained from rape straw, rye straw and willow chips, showed the highest concentrations of potassium compared to all the macro-elements investigated. The overall contents of these elements in all the materials applied, and relative to all the parameters of thermal conversion, are expressed by the following sequence: K > P > Mg [

34]. Borkowska and Lipiński (2007) investigated the concentrations of selected elements in the biomass of energy crops, and reported high contents of calcium and potassium compared to other elements identified in giant miscanthus, Amur silvergrass, and two clones of basket willow [

60]. Szyszlak-Bargłowicz (2014) pointed out that differing levels of fertilizer application did not produce statistically significant effects in the contents of the relevant macro-elements in the biomass of Virginia mallow. Analysis of the N, P, K, Ca and Mg concentrations in the stems and leaves of the plants showed the highest contents of potassium and calcium [

61]. It has been reported that a pyrolysis process conducted at high temperatures may result in reduced bioavailability of macro-elements in the biochars, and may adversely affect the sorption properties of the pyrolysates produced [

62,

63]. It should be pointed out that the pyrolysates from basket willow and giant miscanthus produced in the second year of the experiment were characterised by lower concentrations of the chemical components, compared to those identified the previous year. A lower concentration of the absorbable forms of macro-elements in pyrolysates produced in the second year of research would be reflected in their use as fertilizers. As a result, it would be necessary to increase the fertilizer dose during introduction of pyrolysates into the soil. This fact may be linked with the lower contents of the elements in the aboveground parts of plants obtained in 2017 and used in the production of biochars. Hence, it may be hypothesised that the application of the soil fertilizers during the second year of crop cultivation would contribute to higher contents of the elements in the pyrolysates obtained. It should also be emphasized that climatic conditions could influence the differences in biomass properties. It is recognized that each species of biomass has a specific yield/output, dependent on soil and climate conditions [

64].

In the agricultural aspect of the uses of ashes and biochar, special attention should be paid to their diverse chemical composition, and especially the share of heavy metals. The content of heavy metals in biomass ashes depends on their type, and is much lower than in ashes derived from hard coal combustion. The quality requirements drawn up for biochars, for their safe application to soils, include acceptable levels of heavy metals, furans, polychlorinated biphenyls, dioxins and polycyclic aromatic hydrocarbons content. Acceptable pollution values for biochar, prepared by the International Biochar Initiative (IBI), determine: cadmium 1.4–39, nickel 47–420, lead 121–300, chromium 93−1200, and copper 143–6000 mg kg

−1 dry matter [

65,

66,

67,

68]. The mean concentrations of aluminium in the pyrolysates from basket willow and giant miscanthus biomass produced in 2016 amounted to 0.29 and 0.86 mg kg

−1, respectively. The mean contents of this element in the pyrolysates obtained in 2017 decreased to 0.05 and 0.15 mg kg

−1 (basket willow and giant miscanthus). The biochars obtained were found to contain no arsenic, cadmium, nickel or lead, hence the materials can be used as soil fertilizers without the risk of introducing heavy metals into the soil environment.

5. Conclusions

It is obvious that the raw materials utilised in the process of pyrolysis significantly impact the properties of the pyrolysates produced, just like the duration and temperature of the process. Undoubtedly, soil enhancements affect a number of physicochemical parameters of plants. Given the above, the current study compared selected properties of the pyrolysates from plant biomass obtained from experimental plots where various treatments were applied. It was shown that, because of the high mineral contents, the biomass of perennial energy crops, such as basket willow and giant miscanthus, can effectively be subjected to the pyrolysis process in order to produce high-quality biochars. Research indicates that a high-quality natural fertilizer could be obtained that could compete with mineral fertilizers in terms of properties, economy and environmental aspects. Such a soil additive would not pose a threat of introducing heavy metals into the environment. Additionally, conversion of plant biomass into pyrolysates is important for the environment, due to its effect on the balance of carbon in the atmosphere through its capture and storage in a stable form outside the atmosphere (e.g., in soil). The results of the current study show the highest overall increase in the contents of absorbable forms of phosphorus, potassium and magnesium in the pyrolysis products from basket willow fertilised with ash alone, amounting to 21.6% in relation to the pyrolysates from the control sample. On the other hand, the pyrolysates from giant miscanthus biomass were found with the highest increase in the overall contents of these elements, amounting to 44.4%, in the case of treatment involving the combined use of biochar and ash. These effects were observed during the first year of the study. However, the specific treatments did not produce the same result in the subsequent year of the experiment. Although the pyrolysates obtained in the second year of research were characterized by worse parameters, they still constituted an attractive form of natural fertilizer. Therefore, it seems reasonable to continue research, in order to monitor changes in the parameters of plant biomass and the pyrolysates produced from it.