Post-Curing Effects on the Tensile Properties of Hybrid Fiber-Reinforced Polymers: Experimental and Numerical Insights

Abstract

1. Introduction

2. Materials and Methods

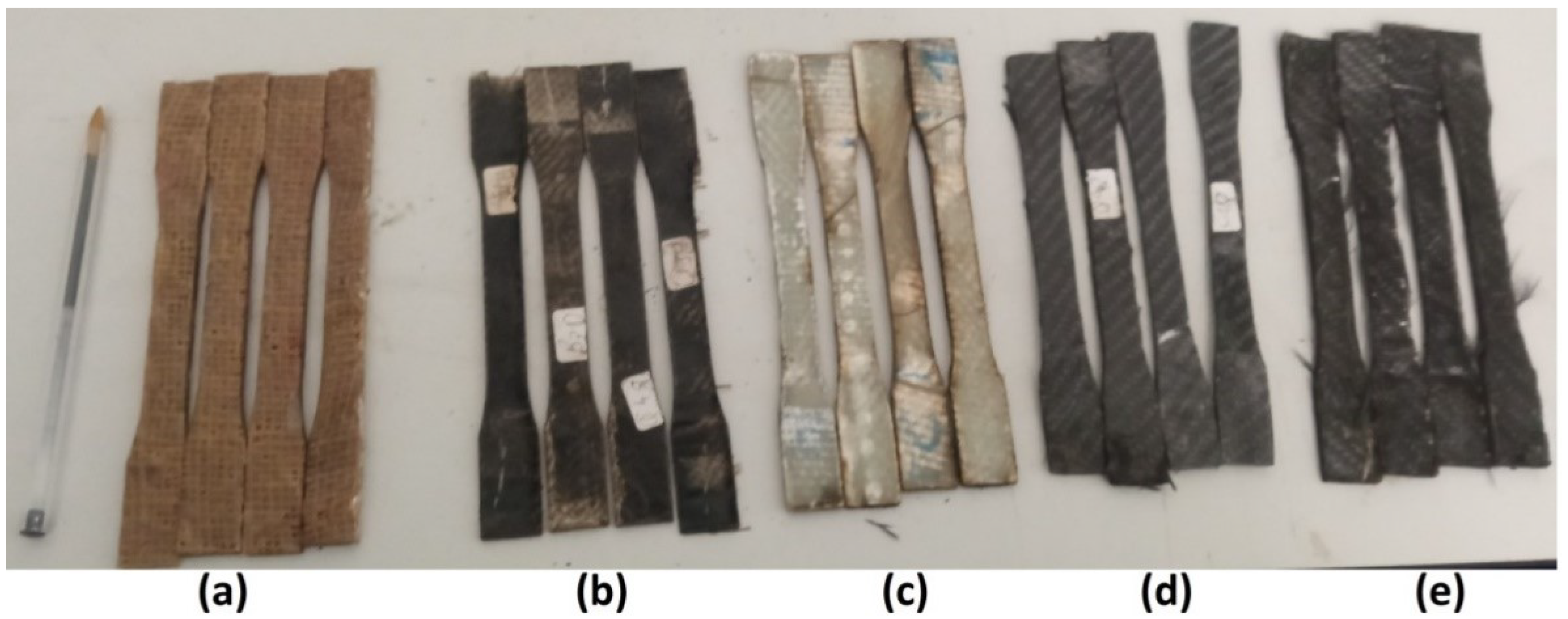

2.1. Specimen Preparation and Characterization

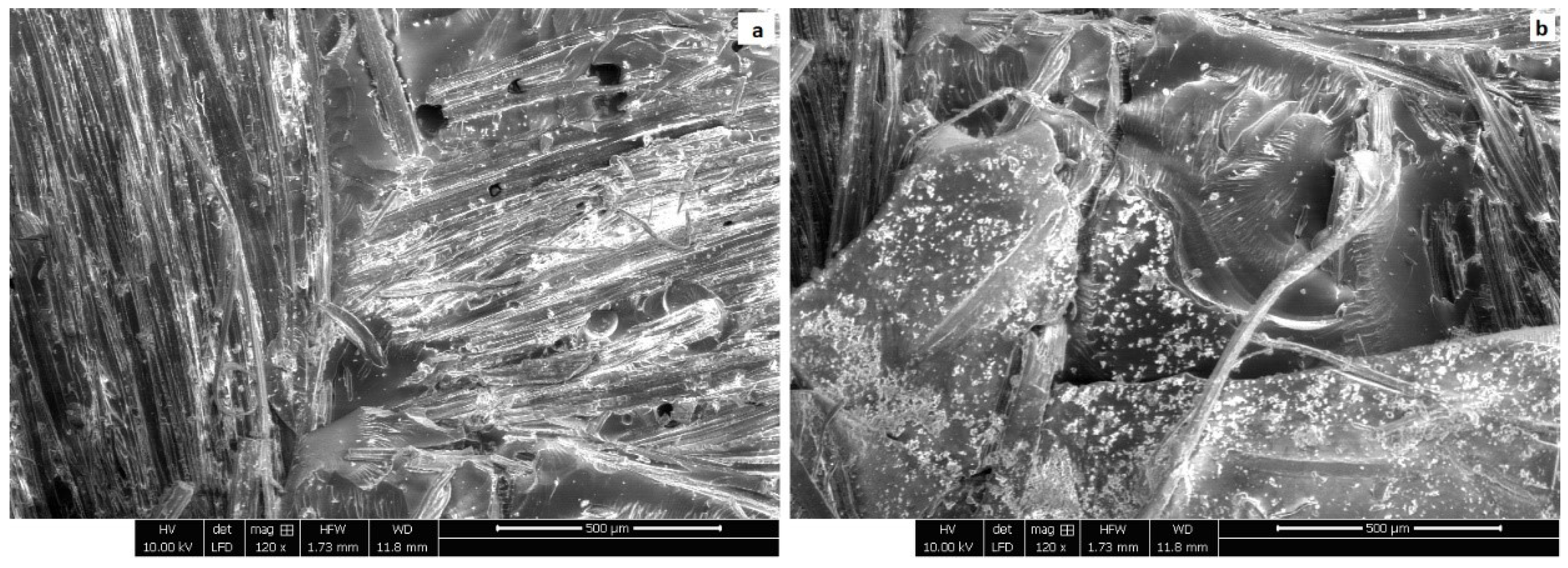

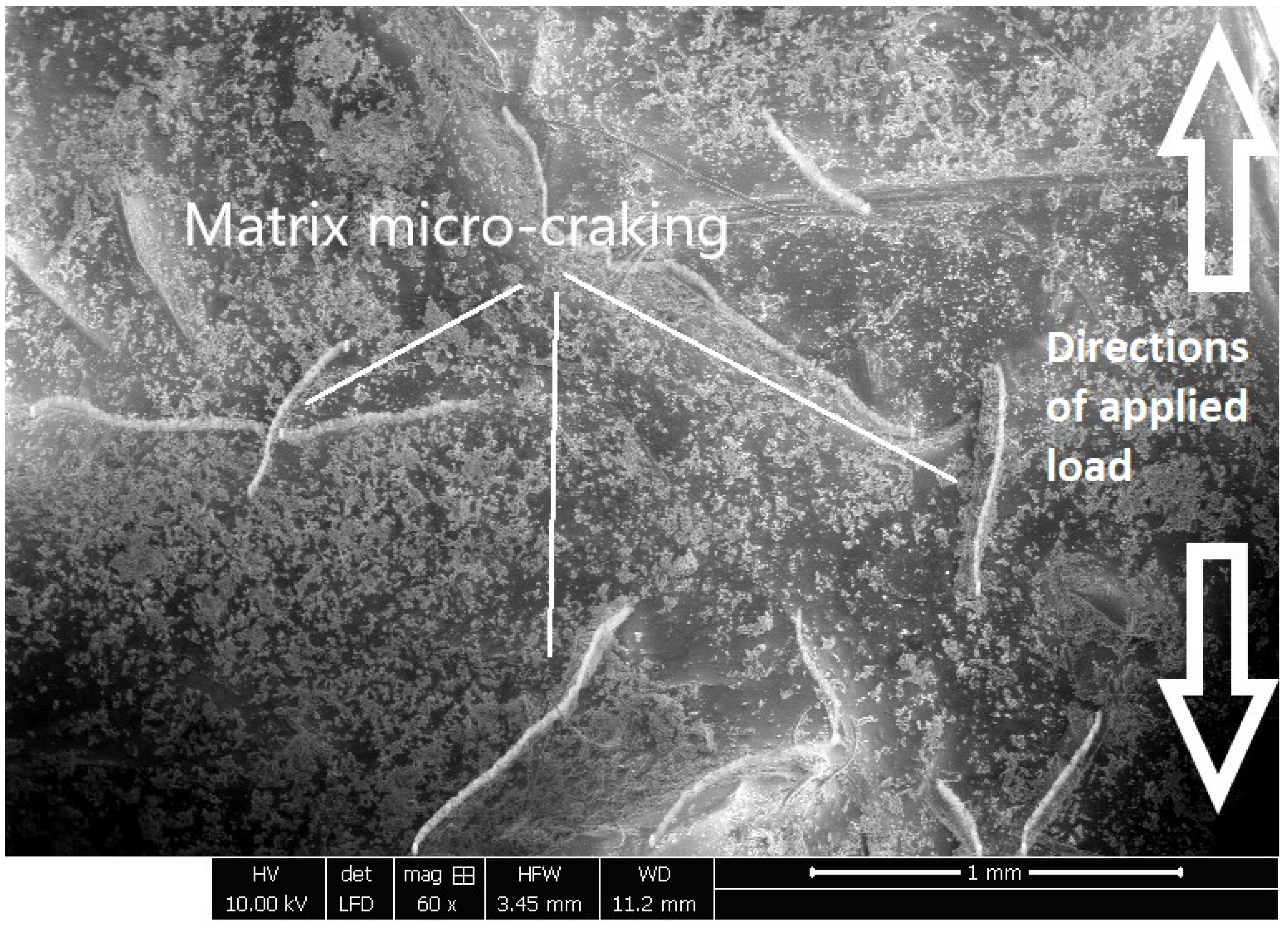

2.2. Scanning Electron Microscopy

2.3. Tensile Testing

2.4. Numerical Simulation

3. Results and Discussion

3.1. Results

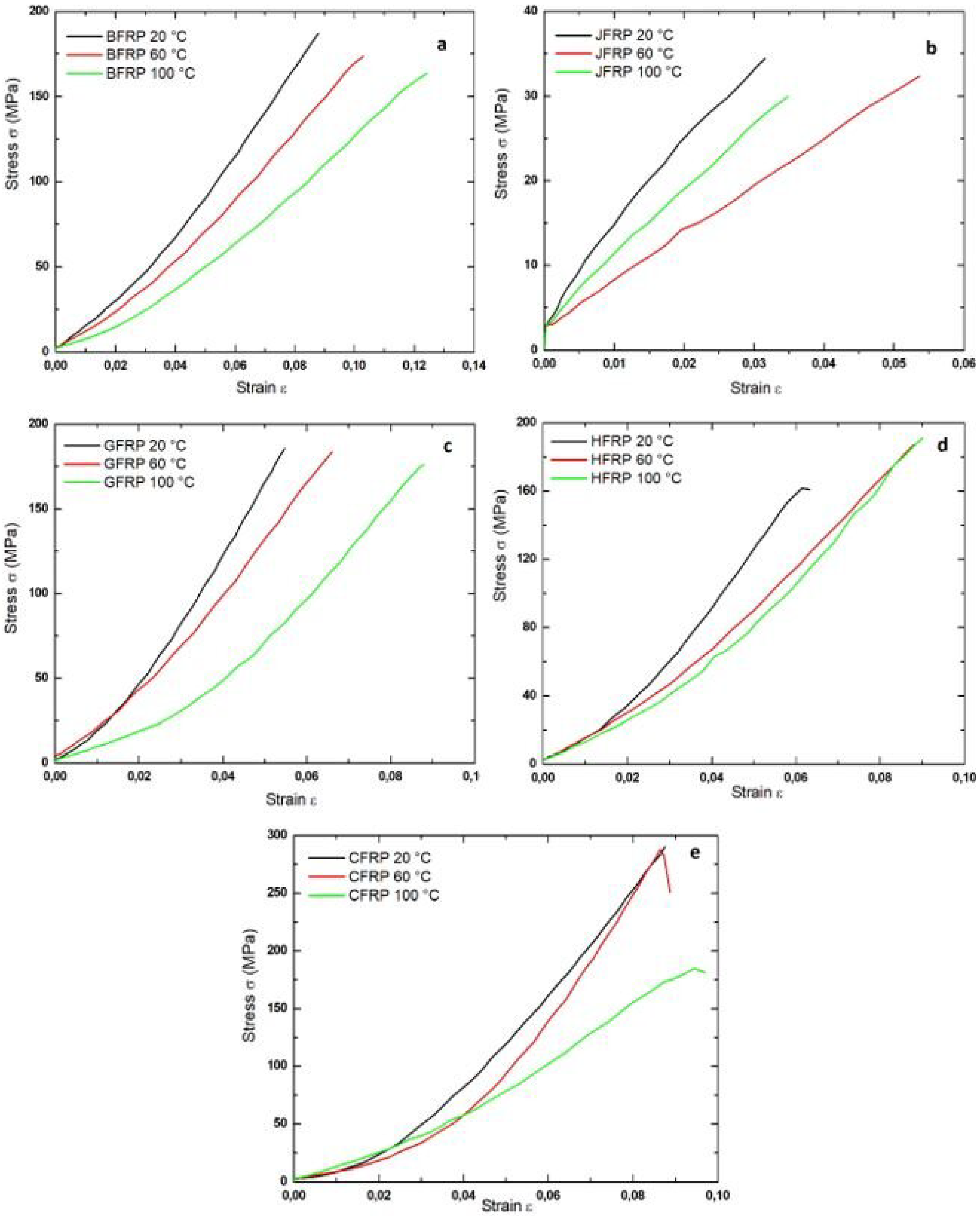

3.1.1. Tensile Properties

3.1.2. Numerical Analysis

3.2. Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Dabholkar, T. Post curing optimization for tensile strength of hybrid ramie-carbon fiber reinforced polymer. Polym. Polym. Compos. 2024, 32, 09673911241254906. [Google Scholar] [CrossRef]

- Karaçor, B.; Özcanlı, M. Post curing temperature effect on mechanical characterization of jute/basalt fiber reinforced hybrid composites. Int. Adv. Res. Eng. J. 2022, 6, 90–99. [Google Scholar] [CrossRef]

- Uzay, Ç.; Boztepe, M.; Bayramoğlu, M.; Geren, N. Effect of post-curing heat treatment on mechanical properties of fiber reinforced polymer (FRP) composites. Mater. Test. 2017, 59, 366–372. [Google Scholar] [CrossRef]

- Essaadaoui, K.; Fqih, M.A.E.; Idiri, M.; Boubeker, B. Experimental investigation on reinforced concrete beams by honeycomb sandwich panel structures: Mechanical properties study. IOP Conf. Ser. Mater. Sci. Eng. 2020, 948, 012027. [Google Scholar] [CrossRef]

- Zaini, M.; Fqih, M.A.E.; Idiri, M.; Bouab, W.; Chafiq, J. Experiment and Simulation Study of the Effect of Fillers on Mechanical Properties of Sustainable Composite. Stroj. Časopis J. Mech. Eng. 2022, 72, 239. [Google Scholar] [CrossRef]

- Lascano, D.; Quiles-Carrillo, L.; Torres-Giner, S.; Boronat, T.; Muñoz, N.M. Optimization of the curing and post-curing conditions for the manufacturing of partially bio-based epoxy resins with improved toughness. Polymers 2019, 11, 1354. [Google Scholar] [CrossRef] [PubMed]

- Ghani, A.F.A.; Mahmud, J. Shear deformation behavior of hybrid composite (GFRP/CFRP). Mater. Werkst. 2017, 48, 273–282. [Google Scholar] [CrossRef]

- Khalifa, M.; Berndt, A.; Shamitha, C.; Pichler, S.; Lammer, H.; Wuzella, G. Hybridization effect of cellulose paper and postcuring conditions on the mechanical properties of flax fiber reinforced epoxy biocomposite. J. Appl. Polym. Sci. 2022, 140, e53297. [Google Scholar] [CrossRef]

- Ismail, A.S.; Jawaid, M.; Naveen, J. Void content, tensile, vibration and acoustic properties of kenaf/bamboo fiber reinforced epoxy hybrid composites. Materials 2019, 12, 2094. [Google Scholar] [CrossRef]

- Thakre, U.; Tewari, A. Effect of residual-stress evolution during curing process on fatigue-life of fiber-reinforced polymers. J. Reinf. Plast. Compos. 2022, 42, 65–81. [Google Scholar] [CrossRef]

- Gonçalves, P.; Arteiro, A.; Rocha, N.; Pina, L. Numerical analysis of micro-residual stresses in a carbon/epoxy polymer matrix composite during curing process. Polymers 2022, 14, 2653. [Google Scholar] [CrossRef] [PubMed]

- Alikhani, H.; Sharifzadeh, F.; Khoramishad, H. The mechanical and physical properties of nylon 6/glass fiber-reinforced hybrid composites manufactured by thermal and ultraviolet-cured pultrusion methods. J. Compos. Mater. 2020, 54, 2899–2912. [Google Scholar] [CrossRef]

- Isna, L.R.; Abdurohman, K.; Nuranto, A.R.; Arum, W.F. Effect of Post-Curing Heat Treatment on Tensile Properties of Carbon UD/Vinyl Ester Composite with VARI Manufacturing Method. Key Eng. Mater. 2023, 941, 265–270. [Google Scholar] [CrossRef]

- Cavalcanti, D.; Banea, M.; Neto, J.; Lima, R.D.A.A.; Silva, L.D.; Carbas, R. Mechanical characterization of intralaminar natural fibre-reinforced hybrid composites. Compos. Part B Eng. 2019, 175, 107149. [Google Scholar] [CrossRef]

- Atmakuri, A.; Palevičius, A.; Vilkauskas, A.; Janusas, G. Numerical and experimental analysis of mechanical properties of natural-fiber-reinforced hybrid polymer composites and the effect on matrix material. Polymers 2022, 14, 2612. [Google Scholar] [CrossRef] [PubMed]

- Khalid, M.; Rashid, A.; Arif, Z.; Sheikh, M.; Arshad, H.; Nasir, M. Tensile strength evaluation of glass/jute fibers reinforced composites: An experimental and numerical approach. Results Eng. 2021, 10, 100232. [Google Scholar] [CrossRef]

- Kumar, T.; Senthilkumar, K.; Chandrasekar, M.; Tengsuthiwat, J.; Rajini, N.; Siengchin, S.; Ismail, S. Investigation into mechanical, absorption and swelling behaviour of hemp/sisal fibre reinforced bioepoxy hybrid composites: Effects of stacking sequences. Int. J. Biol. Macromol. 2019, 140, 637–646. [Google Scholar] [CrossRef]

- ASTM D638-14; Standard Test Method for Tensile Properties of Plastics. ASTM International: West Conshohocken, PA, USA, 2014.

- Essaadaoui, K.; Fqih, M.A.E.; Idiri, M.; Boubeker, B. Numerical Study of Damaged, Failure and Cracking of Concrete Beam Reinforced by Honeycomb Sandwich Panel Structures. Commun. Comput. Inf. Sci. 2020, 1207, 316. [Google Scholar] [CrossRef]

- Hamlaoui, O.; Klinkova, O.; Elleuch, R.; Tawfiq, I. Effect of the glass fiber content of a polybutylene terephthalate reinforced composite structure on physical and mechanical characteristics. Polymers 2022, 14, 17. [Google Scholar] [CrossRef] [PubMed]

- Bounjoum, Y.; Hamlaoui, O.; Hajji, M.K.; Essaadaoui, K.; Chafiq, J.; Fqih, M.A.E. Exploring damage patterns in CFRP reinforcements: Insights from simulation and experimentation. Polymers 2024, 16, 2057. [Google Scholar] [CrossRef]

- Valíček, J.; Harničárová, M.; Öchsner, A.; Kušnerová, M.; Šepelák, V.; Hutyrová, Z.; Tozan, H.; Michenka, V.; Mitaľ, D.; Zajac, J. Quantifying the mechanical properties of materials and the process of elastic-plastic deformation under external stress on material. Materials 2015, 8, 7401–7422. [Google Scholar] [CrossRef] [PubMed]

- ISO 527-1:2019; Plastics—Determination of Tensile Properties—Part 1: General Principles. International Organization for Standardization: Geneva, Switzerland, 2019.

- Ouchte, I.; Chafiq, J.; Fqih, M.A.E.; Chakir, H. Effect of thermal treatment on mechanical properties and thermogravimetric analysis of laminate composite jute/epoxy. Mater. Today Proc. 2022, 66, 135–139. [Google Scholar] [CrossRef]

- Chafiq, J.; Ouchte, I.; Fqih, M.A.E. Investigations of tensile behavior of basalt/glass/carbon/hybrid fiber composite. Mater. Today Proc. 2022, 52, 53–59. [Google Scholar] [CrossRef]

- Ramesh, M.; Vimal, R.; Subramaniyan, K.H.H.; Aswin, C.; Ganesh, B.; Deepa, C. Study of mechanical properties of jute-banana-glass fiber reinforced epoxy composites under various post curing temperature. Appl. Mech. Mater. 2015, 766–767, 211–215. [Google Scholar] [CrossRef]

- Chavan, V.R.; Dinesh, K.R.; Veeresh, K.; Algur, V.; Shettar, M. Influence of post curing on GFRP hybrid composite. MATEC Web Conf. 2018, 144, 02011. [Google Scholar] [CrossRef]

- Khalid, M.Y.; Nasir, M.A.; Ali, A.; Rashid, A.A.; Khan, M.R. Experimental and numerical characterization of tensile property of jute/carbon fabric reinforced epoxy hybrid composites. SN Appl. Sci. 2020, 2, 577. [Google Scholar] [CrossRef]

| Samples Stacking Sequence | Coding | Weight of Fibre (Wf) (g) | Weight of Polymer (Wp) (g) | Weight of Hardener (g) |

|---|---|---|---|---|

| Basalt/Basalt/Basalt | ||||

| Basalt/Basalt/Basalt | ||||

| Basalt/Basalt/Basalt | BFRP | 85 | 56.66 | 28.33 |

| Jute/Jute/Jute | ||||

| Jute/Jute/Jute | ||||

| Jute/Jute/Jute | JFRP | 79 | 52.30 | 26.60 |

| Glass/Glass/Glass | ||||

| Glass/Glass/Glass | ||||

| Glass/Glass/Glass | GFRP | 134 | 89.33 | 44.66 |

| Carbon/Carbon/Carbon | ||||

| Carbon/Carbon/Carbon | ||||

| Carbon/Carbon/Carbon | CFRP | 86 | 57.33 | 28.66 |

| Carbon/Glass/Basalt | ||||

| Carbon/Glass/Basalt | ||||

| Carbon/Glass/Basalt | HFRP | 99 | 66.00 | 33.00 |

| Samples Stacking Sequence | Coding | Average Thickness (mm) | Gauge Length (mm) | Width (mm) |

|---|---|---|---|---|

| Basalt/Basalt/Basalt | ||||

| Basalt/Basalt/Basalt | ||||

| Basalt/Basalt | BFRP | 2.50 | 50 | 13 |

| Jute/Jute/Jute | ||||

| Jute/Jute/Jute | ||||

| Jute/Jute/Jute | JFRP | 3.10 | 50 | 13 |

| Glass/Glass/Glass | ||||

| Glass/Glass/Glass | ||||

| Glass/Glass/Glass | GFRP | 2.88 | 50 | 13 |

| Carbon/Carbon/Carbon | ||||

| Carbon/Carbon/Carbon | ||||

| Carbon/Carbon/Carbon | CFRP | 2.80 | 50 | 13 |

| Carbon/Glass/Basalt | ||||

| Carbon/Glass/Basalt | ||||

| Carbon/Glass/Basalt | HFRP | 2.90 | 50 | 13 |

| Physical Property | Basalt/Epoxy Lamina | Jute/Epoxy Lamina | Glass/Epoxy Lamina | Carbon/Epoxy Lamina | Source |

|---|---|---|---|---|---|

| (MPa) | 2060 | 1040 | 3330 | 3300 | Experimentally |

| (MPa) | 2005 | 990 | 3002 | 3200 | Analytically (rule of mixture) |

| (MPa) | 1070 | 560 | 1520 | 1574 | Analytically |

| (MPa) | 1020 | 510 | 1508 | 1536 | Analytically (rule of mixture) |

| 0.065 | 0.08 | 0.07 | 0.045 | Experimentally | |

| 0.32 | 0.30 | 0.32 | 0.30 | Analytically (rule of mixture) |

| Samples Coding | Young’s Modulus E (GPa) | Tensile Strength (MPa) | Elongation at Break A (%) |

|---|---|---|---|

| BFRP 20 °C | 206 | 187 | 8.79 |

| BFRP 60 °C | 165 | 174 | 10.30 |

| BFRP 100 °C | 13 | 163 | 12.40 |

| JFRP 20 °C | 104 | 34 | 3.16 |

| JFRP 60 °C | 56 | 32 | 5.36 |

| JFRP 100 °C | 8 | 30 | 3.48 |

| GFRP 20 °C | 333 | 185 | 5.47 |

| GFRP 60 °C | 269 | 183 | 6.60 |

| GFRP 100 °C | 194 | 176 | 8.78 |

| CFRP 20 °C | 33 | 290 | 8.75 |

| CFRP 60 °C | 314 | 250 | 8.87 |

| CFRP 100 °C | 194 | 181 | 9.70 |

| HFRP 20 °C | 25 | 161 | 9.00 |

| HFRP 60 °C | 20.38 | 187.18 | 8.79 |

| HFRP 100 °C | 20.72 | 190.95 | 6.33 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zaini, M.; Hamlaoui, O.; Chafiq, J.; El Fqih, M.A.; Idiri, M.; Aqil, S.; Hajji, M.K.; Bal, A.; Tozan, H.; Harnicárová, M.; et al. Post-Curing Effects on the Tensile Properties of Hybrid Fiber-Reinforced Polymers: Experimental and Numerical Insights. Polymers 2025, 17, 1261. https://doi.org/10.3390/polym17091261

Zaini M, Hamlaoui O, Chafiq J, El Fqih MA, Idiri M, Aqil S, Hajji MK, Bal A, Tozan H, Harnicárová M, et al. Post-Curing Effects on the Tensile Properties of Hybrid Fiber-Reinforced Polymers: Experimental and Numerical Insights. Polymers. 2025; 17(9):1261. https://doi.org/10.3390/polym17091261

Chicago/Turabian StyleZaini, Mohammed, Oumayma Hamlaoui, Jalal Chafiq, Mohamed Ait El Fqih, Mohamed Idiri, Said Aqil, Mohamed Karim Hajji, Alperen Bal, Hakan Tozan, Marta Harnicárová, and et al. 2025. "Post-Curing Effects on the Tensile Properties of Hybrid Fiber-Reinforced Polymers: Experimental and Numerical Insights" Polymers 17, no. 9: 1261. https://doi.org/10.3390/polym17091261

APA StyleZaini, M., Hamlaoui, O., Chafiq, J., El Fqih, M. A., Idiri, M., Aqil, S., Hajji, M. K., Bal, A., Tozan, H., Harnicárová, M., & Valicek, J. (2025). Post-Curing Effects on the Tensile Properties of Hybrid Fiber-Reinforced Polymers: Experimental and Numerical Insights. Polymers, 17(9), 1261. https://doi.org/10.3390/polym17091261