Effect of Injection Molding Parameters on the Tensile Strength of Short-Carbon-Fiber-Reinforced Nylon 6

Abstract

1. Introduction

2. Taguchi Method

3. Experimental Details

3.1. Materials

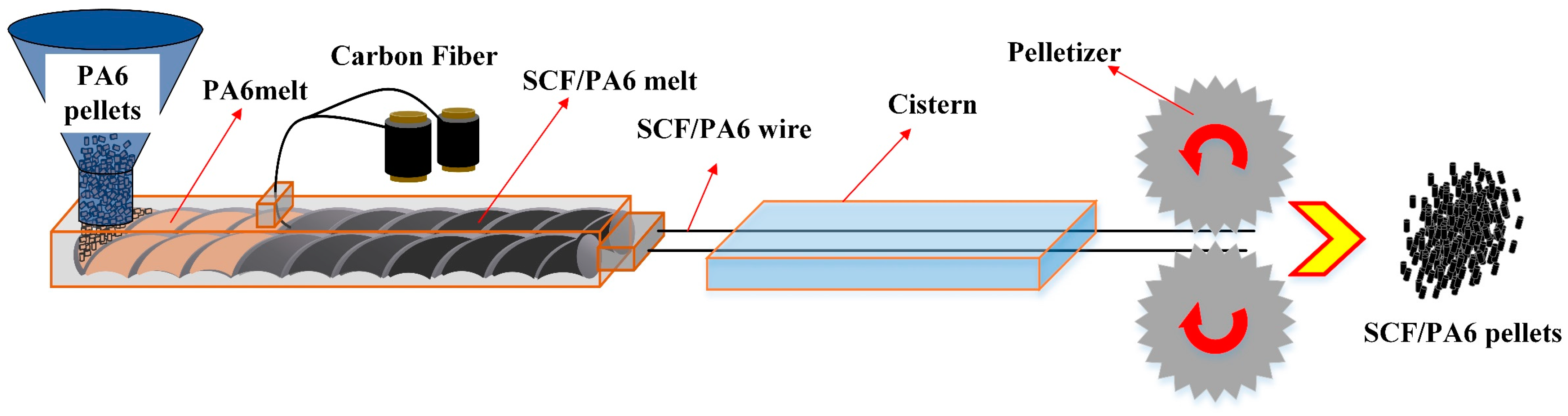

3.2. Extrusion Pelletization and Injection Molding

3.3. Characterization

3.3.1. Tensile Strength

3.3.2. Crystallinity

3.3.3. Rheology

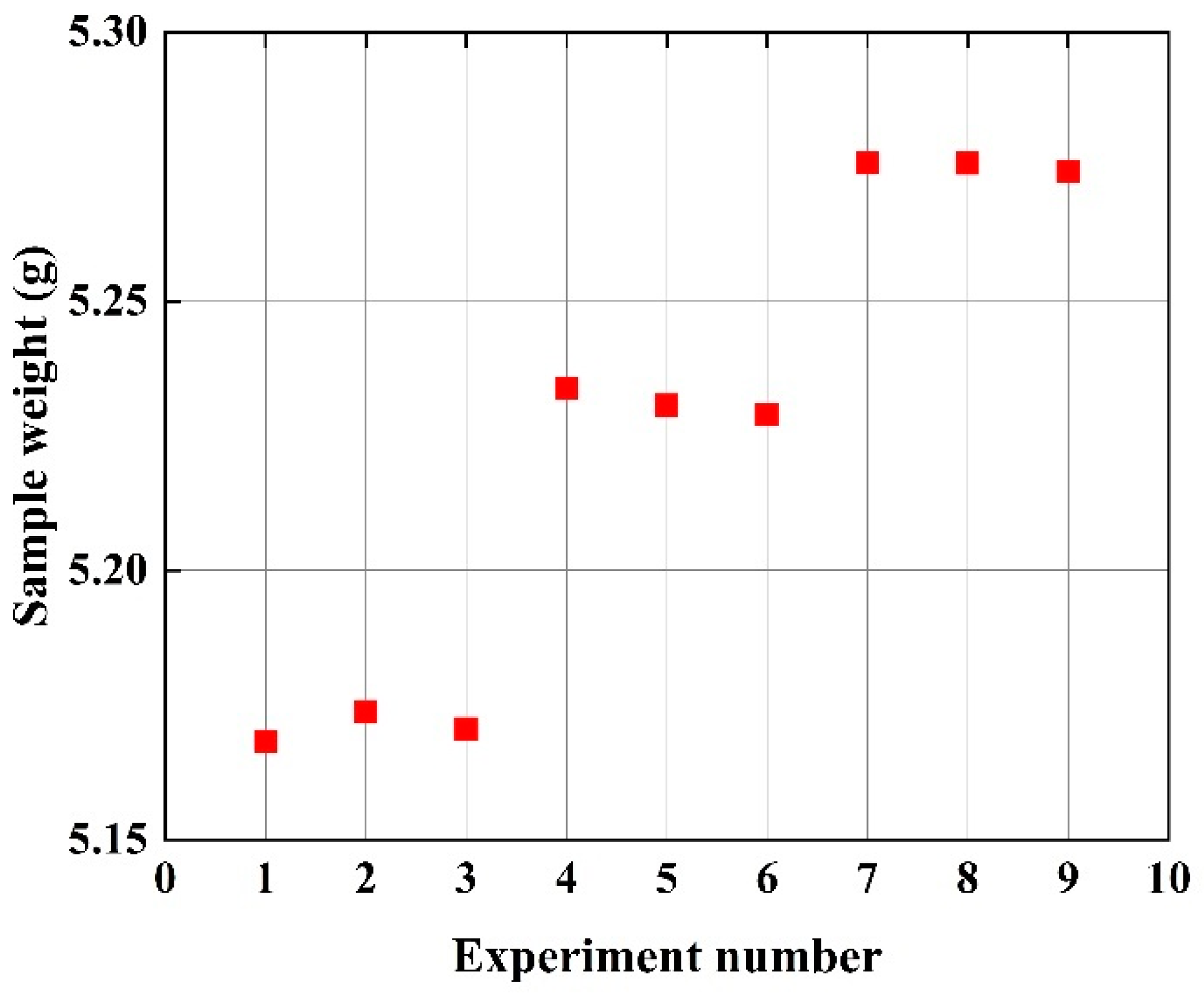

3.3.4. Weight Measurement

3.3.5. Microscopic Morphology

4. Results and Discussion

4.1. Effect of Fiber Orientation Distribution

4.2. Effect of Composite Density

4.3. Effect of Crystallinity of Composite Materials

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Tian, X.; Todoroki, A.; Liu, T.; Wu, L.; Hou, Z.; Ueda, M.; Hirano, Y.; Matsuzaki, R.; Mizukami, K.; Iizuka, K.; et al. 3D Printing of Continuous Fiber Reinforced Polymer Composites: Development, Application, and Prospective. Chin. J. Mech. Eng. Addit. Manuf. Front. 2022, 1, 100016. [Google Scholar] [CrossRef]

- Liu, G.; Xiong, Y.; Zhou, L. Additive manufacturing of continuous fiber reinforced polymer composites: Design opportunities and novel applications. Compos. Commun. 2021, 27, 100907. [Google Scholar] [CrossRef]

- Zhi, Q.; Li, D.; Zhang, Z.; Fu, L.; Zhu, W. High-content continuous carbon fiber reinforced multifunctional prepreg filaments suitable for direct 3D-printing. Compos. Commun. 2023, 44, 101726. [Google Scholar] [CrossRef]

- Mehdipour, H.; Camanho, P.P.; Belingardi, G. Elasto-plastic constitutive equations for short fiber reinforced polymers. Compos. Part B Eng. 2019, 165, 199–214. [Google Scholar] [CrossRef]

- Yang, P.; Chen, Y.; Guo, Z.; Hu, N.; Sun, W. Modeling the effective elastic and viscoelastic properties of randomly distributed short fiber reinforced composites. Compos. Commun. 2022, 35, 101341. [Google Scholar] [CrossRef]

- Zhao, J.; Su, D.-X.; Yi, J.; Cheng, G.; Turng, L.-S.; Osswald, T. The effect of micromechanics models on mechanical property predictions for short fiber composites. Compos. Struct. 2020, 244, 112229. [Google Scholar] [CrossRef]

- Mortazavian, S.; Fatemi, A. Effects of fiber orientation and anisotropy on tensile strength and elastic modulus of short fiber reinforced polymer composites. Compos. Part B Eng. 2015, 72, 116–129. [Google Scholar] [CrossRef]

- Ning, F.; Cong, W.; Hu, Y.; Wang, H. Additive manufacturing of carbon fiber-reinforced plastic composites using fused deposition modeling: Effects of process parameters on tensile properties. J. Compos. Mater. 2017, 51, 451–462. [Google Scholar] [CrossRef]

- Carneiro, O.S.; Silva, A.F.; Gomes, R. Fused deposition modeling with polypropylene. Mater. Des. 2015, 83, 768–776. [Google Scholar] [CrossRef]

- Unnikrishnan, V.; Zabihi, O.; Li, Q.; Ahmadi, M.; Ferdowsi, M.R.G.; Kannangara, T.; Blanchard, P.; Kiziltas, A.; Joseph, P.; Naebe, M. Multifunctional PA6 composites using waste glass fiber and green metal organic framework/graphene hybrids. Polym. Compos. 2022, 43, 5877–5893. [Google Scholar] [CrossRef]

- Güllü, A.; Özdemir, A.; Özdemir, E. Experimental investigation of the effect of glass fibres on the mechanical properties of polypropylene (PP) and polyamide 6 (PA6) plastics. Mater. Des. 2006, 27, 316–323. [Google Scholar] [CrossRef]

- Lee, J.-M.; Moon, J.-S.; Shim, D.; Choi, B.-H. Effect of glass fiber distributions on the mechanical and fracture behaviors of injection-molded glass fiber-filled polypropylene with 2-Hole Tension specimens. Compos. Sci. Technol. 2019, 170, 190–199. [Google Scholar] [CrossRef]

- Tseng, H.-C.; Chang, R.-Y.; Hsu, C.-H. Numerical predictions of fiber orientation and mechanical properties for injection-molded long-glass-fiber thermoplastic composites. Compos. Sci. Technol. 2017, 150, 181–186. [Google Scholar] [CrossRef]

- Karsli, N.G.; Aytac, A. Tensile and thermomechanical properties of short carbon fiber reinforced polyamide 6 composites. Compos. Part B Eng. 2013, 51, 270–275. [Google Scholar] [CrossRef]

- Hendlmeier, A.; Simon, Ž.; Chutani, A.; Henderson, L.C. Generating short carbon fiber polyamide-6 composites from continuous carbon fiber—A preliminary examination of surface treatment and sizing effects. Compos. Part A Appl. Sci. Manuf. 2020, 138, 106058. [Google Scholar] [CrossRef]

- Krebelj, K.; Krebelj, A.; Halilovič, M.; Mole, N. Modeling Injection Molding of High-Density Polyethylene with Crystallization in Open-Source Software. Polymers 2020, 13, 138. [Google Scholar] [CrossRef]

- Huang, C.-T.; Chen, X.-W.; Fu, W.-W. Investigation on the Fiber Orientation Distributions and Their Influence on the Mechanical Property of the Co-Injection Molding Products. Polymers 2019, 12, 24. [Google Scholar] [CrossRef]

- Harris, A.M.; Lee, E.C. Improving mechanical performance of injection molded PLA by controlling crystallinity. J. Appl. Polym. Sci. 2008, 107, 2246–2255. [Google Scholar] [CrossRef]

- Thomason, J.L. The influence of fibre length, diameter and concentration on the modulus of glass fibre reinforced polyamide 6,6. Compos. Part A Appl. Sci. Manuf. 2008, 39, 1732–1738. [Google Scholar] [CrossRef]

- Uetsuji, Y.; Yasuda, S.; Teramoto, Y. Effect of fibre aspect ratio and aggregation on nonlinear material property of random cellulose reinforced composites: A multiscale computational study. Compos. Struct. 2022, 301, 116201. [Google Scholar] [CrossRef]

- Ozcelik, B.; Ozbay, A.; Demirbas, E. Influence of injection parameters and mold materials on mechanical properties of ABS in plastic injection molding. Int. Commun. Heat Mass Transf. 2010, 37, 1359–1365. [Google Scholar] [CrossRef]

- Kuram, E.; Tasci, E.; Altan, A.I.; Medar, M.M.; Yilmaz, F.; Ozcelik, B. Investigating the effects of recycling number and injection parameters on the mechanical properties of glass-fibre reinforced nylon 6 using Taguchi method. Mater. Des. 2013, 49, 139–150. [Google Scholar] [CrossRef]

- Ozcelik, B. Optimization of injection parameters for mechanical properties of specimens with weld line of polypropylene using Taguchi method. Int. Commun. Heat Mass Transf. 2011, 38, 1067–1072. [Google Scholar] [CrossRef]

- Oktem, H.; Erzurumlu, T.; Uzman, I. Application of Taguchi optimization technique in determining plastic injection molding process parameters for a thin-shell part. Mater. Des. 2007, 28, 1271–1278. [Google Scholar] [CrossRef]

- Chen, W.-C.; Nguyen, M.-H.; Chiu, W.-H.; Chen, T.-N.; Tai, P.-H. Optimization of the plastic injection molding process using the Taguchi method, RSM, and hybrid GA-PSO. Int. J. Adv. Manuf. Technol. 2016, 83, 1873–1886. [Google Scholar] [CrossRef]

- Mehat, N.M.; Kamaruddin, S. Multi-Response Optimization of Injection Moulding Processing Parameters Using the Taguchi Method. Polym.-Plast. Technol. Eng. 2011, 50, 1519–1526. [Google Scholar] [CrossRef]

- Yizong, T.; Ariff, Z.M.; Khalil, A.M. Influence of Processing Parameters on Injection Molded Polystyrene Using Taguchi Method as Design of Experiment. Procedia Eng. 2017, 184, 350–359. [Google Scholar] [CrossRef]

- Kamaruddin, S.; Khan, Z.A.; Foong, S.H. Quality characteristic improvement of an injection moulding product made from blends plastic by optimizing the injection moulding parameters using Taguchi method. Int. J. Plast. Technol. 2010, 14, 152–166. [Google Scholar] [CrossRef]

- Altan, M. Reducing shrinkage in injection moldings via the Taguchi, ANOVA and neural network methods. Mater. Des. 2010, 31, 599–604. [Google Scholar] [CrossRef]

- Kashyap, S.; Datta, D. Process parameter optimization of plastic injection molding: A review. Int. J. Plast. Technol. 2015, 19, 1–18. [Google Scholar] [CrossRef]

- Fernandes, C.; Pontes, A.J.; Viana, J.C.; Gaspar-Cunha, A. Modeling and Optimization of the Injection-Molding Process: A Review. Adv. Polym. Technol. 2018, 37, 429–449. [Google Scholar] [CrossRef]

- Bueche, F. The Viscoelastic Properties of Plastics. J. Chem. Phys. 1954, 22, 603–609. [Google Scholar] [CrossRef]

- Lodge, A.S. Elastic recovery and polymer-polymer interactions. Rheol. Acta 1989, 28, 351–362. [Google Scholar] [CrossRef]

- Dusunceli, N.; Colak, O.U. Modelling effects of degree of crystallinity on mechanical behavior of semicrystalline polymers. Int. J. Plast. 2008, 24, 1224–1242. [Google Scholar] [CrossRef]

- Beauson, J.; Schillani, G.; Van Der Schueren, L.; Goutianos, S. The effect of processing conditions and polymer crystallinity on the mechanical properties of unidirectional self-reinforced PLA composites. Compos. Part A Appl. Sci. Manuf. 2022, 152, 106668. [Google Scholar] [CrossRef]

- Zhao, P.; Yang, W.; Wang, X.; Li, J.; Yan, B.; Fu, J. A novel method for predicting degrees of crystallinity in injection molding during packing stage, Proceedings of the Institution of Mechanical Engineers. Part B J. Eng. Manuf. 2019, 233, 204–214. [Google Scholar] [CrossRef]

- Nakamura, K.; Watanabe, T.; Katayama, K.; Amano, T. Some aspects of nonisothermal crystallization of polymers. I. Relationship between crystallization temperature, crystallinity, and cooling conditions. J. Appl. Polym. Sci. 1972, 16, 1077–1091. [Google Scholar] [CrossRef]

- Mileva, D.; Tranchida, D.; Gahleitner, M. Designing polymer crystallinity: An industrial perspective. Polym. Cryst. 2018, 1, e10009. [Google Scholar] [CrossRef]

- Felder, S.; Vu, N.A.; Reese, S.; Simon, J.-W. Modeling the effect of temperature and degree of crystallinity on the mechanical response of Polyamide 6. Mech. Mater. 2020, 148, 103476. [Google Scholar] [CrossRef]

| Experiment Number | Injection Pressure (bar) | Melt Temperature (°C) | Mold Temperature (°C) | Injection Time (s) | Tensile Strength (MPa) | Weight (g) | Crystallinity (%) |

|---|---|---|---|---|---|---|---|

| 1 | 60 | 240 | 60 | 1.0 | 170.59 | 5.1683 | 13.65 |

| 2 | 60 | 260 | 100 | 1.5 | 178.05 | 5.1738 | 14.09 |

| 3 | 60 | 280 | 80 | 2.0 | 180.98 | 5.1706 | 13.70 |

| 4 | 80 | 240 | 100 | 2.0 | 175.30 | 5.2338 | 14.30 |

| 5 | 80 | 260 | 80 | 1.0 | 177.67 | 5.2307 | 13.86 |

| 6 | 80 | 280 | 60 | 1.5 | 181.17 | 5.2289 | 14.67 |

| 7 | 100 | 240 | 80 | 1.5 | 175.87 | 5.2757 | 13.93 |

| 8 | 100 | 260 | 60 | 2.0 | 182.47 | 5.2756 | 13.51 |

| 9 | 100 | 280 | 100 | 1.0 | 184.33 | 5.2741 | 13.53 |

| Factors | Level | Injection Pressure | Melt Temperature | Mold Temperature | Injection Time |

|---|---|---|---|---|---|

| K | 1 | 529.83 | 521.97 | 535.08 | 531.75 |

| 2 | 534.78 | 538.2 | 534.51 | 535.71 | |

| 3 | 541.65 | 546.06 | 537.54 | 538.77 | |

| Kavg | 1 | 176.61 | 173.99 | 178.36 | 177.25 |

| 2 | 178.26 | 179.40 | 178.17 | 178.57 | |

| 3 | 180.55 | 182.02 | 179.18 | 179.59 | |

| Optimal level | - | 3 | 3 | 3 | 3 |

| R | - | 3.94 | 8.03 | 1.01 | 2.34 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, R.; Li, X.; Wang, Z.; Wu, T.; Liang, J. Effect of Injection Molding Parameters on the Tensile Strength of Short-Carbon-Fiber-Reinforced Nylon 6. Polymers 2025, 17, 1264. https://doi.org/10.3390/polym17091264

Zhao R, Li X, Wang Z, Wu T, Liang J. Effect of Injection Molding Parameters on the Tensile Strength of Short-Carbon-Fiber-Reinforced Nylon 6. Polymers. 2025; 17(9):1264. https://doi.org/10.3390/polym17091264

Chicago/Turabian StyleZhao, Runtian, Xiaodong Li, Zhihui Wang, Ting Wu, and Jianguo Liang. 2025. "Effect of Injection Molding Parameters on the Tensile Strength of Short-Carbon-Fiber-Reinforced Nylon 6" Polymers 17, no. 9: 1264. https://doi.org/10.3390/polym17091264

APA StyleZhao, R., Li, X., Wang, Z., Wu, T., & Liang, J. (2025). Effect of Injection Molding Parameters on the Tensile Strength of Short-Carbon-Fiber-Reinforced Nylon 6. Polymers, 17(9), 1264. https://doi.org/10.3390/polym17091264