Research on the Microscopic Aging Characteristics of Asphalt Binder Based on Atomic Force Microscopy

Abstract

1. Introduction

2. Materials and Methods

2.1. Material

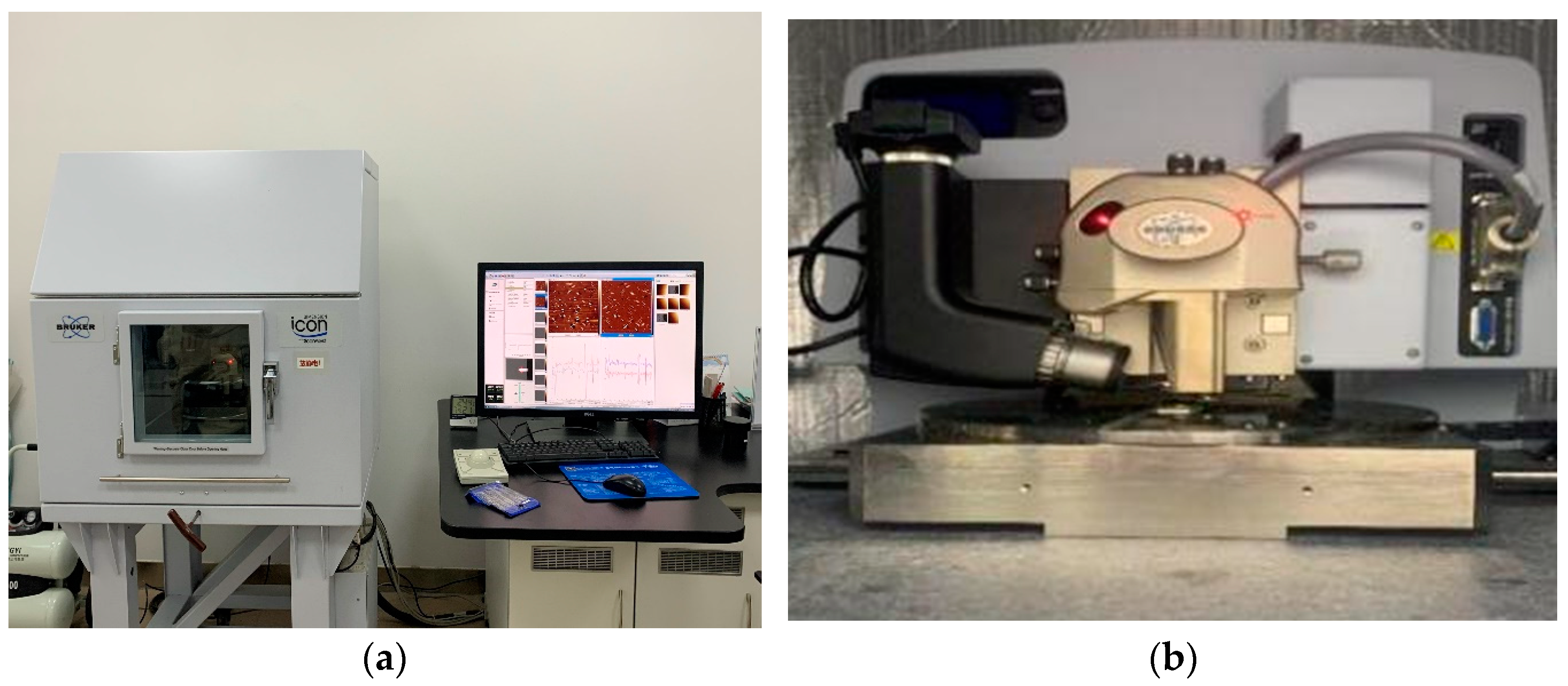

2.2. Test Method

3. Results and Discussion

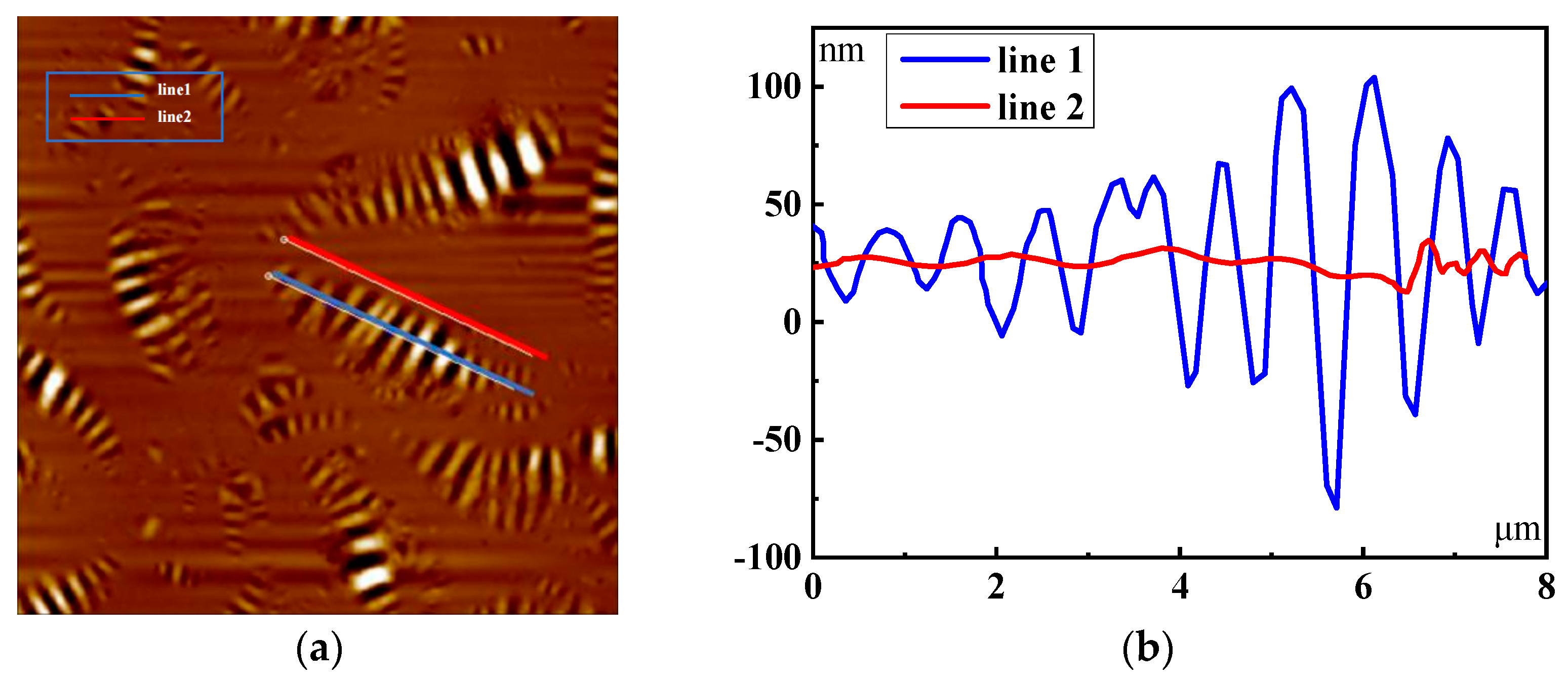

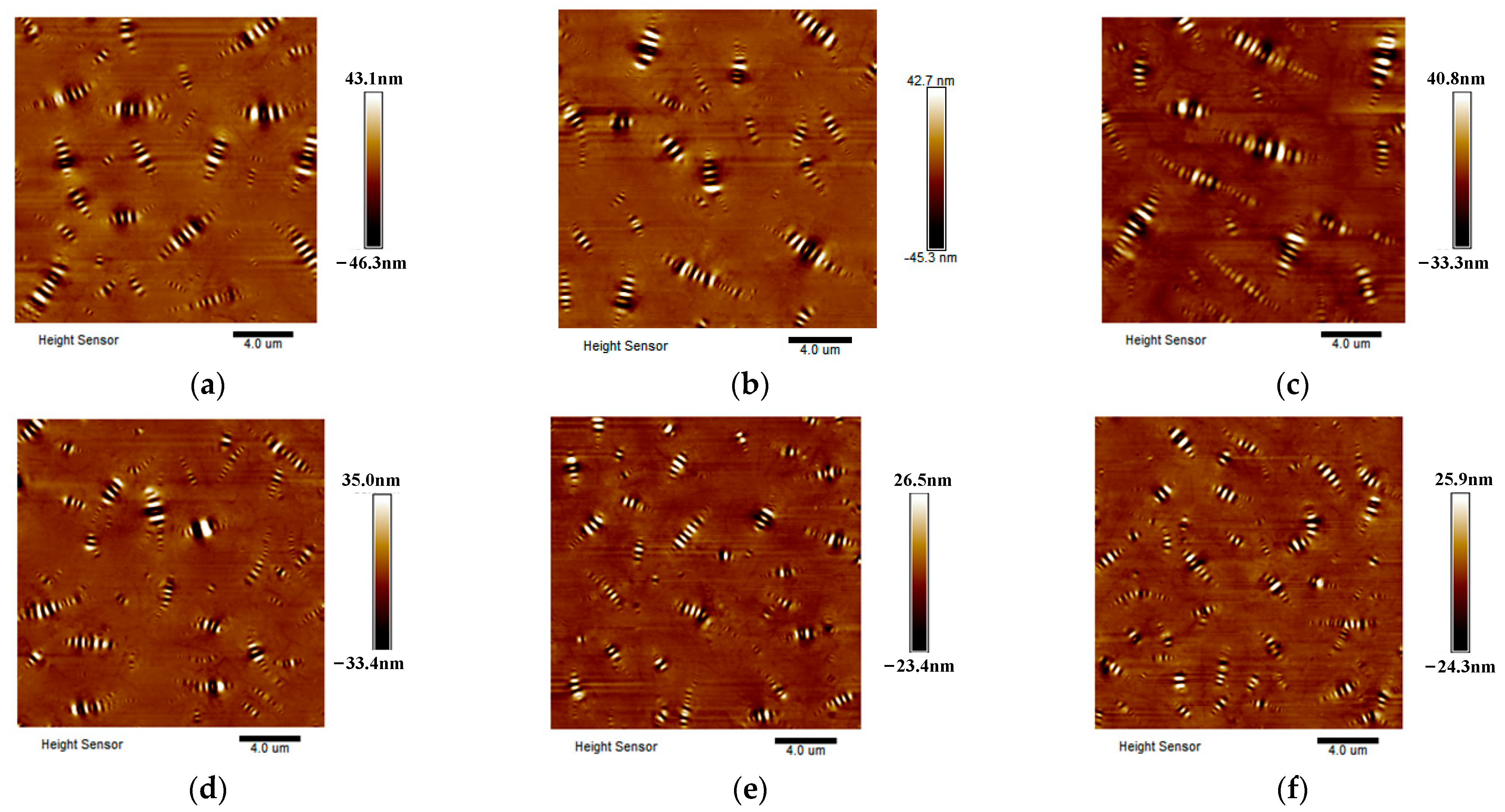

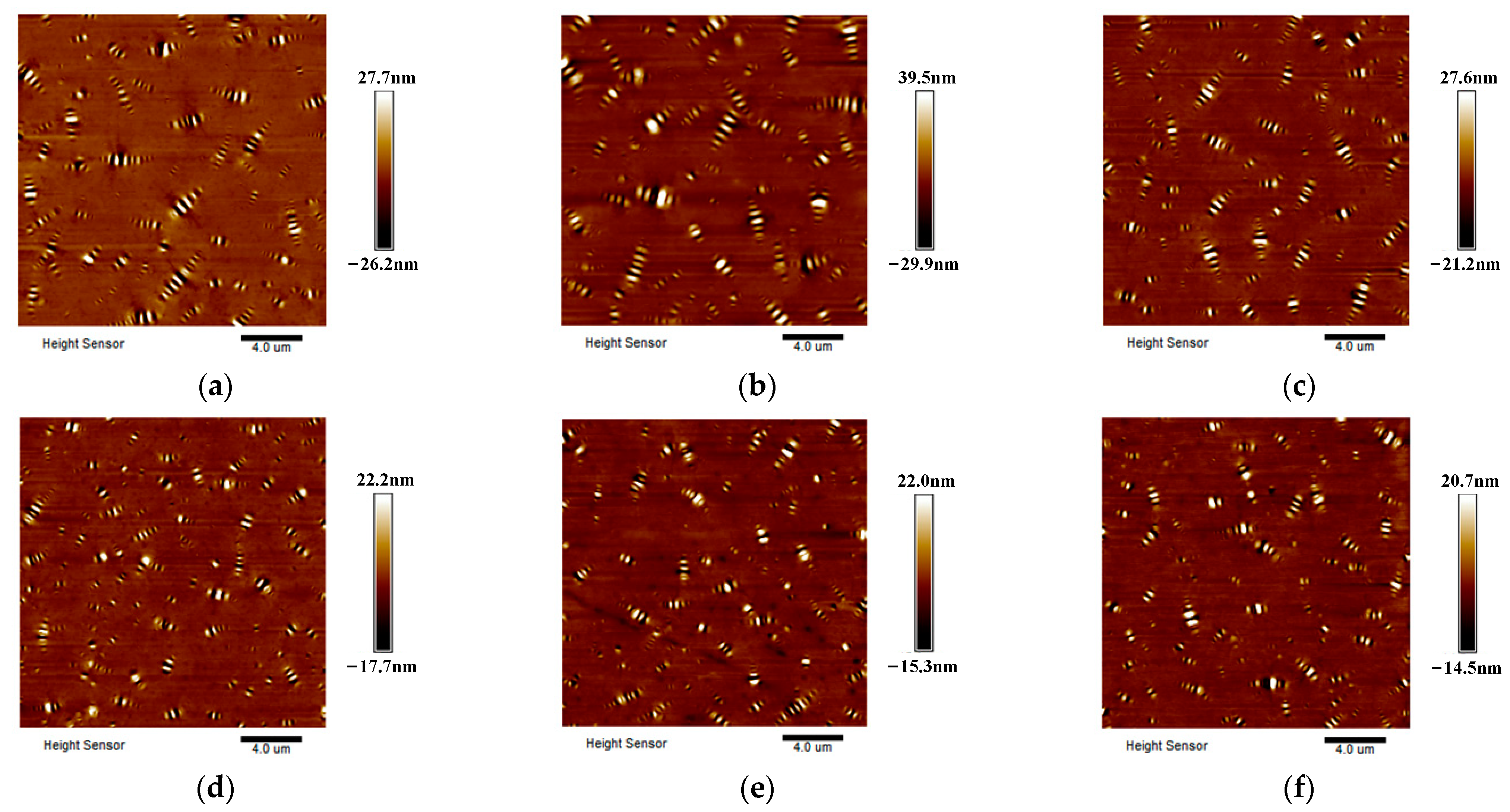

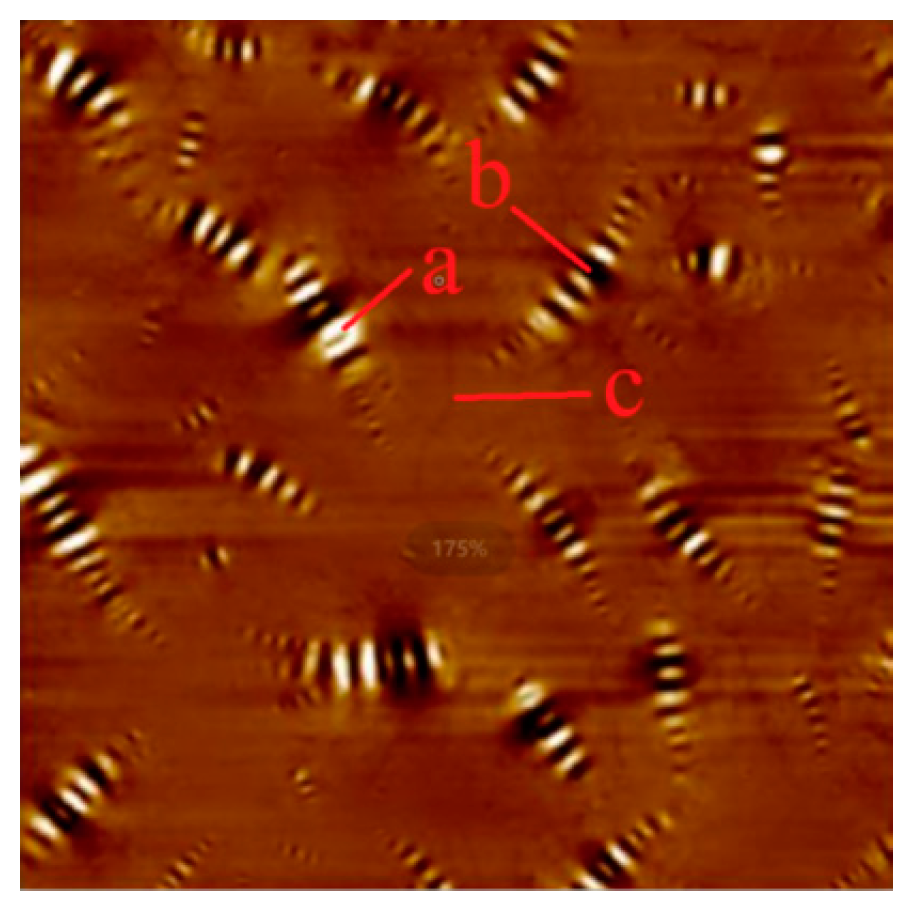

3.1. Morphology and Microstructure

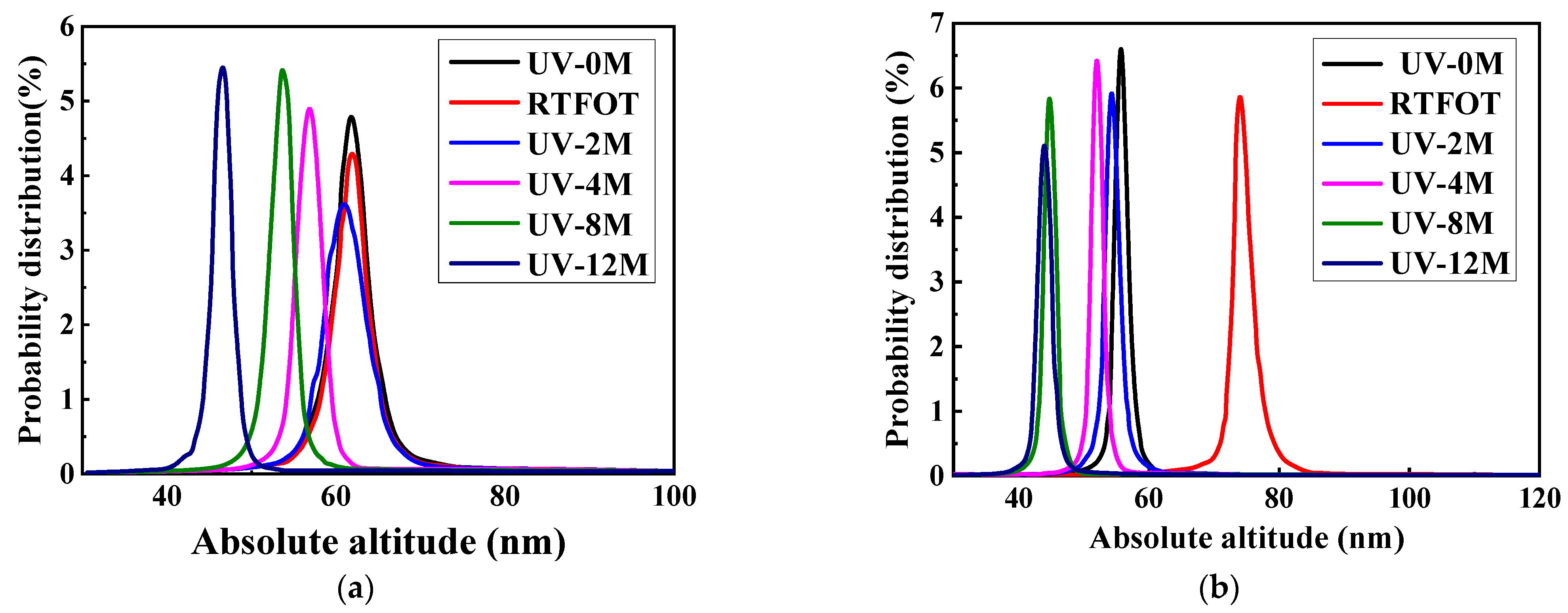

3.2. Roughness Feature Quantification

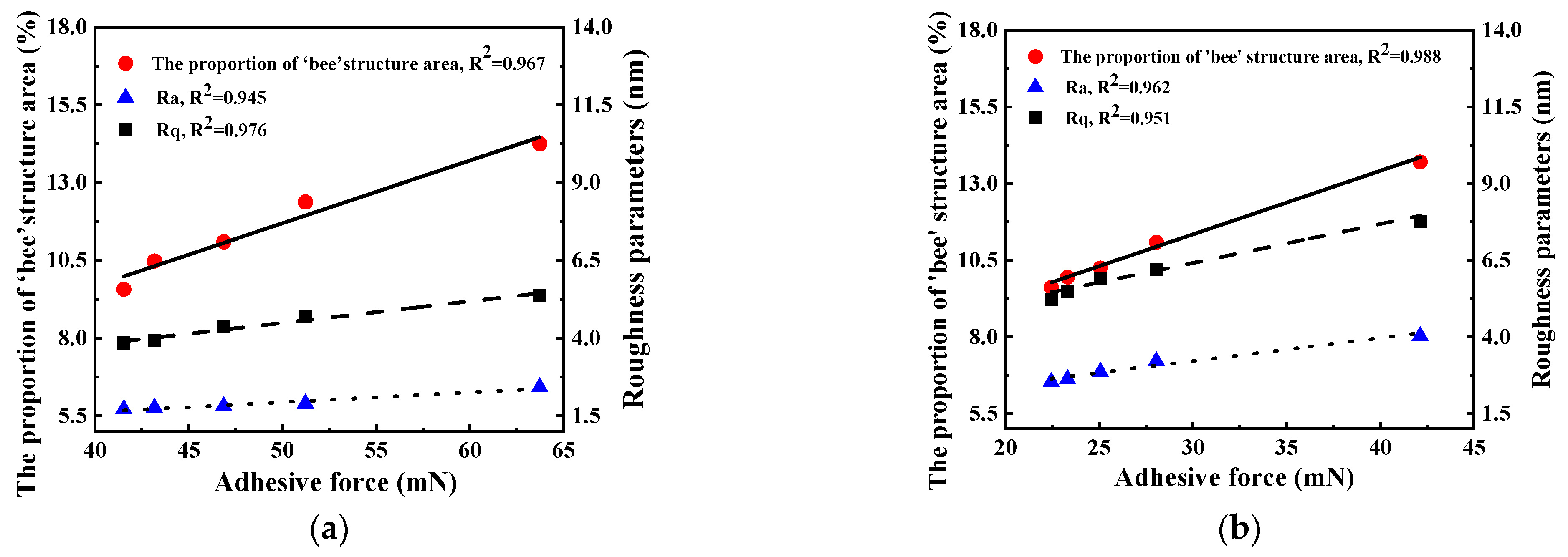

3.3. Adhesion Force Characteristics

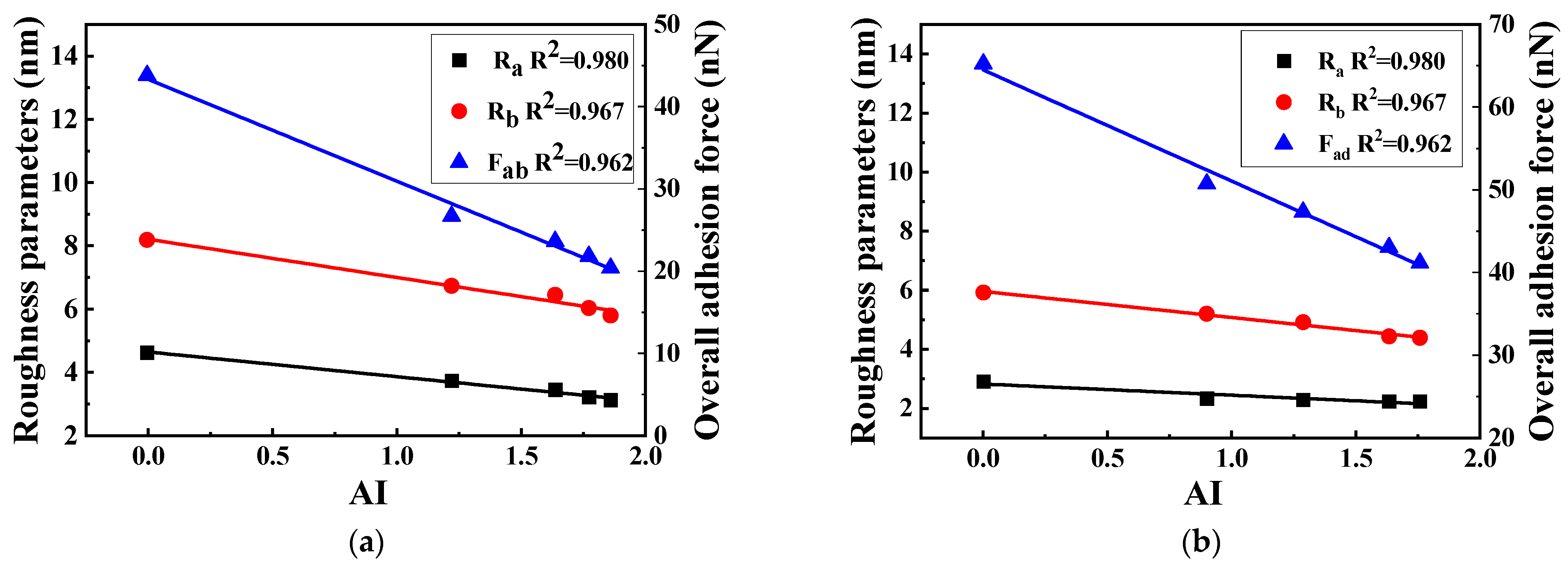

3.4. Nonlinear Prediction of UV Aging

4. Conclusions

- (1)

- The bee structure is closely related to asphalt performance. Throughout the entire aging process, the quantity of bee structures in SBS-modified asphalt is substantially greater than that in base asphalt. UV aging affects the performance of asphalt by changing the number and area of the bee structure in the asphalt. As UV aging progresses, the area of bee structure in asphalt gradually decreases, and the distance between the peak and the valley gradually decreases.

- (2)

- The specific performance is that the roughness of SBS-modified asphalt is relatively stable after short-term aging, and the absolute height of the bee structure experiences a slight increment. Nevertheless, as the UV aging time lengthens, the disparity between the peak and valley of the bee structure of both types of asphalt diminishes. The absolute height of the bee structure keeps dropping, and the surface roughness of the asphalt is gradually decreasing. Notably, the height distribution range of the bee structure in SBS-modified asphalt is narrower and more uniform.

- (3)

- The overall adhesion of asphalt exhibits clear regularity in the relation to the aging time, and the overall adhesion of the two kinds of asphalt decreases with the increase in aging time. As is different from the change rule of base asphalt adhesion, the adhesion of SBS-modified asphalt increases slightly from short-term aging to aging 2 M. Subsequently, with the growth of UV aging time, the adhesion of asphalt decreases progressively.

- (4)

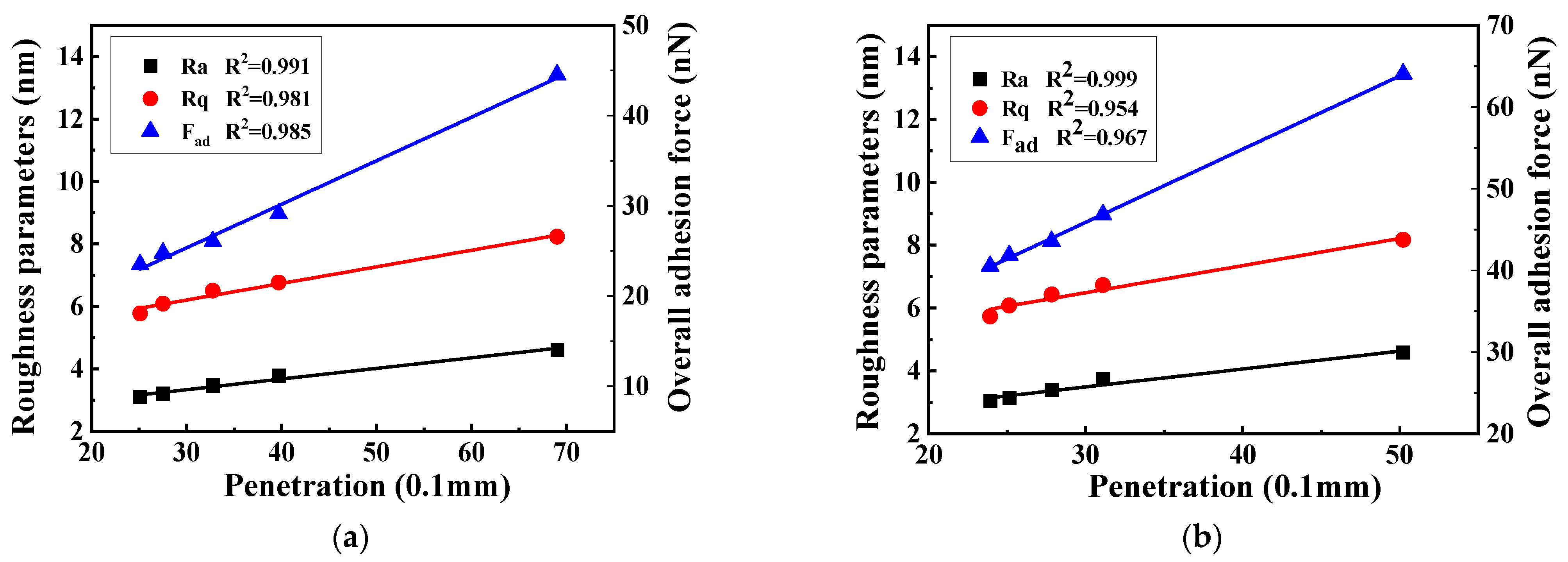

- For the two kinds of asphalt, the penetration and AI under different UV aging durations display an evident linear relationship with the AFM microscopic index. Based on the LM and UGO algorithms, the calculation equations of the morphology height and adhesion force of SBS-modified asphalt and base asphalt under different aging time are obtained. These equations can proficiently characterize the alterations in the micro-morphology and micro-performance of asphalt under UV aging conditions.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Qian, G.; Yao, D.; Gong, X.; Yu, H.; Li, N. Performance evaluation and field application of hard asphalt concrete under heavy traffic conditions. Constr. Build. Mater. 2019, 228, 116729. [Google Scholar] [CrossRef]

- Guo, M.; Ren, X.; Jiao, Y.B.; Liang, M. Review of Aging and Antiaging of Asphalt and Asphalt Mixtures. China J. Highw. Transp. 2022, 35, 41–59. [Google Scholar]

- Editorial Department of China Journal of Highway and Transport. Review on China’s Pavement Engineering Research: 2024. China J. Highw. Transp. 2024, 37, 1–81. [Google Scholar]

- Wang, C.; Gong, G.; Chen, Y. Long-term durability performance assessment of asphalt pavement with the consideration of climate change impact. China Civ. Eng. J. 2023, 56, 110–120. [Google Scholar]

- Xiang, Q.; Xiao, F.; Wu, J.; He, W.; Li, J. Aging Characteristics and Spatiotemporal Evolution Model of Rubberized Reclaimed Asphalt under Acceleration of Artificial Climate. China J. Highw. Transp. 2024, 37, 228–243. [Google Scholar]

- Liu, L.; Dong, W.; Sun, L.; Jiang, T. Ultraviolet Radiation Aging Performance of SBS and SBR Modified Asphalt. J. Build. Mater. 2009, 12, 676–678. [Google Scholar]

- Ma, Y.; Wang, S.; Zhang, M.; Jiang, X.; Polaczyk, P.; Huang, B. Weather aging effects on modified asphalt with rubber- polyethylene composites. Sci. Total Environ. 2023, 865, 161089. [Google Scholar] [CrossRef]

- Li, W.; Zhang, S.; Shi, Q.; Yu, M. Research on Anti-damage Performance of Asphalt Pavement Under UV Aging in Severe Cold Region of Xinjiang. Mater. Rep. 2022, 36, 104–109. [Google Scholar]

- Zhang, Q.; Cui, Y.; Qiu, H. Microstructure, Fatigue, and Self-Healing Properties of SBS-Modified Asphalt under Ultraviolet Radiation. J. Mater. Civ. Eng. 2023, 35, 04023163. [Google Scholar] [CrossRef]

- Xu, G.; Wang, H. Molecular dynamics study of oxidative aging effect on asphalt binder properties. Fuel 2017, 188, 1–10. [Google Scholar] [CrossRef]

- Yan, C.; Huang, W.; Lin, P.; Zhang, Y.; Lv, Q. Chemical and rheological evaluation of aging properties of high content SBS polymer modified asphalt. Fuel 2019, 252, 417–426. [Google Scholar] [CrossRef]

- Xu, Y.; Niu, K.; Zhu, H.; Chen, R.; Ou, L.; Wang, J. Generation and evolution mechanisms of asphalt aging under the combined effects of intense UV radiation and large temperature variations. Constr. Build. Mater. 2024, 438, 136786. [Google Scholar] [CrossRef]

- Zhang, H.; Chen, Z.; Xu, G.; Shi, C. Evaluation of aging behaviors of asphalt binders through different rheological indices. Fuel 2018, 221, 78–88. [Google Scholar] [CrossRef]

- Zhou, X.; Ge, D.; Lv, S.; Wang, X.; Li, Y.; Ju, Z. Influence of variable intensity ultraviolet on the performance of SBS modified asphalt. Case Stud. Constr. Mater. 2024, 21, e03854. [Google Scholar] [CrossRef]

- Xu, Y. Research on Asphalt Aging Mechanism and Rheological Behavior Under the Combined Effects of Intense UV Radiation and Large Temperature Variations. Ph.D. Thesis, Chongqing Jiaotong University, Chongqing, China, 2024. [Google Scholar]

- Xu, S.; Ren, X.; Wu, H.; Liu, H.; Xu Meng Zhu, Z.; Ling, M. Effect of Ultraviolet Aging on Fundamental Properties of Polymer and Crumb Rubber Modified Asphalt and Asphalt Mixtures. J. Mater. Civ. Eng. 2024, 36, 05024005. [Google Scholar] [CrossRef]

- Liu, R.; Zhou, T.; Tan, T.; Cao, L.; Dong, Z. Rejuvenation effect of castor-based bio-oil on asphalt with different aging levels. J. Cent. South Univ. (Sci. Technol.) 2023, 54, 2271–2281. [Google Scholar]

- Zhao, Y.; Wu, X.; Chao, Y.; Liang, N.; Zhou, P.; Li, Z.; Mei, Y. Aging characteristics and microscopic mechanisms of SBS asphalt based on coupled light-heat-water aging. Constr. Build. Mater. 2024, 456, 139190. [Google Scholar] [CrossRef]

- Feng, X.; Yang, H.; Xiao, H.; Zhu, Z. Properties and Mechanism of Reclaimed Asphalt Based on SBS Structure Repair. J. China Foreign Highw. 2024, 44, 56–63. [Google Scholar] [CrossRef]

- Yang, Z.; Zhang, X.; Yu, J.; Xu, W. Study on Multi-scale Characteristics of base Asphalt before and after Aging. J. Build. Mater. 2018, 21, 420–425. [Google Scholar]

- Fan, T.; Han, S.; Si, K. Effect of Ultraviolet Aging on Fatigue Properties of Calcium Sulfate Whisker Modified Asphalt. Mater. Rep. 2014, 599, 125–129. [Google Scholar]

- Liu, F.; Wang, Q.; Zhang, X.; Zhou, Z.; Guo, C. Effect of oxidation kinetic aging on the adhesion behaviour of asphalt-aggregate interfaces from molecular view. Int. J. Pavement Eng. 2024, 25, 2313499. [Google Scholar] [CrossRef]

- Abu Qtaish, L.; Nazzal, M.D.; Abbas, A.; Kaya, S.; Akinbowale, S.; Arefin, M.S.; Kim, S.-S. Micromechanical and Chemical Characterization of Foamed Warm-Mix Asphalt Aging. J. Mater. Civ. Eng. 2018, 30, 04018213. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, Y.; Yu, T.; Liu, Z. Microstructural characteristics of differently aged asphalt samples based on atomic force microscopy (AFM). Constr. Build. Mater. 2020, 255, 119388. [Google Scholar] [CrossRef]

- Loeber, L.; Sutton, O.; Morel, J.; Valleton, J.M.; Muller, G. New direct observations of asphalts and asphalt binders by scanning electron microscopy and atomic force microscopy. J. Microsc. 1996, 182, 32–39. [Google Scholar] [CrossRef]

- Yu, T.; Wang, J.; Zhang, H.; Sun, J. Statistical analysis of aging micro-characteristics for asphalt binder AFM images based on neural network classification. Fuel 2024, 371, 132080. [Google Scholar] [CrossRef]

- Fang, J.; Tu, J. Effect of ultraviolet (UV) aging on rheology properties and microstructure of polyurethane (PU) modified asphalt. Mater. Res. Express 2019, 6, 125318. [Google Scholar] [CrossRef]

- Wang, J.; Ji, M.; Xue, Z.; Liu, H.; Zhang, J. Study on the effect of light-dark alternating ultraviolet aging conditions on the properties of asphalt. J. Build. Mater. 2024, 1–11, in press. [Google Scholar]

- Zhao, Q.; Lu, X.; Jing, S.; Yao, X.; Sun, M.; Geng, L.; Ren, R.; Wang, L.; Liu, J.; Qiu, L. The fatigue mechanism of asphalt mixture with an interlayer under the combined effect of multiple factors. Constr. Build. Mater. 2023, 384, 131428. [Google Scholar] [CrossRef]

- Chhabra, R.S.; Mahadeva, R.; Ransinchung, G.D.R.N. Unconfined compressive strength prediction of recycled cement-treated base mixes using soft computing techniques. Road Mater. Pavement Des. 2024, 25, 423–437. [Google Scholar] [CrossRef]

- Hu, Y.; Sun, Z.; Pei, L.; Han, Y.; Li, W. Evaluate asphalt pavement frictional characteristics based on IGWO-NGBoost using 3D macro-texture data. Expert Syst. Appl. 2024, 242, 122786. [Google Scholar] [CrossRef]

- Chatti, K.; Ji, Y.G.; Harichandran, R. Dynamic time domain backcalculation of layer moduli, damping, and thicknesses in flexible pavements. Transp. Res. Rec. 2004, 1869, 106–116. [Google Scholar] [CrossRef]

- Hsie, M.; Ho, Y.-F.; Lin, C.-T.; Yeh, I.-C. Modeling asphalt pavement overlay transverse cracks using the genetic operation tree and Levenberg-Marquardt Method. Expert Syst. Appl. 2012, 39, 4874–4881. [Google Scholar] [CrossRef]

- Ouyang, Q.; Xie, Z.; Liu, J.; Gong, M.; Yu, H. Application of Atomic Force Microscopy as Advanced Asphalt Testing Technology: A Comprehensive Review. Polymers 2022, 14, 2851. [Google Scholar] [CrossRef]

- Li, X.; Wang, Y.; Wu, Y.; Wang, H.; Wang, Q.; Zhu, X.; Liu, X.; Sun, H.; Fan, L. Effect of Graphene on Modified Asphalt Microstructures Based on Atomic Force Microscopy. Materials 2021, 14, 3677. [Google Scholar] [CrossRef] [PubMed]

- Hu, Y.; Yin, Y.; Sreeram, A.; Si, W.; Airey, G.D.; Li, B.; Singh, B.; Özdemir, D.K.; Zhou, L. Atomic force microscopy (AFM) based microstructural and micromechanical analysis of bitumen during ageing and rejuvenation. Constr. Build. Mater. 2025, 467, 140387. [Google Scholar] [CrossRef]

- JTG E20-2011[S]; Standard Test Methods of Bitumen and Bituminous Mixture for Highway Engineering. China Communications Press: Beijing, China, 2011.

- Li, R.; Wang, P.; Xue, B.; Pei, J. Experimental study on aging properties and modification mechanism of Trinidad lake asphalt modified bitumen. Constr. Build. Mater. 2015, 101, 878–883. [Google Scholar] [CrossRef]

- Tong, S.; Xie, X.; Zhao, D. Nonlinear prediction of road performance of asphalt mixture after ultraviolet aging. Jianzhu Cailiao Xuebao/J. Build. Mater. 2016, 19, 105–110. [Google Scholar]

| Performance Index | Quality Index | Test Result | Quality Index | Test Result | Testing Standards | |

|---|---|---|---|---|---|---|

| Base Asphalt | SBS-Modified Asphalt | |||||

| Penetration (25 °C, 100 g, 5 s) (0.1 mm) | 60~80 | 71.6 | 40~60 | 51.6 | T0604 | |

| Ductility (5 cm/min, 15 °C) (cm) | ≥100 | >100 | ≥20 | 32 | T0605 | |

| Soft pointing (ball and ring method) (°C) | ≥46 | 47.3 | ≥60 | 75.0 | T0606 | |

| Density (15 °C) (g/cm3) | measurement | 1.036 | measurement | 1.024 | T0603 | |

| Solubility (trichloroethylene) (%) | ≥99.5 | 99.80 | ≥99 | 99.90 | T0607 | |

| Storage stability segregation, 48 h softening point difference (°C) | - | - | ≤2.5 | 1.6 | T0661 | |

| RTFOT 163 °C, 85 min | Quality loss (%) | ≤±0.8 | 0.08 | ≤±1.0 | 0.222 | T0610 |

| Residual penetration ratio (25 °C) (%) | ≥61 | 63.6 | ≥65 | 72 | ||

| Ductility (5 cm/min, 15 °C) (cm) | ≥6 | 7 | ≥15 | 18 | ||

| Probe Model | Tip Radius/nm | Frequency/kHz | Stiffness Factor N/m | Cantilever Number | Back Coating |

|---|---|---|---|---|---|

| SCANASMST-AIR | 2 | 70 | 0.4 | 1 | Reflective aluminum |

| Aging Time | Area (%) | Area | Number | ||

|---|---|---|---|---|---|

| White | Black | Gray | |||

| Base asphalt | |||||

| 0 M | 6.41 | 7.30 | 86.29 | 13.71 | 29 |

| RTFOT | 5.92 | 6.09 | 87.99 | 12.01 | 31 |

| 2 M | 5.84 | 5.25 | 88.91 | 11.09 | 32 |

| 4 M | 5.34 | 4.91 | 89.75 | 10.25 | 42 |

| 8 M | 5.32 | 4.63 | 90.05 | 9.95 | 48 |

| 12 M | 5.06 | 4.56 | 90.38 | 9.62 | 56 |

| SBS-modified asphalt | |||||

| 0 M | 5.78 | 6.48 | 87.74 | 12.26 | 65 |

| RTFOT | 7.75 | 6.83 | 85.42 | 14.58 | 66 |

| 2 M | 6.05 | 6.33 | 87.62 | 12.38 | 76 |

| 4 M | 5.23 | 5.91 | 88.85 | 11.14 | 89 |

| 8 M | 5.32 | 5.66 | 89.02 | 10.98 | 84 |

| 12 M | 4.94 | 4.63 | 90.43 | 9.57 | 89 |

| Aging Time | Base Asphalt | SBS-Modified Asphalt | ||||||

|---|---|---|---|---|---|---|---|---|

| Ra | SD | Rq | SD | Ra | SD | Rq | SD | |

| 0 M | 4.03 | 0.21 | 7.66 | 0.68 | 2.42 | 0.20 | 5.38 | 0.36 |

| RTFOT | 3.48 | 0.19 | 7.03 | 0.38 | 3.39 | 0.35 | 7.81 | 2.21 |

| 2 M | 3.21 | 0.22 | 6.20 | 0.20 | 1.83 | 0.10 | 4.68 | 0.17 |

| 4 M | 2.86 | 0.40 | 5.90 | 0.96 | 1.81 | 0.08 | 4.38 | 0.16 |

| 8 M | 2.63 | 0.14 | 5.49 | 0.26 | 1.76 | 0.13 | 3.93 | 0.36 |

| 12 M | 2.54 | 0.07 | 5.22 | 0.01 | 1.71 | 0.19 | 3.84 | 0.27 |

| Aging Time | Proportion of Area in Different Regions/% | Adhesion in Different Regions Fad/nN | Overall Adhesion Force Fad/nN | ||||

|---|---|---|---|---|---|---|---|

| Peak Maximum | Peak Trough | Smooth Region | Peak Maximum | Peak Trough | Smooth Region | ||

| Base asphalt | |||||||

| UV-0 M | 6.41 | 7.30 | 86.29 | 41.19 | 39.68 | 43.18 | 42.79 |

| RTFOT | 5.92 | 6.09 | 87.99 | 30.78 | 31.25 | 32.15 | 32.01 |

| UV-2 M | 5.84 | 5.25 | 88.91 | 27.43 | 26.1 | 28.21 | 28.05 |

| UV-4 M | 5.34 | 4.91 | 89.75 | 24.74 | 24.66 | 25.34 | 25.27 |

| UV-8 M | 5.32 | 4.63 | 90.05 | 22.61 | 22.67 | 23.98 | 23.85 |

| UV-12 M | 5.06 | 4.56 | 90.38 | 20.90 | 20.08 | 22.97 | 22.73 |

| SBS-modified asphalt | |||||||

| UV-0 M | 5.78 | 6.48 | 87.82 | 62.95 | 61.57 | 63.88 | 63.73 |

| RTFOT | 7.75 | 6.83 | 85.42 | 46.57 | 47.41 | 49.77 | 50.29 |

| UV-2 M | 6.05 | 6.33 | 87.62 | 47.63 | 49.78 | 51.24 | 50.43 |

| UV-4 M | 5.23 | 5.91 | 88.91 | 43.33 | 41.78 | 47.63 | 46.87 |

| UV-8 M | 5.32 | 5.66 | 89.02 | 39.1 | 41.8 | 43.49 | 43.17 |

| UV-12 M | 4.94 | 4.63 | 90.43 | 39.57 | 39.20 | 41.77 | 41.54 |

| The Type of Asphalt | AFM Index | r (10−5) | L | Aging Equation | R2 |

|---|---|---|---|---|---|

| Base asphalt | Roughness | 52.787 | 0.283 | H = 1.37/(1 − 0.72 × 10−0.00052782 t) | 0.979 |

| Adhesion | 118.763 | 3.974 | A = 0.87/(1 + 2.97 × 10−0.00118763 t) | 0.951 | |

| SBS-modified asphalt | Roughness | 9.3291 | 0.068 | H = 0.36/(1 − 0.93 × 10−0.000093291 t) | 0.985 |

| Adhesion | 82.126 | 3.793 | A = 0.98/(1 + 2.79 × 10−0.00082126 t) | 0.934 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, W.; Hao, P.; Liu, G.; Li, Z.; Le, C.; Wang, C.; Ma, W.; Li, S. Research on the Microscopic Aging Characteristics of Asphalt Binder Based on Atomic Force Microscopy. Polymers 2025, 17, 1000. https://doi.org/10.3390/polym17081000

Li W, Hao P, Liu G, Li Z, Le C, Wang C, Ma W, Li S. Research on the Microscopic Aging Characteristics of Asphalt Binder Based on Atomic Force Microscopy. Polymers. 2025; 17(8):1000. https://doi.org/10.3390/polym17081000

Chicago/Turabian StyleLi, Wenhui, Peiwen Hao, Guofeng Liu, Zhigang Li, Chen Le, Chun Wang, Wenduo Ma, and Shaohui Li. 2025. "Research on the Microscopic Aging Characteristics of Asphalt Binder Based on Atomic Force Microscopy" Polymers 17, no. 8: 1000. https://doi.org/10.3390/polym17081000

APA StyleLi, W., Hao, P., Liu, G., Li, Z., Le, C., Wang, C., Ma, W., & Li, S. (2025). Research on the Microscopic Aging Characteristics of Asphalt Binder Based on Atomic Force Microscopy. Polymers, 17(8), 1000. https://doi.org/10.3390/polym17081000