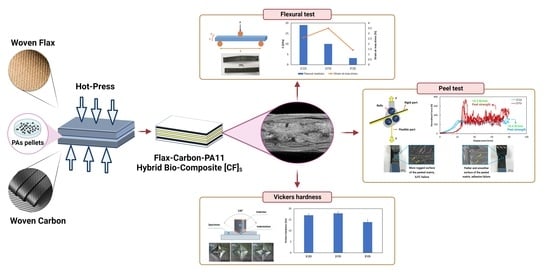

Hybridization Effect on Interlaminar Bond Strength, Flexural Properties, and Hardness of Carbon–Flax Fiber Thermoplastic Bio-Composites

Abstract

:1. Introduction

| Fiber | Density (g/cm3) | Tensile Strength (MPa) | E-Modulus (GPa) | Elongation at Break (%) | Ref. |

|---|---|---|---|---|---|

| Bast fiber | |||||

| Flax | 1.5 | 345–1100 | 27.6 | 0.2–3.2 | [14,15,16,17] |

| Hemp | 1.48 | 690 | 30–70 | 1.6–4 | [14,15,16,18] |

| Jute | 1.3–1.45 | 393–773 | 10.0–30.0 | 1.2–1.8 | [14,15,16,17] |

| Kenaf | - | 930 | 22.0–60.0 | 1.6 | [14,16,17] |

| Leaf fiber | |||||

| Sisal | 1.5 | 468–640 | 9.4–22.0 | 3.0–7.0 | [14,15,19,20] |

| Curaua | 1.4 | 500–1150 | 9–11.8 | 3.7–7.5 | [14,16,17] |

| Pineapple | 1.5 | 413–1627 | 34.5–82.5 | 0.8–1.6 | [17,21,22,23] |

| Fruit/Seed fiber | |||||

| Cotton | 1.5–1.6 | 287–800 | 5.5–12.6 | 7.0–8.0 | [16,17,19] |

| Coir | 1.2 | 131–175 | 4.0–6.0 | 15.0–40 | [14,16,17,19] |

| Oil palm | 0.7–1.55 | 248 | 3.2 | 25.0 | [14,16,17,24] |

| Synthetic fiber | |||||

| Aramid | 1.4 | 3000–3150 | 63.0–67.0 | 3.3–3.7 | [15,17,19] |

| Carbon | 1.7 | 4000 | 230–240 | 1.4–1.8 | [15,17,19] |

| E-glass | 2.5 | 2000–3500 | 70.0 | 2.5 | [15,19,21,25] |

| S-glass | 2.5 | 4570 | 86.0 | 2.8 | [15,17,19,21] |

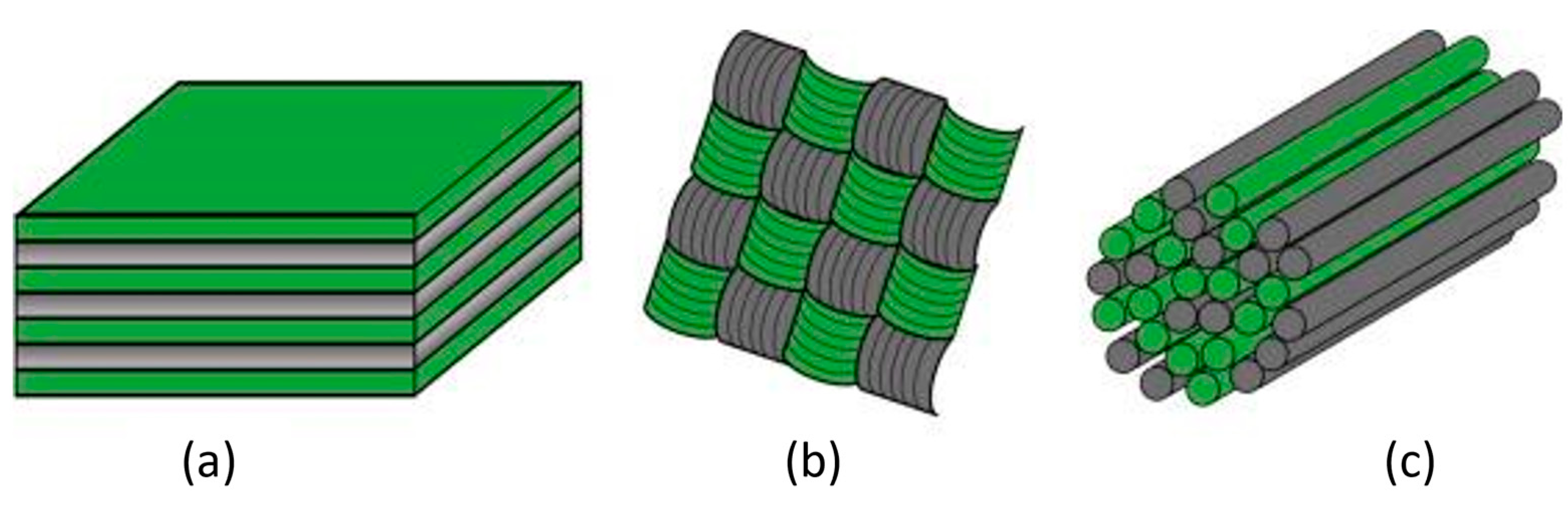

2. Materials and Methods

2.1. Materials

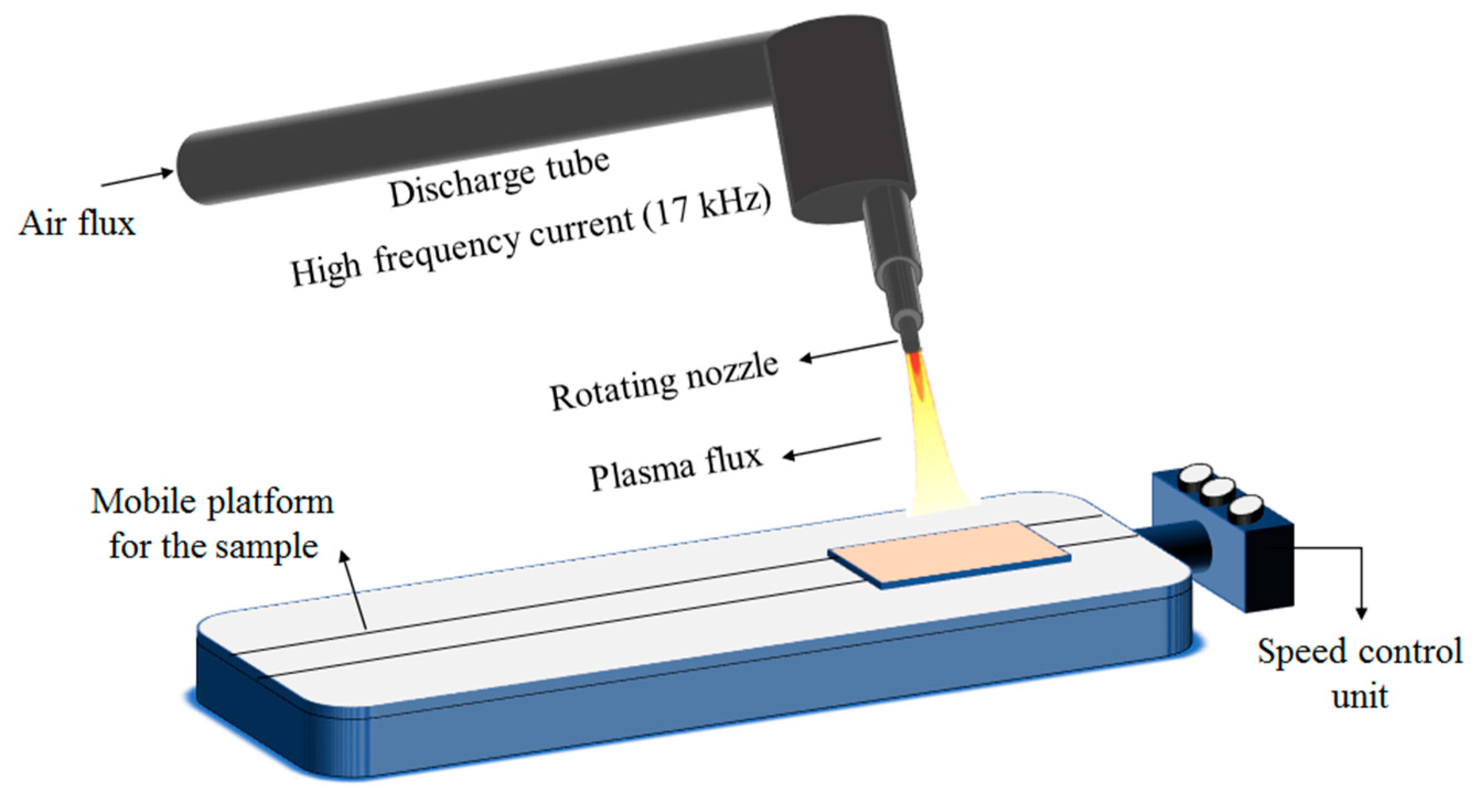

2.2. Surface Treatment

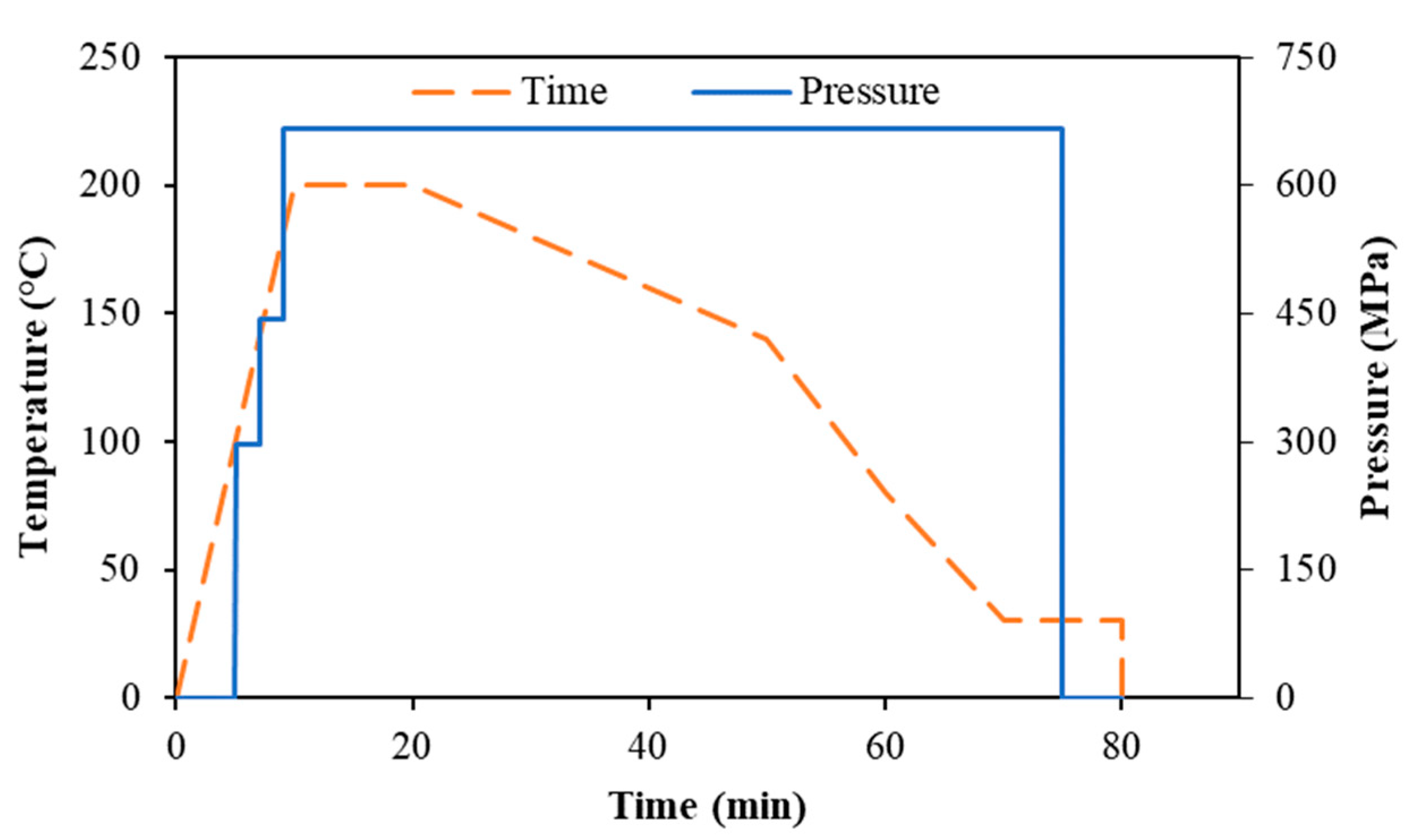

2.3. Composite Manufacturing

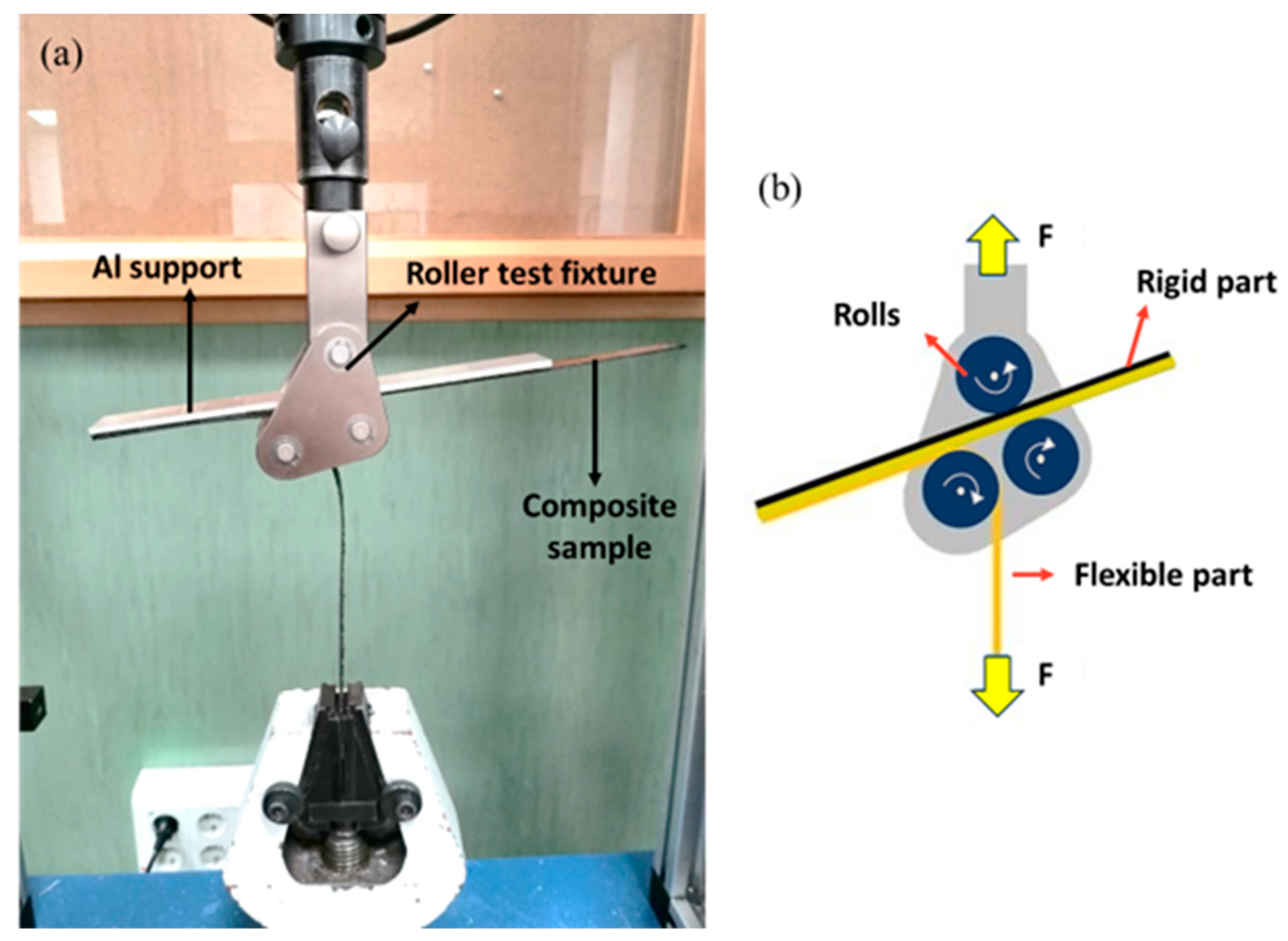

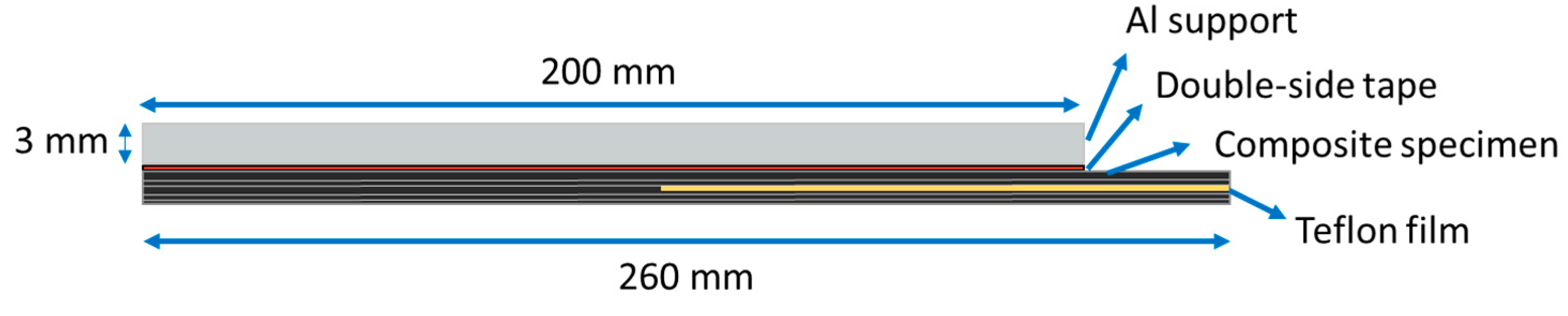

2.4. Peel Test

2.5. Flexural Properties

2.6. Macro-Hardness Test

3. Results

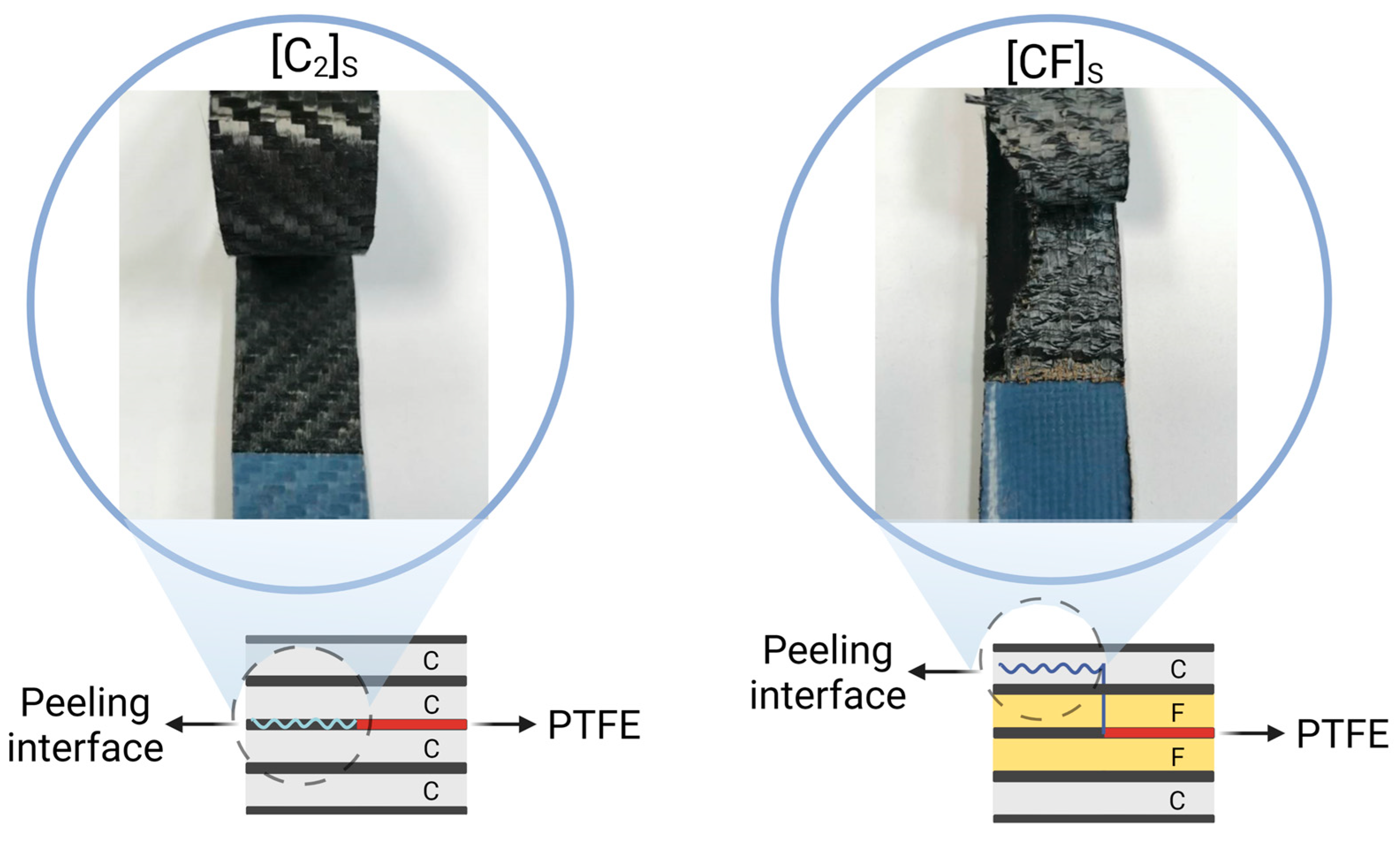

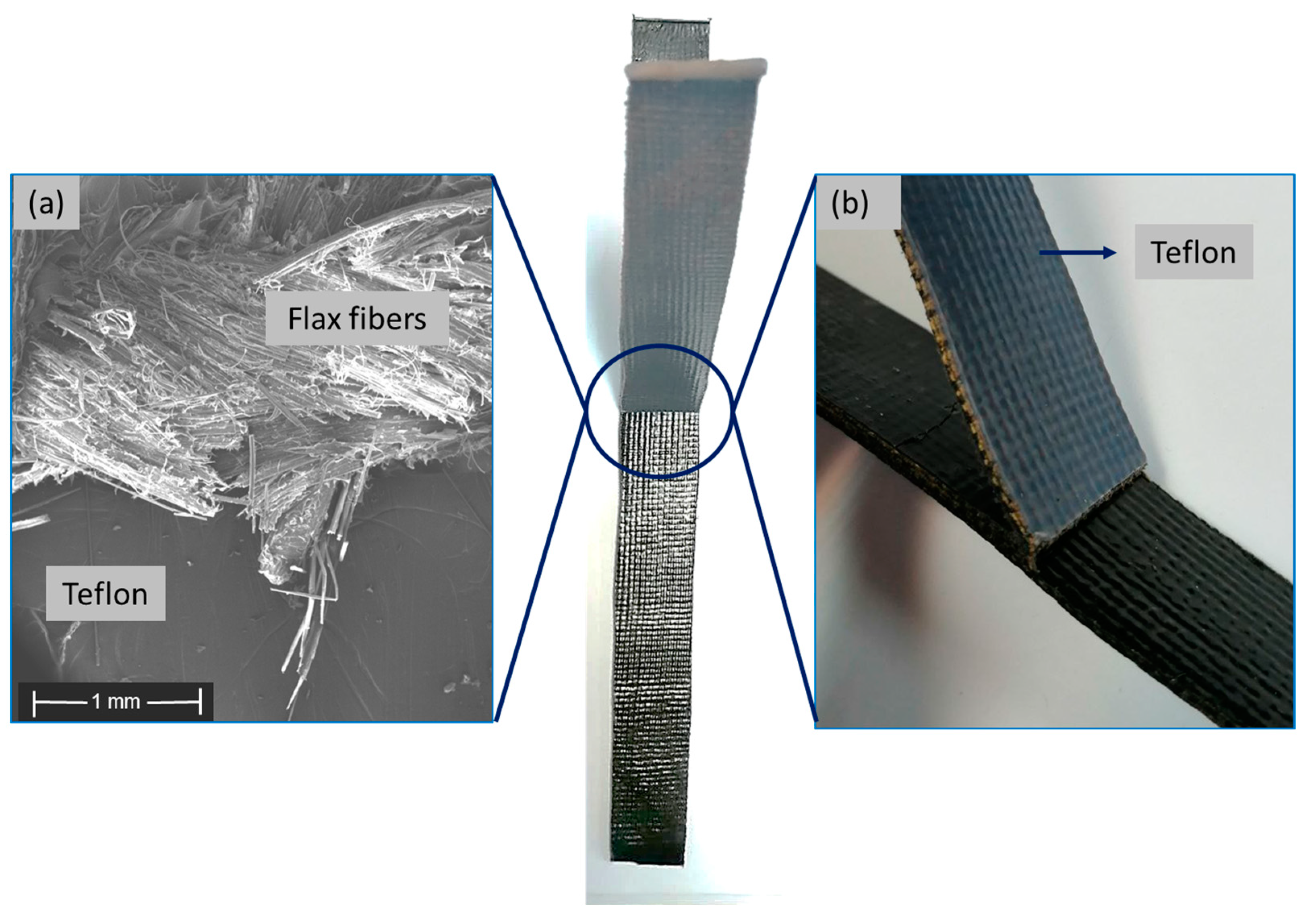

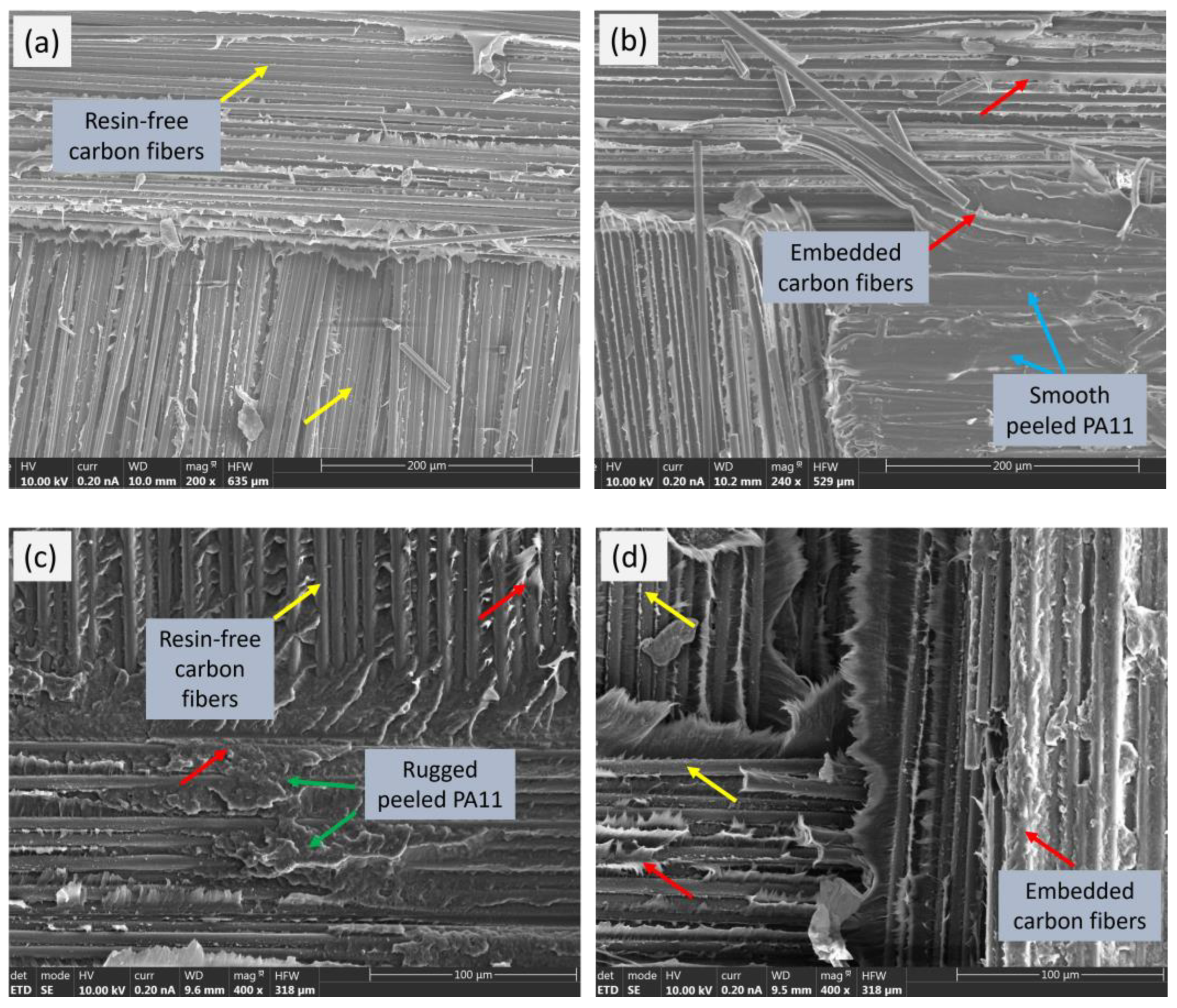

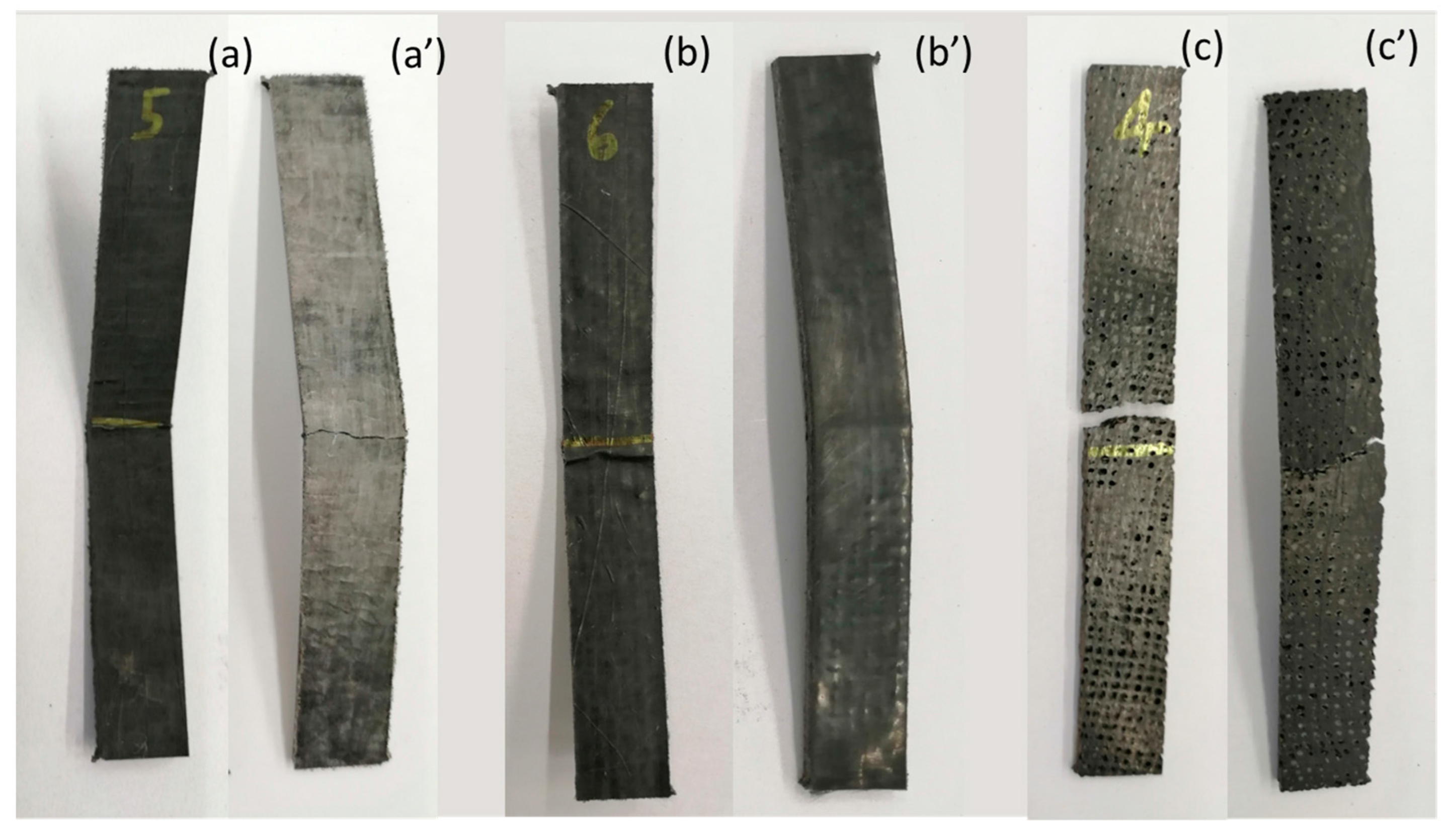

3.1. Peel Test

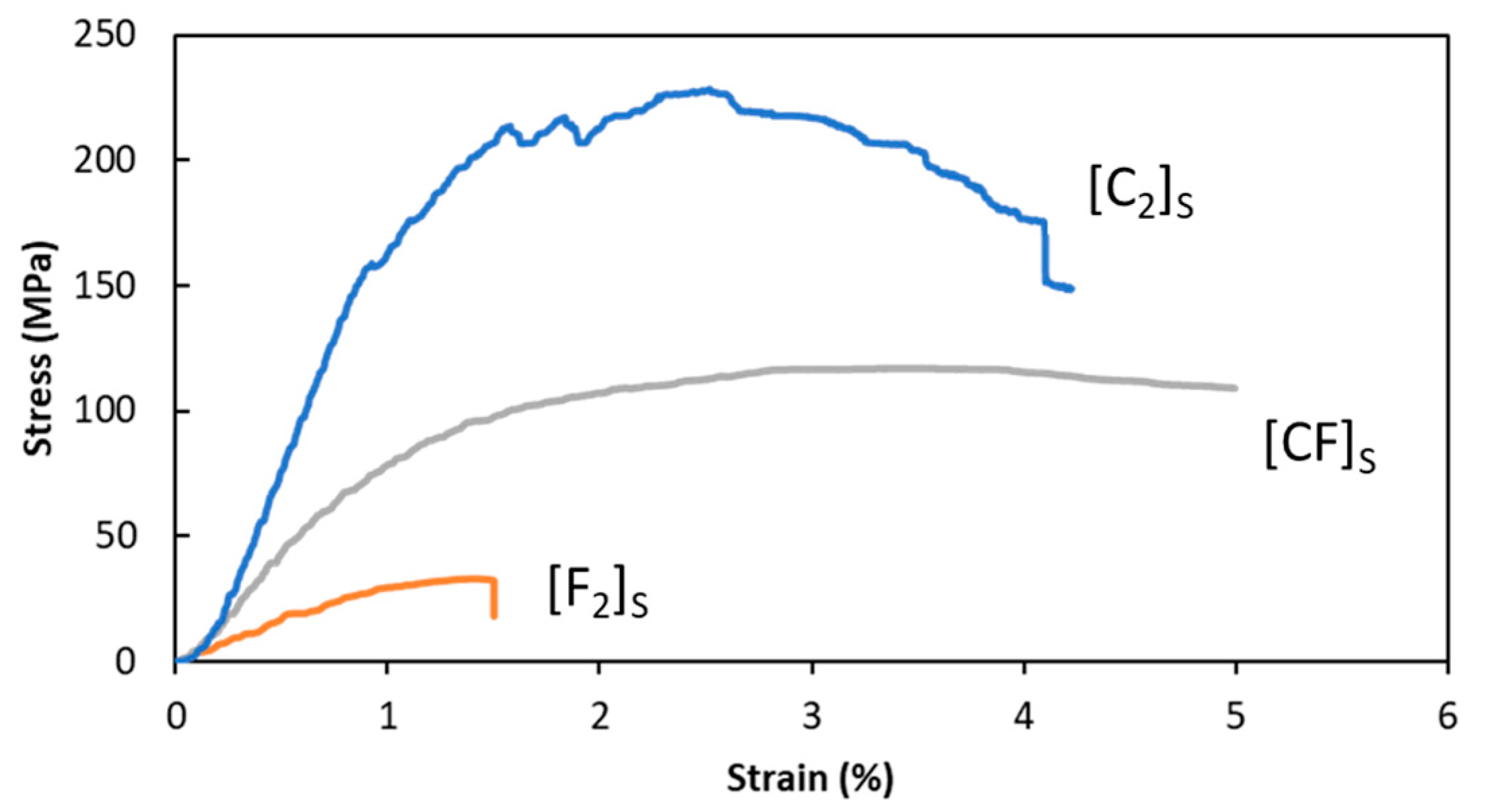

3.2. Flexural Properties

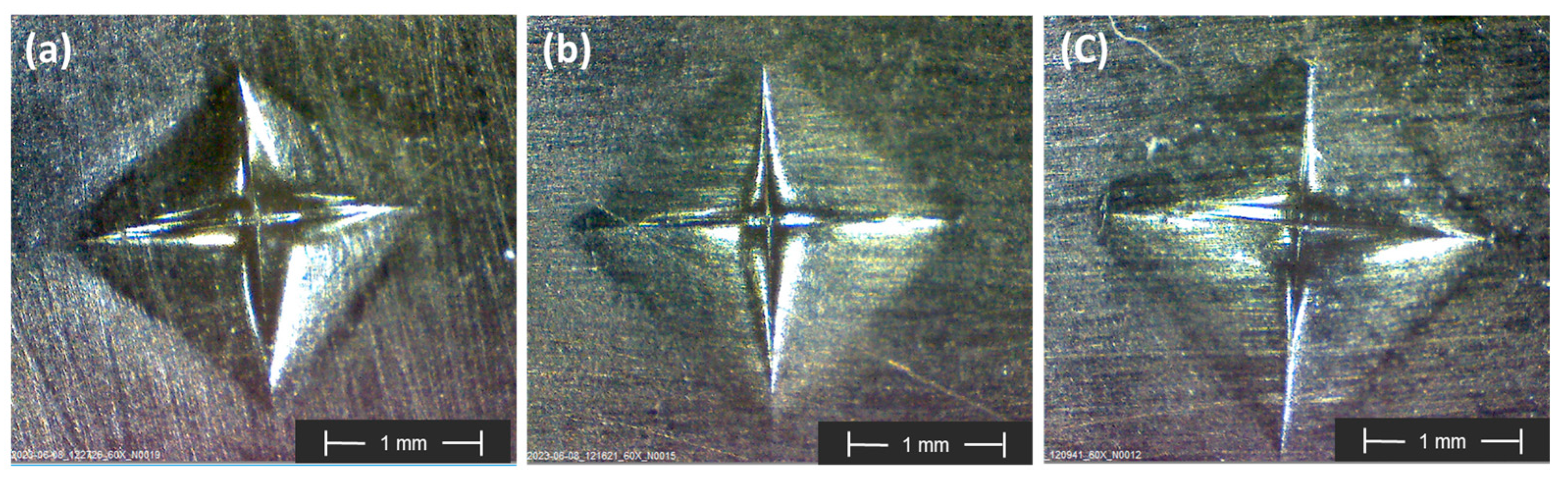

3.3. Macro-Hardness Test

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bahrami, M.; Abenojar, J.; Martínez, M.Á. Recent progress in hybrid biocomposites: Mechanical properties, water absorption, and flame retardancy. Materials 2020, 13, 5145. [Google Scholar] [CrossRef] [PubMed]

- Chichane, A.; Boujmal, R.; El Barkany, A. Bio-composites and bio-hybrid composites reinforced with natural fibers. Mater. Today Proc. 2023, 72, 3471–3479. [Google Scholar] [CrossRef]

- Suriani, M.J.; Ilyas, R.A.; Zuhri, M.Y.M.; Khalina, A.; Sultan, M.T.H.; Sapuan, S.M.; Ruzaidi, C.M.; Wan, F.N.; Zulkifli, F.; Harussani, M.M.; et al. Critical review of natural fiber reinforced hybrid composites: Processing, properties, applications and cost. Polymers 2021, 13, 3514. [Google Scholar] [CrossRef] [PubMed]

- More, A.P. Flax fiber–based polymer composites: A review. Adv. Compos. Hybrid Mater. 2022, 5, 1–20. [Google Scholar] [CrossRef]

- Li, H.; Tang, R.; Dai, J.; Wang, Z.; Meng, S.; Zhang, X.; Cheng, F. Recent progress in flax fiber-based functional composites. Adv. Fiber Mater. 2022, 4, 171–184. [Google Scholar] [CrossRef]

- Malik, K.; Ahmad, F.; Yunus, N.A.; Gunister, E.; Nakato, T.; Mouri, E.; Ali, S. A Review of flax fiber reinforced thermoset polymer composites: Thermal-physical properties, improvements and application. J. Nat. Fibers 2022, 19, 10412–10430. [Google Scholar] [CrossRef]

- Biocomposites Market Size, Trends, Opportunities and Forecast. Available online: https://www.verifiedmarketresearch.com/product/biocomposite-market (accessed on 22 May 2022).

- Carlsson, L.A.; Adams, D.F.; Pipes, R.B. Experimental Characterization of Advanced Composite Materials; CRC Press: Boca Raton, FL, USA, 2014. [Google Scholar]

- Zheng, H.; Zhang, W.; Li, B.; Zhu, J.; Wang, C.; Song, G.; Wu, G.; Yang, X.; Huang, Y.; Ma, L. Recent advances of interphases in carbon fiber-reinforced polymer composites: A review. Compos. Part B Eng. 2022, 233, 109639. [Google Scholar] [CrossRef]

- Rahman, R.; Putra, S.Z.F.S. Tensile Properties of Natural and Synthetic Fiber-Reinforced Polymer Composites. In Mechanical and Physical Testing of Biocomposites; Fibre-Reinforced Composites and Hybrid Composites; Elsevier: Amsterdam, The Netherlands, 2019; pp. 81–102. [Google Scholar]

- Morampudi, P.; Namala, K.K.; Gajjela, Y.K.; Barath, M.; Prudhvi, G. Review on glass fiber reinforced polymer composites. Mater. Today Proc. 2021, 43, 314–319. [Google Scholar] [CrossRef]

- Carbon Fiber Reinforced Plastic (CFRP) Market. 2021. Available online: https://www.futuremarketinsights.com/reports/carbon-fiber-reinforced-plastic-market (accessed on 15 October 2023).

- Glass Fiber Reinforced Plastic (GFRP) Composites Market. Available online: https://www.researchnester.com/reports/glass-fiber-reinforced-plastic-gfrp-composites-market/3829 (accessed on 3 April 2023).

- Faruk, O.; Bledzki, A.K.; Fink, H.-P.; Sain, M. Biocomposites reinforced with natural fibers: 2000–2010. Prog. Polym. Sci. 2012, 37, 1552–1596. [Google Scholar] [CrossRef]

- Li, X.; Tabil, L.G.; Panigrahi, S. Chemical treatments of natural fiber for use in natural fiber-reinforced composites: A review. Polym. Environ. 2007, 15, 25–33. [Google Scholar] [CrossRef]

- John, M.J.; Anandjiwala, R.D. Recent developments in chemical modification and characterization of natural fiber-reinforced composites. Polym. Compos. 2008, 29, 187–207. [Google Scholar] [CrossRef]

- Ramamoorthy, S.K.; Skrifvars, M.; Persson, A. A review of natural fibers used in biocomposites: Plant, animal and regenerated cellulose fibers. Polym. Rev. 2015, 55, 107–162. [Google Scholar] [CrossRef]

- Mwaikambo, L.; Ansell, M. Mechanical properties of alkali treated plant fibres and their potential as reinforcement materials. I. Hemp fibres. Mater. Sci. 2006, 41, 2483–2496. [Google Scholar] [CrossRef]

- Mohanty, A.; Misra Ma Hinrichsen, G. Biofibres, biodegradable polymers and biocomposites: An overview. Macromol. Mater. Eng. 2000, 276, 1–24. [Google Scholar] [CrossRef]

- Li, Y.; Mai, Y.-W.; Ye, L. Sisal fibre and its composites: A review of recent developments. Compos. Sci. Technol. 2000, 60, 2037–2055. [Google Scholar] [CrossRef]

- Jawaid, M.; Khalil, H.A. Cellulosic/synthetic fibre reinforced polymer hybrid composites: A review. Carbohydr. Polym. 2011, 86, 1–18. [Google Scholar] [CrossRef]

- Komuraiah, A.; Kumar, N.S.; Prasad, B.D. Chemical composition of natural fibers and its influence on their mechanical properties. Mech. Compos. Mater. 2014, 50, 359–376. [Google Scholar] [CrossRef]

- Gurunathan, T.; Mohanty, S.; Nayak, S.K. A review of the recent developments in biocomposites based on natural fibres and their application perspectives. Compos. Part A Appl. Sci. Manuf. 2015, 77, 1–25. [Google Scholar] [CrossRef]

- Sathishkumar, T.; Navaneethakrishnan, P.; Shankar, S.; Rajasekar, R.; Rajini, N. Characterization of natural fiber and composites–A review. J. Reinf. Plast. Compos. 2013, 32, 1457–1476. [Google Scholar] [CrossRef]

- Dicker, M.P.; Duckworth, P.F.; Baker, A.B.; Francois, G.; Hazzard, M.K.; Weaver, P.M. Green composites: A review of material attributes and complementary applications. Compos. Part A Appl. Sci. Manuf. 2014, 56, 280–289. [Google Scholar] [CrossRef]

- Alagesan, P.K. Recent advances of hybrid fiber composites for various applications. Hybrid Fiber Compos. Mater. Manuf. Process Eng. 2020, 2020, 381–404. [Google Scholar]

- Cheng, M.; Zhong, Y.; Kureemun, U.; Cao, D.; Hu, H.; Lee, H.P.; Li, S. Environmental durability of carbon/flax fiber hybrid composites. Compos. Struct. 2020, 234, 111719. [Google Scholar] [CrossRef]

- Wang, A.; Wang, X.; Xian, G. Mechanical, low-velocity impact, and hydrothermal aging properties of flax/carbon hybrid composite plates. Polym. Test. 2020, 90, 106759. [Google Scholar] [CrossRef]

- Bahrami, M.; Mehdikhani, M.; Swolfs, Y.; Abenojar, J.; Martínez, M.A. Impact properties of flax-carbon hybrid composites under low-velocity impact. In Proceedings of the 20th European Conference on Composite Materials (ECCM20), Lausanne, Switzerland, 26–30 June 2022. [Google Scholar]

- Ravandi, M.; Kureemun, U.; Banu, M.; Teo, W.; Tong, L.; Tay, T. Effect of interlayer carbon fiber dispersion on the low-velocity impact performance of woven flax-carbon hybrid composites. J. Compos. Mater. 2019, 53, 1717–1734. [Google Scholar] [CrossRef]

- Fairlie, G.; Njuguna, J. Damping properties of flax/carbon hybrid epoxy/fibre-reinforced composites for automotive semi-structural applications. Fibers 2020, 8, 64. [Google Scholar] [CrossRef]

- Rahman, M.Z. Mechanical and damping performances of flax fibre composites–A review. Compos. Part C Open Access 2021, 4, 100081. [Google Scholar] [CrossRef]

- Choudhry, A.; Sharma, A.; Khan, T.A.; Chaudhry, S.A. Flax seeds based magnetic hybrid nanocomposite: An advance and sustainable material for water cleansing. J. Water Process Eng. 2021, 42, 102150. [Google Scholar] [CrossRef]

- Kureemun, U.; Ravandi, M.; Tran, L.; Teo, W.; Tay, T.; Lee, H. Effects of hybridization and hybrid fibre dispersion on the mechanical properties of woven flax-carbon epoxy at low carbon fibre volume fractions. Compos. Part B Eng. 2018, 134, 28–38. [Google Scholar] [CrossRef]

- Amiri, A.; Krosbakken, T.; Schoen, W.; Theisen, D.; Ulven, C.A. Design and manufacturing of a hybrid flax/carbon fiber composite bicycle frame. Proc. Inst. Mech. Eng. Part P J. Sport. Eng. Technol. 2018, 232, 28–38. [Google Scholar] [CrossRef]

- Ghosh, A.K.; De Baere, I.; Van Walleghem, J.; De Thaeye, J.; Degrieck, J. Poster Session I, July 14th 2010—Abstracts Effect of flax fibre reinforcement on the riding comfort of composite racing bicycle frames. Procedia Eng. 2010, 2, 3435. [Google Scholar] [CrossRef]

- Vanwalleghem, J. Damping and Vibration Behaviour of Flax-Carbon Composite Bicycle Racing Frames. Master’s Thesis, Gent University, Gent, Belgium, 2010; p. 89. [Google Scholar]

- Alam, M.A.; Ya, H.; Azeem, M.; Masood, F.; Ahmad, T.; Sapuan, S. Investigation of Natural/Synthetic Hybrid Composite for Marine Application. In Green Hybrid Composite in Engineering and Non-Engineering Applications; Springer: Berlin/Heidelberg, Germany, 2023; pp. 197–210. [Google Scholar]

- Dąbrowska, A. Plant-oil-based fibre composites for boat hulls. Materials 2022, 15, 1699. [Google Scholar] [CrossRef] [PubMed]

- Megahed, M.; Abo-bakr, R.M.; Mohamed, S. Optimization of hybrid natural laminated composite beams for a minimum weight and cost design. Compos. Struct. 2020, 239, 111984. [Google Scholar] [CrossRef]

- Fiore, V.; Valenza, A.; Di Bella, G. Mechanical behavior of carbon/flax hybrid composites for structural applications. J. Compos. Mater. 2012, 46, 2089–2096. [Google Scholar] [CrossRef]

- Corona, A.; Markussen, C.M.; Birkved, M.; Madsen, B. Comparative environmental sustainability assessment of bio-based fibre reinforcement materials for wind turbine blades. Wind Eng. 2015, 39, 53–63. [Google Scholar] [CrossRef]

- Mohammed, S.; Naik, R.L. A critical review of materials and manufacturing techniques for small wind turbine blades. Int. J. Mater. Eng. Innov. 2022, 13, 327–345. [Google Scholar] [CrossRef]

- Wang, A.; Liu, X.; Yue, Q.; Xian, G. Tensile properties hybrid effect of unidirectional flax/carbon fiber hybrid reinforced polymer composites. J. Mater. Res. Technol. 2023, 24, 1373–1389. [Google Scholar] [CrossRef]

- Karacor, B.; Özcanli, M. Analysis of mechanical properties of flax/carbon fiber reinforced hybrid composites produced Using two different production methods. Mühendislik Bilim. Ve Tasarım Derg. 2023, 11, 459–473. [Google Scholar] [CrossRef]

- Kumar, D.; Faisal, N.; Layek, A.; Priyadarshi, G. Enhancement of mechanical properties of carbon and flax fibre hybrid composites for engineering applications. In AIP Conference Proceedings; AIP Publishing: Melville, NY, USA, 2021. [Google Scholar]

- Fehri, M.; Ragueh, R.R.; Vivet, A.; Dammak, F.; Haddar, M. Improvement of natural fiber composite materials by carbon fibers. J. Renew. Mater. 2017, 5, 38–47. [Google Scholar] [CrossRef]

- Nisini, E.; Santulli, C.; Liverani, A. Mechanical and impact characterization of hybrid composite laminates with carbon, basalt and flax fibres. Compos. Part B Eng. 2017, 127, 92–99. [Google Scholar] [CrossRef]

- Sarasini, F.; Tirillò, J.; D’Altilia, S.; Valente, T.; Santulli, C.; Touchard, F. Damage tolerance of carbon/flax hybrid composites subjected to low velocity impact. Compos. Part B Eng. 2016, 91, 144–153. [Google Scholar] [CrossRef]

- Imran, M.; Khan, R.; Badshah, S. A review on the effect of delamination on the performance of composite plate. Pak. J. Sci. Ind. Res. Ser. A Phys. Sci. 2018, 61, 173–182. [Google Scholar] [CrossRef]

- Chatziathanasiou, T.; Soete, J.; Vanhulst, J.; Carrella-Payan, D.; Gorbatikh, L.; Mehdikhani, M. In-situ X-ray computed tomography of mode I delamination in carbon-epoxy composites: The effect of the interface ply orientation. Compos. Part B Eng. 2023, 260, 110761. [Google Scholar] [CrossRef]

- Cañas, J.; Justo, J.; París, F. Evaluation of the interlaminar fracture toughness on composite materials using DCB test on symmetric and unsymmetric configurations. Compos. Struct. 2022, 297, 115944. [Google Scholar] [CrossRef]

- Pappa, E.J.; Quinn, J.A.; Murray, J.J.; Davidson, J.R.; Ó Brádaigh, C.M.; McCarthy, E.D. Experimental study on the interlaminar fracture properties of carbon fibre reinforced polymer composites with a single embedded toughened film. Polymers 2021, 13, 4103. [Google Scholar] [CrossRef] [PubMed]

- Rzeczkowski, J. An experimental analysis of the end-notched flexure composite laminates beams with elastic couplings. Contin. Mech. Thermodyn. 2021, 33, 2331–2343. [Google Scholar] [CrossRef]

- Cañas, J.; Távara, L.; Blázquez, A.; Estefani, A.; Santacruz, G. A new in situ peeling test for the characterisation of composite bonded joints. Compos. Part A Appl. Sci. Manuf. 2018, 113, 298–310. [Google Scholar] [CrossRef]

- Grouve, W.J.B.; Warnet, L.; Rietman, B.; Visser, H.; Akkerman, R. Optimization of the tape placement process parameters for carbon–PPS composites. Compos. Part A Appl. Sci. Manuf. 2013, 50, 44–53. [Google Scholar] [CrossRef]

- Zhou, J.; Huang, Z.-M. Predicting delamination of hybrid laminate via stress modification on interlaminar matrix layer. Eng. Fract. Mech. 2022, 264, 108333. [Google Scholar] [CrossRef]

- Salman, S.D. Partial replacement of synthetic fibres by natural fibres in hybrid composites and its effect on monotonic properties. J. Ind. Text. 2021, 51, 258–276. [Google Scholar] [CrossRef]

- Wu, W.; Wang, Q.; Li, W. Comparison of tensile and compressive properties of carbon/glass interlayer and intralayer hybrid composites. Materials 2018, 11, 1105. [Google Scholar] [CrossRef]

- Ebrahimnezhad-Khaljiri, H.; Eslami-Farsani, R.; Akbarzadeh, E. Effect of interlayer hybridization of carbon, Kevlar, and glass fibers with oxidized polyacrylonitrile fibers on the mechanical behaviors of hybrid composites. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2020, 234, 1823–1835. [Google Scholar] [CrossRef]

- Karthi, N.; Kumaresan, K.; Sathish, S.; Gokulkumar, S.; Prabhu, L.; Vigneshkumar, N. An overview: Natural fiber reinforced hybrid composites, chemical treatments and application areas. Mater. Today Proc. 2020, 27, 2828–2834. [Google Scholar] [CrossRef]

- Enciso, B.; Abenojar, J.; Martínez, M.A. Effect of APPT treatment on mechanical properties and durability of green composites with woven flax. Materials 2020, 13, 4762. [Google Scholar] [CrossRef] [PubMed]

- Enciso, B.; Abenojar, J.; Paz, E.; Martínez, M. Influence of low pressure plasma treatment on the durability of thermoplastic composites LDPE-flax/coconut under thermal and humidity conditions. Fibers Polym. 2018, 19, 1327–1334. [Google Scholar] [CrossRef]

- Pérez-Fonseca, A.A.; Arellano, M.; Rodrigue, D.; González-Núñez, R.; Robledo-Ortíz, J.R. Effect of coupling agent content and water absorption on the mechanical properties of coir-agave fibers reinforced polyethylene hybrid composites. Polym. Compos. 2016, 37, 3015–3024. [Google Scholar] [CrossRef]

- Jawaid, M.; Abdul Khalil, H.; Bhat, A.; Abu Baker, A. Impact properties of natural fiber hybrid reinforced epoxy composites. Adv. Mater. Res. 2011, 264, 688–693. [Google Scholar] [CrossRef]

- Rana, R.; Rana, S.; Purohit, R. Characterization of properties of epoxy sisal/glass fiber reinforced hybrid composite. Mater. Today: Proc. 2017, 4, 5445–5451. [Google Scholar] [CrossRef]

- Swolfs, Y.; Gorbatikh, L.; Verpoest, I. Fibre hybridisation in polymer composites: A review. Compos. Part A Appl. Sci. Manuf. 2014, 67, 181–200. [Google Scholar] [CrossRef]

- Rahim, T.T.; Abdullah, A.; Akil, H.M.; Mohamad, D.; Rajion, Z. The improvement of mechanical and thermal properties of polyamide 12 3D printed parts by fused deposition modelling. Express Polym. Lett. 2017, 11, 963–982. [Google Scholar] [CrossRef]

- Primc, G. Surface modification of polyamides by gaseous plasma—Review and scientific challenges. Polymers 2020, 12, 3020. [Google Scholar] [CrossRef]

- Štěpánová, V.; Šrámková, P.; Sihelník, S.; Stupavská, M.; Jurmanová, J.; Kováčik, D. The effect of ambient air plasma generated by coplanar and volume dielectric barrier discharge on the surface characteristics of polyamide foils. Vacuum 2021, 183, 109887. [Google Scholar] [CrossRef]

- Martino, L.; Basilissi, L.; Farina, H.; Ortenzi, M.A.; Zini, E.; Di Silvestro, G. Bio-based polyamide 11: Synthesis, rheology and solid-state properties of star structures. Eur. Polym. J. 2014, 59, 69–77. [Google Scholar] [CrossRef]

- Lao, S.; Yong, W.; Nguyen, K.; Moon, T.; Koo, J.; Pilato, L. Flame-retardant polyamide 11 and 12 nanocomposites: Processing, morphology, and mechanical properties. J. Compos. Mater. 2010, 44, 2933–2951. [Google Scholar] [CrossRef]

- Jia, N.; Kagan, V.A. Interpretations of tensile properties of polyamide 6 and PET based thermoplastics using ASTM and ISO procedures. Astm Spec. Tech. Publ. 2000, 1369, 54–71. [Google Scholar]

- Lebaupin, Y.; Chauvin, M.; Hoang, T.-Q.T.; Touchard, F.; Beigbeder, A. Influence of constituents and process parameters on mechanical properties of flax fibre-reinforced polyamide 11 composite. J. Thermoplast. Compos. Mater. 2017, 30, 1503–1521. [Google Scholar] [CrossRef]

- Haddou, G.; Dandurand, J.; Dantras, E.; Maiduc, H.; Thai, H.; Giang, N.V. Mechanical properties of continuous bamboo fiber-reinforced biobased polyamide 11 composites. J. Appl. Polym. Sci. 2019, 136, 47623. [Google Scholar] [CrossRef]

- Russo, P.; Simeoli, G.; Vitiello, L.; Filippone, G. Bio-polyamide 11 hybrid composites reinforced with basalt/flax interwoven fibers: A tough green composite for semi-structural applications. Fibers 2019, 7, 41. [Google Scholar] [CrossRef]

- Flaxcomp® Is an Eco-Innovation. Available online: https://www.demgy.com/en/page/solutions/flaxcomp-bio-composite (accessed on 22 May 2022).

- Sports Powered by Natural Flax Fibers. Available online: https://www.jeccomposites.com/news/sports-powered-by-natural-flax-fibres/ (accessed on 22 May 2022).

- Bahrami, M.; Abenojar, J.; Martínez, M.A. Comparative characterization of hot-pressed polyamide 11 and 12: Mechanical, thermal and durability properties. Polymers 2021, 13, 3553. [Google Scholar] [CrossRef]

- Bahrami, M.; Enciso, B.; Gaifami, C.M.; Abenojar, J.; Martinez, M.A. Characterization of hybrid biocomposite poly-butyl-succinate/carbon fibers/flax fibers. Compos. Part B: Eng. 2021, 221, 109033. [Google Scholar] [CrossRef]

- Bahrami, M.; Lavayen-Farfan, D.; Martínez, M.; Abenojar, J. Experimental and numerical studies of polyamide 11 and 12 surfaces modified by atmospheric pressure plasma treatment. Surf. Interfaces 2022, 32, 102154. [Google Scholar] [CrossRef]

- Wei, Y.; Hutchinson, J.W. Interface Strength, Work of Adhesion and Plasticity in the Peel Test; Springer: Berlin/Heidelberg, Germany, 1998. [Google Scholar]

- Kim, J.; Kim, K.; Kim, Y. Mechanical effects in peel adhesion test. J. Adhes. Sci. Technol. 1989, 3, 175–187. [Google Scholar] [CrossRef]

- ASTM International. Standard Test Method for Flexural Properties of Polymer Matrix Composite Materials; ASTM International: West Conshohocken, PA, USA, 2015. [Google Scholar]

- Pereira, J.; Campilho, R.; Nóvoa, P.; Silva, F.J.; Gonçalves, D. Adherend effect on the peel strength of a brittle adhesive. Procedia Struct. Integr. 2022, 37, 722–729. [Google Scholar] [CrossRef]

- de Freitas, S.T.; Sinke, J. Adhesion properties of bonded composite-to-aluminium joints using peel tests. J. Adhes. 2014, 90, 511–525. [Google Scholar] [CrossRef]

- de Freitas, S.T.; Sinke, J. Test method to assess interface adhesion in composite bonding. Appl. Adhes. Sci. 2015, 3, 1–13. [Google Scholar] [CrossRef]

- Flynn, J.; Amiri, A.; Ulven, C. Hybridized carbon and flax fiber composites for tailored performance. Mater. Des. 2016, 102, 21–29. [Google Scholar] [CrossRef]

- Dhakal, H.; Zhang, Z.; Guthrie, R.; MacMullen, J.; Bennett, N. Development of flax/carbon fibre hybrid composites for enhanced properties. Carbohydr. Polym. 2013, 96, 1–8. [Google Scholar] [CrossRef]

- Chapman, M.; Dhakal, H.N. Effects of hybridisation on the low velocity falling weight impact and flexural properties of flax-carbon/epoxy hybrid composites. Fibers 2019, 7, 95. [Google Scholar] [CrossRef]

| Properties | Flax | Carbon |

|---|---|---|

| Density (g/cm3) | 1.5 | 1.7 |

| Diameter (µm) | 20 | 4 |

| Tensile modulus (GPa) | 12 | 240 |

| Tensile strength (MPa) | 106 | 4100 |

| Failure strain (%) | 1.5 | 1.7 |

| Layup | Average Thickness (mm) | Fiber Volume Fraction (%) | ||

|---|---|---|---|---|

| Flax (Vf) | Carbon (Vc) | Vf + Vc | ||

| [C2]S | 1.60 ± 0.06 | 0 | 30 | 30 |

| [CF]S | 2.06 ± 0.03 | 30 | 10 | 40 |

| [F2]S | 2.32 ± 0.04 | 42 | 0 | 42 |

| Layup | Normalized Maximum Force (N) | Normalized Peeling Strength (N/mm) | Failure Mode |

|---|---|---|---|

| [C2]S | 323 ± 28 | 10.4 ± 0.9 | Adhesive |

| [CF]S | 697 ± 52 | 13.2 ± 0.4 | ILFC |

| [F2]S | 434 ± 4 | _ | Matrix/fiber breakage |

| Layup | E (GPa) | Max Strength (Mpa) | Strain at Max Stress (%) |

|---|---|---|---|

| [C2]S | 19 ± 2 | 217 ± 7 | 2.6 ± 0.2 |

| [CF]S | 10 ± 1 | 117 ± 5 | 3.5 ± 0.2 |

| [F2]S | 3.2 ± 0.3 | 32 ± 2 | 1.4 ± 0.4 |

| Layup | Vickers Hardness (Hv) |

|---|---|

| [C2]S | 16.99 ± 0.76 |

| [CF]S | 17.84 ± 0.74 |

| [F2]S | 13.90 ± 1.12 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bahrami, M.; del Real, J.C.; Mehdikhani, M.; Butenegro, J.A.; Abenojar, J.; Martínez, M.Á. Hybridization Effect on Interlaminar Bond Strength, Flexural Properties, and Hardness of Carbon–Flax Fiber Thermoplastic Bio-Composites. Polymers 2023, 15, 4619. https://doi.org/10.3390/polym15244619

Bahrami M, del Real JC, Mehdikhani M, Butenegro JA, Abenojar J, Martínez MÁ. Hybridization Effect on Interlaminar Bond Strength, Flexural Properties, and Hardness of Carbon–Flax Fiber Thermoplastic Bio-Composites. Polymers. 2023; 15(24):4619. https://doi.org/10.3390/polym15244619

Chicago/Turabian StyleBahrami, Mohsen, Juan Carlos del Real, Mahoor Mehdikhani, José Antonio Butenegro, Juana Abenojar, and Miguel Ángel Martínez. 2023. "Hybridization Effect on Interlaminar Bond Strength, Flexural Properties, and Hardness of Carbon–Flax Fiber Thermoplastic Bio-Composites" Polymers 15, no. 24: 4619. https://doi.org/10.3390/polym15244619

APA StyleBahrami, M., del Real, J. C., Mehdikhani, M., Butenegro, J. A., Abenojar, J., & Martínez, M. Á. (2023). Hybridization Effect on Interlaminar Bond Strength, Flexural Properties, and Hardness of Carbon–Flax Fiber Thermoplastic Bio-Composites. Polymers, 15(24), 4619. https://doi.org/10.3390/polym15244619