Nafion-212 Membrane Solvated by Ethylene and Propylene Carbonates as Electrolyte for Lithium Metal Batteries

Abstract

:1. Introduction

2. Materials and Methods

2.1. Membrane Preparation

2.2. Preparation of Polymer Electrolyte

2.3. Study of a Polymer Electrolyte

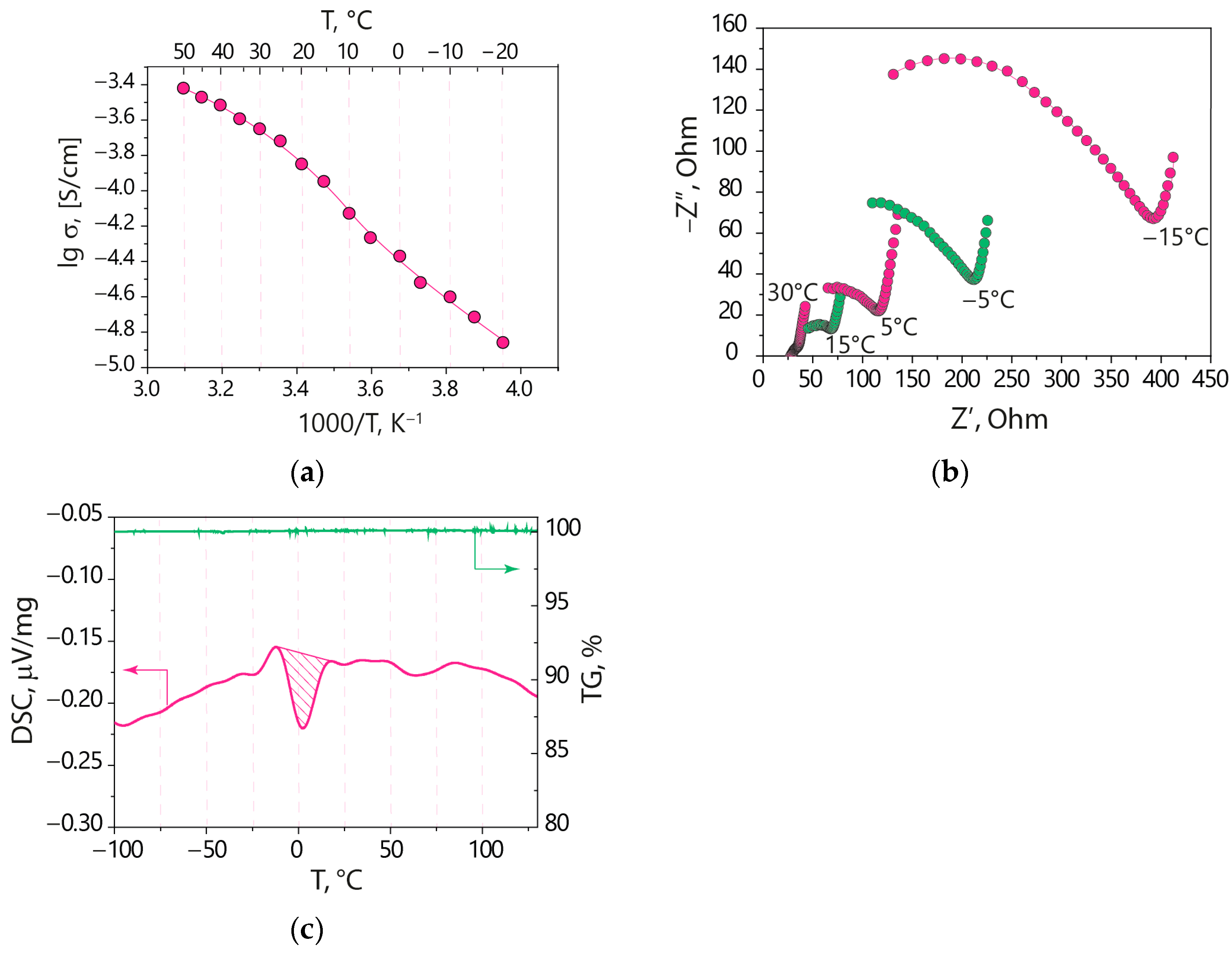

2.3.1. Ionic Conductivity

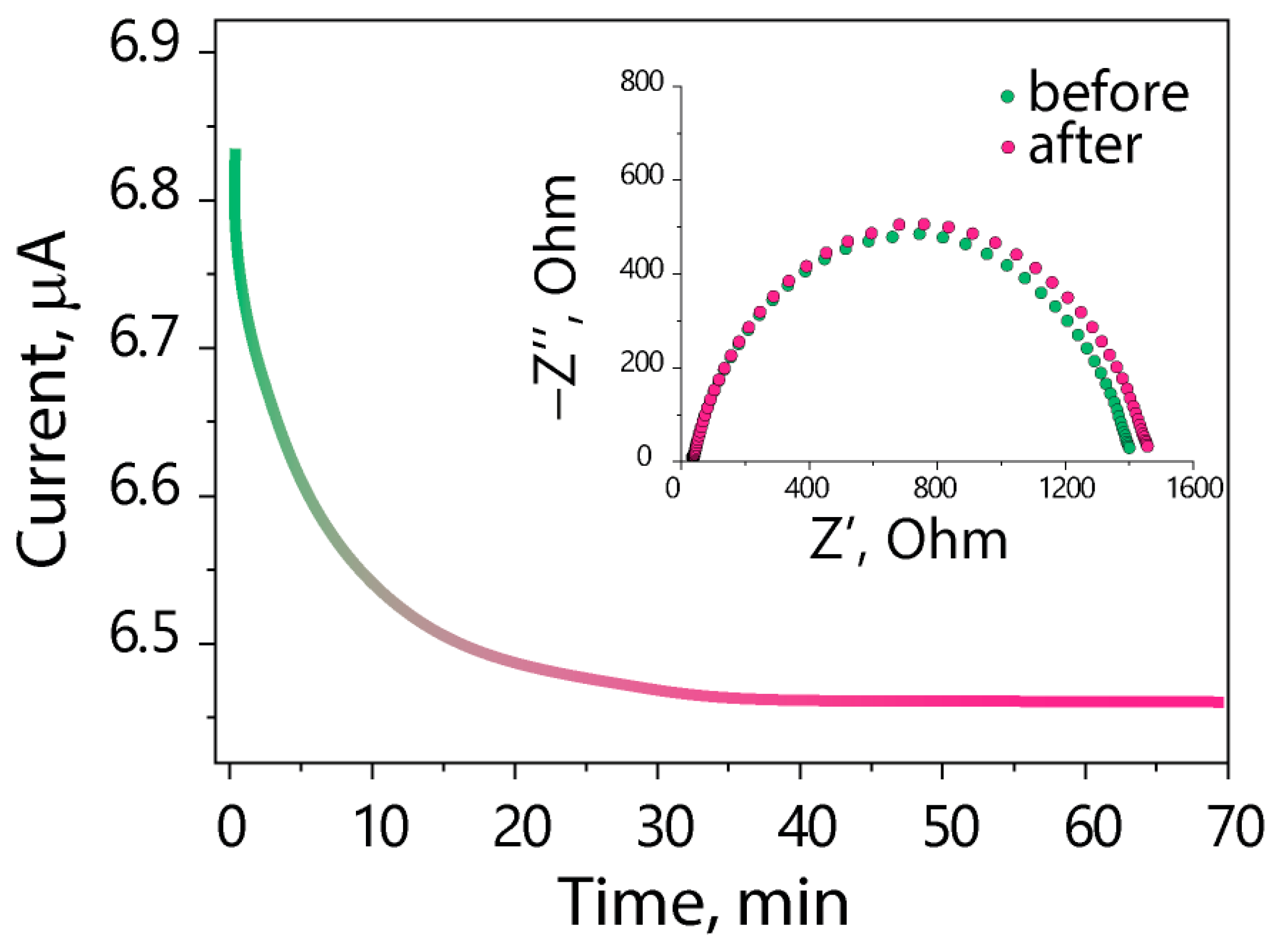

2.3.2. Lithium Transference Numbers

2.3.3. Electrochemical Stability Window

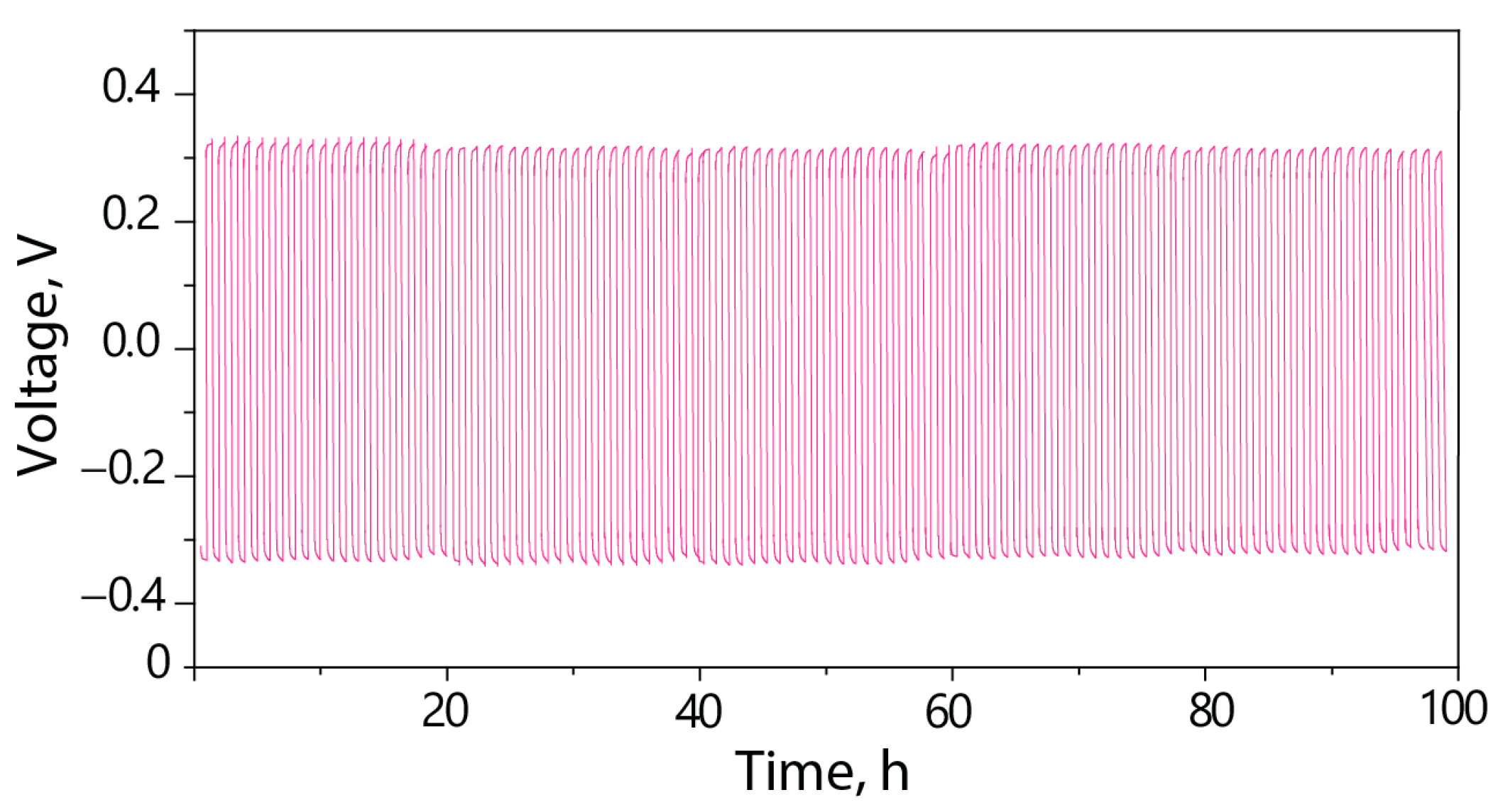

2.3.4. Lithium Metal Batteries

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Li, J.; Kong, Z.; Liu, X.; Zheng, B.; Fan, Q.H.; Garratt, E.; Schuelke, T.; Wang, K.; Xu, H.; Jin, H. Strategies to Anode Protection in Lithium Metal Battery: A Review. InfoMat 2021, 3, 1333–1363. [Google Scholar] [CrossRef]

- Stenina, I.; Novikova, S.; Voropaeva, D.; Yaroslavtsev, A. Solid Electrolytes Based on NASICON-Structured Phosphates for Lithium Metal Batteries. Batteries 2023, 9, 407. [Google Scholar] [CrossRef]

- Cheng, X.-B.; Zhang, R.; Zhao, C.-Z.; Wei, F.; Zhang, J.-G.; Zhang, Q. A Review of Solid Electrolyte Interphases on Lithium Metal Anode. Adv. Sci. 2016, 3, 1500213. [Google Scholar] [CrossRef] [PubMed]

- Li, H.; Xu, Z.; Yang, J.; Wang, J.; Hirano, S. Polymer Electrolytes for Rechargeable Lithium Metal Batteries. Sustain. Energy Fuels 2020, 4, 5469–5487. [Google Scholar] [CrossRef]

- Rao, X.; Lou, Y.; Zhong, S.; Wang, L.; Li, B.; Xiao, Y.; Peng, W.; Zhong, X.; Huang, J. Strategies for Dendrite-Free Lithium Metal Anodes: A Mini-Review. J. Electroanal. Chem. 2021, 897, 115499. [Google Scholar] [CrossRef]

- Ding, P.; Lin, Z.; Guo, X.; Wu, L.; Wang, Y.; Guo, H.; Li, L.; Yu, H. Polymer Electrolytes and Interfaces in Solid-State Lithium Metal Batteries. Mater. Today 2021, 51, 449–474. [Google Scholar] [CrossRef]

- Chazalviel, J.-N. Electrochemical Aspects of the Generation of Ramified Metallic Electrodeposits. Phys. Rev. A 1990, 42, 7355–7367. [Google Scholar] [CrossRef]

- Gorecki, W.; Jeannin, M.; Belorizky, E.; Roux, C.; Armand, M. Physical Properties of Solid Polymer Electrolyte PEO(LiTFSI) Complexes. J. Phys. Condens. Matter 1995, 7, 6823–6832. [Google Scholar] [CrossRef]

- Zugmann, S.; Fleischmann, M.; Amereller, M.; Gschwind, R.M.; Wiemhöfer, H.D.; Gores, H.J. Measurement of Transference Numbers for Lithium Ion Electrolytes via Four Different Methods, a Comparative Study. Electrochim. Acta 2011, 56, 3926–3933. [Google Scholar] [CrossRef]

- Shan, C.; Wang, Y.; Liang, M.; Lu, K.; Xiong, C.; Hu, W.; Liu, B. A Comprehensive Review of Single Ion-Conducting Polymer Electrolytes as a Key Component of Lithium Metal Batteries: From Structural Design to Applications. Energy Storage Mater. 2023, 63, 102955. [Google Scholar] [CrossRef]

- Tu, Z.; Choudhury, S.; Zachman, M.J.; Wei, S.; Zhang, K.; Kourkoutis, L.F.; Archer, L.A. Designing Artificial Solid-Electrolyte Interphases for Single-Ion and High-Efficiency Transport in Batteries. Joule 2017, 1, 394–406. [Google Scholar] [CrossRef]

- Xu, R.; Xiao, Y.; Zhang, R.; Cheng, X.; Zhao, C.; Zhang, X.; Yan, C.; Zhang, Q.; Huang, J. Dual-Phase Single-Ion Pathway Interfaces for Robust Lithium Metal in Working Batteries. Adv. Mater. 2019, 31, 1808392. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Li, C.; Ye, D.; Zhang, Y.; Bao, H.; Cheng, H. Lithiated Polyanion Supported Li1.5Al0.5Ge1.5(PO4)3 Composite Membrane as Single-Ion Conducting Electrolyte for Security and Stability Advancement in Lithium Metal Batteries. J. Memb. Sci. 2021, 620, 118926. [Google Scholar] [CrossRef]

- Deng, K.; Zeng, Q.; Wang, D.; Liu, Z.; Qiu, Z.; Zhang, Y.; Xiao, M.; Meng, Y. Single-Ion Conducting Gel Polymer Electrolytes: Design, Preparation and Application. J. Mater. Chem. A 2020, 8, 1557–1577. [Google Scholar] [CrossRef]

- Zhu, J.; Zhang, Z.; Zhao, S.; Westover, A.S.; Belharouak, I.; Cao, P. Single-Ion Conducting Polymer Electrolytes for Solid-State Lithium–Metal Batteries: Design, Performance, and Challenges. Adv. Energy Mater. 2021, 11, 2003836. [Google Scholar] [CrossRef]

- Yan, X.; Xu, Z.; Yuan, S.; Han, A.; Shen, Y.; Cheng, X.; Liang, Y.; Shen, S.; Zhang, J. Structural and Transport Properties of Ultrathin Perfluorosulfonic Acid Ionomer Film in Proton Exchange Membrane Fuel Cell Catalyst Layer: A Review. J. Power Sources 2022, 536, 231523. [Google Scholar] [CrossRef]

- Bushkova, O.V.; Sanginov, E.A.; Chernyuk, S.D.; Kayumov, R.R.; Shmygleva, L.V.; Dobrovolsky, Y.A.; Yaroslavtsev, A.B. Polymer Electrolytes Based on the Lithium Form of Nafion Sulfonic Cation-Exchange Membranes: Current State of Research and Prospects for Use in Electrochemical Power Sources. Membr. Membr. Technol. 2022, 4, 433–454. [Google Scholar] [CrossRef]

- Nicotera, I.; Simari, C.; Agostini, M.; Enotiadis, A.; Brutti, S. A Novel Li+-Nafion-Sulfonated Graphene Oxide Membrane as Single Lithium-Ion Conducting Polymer Electrolyte for Lithium Batteries. J. Phys. Chem. C 2019, 123, 27406–27416. [Google Scholar] [CrossRef]

- Wu, S.; Wu, M.; Zhang, H.; Tang, H. Single-Ion-Conducting Gel Polymer Electrolyte Based on Lithiated Nafion. ACS Appl. Polym. Mater. 2023, 5, 4266–4273. [Google Scholar] [CrossRef]

- Gao, J.; Sun, C.S.; Xu, L.; Chen, J.; Wang, C.; Guo, D.C.; Chen, H. Lithiated Nafion as polymer electrolyte for solid-state lithium sulfur batteries using carbon-sulfur composite cathode. J. Power Sources 2018, 382, 179–189. [Google Scholar] [CrossRef]

- Kayumov, R.R.; Radaeva, A.P.; Krupina, A.A.; Tarusina, K.A.; Lapshin, A.N.; Shmygleva, L.V. Lithium-Conducting Nafion Membrane Plasticized with a DMSO–Sulfolane Mixture. Russ. J. Phys. Chem. B 2023, 17, 801–809. [Google Scholar] [CrossRef]

- Kayumov, R.R.; Shmygleva, L.V.; Evshchik, E.Y.; Sanginov, E.A.; Popov, N.A.; Bushkova, O.V.; Dobrovolsky, Y.A. Conductivity of Lithium-Conducting Nafion Membranes Plasticized by Binary and Ternary Mixtures in the Sulfolan–Ethylene Carbonate–Diglyme System. Russ. J. Electrochem. 2021, 57, 911–920. [Google Scholar] [CrossRef]

- Evshchik, E.Y.; Sanginov, E.A.; Kayumov, R.R.; Zhuravlev, V.D.; Bushkova, O.V.; Dobrovolsky, Y.A. Li4Ti5O12/LiFePO4 Solid-State Lithium-Ion Full Cell with LithiatedNafion Membrane. Int. J. Electrochem. Sci. 2020, 15, 2216–2225. [Google Scholar] [CrossRef]

- Xu, K. Nonaqueous Liquid Electrolyte for Lithium-Based Rechargeable Batteries. Chem. Rev. 2004, 104, 4303–4417. [Google Scholar] [CrossRef] [PubMed]

- Kusoglu, A.; Weber, A.Z. New Insights into Perfluorinated Sulfonic-Acid Ionomers. Chem. Rev. 2017, 117, 987–1104. [Google Scholar] [CrossRef] [PubMed]

- Berezina, N.P.; Timofeev, S.V.; Kononenko, N.A. Effect of Conditioning Techniques of Perfluorinated Sulphocationic Membranes on Their Hydrophylic and Electrotransport Properties. J. Memb. Sci. 2002, 209, 509–518. [Google Scholar] [CrossRef]

- Evans, J.; Vincent, C.A.; Bruce, P.G. Electrochemical Measurement of Transference Numbers in Polymer Electrolytes. Polymer 1987, 28, 2324–2328. [Google Scholar] [CrossRef]

- Kapaev, R.R.; Novikova, S.A.; Kulova, T.L.; Skundin, A.M.; Yaroslavtsev, A.B. Synthesis of LiFePO4 Nanoplatelets as Cathode Materials for Li-Ion Batteries. Nanotechnol. Russ. 2016, 11, 757–760. [Google Scholar] [CrossRef]

- Voropaeva, D.Y.; Novikova, S.A.; Yaroslavtsev, A.B. Polymer Electrolytes for Metal-Ion Batteries. Russ. Chem. Rev. 2020, 89, 1132–1155. [Google Scholar] [CrossRef]

- Stallworth, P.; Fontanella, J.; Wintersgill, M.; Scheidler, C.D.; Immel, J.J.; Greenbaum, S.; Gozdz, A. NMR, DSC and High Pressure Electrical Conductivity Studies of Liquid and Hybrid Electrolytes. J. Power Sources 1999, 81–82, 739–747. [Google Scholar] [CrossRef]

- Ding, M.S.; Xu, K.; Jow, T.R. Liquid-Solid Phase Diagrams of Binary Carbonates for Lithium Batteries. J. Electrochem. Soc. 2000, 147, 1688. [Google Scholar] [CrossRef]

- Ding, M.S. Liquid-Solid Phase Equilibria and Thermodynamic Modeling for Binary Organic Carbonates. J. Chem. Eng. Data 2004, 49, 276–282. [Google Scholar] [CrossRef]

- Stenina, I.A.; Yaroslavtsev, A.B. Nanomaterials for Lithium-Ion Batteries and Hydrogen Energy. Pure Appl. Chem. 2017, 89, 1185–1194. [Google Scholar] [CrossRef]

- Golubenko, D.V.; Safronova, E.Y.; Ilyin, A.B.; Shevlyakova, N.V.; Tverskoi, V.A.; Dammak, L.; Grande, D.; Yaroslavtsev, A.B. Influence of the Water State on the Ionic Conductivity of Ion-Exchange Membranes Based on Polyethylene and Sulfonated Grafted Polystyrene. Mater. Chem. Phys. 2017, 197, 192–199. [Google Scholar] [CrossRef]

- Diederichsen, K.M.; McShane, E.J.; McCloskey, B.D. Promising Routes to a High Li + Transference Number Electrolyte for Lithium Ion Batteries. ACS Energy Lett. 2017, 2, 2563–2575. [Google Scholar] [CrossRef]

- Li, W.; Song, B.; Manthiram, A. High-Voltage Positive Electrode Materials for Lithium-Ion Batteries. Chem. Soc. Rev. 2017, 46, 3006–3059. [Google Scholar] [CrossRef]

- Lee, T.J.; Kim, H.; Hwang, H.S.; Soon, J.; Jung, J.; Ryu, J.H.; Oh, S.M. Solid Permeable Interface (SPI) on a High-Voltage Positive Electrode of Lithium-Ion Batteries. J. Electrochem. Soc. 2018, 165, A575–A583. [Google Scholar] [CrossRef]

- Fedotov, S.S.; Khasanova, N.R.; Samarin, A.S.; Drozhzhin, O.A.; Batuk, D.; Karakulina, O.M.; Hadermann, J.; Abakumov, A.M.; Antipov, E.V. AVPO4F (A = Li, K): A 4 V Cathode Material for High-Power Rechargeable Batteries. Chem. Mater. 2016, 28, 411–415. [Google Scholar] [CrossRef]

- Bai, P.; Li, J.; Brushett, F.R.; Bazant, M.Z. Transition of Lithium Growth Mechanisms in Liquid Electrolytes. Energy Environ. Sci. 2016, 9, 3221–3229. [Google Scholar] [CrossRef]

- Borzutzki, K.; Dong, K.; Nair, J.R.; Wolff, B.; Hausen, F.; Eichel, R.-A.; Winter, M.; Manke, I.; Brunklaus, G. Lithium Deposition in Single-Ion Conducting Polymer Electrolytes. Cell Rep. Phys. Sci. 2021, 2, 100496. [Google Scholar] [CrossRef]

- Liu, K.; Jiang, S.; Dzwiniel, T.L.; Kim, H.-K.; Yu, Z.; Dietz Rago, N.L.; Kim, J.J.; Fister, T.T.; Yang, J.; Liu, Q.; et al. Molecular Design of a Highly Stable Single-Ion Conducting Polymer Gel Electrolyte. ACS Appl. Mater. Interfaces 2020, 12, 29162–29172. [Google Scholar] [CrossRef] [PubMed]

- Li, C.; Chen, Y.; Zhang, Y.; Bao, H. A Gel Porous Single-Ion Conducting Polyelectrolyte with Double Anionic Functional Group for Enhancing Lithium Ion Battery Performance. Mater. Lett. 2021, 288, 129309. [Google Scholar] [CrossRef]

- Mindemark, J.; Lacey, M.J.; Bowden, T.; Brandell, D. Beyond PEO—Alternative Host Materials for Li+-Conducting Solid Polymer Electrolytes. Prog. Polym. Sci. 2018, 81, 114–143. [Google Scholar] [CrossRef]

- Polymer Electrolytes II: Physical Principles. In Solid State Electrochemistry; Bruce, P.G. (Ed.) Cambrige University Press: Cambrige, UK, 1994; pp. 119–162. [Google Scholar]

- Khudyshkina, A.D.; Butzelaar, A.J.; Guo, Y.; Hoffmann, M.; Bergfeldt, T.; Schaller, M.; Indris, S.; Wilhelm, M.; Théato, P.; Jeschull, F. From Lithium to Potassium: Comparison of Cations in Poly(Ethylene Oxide)-Based Block Copolymer Electrolytes for Solid-State Alkali Metal Batteries. Electrochim. Acta 2023, 454, 142421. [Google Scholar] [CrossRef]

- Dai, H.; Zawodzinski, T.A. Determination of Lithium Ion Transference Numbers by Electrophoretic Nuclear Magnetic Resonance. J. Electrochem. Soc. 1996, 143, L107–L109. [Google Scholar] [CrossRef]

- Bruce, P.G.; Hardgrave, M.T.; Vincent, C.A. The Determination of Transference Numbers in Solid Polymer Electrolytes Using the Hittorf Method. Solid State Ion. 1992, 53–56, 1087–1094. [Google Scholar] [CrossRef]

- Balsara, N.P.; Newman, J. Relationship between Steady-State Current in Symmetric Cells and Transference Number of Electrolytes Comprising Univalent and Multivalent Ions. J. Electrochem. Soc. 2015, 162, A2720–A2722. [Google Scholar] [CrossRef]

- Zhang, H.; Li, C.; Piszcz, M.; Coya, E.; Rojo, T.; Rodriguez-Martinez, L.M.; Armand, M.; Zhou, Z. Single Lithium-Ion Conducting Solid Polymer Electrolytes: Advances and Perspectives. Chem. Soc. Rev. 2017, 46, 797–815. [Google Scholar] [CrossRef]

- Rohan, R.; Sun, Y.; Cai, W.; Zhang, Y.; Pareek, K.; Xu, G.; Cheng, H. Functionalized Polystyrene Based Single Ion Conducting Gel Polymer Electrolyte for Lithium Batteries. Solid State Ion. 2014, 268, 294–299. [Google Scholar] [CrossRef]

- Voropaeva, D.; Novikova, S.; Trofimenko, N.; Yaroslavtsev, A. Polystyrene-Based Single-Ion Conducting Polymer Electrolyte for Lithium Metal Batteries. Processes 2022, 10, 2509. [Google Scholar] [CrossRef]

- Safronov, D.V.; Novikova, S.A.; Skundin, A.M.; Yaroslavtsev, A.B. Lithium Intercalation and Deintercalation Processes in Li4Ti5O12 and LiFePO4. Inorg. Mater. 2012, 48, 57–61. [Google Scholar] [CrossRef]

- Yan, M.; Zhang, G.; Wei, Q.; Tian, X.; Zhao, K.; An, Q.; Zhou, L.; Zhao, Y.; Niu, C.; Ren, W.; et al. In Operando Observation of Temperature-Dependent Phase Evolution in Lithium-Incorporation Olivine Cathode. Nano Energy 2016, 22, 406–413. [Google Scholar] [CrossRef]

- Chen, X.; Gong, Y.; Li, X.; Zhan, F.; Liu, X.; Ma, J. Perspective on Low-Temperature Electrolytes for LiFePO4-Based Lithium-Ion Batteries. Int. J. Miner. Metall. Mater. 2023, 30, 1–13. [Google Scholar] [CrossRef]

- Porcarelli, L.; Shaplov, A.S.; Bella, F.; Nair, J.R.; Mecerreyes, D.; Gerbaldi, C. Single-Ion Conducting Polymer Electrolytes for Lithium Metal Polymer Batteries That Operate at Ambient Temperature. ACS Energy Lett. 2016, 1, 678–682. [Google Scholar] [CrossRef]

- Geng, J.; Zhang, S.; Hu, X.; Ling, W.; Peng, X.; Zhong, S.; Liang, F.; Zou, Z. A Review of Graphene-Decorated LiFePO4 Cathode Materials for Lithium-Ion Batteries. Ionics 2022, 28, 4899–4922. [Google Scholar] [CrossRef]

- Braun, P.V.; Cho, J.; Pikul, J.H.; King, W.P.; Zhang, H. High Power Rechargeable Batteries. Curr. Opin. Solid State Mater. Sci. 2012, 16, 186–198. [Google Scholar] [CrossRef]

- Lain, M.J.; Brandon, J.; Kendrick, E. Design Strategies for High Power vs. High Energy Lithium Ion Cells. Batteries 2019, 5, 64. [Google Scholar] [CrossRef]

- Voropaeva, D.Y.; Safronova, E.Y.; Novikova, S.A.; Yaroslavtsev, A.B. Recent Progress in Lithium-Ion and Lithium Metal Batteries. Mendeleev Commun. 2022, 32, 287–297. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, E.; Zhang, X.; Yu, H. High-Voltage “Single-Crystal” Cathode Materials for Lithium-Ion Batteries. Energy Fuels 2021, 35, 1918–1932. [Google Scholar] [CrossRef]

- Xiang, J.; Wei, Y.; Zhong, Y.; Yang, Y.; Cheng, H.; Yuan, L.; Xu, H.; Huang, Y. Building Practical High-Voltage Cathode Materials for Lithium-Ion Batteries. Adv. Mater. 2022, 34, 2200912. [Google Scholar] [CrossRef]

- Xue, W.; Huang, M.; Li, Y.; Zhu, Y.G.; Gao, R.; Xiao, X.; Zhang, W.; Li, S.; Xu, G.; Yu, Y.; et al. Ultra-High-Voltage Ni-Rich Layered Cathodes in Practical Li Metal Batteries Enabled by a Sulfonamide-Based Electrolyte. Nat. Energy 2021, 6, 495–505. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Voropaeva, D.; Novikova, S.; Stenina, I.; Yaroslavtsev, A. Nafion-212 Membrane Solvated by Ethylene and Propylene Carbonates as Electrolyte for Lithium Metal Batteries. Polymers 2023, 15, 4340. https://doi.org/10.3390/polym15224340

Voropaeva D, Novikova S, Stenina I, Yaroslavtsev A. Nafion-212 Membrane Solvated by Ethylene and Propylene Carbonates as Electrolyte for Lithium Metal Batteries. Polymers. 2023; 15(22):4340. https://doi.org/10.3390/polym15224340

Chicago/Turabian StyleVoropaeva, Daria, Svetlana Novikova, Irina Stenina, and Andrey Yaroslavtsev. 2023. "Nafion-212 Membrane Solvated by Ethylene and Propylene Carbonates as Electrolyte for Lithium Metal Batteries" Polymers 15, no. 22: 4340. https://doi.org/10.3390/polym15224340

APA StyleVoropaeva, D., Novikova, S., Stenina, I., & Yaroslavtsev, A. (2023). Nafion-212 Membrane Solvated by Ethylene and Propylene Carbonates as Electrolyte for Lithium Metal Batteries. Polymers, 15(22), 4340. https://doi.org/10.3390/polym15224340