Material Properties Influencing the Charge Decay of Electret Filters and their Impact on Filtration Performance

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Electrospinning

2.3. Accelerated Environmental Aging

2.4. Evaluation of Filtration Performance

2.5. Material Characterization

2.5.1. Moisture Regain

2.5.2. Contact Angle Measurement

2.5.3. Measurement of Electric Potential

2.5.4. Scanning Electron Microscopy

2.5.5. X-Ray Diffraction Analysis

2.5.6. Analysis of Pore Size Distribution

3. Results and Discussion

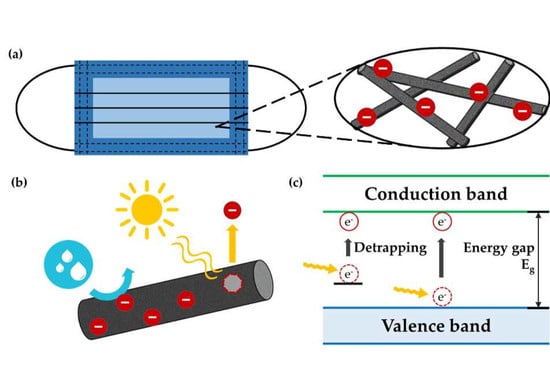

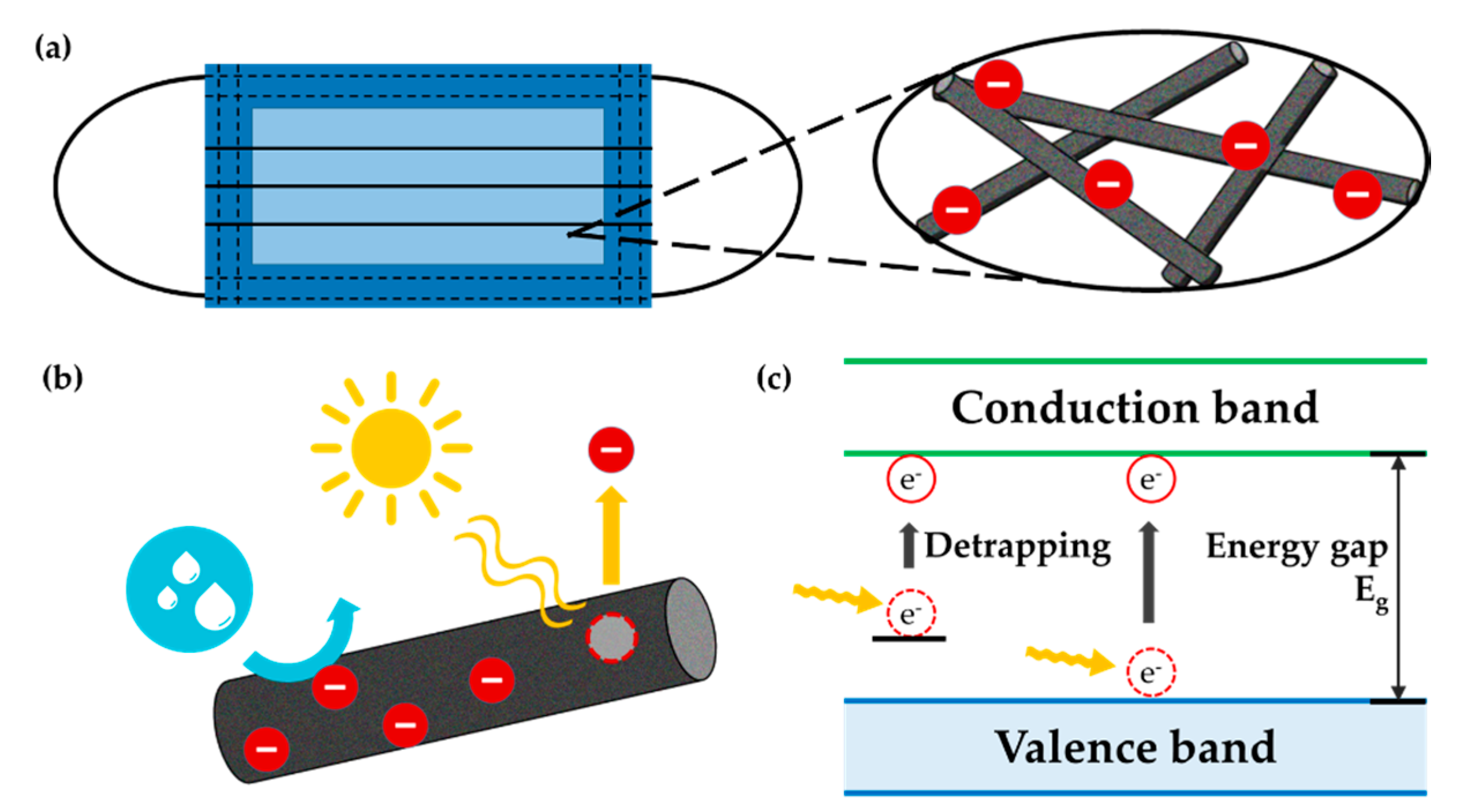

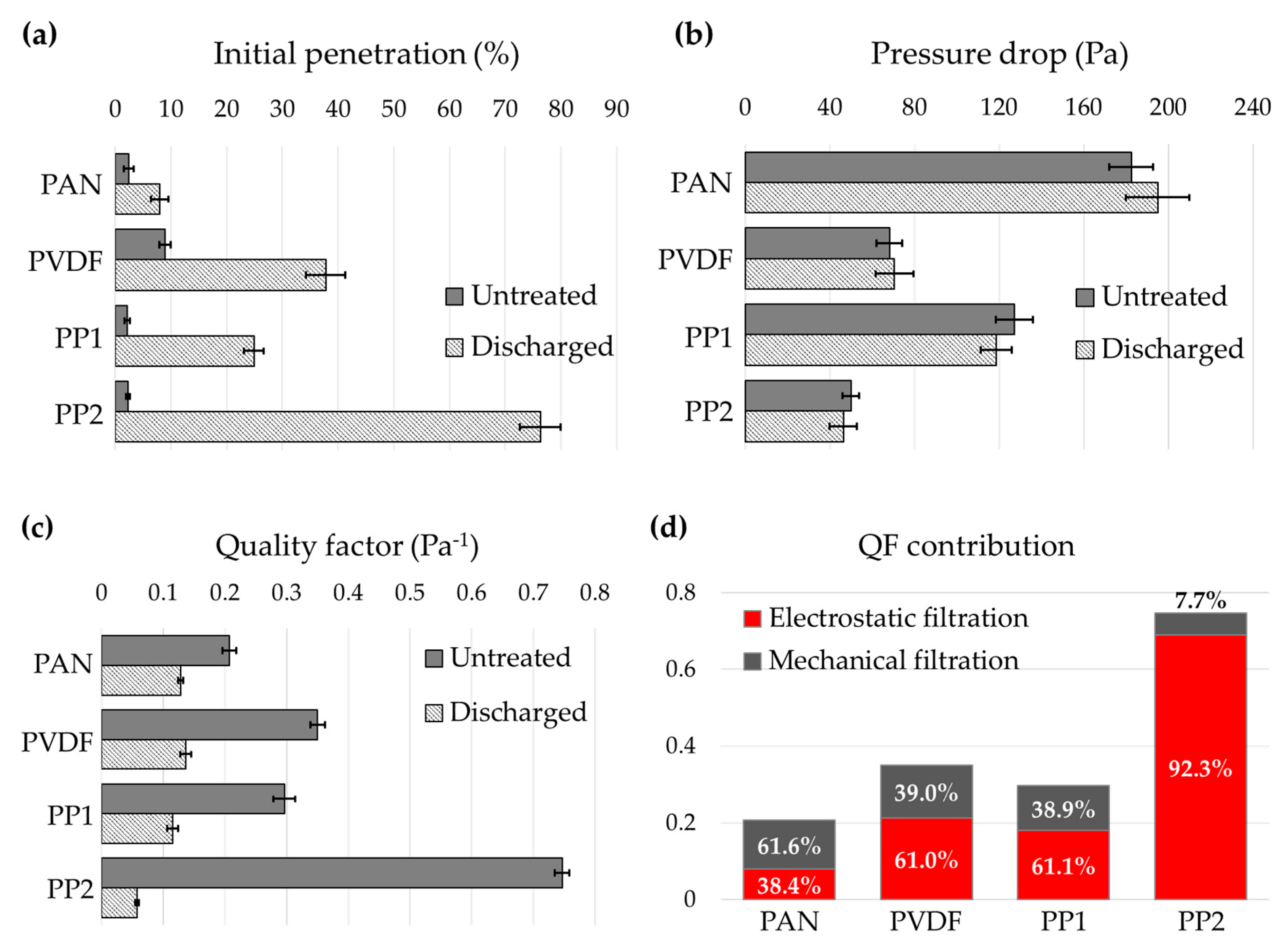

3.1. Electret Filter Materials

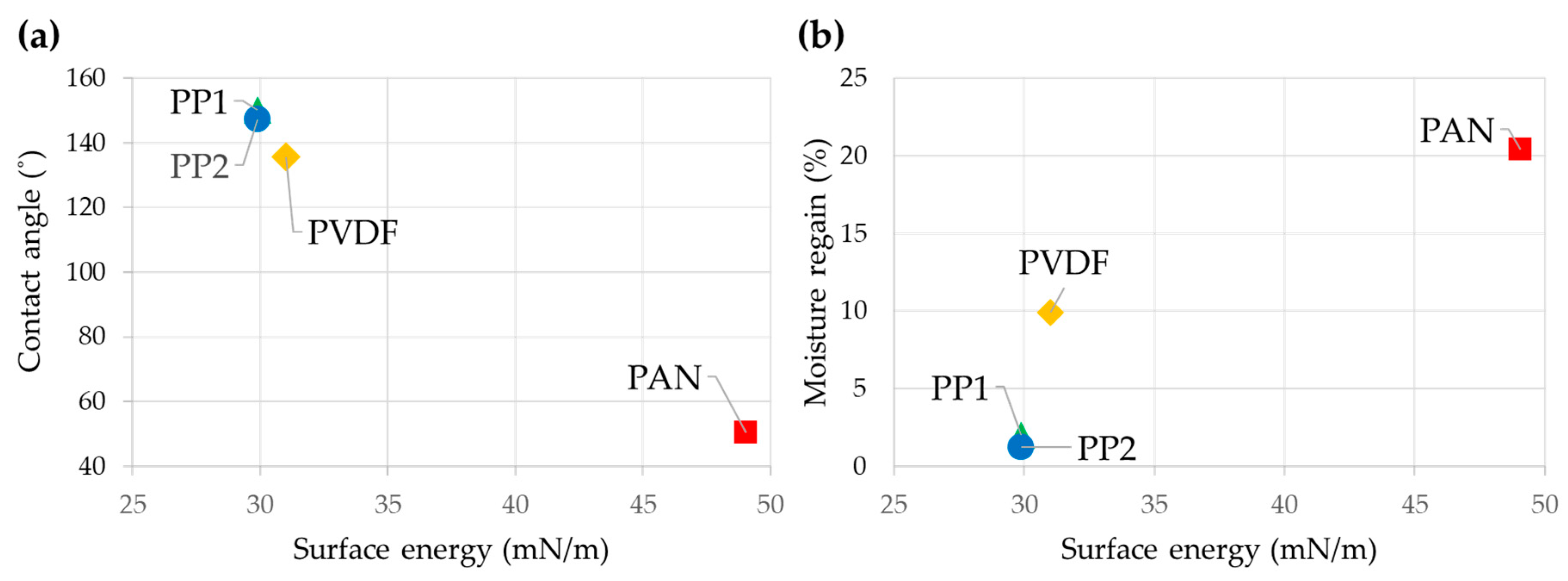

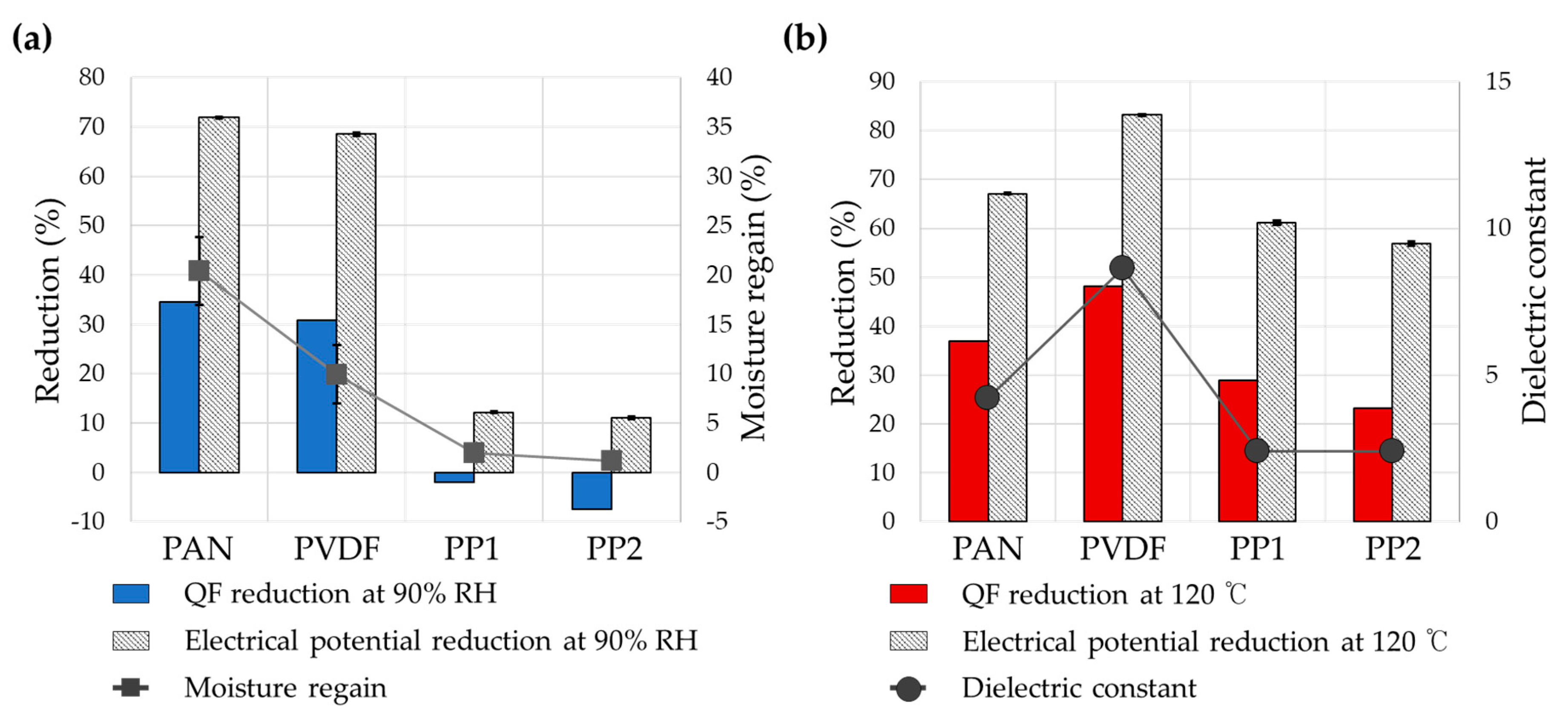

3.2. Effect of Environmental Conditions on the Charge Decay of Electret Filters

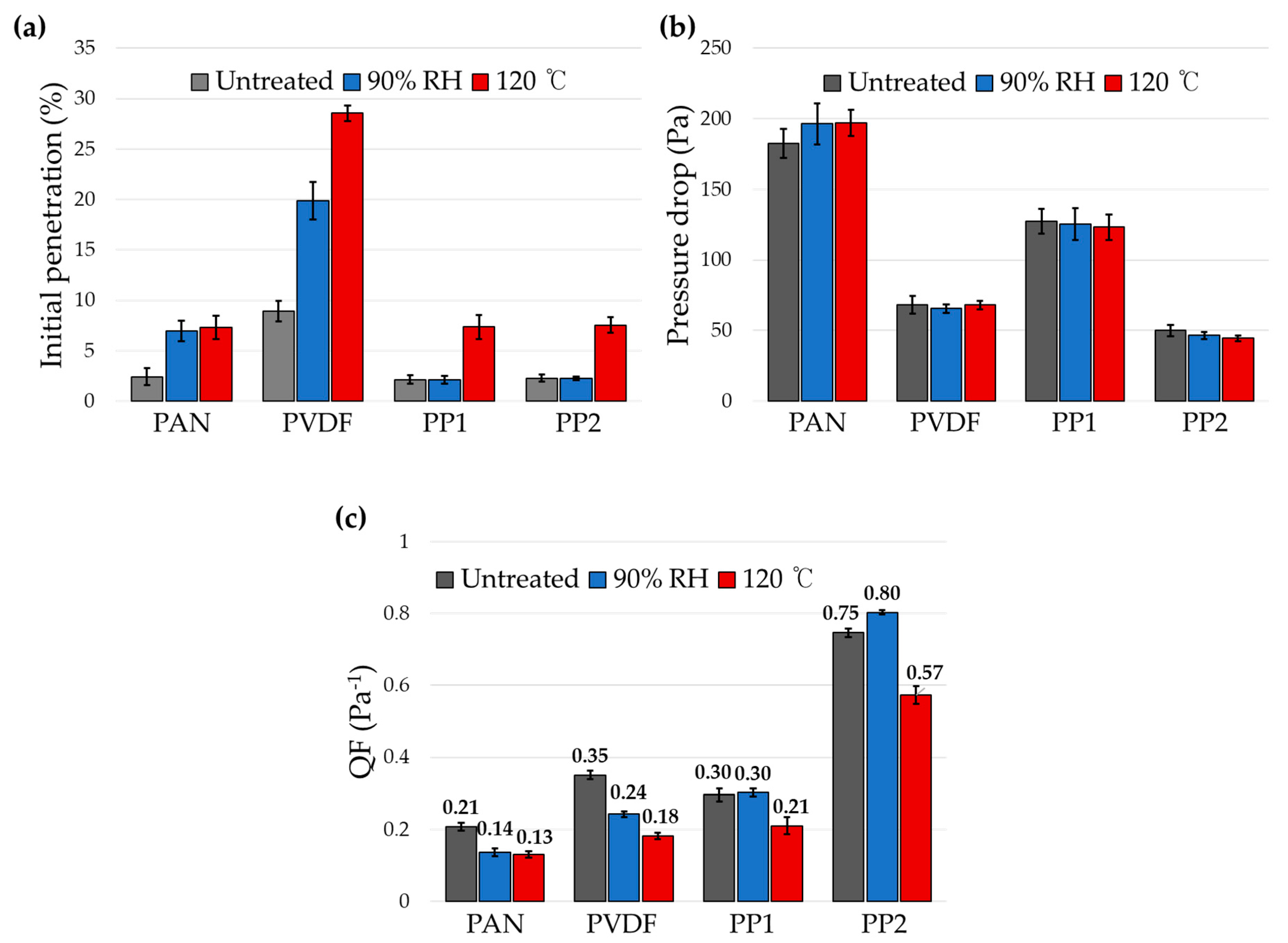

3.3. Effect of Aging Conditions on Filtration Performance

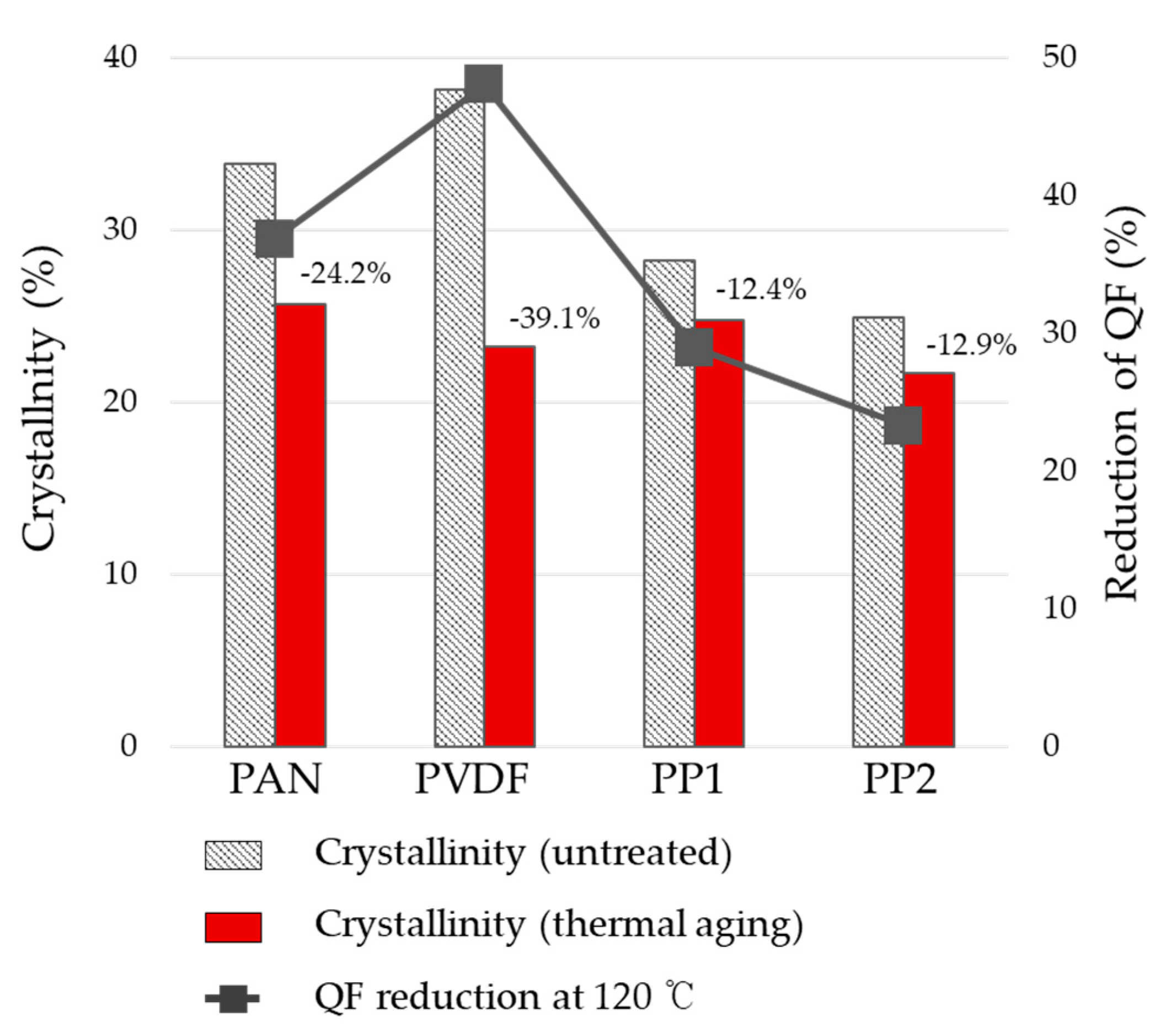

3.4. Effect of Crystallinity on Charge Decay with Thermal Aging

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Gerhard-Multhaupt, R. Electrets: Dielectrics with Quasi-Permanent Charge or Polarization. IEEE Trans. Electr. Insul. 1987, 5, 531–554. [Google Scholar] [CrossRef]

- Kressmann, R.; Sessler, G.M.; Gunther, P. Space-charge electrets. IEEE Trans. Dielectr. Electr. Insul. 1996, 3, 607–623. [Google Scholar] [CrossRef]

- Van Turnhout, J. The use of polymers for electrets. J. Electrost. 1975, 1, 147–163. [Google Scholar] [CrossRef]

- Giacometti, J.A.; Fedosov, S.; Costa, M.M. Corona charging of polymers: Recent advances on constant current charging. Braz. J. Phys. 1999, 29, 269–279. [Google Scholar] [CrossRef]

- Collins, G.; Federici, J.; Imura, Y.; Catalani, L.H. Charge generation, charge transport, and residual charge in the electrospinning of polymers: A review of issues and complications. J. Appl. Phys. 2012, 111, 044701. [Google Scholar] [CrossRef]

- Cho, B.M.; Nam, Y.S.; Cheon, J.Y.; Park, W.H. Residual charge and filtration efficiency of polycarbonate fibrous membranes prepared by electrospinning. J. Appl. Polym. Sci. 2015, 132. [Google Scholar] [CrossRef]

- Li, Z.; Zhong, Z.; Du, B. Dielectric relaxation and trap-modulated DC breakdown of polypropylene blend insulation. Polymer 2019, 185, 121935. [Google Scholar] [CrossRef]

- Xiao, H.; Song, Y.; Chen, G. Correlation between charge decay and solvent effect for melt-blown polypropylene electret filter fabrics. J. Electrost. 2014, 72, 311–314. [Google Scholar] [CrossRef]

- Ahmed Dabbak, Z.S.; Illias, A.H.; Ang, C.B.; Abdul Latiff, A.N.; Makmud, Z.M. Electrical Properties of Polyethylene/Polypropylene Compounds for High-Voltage Insulation. Energies 2018, 11, 1148. [Google Scholar] [CrossRef]

- Zhao, X.; Li, Y.; Hua, T.; Jiang, P.; Yin, X.; Yu, J.; Ding, B. Low-Resistance Dual-Purpose Air Filter Releasing Negative Ions and Effectively Capturing PM2.5. ACS Appl. Mater. Interfaces 2017, 9, 12054–12063. [Google Scholar] [CrossRef]

- Jiang, P.; Zhao, X.; Li, Y.; Liao, Y.; Hua, T.; Yin, X.; Yu, J.; DIng, B. Moisture and oily molecules stable nanofibrous electret membranes for effectively capturing PM2.5. Compos. Commun. 2017, 6, 34–40. [Google Scholar] [CrossRef]

- Jung, S.; An, J.; Na, H.; Kim, J. Surface Energy of Filtration Media Influencing the Filtration Performance against Solid Particles, Oily Aerosol, and Bacterial Aerosol. Polymers 2019, 11, 935. [Google Scholar] [CrossRef] [PubMed]

- Chen, G.; Xu, Z. Charge trapping and detrapping in polymeric materials. J. Appl. Phys. 2009, 106, 123707. [Google Scholar] [CrossRef]

- Lu, H.; Meng, X. Correlation between band gap, dielectric constant, Young’s modulus and melting temperature of GaN nanocrystals and their size and shape dependences. Sci. Rep. 2015, 5, 16939. [Google Scholar] [CrossRef]

- Ravichandran, R.; Wang, A.X.; Wager, J.F. Solid state dielectric screening versus band gap trends and implications. Opt. Mater. 2016, 60, 181–187. [Google Scholar] [CrossRef]

- Schreuder-Gibson, H.; Gibson, P.; Tsai, P.; Gupta, P.; Wilkes, G. Cooperative Charging Effects of Fibers from Electrospinning of Electrically Dissimilar Polymers. Int. Nonwovens. J. 2004, 13, 39–45. [Google Scholar] [CrossRef]

- Motyl, E.; Lowkis, B. Effect of air humidity on charge decay and lifetime of PP electret nonwovens. Fibres Text. East. Eur. 2006, 14, 39–42. [Google Scholar]

- Choi, H.J.; Park, E.S.; Kim, J.U.; Kim, S.H.; Lee, M.H. Experimental Study on Charge Decay of Electret Filter Due to Organic Solvent Exposure. Aerosol Sci. Technol. 2015, 49, 977–983. [Google Scholar] [CrossRef]

- Li, G.; Chen, X.; Zhou, Z.; Wang, F.; Yang, H.; Yang, J.; Xu, B.; Yang, B.; Liu, D. Theoretical insights into the structural, relative stable, electronic, and gas sensing properties of PbnAun (n = 2–12) clusters: A DFT study. RSC Adv. 2017, 7, 45432–45441. [Google Scholar] [CrossRef]

- Teyssedre, G.; Laurent, C. Charge transport modeling in insulating polymers: From molecular to macroscopic scale. IEEE Trans. Dielectr. Electr. Insul. 2005, 12, 857–875. [Google Scholar] [CrossRef]

- Bakulin, A.A.; Rao, A.; Pavelyev, V.G.; Van Loosdrecht, P.H.M.; Pshenichnikov, M.S.; Niedzialek, D.; Cornil, J.; Beljonne, D.; Friend, R.H. The Role of Driving Energy and Delocalized States for Charge Separation in Organic Semiconductors. Science 2012, 335, 1340. [Google Scholar] [CrossRef]

- Wang, S.; Zhao, X.; Yin, X.; Yu, J.; Ding, B. Electret Polyvinylidene Fluoride Nanofibers Hybridized by Polytetrafluoroethylene Nanoparticles for High-Efficiency Air Filtration. ACS Appl. Mater. Interfaces 2016, 8, 23985–23994. [Google Scholar] [CrossRef]

- Deng, L.; Zhang, P.; Zhang, W.; Zhu, R.; Yan, Y. High filtration efficiency fluffy material: Nano-fiber constructing gradient structure on recycled curved PET micro-fibers web. SN Appl. Sci. 2019, 1, 190. [Google Scholar] [CrossRef]

- Pan, C.; Tang, J.; Wang, D.; Luo, Y.; Zhuo, R.; Fu, M. Decay characters of charges on an insulator surface after different types of discharge. Plasma Sci. Technol. 2017, 19, 075503. [Google Scholar] [CrossRef]

- Roh, S.; Kim, S.; Kim, J. Facile Functionalization via Plasma-Enhanced Chemical Vapor Deposition for the Effective Filtration of Oily Aerosol. Polymers 2019, 11, 1490. [Google Scholar] [CrossRef]

- Roh, S.; Park, K.; Kim, J. Design of Web-to-Web Spacing for the Reduced Pressure Drop and Effective Depth Filtration. Polymers 2019, 11, 1822. [Google Scholar] [CrossRef]

- Bożena, Ł. Parameters characterizing the charge state of dielectrics. Mater. Sci. Pol. 2017, 35, 601–605. [Google Scholar]

- Sharma, A.; Yarramaneni, S.; Quamara, J.K. Evaluation of dielectric relaxation parameters from TSDC analysis of pristine and ion irradiated kapton-H polyimide. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2011, 269, 759–763. [Google Scholar] [CrossRef]

- Rambo, M.K.D.; Ferreira, M.M.C. Determination of Cellulose Crystallinity of Banana Residues Using Near Infrared Spectroscopy and Multivariate Analysis. J. Braz. Chem. Soc. 2015, 26, 1491–1499. [Google Scholar] [CrossRef]

- Rotaru, R.; Savin, M.; Tudorachi, N.; Peptu, C.; Samoila, P.; Sacarescu, L.; Harabagiu, V. Ferromagnetic iron oxide–cellulose nanocomposites prepared by ultrasonication. Polym. Chem. 2018, 9, 860–868. [Google Scholar] [CrossRef]

- Gray, D.E. American Institute of Physics Handbook, 3rd ed.; McGraw-Hill: New York, NY, USA, 1972. [Google Scholar]

- Lide, D.R. CRC Handbook of Chemistry and Physics: A Ready-Reference Book of Chemical and Physical Data; CRC Press: Boca Raton, FL, USA, 1995. [Google Scholar]

- Brandrup, J.; Immergut, E.H.; Grulke, E.A.; Abe, A.; Bloch, D.R. Polymer Handbook, 3rd ed.; Brandrup, J., Immergut, E.H., Grulke, E.A., Abe, A., Bloch, D.R., Eds.; Wiley: New York, NY, USA, 1990; pp. 361–362. [Google Scholar]

- Wu, S. Calculation of interfacial tension in polymer systems. J. Polym. Sci. Part C Polym. Symp. 1971, 34, 19–30. [Google Scholar] [CrossRef]

- Pritykin, L.M. Calculation of the surface energy of homo- and copolymers from the cohesion parameters and refractometric characterisics of the respective monomers. J. Colloid Interface Sci. 1986, 112, 539–543. [Google Scholar] [CrossRef]

- Wu, S. Surface tension of solids: An equation of state analysis. J. Colloid Interface Sci. 1979, 71, 605–609. [Google Scholar] [CrossRef]

- Vargha-Butler, E.I.; Zubovits, T.K.; Hamza, H.A.; Neumann, A.W. Surface tenstion effects in the sedimentation of polymer particles in various liquid mixtures. J. Dispers. Sci. Technol. 1985, 6, 357–379. [Google Scholar] [CrossRef]

- Song, K.; Lee, J.; Choi, S.; Kim, J. Interaction of Surface Energy Components between Solid and Liquid on Wettability, and Its Application to Textile Anti-Wetting Finish. Polymers 2019, 11, 498. [Google Scholar] [CrossRef]

- Moody, V.; Needles, H.L. 3—Major Fibers and Their Properties. In Tufted Carpet; Moody, V., Needles, H.L., Eds.; William Andrew Publishing: Norwich, NY, USA, 2004; pp. 35–59. [Google Scholar]

- Lee, L.H. Relationships between surface wettability and glass temperatures of high polymers. J. Appl. Polym. Sci. 1968, 12, 719–730. [Google Scholar] [CrossRef]

- Lippits, D.R.; Rastogi, S.; Höhne, G.W.H. Melting Kinetics in Polymers. Phys. Rev. Lett. 2006, 96, 218303. [Google Scholar] [CrossRef]

- Alexandrovich, P.; Karasz, F.E.; MacKnight, W.J. Thermally stimulated discharge in polymer electrets: Compatibility and impurity effects. J. Appl. Phys. 1976, 47, 4251–4254. [Google Scholar] [CrossRef]

- Turnhout, J.V. Thermally Stimulated Discharge of Polymer Electrets. Polym. J. 1971, 2, 173–191. [Google Scholar] [CrossRef]

- Hervé, P.; Vandamme, L.K.J. General relation between refractive index and energy gap in semiconductors. Infrared Phys. Technol. 1994, 35, 609–615. [Google Scholar] [CrossRef]

- Yang, D.; Yang, R.; Wang, K.; Wu, C.; Zhu, X.; Feng, J.; Ren, X.; Fang, G.; Priya, S.; Liu, S. High efficiency planar-type perovskite solar cells with negligible hysteresis using EDTA-complexed SnO2. Nat. Commun. 2018, 9, 3239. [Google Scholar] [CrossRef]

- Bansal, N.; Reynolds, L.X.; MacLachlan, A.; Lutz, T.; Ashraf, R.S.; Zhang, W.; Nielsen, C.B.; McCulloch, I.; Rebois, D.G.; Kirchartz, T.; et al. Influence of Crystallinity and Energetics on Charge Separation in Polymer–Inorganic Nanocomposite Films for Solar Cells. Sci. Rep. 2013, 3, 1531. [Google Scholar] [CrossRef]

- Zhang, W.; Milner, S.T.; Gomez, E.D. Nematic Order Imposes Molecular Weight Effect on Charge Transport in Conjugated Polymers. ACS Cent. Sci. 2018, 4, 413–421. [Google Scholar] [CrossRef]

- Woo, C.H.; Piliego, C.; Holcombe, T.W.; Toney, M.F.; Fréchet, J.M.J. A Quantitative Correlation between the Mobility and Crystallinity of Photo-Cross-Linkable P3HT. Macromolecules 2012, 45, 3057–3062. [Google Scholar] [CrossRef]

| PAN | PVDF | PP1 | PP2 | |

|---|---|---|---|---|

| Surface Energy (mJ/m2) [34,35,36,37,38,39] | 44.0 ~ 54.1 | 25.5 ~ 36.5 | 27.2 ~ 32.6 | |

| εr (100 Hz, 1 MHz) [31,32] | 4.2 | 8.4 ~ 8.9 | 2.2 ~ 2.6 | |

| Tg (°C) [40] | 95.5 ~ 105 | −50 ~ −20 | −20 ~ −10 | |

| Tm (°C) [41] | 300 ~ 320 | ~ 175 | ~ 173 | |

| Web type | electrospun | electrospun | meltblown | |

| Weight (g/m2) (n = 5) | 2.4 (± 0.26) | 5.1 ( ± 0.28) | 47.3 (± 1.01) | 28.9 (± 0.64) |

| Thickness (mm) (n = 5) | 0.28 (± 0.02) | 0.30 ( ± 0.03) | 0.34 (± 0.02) | 0.29 (± 0.02) |

| Fiber diameter (μm) (n = 30) | 0.55 (± 0.13) | 1.01 (± 0.36) | 2.49 (± 0.87) | 3.44 (± 1.71) |

| X-Tallinity Before Aging (%) | QF Before Aging (Pa−1) | X-Tallinity After Aging (%) | QF After Aging (Pa−1) | X-Tallinity Reduction After Aging (%) | QF Reduction After Aging (%) | |

|---|---|---|---|---|---|---|

| PAN | 33.87 | 0.21 | 25.68 | 0.13 | 24.2 | 36.9 |

| PVDF | 38.21 | 0.35 | 39.08 | 0.18 | 39.1 | 48.1 |

| PP1 | 28.28 | 0.30 | 12.39 | 0.21 | 12.4 | 29.0 |

| PP2 | 24.90 | 0.75 | 12.87 | 0.57 | 12.9 | 23.3 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, J.; Kim, J. Material Properties Influencing the Charge Decay of Electret Filters and their Impact on Filtration Performance. Polymers 2020, 12, 721. https://doi.org/10.3390/polym12030721

Lee J, Kim J. Material Properties Influencing the Charge Decay of Electret Filters and their Impact on Filtration Performance. Polymers. 2020; 12(3):721. https://doi.org/10.3390/polym12030721

Chicago/Turabian StyleLee, Jinwook, and Jooyoun Kim. 2020. "Material Properties Influencing the Charge Decay of Electret Filters and their Impact on Filtration Performance" Polymers 12, no. 3: 721. https://doi.org/10.3390/polym12030721

APA StyleLee, J., & Kim, J. (2020). Material Properties Influencing the Charge Decay of Electret Filters and their Impact on Filtration Performance. Polymers, 12(3), 721. https://doi.org/10.3390/polym12030721