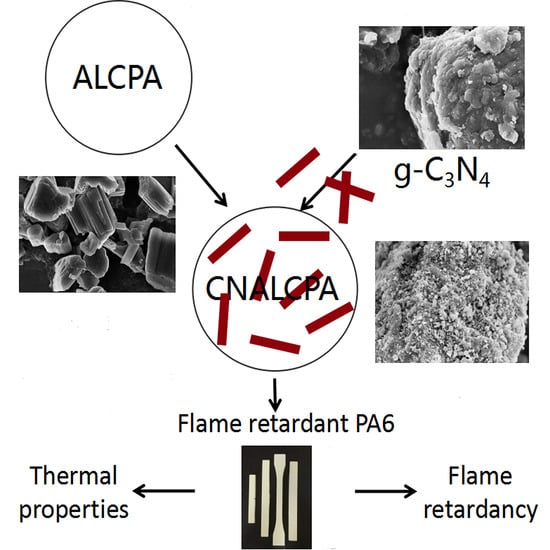

Organic Aluminum Hypophosphite/Graphitic Carbon Nitride Hybrids as Halogen-Free Flame Retardants for Polyamide 6

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

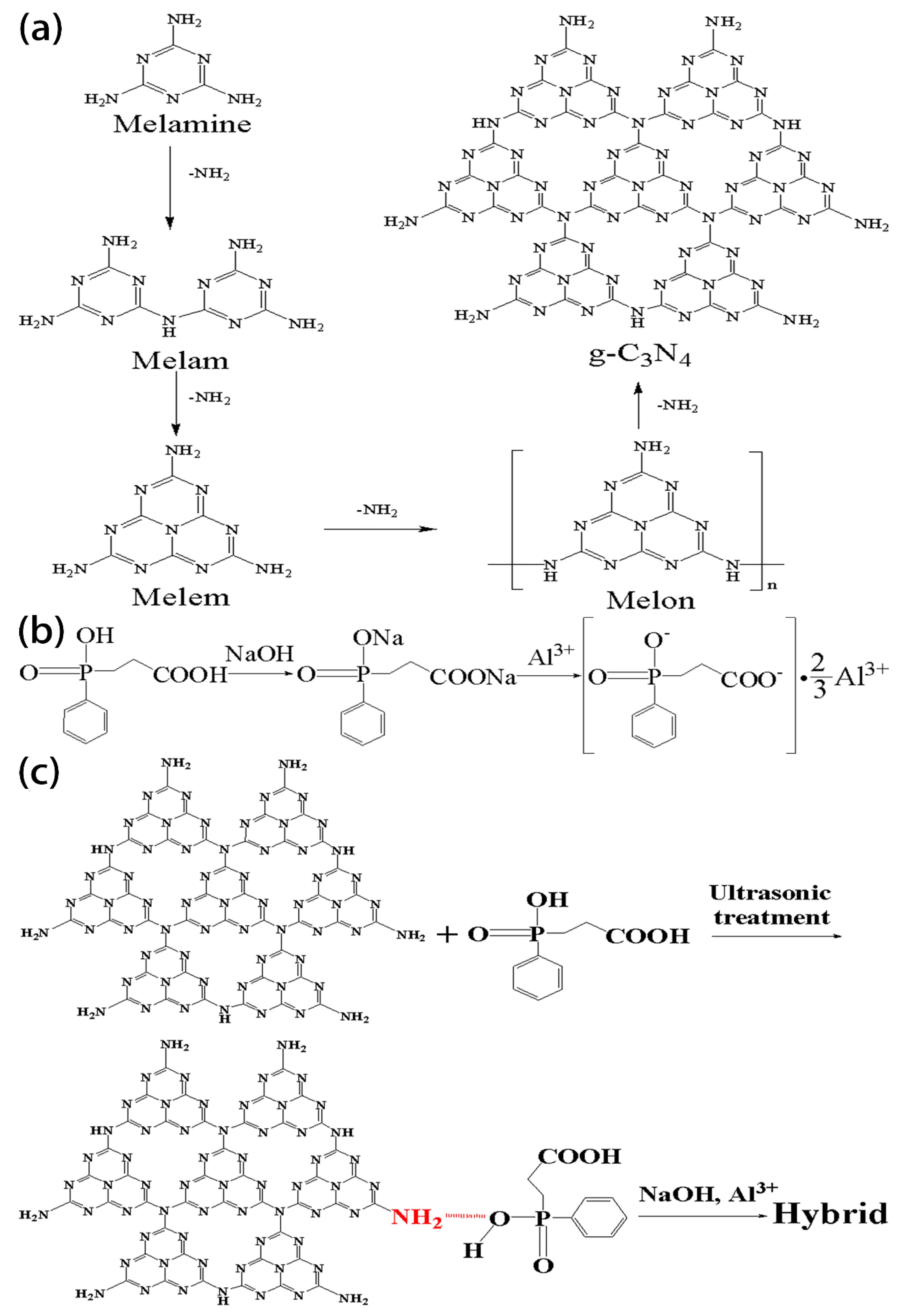

2.2. Synthesis of g-C3N4

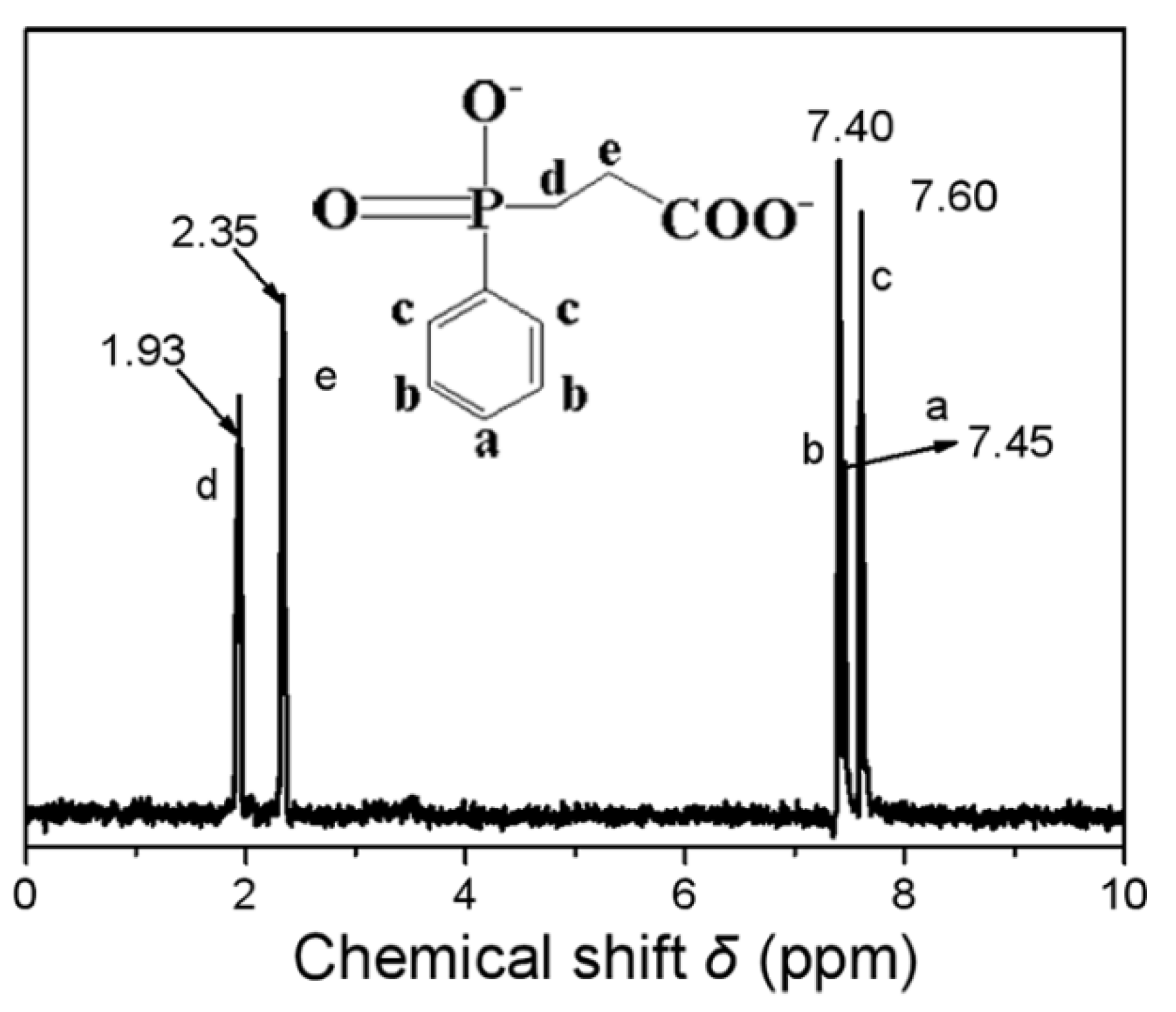

2.3. Synthesis of ALCPA

2.4. Synthesis of CNALCPA

2.5. Preparation of PA6 Composites

2.6. Characterization

3. Results and Discussion

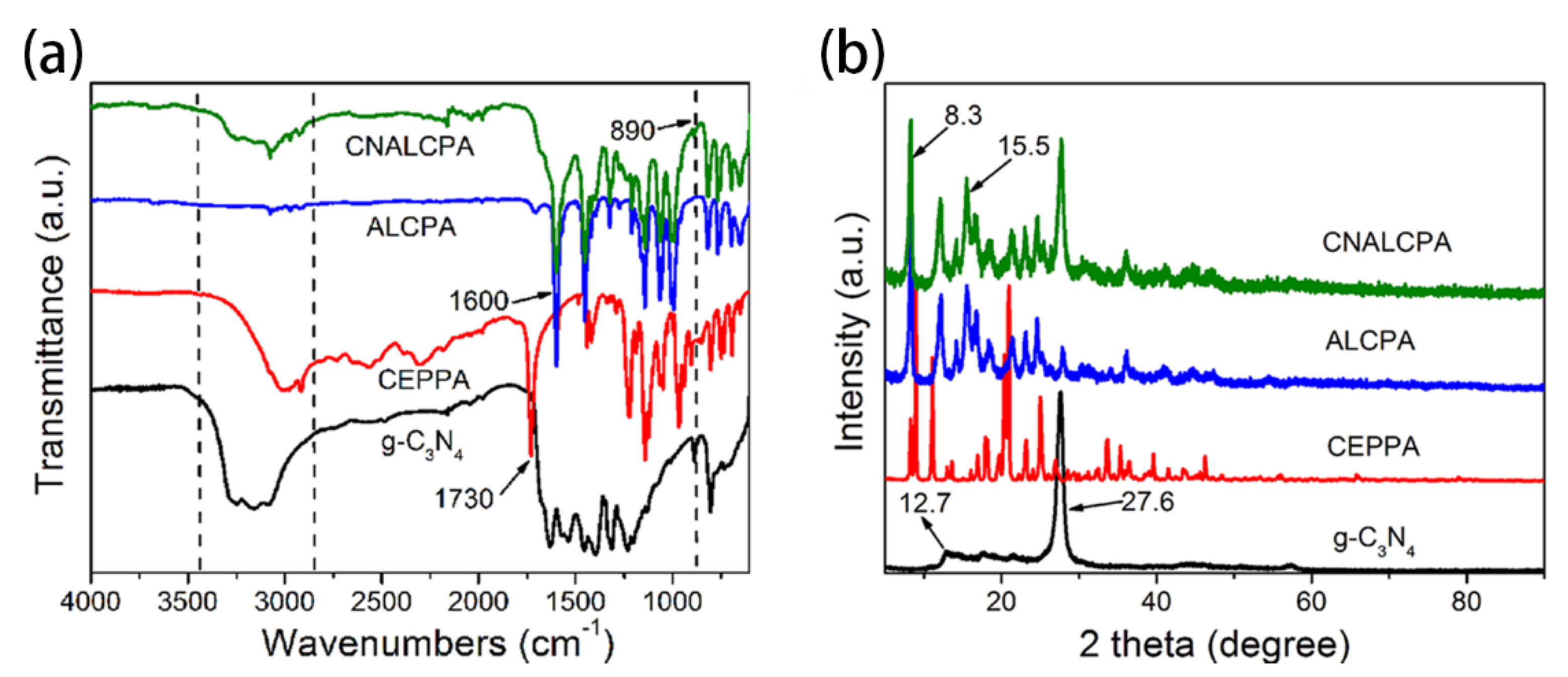

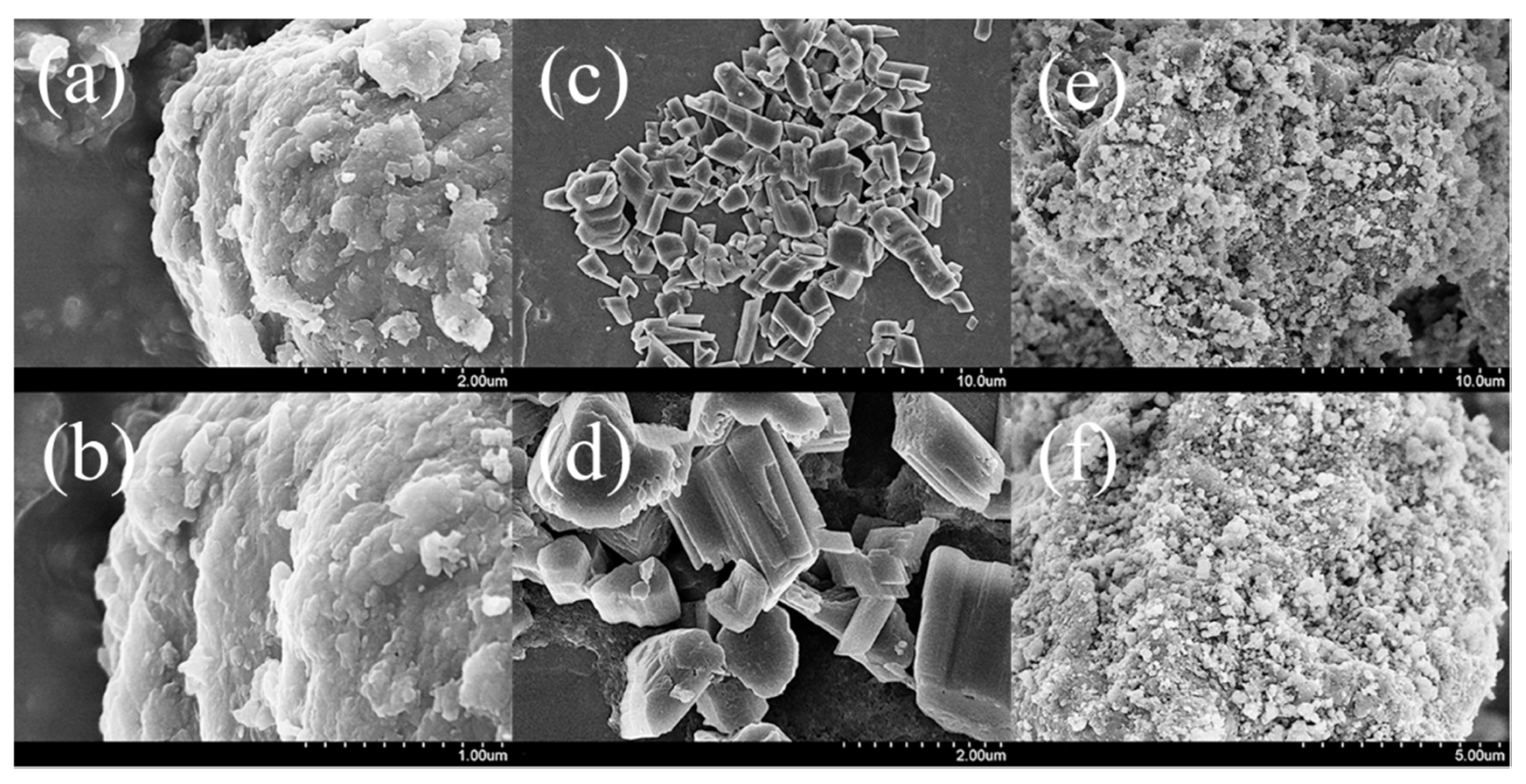

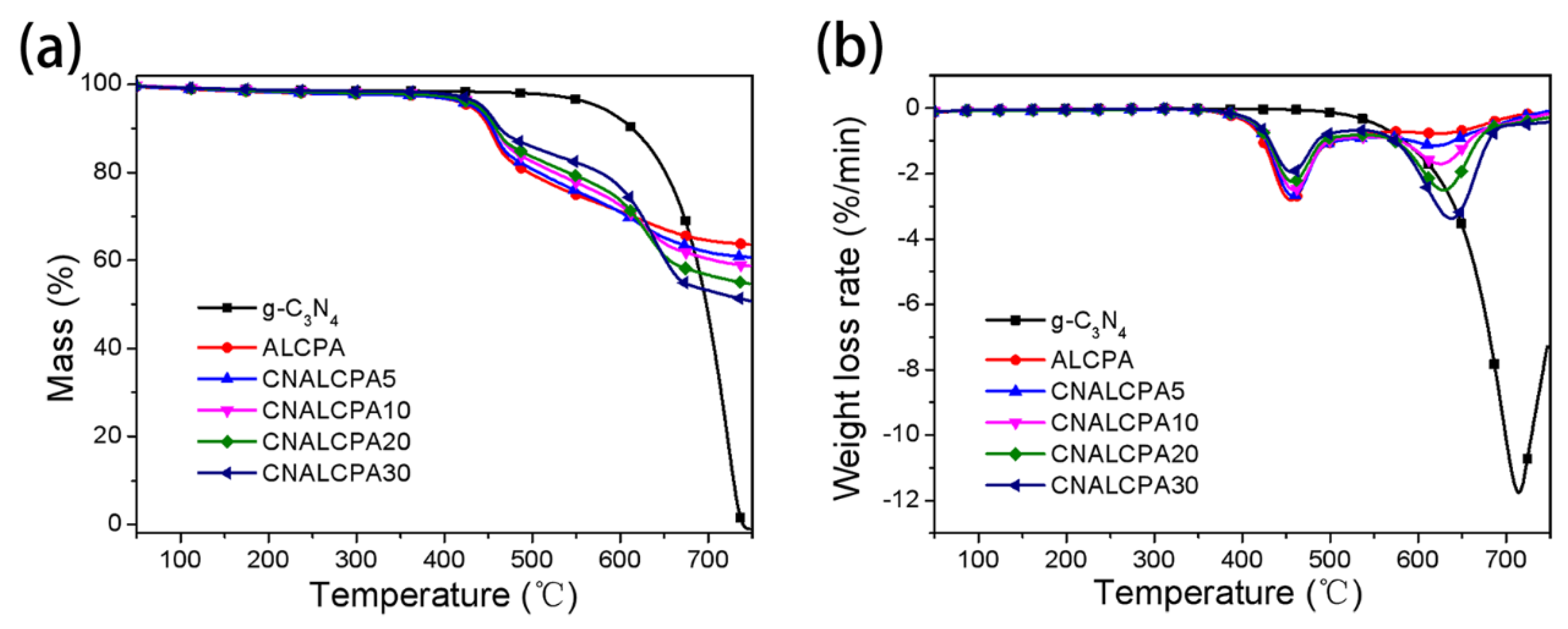

3.1. Characterization of ALCPA and CNALCPA

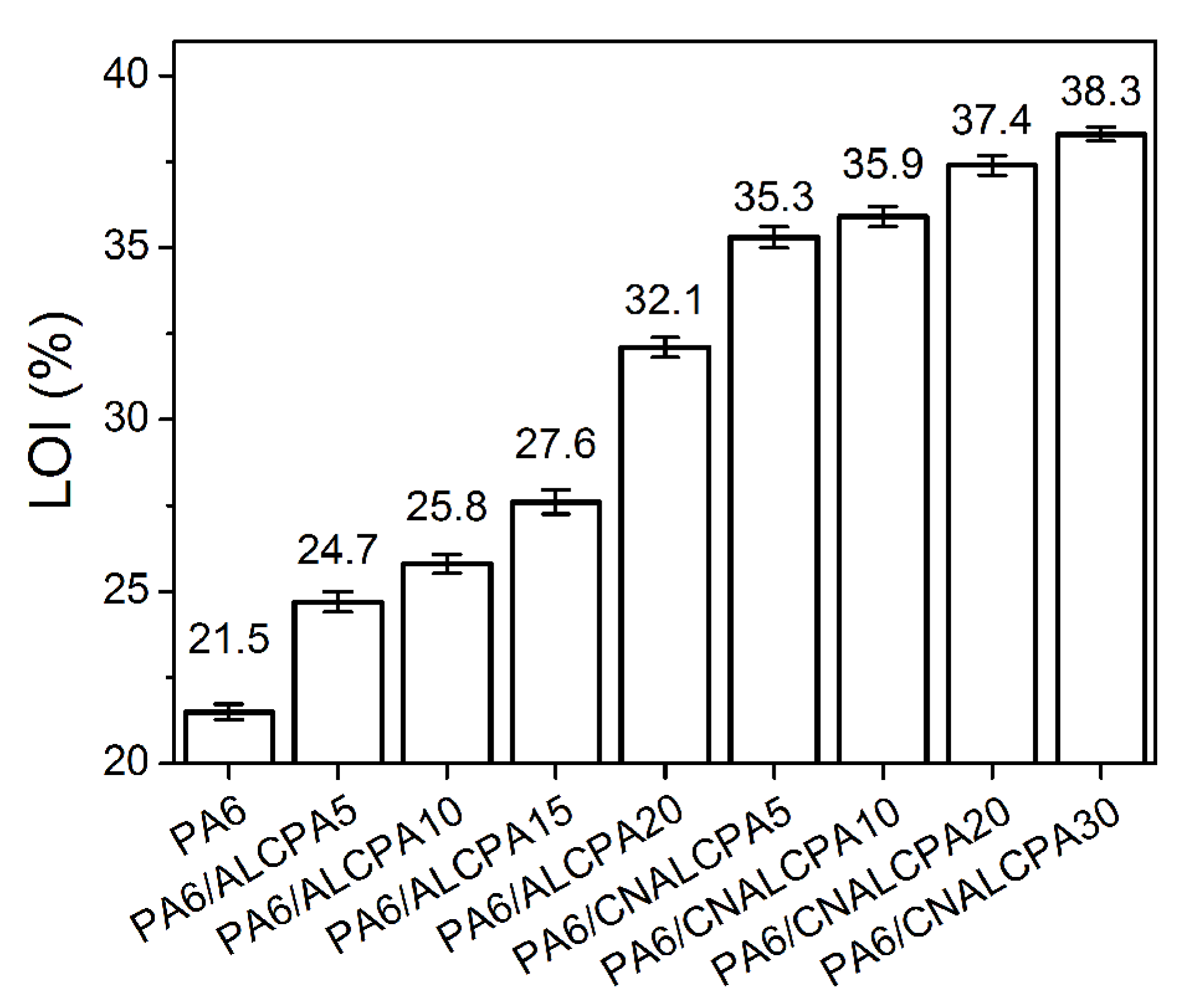

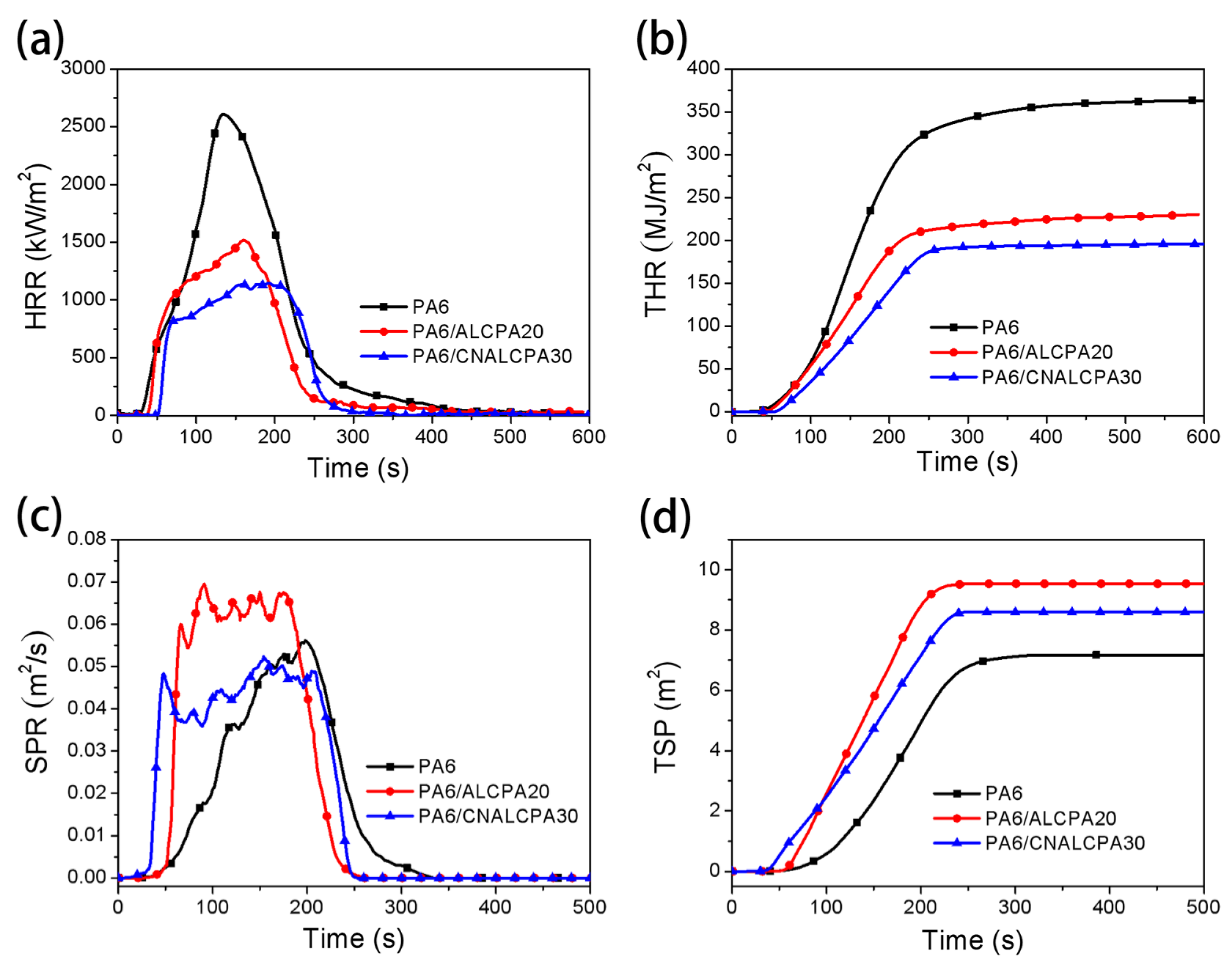

3.2. Fire Properties of PA6 Composites

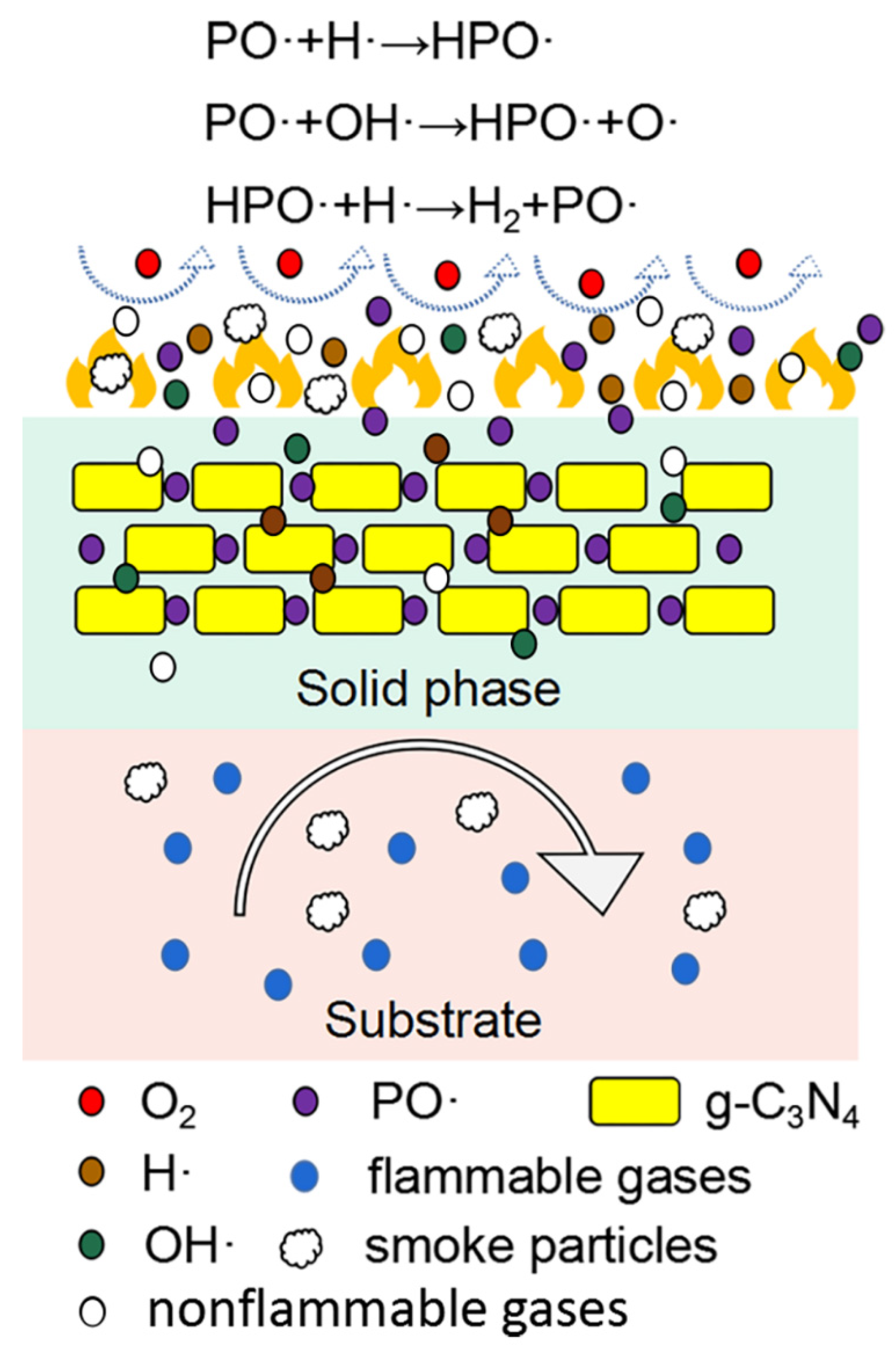

3.3. Flame-Retardant Mechanism of ALCPA and CNALCPA

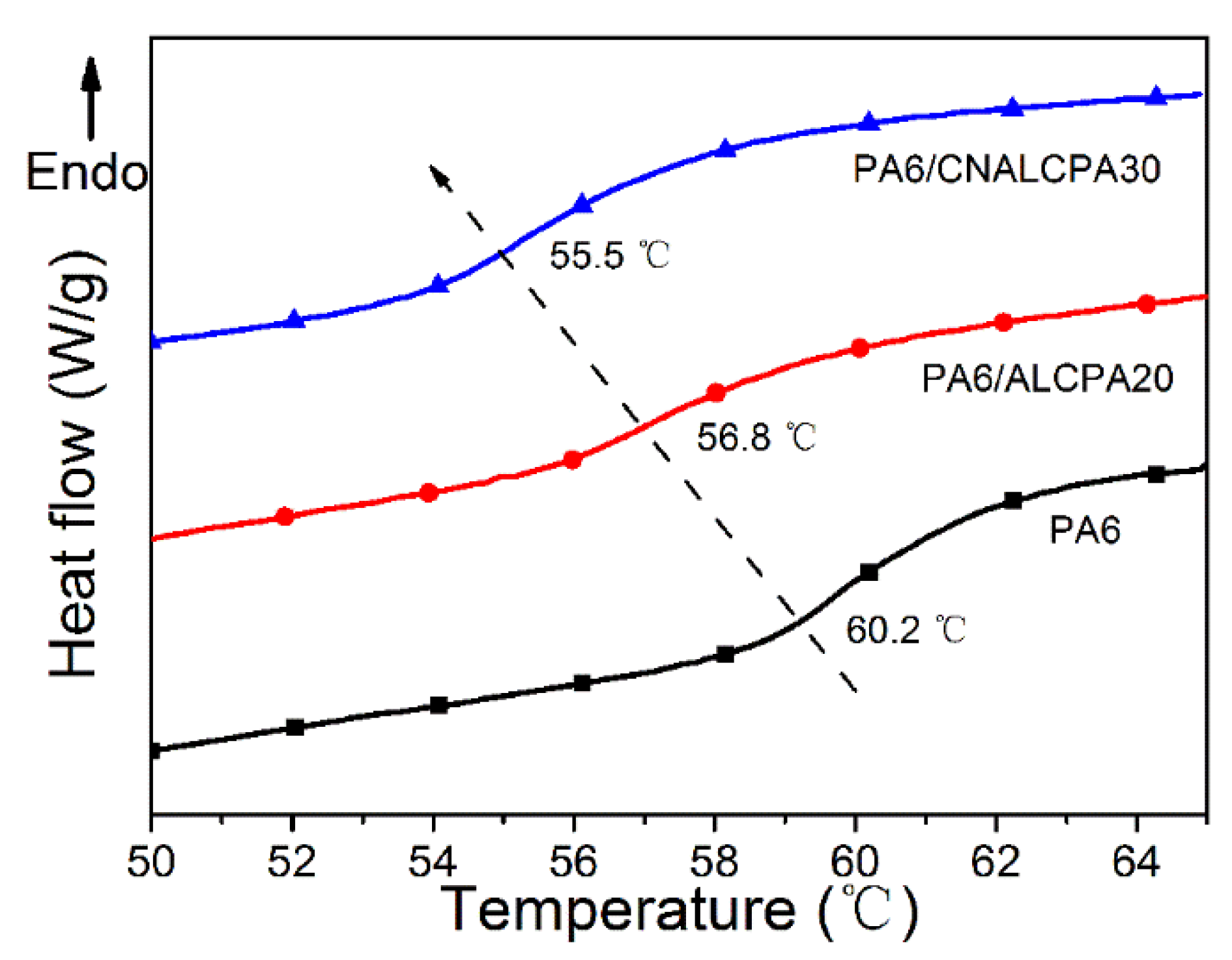

3.4. Mechanical Properties of PA6 Composites

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Zhang, X.L.; Wu, H.; Guo, S.Y.; Wang, Y.Z. Reinforced thermal conductivity and mechanical properties of in situ microfibrillar composites through multistage stretching extrusion. Polym. Compos. 2017, 38, 2663–2669. [Google Scholar] [CrossRef]

- Zhan, Z.S.; Xu, M.J.; Li, B. Synergistic effects of sepiolite on the flame retardant properties and thermal degradation behaviors of polyamide 66/aluminum diethylphosphinate composites. Polym. Degrad. Stabil. 2015, 117, 66–74. [Google Scholar] [CrossRef]

- Long, L.J.; Zhou, W.; Xiang, Y.S.; Li, J.; Huang, S.W.; Qin, S.H.; Xu, G.M.; Yu, J. Function of the aryl group in bis DOPO phosphonate on reducing fire hazards of polyamide 6 composites. J. Appl. Polym. Sci. 2020, 137, 11. [Google Scholar] [CrossRef]

- Holdsworth, A.F.; Horrocks, A.R.; Kandola, B.K. Potential Synergism between Novel Metal Complexes and Polymeric Brominated Flame Retardants in Polyamide 6.6. Polymers 2020, 12, 1543. [Google Scholar] [CrossRef] [PubMed]

- Covaci, A.; Voorspoels, S.; Abdallah, M.A.E.; Geens, T.; Harrad, S.; Law, R.J. Analytical and environmental aspects of the flame retardant tetrabromobisphenol-A and its derivatives. J. Chromatogr. A. 2009, 1216, 346–363. [Google Scholar] [CrossRef] [PubMed]

- Horrocks, A.R.; Smart, G.; Kandola, B.; Holdsworth, A.; Price, D. Zinc stannate interactions with flame retardants in polyamides; Part 1: Synergies with organobromine-containing flame retardants in polyamides 6 (PA6) and 6.6 (PA6.6). Polym. Degrad. Stabil. 2012, 97, 2503–2510. [Google Scholar] [CrossRef]

- Lyu, W.Y.; Cui, Y.H.; Zhang, X.J.; Yuan, J.Y.; Zhang, W. Fire and thermal properties of PA 66 resin treated with poly-N-aniline-phenyl phosphamide as a flame retardant. Fire Mater. 2017, 41, 349–361. [Google Scholar] [CrossRef]

- Tang, G.; Wang, X.; Jiang, S.D.; Zhou, K.Q.; Bai, Z.M.; Wang, B.B.; Tai, Q.L.; Song, L.; Hu, Y. Thermal Degradation and Combustion Behaviors of Flame Retarded Glass Fiber-Reinforced Polyamide 6 Composites Based on Cerium Hypophosphite. Polym. Compos. 2016, 37, 3073–3082. [Google Scholar] [CrossRef]

- Tao, W.; Hu, X.; Sun, J.H.; Qian, L.J.; Li, J. Effects of P–N flame retardants based on cytosine on flame retardancy and mechanical properties of polyamide 6. Polym. Degrad. Stabil. 2020, 174, 10. [Google Scholar] [CrossRef]

- Groenewolt, M.; Antonietti, M. Synthesis of g-C3N4 nanoparticles in mesoporous silica host matrices. Adv. Mater. 2005, 17, 1789–1792. [Google Scholar] [CrossRef]

- Li, X.F.; Zhang, J.; Shen, L.H.; Ma, Y.M.; Lei, W.W.; Cui, Q.L.; Zou, G.T. Preparation and characterization of graphitic carbon nitride through pyrolysis of melamine. Appl. Phys. A-Mater. Sci. Process. 2009, 94, 387–392. [Google Scholar] [CrossRef]

- Yao, C.K.; Wang, R.; Wang, Z.S.; Lei, H.; Dong, X.P.; He, C.Z. Highly dispersive and stable Fe3+ active sites on 2D graphitic carbon nitride nanosheets for efficient visible-light photocatalytic nitrogen fixation. J. Mater. Chem. A 2019, 7, 27547–27559. [Google Scholar] [CrossRef]

- Rahman, M.Z.; Davey, K.; Qiao, S.Z. Carbon, nitrogen and phosphorus containing metal-free photocatalysts for hydrogen production: Progress and challenges. J. Mater. Chem. A 2018, 6, 1305–1322. [Google Scholar] [CrossRef]

- Wu, J.L.; Chen, J.M.; Huang, Y.; Feng, K.; Deng, J.; Huang, W.; Wu, Y.L.; Zhong, J.; Li, Y.G. Cobalt atoms dispersed on hierarchical carbon nitride support as the cathode electrocatalyst for high-performance lithium-polysulfide batteries. Sci. Bull. 2019, 64, 1875–1880. [Google Scholar] [CrossRef]

- Zhuo, Z.S.; Jiao, Y.J.; Chen, L.C.; Li, H.H.; Dai, M.; Lin, Z.Y.; Yang, H.B.; Fu, F.F.; Dong, Y.Q. Ultra-high quantum yield ultraviolet fluorescence of graphitic carbon nitride nanosheets. Chem. Commun. 2019, 55, 15065–15068. [Google Scholar] [CrossRef]

- Angamuthu, G.; Jayabal, E.; Rengarajan, V. Electrochemical performance evaluation of carbon nitride synthesized at different temperatures as an anode material for lithium-ion batteries. Ionics 2020, 26, 3863–3873. [Google Scholar] [CrossRef]

- Xiong, W.; Huang, M.Y.; Huang, F.; Zhang, R.Q. Colorful carbon nitride based composite films. Appl. Surf. Sci. 2020, 511, 7. [Google Scholar] [CrossRef]

- Shi, Y.Q.; Yu, B.; Duan, L.J.; Gui, Z.; Wang, B.B.; Hu, Y.; Yuen, R.K.K. Graphitic carbon nitride/phosphorus-rich aluminum phosphinates hybrids as smoke suppressants and flame retardants for polystyrene. J. Hazard. Mater. 2017, 332, 87–96. [Google Scholar] [CrossRef]

- Zhang, W.W.; Wu, W.H.; Meng, W.H.; Xie, W.Y.; Cui, Y.M.; Xu, J.Z.; Qu, H.Q. Core-shell graphitic carbon nitride/zinc phytate as a novel efficient flame retardant for fire safety and smoke suppression in epoxy resin. Polymers 2020, 12, 212. [Google Scholar] [CrossRef]

- Shi, Y.Q.; Jiang, S.H.; Zhou, K.Q.; Wang, B.B.; Wang, B.A.; Gui, Z.; Hu, Y.; Yuen, R.K.K. Facile preparation of ZnS/g-C3N4 nanohybrids for enhanced optical properties. RSC Adv. 2014, 4, 2609–2613. [Google Scholar] [CrossRef]

- Khabashesku, V.N.; Zimmerman, J.L.; Margrave, J.L. Powder synthesis and characterization of amorphous carbon nitride. Chem. Mat. 2000, 12, 3264–3270. [Google Scholar] [CrossRef]

- Duan, H.J.; Cao, J.F.; Chen, Y.S.; Wang, J.S.; Ji, S.; Ma, H.R. A phosphorus/boron-containing triazine-trione derivative endowing epoxy resin with excellent flame retardance. Express Polym. Lett. 2020, 14, 908–923. [Google Scholar] [CrossRef]

- Braun, U.; Schartel, B.; Fichera, M.A.; Jaeger, C. Flame retardancy mechanisms of aluminium phosphinate in combination with melamine polyphosphate and zinc borate in glass-fibre reinforced polyamide 6,6. Polym. Degrad. Stabil. 2007, 92, 1528–1545. [Google Scholar] [CrossRef]

- Wang, J.; Ma, C.; Mu, X.; Cai, W.; Liu, L.; Zhou, X.; Hu, W.; Hu, Y. Construction of multifunctional MoSe2 hybrid towards the simultaneous improvements in fire safety and mechanical property of polymer. J. Hazard. Mater. 2018, 352, 36–46. [Google Scholar] [CrossRef]

- Xu, W.; Zhang, B.; Wang, X.; Wang, G.; Ding, D. The flame retardancy and smoke suppression effect of a hybrid containing CuMoO4 modified reduced graphene oxide/layered double hydroxide on epoxy resin. J. Hazard. Mater. 2018, 343, 364–375. [Google Scholar] [CrossRef] [PubMed]

- Ran, S.; Fang, F.; Guo, Z.; Song, P.; Cai, Y.; Fang, Z.; Wang, H. Synthesis of decorated graphene with P, N-containing compounds and its flame retardancy and smoke suppression effects on polylactic acid. Compos. Pt. B-Eng. 2019, 170, 41–50. [Google Scholar] [CrossRef]

- Bouvet, N.; Linteris, G.T.; Babushok, V.I.; Takahashi, F.; Katta, V.R.; Kraemer, R. A comparison of the gas-phase fire retardant action of DMMP and Br-2 in co-flow diffusion flame extinguishment. Combust. Flame 2016, 169, 340–348. [Google Scholar] [CrossRef]

- Rwei, S.P.; Chen, Y.M.; Chiang, W.Y.; Ting, Y.T. A Study of the curing and flammability properties of bisphenol a epoxy diacrylate resin utilizing a novel flame retardant monomer, bis di-acryloyloxyethyl -p-tert-butyl-phenyl phosphate. Materials 2017, 202. [Google Scholar] [CrossRef]

- Fang, Y.; Qian, L.; Huang, Z. Synergistic barrier flame-retardant effect of aluminium poly-hexamethylenephosphinate and bisphenol-A bis (diphenyl phosphate) in epoxy resin. Polym. Int. 2017, 66, 719–725. [Google Scholar] [CrossRef]

- Toldy, A.; Szolnoki, B.; Csontos, I.; Marosi, G. Green synthesis and characterization of phosphorus flame retardant crosslinking agents for epoxy resins. J. Appl. Polym. Sci. 2014, 131. [Google Scholar] [CrossRef]

- Wazarkar, K.; Kathalewar, M.; Sabnis, A. Flammability behavior of unsaturated polyesters modified with novel phosphorous containing flame retardants. Polym. Compos. 2017, 38, 1483–1491. [Google Scholar] [CrossRef]

| Sample | Flame Retardant | Addition Amount (wt %) | PA6 (wt %) |

|---|---|---|---|

| PA6 | / | 0 | 100 |

| PA6/ALCPA5 | ALCPA | 5 | 95 |

| PA6/ALCPA10 | ALCPA | 10 | 90 |

| PA6/ALCPA15 | ALCPA | 15 | 85 |

| PA6/ALCPA20 | ALCPA | 20 | 80 |

| PA6/CNALCPA5 | CNALCPA5 | 20 | 80 |

| PA6/CNALCPA10 | CNALCPA10 | 20 | 80 |

| PA6/CNALCPA20 | CNALCPA20 | 20 | 80 |

| PA6/CNALCPA30 | CNALCPA30 | 20 | 80 |

| Sample | Elements (wt %) | C | H | O | P | Al |

|---|---|---|---|---|---|---|

| ALCPA | Theoretical | 46.96 | 3.91 | 27.83 | 13.47 | 7.83 |

| Actual | 46.21 | 3.96 | 28.03 | 12.92 | 8.06 |

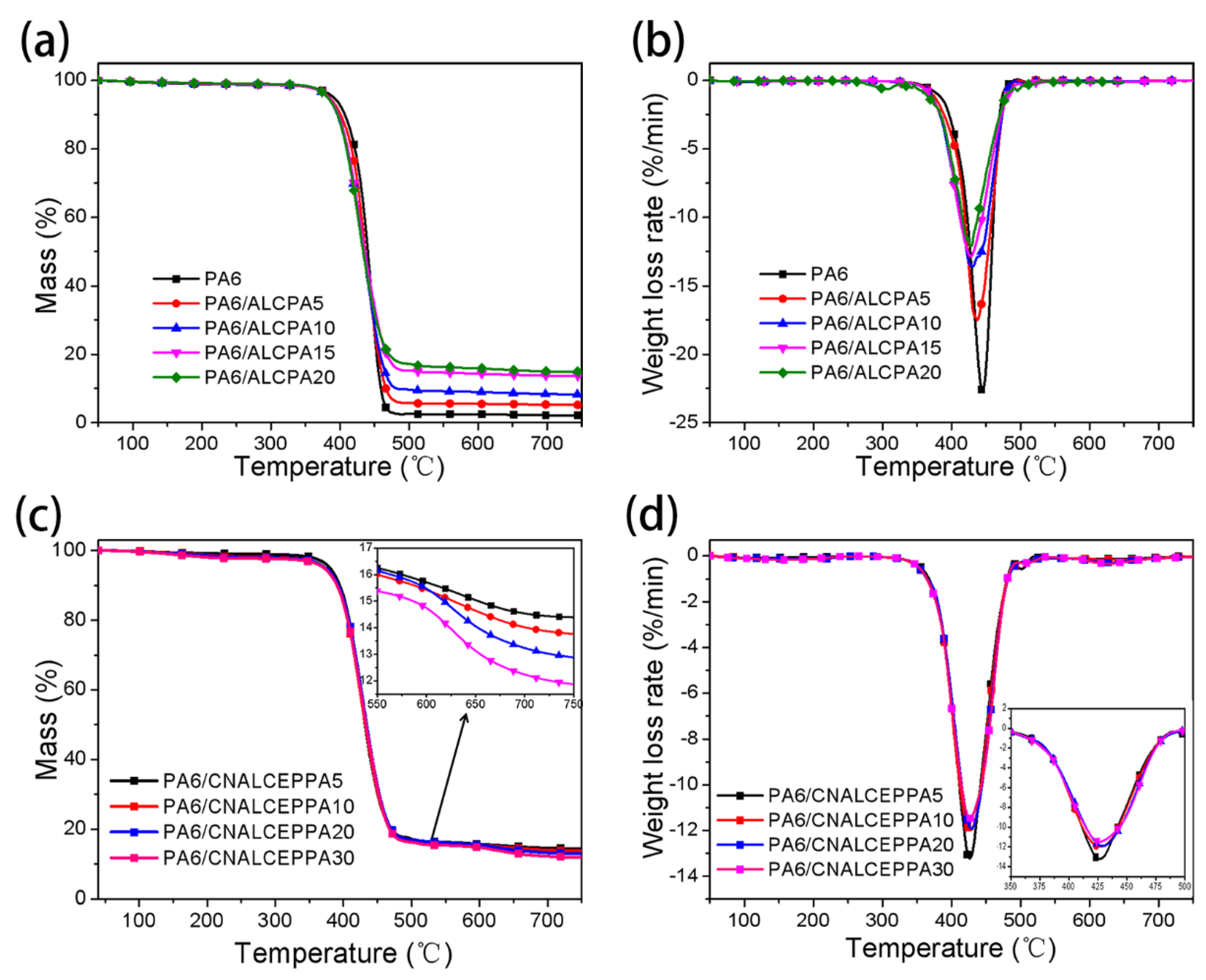

| Samples | T-5 (°C) | T-Max1 (°C) | T-Max2 (°C) | Residue (750 °C, wt %) |

|---|---|---|---|---|

| g-C3N4 | 575.3 | 721.9 | / | 0 |

| ALCPA | 429.3 | 456.1 | / | 63.5 |

| CNALCPA5 | 432.9 | 457.9 | 623.6 | 60.7 |

| CNALCPA10 | 438.6 | 458.4 | 627.2 | 58.7 |

| CNALCPA20 | 439.7 | 457.7 | 631.7 | 54.7 |

| CNALCPA30 | 443.4 | 456.8 | 634.7 | 50.8 |

| Sample | 1.6 mm Thickness | 3.2 mm Thickness | ||||

|---|---|---|---|---|---|---|

| t1/t2 (s) | Dripping | UL94 Rating | t1/t2 (s) | Dripping | UL94 Rating | |

| PA6 | >30/>30 | BC | NR | >30/>30 | BC | NR |

| PA6/ALCPA5 | >30/>30 | BC | NR | 29/>30 | BC | NR |

| PA6/ALCPA10 | >30/>30 | BC | NR | 19.7/26.8 | YES | V-2 |

| PA6/ALCPA15 | >30/>30 | YES | NR | 15.5/26 | YES | V-2 |

| PA6/ALCPA20 | 22.6/24.7 | YES | V-2 | 11.4/22 | NO | V-1 |

| PA6/CNALCPA5 | 14.4/21.8 | YES | V-2 | 9.6/10.8 | NO | V-1 |

| PA6/CNALCPA10 | 10.2/22 | YES | V-2 | 6.9/10.1 | NO | V-1 |

| PA6/CNALCPA20 | 10.6/17.3 | YES | V-1 | 6.2/8.9 | NO | V-0 |

| PA6/CNALCPA30 | 7.9/15.1 | YES | V-1 | 4.9/7.6 | NO | V-0 |

| Sample | TTI (s) | PHRR (kW/m2) | THR (MJ/m2) | FPI (s·m2/kW) | PSPR (m2/s) | TSP (m2) | ECH (MJ/kg) |

|---|---|---|---|---|---|---|---|

| PA6 | 47 | 2605.46 | 363.06 | 0.018 | 0.069 | 7.16 | 194.96 |

| PA6/ALCPA20 | 43 | 1517.59 | 229.08 | 0.028 | 0.056 | 9.53 | 165.06 |

| PA6/CNALCPA30 | 37 | 1143.52 | 195.50 | 0.032 | 0.052 | 8.59 | 124.84 |

| Sample | T-5 (°C) | T-Max (°C) | Residue (750 °C, wt %) |

|---|---|---|---|

| PA6 | 391.2 | 445.0 | 2.15 |

| PA6/ALCPA5 | 385.0 | 436.0 | 5.22 |

| PA6/ALCPA10 | 382.5 | 435.6 | 8.29 |

| PA6/ALCPA15 | 383.6 | 428.8 | 13.66 |

| PA6/ALCPA20 | 382.3 | 426.8 | 14.92 |

| PA6/CNALCPA5 | 380.0 | 426.7 | 14.39 |

| PA6/CNALCPA10 | 372.7 | 427.0 | 13.77 |

| PA6/CNALCPA20 | 373.3 | 428.8 | 12.88 |

| PA6/CNALCPA30 | 371.2 | 427.7 | 11.87 |

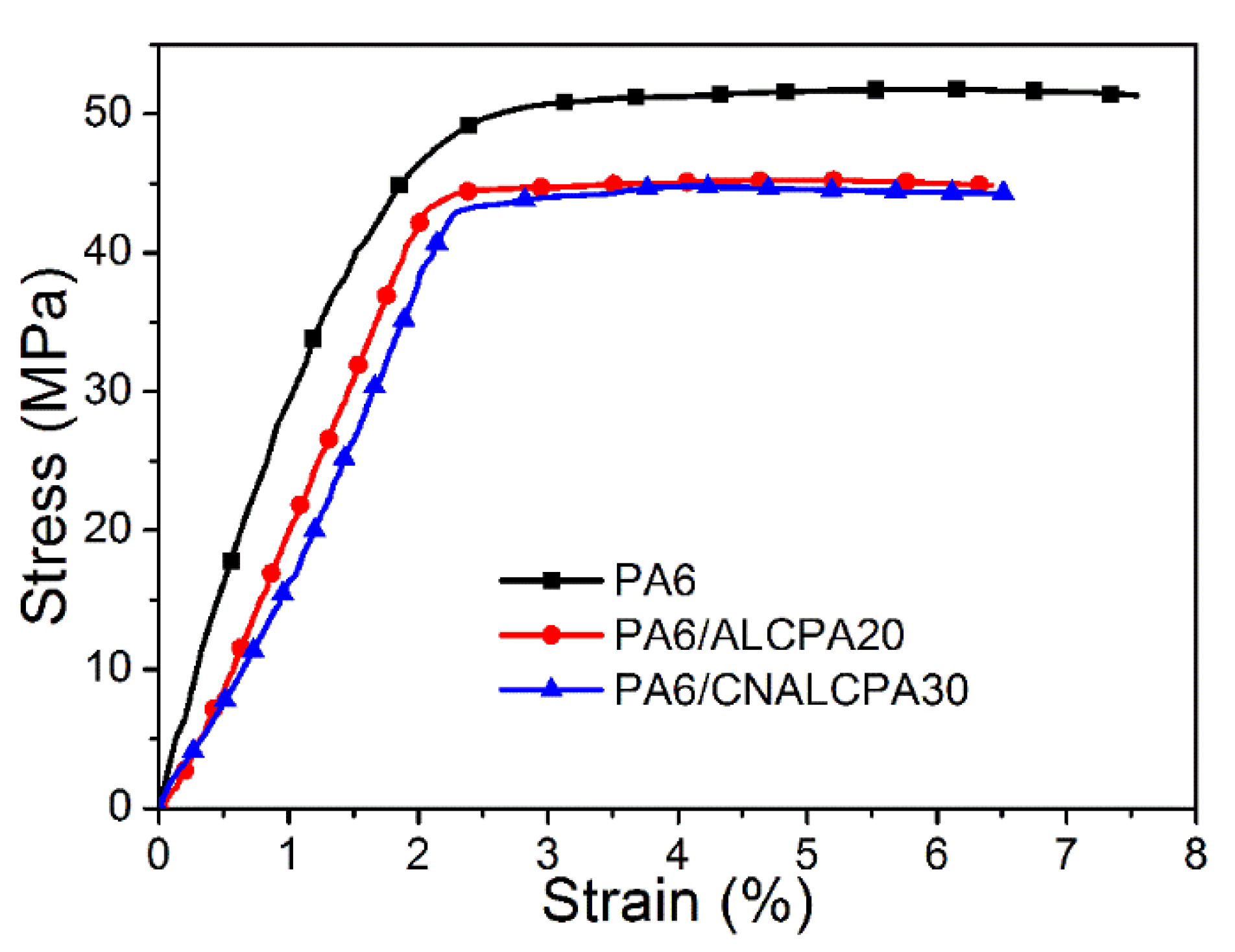

| Sample | Maximal Tensile Strength (MPa) | Elongation at Break (%) | Young’s Modulus (MPa) |

|---|---|---|---|

| PA6 | 51.78 ± 0.84 | 7.54 ± 0.20 | 2600.8 ± 30.3 |

| PA6/ALCPA20 | 45.23 ± 0.80 | 6.42 ± 0.15 | 2056.0 ± 19.7 |

| PA6/CNALCPA30 | 44.78 ± 0.68 | 6.51 ± 0.12 | 1925.1 ± 55.6 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, C.; Zhao, Y.; Ji, G.; Wang, C.; Peng, Z. Organic Aluminum Hypophosphite/Graphitic Carbon Nitride Hybrids as Halogen-Free Flame Retardants for Polyamide 6. Polymers 2020, 12, 2323. https://doi.org/10.3390/polym12102323

Guo C, Zhao Y, Ji G, Wang C, Peng Z. Organic Aluminum Hypophosphite/Graphitic Carbon Nitride Hybrids as Halogen-Free Flame Retardants for Polyamide 6. Polymers. 2020; 12(10):2323. https://doi.org/10.3390/polym12102323

Chicago/Turabian StyleGuo, Chengxin, Yongshuai Zhao, Guichen Ji, Chaosheng Wang, and Zhihan Peng. 2020. "Organic Aluminum Hypophosphite/Graphitic Carbon Nitride Hybrids as Halogen-Free Flame Retardants for Polyamide 6" Polymers 12, no. 10: 2323. https://doi.org/10.3390/polym12102323

APA StyleGuo, C., Zhao, Y., Ji, G., Wang, C., & Peng, Z. (2020). Organic Aluminum Hypophosphite/Graphitic Carbon Nitride Hybrids as Halogen-Free Flame Retardants for Polyamide 6. Polymers, 12(10), 2323. https://doi.org/10.3390/polym12102323