Abstract

The cast nickel-based superalloy K417G exhibits excellent high-temperature strength, but non-equilibrium solidification during casting can cause defects such as irreparable interdendritic microporosity, which significantly degrades its fatigue and creep properties. This study uses hot isostatic pressing (HIP) to eliminate internal flaws such as porosity in the K417G alloy, aiming to improve its mechanical properties. We investigated the microstructure and mechanical properties of K417G under two thermal conditions: solution heat treatment (SHT) and hot isostatic pressing (HIP). The results indicate that HIP significantly reduces microporosity. Compared to SHT, HIP improves the mechanical performance of K417G. The creep fracture mechanism shifts from intergranular brittle fracture (SHT) to ductile fracture (HIP). Consequently, HIP increases the alloy′s creep life approximately threefold and raises its fatigue limit by about 20 MPa. This improvement is attributed to pore density reduction, which decreases stress concentration zones and homogenizes the microstructure, thereby impeding fatigue crack nucleation and extending the crack incubation period.

1. Introduction

Superalloys serve as indispensable materials for critical hot-section components in aero-engines, particularly in the manufacturing process of high-pressure compressor blades and turbine blades []. These materials must operate continuously under extreme thermal conditions (600~1300 °C) while withstanding complex mechanical loads, including creep and high/low cycle fatigue []. Enhancing their mechanical properties can affect key performance metrics of aero-engines, such as their thrust-to-weight ratio and fuel efficiency, and ultimately determine the operational reliability and service life of engine assemblies [].

Titanium alloys serve as critical structural materials in modern aero-engines. However, their work temperature is limited to 540 °C, which is significantly lower than that of nickel-based superalloys [,,,]. Nickel-based superalloys demonstrate superior thermal tolerance, primarily reinforced by thermally stable γ′ phases with L12-type ordered structures []. These nanoscale γ′ precipitates maintain excellent stability above 700 °C, providing coherent strengthening that enhances the alloy′s resistance at elevated temperatures []. Nevertheless, solidification-induced microporosity defects arise from restricted interdendritic liquid feeding during casting, where residual melt becomes entrapped between primary dendrite arms. Such defects substantially degrade the alloy2032s high-temperature creep resistance and fatigue performance [,,].

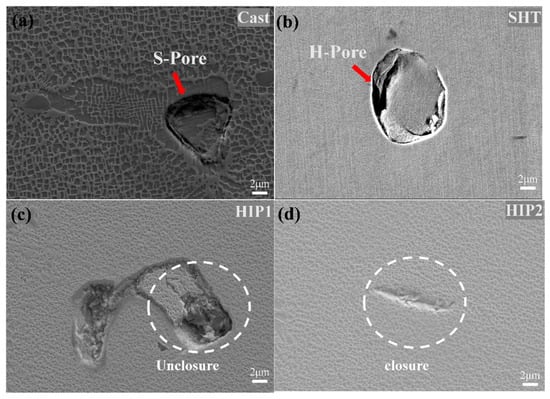

Due to the rapid solidification rate of high-temperature alloy castings, porosity is currently the most common defect in cast equiaxed crystal high-temperature alloys [,]. Micropores can be categorized into two types: shrinkage pores (S-pores) formed during the casting process [], and soluble pores (H-pores) generated during heat treatment []. Bortoluci Ormastroni et al. investigated the low-cycle fatigue (LCF) behavior of third-generation nickel-based SX superalloys at 650 °C. They found that when fatigue cycles exceed 103, the crack initiation points are primarily located at the micropores within the alloy []. Controlling the size of micropores has become a fundamental method to improve the fatigue life of nickel-based SX superalloys. Introducing the hot isostatic pressing (HIP) process into the heat treatment sequence is an effective way to reduce the porosity of nickel-based SX superalloys []. Roncery et al. applied HIP treatment (above the γ′ phase dissolution temperature) to the ERBO alloy, resulting in a significant reduction in porosity []. At present, the research on K417G superalloy primarily focuses on the control of solidification process and the influence of conventional heat treatment on creep properties [,,,]. However, comparatively little attention has been directed toward its fatigue behavior under high-speed rotational conditions, where the material is subjected to complex fatigue deformation induced by rotating bending stresses. Among the microstructural factors, porosity plays a critical role in degrading both creep and fatigue performance. Consequently, exploring the influence of hot isostatic pressing (HIP) on the intermediate-temperature mechanical behavior and clarifying the underlying mechanisms of pore closure in K417G is of considerable scientific and engineering significance.

This work investigated the microstructure and mechanical properties of K417G superalloy under solution-treated and hot isostatically pressed conditions. Microstructural characterization revealed critical variations in porosity features across different processing states. Subsequently, the creep performance at 760 °C/650 MPa and the intermediate-temperature fatigue behavior at 760 °C were evaluated. Fractographic analysis was conducted to elucidate the underlying mechanisms responsible for the observed variations in mechanical performance. It will help to optimize the heat treatment scheme with HIP and improve the fatigue properties of nickel-based superalloys.

2. Materials and Methods

2.1. Materials

The K417G nickel-based cast superalloy contains 9.95% Co, 5.26% Al, 9.08% Cr, 4.38% Ti, 2.97% Mo, 0.066% Zr, 0.74% V, 0.16% C, and 0.017% B, with Ni as balance (wt.%). One set of specimens underwent solution heat treatment exclusively at 1240 °C for 4 h, followed by air cooling, and these resulting samples are designated as “SHT.” To elucidate the individual effects of pressure and temperature on microporosity healing, as-cast specimens were subsequently subjected to hot isostatic pressing (HIP) under two distinct conditions: 1180 °C at 160 MPa for 4 h (designated HIP1, serving as the control group) and 1240 °C at 160 MPa for 4 h (designated HIP2).

2.2. Methods

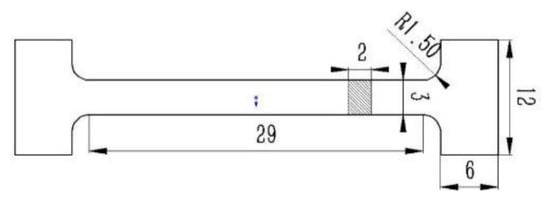

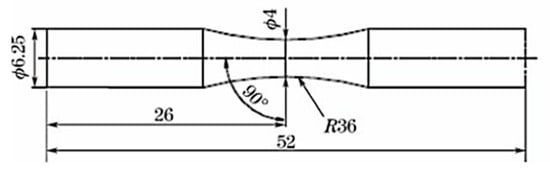

Creep testing was conducted using CTM-series elevated-temperature creep rupture testing systems, equipped with a three-zone temperature monitoring system. Specimens were thermally stabilized (10 min holding at target temperature) before load application, and data was acquired at 5 min−1 intervals until fracture. The geometry of the creep specimen is shown in Figure 1. High-cycle rotational bending fatigue tests were performed on machined specimens (Figure 2) using a QWP-10000 rotating-beam fatigue testing machine. The fatigue endurance limit (107 cycles) was determined using the staircase method under 760 °C testing conditions with a sinusoidal waveform (stress ratio R = −1) at a rotational speed of 5000 r/min.

Figure 1.

Dimension (in mm) of the specimens used in the creep test at 760 °C/650 MPa.

Figure 2.

Dimension (in mm) of the specimens used in the high-cycle rotating bending fatigue test at 760 °C.

For microstructural investigation, metallographic specimens were mechanically polished and chemically etched in a solution containing 20 mL H2O, 20 mL HCl, and 5 g CuSO4. Microstructural characterization was performed using optical microscopy (OM) and scanning electron microscopy (SEM, FEI Quanta 450) to examine micropores, cracks, and γ′ precipitates. Quantitative analysis of micropore volume fraction and size distribution was conducted through statistical evaluation of micrographs using Image-J 1.54g software.

3. Results and Discussion

3.1. The Influence of HIP on the Microstructure of K417G Alloy

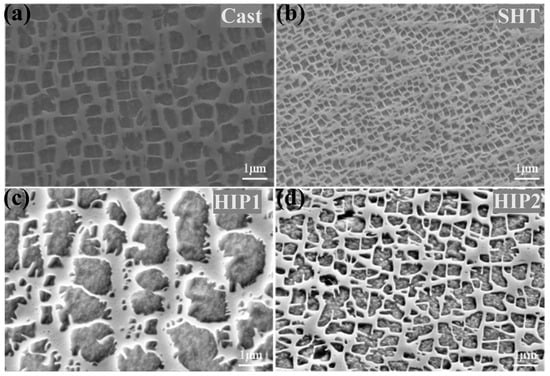

Figure 3a–d illustrate the morphological evolution and quantitative variations of γ′ precipitates in dendrite core regions across different processing states of K417G, with corresponding dimensional and volumetric data summarized in Table 1. The as-cast microstructure exhibited interconnected near-cubic γ′ precipitates with heterogeneous sizes averaging 316 nm. Solution heat treatment (SHT) produced uniformly distributed cubic γ′ precipitates showing significant size refinement (119 nm average). After the HIP1 treatment at 1180 °C, coarsening of the γ′ phase was observed, accompanied by the distinct precipitation of tertiary γ′ within the γ channels. In contrast, the HIP2 treatment at 1240 °C resulted in an average γ′ phase size of 331 nm, which was comparable to that of the as-cast alloy. Particularly, all four states maintained comparable γ′ volume fractions approximating 55%, despite substantial morphological variations.

Figure 3.

The transformation of the γ′ phase in the microstructure of K417G alloy. (a) Cast; (b) SHT, 1240 °C/4 h; (c) HIP1, 1180 °C/160 MPa/4 h; (d) HIP2, 1240 °C/160 MPa/4 h.

Table 1.

The size and volume fraction of the γ′ phase in K417G.

The dimensional characteristics and morphological distribution of γ′ phases are strongly influenced by thermal processing parameters, including temperature, pressure, and cooling rate []. Typically, γ′ precipitate dimensions are governed by cooling kinetics, showing an inverse relationship between particle size and cooling velocity. Following standard solution heat treatment with air cooling, the rapid thermal dissipation promotes the precipitation of refined γ′ phases. In contrast, furnace cooling after hot isostatic pressing (HIP) enables γ′ coalescence and coarsening through prolonged thermal exposure, resulting in heterogeneous γ′ morphologies with enlarged dimensions (Figure 3c). Comparative analysis reveals that HIP1-treated specimens (1180 °C) contain coarser γ′ precipitates than HIP2-processed counterparts (1240 °C), as shown in Figure 3c,d. This phenomenon is attributed to incomplete γ′ dissolution during HIP1 treatment, where residual precipitates merge with newly formed phases during subsequent cooling. The experimental findings confirm that accelerated cooling rates suppress γ′ growth through kinetic constraints, while gradual cooling facilitates particle coarsening. Moreover, higher HIP temperatures (HIP2 at 1240 °C) enable near-complete dissolution of γ′ phases, facilitating homogeneous reprecipitation during controlled cooling with improved dimensional uniformity (Figure 3d).

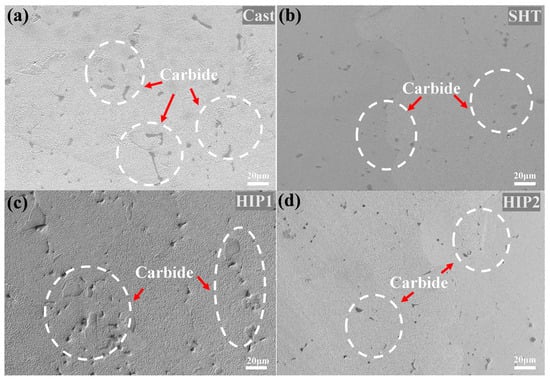

Figure 4 displays the carbide microstructures of K417G alloy after various treatments. In Figure 4a, the as-cast microstructure shows carbides in the form of blocky and fine rod-like shapes, with some carbides connected to the eutectic structure. After solution heat treatment (SHT), the eutectic structure almost disappears, and the carbide size is significantly reduced (Figure 4b). As shown in Figure 4c, following HIP1 treatment, large carbides connected to the eutectic structure can be observed due to the relatively low HIP1 temperature. When the hot isostatic pressing temperature is increased to 1240 °C (HIP2), the carbide size is noticeably smaller compared to the as-cast condition, and the carbide morphology is similar to that after SHT, presenting as blocky and elongated shapes (Figure 4d).

Figure 4.

The transformation of the carbide in the microstructure of K417G alloy. (a) Cast; (b) SHT, 1240 °C/4 h; (c) HIP1, 1180 °C/160 MPa/4 h; (d) HIP2, 1240 °C/160 MPa/4 h.

Figure 5a–d display the typical micropores in K417G under various processing conditions. Untreated specimens exhibit substantial porosity distributed throughout the matrix. In the as-cast microstructure (Figure 5a), pore density varies regionally with preferential accumulation at interdendritic zones, particularly near γ/γ′ eutectic tails and grain boundary junctions. As shown in Figure 5b, after the solution treatment, the specimens exhibited micropores with edges integrated into the matrix and surfaces that were visibly collapsed inward. After HIP 1 treatment, the micropores were not completely closed. In contrast, the samples treated with HIP 2 showed a significant closure of micropores, as exhibited in Figure 5c,d. During the HIP treatment process, the primary means of eliminating micropores is pore closure caused by pressure.

Figure 5.

The typical micropores in K417G alloys under different conditions. (a) Cast; (b) SHT, 1240 °C/4 h; (c) HIP1, 1180 °C/160 MPa/4 h; (d) HIP2, 1240 °C/160 MPa/4 h.

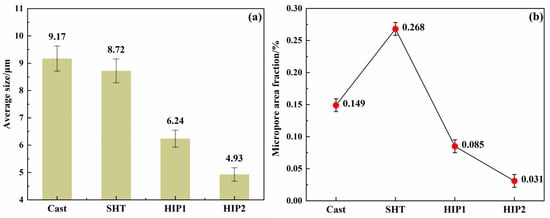

The statistical results in Figure 6 show a significant increase in the porosity area fraction and a higher proportion of large-diameter pores in the K417G alloy after solution heat treatment (SHT). This phenomenon can be attributed to the Kirkendall effect, where elements with different diffusion rates form new pores during SHT, leading to a substantial increase in porosity. After hot isostatic pressing (HIP) at 1180 °C/160 MPa/4 h (HIP1), the number of pores in the K417G alloy was significantly reduced, with the equivalent average diameter of remaining unclosed pores decreasing from 9 μm to 6 μm (Figure 6). However, some pores were still incompletely closed. In contrast, HIP treatment at 1240 °C/160 MPa/4 h (HIP 2) led to a significant reduction in porosity, with the pore area fraction decreasing to 0.031%. Compared with the as-cast specimen, the number of large-diameter pores was significantly reduced, and the pore closure rate reached 79.2%. Comparing SHT and HIP2 results, it is evident that the application of isostatic pressure at the same temperature significantly reduces porosity, indicating that pressure can effectively close both casting- and solution-induced pores at 1240 °C. Comparing HIP1 and HIP2, it is clear that at a constant pressure, higher temperatures lead to more effective pore closure, with microvoids being essentially closed.

Figure 6.

The micropores parameters of K417G alloys under different conditions. (a) Average size; (b) micropore area fraction.

The chemical composition critically governs the microstructural characteristics and mechanical performance of the K417G superalloy. With 9.95 wt% Co and comparatively lower refractory element content (2.97 wt% Mo), this alloy contains 4.38 wt% Ti as the primary γ′-forming element. In conventional alloy design, solution-strengthening elements (Co, W, Mo) enhance atomic bonding strength and increase diffusion activation energy, thereby impeding elemental migration during thermal exposure [,]. Titanium preferentially substitutes for a portion of Al in the γ matrix, reducing Al solubility and promoting γ′ precipitation through enhanced lattice misfit. This substitution mechanism facilitates coherent γ/γ′ interface formation while maintaining the thermodynamic stability of the strengthening phase.

Wasielewski et al. proposed that the HIP process involves a coupled creep-diffusion mechanism []. Applied stress initially induces creep deformation around pores, causing pore contraction and surface contact, followed by diffusion bonding. Figure 5 demonstrates that under identical thermal conditions, isostatic pressure effectively reduces casting-induced microporosity while suppressing pore formation during solution treatment, significant pore closure morphology was observed after HIP. The elliptical pore in K417G alloy (Figure 5d) exhibits characteristic shrinkage features after HIP treatment, showing narrowed tips and sharpened morphology. This suggests a sequential healing mechanism: pressure-induced plastic flow facilitates pore surface contact, succeeded by diffusion bonding [,]. Figure 6 reveals lower porosity in HIP2-treated specimens compared to HIP1 under identical pressure, attributable to enhanced γ′ phase dissolution at elevated temperatures which promotes creep deformation near pores. Isostatic pressure remains the dominant factor contributing to microdefect elimination in HIP technology [].

3.2. The Effect of HIP on Mechanical Properties at 760 °C

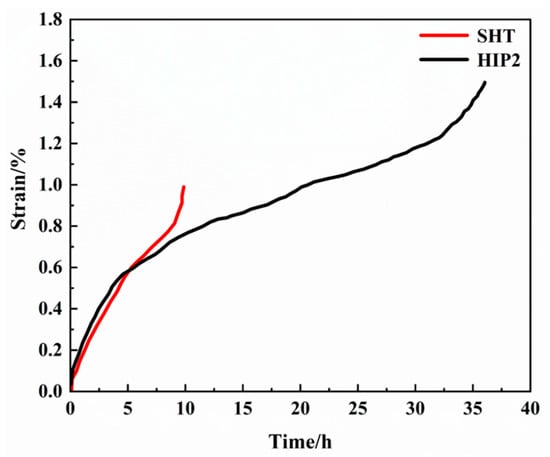

Figure 7 compares the creep performance of HIP-treated and solution-treated specimens under 760 °C/650 MPa conditions. The HIP-processed K417G alloy demonstrates superior creep resistance with a rupture life of 36.5 h and elongation of 1.6%, In contrast, the solution-treated specimens displays significantly reduced performance (9.9 h rupture life, 1.0% elongation). HIP treatment achieves remarkable improvements of 268.7% in creep duration and 60% in elongation compared to solution heat-treated specimens.

Figure 7.

Creep strain–time curves for the K417G specimens at 760 °C/650 MPa.

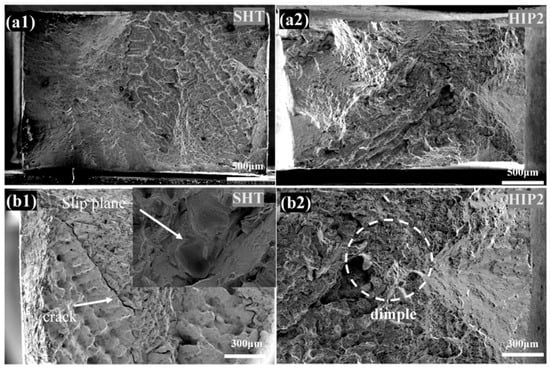

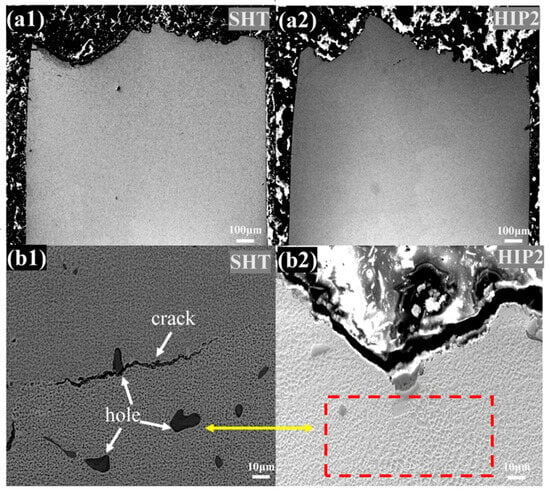

As shown in Figure 8b1, the solution-treated K417G alloy exhibited typical brittle fracture characteristics, with macro-fractography revealing distinct smooth shear zones and intergranular cracking. Micropores acted as stress concentration regions, promoting slip plane formation that interconnected with adjacent defects under loading. In contrast, HIP-treated specimens displayed a textured fracture surface with high-density dimple distribution, lacking intergranular fracture characteristics (Figure 8b2).

Figure 8.

The microscopic appearances of the creep fracture at 760 °C/650 MPa for K417G alloys. (a) The fracture surface; (b) the enlarged views of the fracture surface in (a). (1) SHT; (2) HIP2.

Under 760 °C/650 MPa creep conditions, micropores in stress concentration zones critically govern deformation behavior. Compared with the samples of HIP2, solution-treated specimens displays accelerated creep failure due to their higher porosity (Figure 6) and finer γ′ precipitates (Figure 3b). The reduced γ′ dimensions intensify matrix-strengthening effects, promoting stress concentration around pores and ultimately driving pore growth and coalescence. In addition, distinct intergranular cracking was observed in the specimens subjected to solution heat treatment (Figure 8b1). HIP-treated specimens demonstrate enhanced performance through dual mechanisms: porosity reduction minimizes stress concentration sites. Residual stress concentrations primarily localize at interdendritic carbides rather than pervasive pore networks, collectively contributing to superior creep resistance and fracture elongation.

Figure 9 presents the longitudinal section of a creep fracture. Microdefects in stress concentration zones are the main cause of alloy creep deformation. As shown in Figure 9b1, SHT samples have many pores and small γ′ phase sizes. This increases matrix creep deformation resistance, creating stress concentration areas around pores []. It leads to pore growth, coalescence, and sample fracture. Figure 9b2 shows that after hot isostatic pressing, pores are eliminated, there are larger γ′ phase sizes, and creep deformation resistance is reduced. Stress concentration is limited to interdendritic carbides; as such, HIP2 samples achieve creep performance and fracture elongation, significantly increasing the time to creep fracture (Figure 7).

Figure 9.

The microscopic appearances of the creep fracture at 760 °C/650 MPa for K417G alloys. (a) The longitudinal section of fracture surface; (b) the enlarged views of the fracture surface in (a). (1) SHT; (2) HIP2.

The creep data and fracture morphology indicate that the hot isostatic pressure fundamentally alters the creep fracture mechanism of the alloy under identical thermal processing conditions. Although solution heat treatment produces refined γ′ precipitates that effectively hinder dislocation motion within γ channels [], the creep rate of the SHT samples in the second stage of creep is significantly higher than that of HIP2 (Figure 7). This indicates that the increase in porosity has generated more stress concentration regions, and the solution-treated specimens demonstrate a notably shorter secondary creep stage, rapidly transitioning to the tertiary stage characterized by accelerated creep. During this stage, microvoids and the cavities formed by the separation of fragmented carbides from the matrix rapidly expanded and aggregated during this stage, leading to the formation of numerous microcracks. The interconnection of these microcracks eventually led to the fracture of the specimens. In contrast, HIP-treated specimens with densified microstructures enter the steady-state creep phase more rapidly, maintaining lower steady-state creep rates. According to the studies of Dunne et al. [], Mughrabi et al. [,], Cheong and Busso [] and Manonukul and Dunne [], the accumulation of plastic slip is the main cause of crack initiation. It can lead to different incompatible shape changes in neighboring grains, which impels intergranular crack initiation. These microcracks interconnect with cavities generated by carbide fragmentation and interfacial separation at healed pore sites, ultimately developing slip-induced fracture morphology.

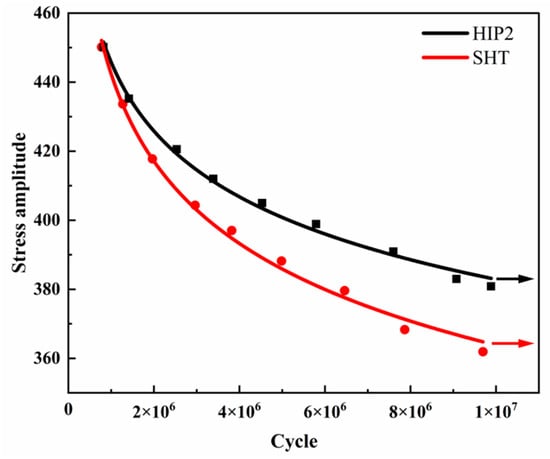

Fatigue failure constitutes a predominant failure mode in aero-engine turbine blades [,,]. This operational reality necessitates systematically evaluating the K417G superalloy′s fatigue performance across different processing states to elucidate heat treatment effects. Figure 10 presents rotating bending fatigue S-N curves for smooth specimens, demonstrating a strong correlation between applied stress and fatigue life. At 450 MPa, minimal life disparity exists between solution heat-treated (SHT) and hot isostatically pressed (HIP2) specimens. However, significant divergence emerges with decreasing stress levels: SHT specimens withstand over 1.0 × 107 cycles without fracture at 360 MPa, while HIP-treated counterparts achieve their fatigue limit (≥1.0 × 107 cycles) at 380 MPa, achieving a 20 MPa enhancement in fatigue endurance limit through HIP treatment (Figure 10).

Figure 10.

The 760 °C S-N curves of K417G alloys in HIP and SHT conditions.

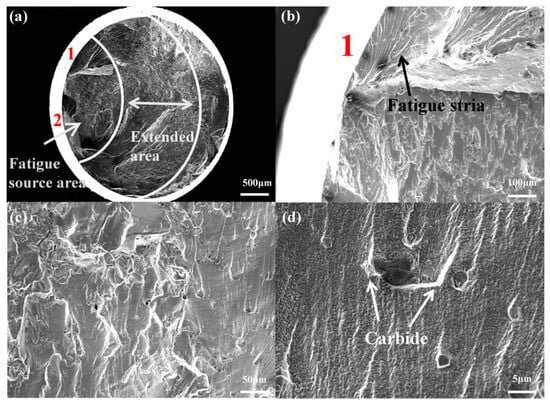

Figure 11 displays the fatigue fracture surface of HIP-treated K417G alloy under 760 °C/380 MPa cycling. As shown in Figure 11b, region 1 shows the primary crack initiation region located at the specimen surface. Region 2 displays a smaller crack origin containing microporosity with limited propagation morphology. Both initiation sites are near the surface, developing riverine propagation patterns toward the specimen center before terminating in final rupture zones. The crack propagation area exhibits characteristic flow obstruction patterns formed by carbide interactions during crack advancement. All fracture regions contain discernible microdefects accompanied by localized rough tear ridges, indicative of accelerated crack propagation mechanisms.

Figure 11.

The fatigue fracture morphology of K417G alloy at 760 °C/380 MPa. (a) Macroscopic morphology of the fracture; (b) the enlarged views of the fatigue source area; (c) extended area; (d) carbide.

As shown in Figure 11a,b, cracks in the alloy samples after hot isostatic pressing predominantly nucleate at the surface or near-surface stress concentration sites, consistent with the findings of most studies []. These cracks then propagate inward under cyclic loading until a critical threshold is reached, leading to sample fracture and the formation of a tearing structure. The presence of carbides, which form a blocking waveform, indicates that they impede crack propagation [], thereby enhancing fatigue life during the crack growth stage (Figure 11c,d). Pores tend to widen the spacing between fatigue striations, thereby accelerating the fatigue fracture of the alloy.

After hot isostatic pressing, the reduction in porosity makes the internal microstructure more continuous []. This reduces stress concentration zones during service, prolongs the time required for crack initiation, and enhances fatigue life, as the majority of fatigue life is consumed during the crack initiation stage []. Carbides and smaller micropores become new sources of crack initiation, further extending the fatigue life of the K417G alloy. Additionally, the decreased density of defects such as pores and porosity slows down crack propagation compared to solution-treated specimens, significantly increasing the fatigue life.

4. Conclusions

This study investigates the effects of hot isostatic pressing (HIP) on the microstructure and mechanical properties of K417G nickel-based superalloys. The micropores characteristics of the alloy under different heat treatment conditions were observed and analyzed. Furthermore, the effects of SHT and HIP on creep and rotating bending fatigue properties were comprehensively analyzed, with particular focus on the correlation between micropores and mechanical performance. The following conclusions were obtained:

HIP can dramatically reduce the size and fraction of micropores within the K417G alloy, and healing efficacy is positively correlated with processing temperature. Compared to the as-cast condition, HIP treatment at 1240 °C/160 MPa achieves a pore closure rate of 79.2% in the K417G alloy.

The HIP significantly enhances the mechanical performance of the alloy. The K417G alloy exhibits a 268.7% improvement in creep life and a 60.0% increase in elongation compared to its solution-treated state. While intergranular fracture dominates in solution-treated specimens, HIP-induced pore reduction restricts rapid crack propagation pathways, resulting in ductile fracture as the predominant failure mechanism.

Microstructural defects critically influence the rotating bending fatigue behavior of the K417G alloy. Pores near the surface of K417G alloy create stress concentration zones, leading to crack initiation. After HIP treatment, the fatigue limit of the alloy was increased from 360 MPa to 380 MPa, which is attributed to the reduction in porosity, resulting in fewer stress concentration areas, an extended crack initiation time, and improved fatigue performance.

Author Contributions

Conceptualization, Y.W. and F.W.; Methodology, Y.Z. and W.G.; Software, Z.Y.; Validation, Y.W., F.W. and H.Z.; Formal Analysis, Y.W.; Investigation, Y.Z.; Resources, H.Z.; Data Curation, J.J.; Writing—Original Draft Preparation, Y.W. and F.W.; Writing—Review and Editing, Y.W.; Visualization, Y.W.; Supervision, H.Z.; Project Administration, W.G. and S.L.; Funding Acquisition, H.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This work is financially supported by the National Key Research and Development Program of China (No. 2023YFB3712100) and National Natural Science Foundation (No. 52301126).

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Acknowledgments

The authors would like to acknowledge the supports provided by Research Institute of Aero-Engine, Beihang University.

Conflicts of Interest

Author Jinghui Jia was employed by the company Gui Yang AECC Power Precision Casting Co., Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Gudivada, G.; Pandey, A.K. Recent developments in nickel-based superalloys for gas turbine applications: Review. J. Alloys Compd. 2023, 963, 171128. [Google Scholar] [CrossRef]

- Reed, R.C. The Superalloys: Fundamentals and Applications; Cambridge University Press: Cambridge, UK, 2008. [Google Scholar]

- Zhao, B.; Wang, Y.; Peng, J.; Wang, X.; Ding, W.; Lei, X.; Wu, B.; Zhang, M.; Xu, J.; Zhang, L. Overcoming challenges: Advancements in cutting techniques for high strength-toughness alloys in aero-engines. Int. J. Extrem. Manuf. 2024, 6, 062012. [Google Scholar] [CrossRef]

- Ebach-Stahl, A.; Eilers, C.; Laska, N.; Braun, R. Cyclic oxidation behaviour of the titanium alloys Ti-6242 and Ti-17 with Ti–Al–Cr–Y coatings at 600 and 700 C in air. Surf. Coat. Technol. 2013, 223, 24–31. [Google Scholar] [CrossRef]

- Satko, D.P.; Shaffer, J.B.; Tiley, J.S.; Semiatin, S.L.; Pilchak, A.L.; Kalidindi, S.R.; Kosaka, Y.; Glavicic, M.G.; Salem, A.A. Effect of microstructure on oxygen rich layer evolution and its impact on fatigue life during high-temperature application of α/β titanium. Acta Mater. 2016, 107, 377–389. [Google Scholar] [CrossRef]

- Berthaud, M.; Popa, I.; Chassagnon, R.; Heintz, O.; Lavková, J.; Chevalier, S. Study of titanium alloy Ti6242S oxidation behaviour in air at 560 C: Effect of oxygen dissolution on lattice parameters. Corros. Sci. 2020, 164, 108049. [Google Scholar] [CrossRef]

- Gialanella, S.; Malandruccolo, A.; Gialanella, S.; Malandruccolo, A. Titanium and titanium alloys. In Aerospace Alloys; Springer: Berlin/Heidelberg, Germany, 2020; pp. 129–189. [Google Scholar]

- Fecht, H.; Furrer, D. Processing of Nickel—Base Superalloys for Turbine Engine Disc Applications. Adv. Eng. Mater. 2000, 2, 777–787. [Google Scholar] [CrossRef]

- Lee, H.-T.; Hou, W.-H. Development of fine-grained structure and the mechanical properties of nickel-based Superalloy 718. Mater. Sci. Eng. A 2012, 555, 13–20. [Google Scholar] [CrossRef]

- Lamm, M.; Singer, R. The effect of casting conditions on the high-cycle fatigue properties of the single-crystal nickel-base superalloy PWA 1483. Metall. Mater. Trans. A 2007, 38, 1177–1183. [Google Scholar] [CrossRef]

- Cervellon, A.; Cormier, J.; Mauget, F.; Hervier, Z. VHCF life evolution after microstructure degradation of a Ni-based single crystal superalloy. Int. J. Fatigue 2017, 104, 251–262. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, X.; Li, J.; Cheng, Y.; Yang, Y.; Meng, J.; Liu, J.; Liu, J.; Zhou, Y.; Sun, X. The low-cycle fatigue deformation mechanisms of two single crystal superalloys at room temperature and 600 °C. Scr. Mater. 2019, 171, 122–125. [Google Scholar] [CrossRef]

- Roncery, L.M.; Lopez-Galilea, I.; Ruttert, B.; Bürger, D.; Wollgramm, P.; Eggeler, G.; Theisen, W. On the effect of hot isostatic pressing on the creep life of a single crystal superalloys. Adv. Eng. Mater. 2016, 18, 1381–1387. [Google Scholar] [CrossRef]

- Epishin, A.; Camin, B.; Hansen, L.; Schmidt, J. Synchrotron 3D μ-Tomography of Porosity during Hot Isostatic Pressing of a Single-Crystal Nickel-Base Superalloy. In Proceedings of the Materials Science Forum, Edinburgh, UK, 4–6 November 2021; pp. 102–106. [Google Scholar]

- Whitesell III, H.S. Influence of Solidification Variables on the Cast Microstructure and Porosity in Directionally Solidified Mar-M247; Auburn University: Auburn, AL, USA, 2002. [Google Scholar]

- Bokstein, B.; Epishin, A.; Link, T.; Esin, V.; Rodin, A.; Svetlov, I. Model for the porosity growth in single-crystal nickel-base superalloys during homogenization. Scr. Mater. 2007, 57, 801–804. [Google Scholar] [CrossRef]

- Ormastroni, L.M.B.; Suave, L.M.; Cervellon, A.; Villechaise, P.; Cormier, J. LCF, HCF and VHCF life sensitivity to solution heat treatment of a third-generation Ni-based single crystal superalloy. Int. J. Fatigue 2020, 130, 105247. [Google Scholar]

- Zhao, Y.; He, S.; Li, L. Application of hot isostatic pressing in nickel-based single crystal superalloys. Crystals 2022, 12, 805. [Google Scholar] [CrossRef]

- Roncery, L.M.; Lopez-Galilea, I.; Ruttert, B.; Huth, S.; Theisen, W. Influence of temperature, pressure, and cooling rate during hot isostatic pressing on the microstructure of an SX Ni-base superalloy. Mater. Des. 2016, 97, 544–552. [Google Scholar] [CrossRef]

- Li, X.; Wang, L.; Dong, J.; Lou, L. Effect of solidification condition and carbon content on the morphology of MC carbide in directionally solidified nickel-base superalloys. J. Mater. Sci. Technol. 2014, 30, 1296–1300. [Google Scholar] [CrossRef]

- Gong, L.; Chen, B.; Yang, Y.; Du, Z.; Liu, K. Effect of N content on microsegregation, microstructure and mechanical property of cast Ni-base superalloy K417G. Mater. Sci. Eng. A 2017, 701, 111–119. [Google Scholar] [CrossRef]

- Du, B.; Hu, Z.; Sheng, L.; Cui, C.; Yang, J.; Zheng, Y.; Sun, X. Tensile, creep behavior and microstructure evolution of an as-cast Ni-based K417G polycrystalline superalloy. J. Mater. Sci. Technol. 2018, 34, 1805–1816. [Google Scholar] [CrossRef]

- Gong, L.; Chen, B.; Du, Z.; Zhang, M.; Liu, R.; Liu, K. Investigation of solidification and segregation characteristics of cast Ni-base superalloy K417G. J. Mater. Sci. Technol. 2018, 34, 541–550. [Google Scholar] [CrossRef]

- Jackson, M.; Reed, R. Heat treatment of UDIMET 720Li: The effect of microstructure on properties. Mater. Sci. Eng. A 1999, 259, 85–97. [Google Scholar] [CrossRef]

- Cao, Z.; Jin, N.; Ye, J.; Zhuang, D.; Liu, Y. A first principles investigation on the solid solution behavior of transition metal elements (W, Mo, Ta, Cr) in Ti (C, N). Int. J. Refract. Met. Hard Mater. 2021, 99, 105605. [Google Scholar] [CrossRef]

- Gaag, T.; Ritter, N.; Peters, A.; Volz, N.; Gruber, D.; Neumeier, S.; Zenk, C.; Körner, C. Improving the effectiveness of the solid-solution-strengthening elements Mo, Re, Ru and W in single-crystalline nickel-based superalloys. Metals 2021, 11, 1707. [Google Scholar] [CrossRef]

- Wasielewski, G. Elimination of Casting Defects using HIP, Superalloy. In Proceedings of the Processing, Proceedings 2nd International Conference, Champion, PA, USA, 18–20 September 1972; pp. D1–D24. [Google Scholar]

- Epishin, A.; Fedelich, B.; Link, T.; Feldmann, T.; Svetlov, I.L. Pore annihilation in a single-crystal nickel-base superalloy during hot isostatic pressing: Experiment and modelling. Mater. Sci. Eng. A 2013, 586, 342–349. [Google Scholar] [CrossRef]

- Bokstein, B.S.; Epishin, A.; Esin, V.; Mendelev, M.; Rodin, A.; Zhevnenko, S. Cross diffusion-stresses effects. In Proceedings of the Defect and Diffusion Forum, Lillafüred, Hungary, 19–22 September 2007; pp. 79–89. [Google Scholar]

- Liu, G.; Cantó, J.S.; Birosca, S.; Wang, S.; Zhao, Y. A study of high cycle fatigue life and its correlation with microstructural parameters in IN713C nickel-based superalloy. Mater. Sci. Eng. A 2023, 877, 145161. [Google Scholar] [CrossRef]

- Coyne-Grell, A.; Blaizot, J.; Rahimi, S.; Violatos, I.; Nouveau, S.; Dumont, C.; Nicolaÿ, A.; Bozzolo, N. Recrystallization mechanisms and associated microstructure evolution during billet conversion of a gamma-gamma′ nickel based superalloy. J. Alloys Compd. 2022, 916, 165465. [Google Scholar] [CrossRef]

- Dunne, F.P.E.; Wilkinson, A.J.; Allen, R. Experimental and computational studies of low cycle fatigue crack nucleation in a polycrystal. Int. J. Plast. 2007, 23, 273–295. [Google Scholar] [CrossRef]

- Mughrabi, H. Dislocations in fatigue. In Dislocations and Properties of Real Materials; Institute of Metals: London, UK, 1984; pp. 244–262. [Google Scholar]

- Mughrabi, H. Microstructural fatigue mechanisms: Cyclic slip irreversibility, crack initiation, non-linear elastic damage analysis. Int. J. Fatigue 2013, 57, 2–8. [Google Scholar] [CrossRef]

- Cheong, K.-S.; Busso, E.P. Effects of lattice misorientations on strain heterogeneities in FCC polycrystals. J. Mech. Phys. Solids 2006, 54, 671–689. [Google Scholar] [CrossRef]

- Manonukul, A.; Dunne, F.P.E. High–and low–cycle fatigue crack initiation using polycrystal plasticity. Proc. R. Soc. London Ser. A Math. Phys. Eng. Sci. 2004, 460, 1881–1903. [Google Scholar] [CrossRef]

- Pineau, A.; McDowell, D.L.; Busso, E.P.; Antolovich, S.D. Failure of metals II: Fatigue. Acta Mater. 2016, 107, 484–507. [Google Scholar] [CrossRef]

- Wang, R.; Zhang, B.; Hu, D.; Jiang, K.; Liu, H.; Mao, J.; Jing, F.; Hao, X. Thermomechanical fatigue experiment and failure analysis on a nickel-based superalloy turbine blade. Eng. Fail. Anal. 2019, 102, 35–45. [Google Scholar] [CrossRef]

- Han, L.; Huang, D.; Yan, X.; Chen, C.; Zhang, X.; Qi, M. Combined high and low cycle fatigue life prediction model based on damage mechanics and its application in determining the aluminized location of turbine blade. Int. J. Fatigue 2019, 127, 120–130. [Google Scholar] [CrossRef]

- Ranc, N.; Wagner, D.; Paris, P.C. Study of thermal effects associated with crack propagation during very high cycle fatigue tests. Acta Mater. 2008, 56, 4012–4021. [Google Scholar] [CrossRef]

- Al-Jarba, K.; Fuchs, G. Effect of carbon additions on the as-cast microstructure and defect formation of a single crystal Ni-based superalloy. Mater. Sci. Eng. A 2004, 373, 255–267. [Google Scholar] [CrossRef]

- He, S.; Li, L.; Zhao, Y.; An, W.; Lu, F.; Zhang, J.; Lu, S.; Cormier, J.; Feng, Q. Low-cycle fatigue behavior of a solution-treated and HIPped nickel-based single-crystal superalloy at 760 °C. Mater. Sci. Eng. A 2023, 881, 145369. [Google Scholar] [CrossRef]

- Hong, Y.; Lei, Z.; Sun, C.; Zhao, A. Propensities of crack interior initiation and early growth for very-high-cycle fatigue of high strength steels. Int. J. Fatigue 2014, 58, 144–151. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).