Low-Cycle Fatigue Behavior of Nuclear-Grade Austenitic Stainless Steel Fabricated by Additive Manufacturing

Abstract

1. Introduction

2. Materials and Methods

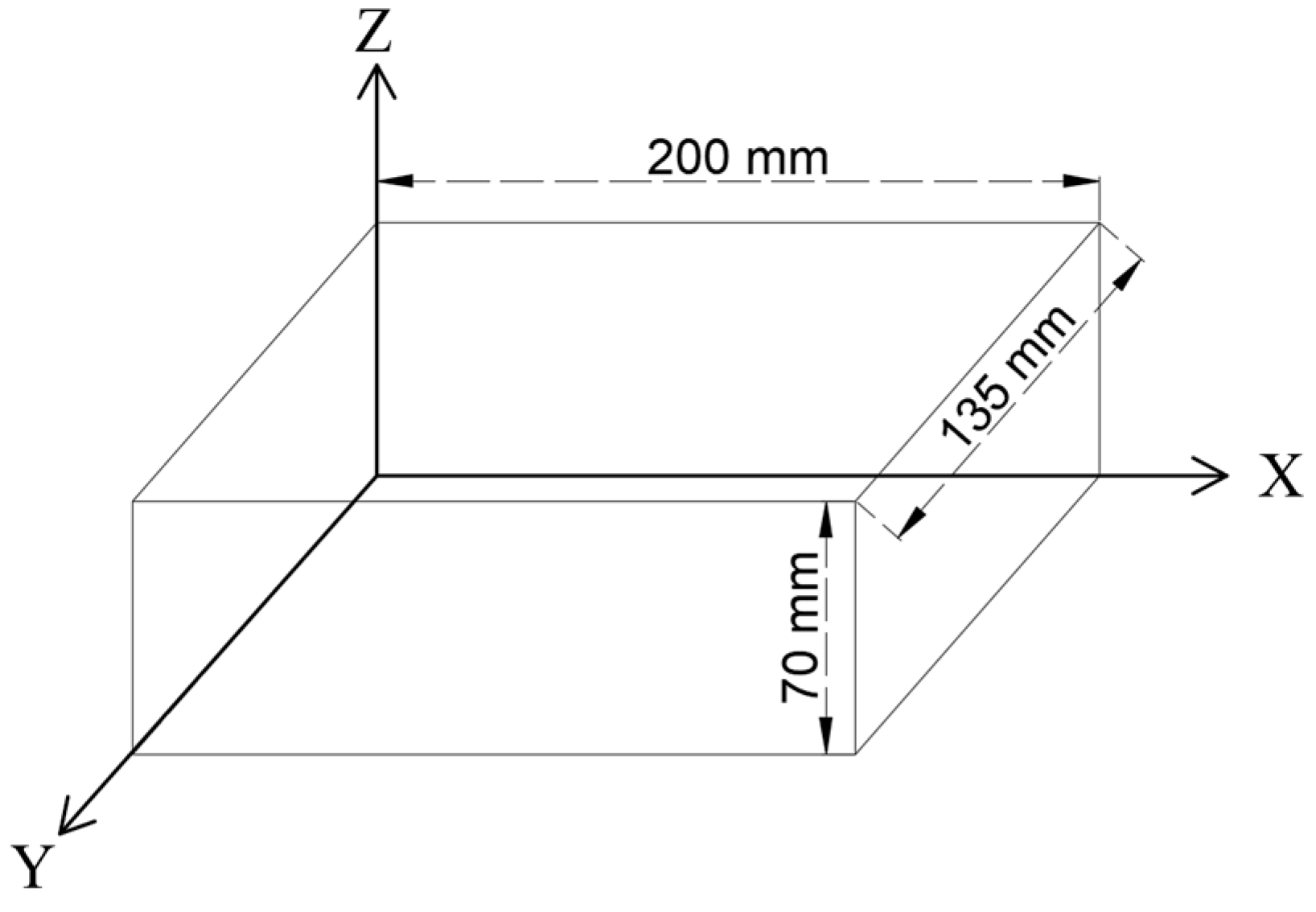

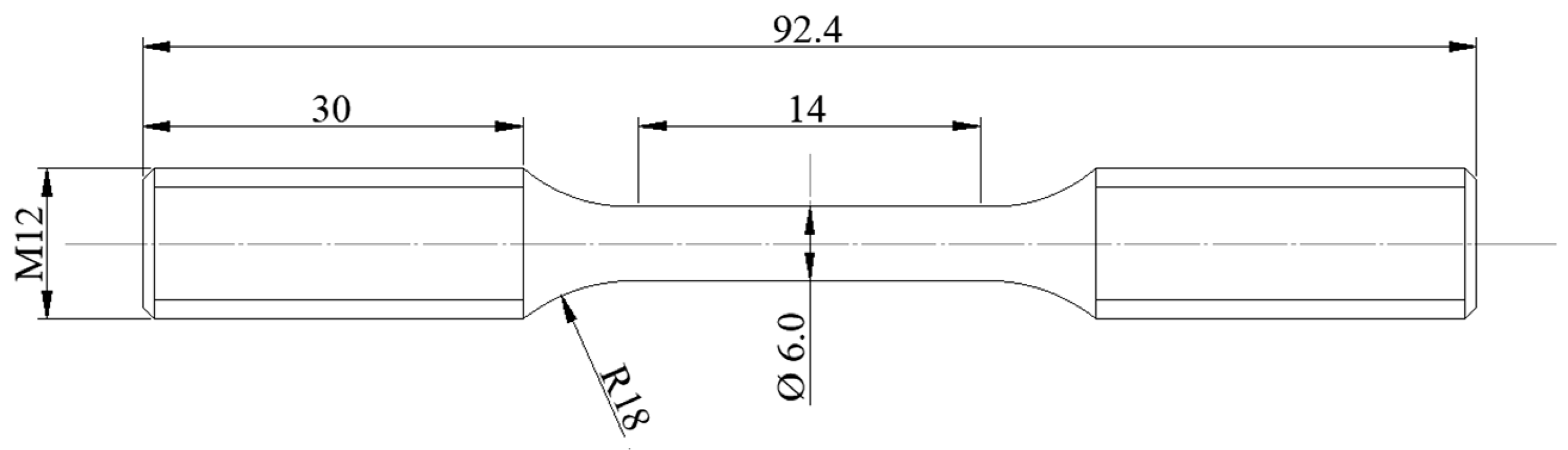

2.1. Materials

2.2. Methods

3. Results and Discussion

3.1. Microstructure and Mechanical Properties

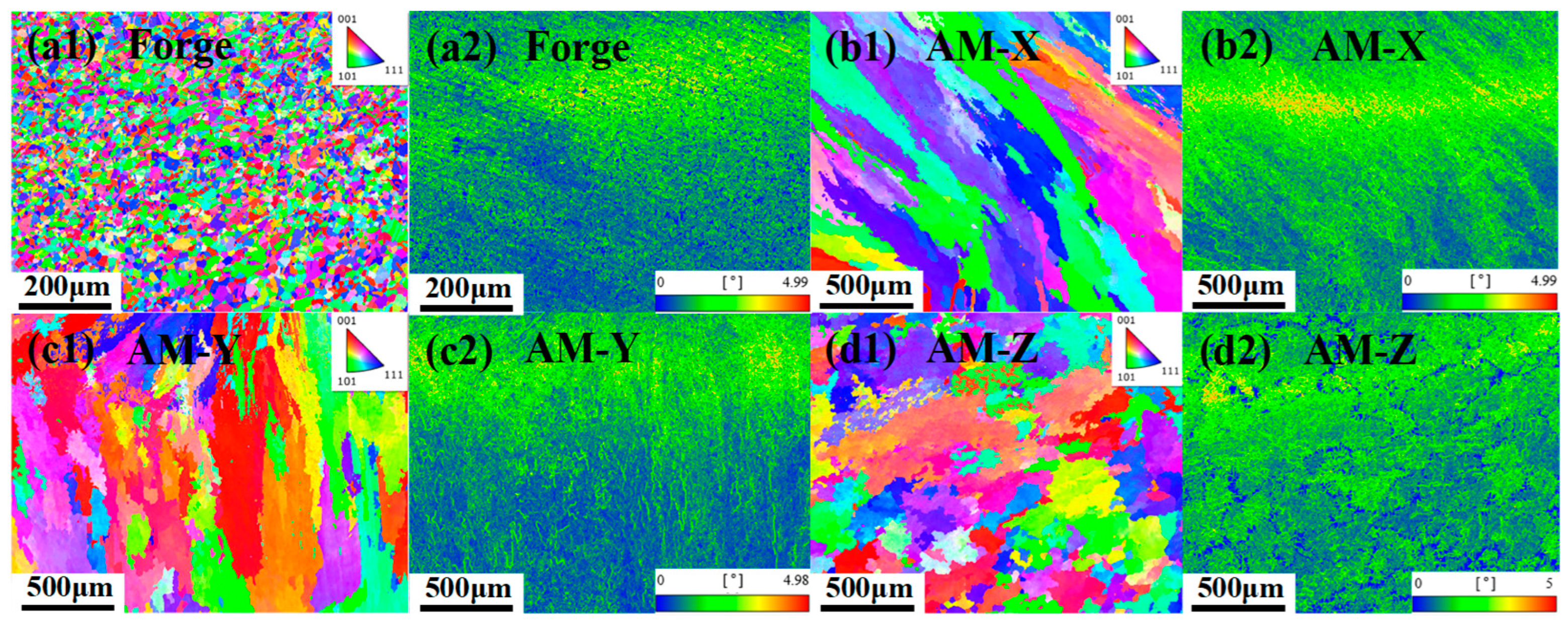

3.1.1. Microstructure

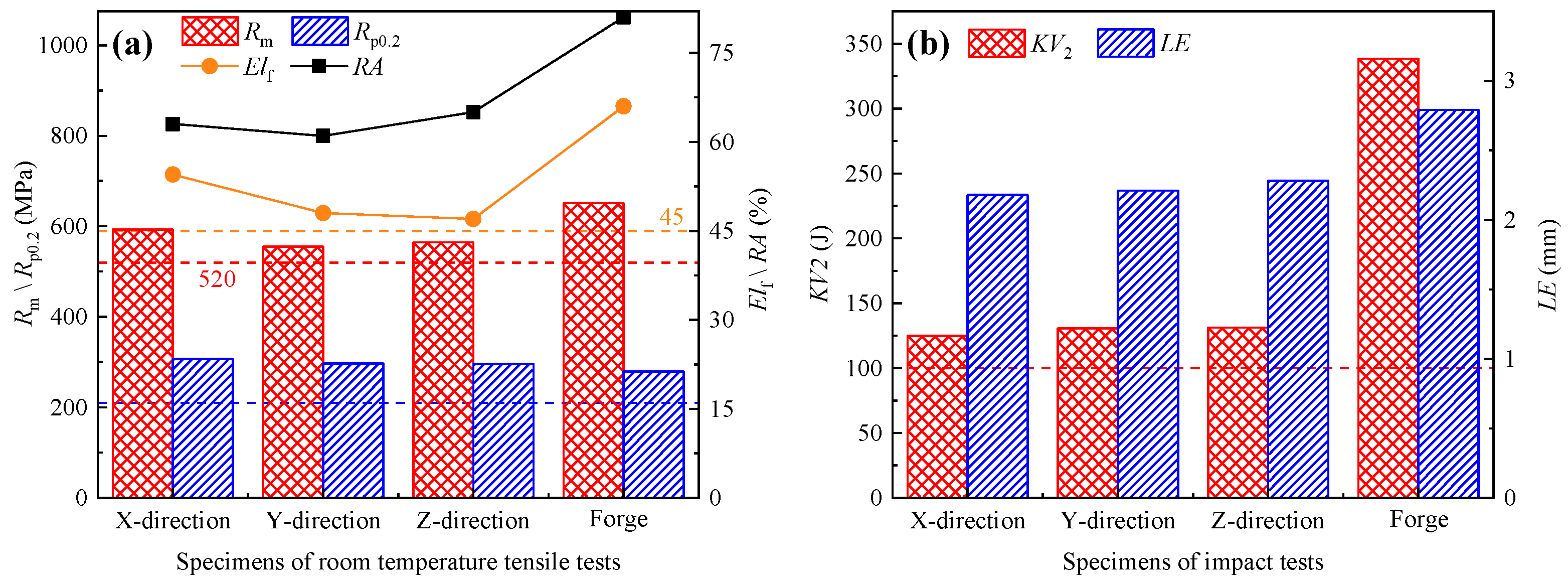

3.1.2. Mechanical Properties

3.2. Fatigue Behaviors

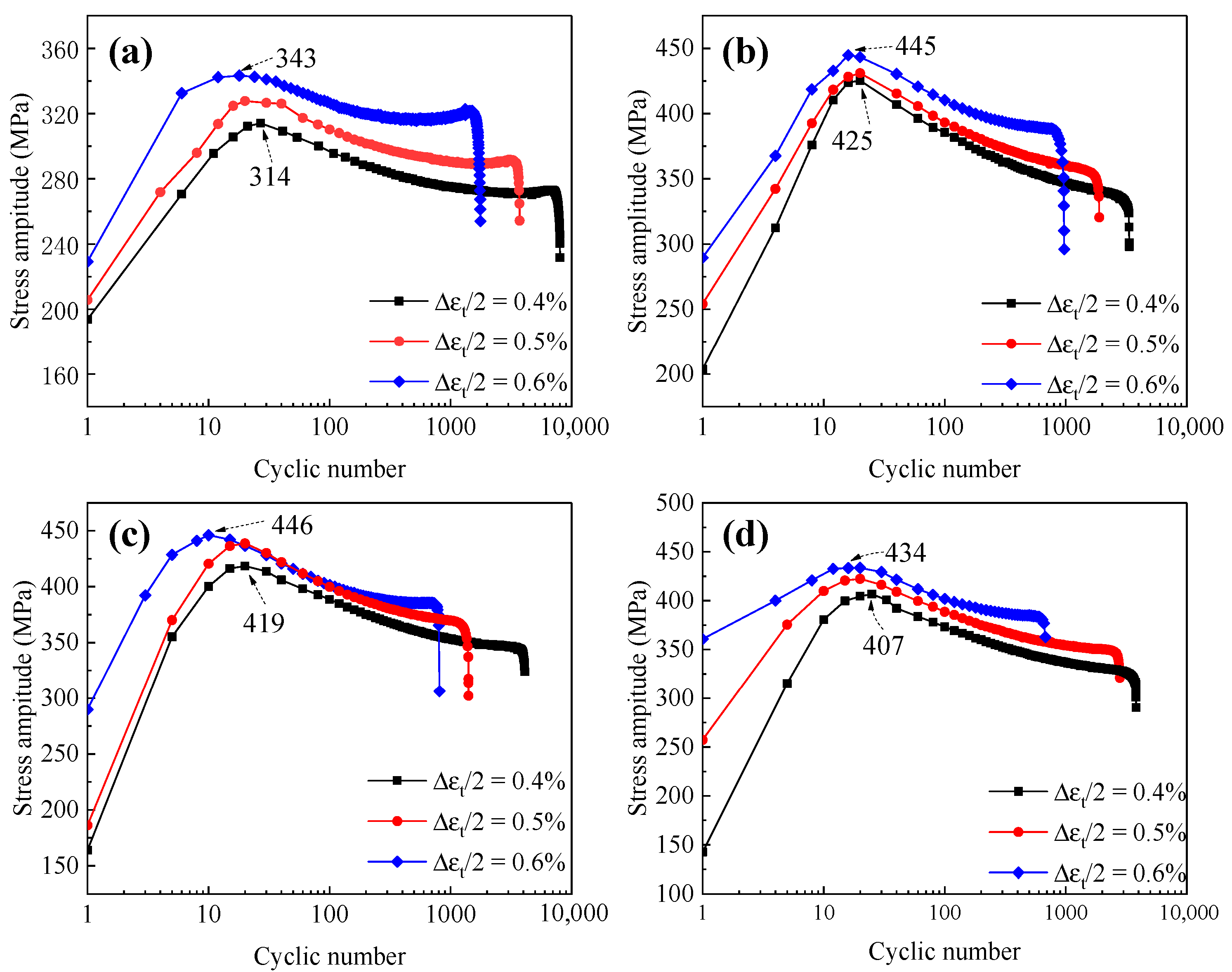

3.2.1. Cyclic Stress Response Curve

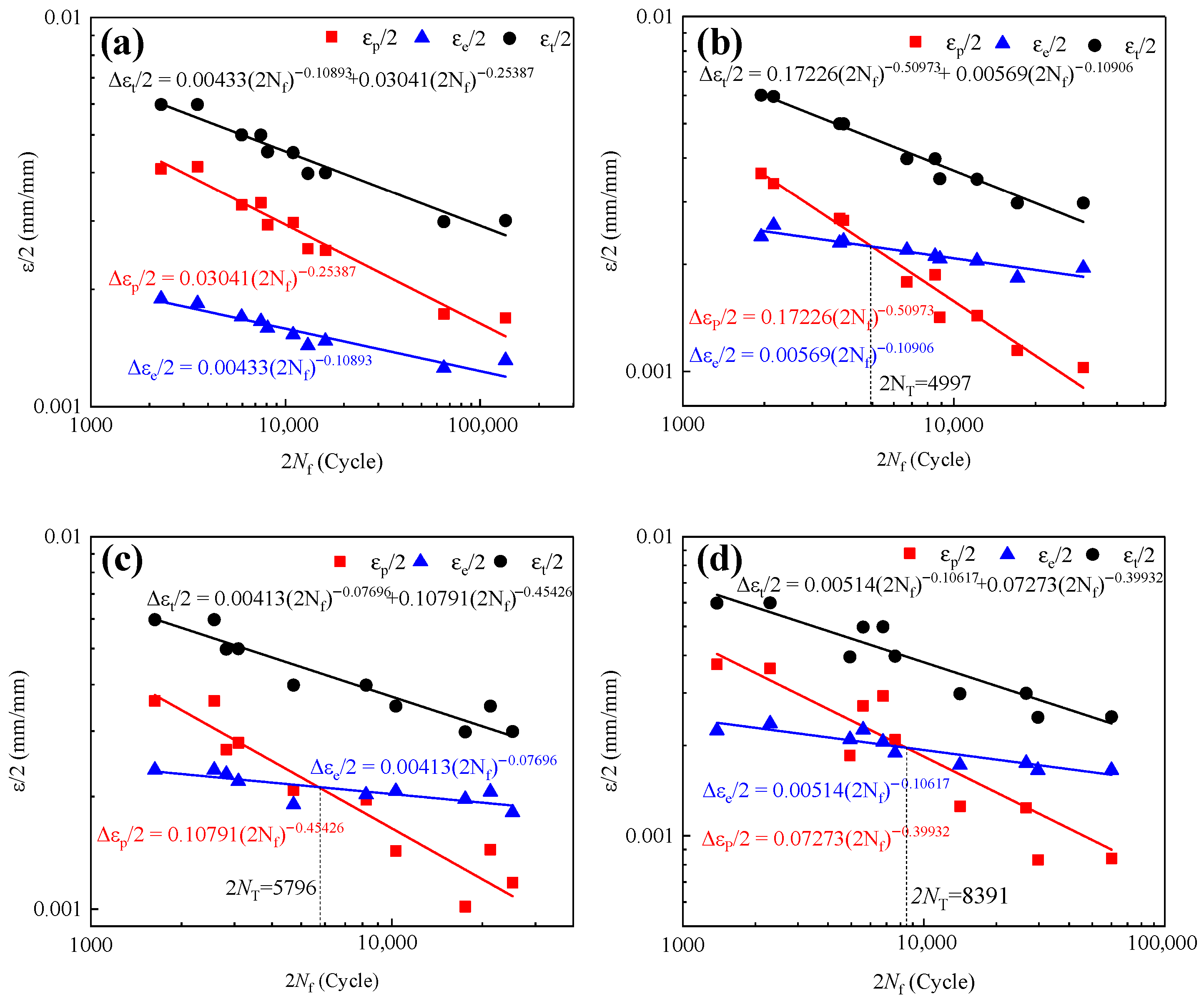

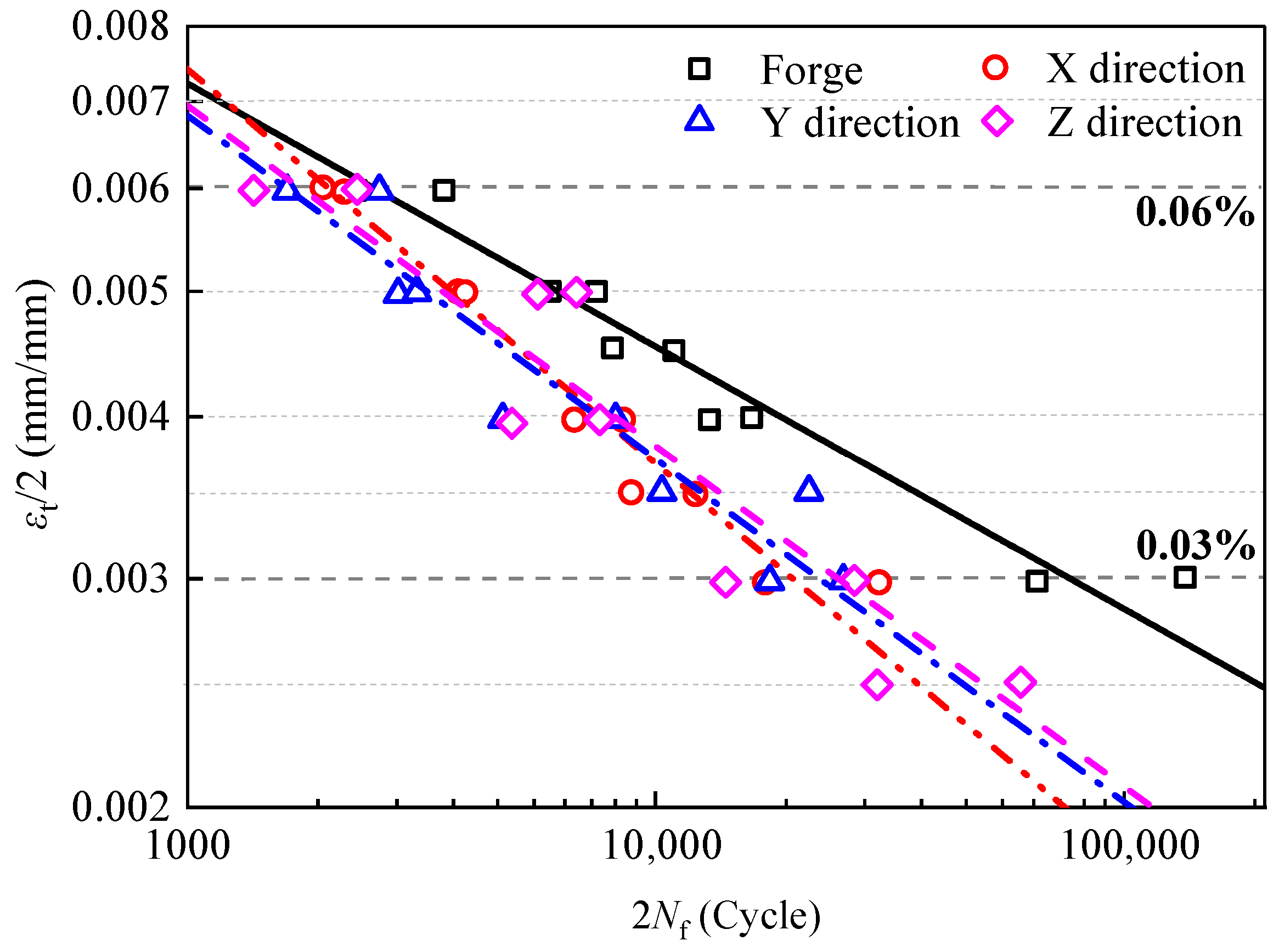

3.2.2. Strain–Fatigue Life Relationship

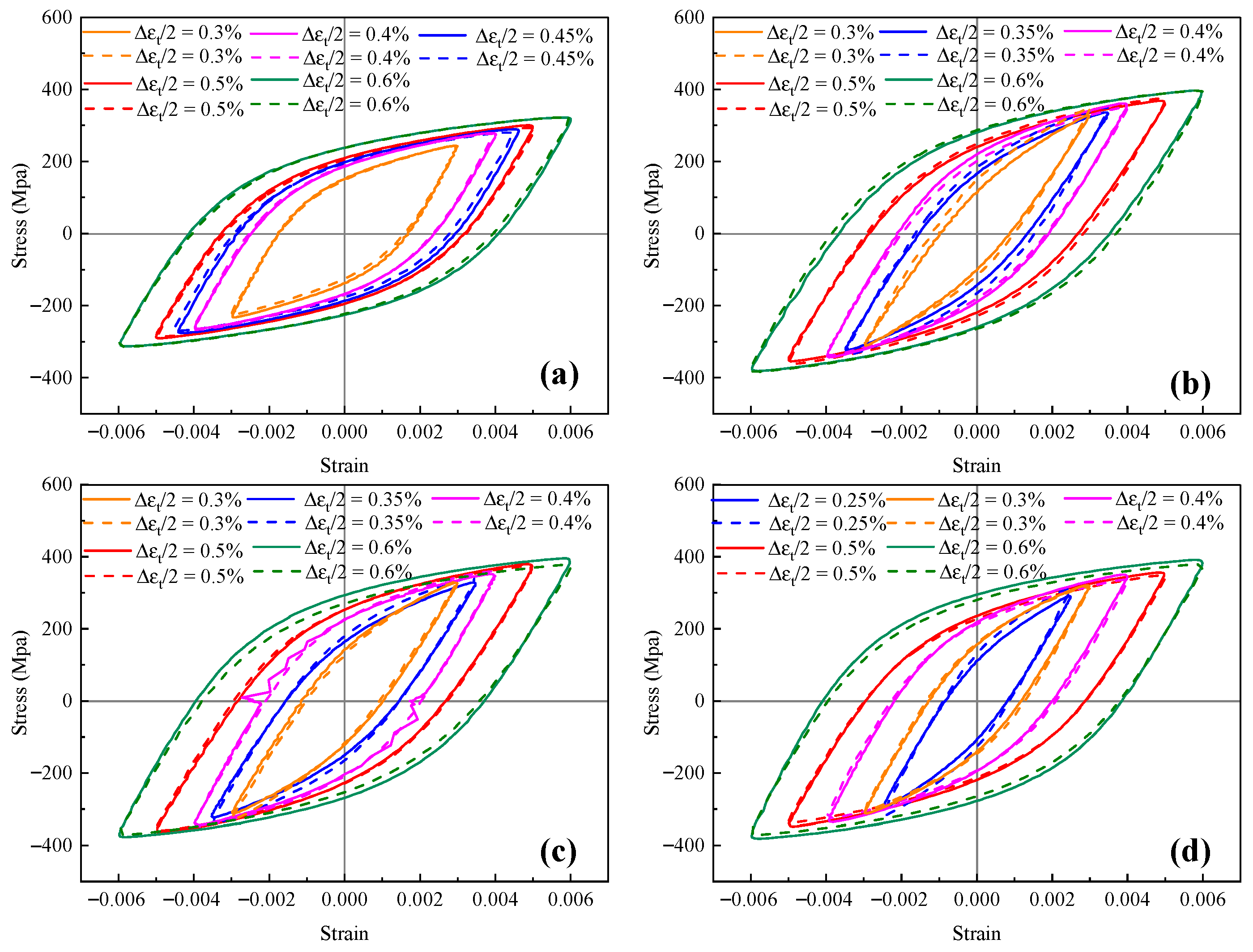

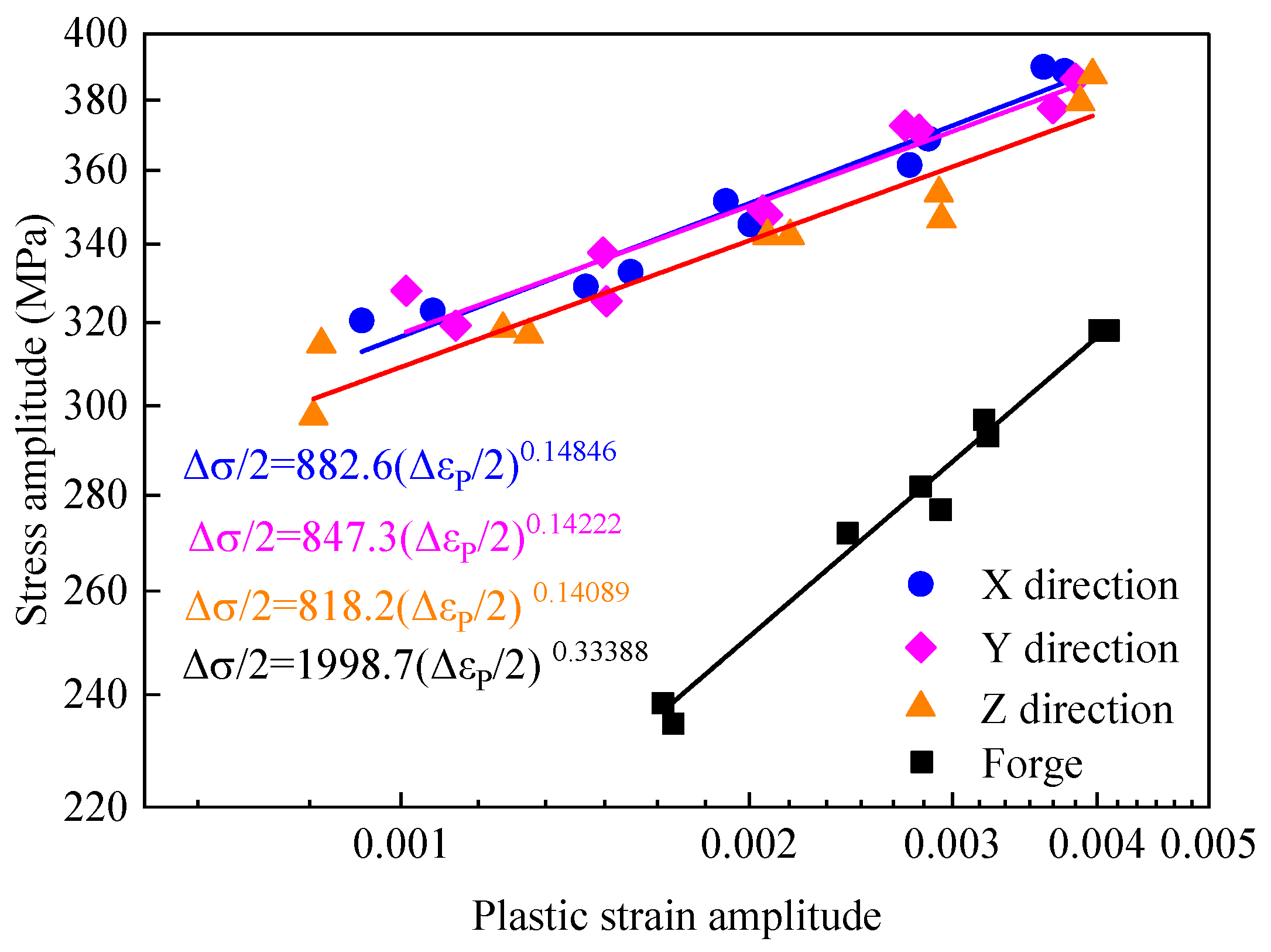

3.2.3. Cyclic Stress–Strain Relationship

3.3. Fatigue Fracture Morphology and Microstructure

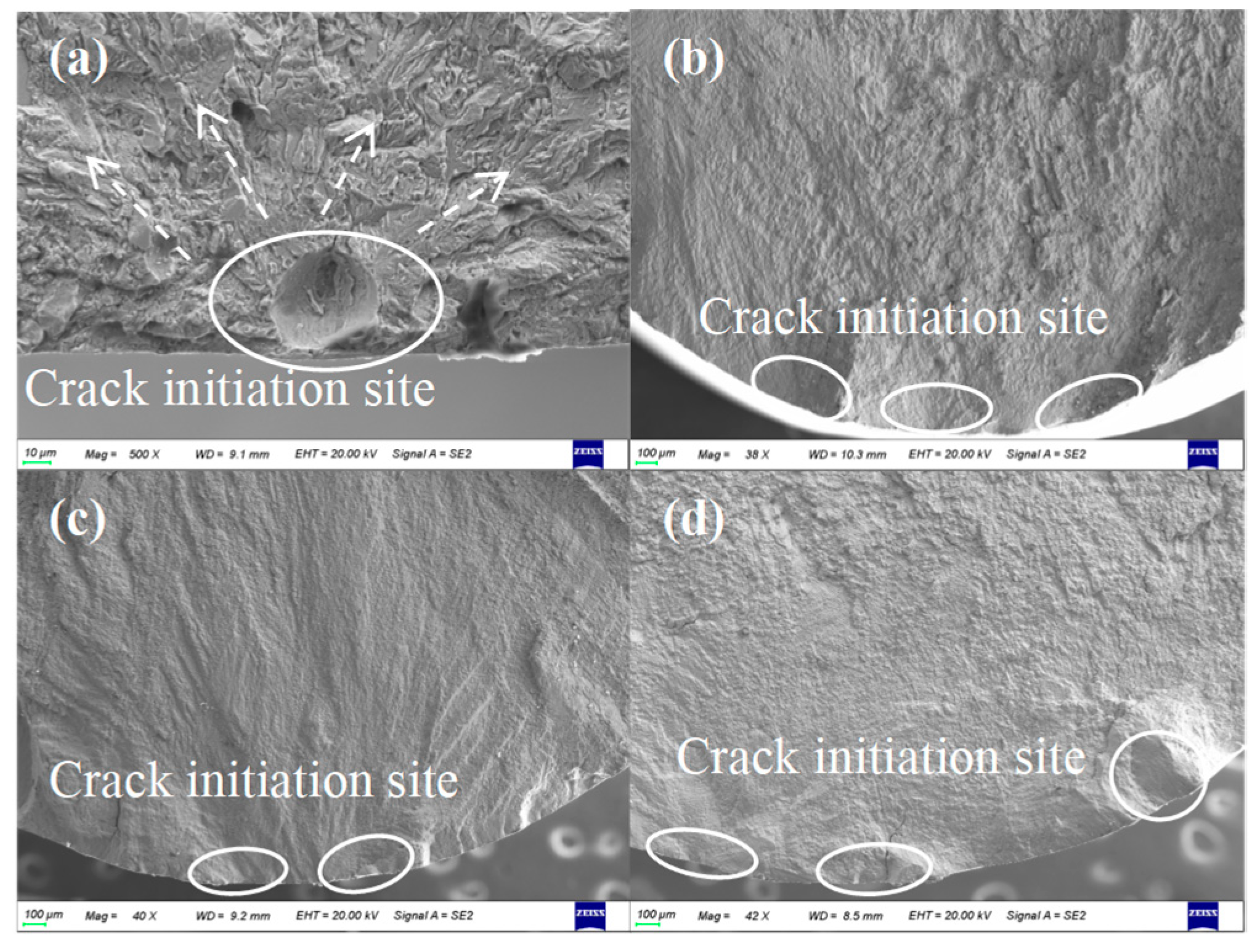

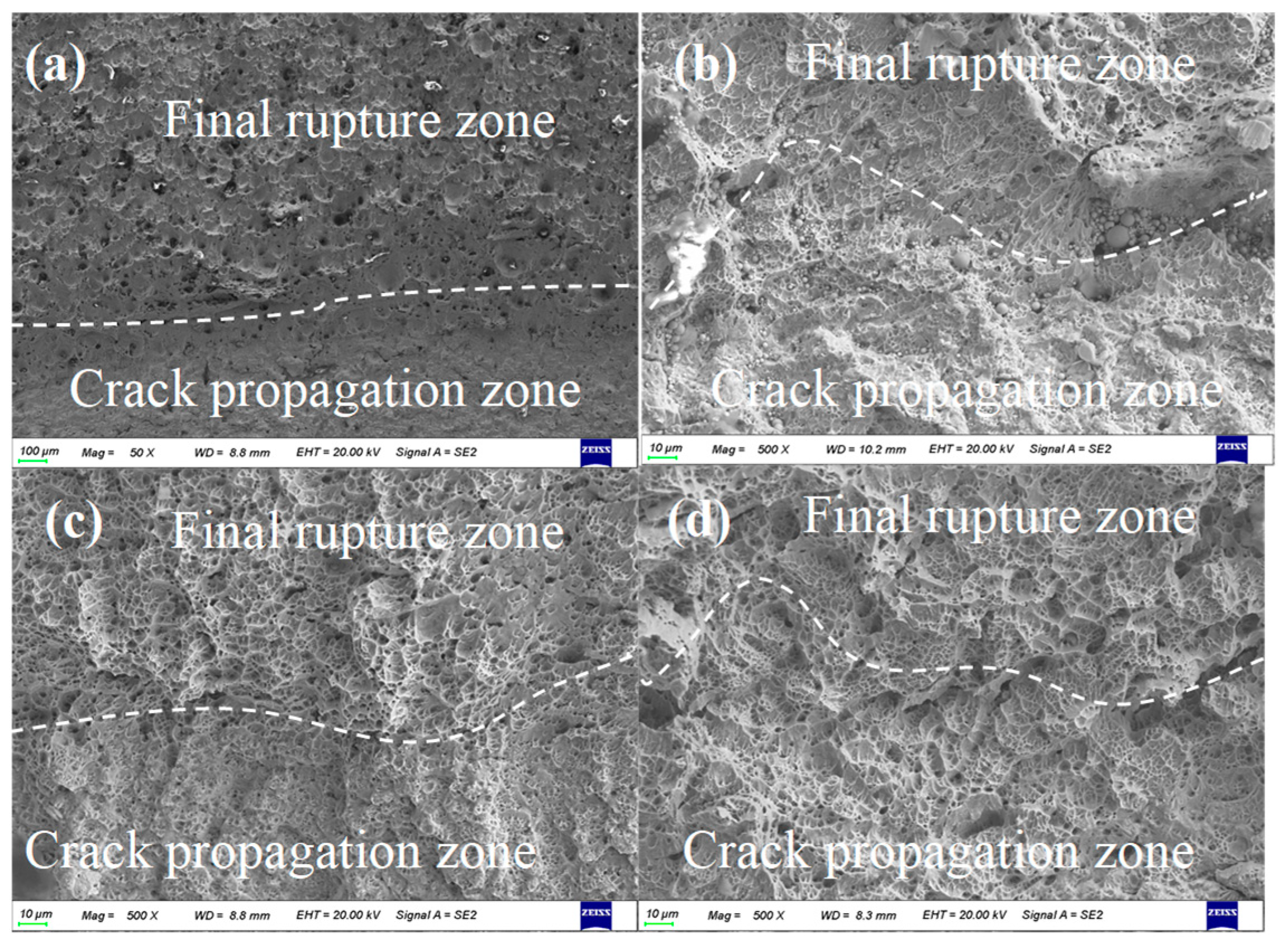

3.3.1. Fatigue Fracture Morphology

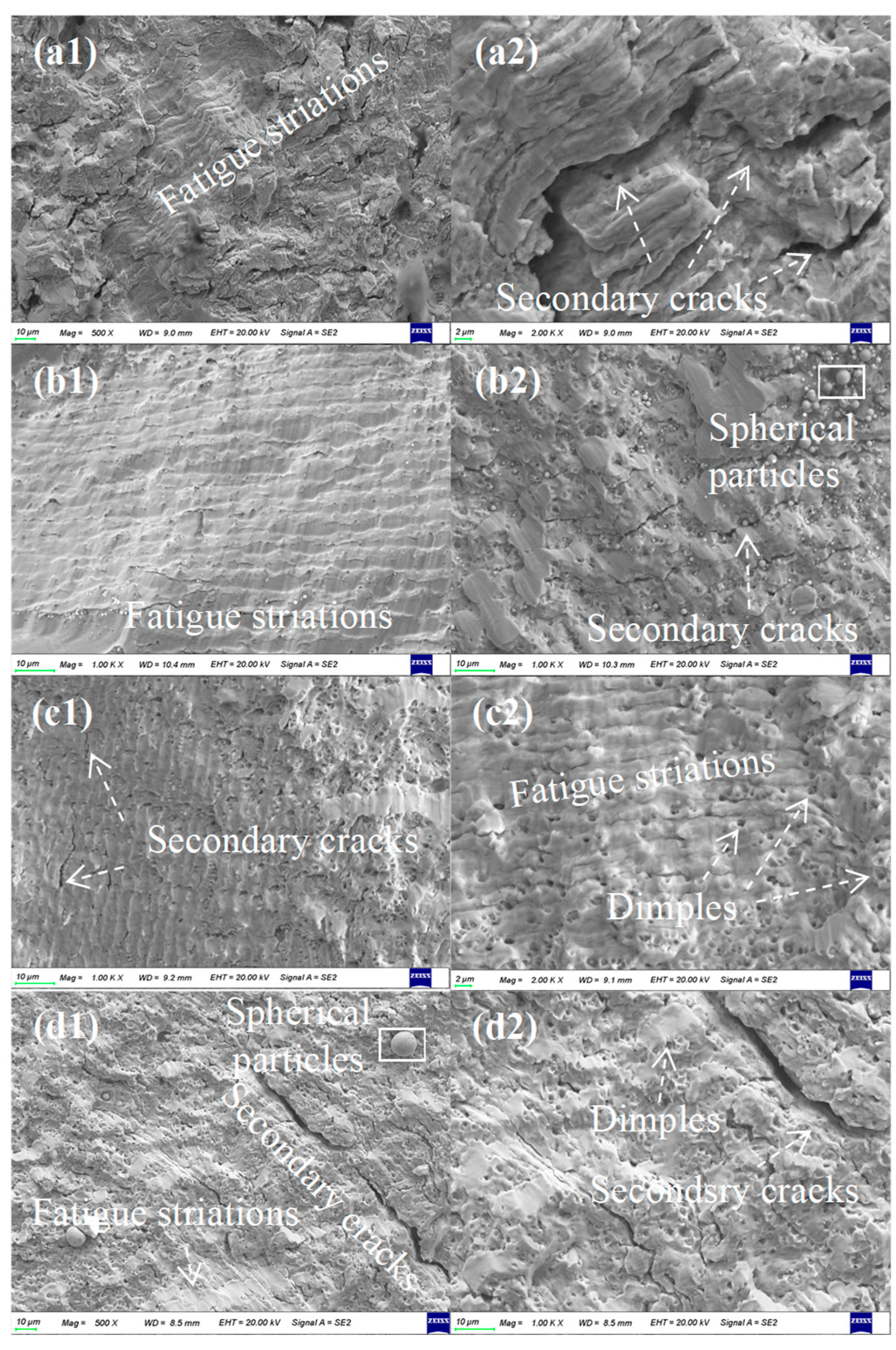

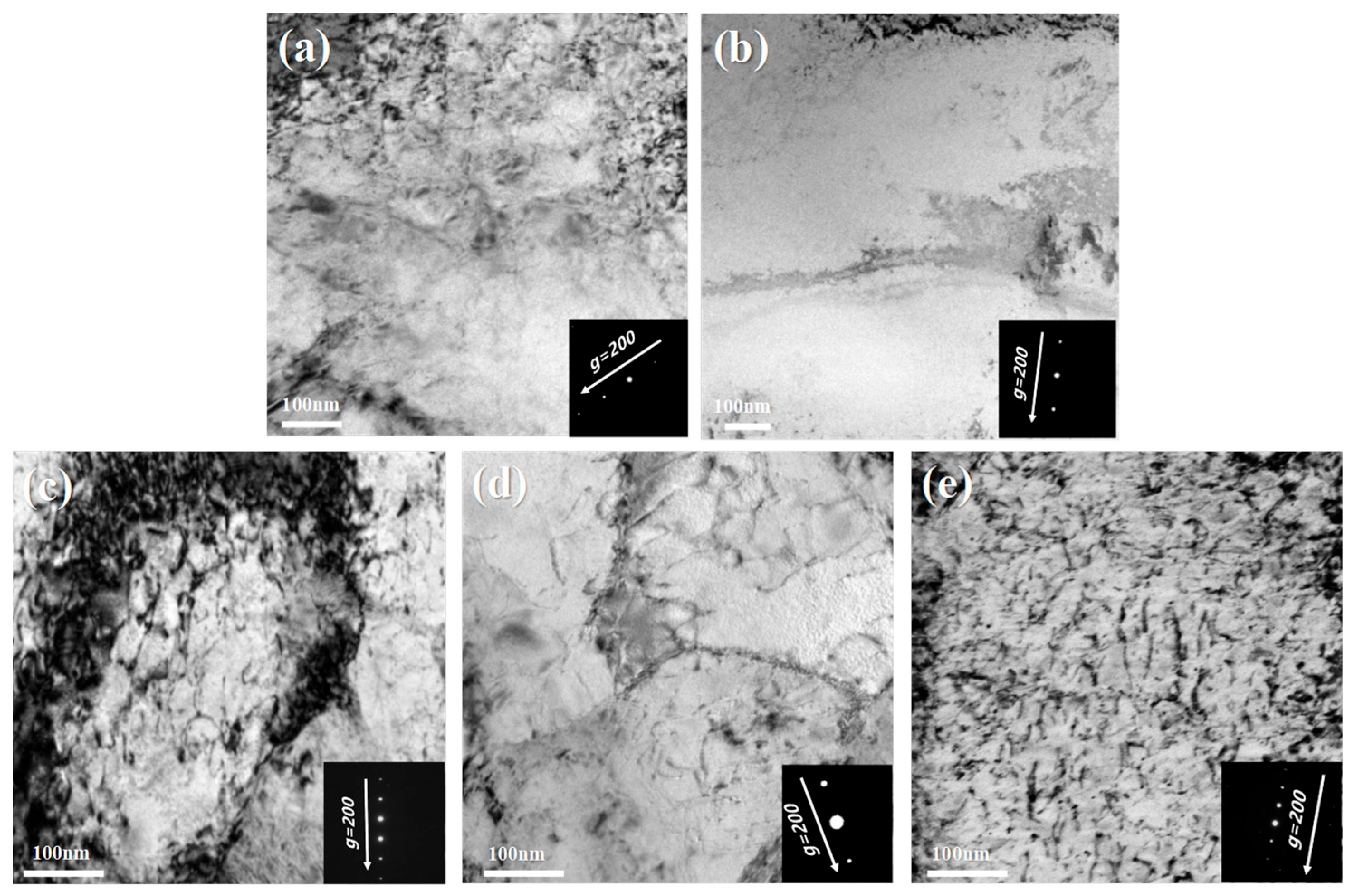

3.3.2. Fatigue Fracture Microstructure

4. Conclusions

- (1)

- The microstructure of the AM materials showed anisotropy in the X, Y, and Z directions. The residual strain for AM materials was more obvious than forged material. The tensile and impact properties of the X, Y, and Z directions in AM materials were similar, while lower than forged materials.

- (2)

- The fatigue stresses of AM specimens were obviously higher than forged specimens at the same strain amplitude. The fatigue lifes of most Z-direction specimens were lower than X- and Y-directions, and all directions specimens lower than forged specimens.

- (3)

- During the fatigue strain amplitude range of 0.3% to 0.6%, the Z-direction specimens of AM materials showed the best plastic strain by the highest NT, while the Nf of the Z direction was obviously dispersed compared to the X and Y directions. The forged specimens showed the best fatigue properties under the plastic strain amplitude control mode.

- (4)

- Fatigue fracture surfaces of AM and forged materials exhibited multiple and single fatigue crack initiation sites, respectively, which was attributed to the presence of incompletely melted particles and manufacturing defects inside the AM specimens. The dislocation density of the forged fatigue specimens was the highest in the Z- and X-direction specimens of AM specimens, consistent with the fatigue life trend.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| AM | Additive manufactured |

| WAAM | Wire Arc Additive Manufacturing |

| SS | stainless steel |

| SEM | Scanning electron microscopy |

| TEM | Transmission electron microscopy |

| EBSD | Electron backscatter diffraction |

| Rm | Tensile strength |

| Rp0.2 | Yield strength |

| Elf | The lower elongation after fracture |

| RA | The reduction of area |

| KV2 | Impact absorption energy |

| LE | Lateral expansion |

| Nf | The fatigue life |

| NT | Transitional fatigue life |

| Δεp | Plastic strain amplitude |

| Δεe/2 | Elastic strain amplitude |

| Δεt/2 | Total strain amplitude |

References

- Luo, Q.; Chen, Y.; Liu, S. The studies on the corrosion behaviors of 316NG and 304NG nitrogen-containing stainless steels made in China. Procedia Eng. 2012, 27, 1560–1567. [Google Scholar] [CrossRef][Green Version]

- Şahin, S.; Übeyli, M. A Review on the Potential Use of Austenitic Stainless Steels in Nuclear Fusion Reactors. J. Fusion Energy 2008, 27, 271–277. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, C.; Ren, R.; Xue, Z.; Wang, H.; Zhang, Y.; Wang, J.; Wang, J.; Chen, L.; Mu, W. Ferrite formation and decomposition in 316H austenitic stainless steel electro slag remelting ingot for nuclear power applications. Mater. Charact. 2024, 218, 114581. [Google Scholar] [CrossRef]

- Chen, Y.; Jing, S.; Liang, C.; Wang, Z.; Bin, F.; Bu, X.; Zhang, J.; Ling, Z.; Wang, X.; Zhang, R.; et al. Additive manufacturing of continuous fiber composite curved thin-walled structures with conformal honeycomb-stiffeners based on topology optimization. Mater. Des. 2025, 254, 114000. [Google Scholar] [CrossRef]

- Wu, B.; Pan, Z.; Ding, D.; Cuiuri, D.; Li, H.; Xu, J.; Norrish, J. A review of the wire arc additive manufacturing of metals: Properties, defects and quality improvement. J. Manuf. Process. 2018, 35, 127–139. [Google Scholar] [CrossRef]

- Zheng, J.; Hu, J.; Jiang, Y.; Wang, Q.; Yang, K. High temperature effects on fatigue performance and crack initiation mechanisms of 316LN stainless steel for nuclear power pipelines. J. Mater. Res. Technol. 2025, 35, 3281–3292. [Google Scholar] [CrossRef]

- Xiao, J.; Guo, W.; Zhang, H.; Dai, W.; Zhu, Y.; Cong, B.; Qi, Z.; Zhu, H.; Ren, X.; Li, M. Microstructure and mechanical properties of wire and arc additive manufactured 2319 aluminum alloy treated by laser shock peening. Mater. Charact. 2024, 217, 114354. [Google Scholar] [CrossRef]

- Braun, M.; Chen, T.; Shen, J.; Fassmer, H.; Klusemann, B.; Sheikhi, S.; Ehlers, S.; Müller, E.; Sarmast, A.; Schubnell, J. Fatigue crack initiation and propagation in plain and notched PBF-LB/M, WAAM, and wrought 316L stainless steel specimens. Mater. Des. 2024, 244, 113122. [Google Scholar] [CrossRef]

- Mendez-Morales, M.; Jesus, J.S.; Branco, R.; Tankova, T.; Rebelo, C. Fatigue crack growth of untreated and heat-treated WAAM ER70S-6 carbon steel. Int. J. Fatigue 2025, 198, 109008. [Google Scholar] [CrossRef]

- Ayan, Y.; Kahraman, N. Bending fatigue properties of structural steel fabricated through wire arc additive manufacturing (WAAM). Eng. Sci. Technol. Int. J. 2022, 35, 101247. [Google Scholar] [CrossRef]

- Gordon, J.V.; Haden, C.V.; Nied, H.F.; Vinci, R.P.; Harlow, D.G. Fatigue crack growth anisotropy, texture and residual stress in austenitic steel made by wire and arc additive manufacturing. Mater. Sci. Eng. A 2018, 724, 431–438. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, S.; Yu, W.; Li, B.; Xuan, F.; Chen, X. Multiaxial low cycle fatigue behavior and life prediction of wire arc additive manufactured 308L stainless steel. Int. J. Fatigue 2024, 183, 108241. [Google Scholar] [CrossRef]

- Muhammad, M.; Lee, S.; Frye, P.; Simsiriwong, J.; Shao, S.; Shamsaei, N. High cycle and very high cycle fatigue behavior of additively manufactured Inconel 718: Effects of stress-relieving, surface texture, part orientation, and test frequency. Eng. Fail. Anal. 2025, 169, 109227. [Google Scholar] [CrossRef]

- Alhajeri, A.; Aremu, O.; Almutahhar, M.; Yousif, M.; Albinmousa, J.; Ali, U. On the effect of loading and printing parameters that influence the fatigue behavior of laser powder-bed fusion additively manufactured steels. Heliyon 2024, 10, e29229. [Google Scholar] [CrossRef] [PubMed]

- Ajay, V.; Nakrani, J.; Mishra, N.K.; Shrivastava, A. Anisotropic fatigue crack propagation in wire arc additively manufactured 316L stainless steel. Int. J. Fatigue 2023, 177, 107976. [Google Scholar] [CrossRef]

- Hong, X.; Liu, T.; Zhang, J.; Ding, D.; Yuan, L. A review of strategies to control process-induced cracks in metal additive manufacturing and remanufacturing. Mater. Today Commun. 2025, 43, 111801. [Google Scholar] [CrossRef]

- Hu, Y.; Chen, Z.; Xi, J.; Jiang, J.; Berto, F.; Nikbin, K. Defect characteristics-based low-cycle fatigue life prediction model for additive manufactured Ti-6Al-4 V alloys. Theor. Appl. Fract. Mech. 2024, 134, 104737. [Google Scholar] [CrossRef]

- Zhang, W.; Li, R.; Peng, Y.; Xu, H. A static and high-cycle fatigue characterization framework of metallic lattice structures additive manufactured via fused deposition modeling based method. Mater. Des. 2025, 252, 113761. [Google Scholar] [CrossRef]

- Aguiar, J.A.; Jokisaari, A.M.; Kerr, M. Allen Roach, R. Bringing nuclear materials discovery and qualification into the 21st century. Nat. Commun. 2020, 11, 2556. [Google Scholar] [CrossRef]

- Weixing, X.U.; Weicheng, X.U. Comparison and understanding of the main revision contents of GB/T 228.1—2021. Phys. Test. Chem. Anal. Part A Phys. Test. 2022, 58, 1–4. [Google Scholar]

- Liu, Y.; Zheng, X.-M.; Li, Q.-M.; Liu, P.-Y.; Ji, H.-C.; Du, L.-X. Microstructure and Properties of Coarse Grain Zone in Single-Pass Welding of V-N Microalloyed Steel. J. Mater. Eng. Perform. 2025, 34, 4350–4358. [Google Scholar] [CrossRef]

- Guo, N.; Yu, J.; Zhou, Q.; Wang, J.; Xiao, G.; Tang, B.; Zhang, Z. Enhancing low-cycle fatigue performance of high-efficient laser additively manufactured TC11 titanium alloy: Mechanisms of cyclic softening/hardening and microstructural refinement. J. Mater. Res. Technol. 2025, 36, 2485–2500. [Google Scholar] [CrossRef]

- Han, S.; Dung Dinh, T.; De Baere, I.; Van Paepegem, W. Relation between ASTM E606 specimen geometry and misalignment in strain-controlled fatigue testing. Int. J. Fatigue 2023, 166, 107282. [Google Scholar] [CrossRef]

- Wang, H.; Liu, C.-W.; Wu, T.; Peng, H.-X. Laser-Directed EnergYDeposited Ti-6Al-4V: The Anisotropy of Its Microstructure, Mechanical Properties, and Fracture Behavior. Materials 2025, 18, 2360. [Google Scholar] [CrossRef]

- Pang, J.C.; Li, S.X.; Wang, Z.G.; Zhang, Z.F. General relation between tensile strength and fatigue strength of metallic materials. Mater. Sci. Eng. A 2013, 564, 331–341. [Google Scholar] [CrossRef]

- Lukáš, P.; Klesnil, M. Cyclic stress-strain response and fatigue life of metals in low amplitude region. Mater. Sci. Eng. 1973, 11, 345–356. [Google Scholar] [CrossRef]

- Suthar, H.; Sharma, M.; Bhattacharya, A.; Kumar Paul, S. Zone-wise low cycle fatigue behavior of AA6061-T6 similar friction stir welding. Int. J. Fatigue 2024, 182, 108155. [Google Scholar] [CrossRef]

- Raman, S.G.S.; Radhakrishnan, V.M. On cyclic stress–strain behaviour and low cycle fatigue life. Mater. Des. 2002, 23, 249–254. [Google Scholar] [CrossRef]

- Kappacher, J.; Renk, O.; Kiener, D.; Clemens, H.; Maier-Kiener, V. How grain boundary characteristics influence plasticity close to and above the critical temperature of ultra-fine grained bcc Ta2.5W. Acta Mater. 2021, 216, 117110. [Google Scholar] [CrossRef]

- Abareshi, M.; Emadoddin, E. Effect of retained austenite characteristics on fatigue behavior and tensile properties of transformation induced plasticity steel. Mater. Des. 2011, 32, 5099–5105. [Google Scholar] [CrossRef]

- Zhong, Y.; Shan, Y.; Xiao, F.; Yang, K. Effect of toughness on low cycle fatigue behavior of pipeline steels. Mater. Lett. 2005, 59, 1780–1784. [Google Scholar] [CrossRef]

- Javidrad, H.; Bahattin, K.; Hakan, B.; Ugur, S.; Gunaydin, K. Fatigue performance of metal additive manufacturing: A comprehensive overview. Virtual Phys. Prototyp. 2024, 19, 1745–2759. [Google Scholar] [CrossRef]

- Lefebvre, D.; Ellyin, F. Cyclic response and inelastic strain energy in low cycle fatigue. Int. J. Fatigue 1984, 6, 9–15. [Google Scholar] [CrossRef]

- Carneiro, L.; Jalalahmadi, B.; Ashtekar, A.; Jiang, Y. Cyclic deformation and fatigue behavior of additively manufactured 17–4 PH stainless steel. Int. J. Fatigue 2019, 123, 22–30. [Google Scholar] [CrossRef]

- Kamaya, M. Ramberg–Osgood type stress–strain curve estimation using yield and ultimate strengths for failure assessments. Int. J. Press. Vessel. Pip. 2016, 137, 1–12. [Google Scholar] [CrossRef]

- An, D.; Liu, X.; Xiao, Y.; Li, X.; Chen, J. Correlating the evolution of spatial-resolved microscale residual stress and the associated dislocation behavior in additively manufactured 316L stainless steel upon short-term annealing. Addit. Manuf. 2025, 106, 104807. [Google Scholar] [CrossRef]

- Cao, F.; Zhang, T.; Ryder, M.A.; Lados, D.A. A Review of the Fatigue Properties of Additively Manufactured Ti-6Al-4V. JOM 2018, 70, 349–357. [Google Scholar] [CrossRef]

- Li, J.; Sun, J.; Qian, G.; Shi, L. Defect-induced cracking and fine granular characteristics in verYhigh-cycle fatigue of laser powder bed fusion AlSi10Mg alloy. Int. J. Fatigue 2022, 158, 106770. [Google Scholar] [CrossRef]

- Sanaei, N.; Fatemi, A. Defects in additive manufactured metals and their effect on fatigue performance: A state-of-the-art review. Prog. Mater Sci. 2021, 117, 100724. [Google Scholar] [CrossRef]

- Xu, W.; Jiang, R.; Xu, M.; Delaney, C.; Yang, Y.; Torresani, E.; Shaikh, M.; Yan, Y.; Olevsky, E. High dislocation density formation in metallic materials by ultra-intense nanopulsing electric current. J. Alloys Compd. 2025, 1025, 180267. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhang, Z.; Huang, C.; Yang, J.; Tan, C.; Wan, M.; Zhao, Y. Influence of multilevel lamellar microstructure on notch high cycle fatigue properties and crack initiation behavior of Ti-55531 alloy. J. Alloys Compd. 2025, 1010, 177684. [Google Scholar] [CrossRef]

- Liu, S.M.; Li, S.-H.; Han, W.-Z. Effect of ordered helium bubbles on deformation and fracture behavior of α-Zr. J. Mater. Sci. Technol. 2019, 35, 1466–1472. [Google Scholar] [CrossRef]

- Ispánovity, P.D.; Ugi, D.; Péterffy, G.; Knapek, M.; Kalácska, S.; Tüzes, D.; Dankházi, Z.; Máthis, K.; Chmelík, F.; Groma, I. Dislocation avalanches are like earthquakes on the micron scale. Nat. Commun. 2022, 13, 1975. [Google Scholar] [CrossRef] [PubMed]

| Manufacturing Method | C | Si | Mn | P | S | Cr | Ni | Cu | N |

|---|---|---|---|---|---|---|---|---|---|

| AM | 0.025 | 0.52 | 1.98 | 0.020 | <0.010 | 19.96 | 9.43 | <0.04 | 0.037 |

| Forge | 0.023 | 0.50 | 1.37 | 0.023 | <0.010 | 18.70 | 9.06 | 0.068 | 0.066 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, J.; Liu, H.; Liu, Z.; Wang, R.; Wu, H.; Dong, H.; Meng, X.; Yu, M. Low-Cycle Fatigue Behavior of Nuclear-Grade Austenitic Stainless Steel Fabricated by Additive Manufacturing. Crystals 2025, 15, 644. https://doi.org/10.3390/cryst15070644

Shi J, Liu H, Liu Z, Wang R, Wu H, Dong H, Meng X, Yu M. Low-Cycle Fatigue Behavior of Nuclear-Grade Austenitic Stainless Steel Fabricated by Additive Manufacturing. Crystals. 2025; 15(7):644. https://doi.org/10.3390/cryst15070644

Chicago/Turabian StyleShi, Jianhui, Huiqiang Liu, Zhengping Liu, Runzhong Wang, Huanchun Wu, Haitao Dong, Xinming Meng, and Min Yu. 2025. "Low-Cycle Fatigue Behavior of Nuclear-Grade Austenitic Stainless Steel Fabricated by Additive Manufacturing" Crystals 15, no. 7: 644. https://doi.org/10.3390/cryst15070644

APA StyleShi, J., Liu, H., Liu, Z., Wang, R., Wu, H., Dong, H., Meng, X., & Yu, M. (2025). Low-Cycle Fatigue Behavior of Nuclear-Grade Austenitic Stainless Steel Fabricated by Additive Manufacturing. Crystals, 15(7), 644. https://doi.org/10.3390/cryst15070644