A Comparative Analysis of the Tribological Behavior of Hard Layers Obtained by Three Different Hardened-Surface Processes on the Surface of AISI 4140 Steel

Abstract

:1. Introduction

2. Materials and Methods

2.1. Thermochemical Treatments

2.2. Surface Characterization

2.3. Tribological Tests

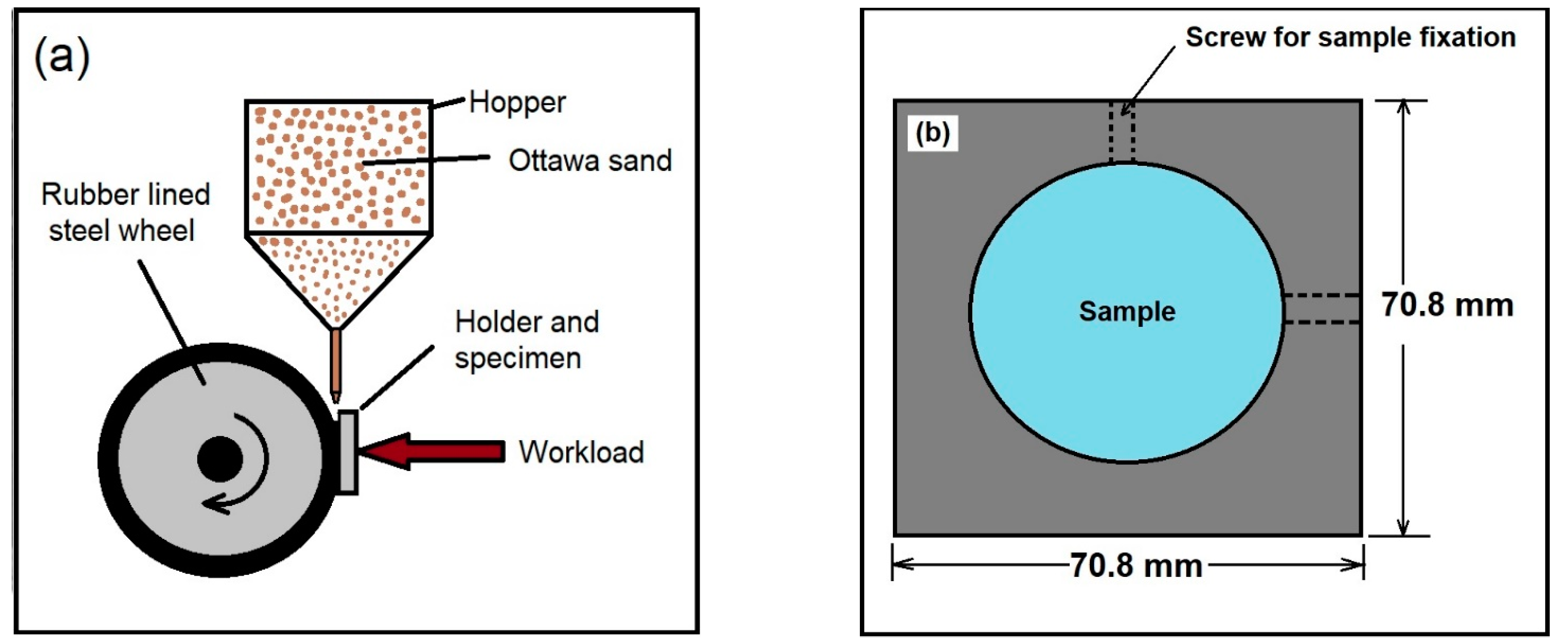

2.3.1. Abrasive Wear Tests

2.3.2. Pin-on-Disk Tests

2.4. Importance of the Statistical Analysis

3. Results and Discussion

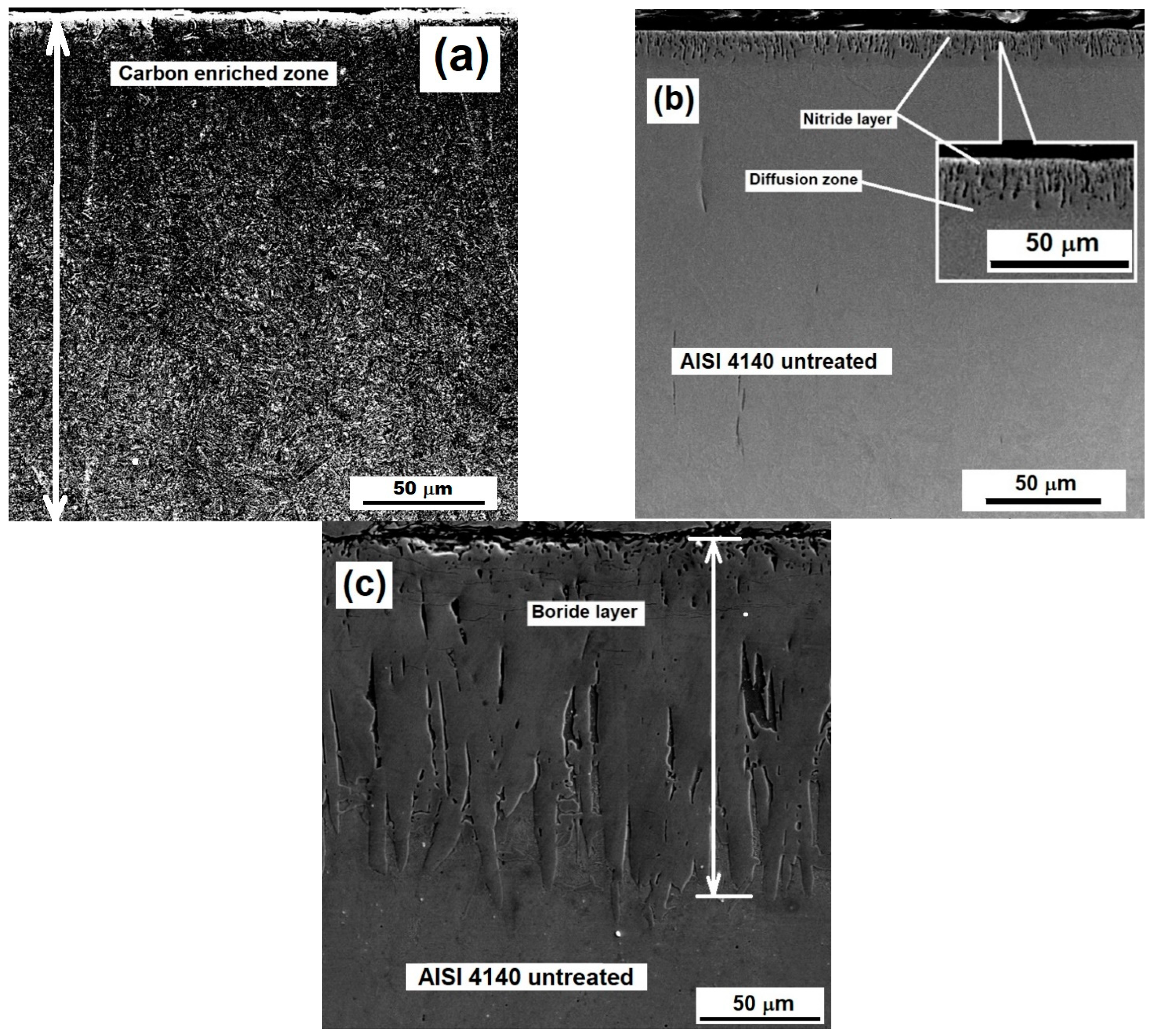

3.1. Surface Characterization

3.2. X-ray Diffraction Analysis

3.3. Mechanical Characterization

3.4. Tribological Tests

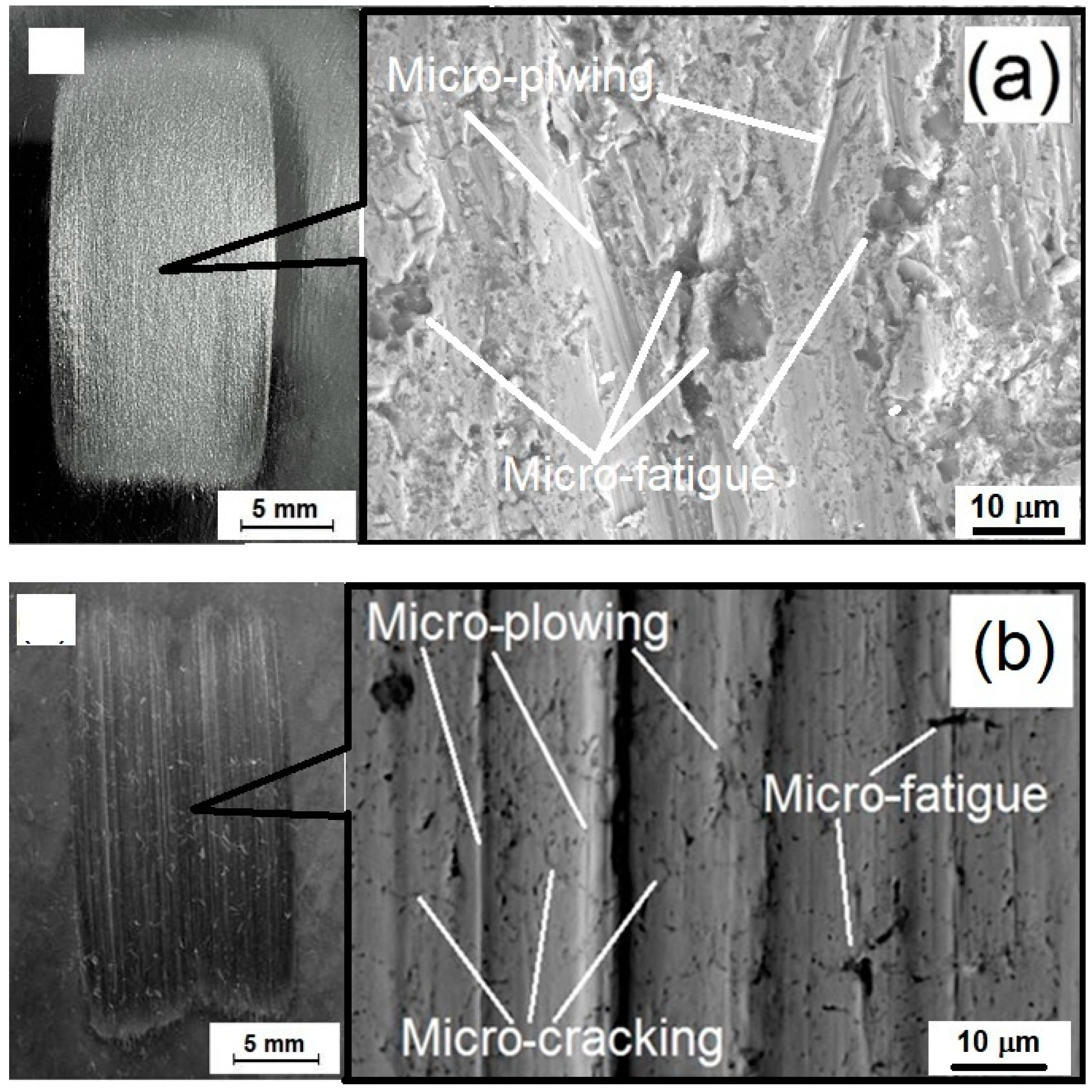

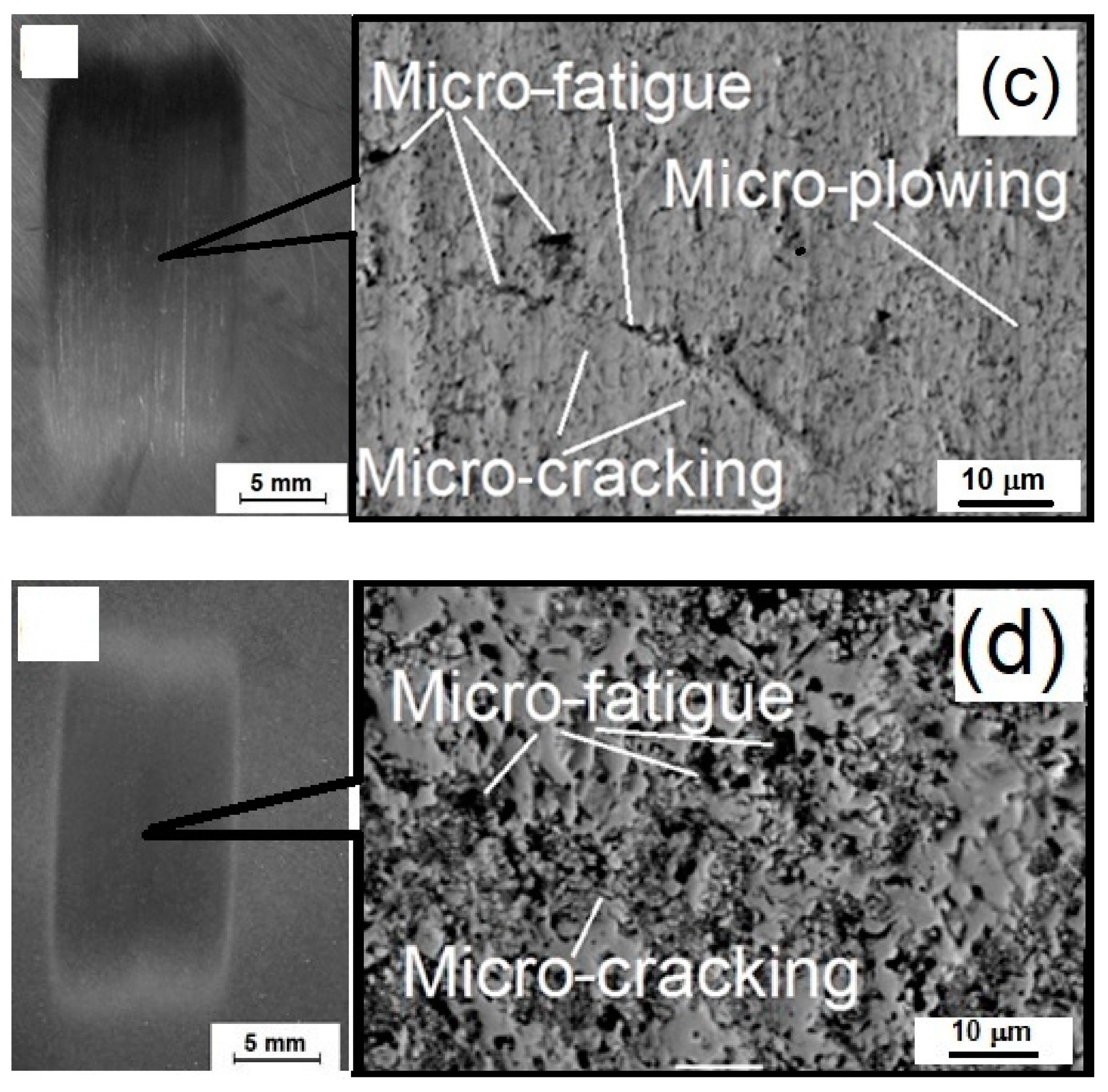

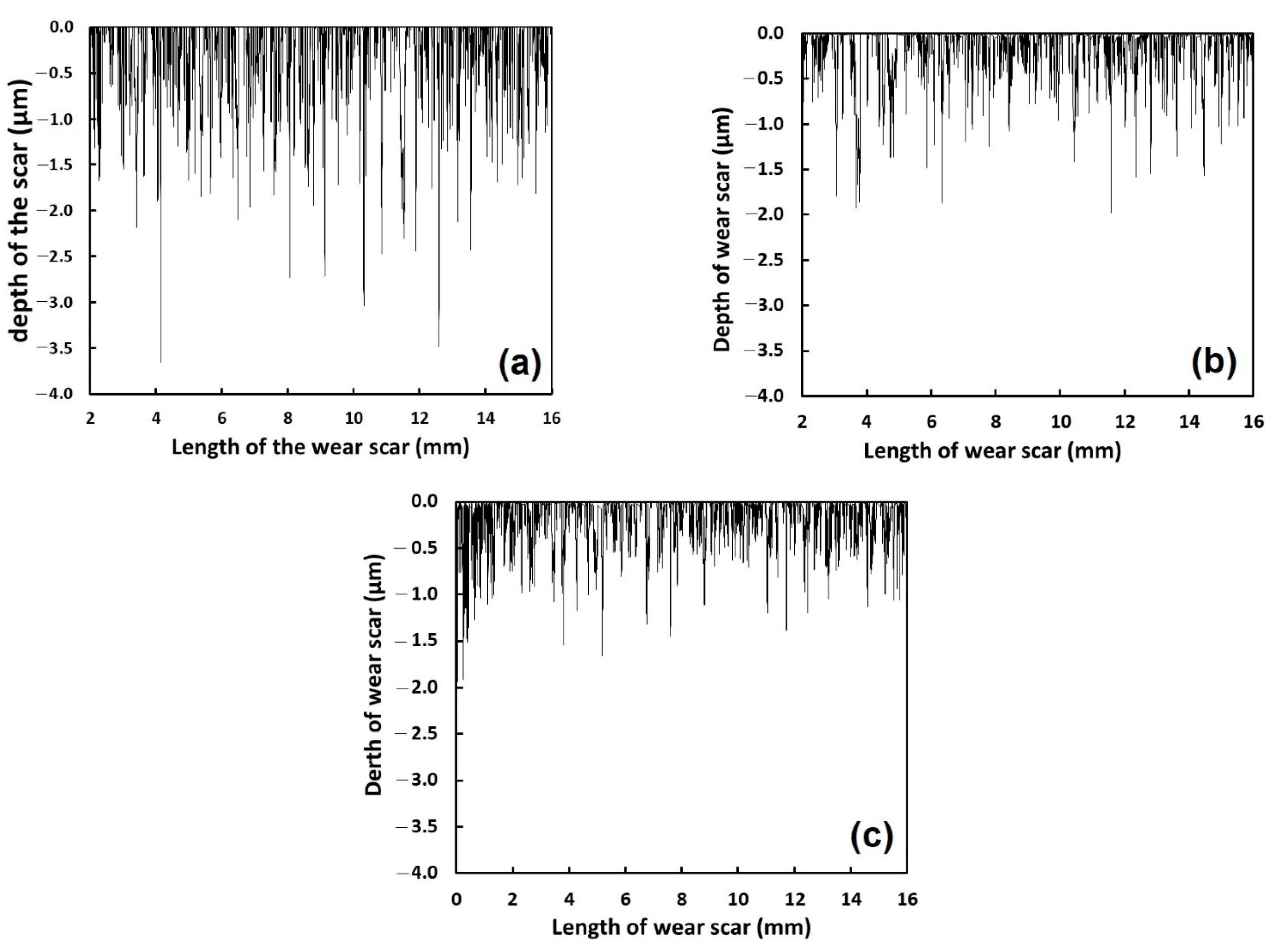

3.4.1. Wear Tests

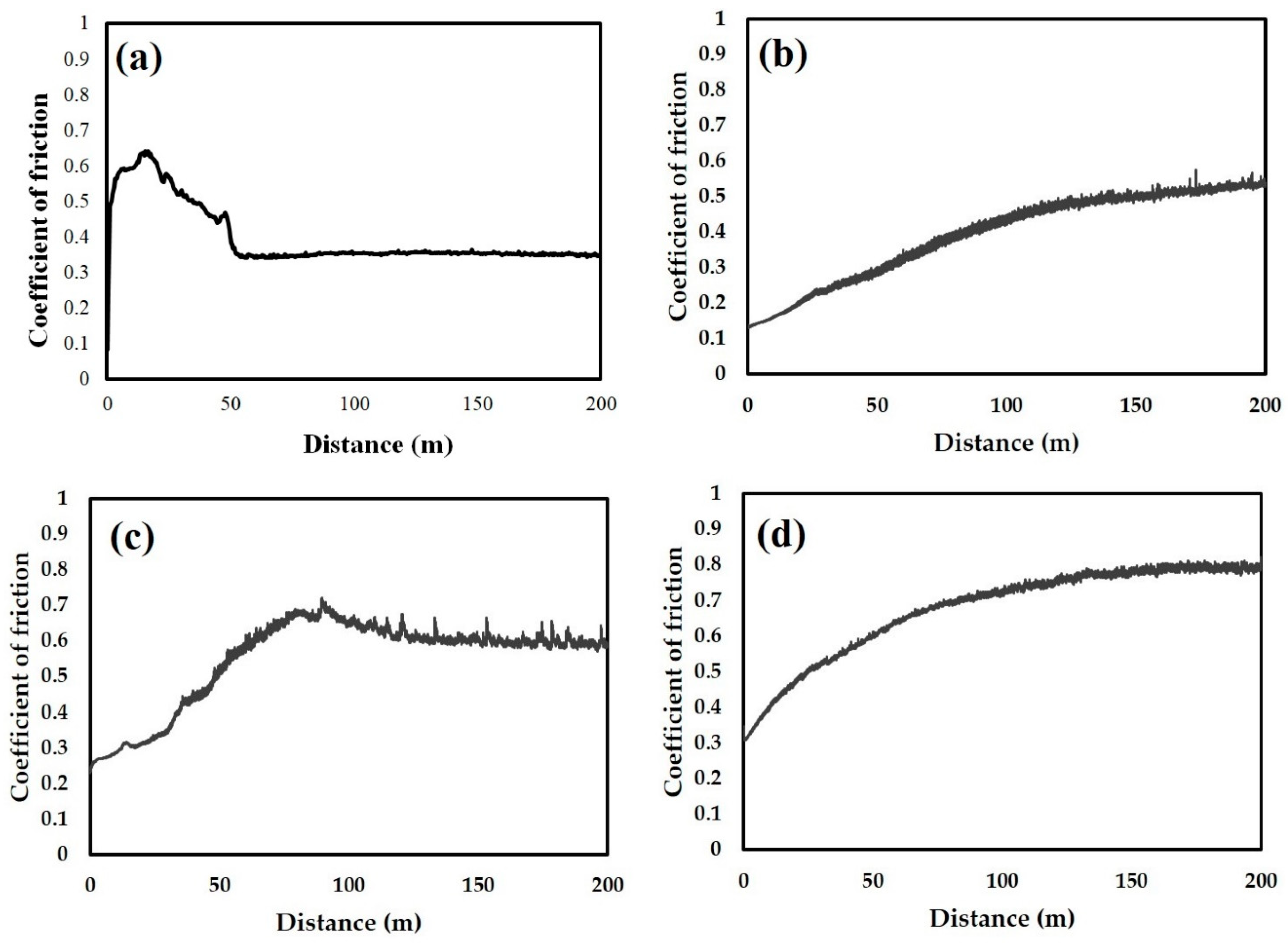

3.4.2. Pin-on-Disk Tests

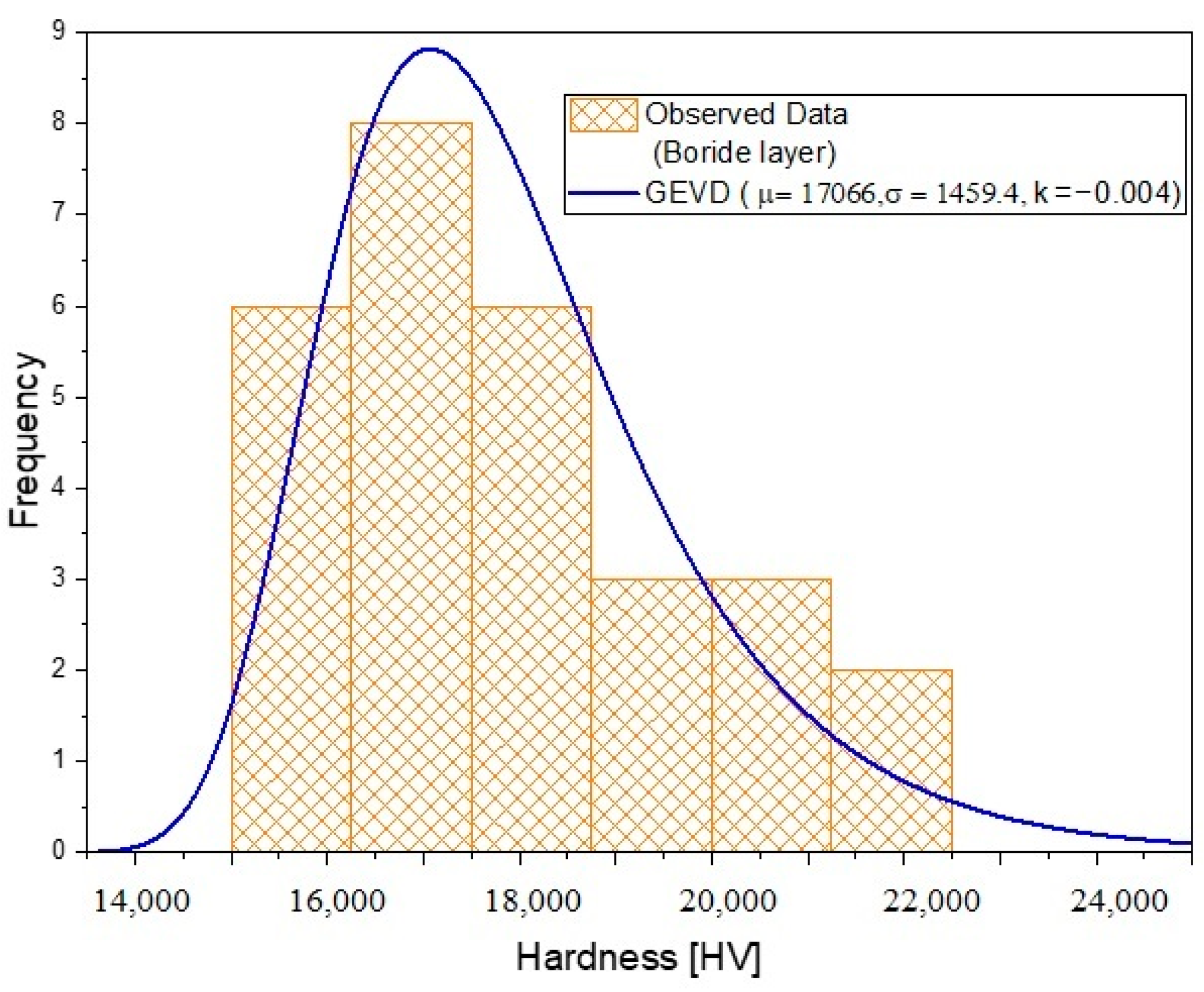

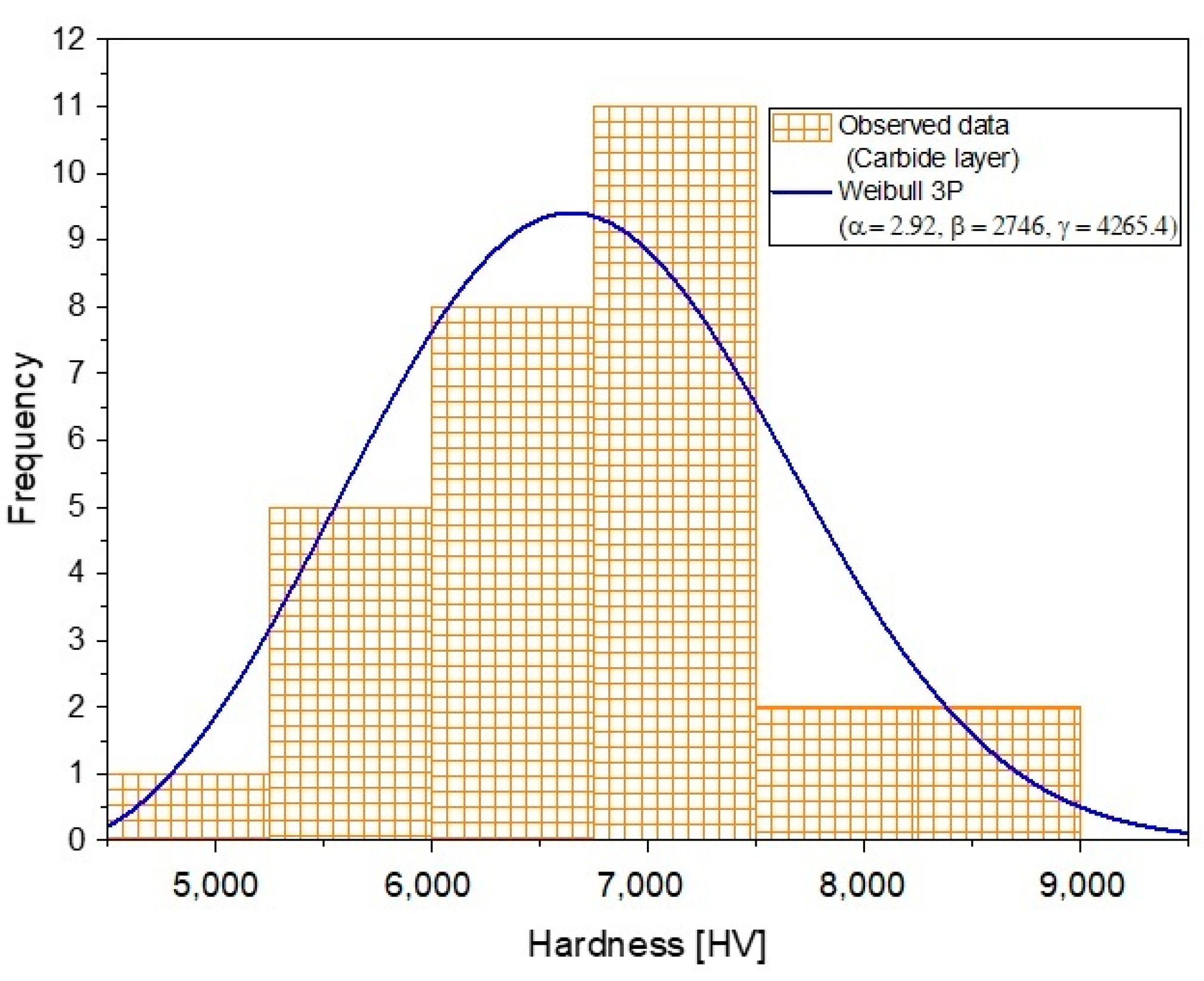

3.5. Statistical Analysis

4. Conclusions

- (a)

- During the surface-hardening processes applied to the samples, layers with different thicknesses and harnesses were obtained.

- (b)

- The differences in loss of mass and volume during the wear tests can be attributed to the differences in hardness resulting from the different surface-hardening processes that were applied (i.e., nitriding, carburizing, and boriding).

- (c)

- The samples with the lowest CoF were not those with the highest hardness, which suggests that the coefficient of friction could be not directly related to the hardness of the materials.

- (d)

- The samples with the lowest hardness (i.e., carburized) exhibited wear signs, such as micro-plowing, micro-cracking, micro-fatigue, and micro-cutting. In contrast, the samples with the highest hardness values showed less damage and only exhibited some minor marks of micro-fatigue and micro-cracking.

- (e)

- The main reason for the tribological behavior of the borided samples appears to be the naturally occurring boric acid films when the boride layers were exposed to open air.

- (f)

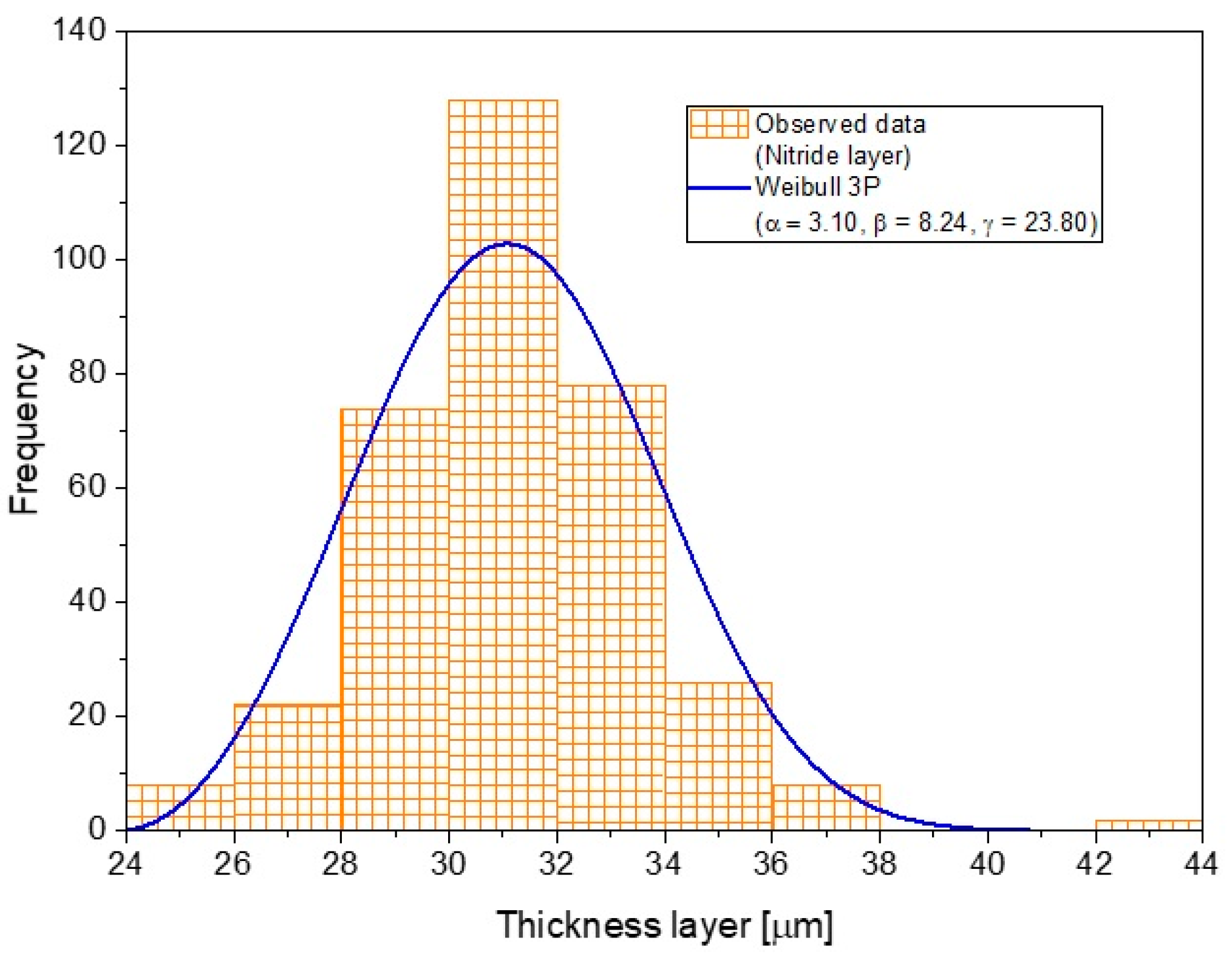

- In the three layers studied in this research work, it was possible to confirm that the layer thickness and the layer hardness had a random behavior. The confirmation of this behavior could assist in modeling the layer growth and optimize the formation process.

- (g)

- Layer thickness and surface hardness can be studied as random variables, and they can be analyzed using generalized extreme valued distribution and Weibull 3P distribution with enough confidence degree.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Findik, F. Latest progress on tribological properties of industrial materials. Mater. Des. 2014, 572, 18–24. [Google Scholar] [CrossRef]

- Erdemir, A.; Eryilmaz, O.L. Chapter 16, Superlubricity in Diamond-Like Carbon Films, Superlubricity; Elsevier Science: Amsterdam, The Netherlands, 2007; pp. 253–271. [Google Scholar]

- García, B.S.; Muruzabal, T.C.; Royo, L.P.; Mata, J.S.; Íñigo, E.S. Interface patológica por fricción metal-metal y metal-polietileno, diferencias microscópicas. Rev. Esp. Cir. Osteoartic. 1996, 31, 171–176. [Google Scholar]

- Sánchez, E.H.; Avila, I.P.T.; Chino-Ulloa, A.; Alvarez, C.O.; Hernández-Rodríguez, M.A.L.; Tadeo-Rosas, R.; Carrera-Espinoza, R.; Yescas-Hernández, J.A. Tribological Behavior of a Self-Lubricant Surface Film of H3BO3 Formed on a Borided Biomedical Steel by a Post-Treatment. Defect Diffus. Forum 2020, 400, 65–74. [Google Scholar] [CrossRef]

- Hasan, M.Z.; Hussein, A.A.; Hasan, A.S.; Ali, O.M. Improvement of AISI 1018 Carbon Steel Gr 1018 mechanical properties by liquid carburizing in salt bath. Mater. Today Proc. 2020, 20, 512–516. [Google Scholar] [CrossRef]

- Navío, C.; Capitán, M.J.; Álvarez, J.; Miranda, R.; Yndurain, F. Formation of a non-magnetic metallic iron nitride layer on bcc Fe (100). New J. Phys. 2010, 12, 073004. [Google Scholar] [CrossRef]

- Hernández-Sanchez, E.; Velázquez, J.C. Kinetics of growth of iron boride layers on a low-carbon steel surface. In Laboratory Unit Operations and Experimental Methods in Chemical Engineering, 1st ed.; InTechOpen: London, UK, 2018; Chapter 3. [Google Scholar]

- 15 Common Applications for Versatile 4140 Steel. 2021. Available online: https://www.astmsteel.com/steel-knowledge/15-application-4140-steel/ (accessed on 19 February 2022).

- 10 Common Applications for 4140 Steel. 2021. Available online: https://wisconsinmetaltech.com/4140-steel-applications-top-10/ (accessed on 19 February 2022).

- Aircraft Alloy Steel AISI 4140. 2021. Available online: https://www.aircraftmaterials.com/data/alstst/4140.html (accessed on 19 February 2022).

- Meysami, A.H.; Ghasemzadeh, R.; Seyedein, S.H.; Aboutalebi, M.R. An investigation on the microstructure and mechanical properties of direct-quenched and tempered AISI 4140 steel. Mater. Des. 2010, 31, 1570–1575. [Google Scholar] [CrossRef]

- Ulutan, M.; Celik, O.N.; Gasan, H.; Er, U. Effect of different surface treatment methods on the friction and wear behavior of AISI 4140 steel. J. Mater. Sci. Technol. 2010, 26, 251–257. [Google Scholar] [CrossRef]

- Ulutan, M.; Yildirim, M.M.; Çelik, O.N.; Buytoz, S. Tribological properties of borided AISI 4140 steel with the powder pack-boriding method. Tribol. Lett. 2010, 38, 231–239. [Google Scholar] [CrossRef]

- ASTM G65-16e1; Standard Test Method for Measuring Abrasion Using the Dry Sand/Rubber Wheel Apparatus. ASTM International: West Conshohocken, PA, USA, 2016.

- Holmberg, K.; Ronkainen, H.; Matthews, A. Tribology of thin coatings. Ceram. Int. 2000, 26, 787–795. [Google Scholar] [CrossRef]

- Von Matuschka, M.G. Boronizing, 1st ed.; Carl Hanser: Munich, Germany, 1980. [Google Scholar]

- Velázquez-Altamirano, J.C.; Torres-Avila, I.P.; Teran-Méndez, G.; Capula-Colindres, S.I.; Cabrera-Sierra, R.; Carrera-Espinoza, R.; Hernández-Sánchez, E. A stochastic model and investigation into the probability distribution of the thickness of boride layers formed on low-carbon steel. Coatings 2019, 9, 756. [Google Scholar] [CrossRef] [Green Version]

- Amuth, S.; Sasidhar, K.N.; Meka, S.R. High nitrogen alloying of AISI 316 L stainless steel powder by nitriding. Powder Technol. 2021, 39, 456–463. [Google Scholar]

- Wang, B.; Liu, B.; Zhang, X.; Gu, J. Enhancing heavy load wear resistance of AISI 4140 steel through the formation of a severely deformed compound-free nitrided surface layer. Surf. Coat. Tech. 2018, 356, 89–95. [Google Scholar] [CrossRef]

- Da Costa-Aichholz, S.A.; Meruvia, M.S.; Soares, P.C.; Torres, J.R.D. Tribocorrosion behavior of boronized AISI 4140 steel. Surf. Coat. Tech. 2018, 352, 265–272. [Google Scholar] [CrossRef]

- Jenson, A.D.; Roy, S.; Sundararajan, S. The evolution of hardness and tribofilm growth during running-in of case carburized steel under boundary lubrication. Tribol. Int. 2018, 118, 1–10. [Google Scholar] [CrossRef] [Green Version]

- Staia, M.H.; Pérez-Delgado, Y.; Sanchez, C.; Castro, A.; le Bourhis, E.; Puchi-Cabrera, E.S. Hardness properties and high-temperature wear behavior of nitrided AISI D2 tool steel, prior and after PAPVD coating. Wear 2009, 267, 1452–1461. [Google Scholar] [CrossRef]

- Kartal, G.; Eryilmaz, O.L.; Krumdick, G.; Erdemir, A.; Timur, S. Kinetics of electrochemical boriding of low carbon steel. Appl. Surf. Sci. 2011, 257, 6928–6934. [Google Scholar] [CrossRef]

- Campos-Silva, I.; Hernández-Sánchez, E.; Rodríguez-Castro, G.; Cimenoglu, H.; Nava-Sánchez, J.L.; Meneses-Amador, A.; Carrera-Espinoza, R. A study of indentation for mechanical characterization of the Fe2B layer. Surf. Coat. Technol. 2013, 232, 173–181. [Google Scholar] [CrossRef]

- Tromas, C.; Stinville, J.C.; Templier, C.; Villechaise, P. Hardness and elastic modulus gradients in plasma-nitrided 316L polycrystalline stainless steel investigated by nanoindentation tomography. Acta Mater. 2012, 60, 1965–1973. [Google Scholar] [CrossRef]

- Selçuk, B.; Ipek, R.; Karamiş, M.B.; Kuzucu, V. An investigation on surface properties of treated low carbon and alloyed steels (boriding and carburizing). J. Mater. Process. Tech. 2000, 103, 310–317. [Google Scholar] [CrossRef]

- Erdemir, A.; Bindal, C.; Zuiker, C.; Savrun, E. Tribology of naturally occurring boric acid films on boron carbide. Surf. Coat. Tech. 1996, 86–87, 507–510. [Google Scholar] [CrossRef]

- Hernández-Sanchez, E.; Herrera-Hernández, H.; Chino-Ulloa, A.; Velázquez, J.C.; Velázquez-Mancilla, R.; Carrera-Espinoza, R. Effect of Relative Humidity on the Tribological Properties of Self-Lubricating H3BO3 Films Formed on the Surface of Steel Suitable for Biomedical Applications. Adv. Mater. Sci. Eng. 2015, 2015, 436597. [Google Scholar] [CrossRef] [Green Version]

- Sen, S.; Sen, U.; Bindal, C. Tribological properties of oxidised boride coatings grown on AISI 4140 steel. Mater. Lett. 2006, 60, 3481–3486. [Google Scholar] [CrossRef]

- Castillo, E.; Hadi, A.S.; Balakrishnan, N.; Sarabia, J.M. Extreme Value and Related Models with Applications in Engineering and Science; John Wiley and Sons, Inc.: Hoboken, NJ, USA, 2005. [Google Scholar]

- EasyFit. Distribution Fitting Software, Version 5.6. MathWave Technologies. 2015. Available online: https://easyfit.informer.com (accessed on 26 November 2021).

- Coles, S. An Introduction to Statistical Modeling of Extreme Values; Springer Series in Statistics; Springer: London, UK, 2001. [Google Scholar]

- Kowaka, M. Introduction to Life Prediction of Industrial Plant Materials: Application of the Extreme Value Statistical Method for Corrosion Analysis; Allerton Press, Inc.: New York, NY, USA, 1994. [Google Scholar]

- Walpole, R.E.; Myers, R.H. Probability and Statistics for Engineers and Scientists; Macmillan Publishing Company: New York, NY, USA, 1989. [Google Scholar]

- Dekking, F.; Kraaikamp, C.; Lopuha, H.; Meester, L.A. Modern Introduction to Probability and Statistics—Understanding Why and How; Springer Texts in Statistics; Springer: London, UK, 2005. [Google Scholar]

| Aerospace Industry | Oil and Gas Industry | Automotive Industry | Manufacturing Industry | Other Industries |

|---|---|---|---|---|

|

|

|

|

|

| Nominal Composition | |

|---|---|

| Element | Content (wt.%) |

| Carbon | 0.40 |

| Manganese | 0.90 |

| Silicon | 0.30 |

| Chromium | 1.00 |

| Molybdenum | 0.20 |

| Iron | Balance |

| Treatment | Applied Load (g) | Distance from the Surface (µm) | Number of Indentations (n) |

|---|---|---|---|

| Carburizing | 25 | 180 | 10 |

| Nitriding | 25 | 15 | 10 |

| Boriding | 25 | 65 | 10 |

| Test Type (ASTM-G65) | Load (N) | Speed (rpm) | Sliding Distance (m) | Time (s) | Sand Flow (g/min) |

|---|---|---|---|---|---|

| C | 130 | 100 | 71.8 | 30 | 300–400 |

| Material | Density (g cm−3) |

|---|---|

| FeB | 6.72 |

| Fe2B | 7.43 |

| FeN | 5.81 |

| Fe2N | 7.15 |

| Fe3N | 7.12 |

| Fe3C | 7.78 |

| AISI 4140 | 7.85 (literature) |

| Treatment Condition | Layer Thickness (µm) | Number of Measurements (n) |

|---|---|---|

| Carburizing | 365.6 ± 7.9 | 100 |

| Nitriding | 30.9 ± 4.1 | 100 |

| Boriding | 126.6 ± 26.2 | 100 |

| Treatment Condition | Hardness (GPa) | Elastic Modulus (GPa) |

|---|---|---|

| Untreated | 0.305 ± 0.03 | 198.3 ± 2.3 |

| Carburizing | 5.533 ± 0.35 | 248.5 ± 9.2 |

| Nitriding | 9.462 ± 0.76 | 129.9 ± 13.0 |

| Boriding | 18.988 ± 056 | 330.3 ± 12.4 |

| Treatment Condition | Initial Mass (g) | Final Mass (g) | Mass Loss (g) | Loss of Volume (mm−3) | Wear Rate (mm3 N−1 m−1) |

|---|---|---|---|---|---|

| Untreated | 197.4762 ± 0.1197 | 197.4564 ± 0.1187 | 0.0198 ± 0.0020 | 2.5352 ± 0.2561 | 2.7161 × 10−4 |

| Carburizing | 189.1966 ± 0.929 | 189.1867 ± 0.0966 | 0.0099 ± 0.0038 | 1.2734 ± 0.4872 | 1.3633 × 10−4 |

| Nitriding | 186.475 ± 0.2360 | 186.46777 ± 0.2373 | 0.077 ± 0.0017 | 0.9766 ± 0.2156 | 1.1538 × 10−4 |

| Boriding | 178.5808 ± 0.1889 | 178.5735 ± 0.1895 | 0.073 ± 0.0006 | 0.9299 ± 0.0764 | 1.01526 × 10−4 |

| Distribution | Probability Density Function | The p-Value for Each Hard Layer | Reference |

|---|---|---|---|

| Generalized Extreme Value | Boride layer p-value = 0.74 | [30,32] | |

| Nitride layer p-value = 0.80 | |||

| Carbide layer p-value = 0.86 | |||

| Weibull 3P | Boride layer p-value = 0.13 | [33] | |

| Nitride layer p-value = 0.92 | |||

| Carbide layer p-value = 0.87 | |||

| Fréchet 3P | Boride layer p-value = 0.63 | [30] | |

| Nitride layer p-value = 0.77 | |||

| Carbide layer p-value = 0.68 | |||

| Log-normal 3P | Boride layer p-value = 0.45 | [34,35] | |

| Nitride layer p-value = 0.55 | |||

| Carbide layer p-value = 0.83 |

| Hard Layer | Probability Density Function | K–S p-Value |

|---|---|---|

| Boride layer | GEV | 0.70 |

| Weibull 3P | 0.53 | |

| Fréchet 3P | 0.50 | |

| Log-normal 3P | 0.45 | |

| Nitride Layer | GEV | 0.81 |

| Weibull 3P | 0.94 | |

| Fréchet 3P | 0.77 | |

| Log-normal 3P | 0.55 | |

| Carbide layer | GEV | 0.85 |

| Weibull 3P | 0.87 | |

| Fréchet 3P | 0.69 | |

| Log-normal 3P | 0.85 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ruiz-Trabolsi, P.A.; Chino-Ulloa, A.; Miranda-Hernández, J.G.; Tadeo-Rosas, R.; Carrera-Espinoza, R.; Velázquez, J.C.; Hernández-Sánchez, E. A Comparative Analysis of the Tribological Behavior of Hard Layers Obtained by Three Different Hardened-Surface Processes on the Surface of AISI 4140 Steel. Crystals 2022, 12, 298. https://doi.org/10.3390/cryst12020298

Ruiz-Trabolsi PA, Chino-Ulloa A, Miranda-Hernández JG, Tadeo-Rosas R, Carrera-Espinoza R, Velázquez JC, Hernández-Sánchez E. A Comparative Analysis of the Tribological Behavior of Hard Layers Obtained by Three Different Hardened-Surface Processes on the Surface of AISI 4140 Steel. Crystals. 2022; 12(2):298. https://doi.org/10.3390/cryst12020298

Chicago/Turabian StyleRuiz-Trabolsi, Pablo Alfredo, Alexis Chino-Ulloa, José Guadalupe Miranda-Hernández, Raúl Tadeo-Rosas, Rafael Carrera-Espinoza, Julio César Velázquez, and Enrique Hernández-Sánchez. 2022. "A Comparative Analysis of the Tribological Behavior of Hard Layers Obtained by Three Different Hardened-Surface Processes on the Surface of AISI 4140 Steel" Crystals 12, no. 2: 298. https://doi.org/10.3390/cryst12020298

APA StyleRuiz-Trabolsi, P. A., Chino-Ulloa, A., Miranda-Hernández, J. G., Tadeo-Rosas, R., Carrera-Espinoza, R., Velázquez, J. C., & Hernández-Sánchez, E. (2022). A Comparative Analysis of the Tribological Behavior of Hard Layers Obtained by Three Different Hardened-Surface Processes on the Surface of AISI 4140 Steel. Crystals, 12(2), 298. https://doi.org/10.3390/cryst12020298