Rice Husk Ash-Based Concrete Composites: A Critical Review of Their Properties and Applications

Abstract

1. Introduction

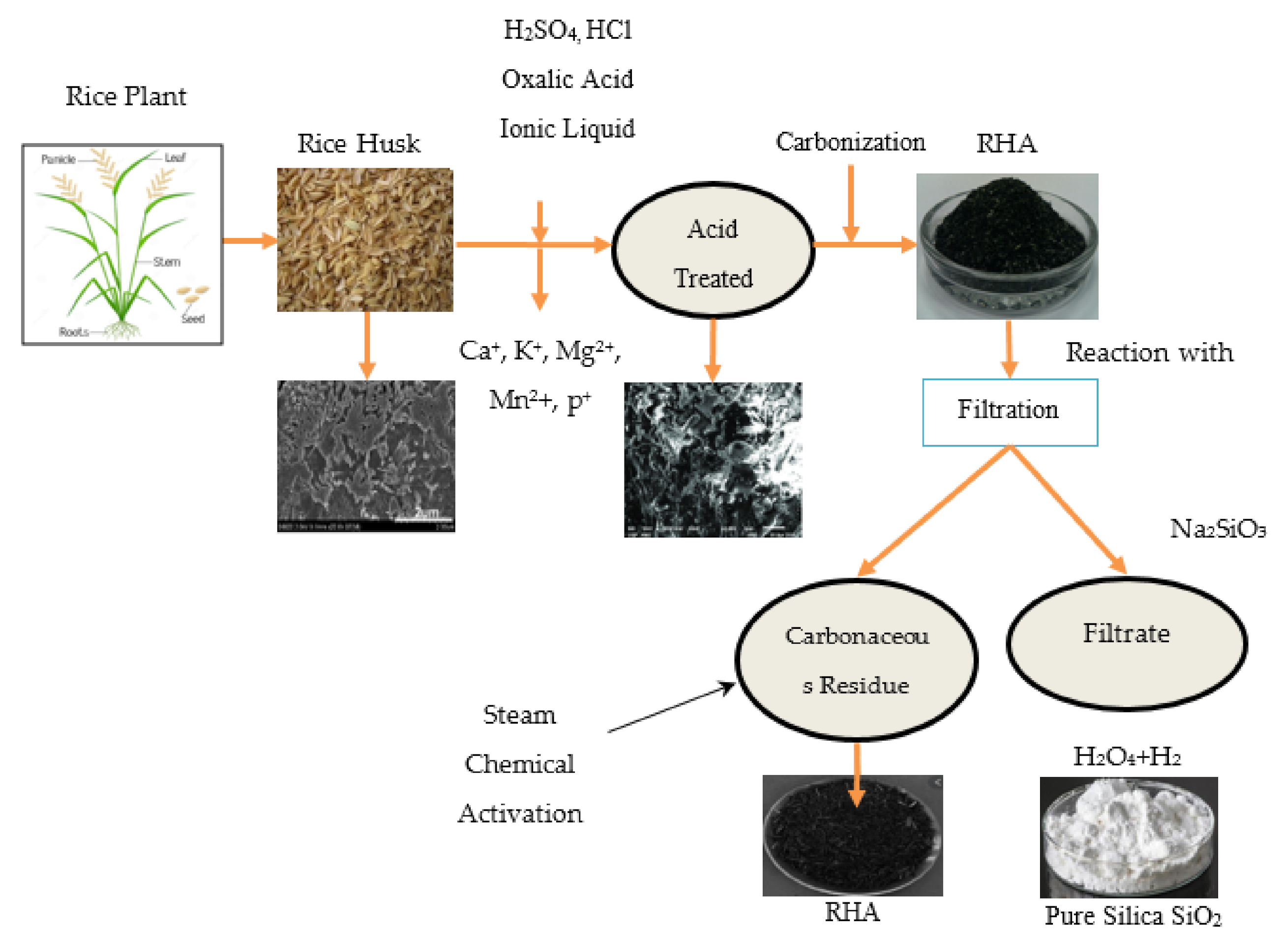

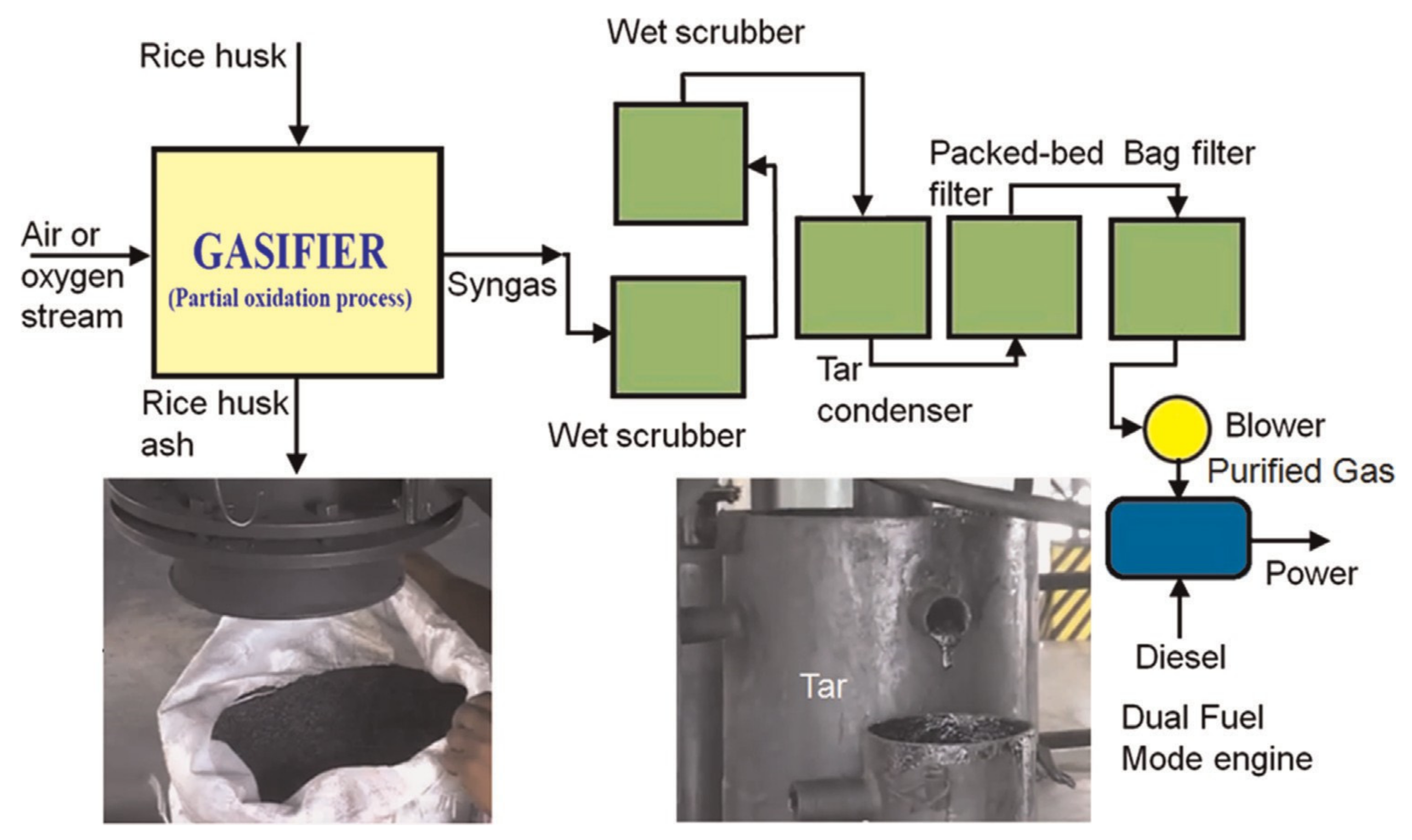

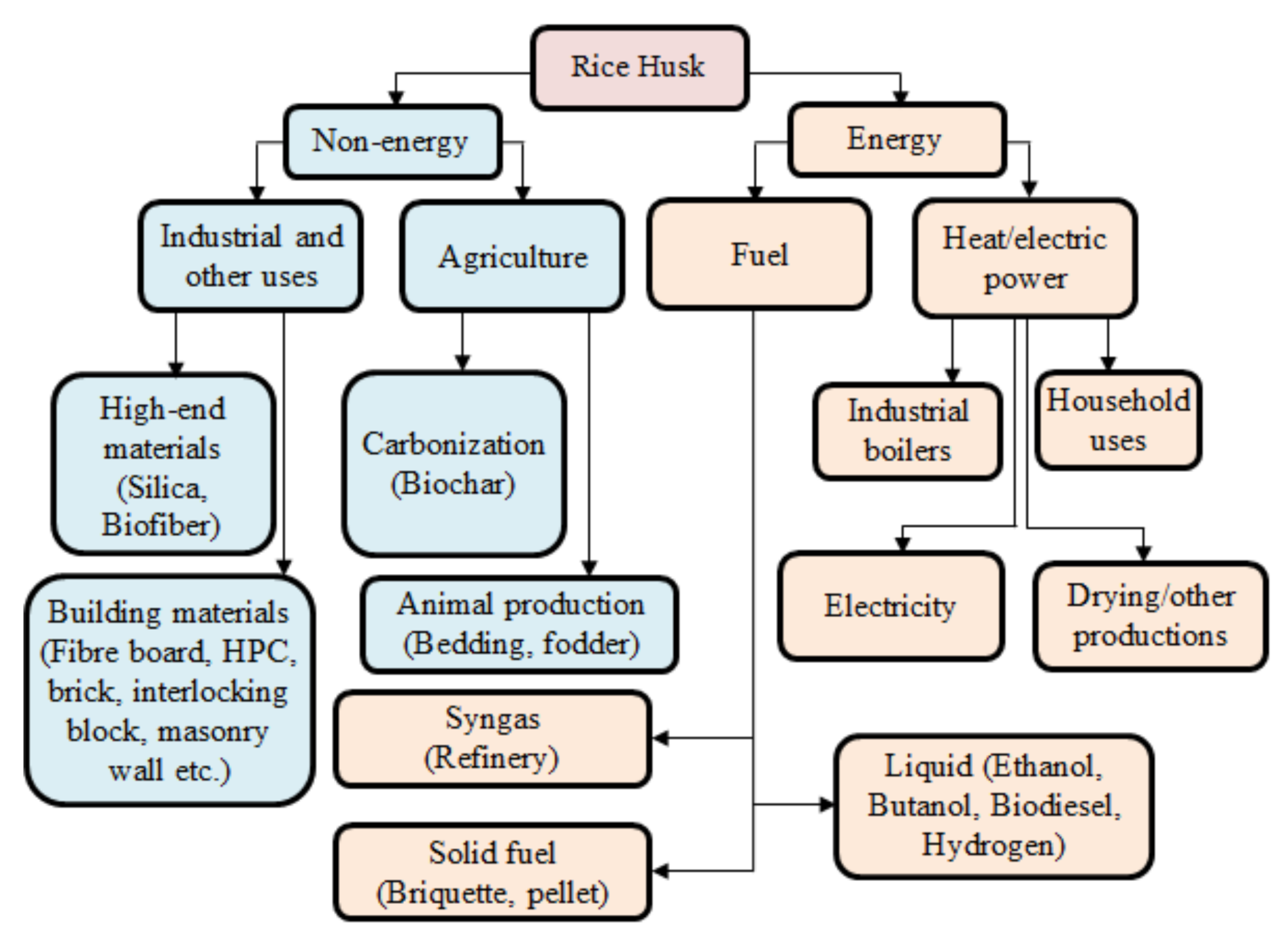

2. Clean Production of RHA

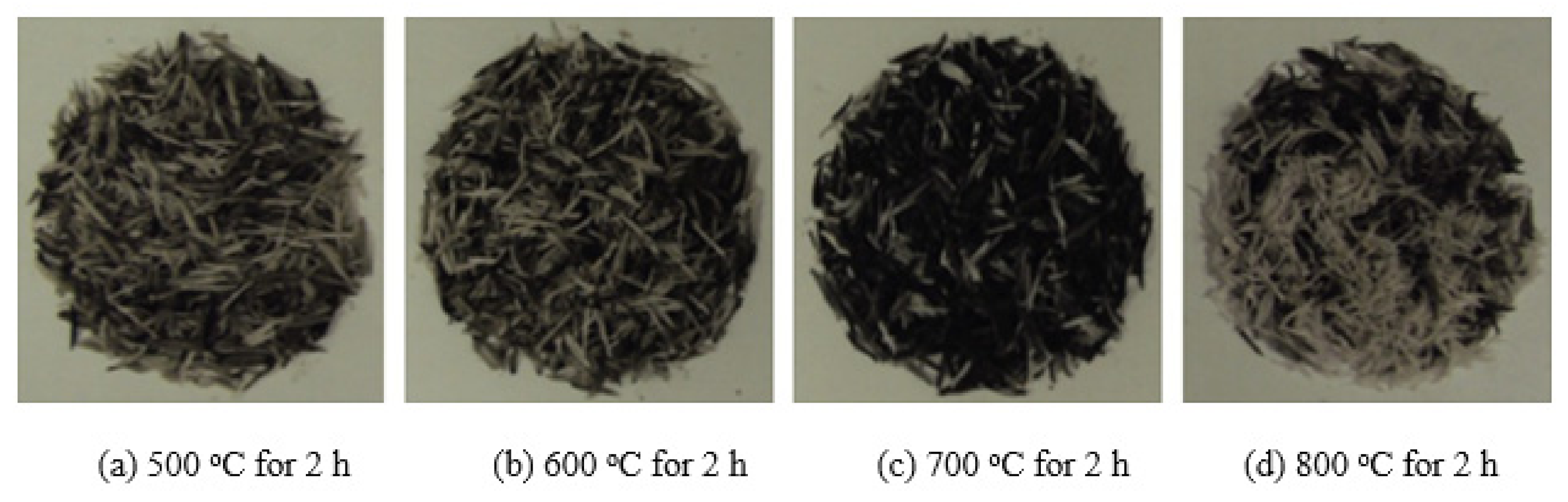

Effect of Production Techniques

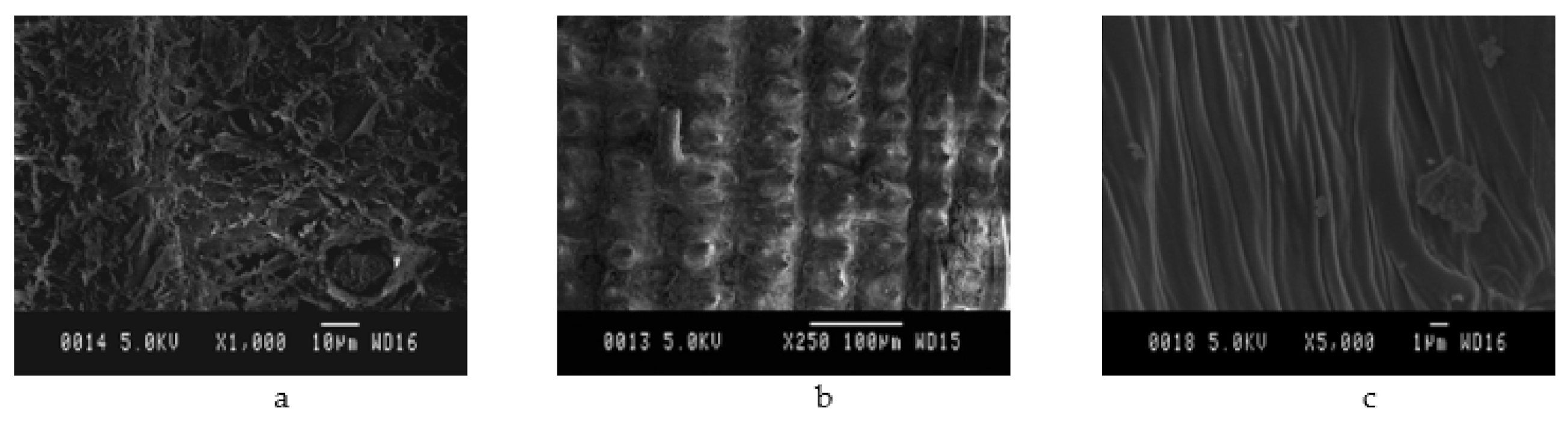

3. Pozzolanic Activity

- During the 12 h, the rate of growth in the hydration heat of the RHA is very alike to the rate of growth for Portland cement [3]. However, the pozzolanic properties of the RHA are much higher than for the other ashes; for example, fly ash.

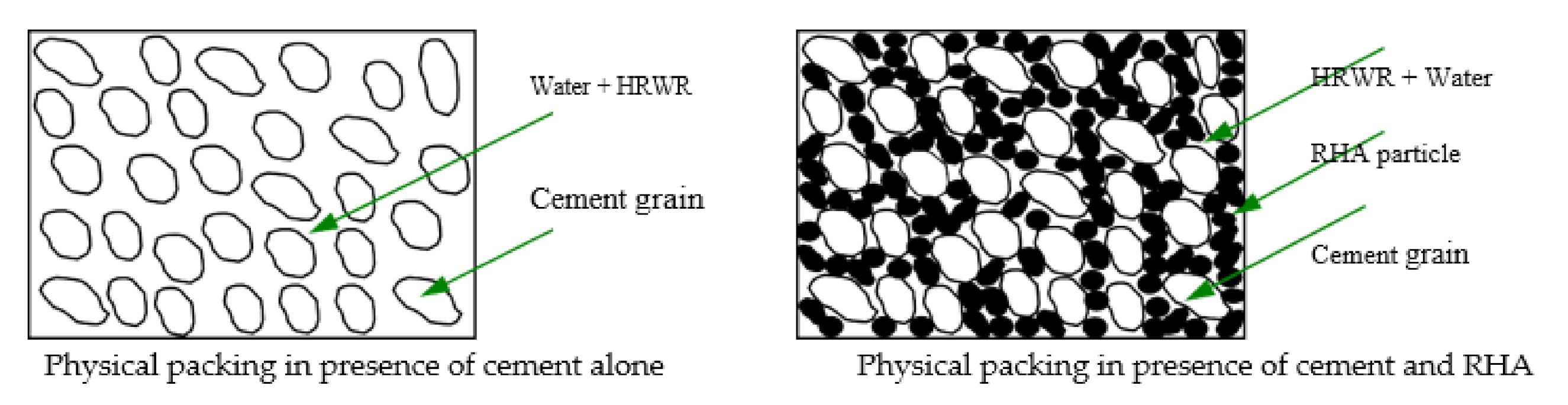

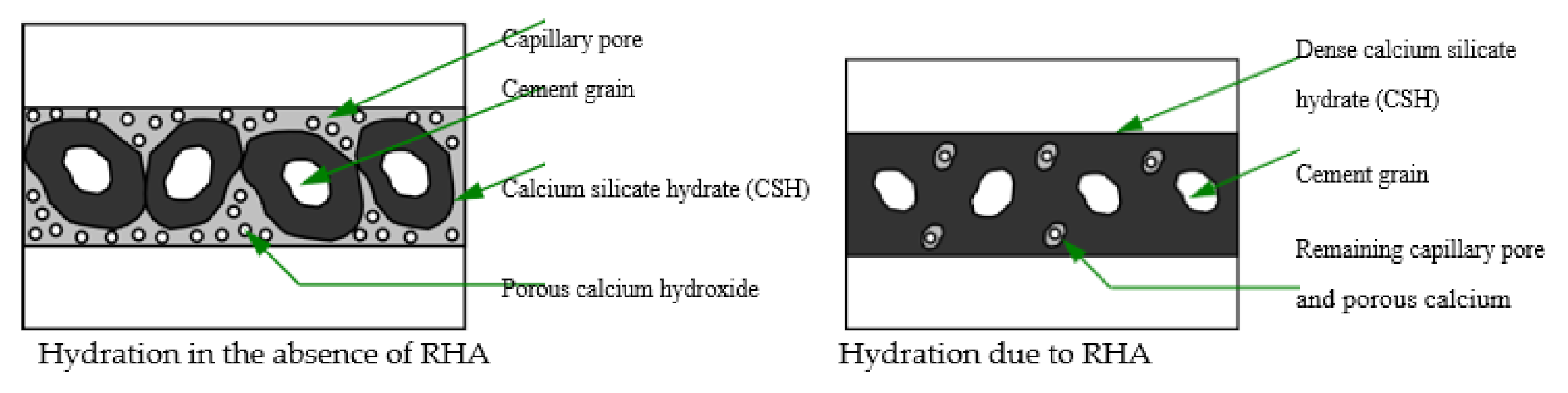

- As a result of the high content of the silicon dioxide amorphous phase of the RHA with high activity, a sharp rise in the strength of the RHA mortar was observed relative to the mortar made without RHA [13,23,59]. The cement mortar containing RHA particles usually has a lower Ca(OH)2 content after 7 days. Meanwhile, when RHA is added, smaller pores sizes can be formed in the hardened composite [45,60,61].

4. Chemical Composition

5. Physical properties

5.1. Bulk Density

5.2. Strength Activity Index, Color and Microstructure

5.3. Particle Size and Distribution

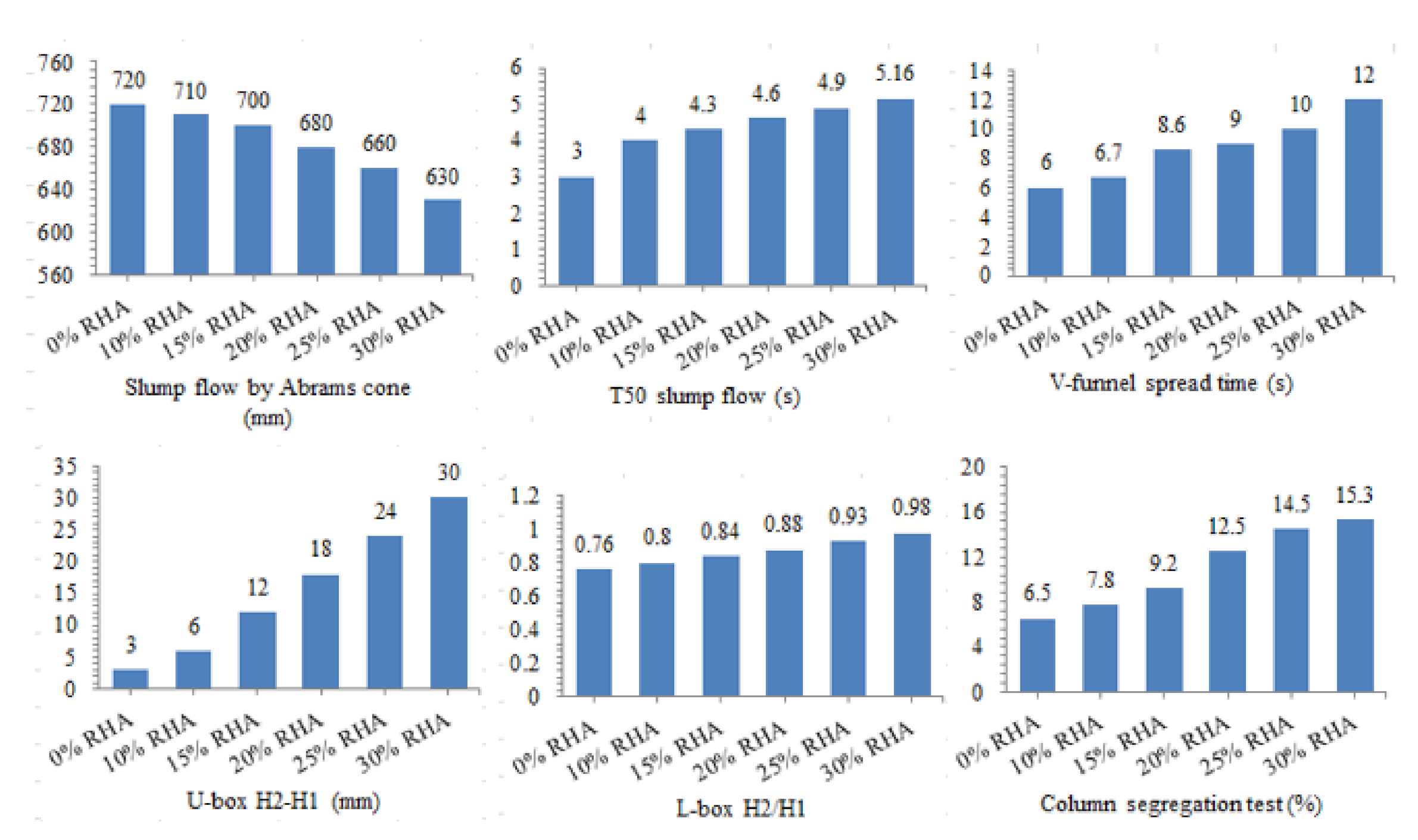

6. Fresh Properties

6.1. Workability

6.2. Setting Time

6.3. Segregation and Bleeding

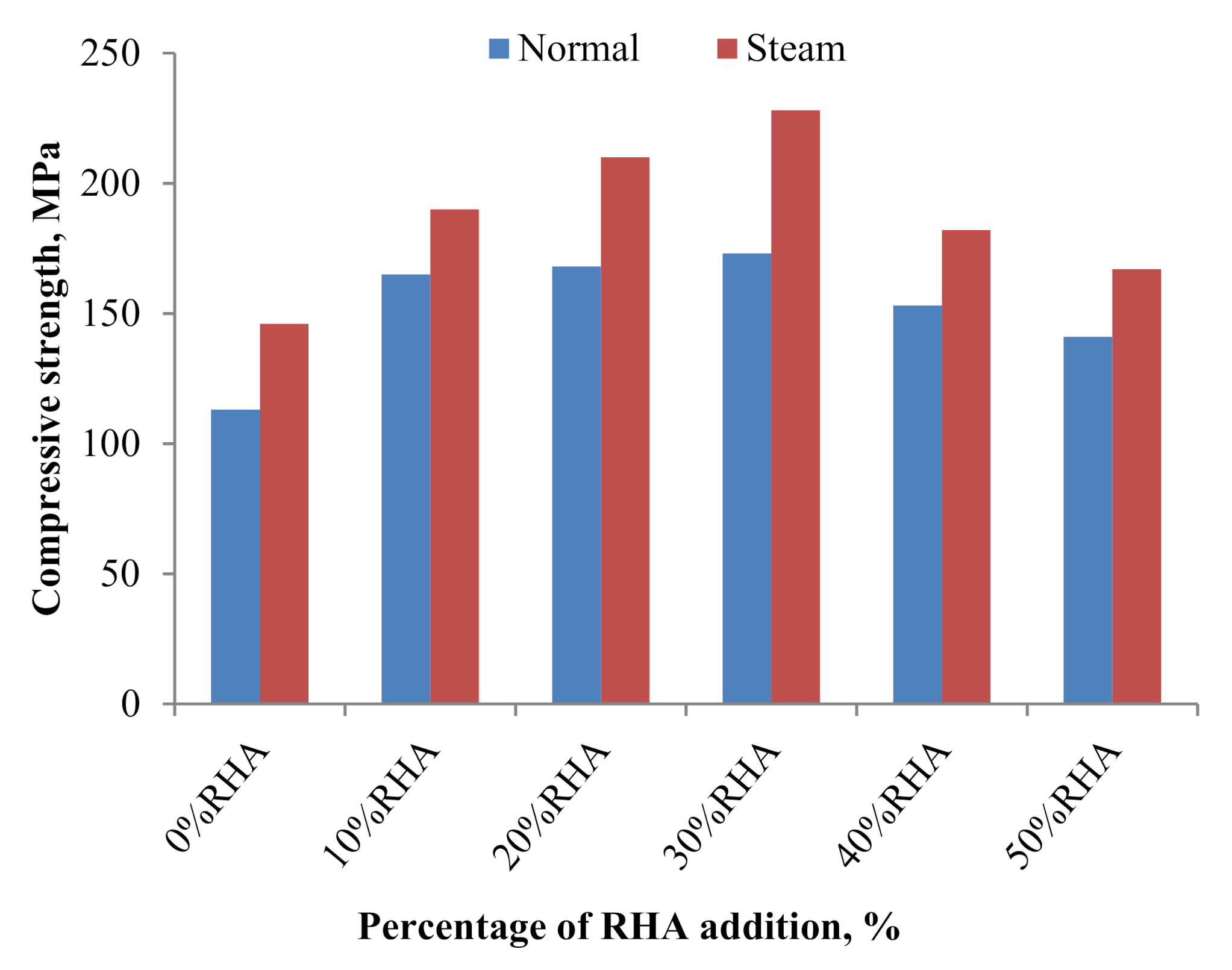

7. Mechanical Properties

7.1. Compressive Strength

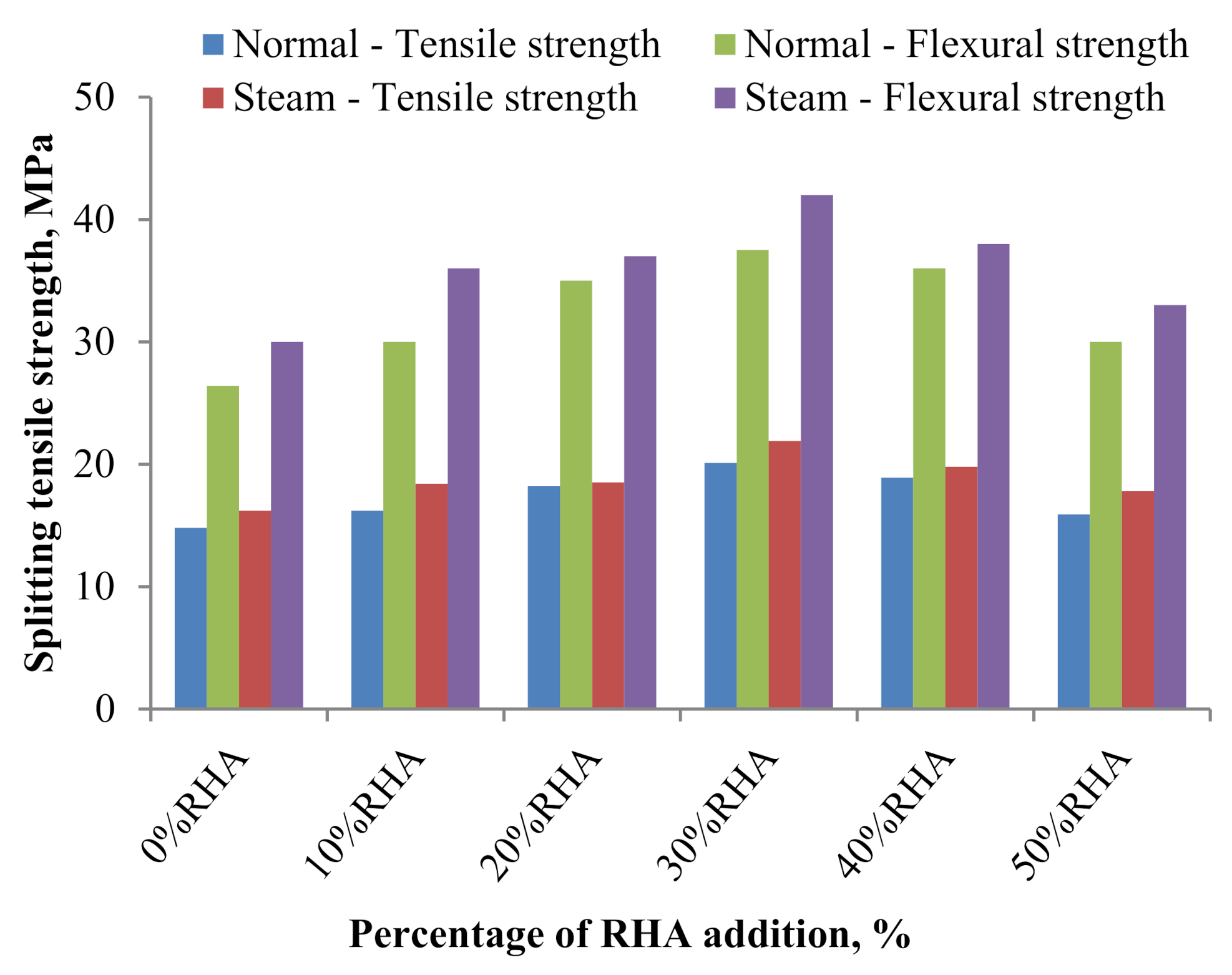

7.2. Flexural and Splitting Tensile Strengths

7.3. Modulus of Elasticity

8. Durability Properties

8.1. Drying Shrinkage

8.2. Permeability

8.3. Water Absorption and Sorptivity

8.4. Chloride Penetration

8.5. Resistance to Freezing and Thawing

8.6. Resistance to Acid and Sulphate Attack

8.7. Alkali–Silica Reaction Resistance

8.8. Resistance to Carbonation

8.9. Electrical and Thermal Conductivity

8.10. Fire Resistance

9. Applications of RHA

10. Conclusions

- -

- Further investigations are recommended to ensure that the correlation of production–structure–performance is clear;

- -

- Most of the RHA-based concretes are brittle and sensitive to cracking, and such behavior not only imposes constraints in applications, but also affects the long-term durability of the RHA concretes;

- -

- The use of RHA-based concretes for toxic metals adsorption and immobilization and for sealing CO2 is still unsatisfactory;

- -

- New applications of RHA concretes are worth exploring and can be found, such as RHA-based concretes with biomass can be developed as a class of novel lightweight fireproofing;

- -

- To further study the potential use of RHA materials to develop self-consolidating and high-strength performance concretes;

- -

- To increase the strength and durability of RHA in a hardened state using fibers; and

- -

- To further extend the possible utilization of RHA in the construction of green buildings and future sustainable cities with a reduced carbon footprint.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ASR | Alkali–silica reaction |

| BET | Brunauer–Emmett–Teller |

| CO2 | Carbon dioxide |

| CPR | Chloride penetration rate ratio |

| FA | Fly ash |

| GGBFS | Ground granulated blast furnace slag |

| HRWR | High-range water reducers |

| C-S-H | Hydrates of calcium silicate |

| HCL | Hydrochloric acid |

| ITZ | Interfacial transition zone |

| MIP | Mercury intrusion porosimetry |

| MK | Metakaolin |

| MoE | Modulus of elasticity |

| NT | Nano-TiO2 |

| OPC | Ordinary Portland cement/concrete |

| PF | Polypropylene fiber |

| RCPT | Rapid chloride permeability testing |

| RiH | Rice husk |

| RHA | Rice husk ash |

| SCC | Self-compacting concrete |

| SF | Silica fume |

| SSA | Specific surface area |

| SP | Super-plasticizer |

| SCM | Supplementary cementitious material |

| UHPC | Ultrahigh-performance concrete |

| W/C | water to cement ratio |

| XRD | X-ray diffractograms |

References

- Gandhi, H.; Tamaskar, A.N.; Parab, H.; Purohit, S. Extraction of silica from rice husk ash. J. Basic Appl. Eng. Res. 2016, 2, 330–333. [Google Scholar]

- Paris, J.M.; Roessler, J.G.; Ferraro, C.C.; Deford, H.D.; Townsend, T.G. A review of waste products utilized as supplements to Portland cement in concrete. J. Clean. Prod. 2016, 121, 1–18. [Google Scholar] [CrossRef]

- Gravitt, D. Eco-efficient construction and building materials. Constr. Manag. Econ. 2013. [Google Scholar] [CrossRef]

- Singh, B. Rice husk ash. Waste Suppl. Cem. Mater. Concr. 2018. [Google Scholar] [CrossRef]

- Aprianti, E.; Shafigh, P.; Bahri, S.; Farahani, J.N. Supplementary cementitious materials origin from agricultural wastes-A review. Constr. Build. Mater. 2015. [Google Scholar] [CrossRef]

- Thomas, B.S. Green concrete partially comprised of rice husk ash as a supplementary cementitious material–A comprehensive review. Renew. Sustain. Energy Rev. 2018. [Google Scholar] [CrossRef]

- Hossain, S.K.S.; Mathur, L.; Roy, P.K. Rice husk/rice husk ash as an alternative source of silica in ceramics: A review. J. Asian Ceram. Soc. 2018. [Google Scholar] [CrossRef]

- Shahbandeh, M. Global Rice Consumption 2019/2019, by Country. Statista. Available online: https://www.statista.com/statistics/255971/top-countries-based-on-rice-consumption-2012-2013/ (accessed on 8 July 2020).

- Kishore, R.; Bhikshma, V.; Jeevana Prakash, P. Study on strength characteristics of high strength Rice Husk Ash concrete. Procedia Eng. 2011. [Google Scholar] [CrossRef]

- Siddique, R. Waste Materials and by-Products in Concrete; Springer: Berlin, Germany, 2008. [Google Scholar] [CrossRef]

- Antiohos, S.K.; Papadakis, V.G.; Tsimas, S. Rice husk ash (RHA) effectiveness in cement and concrete as a function of reactive silica and fineness. Cem. Concr. Res. 2014. [Google Scholar] [CrossRef]

- International Rice Research Institute (IRRI). Rice Husk. Available online: http://www.knowledgebank.irri.org/step-by-step-production/postharvest/rice-by-products/rice-husk (accessed on 1 July 2020).

- Ye, G.; Huang, H.; van Tuan, N. Rice Husk Ash; Springer: Berlin, Germany, 2018. [Google Scholar] [CrossRef]

- De Paula, M.O.; Ferreira Tinoco, I.D.F.; de Souza Rodrigues, C.; Osorio Saraz, J.A. Sugarcane bagasse ash as a partial-port-land-cement-replacement material. DYNA 2010, 77, 47–54. [Google Scholar]

- Choi, N.W.; Mori, I.; Ohama, Y. Development of rice husks-plastics composites for building materials. Waste Manag. 2006. [Google Scholar] [CrossRef] [PubMed]

- Foletto, E.L.; Hoffmann, R.; Hoffmann, R.S.; Portugal, U.L.; Jahn, S.L. Applicability of rice husk ash. Quim. Nova. 2005. [Google Scholar] [CrossRef]

- Gonçalves, M.R.F.; Bergmann, C.P. Thermal insulators made with rice husk ashes: Production and correlation between properties and microstructure. Constr. Build. Mater. 2007. [Google Scholar] [CrossRef]

- Soltani, N.; Bahrami, A.; Pech-Canul, M.I.; González, L.A. Review on the physicochemical treatments of rice husk for production of advanced materials. Chem. Eng. J. 2015. [Google Scholar] [CrossRef]

- Liu, X.; Chen, X.; Yang, L.; Chen, H.; Tian, Y.; Wang, Z. A review on recent advances in the comprehensive application of rice husk ash. Res. Chem. Intermed. 2016. [Google Scholar] [CrossRef]

- Shen, Y. Rice husk silica derived nanomaterials for sustainable applications. Renew. Sustain. Energy Rev. 2017. [Google Scholar] [CrossRef]

- Shen, Y.; Zhao, P.; Shao, Q. Porous silica and carbon derived materials from rice husk pyrolysis char. Microporous Mesoporous Mater. 2014. [Google Scholar] [CrossRef]

- Prasara, A.J.; Gheewala, S.H. Sustainable utilization of rice husk ash from power plants: A review. J. Clean. Prod. 2017. [Google Scholar] [CrossRef]

- Muthadhi, A.; Anitha, R.; Kothandaraman, S. Rice husk ash-Properties and its uses: A review. J. Inst. Eng. Civ. Eng. Div. 2007, 88, 50–56. [Google Scholar]

- Al-Khalaf, M.N.; Yousif, H.A. Use of rice husk ash in concrete. Int. J. Cem. Compos. Light. Concr. 1984. [Google Scholar] [CrossRef]

- Sata, V.; Sathonsaowaphak, A.; Chindaprasirt, P. Resistance of lignite bottom ash geopolymer mortar to sulfate and sulfuric acid attack. Cem. Concr. Compos. 2012. [Google Scholar] [CrossRef]

- Chindaprasirt, P.; Kanchanda, P.; Sathonsaowaphak, A.; Cao, H.T. Sulfate resistance of blended cements containing fly ash and rice husk ash. Constr. Build. Mater. 2007. [Google Scholar] [CrossRef]

- Della, V.P.; Kühn, I.; Hotza, D. Rice husk ash as an alternate source for active silica production. Mater. Lett. 2002. [Google Scholar] [CrossRef]

- Rukzon, S.; Chindaprasirt, P.; Mahachai, R. Effect of grinding on chemical and physical properties of rice husk ash. Int. J. Miner. Metall. Mater. 2009. [Google Scholar] [CrossRef]

- Chindaprasirt, P.; Cao, T. The properties and durability of high-pozzolanic industrial by-products content concrete masonry blocks. Bricks Blocks Des. Prop. Durab. 2015. [Google Scholar] [CrossRef]

- Habeeb, G.A.; Fayyadh, M.M. Rice husk ash concrete: The effect of RHA average particle size on mechanical properties and drying shrinkage. Aust. J. Basic Appl. Sci. 2009, 3, 1616–1622. [Google Scholar]

- Habeeb, G.A.; Bin Mahmud, H. Study on properties of rice husk ash and its use as cement replacement material. Mater. Res. 2010, 13, 185–190. [Google Scholar] [CrossRef]

- Givi, A.N.; Rashid, S.A.; Aziz, F.N.A.; Salleh, M.A.M. Assessment of the effects of rice husk ash particle size on strength, water permeability and workability of binary blended concrete. Constr. Build. Mater. 2010. [Google Scholar] [CrossRef]

- Chindaprasirt, P.; Rukzon, S. Strength, porosity and corrosion resistance of ternary blend Portland cement, rice husk ash and fly ash mortar. Constr. Build. Mater. 2008. [Google Scholar] [CrossRef]

- Pode, R. Potential applications of rice husk ash waste from rice husk biomass power plant. Renew. Sustain. Energy Rev. 2016. [Google Scholar] [CrossRef]

- Fernandes, I.J.; Calheiro, D.; Kieling, A.G.; Moraes, C.A.M.; Rocha, T.L.A.C.; Brehm, F.A.; Modolo, R.C.E. Characterization of rice husk ash produced using different biomass combustion techniques for energy. Fuel 2016. [Google Scholar] [CrossRef]

- Kumar, S.; Sangwan, P.; Bidra, D.R.M.V.S. Utilization of rice husk and their ash: A review. J. Chem. Environ. Sci. 2013, 1, 126–129. [Google Scholar]

- Raut, S.P.; Ralegaonkar, R.V.; Mandavgane, S.A. Development of sustainable construction material using industrial and agricultural solid waste: A review of waste-create bricks. Constr. Build. Mater. 2011. [Google Scholar] [CrossRef]

- Amran, Y.H.M.; Alyousef, R.; Alabduljabbar, H.; El-Zeadani, M. Clean production and properties of geopolymer concrete: A review. J. Clean. Prod. 2020. [Google Scholar] [CrossRef]

- Gastaldini, A.L.G.; Isaia, G.C.; Gomes, N.S.; Sperb, J.E.K. Chloride penetration and carbonation in concrete with rice husk ash and chemical activators. Cem. Concr. Compos. 2007. [Google Scholar] [CrossRef]

- Ghosh, R. A review study on precipitated silica and activated carbon from rice husk. J. Chem. Eng. Process Technol. 2013. [Google Scholar] [CrossRef]

- Zareei, S.A.; Ameri, F.; Dorostkar, F.; Ahmadi, M. Rice husk ash as a partial replacement of cement in high strength concrete containing micro silica: Evaluating durability and mechanical properties. Case Stud. Constr. Mater. 2017. [Google Scholar] [CrossRef]

- Nair, D.G.; Fraaij, A.; Klaassen, A.A.K.; Kentgens, A.P.M. A structural investigation relating to the pozzolanic activity of rice husk ashes. Cem. Concr. Res. 2008. [Google Scholar] [CrossRef]

- Chopra, D.; Siddique, R. Strength, permeability and microstructure of self-compacting concrete containing rice husk ash. Biosyst. Eng. 2015. [Google Scholar] [CrossRef]

- Hesami, S.; Ahmadi, S.; Nematzadeh, M. Effects of rice husk ash and fiber on mechanical properties of pervious concrete pavement. Constr. Build. Mater. 2014. [Google Scholar] [CrossRef]

- Jamil, M.; Khan, M.N.N.; Karim, M.R.; Kaish, A.B.M.A.; Zain, M.F.M. Physical and chemical contributions of Rice Husk Ash on the properties of mortar. Constr. Build. Mater. 2016. [Google Scholar] [CrossRef]

- Atta, A.Y.; Jibril, B.Y.; Aderemi, B.O.; Adefila, S.S. Preparation of analcime from local kaolin and rice husk ash. Appl. Clay Sci. 2012. [Google Scholar] [CrossRef]

- Safiuddin, M.; West, J.S.; Soudki, K.A. Hardened properties of self-consolidating high performance concrete including rice husk ash. Cem. Concr. Compos. 2010. [Google Scholar] [CrossRef]

- Safiuddin, M.; West, J.S.; Soudki, K.A. Flowing ability of self-consolidating concrete and its binder paste and mortar components incorporating rice husk ash. Can. J. Civ. Eng. 2010. [Google Scholar] [CrossRef]

- Mistry, B. Properties and Industrial Applications of Rice Husk. Int. J. Eng. Sci. 2016, 6, 2677–2679. [Google Scholar]

- Doan, T.; Louda, P.; Kroisova, D.; Bortnovsky, O.; Thang, N. New generation of geopolymer composite for fire-resistance. Adv. Compos. Mater. Anal. Nat. Man Made Mater. 2011. [Google Scholar] [CrossRef]

- Zou, Y.; Yang, T. Rice husk, rice husk ash and their applications, in: Rice Bran Rice Bran Oil Chem. Process. Util. 2019. [Google Scholar] [CrossRef]

- Hincapié-Rojas, D.F.A.; Rosales-Rivera, P. Pineda-Gomez, Synthesis and characterisation of submicron silica particles from rice husk. Green Mater. 2018. [Google Scholar] [CrossRef]

- Park, K.B.; Kwon, S.J.; Wang, X.Y. Analysis of the effects of rice husk ash on the hydration of cementitious materials. Constr. Build. Mater. 2016. [Google Scholar] [CrossRef]

- Mohseni, E.; Khotbehsara, M.M.; Naseri, F.; Monazami, M.; Sarker, P. Polypropylene fiber reinforced cement mortars containing rice husk ash and nano-alumina. Constr. Build. Mater. 2016. [Google Scholar] [CrossRef]

- Koushkbaghi, M.; Alipour, P.; Tahmouresi, B.; Mohseni, E.; Saradar, A.; Sarker, P.K. Influence of different monomer ratios and recycled concrete aggregate on mechanical properties and durability of geopolymer concretes. Constr. Build. Mater. 2019. [Google Scholar] [CrossRef]

- Cisse, I.K.; Laquerbe, M. Mechanical characterization of filler sandcretes with rice husk ash additions. Study applied to Senegal. Cem. Concr. Res. 2000. [Google Scholar] [CrossRef]

- Jaturapitakkul, C.; Roongreung, B. Cementing material from calcium carbide residue-rice husk ash. J. Mater. Civ. Eng. 2003. [Google Scholar] [CrossRef]

- Tambichik, M.A.; Mohamad, N.; Samad, A.A.A.; Bosro, M.Z.M.; Iman, M.A. Utilization of construction and agricultural waste in Malaysia for development of green concrete: A review. IOP Conf. Ser. Earth Environ. Sci. 2018. [Google Scholar] [CrossRef]

- Sandhu, R.K.; Siddique, R. Influence of rice husk ash (RHA) on the properties of self-compacting concrete: A review. Constr. Build. Mater. 2017. [Google Scholar] [CrossRef]

- Ferraro, R.M.; Nanni, A. Effect of off-white rice husk ash on strength, porosity, conductivity and corrosion resistance of white concrete. Constr. Build. Mater. 2012. [Google Scholar] [CrossRef]

- Siddique, R.; Singh, K.; Kunal, P.; Singh, M.; Corinaldesi, V.; Rajor, A. Properties of bacterial rice husk ash concrete. Constr. Build. Mater. 2016. [Google Scholar] [CrossRef]

- Neville, A.M.; Brooks, J.J. Properties of concrete. Build. Environ. 2010. [Google Scholar] [CrossRef]

- Givi, M.A.; Abdul Rashid, A.N.; Abdul Aziz, S.; Mohd Salleh, F.N. Contribution of rice husk ash to the properties of mortar and concrete: A review. J. Am. Sci. 2010, 6, 157–165. [Google Scholar]

- Mahzabin, M.S.; Hock, L.J.; Hossain, M.S.; Kang, L.S. The influence of addition of treated kenaf fibre in the production and properties of fibre reinforced foamed composite. Constr. Build. Mater. 2018. [Google Scholar] [CrossRef]

- ACTM C 618-03 Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete; ASTM International: West Conshohocken, PA, USA, 2003. [CrossRef]

- Hegazy, B.E.D.E.; Fouad, H.A.; Hassanain, A.M. Brick manufacturing from water treatment sludge and rice husk ash. Aust. J. Basic Appl. Sci. 2012, 6, 453–461. [Google Scholar]

- Pabst, W.; Gregorová, E. Elastic properties of silica polymorphs-a review. Ceram. Silikaty. 2013, 57, 167–184. [Google Scholar]

- Shinohara, Y.; Kohyama, N. Quantitative analysis of tridymite and cristobalite crystallized in rice husk ash by heating. Ind. Health. 2004. [Google Scholar] [CrossRef]

- Van Tuan, N.; Ye, G.; Van Breugel, K.A.; Fraaij, A.L.; Bui, D.D. The study of using rice husk ash to produce ultra-high performance concrete. Constr. Build. Mater. 2011. [Google Scholar] [CrossRef]

- Berkin, G. Heat absorbing glass from rice husk ash for a sustainable environment. WIT Trans. Ecol. Environ. 2008. [Google Scholar] [CrossRef]

- Boontawee, K.; Pansuk, W.; Tachai, L.; Kondoh, K. Effect of Rice Husk Ash Silica as Cement Replacement for Making Construction Mortar. Key Eng. Mater. 2018. [Google Scholar] [CrossRef]

- Lertsatitthanakorn, C.; Atthajariyakul, S.; Soponronnarit, S. Techno-economical evaluation of a rice husk ash (RHA) based sand-cement block for reducing solar conduction heat gain to a building. Constr. Build. Mater. 2009. [Google Scholar] [CrossRef]

- Sakr, K. Effects of silica fume and rice husk ash on the properties of heavy weight concrete. J. Mater. Civ. Eng. 2006. [Google Scholar] [CrossRef]

- Raheem, M.; Otuose, H.S.; Abdulhafiz, U. Properties of rice husk ash stabilized laterite roof tiles, leonardo electron. J. Pract. Technol. 2013, 23, 41–50. [Google Scholar]

- Rahman, M.E.; Muntohar, A.S.; Pakrashi, V.; Nagaratnam, B.H.; Sujan, D. Self compacting concrete from uncontrolled burning of rice husk and blended fine aggregate. Mater. Des. 2014. [Google Scholar] [CrossRef]

- Kulkarni, M.S.; Govind Mirgal, P.; Prakash Bodhale, P.; Tande, S.N.; Students, M.T. Effect of rice husk ash on properties of concrete. J. Civ. Eng. Environ. Technol. 2014. [Google Scholar]

- Kumar, A.; Singha, S.; Dasgupta, D.; Datta, S.; Mandal, T. Simultaneous recovery of silica and treatment of rice mill wastewater using rice husk ash: An economic approach. Ecol. Eng. 2015. [Google Scholar] [CrossRef]

- Zemke, N.; Woods, E. Rice husk ash. Rice Husk Ash 2009, 7, 1–12. [Google Scholar]

- Sadrmomtazi, A.; Sobhani, J.; Mirgozar, M.A.; Najimi, M. Properties of multi-strength grade EPS concrete containing silica fume and rice husk ash. Constr. Build. Mater. 2012. [Google Scholar] [CrossRef]

- James, J.; Subba Rao, M. Reactivity of rice husk ash. Cem. Concr. Res. 1986. [Google Scholar] [CrossRef]

- Gursel, A.P.; Maryman, H.; Ostertag, C. A life-cycle approach to environmental, mechanical, and durability properties of “green” concrete mixes with rice husk ash. J. Clean. Prod. 2016. [Google Scholar] [CrossRef]

- Rodríguez De Sensale, G. Effect of rice-husk ash on durability of cementitious materials. Cem. Concr. Compos. 2010. [Google Scholar] [CrossRef]

- Zahedi, M.; Ramezanianpour, A.A.; Ramezanianpour, A.M. Evaluation of the mechanical properties and durability of cement mortars containing nanosilica and rice husk ash under chloride ion penetration. Constr. Build. Mater. 2015. [Google Scholar] [CrossRef]

- Day, K.; Aldred, J.; Hudson, B. Properties of concrete. Concr. Mix Des. Qual. Control. Specif. 2013. [Google Scholar] [CrossRef]

- Xu, W.; Lo, T.Y.; Memon, S.A. Microstructure and reactivity of rich husk ash. Constr. Build. Mater. 2012. [Google Scholar] [CrossRef]

- Madheswaran, C.; Gnanasundar, G.; Gopalakrishnan, N. Effect of molarity in geopolymer concrete. Int. J. Civ. Struct. Eng. 2013, 4, 106–115. [Google Scholar] [CrossRef]

- Antiohos, S.K.; Tapali, J.G.; Zervaki, M.; Sousa-Coutinho, J.; Tsimas, S.; Papadakis, V.G. Low embodied energy cement containing untreated RHA: A strength development and durability study. Constr. Build. Mater. 2013. [Google Scholar] [CrossRef]

- Yu, R.; Spiesz, P.; Brouwers, H.J.H. Mix design and properties assessment of Ultra-High Performance Fibre Reinforced Concrete (UHPFRC). Cem. Concr. Res. 2014, 56, 29–39. [Google Scholar] [CrossRef]

- Görhan, G.; Şimşek, O. Porous clay bricks manufactured with rice husks. Constr. Build. Mater. 2013. [Google Scholar] [CrossRef]

- Fediuk, R.S.; Lesovik, V.S.; Svintsov, A.P.; Mochalov, A.V.; Kulichkov, S.V.; Stoyushko, N.Y.; Gladkova, N.A.; Timokhin, R.A. Self-compacting concrete using pretreatmented rice husk ash. Mag. Civ. Eng. 2018, 79. [Google Scholar] [CrossRef]

- Nehdi, M.; Duquette, J.; El Damatty, A. Performance of rice husk ash produced using a new technology as a mineral admixture in concrete. Cem. Concr. Res. 2003, 33, 1203–1210. [Google Scholar] [CrossRef]

- Le, H.T.; Ludwig, H.M. Effect of rice husk ash and other mineral admixtures on properties of self-compacting high performance concrete. Mater. Des. 2016. [Google Scholar] [CrossRef]

- Yuzer, N.; Cinar, Z.; Akoz, F.; Biricik, H.; Gurkan, Y.Y.; Kabay, N.; Kizilkanat, A.B. Influence of raw rice husk addition on structure and properties of concrete. Constr. Build. Mater. 2013. [Google Scholar] [CrossRef]

- Kizhakkumodom Venkatanarayanan, H.; Rangaraju, P.R. Effect of grinding of low-carbon rice husk ash on the microstructure and performance properties of blended cement concrete. Cem. Concr. Compos. 2015. [Google Scholar] [CrossRef]

- El-Dakroury, A.; Gasser, M.S. Rice husk ash (RHA) as cement admixture for immobilization of liquid radioactive waste at different temperatures. J. Nucl. Mater. 2008. [Google Scholar] [CrossRef]

- Ganesan, K.; Rajagopal, K. Rice husk ash blended cement: Assessment of optimal level of replacement for strength and permeability properties of concrete. Constr. Build. Mater. 2008. [Google Scholar] [CrossRef]

- Siddique, R.; Iqbal Khan, M. Supplementary Cementing Materials; Springer: Berlin, Germany, 2011. [Google Scholar]

- Singh, M.; Siddique, R. Properties of concrete containing high volumes of coal bottom ash as fine aggregate. J. Clean. Prod. 2015, 91, 269–278. [Google Scholar] [CrossRef]

- Jongpradist, P.; Homtragoon, W.; Sukkarak, R.; Kongkitkul, W.; Jamsawang, P. Efficiency of rice husk ash as cementitious material in high-strength cement-admixed clay. Adv. Civ. Eng. 2018. [Google Scholar] [CrossRef]

- Singh, N.B.; Singh, V.D.; Rai, S.; Chaturvedi, S. Effect of lignosulfonate, calcium chloride and their mixture on the hydration of RHA-blended portland cement. Cem. Concr. Res. 2002. [Google Scholar] [CrossRef]

- Yüksel, S.; Siddique, R.; Özkan, Ö. Influence of high temperature on the properties of concretes made with industrial by-products as fine aggregate replacement. Constr. Build. Mater. 2011. [Google Scholar] [CrossRef]

- Khan, M.I.; Siddique, R. Utilization of silica fume in concrete: Review of durability properties. Resour. Conserv. Recycl. 2011. [Google Scholar] [CrossRef]

- Sua-Iam, G.; Makul, N. Utilization of high volumes of unprocessed lignite-coal fly ash and rice husk ash in self-consolidating concrete. J. Clean. Prod. 2014. [Google Scholar] [CrossRef]

- Aslam, M.; Shafigh, P.; Jumaat, M.Z. Oil-palm by-products as lightweight aggregate in concrete mixture: A review. J. Clean. Prod. 2016. [Google Scholar] [CrossRef]

- Obi, F.; Ugwuishiwu, B.; Nwakaire, J. Agricultural waste concept, generation, utilization and management. Niger. J. Technol. 2016. [Google Scholar] [CrossRef]

- Van, V.T.A.; Rößler, C.; Bui, D.D.; Ludwig, H.M. Rice husk ash as both pozzolanic admixture and internal curing agent in ultra-high performance concrete. Cem. Concr. Compos. 2014. [Google Scholar] [CrossRef]

- Sathawane, S.H.; Vairagade, V.S.; Kene, K.S. Combine effect of rice husk ash and fly ash on concrete by 30% cement replacement. Procedia Eng. 2013. [Google Scholar] [CrossRef]

- Jittin, V.; Bahurudeen, A.; Ajinkya, S.D. Utilisation of rice husk ash for cleaner production of different construction products. J. Clean. Prod. 2020, 263, 121578. [Google Scholar] [CrossRef]

- Jamil, M.; Kaish, A.B.M.A.; Raman, S.N.; Zain, M.F.M. Pozzolanic contribution of rice husk ash in cementitious system. Constr. Build. Mater. 2013, 47, 588–593. [Google Scholar] [CrossRef]

- Joshaghani, A.; Moeini, M.A. Evaluating the effects of sugarcane-bagasse ash and rice-husk ash on the mechanical and durability properties of mortar. J. Mater. Civ. Eng. 2018, 30, 1–14. [Google Scholar] [CrossRef]

- Bazargan, A.; Bazargan, M.; McKay, G. Optimization of rice husk pretreatment for energy production. Renew. Energy 2015. [Google Scholar] [CrossRef]

- Das, S.K.; Mishra, J.; Singh, S.K.; Mustakim, S.M.; Patel, A.; Das, S.K.; Behera, U. Characterization and utilization of rice husk ash (RHA) in fly ash–Blast furnace slag based geopolymer concrete for sustainable future. Mater. Today Proc. 2020. [Google Scholar] [CrossRef]

- Gastaldini, A.L.G.; Isaia, G.C.; Hoppe, T.F.; Missau, F.; Saciloto, A.P. Influence of the use of rice husk ash on the electrical resistivity of concrete: A technical and economic feasibility study. Constr. Build. Mater. 2009. [Google Scholar] [CrossRef]

- Vigneshwari, M.; Arunachalam, K.; Angayarkanni, A. Replacement of silica fume with thermally treated rice husk ash in Reactive Powder Concrete. J. Clean. Prod. 2018. [Google Scholar] [CrossRef]

- Rodríguez De Sensale, G. Strength development of concrete with rice-husk ash. Cem. Concr. Compos. 2006. [Google Scholar] [CrossRef]

- Makul, N.; Sua-iam, G. Effect of granular urea on the properties of self-consolidating concrete incorporating untreated rice husk ash: Flowability, compressive strength and temperature rise. Constr. Build. Mater. 2018. [Google Scholar] [CrossRef]

- Memon, S.A.; Shaikh, M.A.; Akbar, H. Utilization of rice husk ash as viscosity modifying agent in self compacting concrete. Constr. Build. Mater. 2011. [Google Scholar] [CrossRef]

- Atan, M.N.; Awang, H. The compressive and flexural strengths of self-compacting concrete using raw rice husk ash. J. Eng. Sci. Technol. 2011, 6, 720–732. [Google Scholar]

- Ramezanianpour, A.A.; Mahdikhani, M.; Ahmadibeni, G. The effect of rice husk ash on mechanical properties and durability of sustainable concretes. Int. J. Civ. Eng. 2009, 7, 83–91. [Google Scholar]

- Chatveera, B.; Lertwattanaruk, P. Durability of conventional concretes containing black rice husk ash. J. Environ. Manage. 2011. [Google Scholar] [CrossRef]

- Garg, N.; Gandhi, L.; Kumar, A.; Kumar, P.; Saini, P.K. Measurement uncertainty in airborne sound insulation and single-number quantities using sound pressure and sound intensity approaches. Noise Control. Eng. J. 2016. [Google Scholar] [CrossRef]

- He, J.; Jie, Y.; Zhang, J.; Yu, Y.; Zhang, G. Synthesis and characterization of red mud and rice husk ash-based geopolymer composites. Cem. Concr. Compos. 2013. [Google Scholar] [CrossRef]

- Hai He, Z.; Yuan, L.; Li, S.; Gui, D. Creep analysis of concrete containing rice husk ash. Cem. Concr. Compos. 2017. [Google Scholar] [CrossRef]

- Amin, M.; Abdelsalam, B.A. Efficiency of rice husk ash and fly ash as reactivity materials in sustainable concrete. Sustain. Environ. Res. 2019. [Google Scholar] [CrossRef]

- Foong, K.Y.; Alengaram, U.J.; Jumaat, M.Z.; Mo, K.H. Enhancement of the mechanical properties of lightweight oil palm shell concrete using rice husk ash and manufactured sand. J. Zhejiang Univ. Sci. A 2015. [Google Scholar] [CrossRef]

- Detphan, S.; Chindaprasirt, P. Preparation of fly ash and rice husk ash geopolymer. Int. J. Miner. Metall. Mater. 2009, 16, 720–726. [Google Scholar] [CrossRef]

- Ahmadi, M.A.; Alidoust, O.; Sadrinejad, I.; Nayeri, M.; Cement, A.; Ash, B.R.H. Development of mechanical properties of self compacting concrete contain rice husk ash. World Acad. Sci. Eng. Technol. 2007, 1, 259–262. [Google Scholar]

- Jauberthie, R.; Rendell, F.; Tamba, S.; Cisse, I. Origin of the pozzolanic effect of rice husks. Constr. Build. Mater. 2000. [Google Scholar] [CrossRef]

- Zhang, M.H.; Malhotra, V.M. Characteristics of a thermally activated alumino-silicate pozzolanic material and its use in concrete. Cem. Concr. Res. 1995. [Google Scholar] [CrossRef]

- Ukrainczyk, N.; Koenders, E.A.B. Sustainability aspects in mass concrete. RILEM State Art Rep. 2019. [Google Scholar] [CrossRef]

- Sangeetha, B.N. Effect of rice husk ash and GGBS on performance of concrete. Int. J. Eng. Res. 2015, 4, 491–495. [Google Scholar] [CrossRef]

- Chindaprasirt, P.; Rukzon, S. Pore structure changes of blended cement pastes containing fly ash, rice husk ash, and palm oil fuel ash caused by carbonation. J. Mater. Civ. Eng. 2009, 21, 666–671. [Google Scholar] [CrossRef]

- Zunino, F.; Lopez, M. Decoupling the physical and chemical effects of supplementary cementitious materials on strength and permeability: A multi-level approach. Cem. Concr. Compos. 2016. [Google Scholar] [CrossRef]

- Hossain, M.M.; Karim, M.R.; Hasan, M.; Hossain, M.K.; Zain, M.F.M. Durability of mortar and concrete made up of pozzolans as a partial replacement of cement: A review. Constr. Build. Mater. 2016. [Google Scholar] [CrossRef]

- Zhuang, X.Y.; Chen, L.; Komarneni, S.; Zhou, C.H.; Tong, D.S.; Yang, H.M.; Yu, W.H.; Wang, H. Fly ash-based geopolymer: Clean production, properties and applications. J. Clean. Prod. 2016, 125, 253–267. [Google Scholar] [CrossRef]

- Hamzeh, Y.; Ziabari, K.P.; Torkaman, J.; Ashori, A.; Jafari, M. Study on the effects of white rice husk ash and fibrous materials additions on some properties of fiber-cement composites. J. Environ. Manage. 2013. [Google Scholar] [CrossRef]

- Kannan, V.; Ganesan, K. Chloride and chemical resistance of self-compacting concrete containing rice husk ash and metakaolin. Constr. Build. Mater. 2014. [Google Scholar] [CrossRef]

- Davidovits, J. Geopolymer chemistry & applications. Tech. Pap. 2015, 21, 1–11. [Google Scholar]

- Venkatesan, R.P.; Pazhani, K.C. Strength and durability properties of geopolymer concrete made with Ground Granulated Blast Furnace Slag and Black Rice Husk Ash. KSCE J. Civ. Eng. 2016. [Google Scholar] [CrossRef]

- Salas, A.; Delvasto, S.; de Gutierrez, R.M.; Lange, D. Comparison of two processes for treating rice husk ash for use in high performance concrete. Cem. Concr. Res. 2009. [Google Scholar] [CrossRef]

- Hu, Y.; Wei, G.; Fang, S.; Li, L.; Zhang, B. Influence of aggregate type on the properties of traditional sticky rice-lime mortar. Tumu Yu Huanjing Gongcheng Xuebao/J. Civ. Environ. Eng 2019. [Google Scholar] [CrossRef]

- Zhang, M.H.; Malhotra, V.M. High-performance concrete incorporating rice husk ash as a supplementary cementing material. ACI Mater. J. 1996. [Google Scholar] [CrossRef]

- Park, C.; Salas, A.; Chung, C.W.; Lee, C.J. Freeze-thaw resistance of concrete using acid-leached rice husk ash. KSCE J. Civ. Eng. 2014. [Google Scholar] [CrossRef]

- Ramasamy, V. Compressive strength and durability properties of Rice Husk Ash concrete. KSCE J. Civ. Eng. 2012. [Google Scholar] [CrossRef]

- Malhotra, V.M.; Povindar, K.; Mehta, K. Pozzolanic and Cementitious Materials; Gordon and Breach: New York, NY, USA, 1996. [Google Scholar]

- Neville, A.M.; Brooks, J.J. Concrete Technology, 2nd ed.; Pearson Educ. Ltd.: Harlow, UK, 2010. [Google Scholar] [CrossRef]

- Zerbino, R.; Giaccio, G.; Batic, O.R.; Isaia, G.C. Alkali-silica reaction in mortars and concretes incorporating natural rice husk ash. Constr. Build. Mater. 2012. [Google Scholar] [CrossRef]

- Zerbino, R.; Giaccio, G.; Marfil, S. Evaluation of alkali-silica reaction in concretes with natural rice husk ash using optical microscopy. Constr. Build. Mater. 2014. [Google Scholar] [CrossRef]

- Bondar, D.; Lynsdale, C.J.; Milestone, N.B.; Hassani, N.; Ramezanianpour, A.A. Effect of heat treatment on reactivity-strength of alkali-activated natural pozzolans. Constr. Build. Mater. 2011. [Google Scholar] [CrossRef]

- Kamath, A.; Khan, M.S. Green concrete. Imp. J. Interdiscip. Res. 2016, 3, 141–150. [Google Scholar]

- Xi, F.; Davis, S.J.; Ciais, P.; Crawford-brown, D.; Guan, D.; Pade, C.; Shi, T.; Syddall, M.; Lv, J.; Ji, L.; et al. Substantial global carbon uptake by cement carbonation. Nat. Geosci. 2016, 1. [Google Scholar] [CrossRef]

- Šavija, B.; Luković, M. Carbonation of cement paste: Understanding, challenges, and opportunities. Constr. Build. Mater. 2016, 117, 285–301. [Google Scholar] [CrossRef]

- Feng, Q.; Yamamichi, H.; Shoya, M.; Sugita, S. Study on the pozzolanic properties of rice husk ash by hydrochloric acid pretreatment. Cem. Concr. Res. 2004. [Google Scholar] [CrossRef]

- Sideris, K.K.; Savva, A.E.; Papayianni, J. Sulfate resistance and carbonation of plain and blended cements. Cem. Concr. Compos. 2006. [Google Scholar] [CrossRef]

- An, D.; Guo, Y.; Zhu, Y.; Wang, Z. A green route to preparation of silica powders with rice husk ash and waste gas. Chem. Eng. J. 2010. [Google Scholar] [CrossRef]

- Chindaprasirt, P.; Rukzon, S.; Sirivivatnanon, V. Resistance to chloride penetration of blended Portland cement mortar containing palm oil fuel ash, rice husk ash and fly ash. Constr. Build. Mater. 2008. [Google Scholar] [CrossRef]

- Monfore, G.E. The electrical resistivity of concrete. Portl. Cem. Assoc. R. D. Lab. Bull. 2012. [Google Scholar] [CrossRef]

- Chabannes, M.; Bénézet, J.C.; Clerc, L.; Garcia-Diaz, E. Use of raw rice husk as natural aggregate in a lightweight insulating concrete: An innovative application. Constr. Build. Mater. 2014. [Google Scholar] [CrossRef]

- Wang, H.; Hu, L.; Cao, P.; Luo, B.; Tang, J.; Shi, F.; Yu, J.; Li, H.; Jin, K. The application of electrical parameters to reflect the hydration process of cement paste with rice husk ash. Materials 2019, 12, 2815. [Google Scholar] [CrossRef] [PubMed]

- ACI Committee 222. Protection of Metals in Concrete Against Corrosion; Aci 222R-01: Farmington Hills, MI, USA, 2001. [Google Scholar]

- Bruno, L. Thermal insulating products for building applications-Determination of long term water absorption by immersion. J. Chem. Inf. Model. 2019. [Google Scholar] [CrossRef]

- Bagheri, A.; Rastegar, M.M. Investigation of passive layer formation on steel rebars in foamed concrete. Mater. Corros. 2019. [Google Scholar] [CrossRef]

- Perná, I.; Hanzlíček, T. The solidification of aluminum production waste in geopolymer matrix. J. Clean. Prod. 2014. [Google Scholar] [CrossRef]

- Degirmenci, F.N. Freeze-Thaw and fire resistance of geopolymer mortar based on natural and waste pozzolans. Ceram. Silikaty. 2018. [Google Scholar] [CrossRef]

- Bilow, D.; Kamara, M. Fire and concrete structures effect of fire on building materials. Struct. Congr. 2008, 1, 1–10. [Google Scholar]

- Chan, Y.N.; Luo, X.; Sun, W. Compressive strength and pore structure of high-performance concrete after exposure to high temperature up to 800 °C. Cem. Concr. Res. 2000. [Google Scholar] [CrossRef]

- Nasr, D.; Pakshir, A.H.; Ghayour, H. The influence of curing conditions and alkaline activator concentration on elevated temperature behavior of alkali activated slag (AAS) mortars. Constr. Build. Mater. 2018. [Google Scholar] [CrossRef]

- Ismail, M.; Elgelany Ismail, M.; Muhammad, B. Influence of elevated temperatures on physical and compressive strength properties of concrete containing palm oil fuel ash. Constr. Build. Mater. 2011. [Google Scholar] [CrossRef]

- Azadi, M.; Bahrololoom, M.E.; Heidari, F. Enhancing the mechanical properties of an epoxy coating with rice husk ash, a green product. J. Coatings Technol. Res. 2011. [Google Scholar] [CrossRef]

- Lemay, L. Life cycle assessment of concrete buildings. Natl. Ready Mix. Concr. Assoc. 2011, 4, 1–12. [Google Scholar]

- Moayedi, H.; Aghel, B.; Abdullahi, M.M.; Nguyen, H.; Safuan, A.; Rashid, A. Applications of rice husk ash as green and sustainable biomass. J. Clean. Prod. 2019. [Google Scholar] [CrossRef]

- Fapohunda, C.; Akinbile, B.; Shittu, A. Structure and properties of mortar and concrete with rice husk ash as partial replacement of ordinary Portland cement–A review. Int. J. Sustain. Built Environ. 2017. [Google Scholar] [CrossRef]

- Mendes Moraesa, C.A.; Kielinga, A.G.; Caetanob, M.O.; Gomesb, L.P. Life cycle analysis (LCA) for the incorporation of rice husk ash in mortar coating. Resour. Conserv. Recycl. 2010. [Google Scholar] [CrossRef]

- Hwang, C.L.; Huynh, T.P. Investigation into the use of unground rice husk ash to produce eco-friendly construction bricks. Constr. Build. Mater. 2015. [Google Scholar] [CrossRef]

- Silalertruksa, T.; Gheewala, S.H. A comparative LCA of rice straw utilization for fuels and fertilizer in Thailand. Bioresour. Technol. 2013. [Google Scholar] [CrossRef] [PubMed]

- Mahlia, M.; Logeswaran, T.M.I.; Anwar, J.M.; Silitonga, A.S.; Rahman, S.M.A.; Shamsuddin, A.H. Potential of rice industry biomass as a renewable energy source. Energies 2019, 12, 4116. [Google Scholar] [CrossRef]

- Isaia, G.C. High-performance concrete for sustainable constructions. Waste Manag. Ser. 2000. [Google Scholar] [CrossRef]

- Liu, Y.; Guo, Y.; Zhu, Y.; An, D.; Gao, W.; Wang, Z.; Ma, Y.; Wang, Z. A sustainable route for the preparation of activated carbon and silica from rice husk ash. J. Hazard. Mater. 2011. [Google Scholar] [CrossRef] [PubMed]

- Khan, R.; Jabbar, A.; Ahmad, I.; Khan, W.; Khan, A.N.; Mirza, J. Reduction in environmental problems using rice-husk ash in concrete. Constr. Build. Mater. 2012. [Google Scholar] [CrossRef]

- Shackley, S.; Carter, S.; Knowles, T.; Middelink, E.; Haefele, S.; Haszeldine, S. Sustainable gasification-biochar systems? A case-study of rice-husk gasification in Cambodia, Part II: Field trial results, carbon abatement, economic assessment and conclusions. Energy Policy 2012. [Google Scholar] [CrossRef]

- Bosio, A.; Zacco, A.; Borgese, L.; Rodella, N.; Colombi, P.; Benassi, L.; Depero, L.E.; Bontempi, E. A sustainable technology for Pb and Zn stabilization based on the use of only waste materials: A green chemistry approach to avoid chemicals and promote CO2 sequestration. Chem. Eng. J. 2014. [Google Scholar] [CrossRef]

- Ahmad-Alyosef, H.; Uhlig, H.; Münster, T.; Kloess, G.; Einicke, W.D.; Gläser, R.; Enke, D. Biogenic silica from rice husk ashf-sustainable sources for the synthesis of value added silica. Chem. Eng. Trans. 2014. [Google Scholar] [CrossRef]

- Balo, F. Feasibility study of “green” insulation materials including tall oil: Environmental, economical and thermal properties. Energy Build. 2015. [Google Scholar] [CrossRef]

- Hu, L.; He, Z.; Zhang, S. Sustainable use of rice husk ash in cement-based materials: Environmental evaluation and performance improvement. J. Clean. Prod. 2020. [Google Scholar] [CrossRef]

| Country | 2002 | 2004 | 2007 | 2010 | 2015 | 2017 | 2018 | 2020 |

|---|---|---|---|---|---|---|---|---|

| [5] | [6] | [2] | [5] | [7] | [7] | [8] | ||

| India | 123 | 127 | 133.7 | 120.6 | 160 | 163 | 167 | 183 |

| China | 177.6 | 183 | 196.7 | 197.2 | 200 | 210 | 216 | 231 |

| Indonesia | 48.7 | 53.4 | 64.4 | 66.4 | 90 | 74 | 77 | 82 |

| West Africa | 10.7 | 10.9 | - | - | 13.4 | - | 16.2 | 18.3 |

| Vietnam | 31.3 | 37.2 | 40 | 40 | 40 | 44 | 56 | 67 |

| Bangladesh | 39 | 42.3 | 47.7 | 49.4 | 45 | 53 | 55 | 66 |

| Brazil | 10.5 | 11.2 | - | - | 12.3 | 11.9 | 12.4 | 13.9 |

| Malaysia | 2.7 | 2.9 | - | - | 3 | - | 4.6 | 6.1 |

| Egypt | 5.7 | 5.9 | - | - | 6.1 | 6.2 | 6.5 | 8.5 |

| Pakistan | 5.8 | 6.1 | - | - | 9 | 10.3 | 10.9 | 13.1 |

| Europe | 1.7 | 1.9 | - | - | 2.9 | - | 3.4 | 4.9 |

| Thailand | - | 29.2 | 32.1 | 31.6 | - | 33 | 34.5 | 38.5 |

| Australia | 0.9 | 1.0 | - | - | 1.2 | - | 1.55 | 2.03 |

| Element | Outer Superficial Area | Inner Superficial Area | References | ||||

|---|---|---|---|---|---|---|---|

| By Percentage (%) | |||||||

| by Weight | by Atomic | by Weight | by Atomic | by Weight | by Atomic | ||

| C | 6.91 | 11.11 | 62.54 | 69.54 | 30.20 | 40.93 | [10,13,36,51] |

| O | 47.93 | 57.84 | 35.19 | 29.38 | 42.53 | 43.27 | |

| Si | 45.16 | 31.05 | 2.27 | 1.08 | 27.27 | 15.80 | |

| Total | 100 | 100 | 100 | 100 | 100 | 100 | |

| Chemical Constituents | Countries of Cultivation, % | Range (%) | References | |||||

|---|---|---|---|---|---|---|---|---|

| Vietnam | India | USA | Brazil | Malaysia | Russia | |||

| SiO2 | 86.9 | 90.7 | 94.5 | 92.9 | 93.1 | 84.3 | 85–95 | [6,63,64] |

| CaO | 1.4 | 0.4 | 0.25 | 1.03 | 0.41 | 0.5 | 0.25–1.5 | |

| Fe2O3 | 0.73 | 0.4 | - | 0.43 | 0.21 | 0.3 | 0.20–0.75 | |

| Al2O3 | 0.84 | 0.4 | - | 0.1 | 0.21 | 1.1 | 0.1–0.9 | |

| MgO | 0.57 | 0.5 | 0.23 | 0.35 | 1.59 | 0.9 | 0.20–1.6 | |

| K2O | 2.46 | 2.2 | 1.1 | 0.72 | 2.31 | 3.7 | 0.7–4.0 | |

| Na2O | 0.1 | 0.1 | 0.78 | 0.02 | - | 1.0 | 0–0.8 | |

| SO3 | - | 0.1 | 1.13 | 0.1 | - | 0.1 | 0–0.15 | |

| Loss of ignition | 5.14 | 4.8 | - | - | 2.36 | 8.1 | - | |

| Chemical Composition | [70] | [71] | [72] | [73] | [74] | [75] | [75] | [76] | [77] | [78] |

|---|---|---|---|---|---|---|---|---|---|---|

| SiO2 | 87.2 | 92.71 | 86.98 | 80–95.9 | 87.3 | 87.3 | 86.98 | 87.96 | 91.56 | 87.4 |

| CaO | 0.55 | 1.26 | 1.40 | 1.1–1.5 | 0.55 | 0.55 | 1.4 | 1.14 | 1.07 | 0.9 |

| Fe2O3 | 0.16 | 0.19 | 0.73 | 0.2–2.9 | 0.16 | 0.16 | 0.73 | 0.52 | 0.17 | 0.3 |

| Al2O3 | 0.15 | 0.21 | 0.84 | 0.4–0.4 | 0.15 | 0.15 | 0.84 | 0.30 | 0.19 | 0.4 |

| MgO | 0.35 | 0.33 | 0.57 | 0.3–0.9 | 0.35 | 0.35 | 0.57 | - | 0.65 | 0.6 |

| K2O | 0.24 | 2.89 | - | 2.8–6.6 | 0.24 | 3.68 | 2.46 | - | 3.76 | 3.39 |

| Na2O | 3.68 | 0.19 | 2.46 | 0.8–2.1 | 3.68 | 1.12 | 0.11 | 0.3 | 0.16 | 0.04 |

| SO3 | 1.12 | - | 0.11 | 0.7–1.2 | 1.12 | 0.24 | - | 2.4 | 0.47 | 0.4 |

| Loss of ignition | 8.55 | - | 5.14 | up to 12% | 8.55 | 8.55 | 5.14 | 1.3 | 1.97 | 0.2 |

| Property | Values | References |

|---|---|---|

| Dry density, kg/m3 | 2060–2160 | [81] |

| Bulk density, kg/m3 | 420.0–429.1 | |

| Superficial area, m2/kg | 240–2765 | [82] |

| Pozzolanic activity index, % | 81.25–88.90 | |

| Average particle size, µm | 5.0–7.41 | [6] |

| Nitrogen adsorption, kg/m2 | 24.3–28.8 | |

| Volume of pores, mL/g | 0.073 | [83] |

| Study | w/b | RHA (%) | Superplasticizer (%) | Concrete Compressive Strength (MPa) | ||||

|---|---|---|---|---|---|---|---|---|

| 7 Day | 14 Day | 28 Day | 56 Day | 91 Day | ||||

| [43] | 0.41 | 0 | 1 | 29.0 | – | 36.7 | 39.6 | – |

| 0.41 | 15 | 1 | 36.2 | – | 48.8 | 53.7 | – | |

| 0.41 | 10 | 1 | 32.6 | – | 41.2 | 46.4 | – | |

| 0.41 | 20 | 1 | 30.4 | – | 40.2 | 53.0 | – | |

| [115] | 0.5 | 20 | 3.5 | 37.2 | – | 42.9 | – | – |

| 0.38 | 0 | 1.8 | 32.8 | – | 48.5 | – | – | |

| 0.5 | 40 | 3.5 | 28.1 | – | 33.5 | – | – | |

| 0.5 | 30 | 3.5 | 35.1 | – | 40.9 | – | – | |

| [116] | 0.31 | 10 | 2 | 48.4 | – | 54.8 | – | 72.6 |

| 0.22 | 0 | 2 | 55.9 | – | 65.0 | – | 82.8 | |

| 0.75 | 40 | 2 | 13.8 | – | 19.1 | – | 26.4 | |

| 0.46 | 20 | 2 | 21.2 | – | 28.0 | – | 39.6 | |

| 1.17 | 60 | 2 | 8.3 | – | 10.4 | – | 14.8 | |

| 2.18 | 100 | 2 | 1.5 | – | 2.0 | – | 2.6 | |

| 1.80 | 80 | 2 | 2.8 | – | 4.1 | – | 5.7 | |

| [117] | 0.38 | 5 | 3.5 | 25.2 | – | 38.0 | – | – |

| 0.4 | 0 | 3.5 | 10.5 | – | 28.4 | – | – | |

| 0.36 | 10 | 3.5 | 22.5 | – | 36.2 | – | – | |

| 0.38 | 5 | 4 | 21.4 | – | 37.8 | – | – | |

| 0.4 | 0 | 4 | 6.8 | – | 18.3 | – | – | |

| 0.4 | 0 | 45 | 1.2 | – | 8.6 | – | – | |

| 0.36 | 10 | 4 | 36.8 | – | 41.4 | – | – | |

| 0.36 | 10 | 45 | 38.3 | – | 48.5 | – | – | |

| 0.38 | 5 | 45 | 11.9 | – | 22.2 | – | – | |

| [118] | 0.54 | 15 | 2.2 | 22.7 | 29.6 | 39.8 | – | 42.5 |

| 0.39 | 0 | 2.2 | 36.5 | 37.6 | 37.8 | – | 44.7 | |

| [96] | 0.51 | 0 | 0 | 27.2 | 37.1 | 38.3 | – | – |

| 0.58 | 10 | 1.2 | 28.0 | 41.3 | 44.8 | – | – | |

| 0.57 | 5 | 1.2 | 27.6 | 40.0 | 43.3 | – | – | |

| 0.66 | 20 | 1.2 | 29.7 | 42.5 | 46.0 | – | – | |

| 0.6 | 15 | 1.2 | 29.3 | 41.8 | 45.7 | – | – | |

| Authors | Mineral Admixture | Content, % | w/c or w/b Ratio | Elastic Modulus (GPa) | Remark | ||

|---|---|---|---|---|---|---|---|

| [10,30,36] | Control | 0 | 0.53 | 29.6 | 30.5 | 31 | — |

| RHA | 20 | 30.1 | 30.8 | 31.4 | RiH ground for 180 min | ||

| 20 | 30.2 | 31.4 | 31.7 | RiH ground for 270 min | |||

| 20 | 30.5 | 32.3 | 32.9 | RiH ground for 360 min | |||

| [1,61,129] | Control | 0 | 29.6 | — | — | High strength concrete | |

| RHA | 10 | 0.4 | 29.6 | — | — | ||

| Temperature | Structure of RHA | Specific Surface Area (m2/g) | References |

|---|---|---|---|

| Up to 500 | Particles are globular spherical or in form with permeable structure | 0.5 to 2.1 | [93,171,172] |

| 500 to 600 | Particles are partially crystalline and non-crystalline. It has a fine porous crystalline grain, not more than 1 µm, perhaps establishing the transition between the crystalline and the amorphous state | 76 to 122 | |

| 600 to 700 | Diameter of pores, and amorphous particles is uppermost | 100 to 150 at a lower temperature | |

| 700 to 800 | Partially crystalline, formulation of coral-formed crystals | 6 to 10 | |

| 800 to 900 | Crystalline | Not more than 5 | |

| 900 to and 1000 | The formulation of coral-formed crystals augmented, and increasingly finer and molted significantly | - |

| Silica (Amorphous) | Liquid Sodium Silicate | Activated Carbon |

|---|---|---|

| Waterproofing Chemicals | Binders and Ceramics | Water Purification |

| Ceramic Glaze | Cements and Adhesives | Solvent Recovery |

| Oil Spill Absorbent | Textile Processing | Air Purification |

| Catalysts, Coatings | Paper and Pulp Processing | Sweetener |

| Green Concrete | Cleaning Compounds and Detergents | Pharmaceuticals |

| Soap And Detergents | Mineral Ana Mining Processing | |

| Cosmetics, Healthcare, Food, | Petrochemical Processing | |

| High Performance Concrete | Water Treatment | |

| Carrier For Pesticides | Coatings And Paints | |

| Rubber and Plastic Bars | ||

| Bio Fertilizers and Insecticides | ||

| Flame Retardants | ||

| Insulator, Refractory | ||

| Specialty Paints | ||

| Paper and Pulp Processing | ||

| Roofing Shingles | ||

| Solar Panels |

| Type of Application | Year | Rate of Used | Product | Type of Impact | Refs. | ||||

|---|---|---|---|---|---|---|---|---|---|

| Fully | Partially | Technical | Social | Economic | Environmental | ||||

| HPC | 2000 | - | √ | OPC | √ | - | √ | - | [177] |

| Heat absorbing | 2008 | √ | Sand | √ | - | - | - | [70] | |

| Sand–cement block | 2009 | √ | - | Clay brick | √ | - | √ | - | [72] |

| Silica powders | 2010 | √ | Commercial silica | √ | - | - | - | [155] | |

| Silica | 2011 | √ | - | Sodium powder and quartz | √ | - | - | - | [178] |

| Epoxy coating | - | √ | Epoxy paint | √ | - | - | - | [169] | |

| Activated carbon | √ | Commercial Activated carbon | √ | - | - | - | [178] | ||

| Concrete | 2012 | - | √ | OPC | √ | - | √ | - | [179] |

| Bio-char | - | √ | Charcoal | √ | √ | √ | √ | [180] | |

| Soil conditioner | 2013 | - | √ | N fertilizer | - | - | - | √ | [175] |

| Concrete block | - | √ | OPC | - | - | - | √ | ||

| Brick | - | √ | √ | - | - | √ | [87] | ||

| Mortar coating Concrete | - | √ | √ | - | - | - | |||

| Brick | - | √ | clay | - | - | - | √ | [175] | |

| Pb and Zn stabilization | 2014 | √ | - | Commercial adsorbents | √ | - | - | - | [181] |

| Porous silica | √ | - | Water glass | √ | - | - | - | [182] | |

| Concrete | - | √ | OPC | √ | - | - | √ | [75] | |

| - | √ | √ | - | - | - | [94] | |||

| Pure white silica | 2015 | √ | - | Commercial silica | √ | - | - | - | [77] |

| glass | - | √ | Natural sand | √ | - | - | - | [174] | |

| Insulator | √ | - | Commercial insulator | √ | - | √ | √ | [183] | |

| Rice mill wastewater treatment | √ | - | Commercial adsorbents | √ | - | - | - | [77] | |

| Concrete | 2016 | - | √ | OPC | √ | - | - | - | [133] |

| √ | √ | - | - | √ | [81] | ||||

| Ultra-HSC | 2019 | - | √ | √ | √ | √ | √ | [13] | |

| Cement-based materials | 2020 | √ | - | Resistant to sulfate attack | √ | √ | √ | √ | [184] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Amran, M.; Fediuk, R.; Murali, G.; Vatin, N.; Karelina, M.; Ozbakkaloglu, T.; Krishna, R.S.; Sahoo, A.K.; Das, S.K.; Mishra, J. Rice Husk Ash-Based Concrete Composites: A Critical Review of Their Properties and Applications. Crystals 2021, 11, 168. https://doi.org/10.3390/cryst11020168

Amran M, Fediuk R, Murali G, Vatin N, Karelina M, Ozbakkaloglu T, Krishna RS, Sahoo AK, Das SK, Mishra J. Rice Husk Ash-Based Concrete Composites: A Critical Review of Their Properties and Applications. Crystals. 2021; 11(2):168. https://doi.org/10.3390/cryst11020168

Chicago/Turabian StyleAmran, Mugahed, Roman Fediuk, Gunasekaran Murali, Nikolai Vatin, Maria Karelina, Togay Ozbakkaloglu, R. S. Krishna, Ankit Kumar Sahoo, Shaswat Kumar Das, and Jyotirmoy Mishra. 2021. "Rice Husk Ash-Based Concrete Composites: A Critical Review of Their Properties and Applications" Crystals 11, no. 2: 168. https://doi.org/10.3390/cryst11020168

APA StyleAmran, M., Fediuk, R., Murali, G., Vatin, N., Karelina, M., Ozbakkaloglu, T., Krishna, R. S., Sahoo, A. K., Das, S. K., & Mishra, J. (2021). Rice Husk Ash-Based Concrete Composites: A Critical Review of Their Properties and Applications. Crystals, 11(2), 168. https://doi.org/10.3390/cryst11020168