X-ray Based in Situ Investigation of Silicon Growth Mechanism Dynamics—Application to Grain and Defect Formation

Abstract

1. Introduction

2. Materials and Methods

2.1. GaTSBI Tool

2.1.1. Directional Solidification Furnace

- Step 1—Preheating: the silicon sample cut inside ingots of different origins is heated by applying the same temperature to the bottom and top resistances of the furnace (isotherm conditions) up to 1373 K.

- Step 2—Temperature gradient: a vertical temperature gradient is applied by imposing a controlled temperature difference between both heaters. The same temperature gradient is maintained until step 5.

- Step 3—Partial melting: the sample is partially melted (Si melting temperature: 1687 K). This is monitored by imaging during the heating phase. A seed crystal, preserving the initial orientation of the sample, is kept within the field of view of the X-ray imaging.

- Step 4—Solidification: both heaters are cooled at the same controlled cooling rate until the region of the silicon sample observed within the field of view is fully solidified. The same cooling rate is applied on both heaters to maintain a constant temperature gradient during solidification. In some particular cases, not reported in this manuscript, solidification is conducted by pulling the sample downwards. In both cases, the solidification is directional in the upward direction due to the imposed vertical temperature gradient.

- In some experiments, a new cycle is started again from step 3.

- Step 5—Controlled cooling down: the sample is cooled down until 923 K by applying cooling rates of −13 and −10.4 K/min to the top and bottom heaters, respectively.

- Step 6—Cooling down to room temperature: free cooling down takes place from 923 K as temperatures below this value cannot be controlled by design of the furnace.

2.1.2. Crucible Assembly

2.1.3. Origin of the Silicon Samples

2.1.4. X-Ray Imaging

2.1.5. X-Ray Radiography

- Division by the first image taken after cooling starts:

- Division of two successive images:

2.1.6. X-Ray Bragg Diffraction Imaging—Topography

2.2. Orientation Contrast

2.3. Dynamic Evolution

2.4. Ex Situ Complementary Investigations

3. Results and Discussion

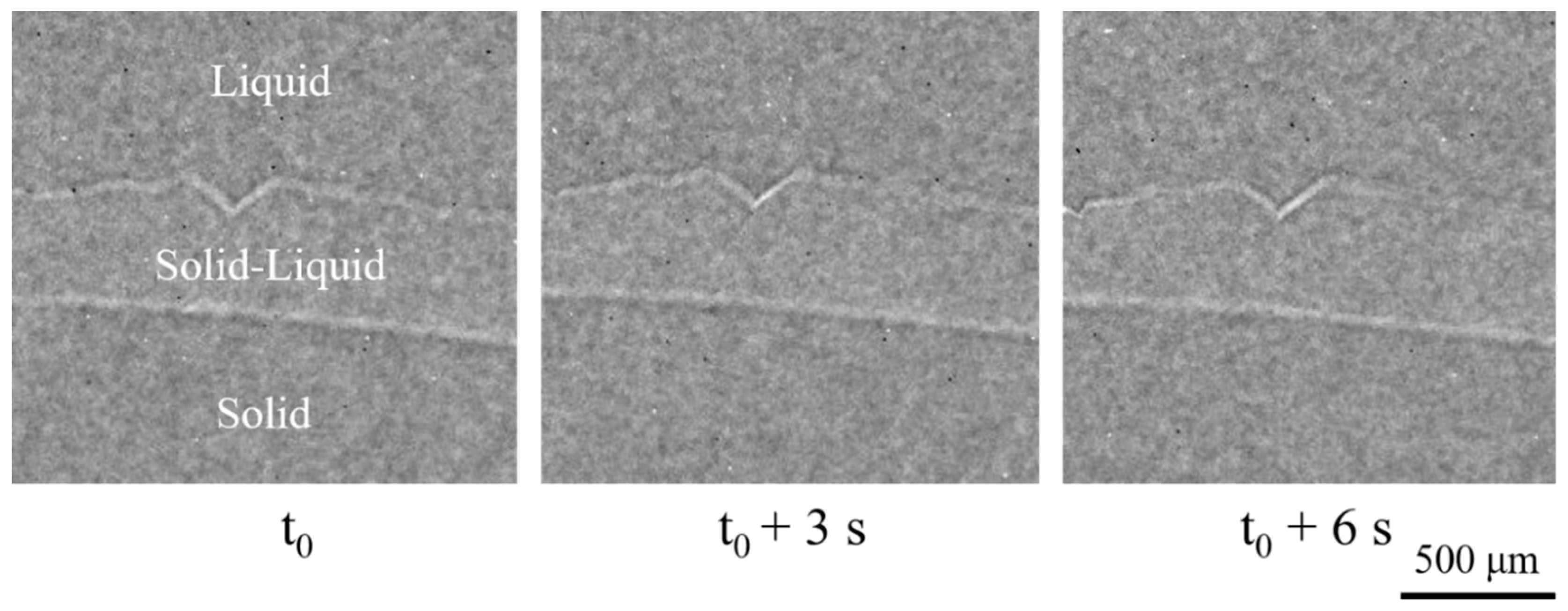

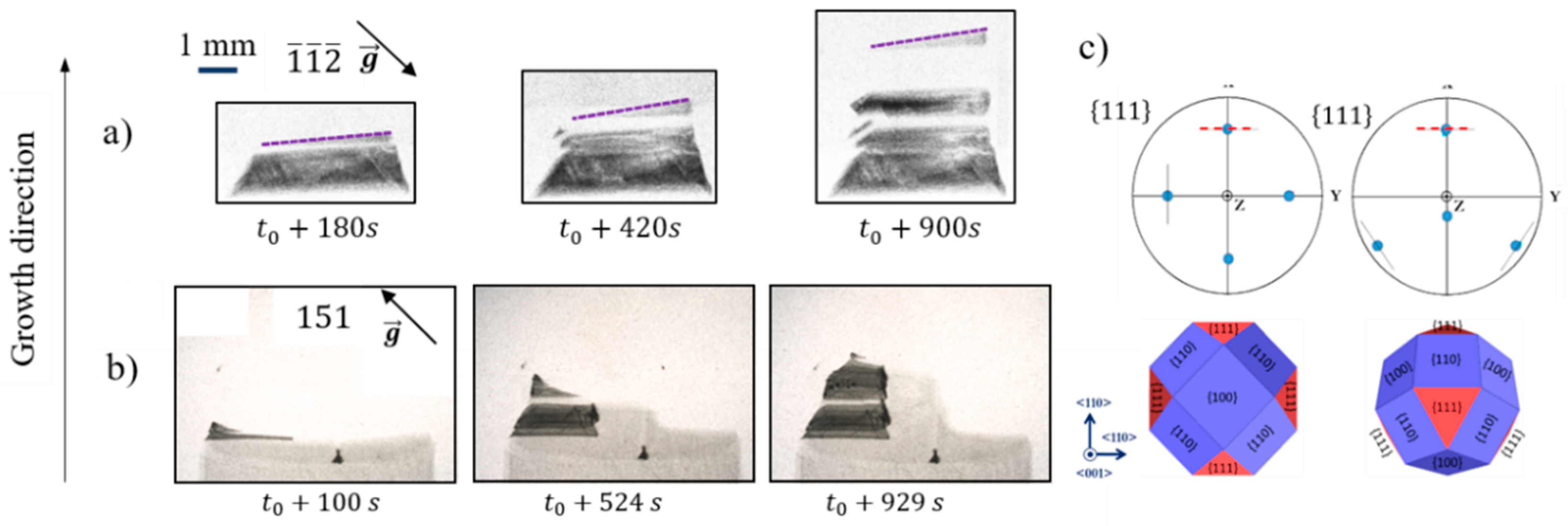

3.1. {111} Facet Growth and Undercooling

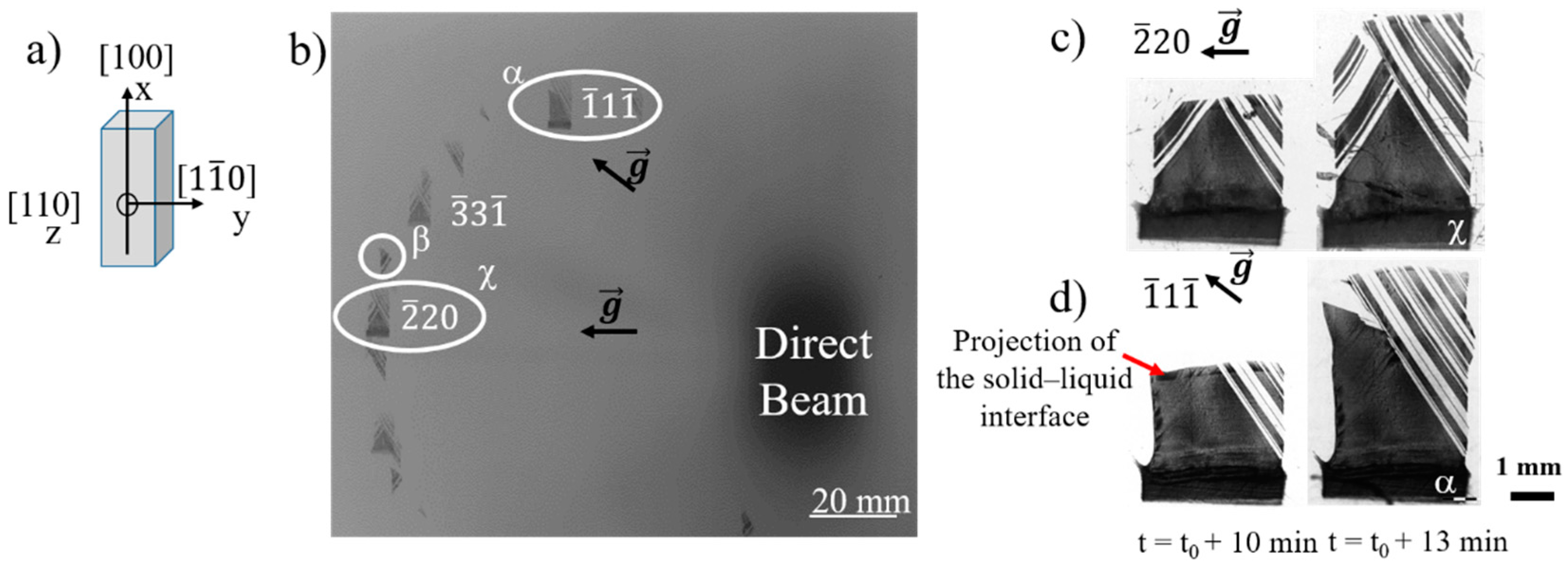

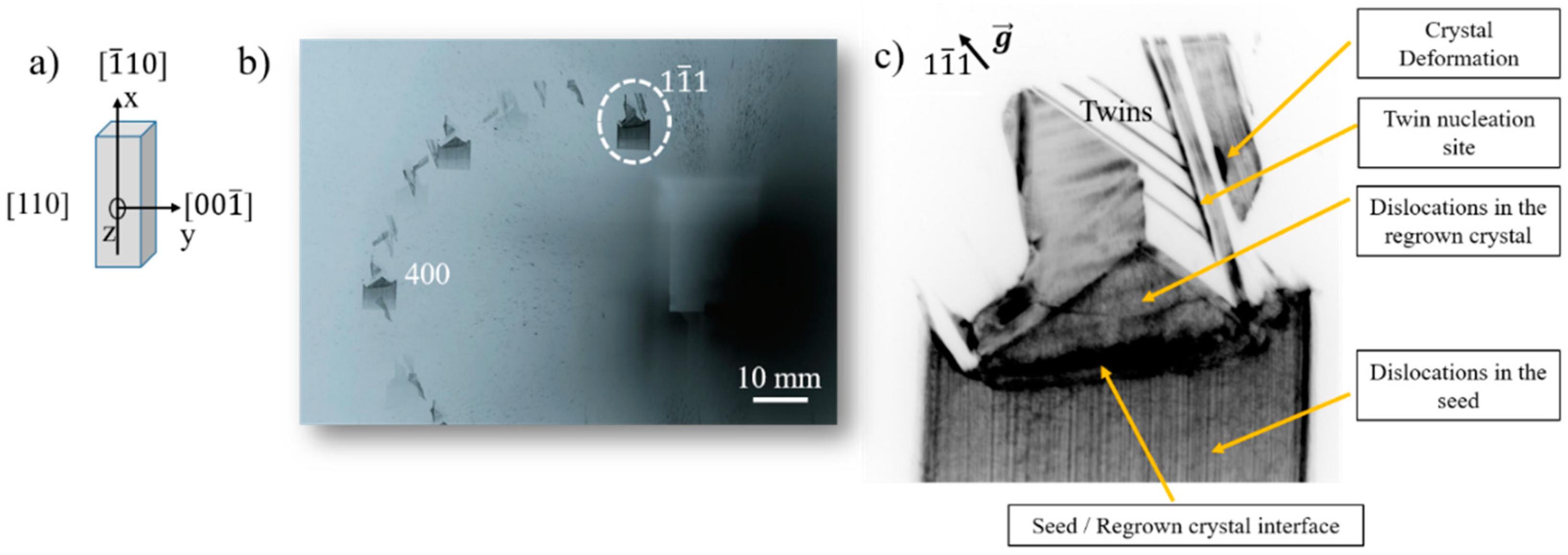

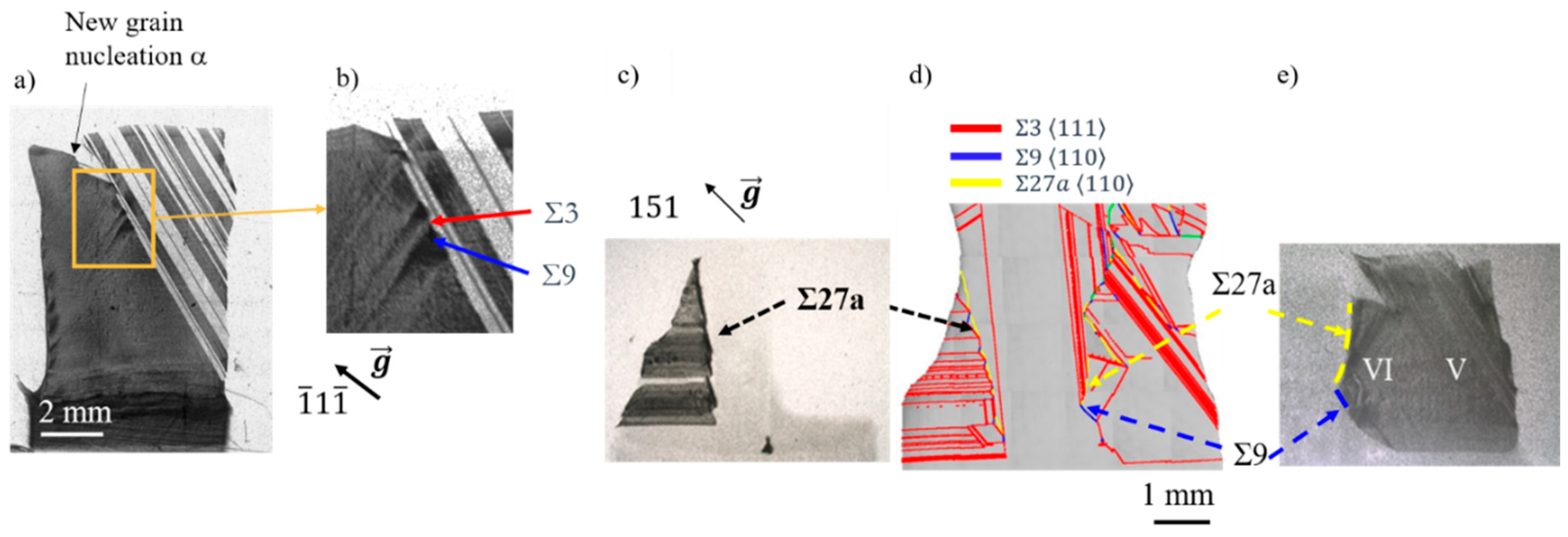

3.2. Twinning During Solidification

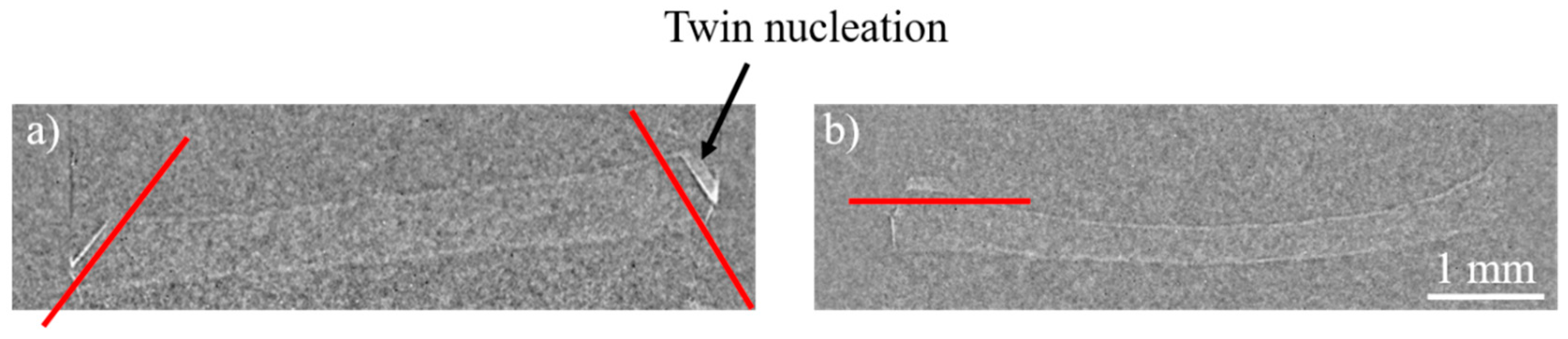

3.2.1. Twin Nucleation

3.2.2. Successive Twinning

3.2.3. Twin Growth

3.3. Grain Competition and Higher Order Twin Boundaries

3.4. Strain Building During Growth

3.4.1. Strain and Σ3{111}1,2 Twins

3.4.2. Strain Building Due to Competition

3.4.3. Grain Nucleation Related to Strain Accumulation

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Usami, N.; Takahashi, I.; Kutsukake, K.; Fujiwara, K.; Nakajima, K. Implementation of faceted dendrite growth on floating cast method to realize high-quality multicrsytalline Si ingot for solar cells. J. Appl. Phys. 2011, 109, 083527. [Google Scholar] [CrossRef]

- Fujiwara, K.; Pan, W.; Usami, N.; Sawada, K.; Tokairin, M.; Nose, Y.; Nomura, A.; Shishido, T.; Nakajima, K. Growth of structure-controlled polycrystalline silicon ingots for solar cells by casting. Acta Mater. 2006, 54, 3191–3197. [Google Scholar] [CrossRef]

- Jouini, A.; Ponthenier, D.; Lignier, H.; Enjalbert, N.; Marie, B.; Drevet, B.; Pihan, E.; Cayron, C.; Lafford, T.; Camel, D. Improved multicrystalline silicon ingot crystal quality through seed growth for high efficiency solar cells. Prog. Photovolt. Res. Appl. 2012, 20, 735–746. [Google Scholar] [CrossRef]

- Oliveira, V.A.; Marie, B.; Cayron, C.; Marinova, M.; Tsoutsouva, M.G.; Sio, H.C.; Lafford, T.A.; Baruchel, J.; Audoit, G.; Grenier, A.; et al. Formation mechanism and properties of twinned structures in (111) seeded directionally solidified solar grade silicon. Acta Mater. 2016, 121, 24–36. [Google Scholar] [CrossRef]

- Stoddard, N.; Wu, B.; Witting, I.; Wagener, M.C.; Park, Y.; Rozgonyi, G.A.; Clark, R. Casting single crystal silicon: Novel defect profiles from BP solar’s mono2 TM wafers. Solid State Phenom. 2008, 131, 1–8. [Google Scholar]

- Lan, C.W.; Lan, A.; Yang, C.F.; Hsu, H.P.; Yang, M.; Yu, A.; Hsu, B.; Hsu, W.C.; Yang, A. The emergence of high-performance multi-crystalline silicon in photovoltaics. J. Cryst. Growth 2017, 468, 17–23. [Google Scholar] [CrossRef]

- Trempa, M.; Reimann, C.; Friedrich, J.; Müller, G.; Oriwol, D. Mono-crystalline growth in directional solidification of silicon with different orientation and splitting of seed crystals. J. Cryst. Growth 2012, 351, 131–140. [Google Scholar] [CrossRef]

- Oliveira, V.A.; Rocha, M.; Lantreibecq, A.; Tsoutsouva, M.G.; Tran-Thi, T.N.; Baruchel, J.; Camel, D. Cellular dislocations patterns in monolike silicon: Influence of stress, time under stress and impurity doping. J. Cryst. Growth 2018, 489, 42–50. [Google Scholar] [CrossRef]

- Tsoutsouva, M.G.; Oliveira, V.A.; Camel, D.; Baruchel, J.; Marie, B.; Lafford, T.A. Mono-like silicon ingots grown on low angle misoriented seeds: Defect characterization by synchrotron X-ray diffraction imaging. Acta Mater. 2015, 88, 112–120. [Google Scholar] [CrossRef]

- Tsoutsouva, M.G.; Oliveira, V.A.; Camel, D.; Tran Thi, T.N.; Baruchel, J.; Marie, B.; Lafford, T.A. Segregation, precipitation and dislocation generation between seeds in directionally solidified mono-like silicon for photovoltaic applications. J. Cryst. Growth 2014, 401, 397–403. [Google Scholar] [CrossRef]

- Ekstrøm, K.E.; Stokkan, G.; Søndenå, R.; Dalaker, H.; Lehmann, T.; Arnberg, L.; Di Sabatino, M. Structure and dislocation development in mono-like silicon. Phys. Status Solidi A 2015, 212, 2278–2288. [Google Scholar] [CrossRef]

- Autruffe, A.; Stenhjem Hagen, V.; Arnberg, L.; Di Sabatino, M. Dislocation generation at near-coincidence site lattice grain boundaries during silicon directional solidification. J. Cryst. Growth 2015, 411, 12–18. [Google Scholar] [CrossRef]

- Autruffe, A.; Vines, L.; Arnberg, L.; Di Sabatino, M. Coincident site lattice bi-crystals growth—Impurity segregation towards grain boundaries. J. Cryst. Growth 2015, 416, 8–11. [Google Scholar] [CrossRef]

- Trempa, M.; Reimann, C.; Friedrich, J.; Müller, G.; Sylla, L.; Krause, A.; Richter, T. Investigation of iron contamination of seed crystals and its impact on lifetime distribution in Quasimono silicon ingots. J. Cryst. Growth 2015, 429, 56–62. [Google Scholar] [CrossRef]

- Trempa, M.; Reimann, C.; Friedrich, J.; Müller, G.; Krause, A.; Sylla, L.; Richter, T. Influence of grain boundaries intentionally induced between seed plates on the defect generation in quasi-mono-crystalline silicon ingots. Cryst. Res. Technol. 2015, 50, 124–132. [Google Scholar] [CrossRef]

- Trempa, M.; Reimann, C.; Friedrich, J.; Müller, G.; Krause, A.; Sylla, L.; Richter, T. Defect formation induced by seed-joints during directional solidification of quasi-mono-crystalline silicon ingots. J. Cryst. Growth 2014, 405, 131–141. [Google Scholar] [CrossRef]

- Stokkan, G.; Song, A.; Ryningen, B. Investigation of the grain boundary character and dislocation density of different types of high performance multicrystalline silicon. Crystals 2018, 8, 341. [Google Scholar] [CrossRef]

- Hurle, D.T.J. A mechanism for twin formation during Czochralski and encapsulated vertical Bridgman growth of III–V compound semiconductors. J. Cryst. Growth 1995, 147, 239–250. [Google Scholar] [CrossRef]

- Von Ammon, W. FZ and CZ crystal growth: Cost driving factors and new perspectives. Phys. Status Solidi A 2014, 211, 2461–2470. [Google Scholar] [CrossRef]

- Oliveira, V.A.; Sio, H.C.; Faujour, A.; Piot, L.; Chabli, A.; Camel, D. Recombination activity of 2D extended defects in monolike silicon. Energy Procedia 2016, 92, 755–763. [Google Scholar] [CrossRef]

- Woo, S.; Bertoni, M.; Choi, K.; Nam, S.; Castellanos, S.; Powell, D.M.; Buonassisi, T.; Choi, H. An insight into dislocation density reduction in multicrystalline silicon. Sol. Energy Mater. Sol. Cells 2016, 155, 88–100. [Google Scholar] [CrossRef]

- Wang, Z.-J.; Tsurekawa, S.; Ikeda, K.; Sekiguchi, T.; Watanabe, T. Relationship between electrical activity and grain boundary structural configuration in polycrystalline silicon. Interface Sci. 1999, 7, 197–205. [Google Scholar] [CrossRef]

- Fedotov, A.; Evtodyi, B.; Fionova, L.; Ilyashuk, Y.; Katz, E.; Polyak, L. Electrical-activity of grain-boundaries in shaped grown silicon. Phys. Status Solidi A 1990, 119, 523–534. [Google Scholar] [CrossRef]

- Kivambe, M.; Ervik, T.; Ryningen, B.; Stokkan, G. On the role of stacking faults on dislocation generation and dislocation cluster formation in multicrystalline silicon. J. Appl. Phys. 2012, 112, 103528. [Google Scholar] [CrossRef]

- Binetti, S.; Libal, J.; Acciarri, M.; Di Sabatino, M.; Nordmark, H.; Øvrelid, E.J.; Walmsley, J.C.; Holmestad, R. Study of defects and impurities in multicrystalline silicon grown from metallurgical silicon feedstock. Mater. Sci. Eng. B 2009, 159, 274–277. [Google Scholar] [CrossRef]

- Oriwol, D.; Carl, E.R.; Danilewsky, A.N.; Sylla, L.; Seifert, W.; Kittler, M.; Leipner, H.S. Small-angle subgrain boundaries emanating from dislocation pile-ups in multicrystalline silicon studied with synchrotron white-beam X-ray topography. Acta Mater. 2013, 61, 6903–6910. [Google Scholar] [CrossRef]

- Adamczyk, K.; Søndenå, R.; Stokkan, G.; Looney, E.; Jensen, M.; Lai, B.; Rinio, M.; Sabatino, M.D. Recombination activity of grain boundaries in high-performance multicrystalline Si during solar cell processing. J. Appl. Phys. 2018, 123, 055705. [Google Scholar] [CrossRef]

- Wang, H.Y.; Usami, N.; Fujiwara, K.; Kutsukake, K.; Nakajima, K. Microstructures of Si multicrystals and their impact on minority carrier diffusion length. Acta Mater. 2009, 57, 3268–3276. [Google Scholar] [CrossRef]

- Autruffe, A.; Søndenå, R.; Vines, L.; Arnberg, L.; Di Sabatino, M. Influence of pulling rate on multicrystalline silicon ingots’ properties. J. Cryst. Growth 2014, 386, 199–203. [Google Scholar] [CrossRef]

- Duffar, T. Comprehensive review on grain and twin structures in bulk photovoltaic silicon. Recent Res. Dev. Cryst. Growth 2009, 5, 61–111. [Google Scholar]

- Gallien, B.; Duffar, T.; Lay, S.; Robaut, F. Analysis of grain orientationin cold crucible continuous casting of photovoltaic Si. J. Cryst. Growth 2011, 318, 208–211. [Google Scholar] [CrossRef]

- Lan, C.W.; Lee, T.F.; Yu, A.; Yang, Y.M.; Hsu, W.C.; Hsu, B.; Yang, A. Grain control in directional solidification of photovoltaic silicon. J. Cryst. Growth 2012, 360, 68–75. [Google Scholar] [CrossRef]

- Reimann, C.; Müller, G.; Friedrich, J.; Lauer, K.; Simonis, A.; Wätzig, H.; Krehan, S.; Hartmann, R.; Kruse, A. Systematic characterization of multi-crystalline silicon String Ribbon wafer. J. Cryst. Growth 2012, 361, 38–43. [Google Scholar] [CrossRef]

- Zhou, N.; Wei, X.; Zhou, L. Formation of dislocations in the growth of silicon along different crystallographic directions—A molecular dynamics study. Crystals 2018, 8, 346. [Google Scholar] [CrossRef]

- Nagashio, K.; Adachi, M.; Higuchi, K.; Mizuno, A.; Watanabe, M.; Kuribayashi, K.; Katayama, Y. Real-time x-ray observation of solidification from undercooled Si melt. J. Appl. Phys. 2006, 100, 033524. [Google Scholar] [CrossRef]

- Nagashio, K.; Murata, H.; Kuribayashi, K. In situ observation of solidification behavior of Si melt dropped on Si wafer by IR thermography. J. Cryst. Growth 2005, 275, e1685–e1690. [Google Scholar] [CrossRef]

- Fujiwara, K.; Maeda, K.; Usami, N.; Sazaki, G.; Nose, Y.; Nomura, A.; Shishido, T.; Nakajima, K. In situ observation of Si faceted dendrite growth from low-degree-of-undercooling melts. Acta Mater. 2008, 56, 2663–2668. [Google Scholar] [CrossRef]

- Fujiwara, K.; Obinata, Y.; Ujihara, T.; Usami, N.; Sazaki, G.; Nakajima, K. Grain growth behaviors of polycrystalline silicon during melt growth processes. J. Cryst. Growth 2004, 266, 441–448. [Google Scholar] [CrossRef]

- Fujiwara, K.; Maeda, K.; Usami, N.; Sazaki, G.; Nose, Y.; Nakajima, K. Formation mechanism of parallel twins related to Si-facetted dendrite growth. Scr. Mater. 2007, 57, 81–84. [Google Scholar] [CrossRef]

- Fujiwara, K.; Nakajima, K.; Ujihara, T.; Usami, N.; Sazaki, G.; Hasegawa, H.; Mizoguchi, S.; Nakajima, K. In situ observations of crystal growth behavior of silicon melt. J. Cryst. Growth 2002, 243, 275–282. [Google Scholar] [CrossRef]

- Chuang, L.-C.; Maeda, K.; Morito, H.; Shiga, K.; Miller, W.; Fujiwara, K. In situ observation of interaction between grain boundaries during directional solidification of Si. Scr. Mater. 2018, 148, 37–41. [Google Scholar] [CrossRef]

- Chikawa, J.-I. Technique for the video display of X-ray topographic images and its application to the study of crystal growth. J. Cryst. Growth 1974, 24, 61–68. [Google Scholar] [CrossRef]

- Chikawa, J.-I.; Shirai, S. Melting of silicon crystals and a possible origin of swirl defects. J. Cryst. Growth 1977, 39, 328–340. [Google Scholar] [CrossRef]

- Riberi-Béridot, T.; Mangelinck-Noël, N.; Tandjaoui, A.; Reinhart, G.; Billia, B.; Lafford, T.; Baruchel, J.; Barrallier, L. On the impact of twinning on the formation of the grain structure of multi-crystalline silicon for photovoltaic applications during directional solidification. J. Cryst. Growth 2015, 418, 38–44. [Google Scholar] [CrossRef]

- Tsoutsouva, M.G.; Riberi-Béridot, T.; Regula, G.; Reinhart, G.; Baruchel, J.; Guittonneau, F.; Barrallier, L.; Mangelinck-Noël, N. In situ investigation of the structural defect generation and evolution during the directional solidification of <110> seeded growth Si. Acta Mater. 2016, 115, 210–223. [Google Scholar] [CrossRef]

- Riberi-Béridot, T.; Tsoutsouva, M.G.; Regula, G.; Reinhart, G.; Guittonneau, F.; Barrallier, L.; Mangelinck-Noël, N. Strain building and correlation with grain nucleation during silicon growth. Acta Mater. 2019, 177, 141–150. [Google Scholar] [CrossRef]

- Riberi-Béridot, T.; Tsoutsouva, M.G.; Regula, G.; Reinhart, G.; Périchaud, I.; Baruchel, J.; Mangelinck-Noël, N. Growth undercooling in multi-crystalline pure silicon and in silicon containing light impurities (C and O). J. Cryst. Growth 2017, 466, 64–70. [Google Scholar] [CrossRef]

- Stamelou, V.; Tsoutsouva, M.G.; Riberi-Béridot, T.; Reinhart, G.; Regula, G.; Baruchel, J.; Mangelinck-Noël, N. {111} facet growth laws and grain competition during silicon crystallization. J. Cryst. Growth 2017, 479, 1–8. [Google Scholar] [CrossRef]

- Tandjaoui, A.; Mangelinck-Noël, N.; Reinhart, G.; Billia, B.; Furter, J.J.; Lafford, T.; Baruchel, J.; Guichard, X. Real time observation of the directional solidification of multicrystalline silicon: X-ray imaging characterization. Energy Procedia 2012, 27, 82–87. [Google Scholar] [CrossRef][Green Version]

- Tandjaoui, A.; Mangelinck-Noël, N.; Reinhart, G.; Billia, B.; Guichard, X. Twinning occurrence and grain competition in multicrystalline silicon during solidification. C. R. Phys. 2013, 14, 8. [Google Scholar] [CrossRef]

- Tandjaoui, A.; Mangelinck-Noel, N.; Reinhart, G.; Billia, B.; Lafford, T.; Baruchel, J. Investigation of grain boundary grooves at the solid–liquid interface during directional solidification of multi-crystalline silicon: In situ characterization by X-ray imaging. J. Cryst. Growth 2013, 377, 203–211. [Google Scholar] [CrossRef]

- Becker, M.; Regula, G.; Reinhart, G.; Boller, E.; Valade, J.-P.; Rack, A.; Tafforeau, P.; Mangelinck-Noel, N. Simultaneous X-ray radiography and diffraction topography imaging applied to silicon for defect analysis during melting and crystallization. J. Appl. Crystallogr. 2019, 52, 1312–1320. [Google Scholar] [CrossRef]

- Ouaddah, H.; Périchaud, I.; Barakel, D.; Palais, O.; Di Sabatino, M.; Reinhart, G.; Regula, G.; Mangelinck-Noël, N. Role of impurities in silicon solidification and electrical properties studied by complementary In Situ and Ex Situ methods. Phys. Status Solidi A 2019, 216, 1–10. [Google Scholar] [CrossRef]

- Baruchel, J.; Buffiere, J.-Y.; Cloetens, P.; Di Michiel, M.; Ferrie, E.; Ludwig, W.; Maire, E.; Salvo, L. Advances in synchrotron radiation microtomography. Scr. Mater. 2006, 55, 41–46. [Google Scholar] [CrossRef]

- Cloetens, P.; Barrett, R.; Baruchel, J.; Guigay, J.-P.; Schlenker, M. Phase objects in synchrotron radiation hard x-ray imaging. J. Phys. D Appl. Phys. 1996, 29, 133–146. [Google Scholar] [CrossRef]

- Reinhart, G.; Grange, D.; Abou-Khalil, L.; Mangelinck-Noël, N.; Niane, N.T.; Maguin, V.; Guillemot, G.; Gandin, C.A.; Nguyen-Thi, H. Impact of solute flow during directional solidification of a Ni-based alloy: In-situ and real-time X-radiography. Acta Mater. 2020, 194, 68–79. [Google Scholar] [CrossRef]

- Schneider, C.A.; Rasband, W.S.; Eliceiri, K.W. NIH Image to ImageJ: 25 years of image analysis. Nat. Methods 2012, 9, 671–675. [Google Scholar] [CrossRef]

- Mittone, A.; Manakov, I.; Broche, L.; Jarnias, C.; Coan, P.; Bravin, A. Characterization of a sCMOS-based high-resolution imaging system. J. Synchrotron Radiat. 2017, 24, 1226–1236. [Google Scholar] [CrossRef]

- Lang, A.R. The early days of high-resolution X-ray topography. J. Phys. D Appl. Phys. 1993, 26, A1–A8. [Google Scholar] [CrossRef]

- Härtwig, J. Hierarchy of dynamical theories of x-ray diffraction for deformed and perfect crystals. J. Phys. D Appl. Phys. 2001, 34, A70–A77. [Google Scholar] [CrossRef]

- Burns, R.C.; Chumakov, A.I.; Connell, S.H.; Dube, D.; Godfried, H.P.; Hansen, J.O.; Härtwig, J.; Hoszowska, J.; Masiello, F.; Mkhonza, L.; et al. HPHT growth and x-ray characterization of high-quality type IIa diamond. J. Phys. Condens. Matter 2009, 21, 364224. [Google Scholar] [CrossRef] [PubMed]

- Authier, A. Contrast of dislocation images in X-Ray transmission topography. Adv. X Ray Anal. 1966, 10, 9–31. [Google Scholar] [CrossRef]

- De Graef, M.; McHenry, M.E. Structure of Materials: An Introduction to Crystallography, Diffraction and Symmetry; Cambridge University Press: Cambridge, UK, 2007. [Google Scholar]

- Danilewsky, A.N.; Wittge, J.; Croell, A.; Allen, D.; McNally, P.; Vagovič, P.; Dos Santos Rolo, T.; Li, Z.; Baumbach, T.; Gorostegui-Colinas, E.; et al. Dislocation dynamics and slip band formation in silicon: In-situ study by X-ray diffraction imaging. J. Cryst. Growth 2011, 318, 1157–1163. [Google Scholar] [CrossRef]

- Vallino, F.; Chateau, J.P.; Jacques, A.; George, A. Dislocation multiplication during the very first stages of plastic deformation in silicon observed by X-ray topography. Mat. Sci. Eng. A 2001, 319, 152–155. [Google Scholar] [CrossRef]

- Danilewsky, A.; Wittge, J.; Kiefl, K.; Allen, D.; McNally, P.; Garagorri, J.; Elizalde, M.R.; Baumbach, T.; Tanner, B.K. Crack propagation and fracture in silicon wafers under thermal stress. J. Appl. Crystallogr. 2013, 46 Pt 4, 849–855. [Google Scholar] [CrossRef]

- Lafford, T.A.; Villanova, J.; Plassat, N.; Dubois, S.; Camel, D. Synchrotron X-ray imaging applied to solar photovoltaic silicon. J. Phys. Conf. Ser. 2013, 425, 192019. [Google Scholar] [CrossRef]

- Yao, Y.; Sugawara, Y.; Ishikawa, Y. Observation of dislocations in β-Ga2O3 single-crystal substrates by synchrotron X-ray topography, chemical etching, and transmission electron microscopy. Jpn. J. Appl. Phys. 2020, 59, 045502. [Google Scholar] [CrossRef]

- Lantreibecq, A.; Monchoux, J.P.; Pihan, E.; Marie, B.; Legros, M. Subgrains, micro-twins and dislocations characterization in monolike Si using TEM and in-situ TEM. Mater. Today Proc. 2018, 5, 14732–14747. [Google Scholar] [CrossRef]

- Qiang, Z.; Peizhen, D.; Fuxi, G. X-ray topographic observation of dislocation structure in sapphire single crystal grown by temperature gradient technique. J. Cryst. Growth 1991, 108, 377–384. [Google Scholar] [CrossRef]

- Tsoutsouva, M.G.; Riberi-Béridot, T.; Regula, G.; Reinhart, G.; Baruchel, J.; Mangelinck-Noël, N. In Situ imaging of dislocation expansion in FZ-Si seeds during temperature ramp heating process. Phys. Status Solidi A 2018, 215, 1700758. [Google Scholar] [CrossRef]

- Miller, W. Some remarks on the undercooling of the Si(111) facet and the “Monte Carlo modeling of silicon crystal growth” by Kirk M. Beatty & Kenneth A.; Jackson, J. Crystal Growth 211 (2000) 13. J. Cryst. Growth 2011, 325, 101–103. [Google Scholar]

- Voronkov, V.V. Supercooling at the facet developing on a a rounded crystalization front. Sov. Phys. Crystallogr. 1973, 17, 807–813. [Google Scholar]

- Nadri, A.; Duterrail-Couvat, Y.; Duffar, T. Two-dimensional numerical modeling of grain structure in multi-crystalline silicon ingot. J. Cryst. Growth 2014, 385, 16–21. [Google Scholar] [CrossRef]

- Lin, H.K.; Lan, C.W. Phase field modeling of grain structure evolution during directional solidification of multi-crystalline silicon sheet. J. Cryst. Growth 2017, 475, 150–157. [Google Scholar] [CrossRef]

- Pineau, A.; Guillemot, G.; Reinhart, G.; Regula, G.; Mangelinck-Noël, N.; Gandin, C.A. Three-dimensional cellular automaton modeling of silicon crystallization with grains in twin relationships. Acta Mater. 2020, 191, 230–244. [Google Scholar] [CrossRef]

- Coriell, S.R.; Sekerya, R.F. Morphological stability near a grain boundary groove in a solid-liquid interface during solidification of a binary alloy. J. Cryst. Growth 1973, 19, 285–293. [Google Scholar] [CrossRef]

- Duffar, T.; Nadri, A. The grain–grain–liquid triple phase line during solidification of multi-crystalline silicon. C. R. Phys. 2013, 14, 185–191. [Google Scholar] [CrossRef]

- Jackson, K.A. Crystal growth kinetics. Mater. Sci. Eng. 1984, 65, 7–13. [Google Scholar] [CrossRef]

- Dash, J.G.; Hodgkin, V.A.; Wettlaufer, J.S. Dynamics of faceted grain boundary grooves. J. Stat. Phys. 1999, 95, 1311–1322. [Google Scholar] [CrossRef]

- Ervik, T.; Stokkan, G.; Buonassisi, T.; Mjøs, Ø.; Lohne, O. Dislocation formation in seeds for quasi-monocrystalline silicon for solar cells. Acta Mater. 2014, 67, 199–206. [Google Scholar] [CrossRef]

- Lin, H.K.; Wu, M.C.; Chen, C.C.; Lan, C.W. Evolution of grain structures during directional solidification of silicon wafers. J. Cryst. Growth 2016, 439, 40–46. [Google Scholar] [CrossRef]

- Stockmeier, L.; Müller, G.; Seidl, A.; Lehmann, T.; Reimann, C.; Friedrich, J. Preferred grain orientations in silicon ribbons grown by the string ribbon and the edge-defined film-fed growth methods. J. Cryst. Growth 2014, 395, 74–79. [Google Scholar] [CrossRef]

- Heilbronn, B.; De Moro, F.; Jolivet, E.; Tupin, E.; Chau, B.; Varrot, R.; Drevet, B.; Bailly, S.; Rey, D.; Lignier, H.; et al. Fast growth of thin multi-crystalline silicon ribbons by the RST method. Cryst. Res. Technol. 2014, 50, 101–114. [Google Scholar] [CrossRef]

- Mangelinck-Noël, N.; Pihan, E. Le renouveau du silicium dope les pannneaux solaires. Rech. Sept. 2018, 2018, 539. [Google Scholar]

- Jhang, J.W.; Regula, G.; Reinhart, G.; Mangelinck-Noël, N.; Lan, C.W. Heterogeneous twinning during directional solidification of multi-crystalline silicon. J. Cryst. Growth 2019, 508, 42–49. [Google Scholar] [CrossRef]

- Alexander, H.; Haasen, P. Dislocations and plastic flow in the diamond structure. Solid State Phys. 1968, 22, 27. [Google Scholar]

- Takahashi, I.; Usami, N.; Kutsukake, K.; Stokkan, G.; Morishita, K.; Nakajima, K. Generation mechanism of dislocations during directional solidification of multicrystalline silicon using artificially designed seed. J. Cryst. Growth 2010, 312, 897–901. [Google Scholar] [CrossRef]

- Ryningen, B.; Stokkan, G.; Kivambe, M.; Ervik, T.; Lohne, O. Growth of dislocation clusters during directional solidification of multicrystalline silicon ingots. Acta Mater. 2011, 59, 7703–7710. [Google Scholar] [CrossRef]

- Lim, R.C.; Raj, R. Interaction between lattice and grain boundary dislocations and their role in mechanical properties of interfaces. J. Phys. Colloq. 1985, 46, 581–595. [Google Scholar] [CrossRef]

- Brokman, A.; Bristowe, P.D.; Balluffi, R.W. Atomistic faceting of asymmetric tilt boundaries. Scr. Metall. 1981, 15, 201–206. [Google Scholar] [CrossRef]

- Stoffers, A.; Ziebarth, B.; Barthel, J.; Cojocaru-Mirédin, O.; Elsässer, C.; Raabe, D. Complex nanotwin substructure of an asymmetric S9 tilt grain boundary in a silicon polycrystal. Phys. Rev. Lett. 2015, 115, 235502. [Google Scholar] [CrossRef] [PubMed]

- Stokkan, G.; Hu, Y.; Mjøs, Ø.; Juel, M. Study of evolution of dislocation clusters in high performance multicrystalline silicon. Sol. Energy Mater. Sol. Cells 2014, 130, 679–685. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ouaddah, H.; Becker, M.; Riberi-Béridot, T.; Tsoutsouva, M.; Stamelou, V.; Regula, G.; Reinhart, G.; Périchaud, I.; Guittonneau, F.; Barrallier, L.; et al. X-ray Based in Situ Investigation of Silicon Growth Mechanism Dynamics—Application to Grain and Defect Formation. Crystals 2020, 10, 555. https://doi.org/10.3390/cryst10070555

Ouaddah H, Becker M, Riberi-Béridot T, Tsoutsouva M, Stamelou V, Regula G, Reinhart G, Périchaud I, Guittonneau F, Barrallier L, et al. X-ray Based in Situ Investigation of Silicon Growth Mechanism Dynamics—Application to Grain and Defect Formation. Crystals. 2020; 10(7):555. https://doi.org/10.3390/cryst10070555

Chicago/Turabian StyleOuaddah, Hadjer, Maike Becker, Thècle Riberi-Béridot, Maria Tsoutsouva, Vasiliki Stamelou, Gabrielle Regula, Guillaume Reinhart, Isabelle Périchaud, Fabrice Guittonneau, Laurent Barrallier, and et al. 2020. "X-ray Based in Situ Investigation of Silicon Growth Mechanism Dynamics—Application to Grain and Defect Formation" Crystals 10, no. 7: 555. https://doi.org/10.3390/cryst10070555

APA StyleOuaddah, H., Becker, M., Riberi-Béridot, T., Tsoutsouva, M., Stamelou, V., Regula, G., Reinhart, G., Périchaud, I., Guittonneau, F., Barrallier, L., Valade, J.-P., Rack, A., Boller, E., Baruchel, J., & Mangelinck-Noël, N. (2020). X-ray Based in Situ Investigation of Silicon Growth Mechanism Dynamics—Application to Grain and Defect Formation. Crystals, 10(7), 555. https://doi.org/10.3390/cryst10070555