Shear Deformation Helps Phase Transition in Pure Iron Thin Films with “Inactive” Surfaces: A Molecular Dynamics Study

Abstract

:1. Introduction

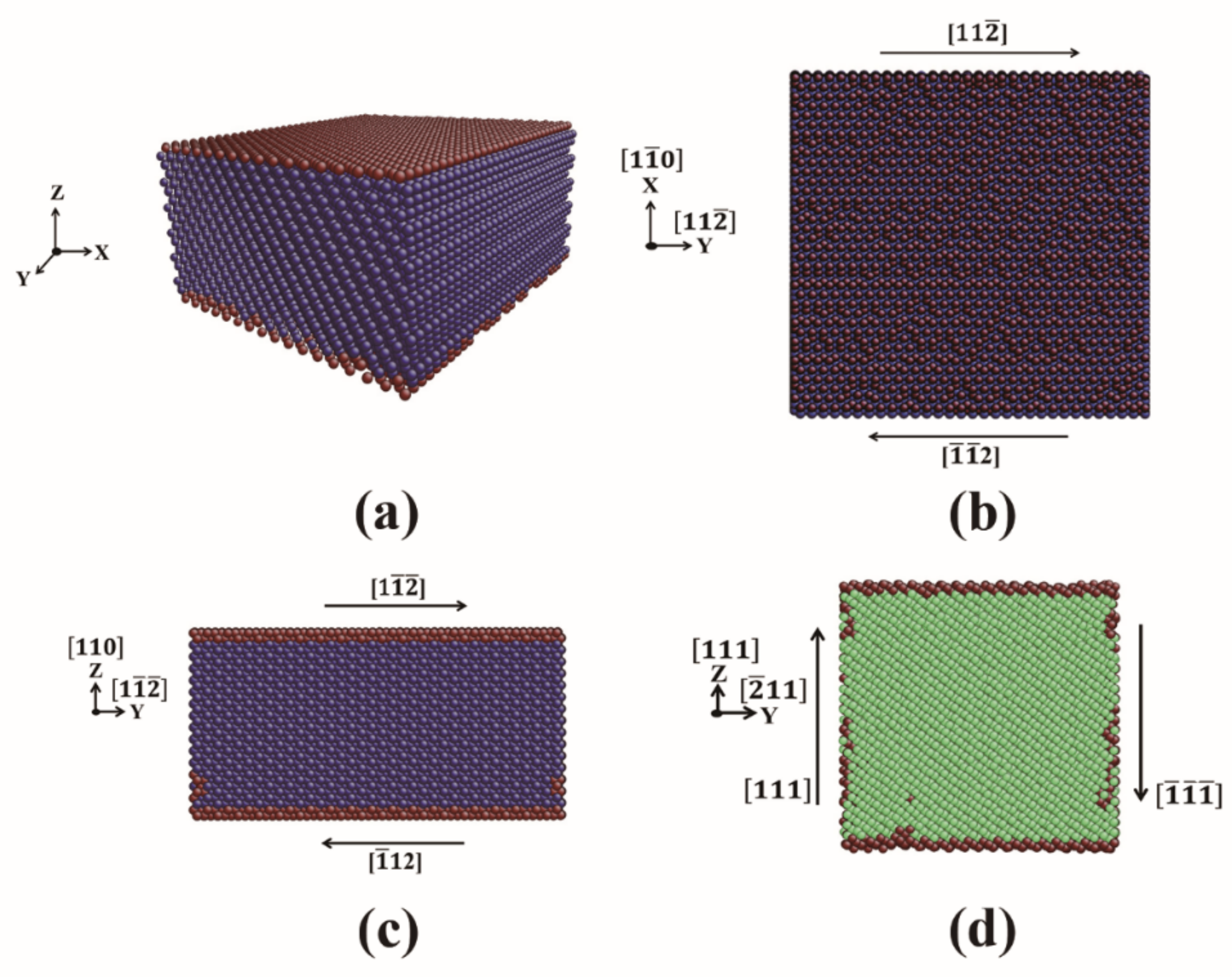

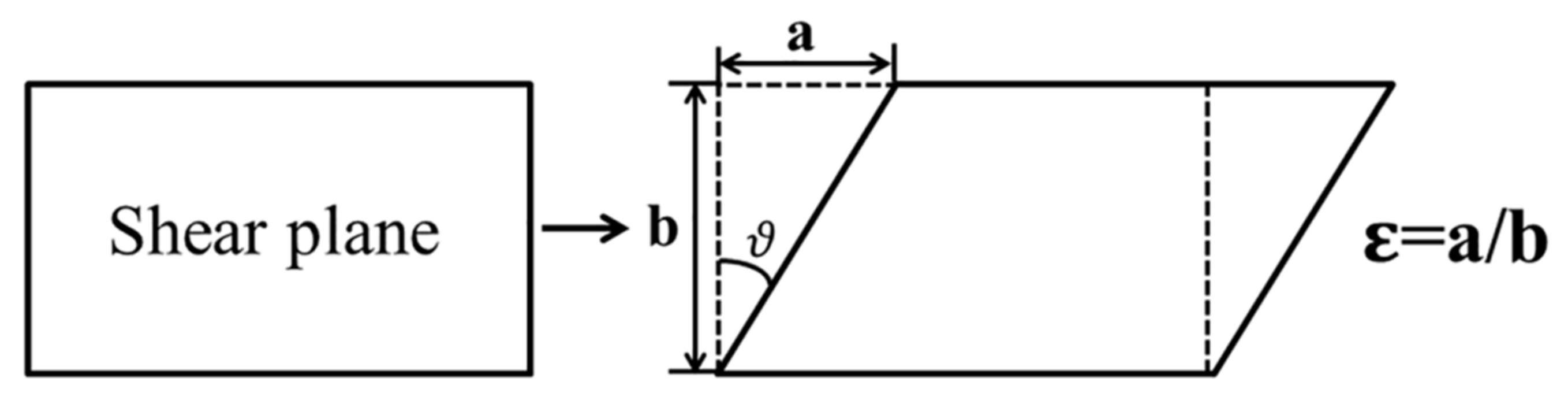

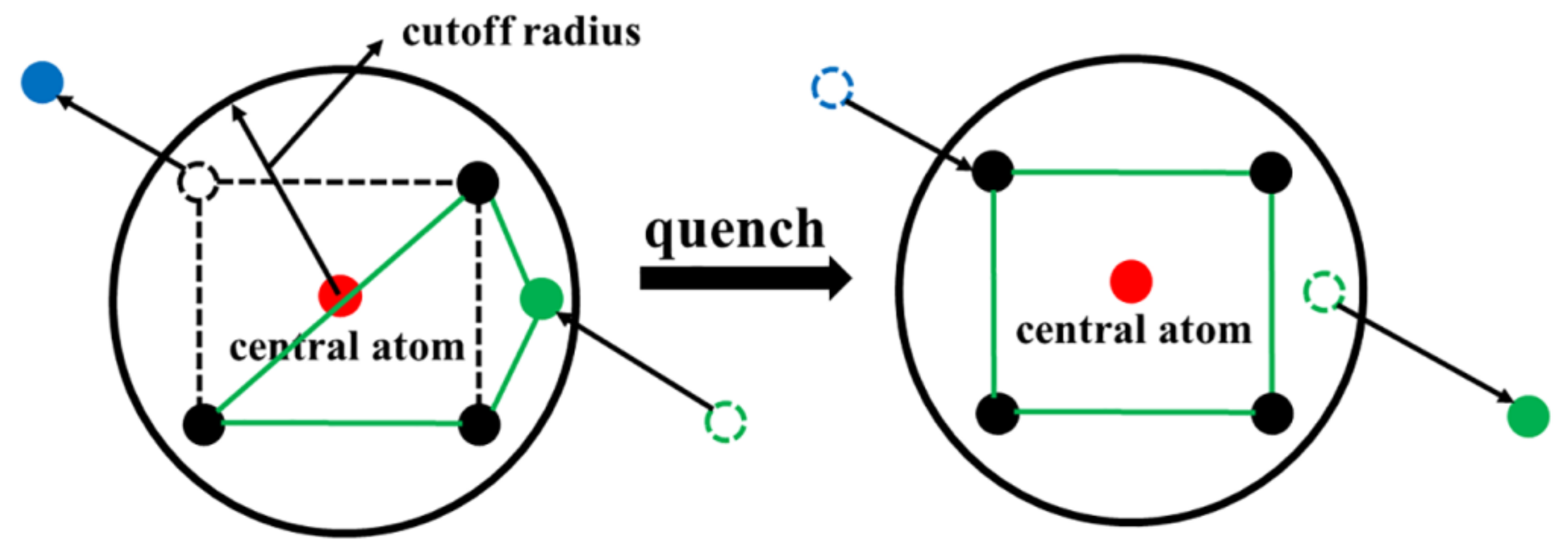

2. Simulation Method

3. Results

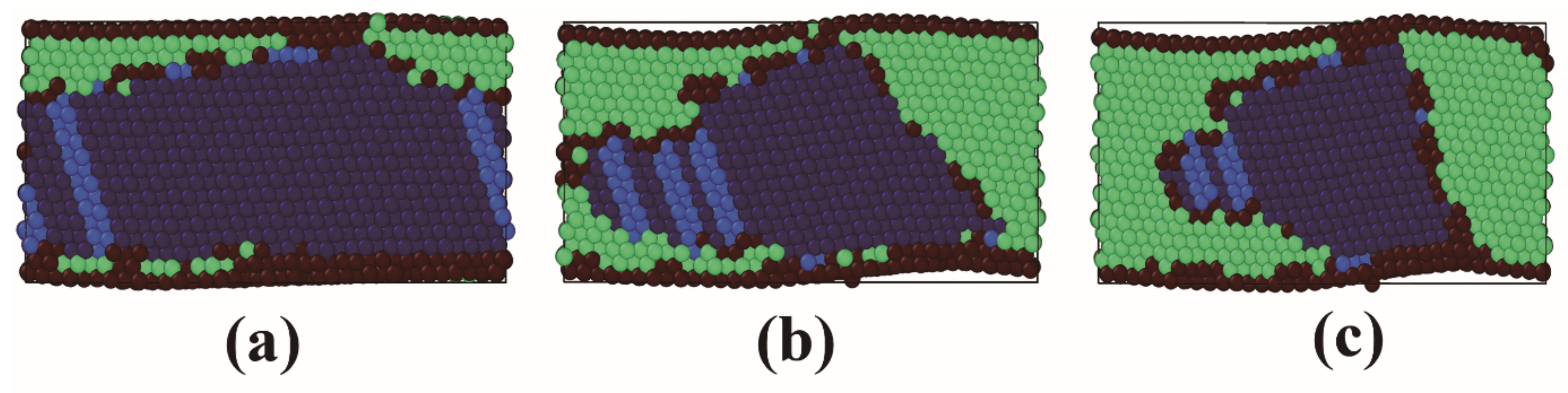

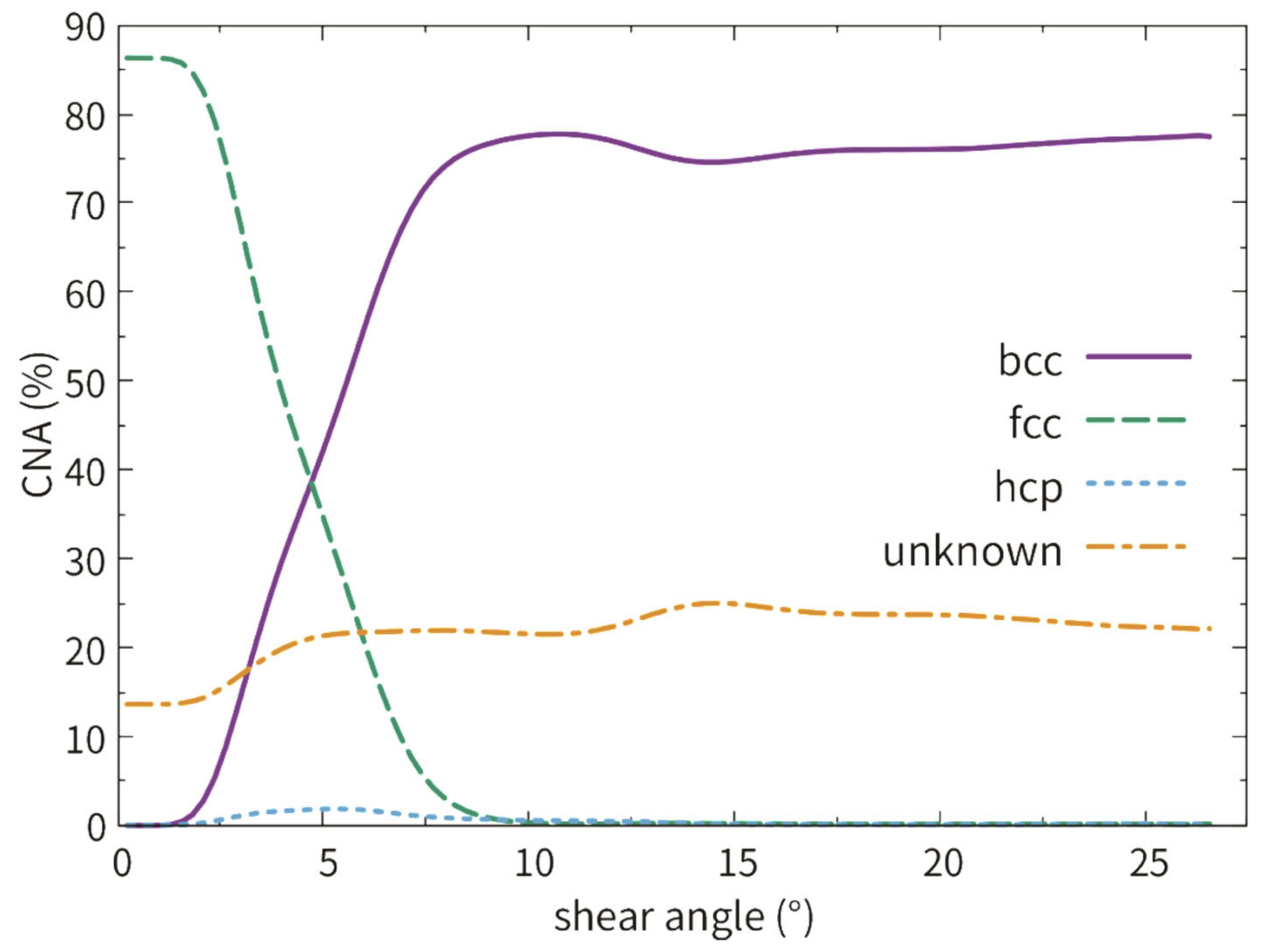

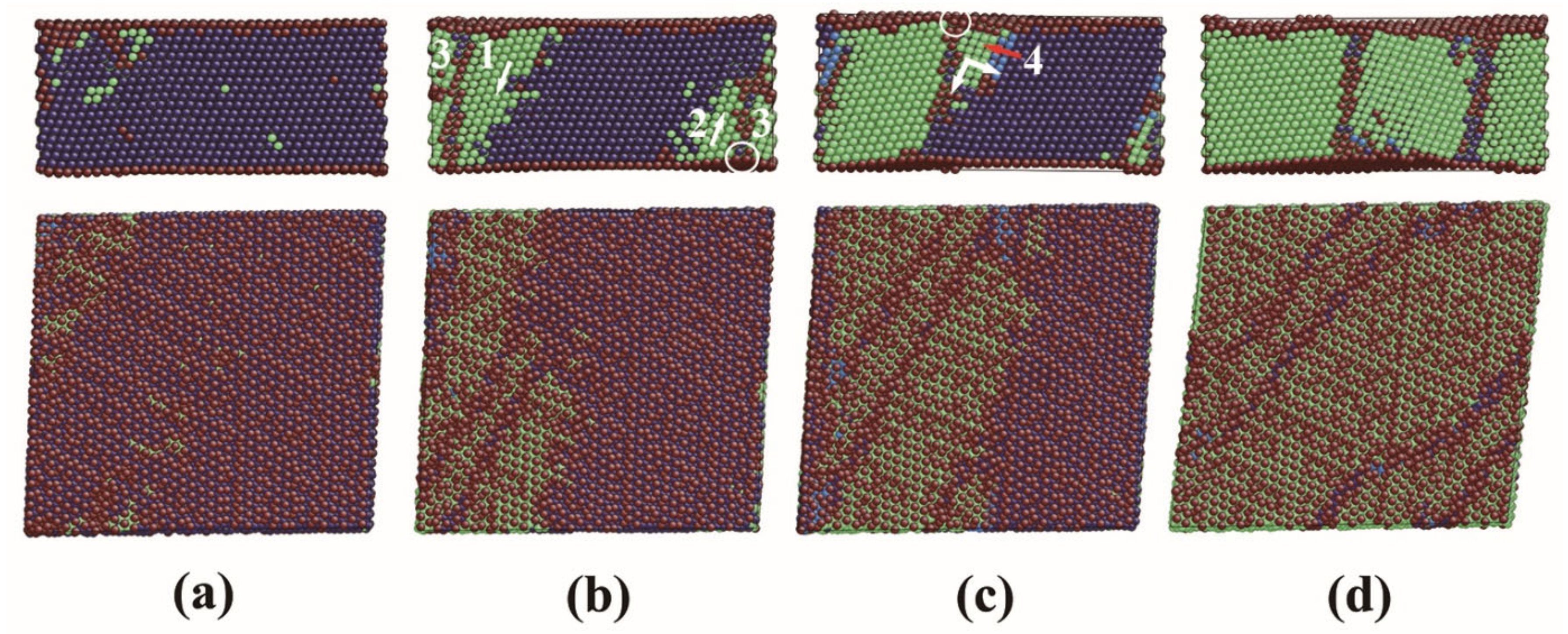

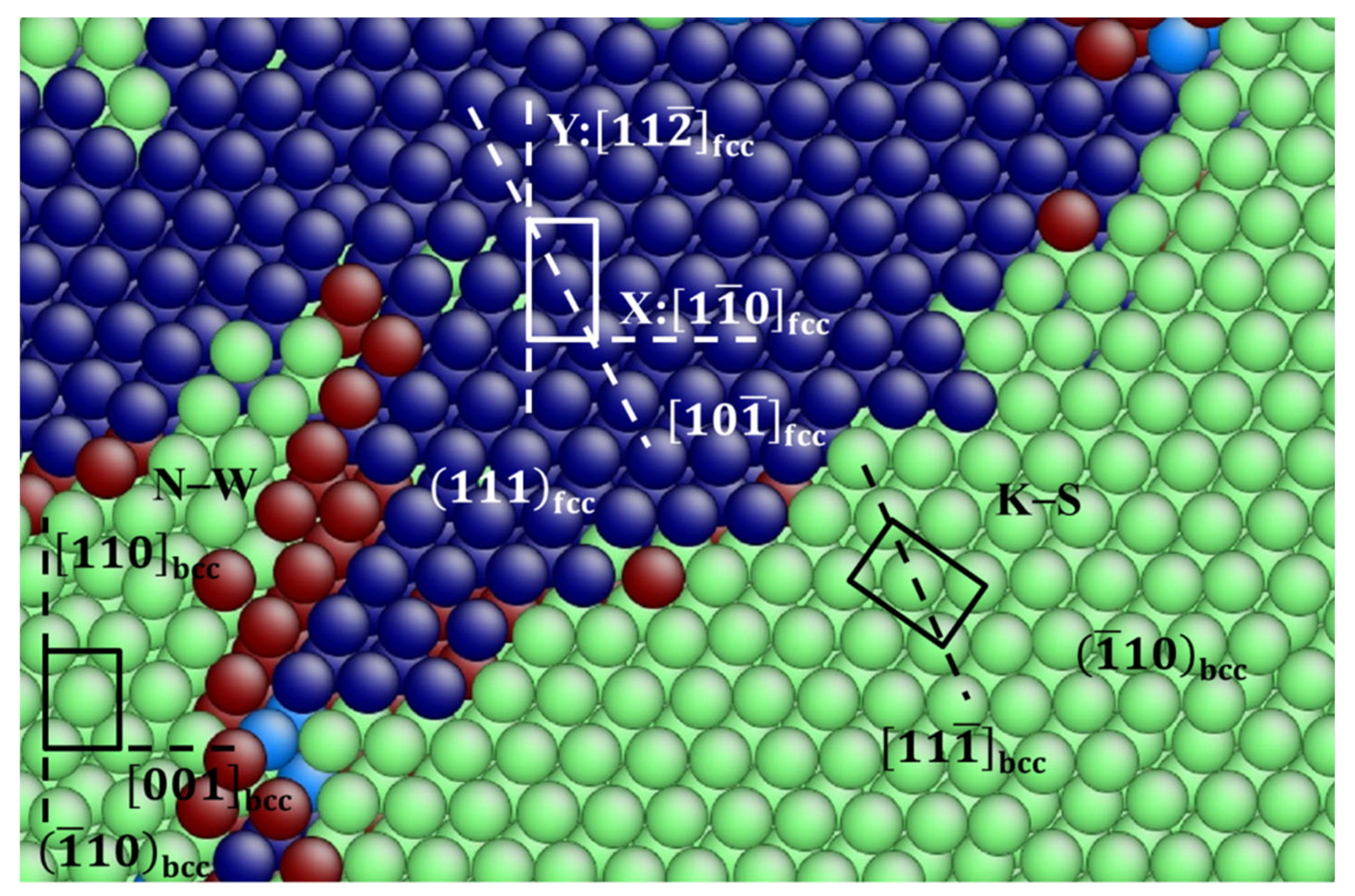

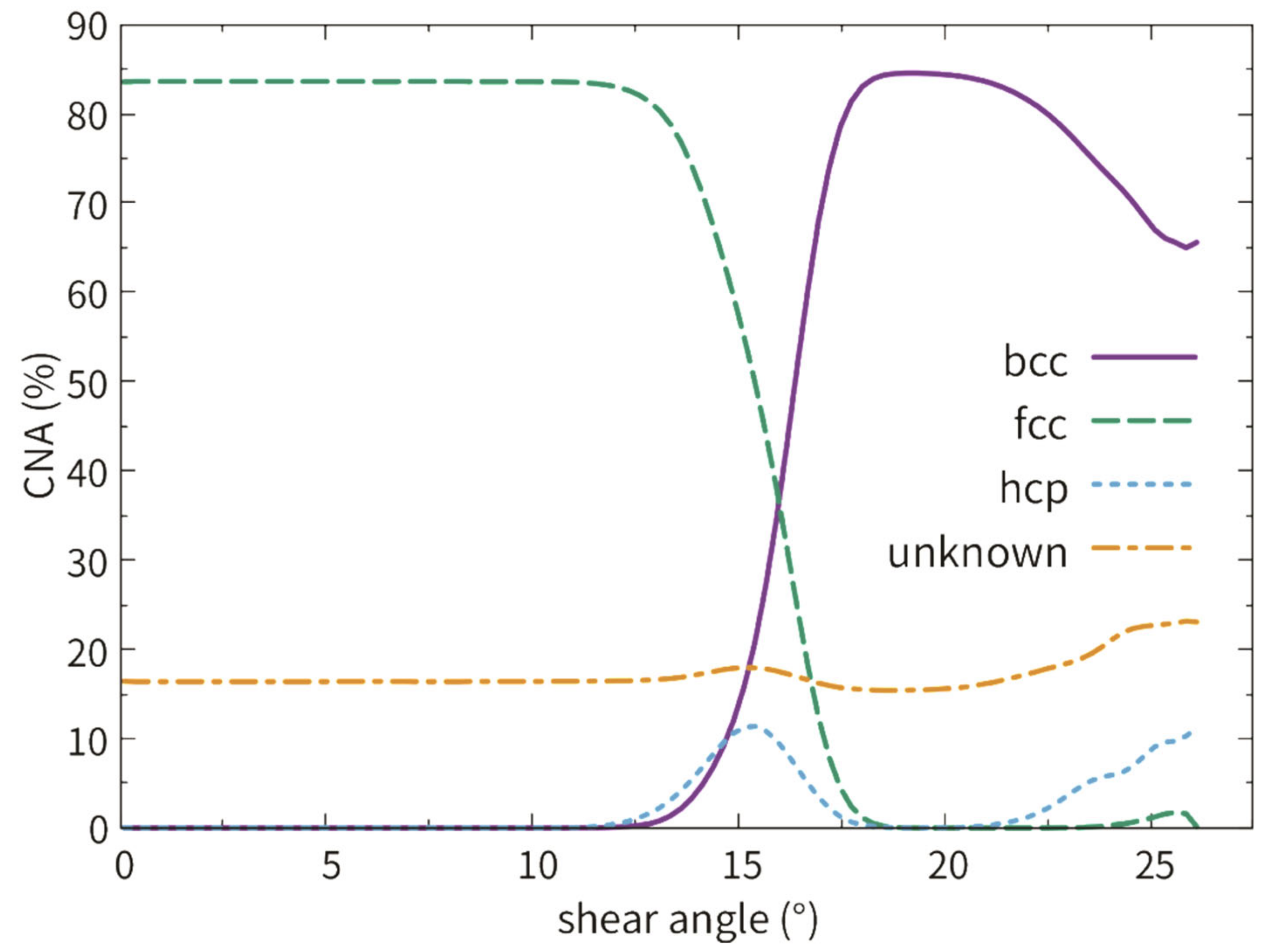

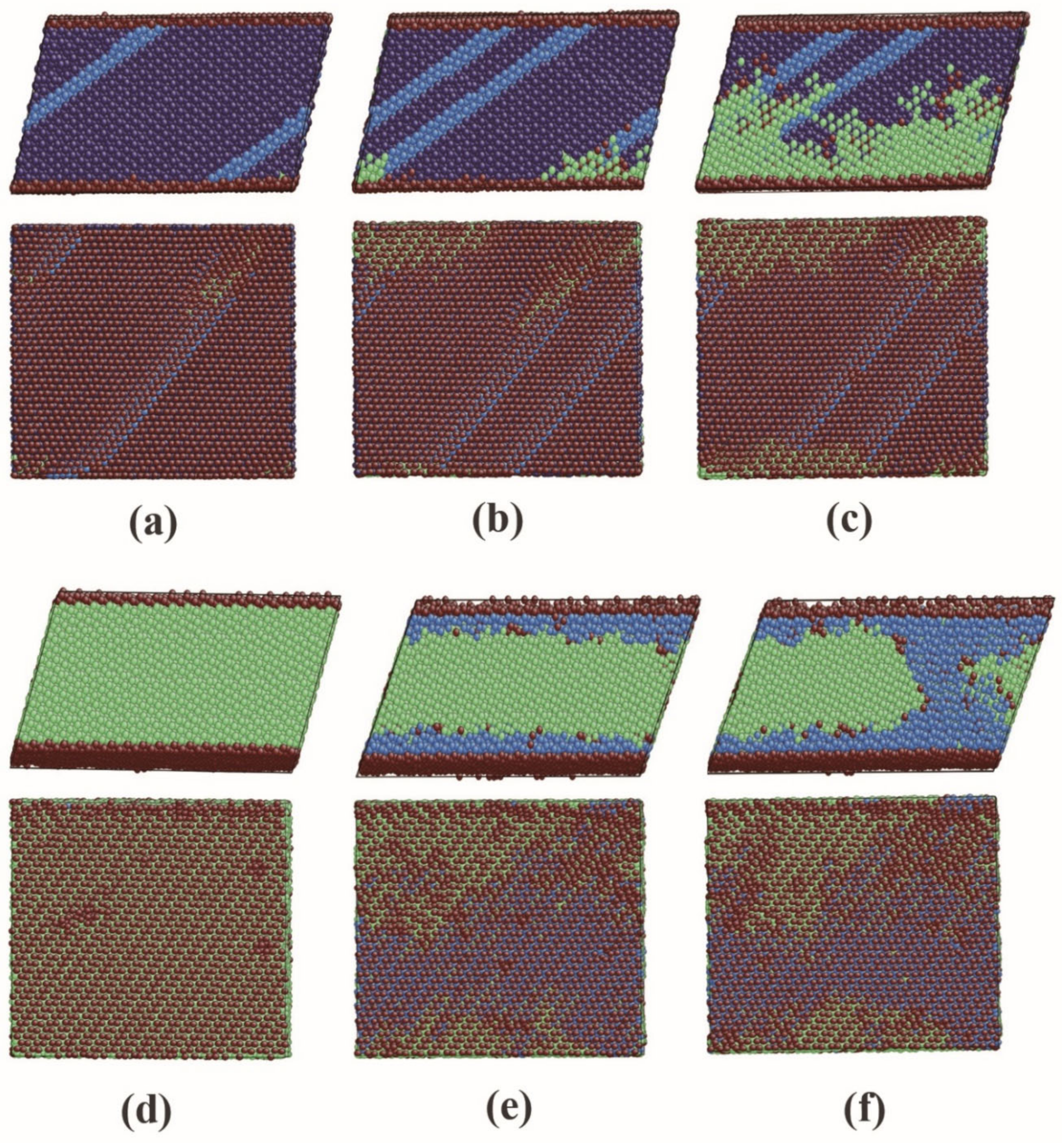

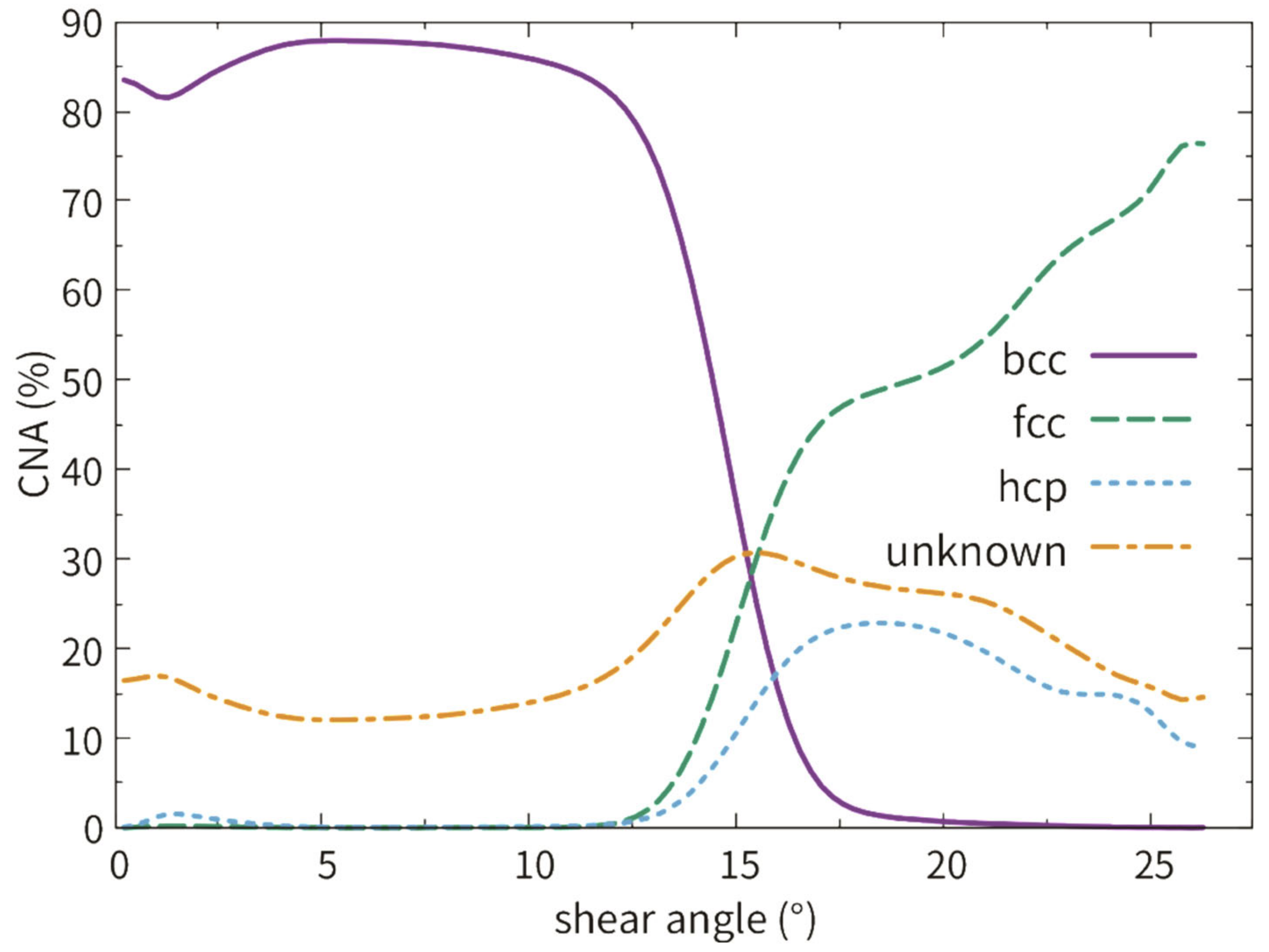

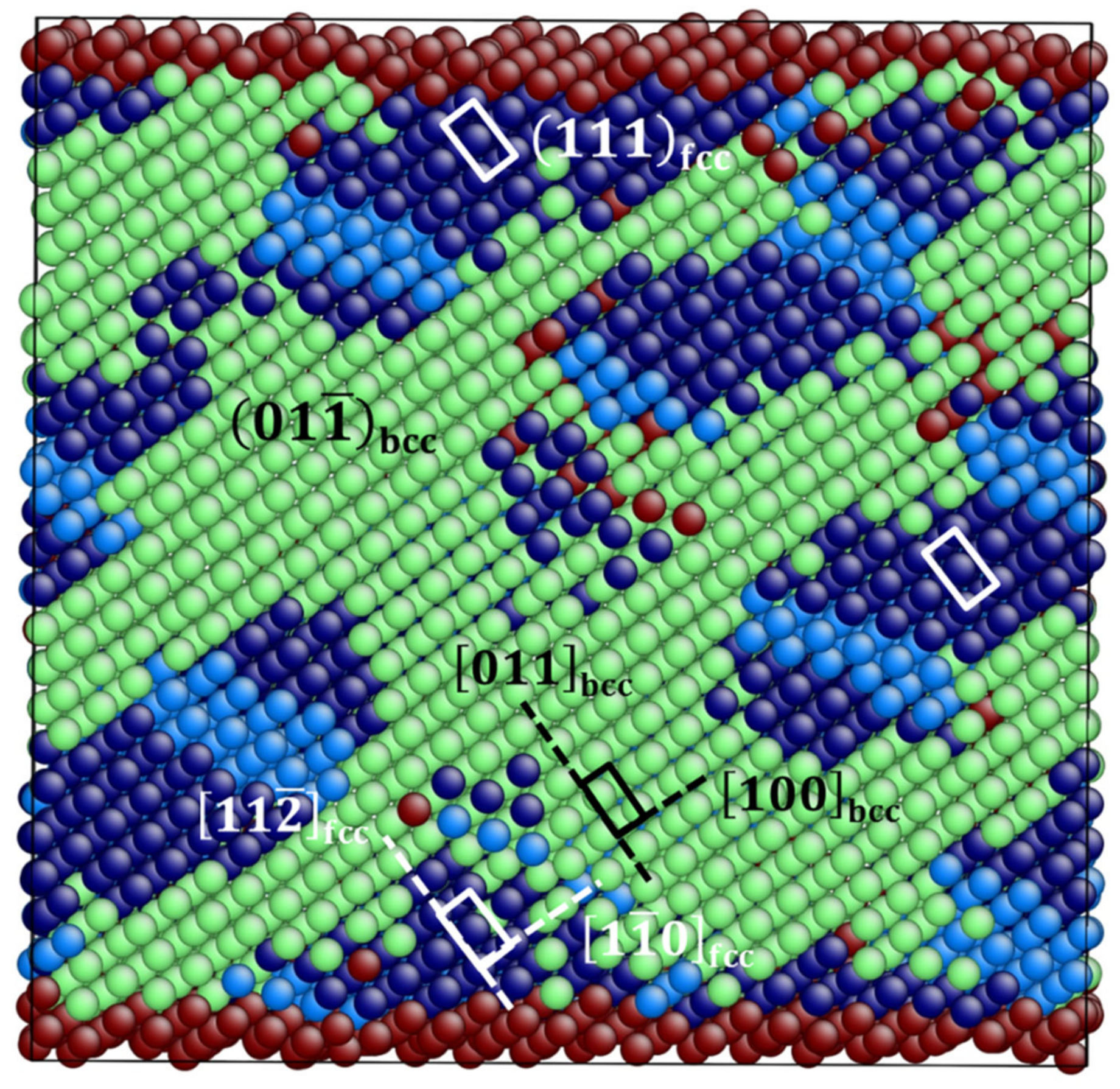

3.1. Fcc Film 1 with the (111) Free Surface

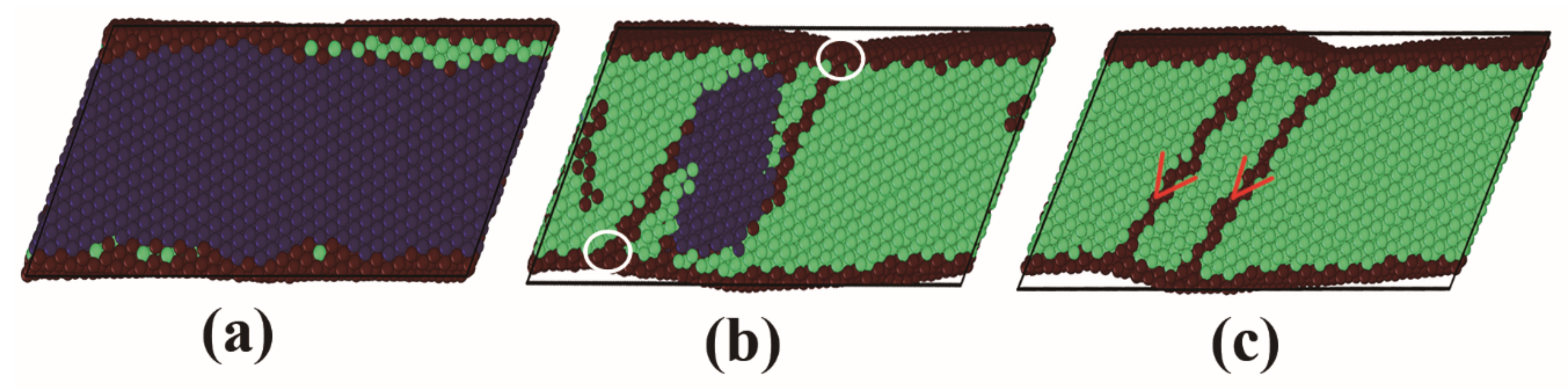

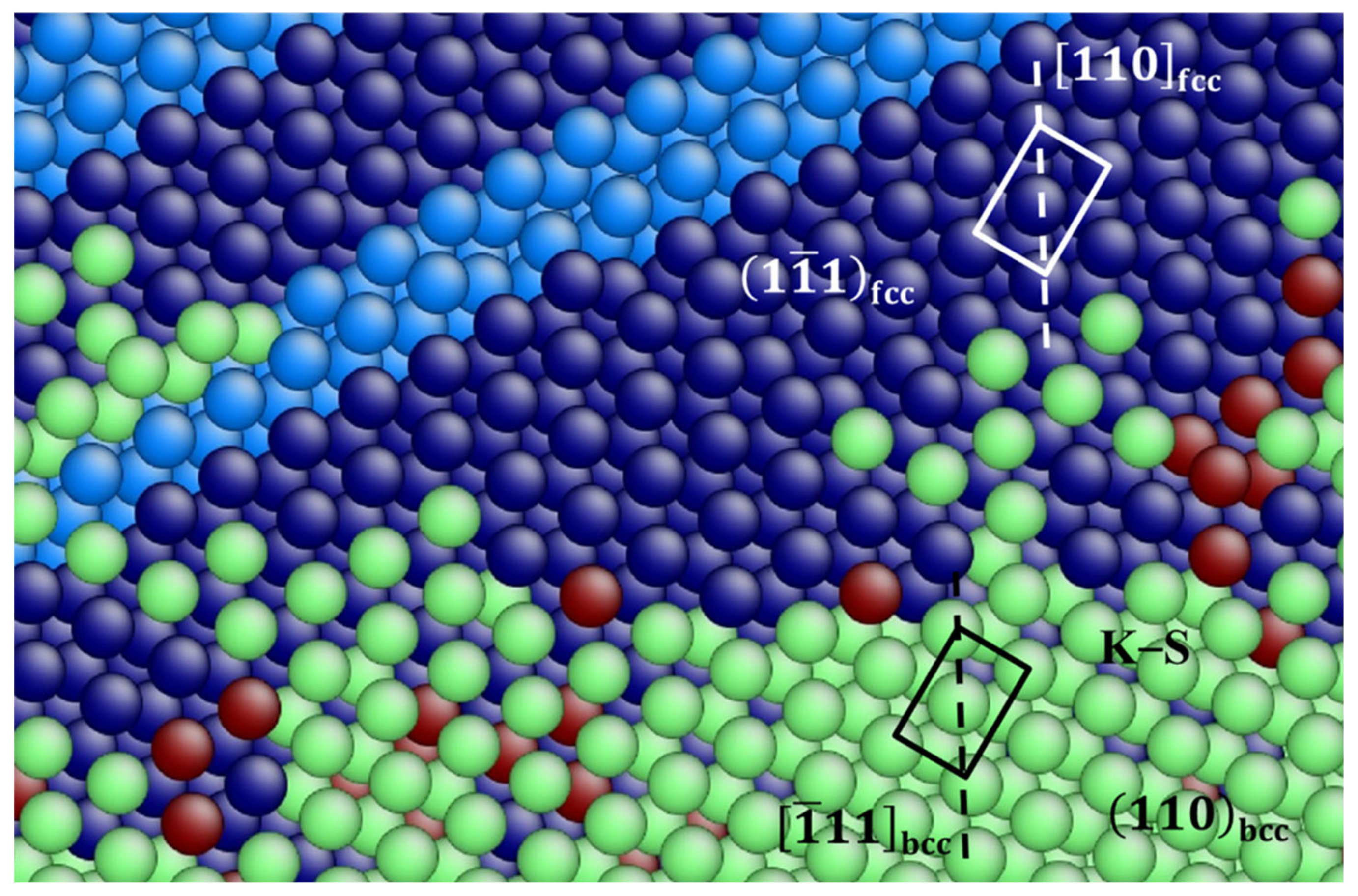

3.2. Fcc Film 2 with the (110) Free Surface

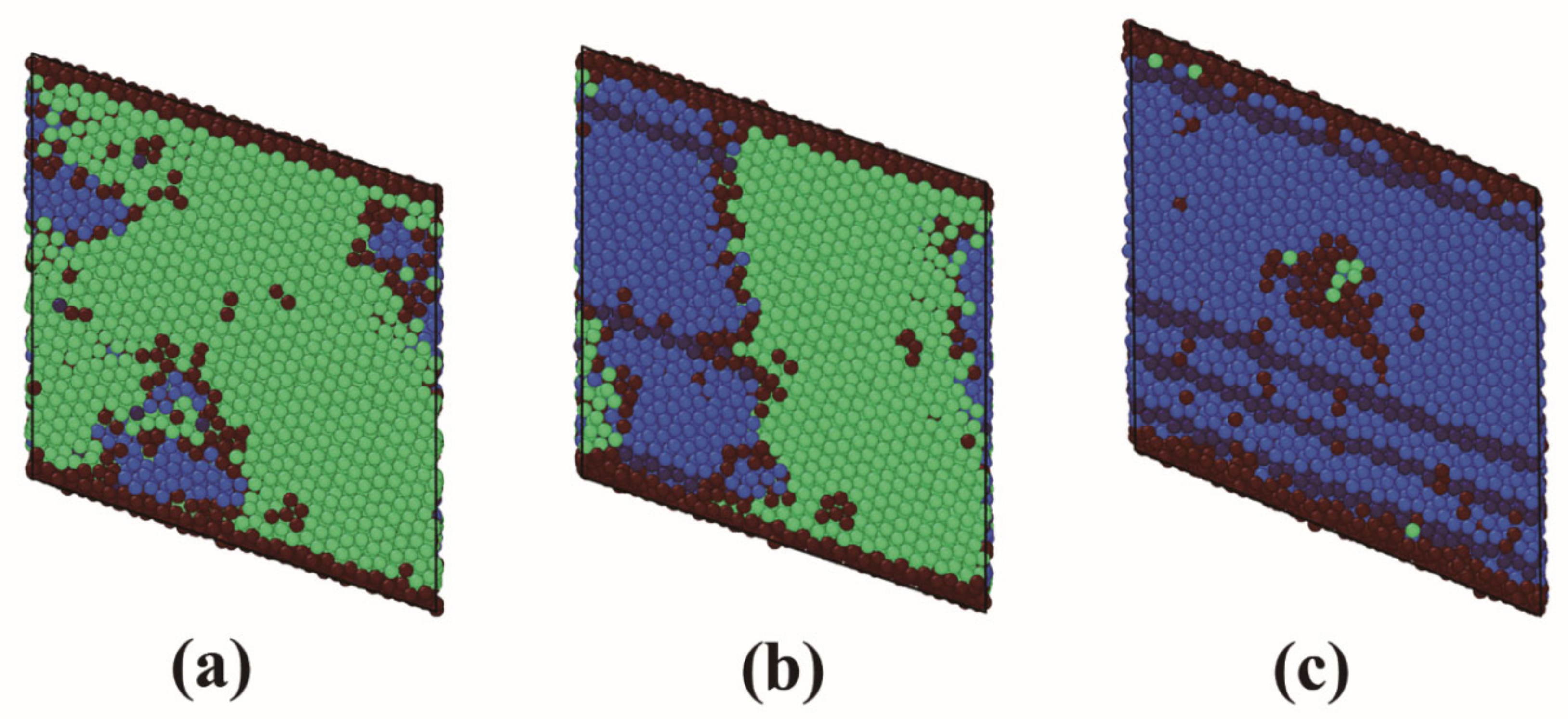

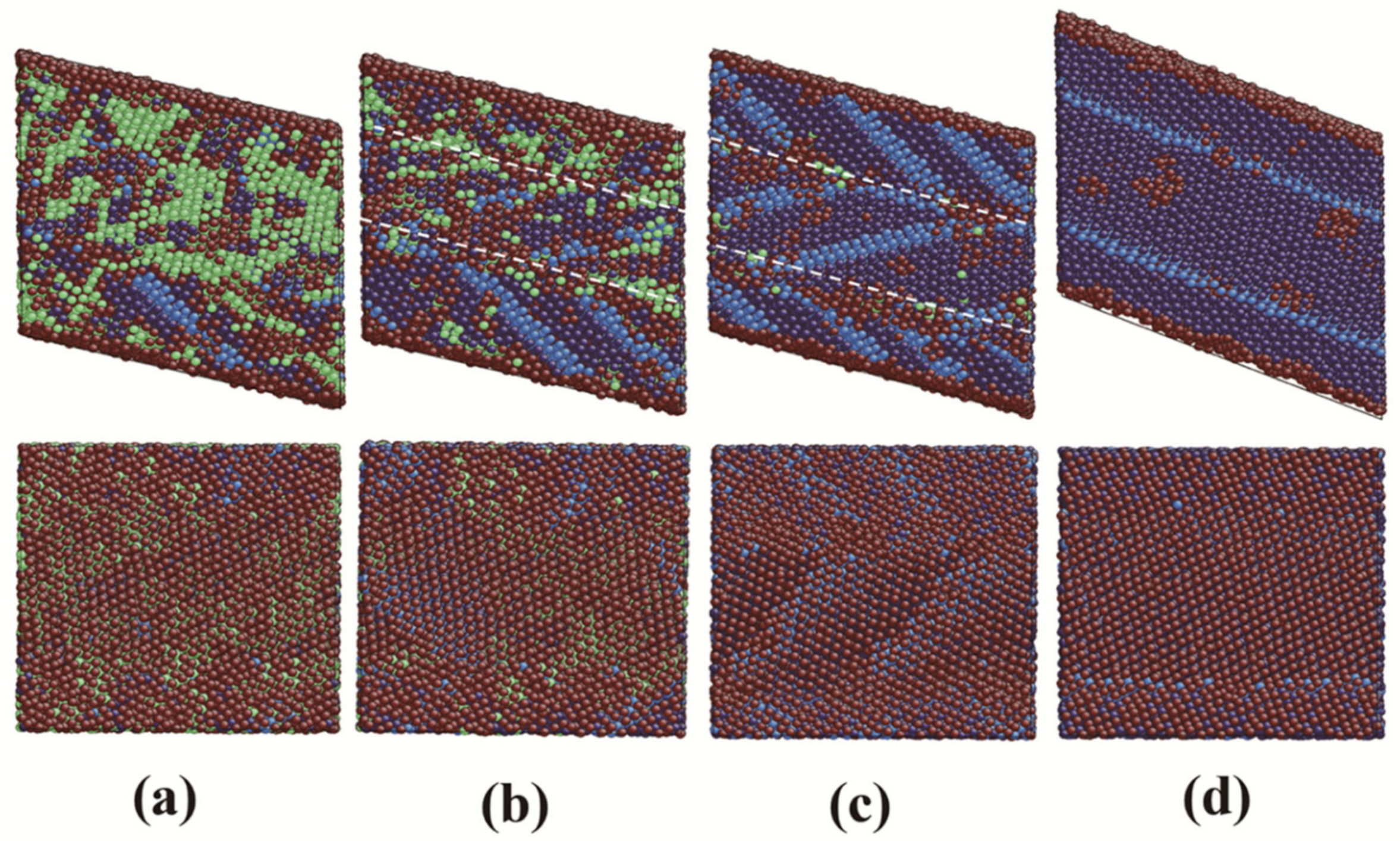

3.3. Bcc Film 3 with the (111) Free Surface

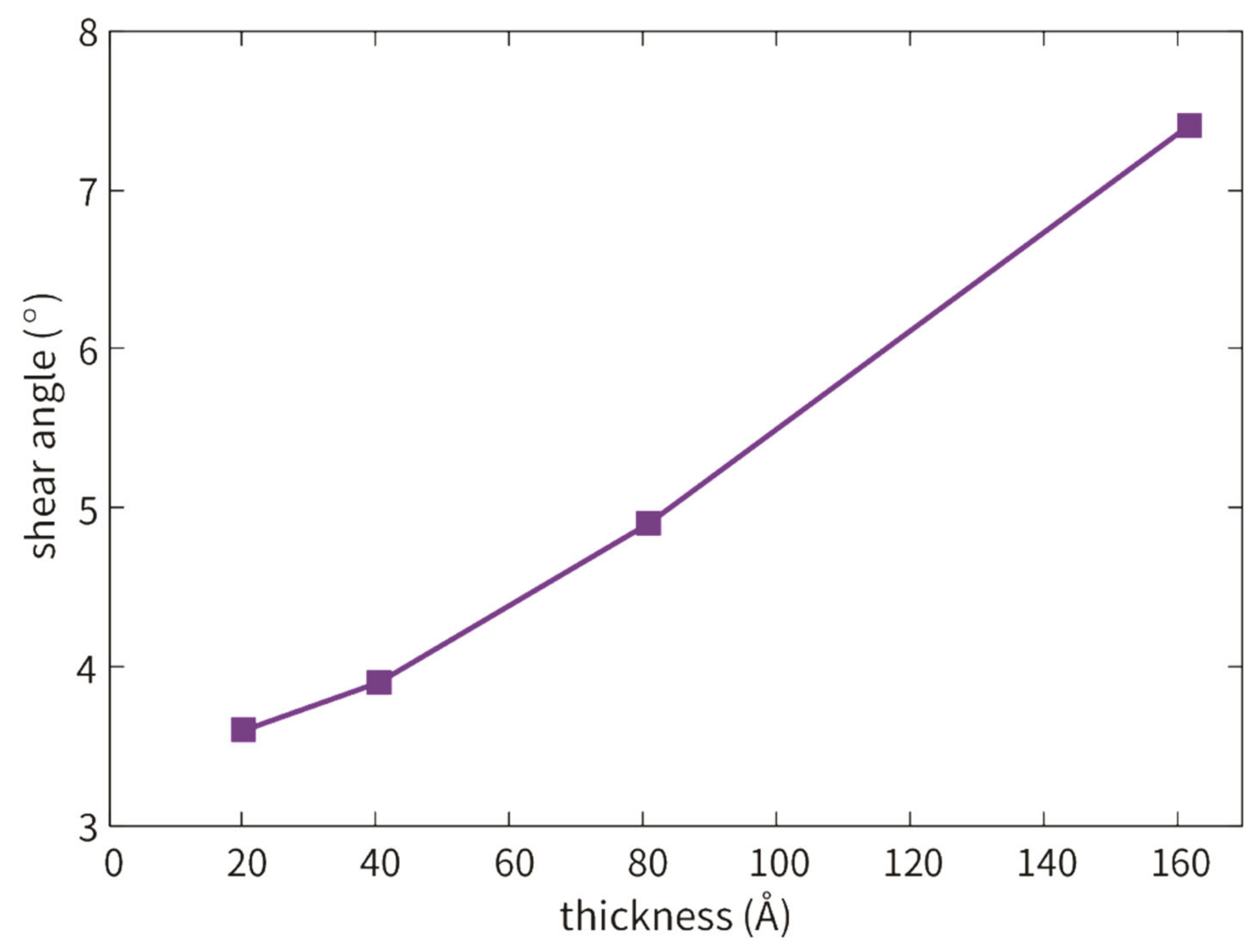

3.4. Dependence on Film Thickness

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

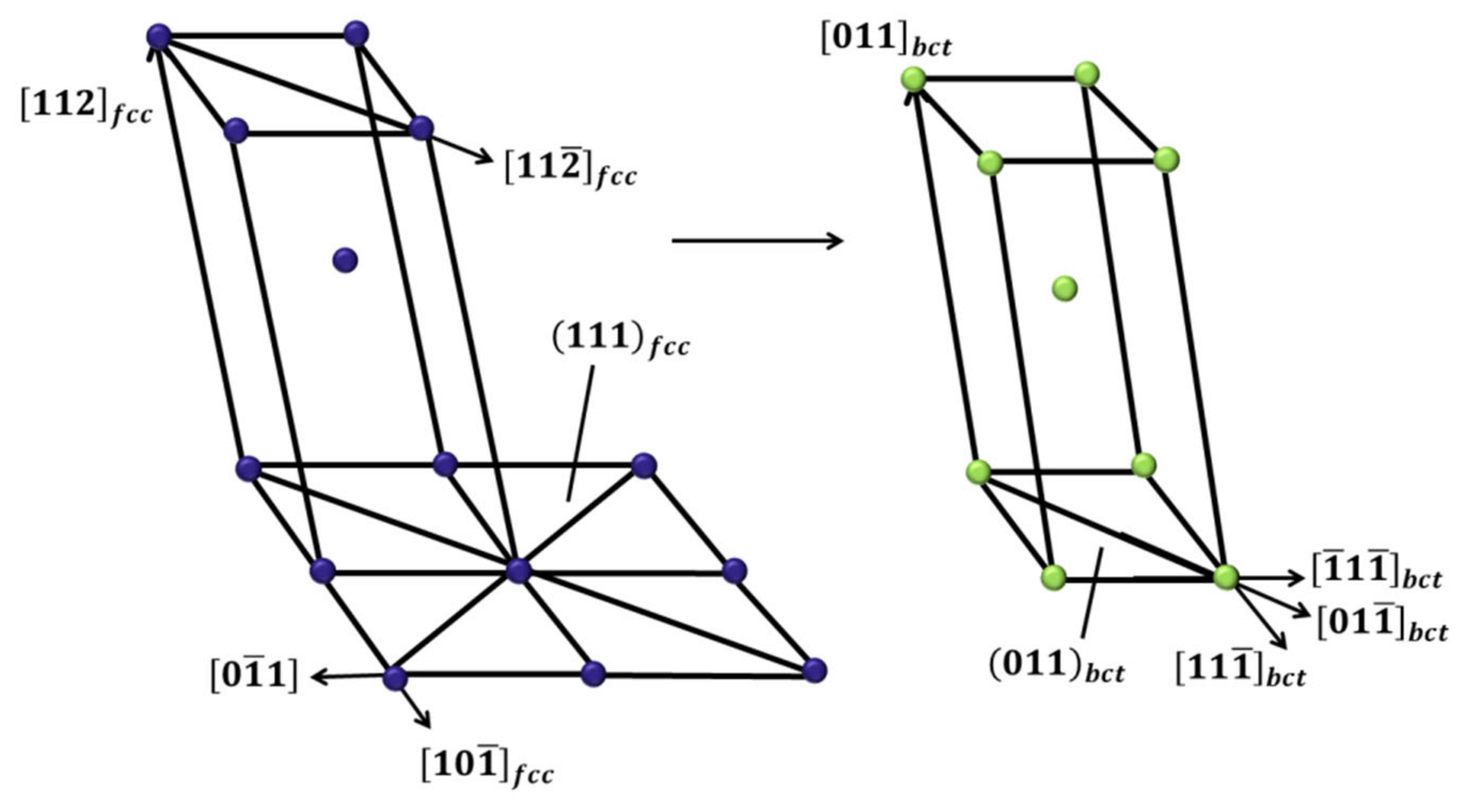

Appendix A

Simulation Using the Müller Potential

References

- Tian, F.; Zhu, J.; Wei, D. Phase transition and magnetism of Ni nanowire arrays. J. Phys. Chem. C 2007, 111, 6994–6997. [Google Scholar] [CrossRef]

- Sandoval, L.; Urbassek, H.M. Finite-size effects in Fe-nanowire solid-solid phase transitions: A molecular dynamics approach. Nano Lett. 2009, 9, 2290–2294. [Google Scholar] [CrossRef] [PubMed]

- Wang, B.; Urbassek, H.M. Computer simulation of strain-induced phase transformations in thin Fe films. Model. Simul. Mater. Sci. Eng. 2013, 24, 5007. [Google Scholar] [CrossRef]

- Sak-Saracino, E.; Urbassek, H.M. Effect of uni- and biaxial strain on phase transformations in Fe thin films. Int. J. Comput. Mater. Sci. Eng. 2016, 5, 1650001. [Google Scholar] [CrossRef]

- Ma, F.; Xu, K.W. Size-dependent theoretical tensile strength and other mechanical properties of [001] oriented Au, Ag, and Cu nanowires. J. Mater. Res. 2006, 21, 2810–2816. [Google Scholar] [CrossRef]

- Vazinishayan, A.; Yang, S.; Duongthipthewa, A.; Wang, L.M. Effects of cross-section on mechanical properties of Au nanowire. AIP Adv. 2016, 6, 113–2005. [Google Scholar] [CrossRef]

- Tripathi, J.; Sharma, A.; Bisen, R.; Kumar, D.; Gupta, M.; Gupta, P.; Tripathi, S. Thickness dependent structural and magnetic properties of Au/Co/Si (100) ultra-thin wedge film. DAE Solid State Phys. Symp. 2018 2019, 2115, 030305. [Google Scholar]

- Vaz, C.A.F.; Bland, J.A.C.; Lauhoff, G. Magnetism in ultrathin film structures. Rep. Prog. Phys. 2008, 71, 863–882. [Google Scholar] [CrossRef]

- Dmitriev, S.V.; Kashchenko, M.P.; Baimova, J.A.; Babicheva, R.I.; Pushin, V.G. Molecular dynamics simulation of the effect of dislocations on the martensitic transformations in a two-dimensional model. Lett. Mater. 2017, 7, 442–446. [Google Scholar] [CrossRef]

- Wang, B.J.; Jiang, Y.Q.; Xu, C. Phase transition in iron thin films containing coherent twin boundaries: A molecular dynamics approach. Materials 2020, 13, 3631. [Google Scholar] [CrossRef]

- Griesser, S.; Bernhard, C.; Dippenaar, R. Effect of nucleation undercooling on the kinetics and mechanism of the peritectic phase transition in steel. Acta Mater. 2014, 81, 111–120. [Google Scholar] [CrossRef]

- Porter, D.A.; Easterling, K.E.; Sherif, M. Phase transformations in metals and alloys, 2nd edition. Ref. User Ser. Q. 1992, 1, 245. [Google Scholar]

- Teodorescu, V.S.; Mihailescu, I.N.; Dinescu, M.; Chitica, N.; Nistor, L.C.; Landuyt, J.V.; Barborica, A. Laser induced phase transition in iron thin films. J. Phys. IV 1994, 4, C4-127–C4-130. [Google Scholar] [CrossRef]

- Teodorescu, V.S.; Nistor, L.C.; Landuyt, J.V.; Dinescu, M. TEM study of laser induced phase transition in iron thin films. Mater. Res. Bull. 1994, 29, 63–71. [Google Scholar] [CrossRef]

- Cuenya, B.R.; Doi, M.; Löbus, S.; Courths, R.; Keune, W. Observation of the fcc-to-bcc Bain transformation in epitaxial Fe ultrathin films on Cu3Au. Surf. Sci. 2001, 493, 338–360. [Google Scholar] [CrossRef]

- Bain, E.C.; Dunkirk, N.Y. The nature of martensite. Trans. AIME 1924, 70, 25. [Google Scholar]

- Pitsch, W. The martensite transformation in thin foils of iron-nitrogen alloys. Philos. Mag. 1959, 4, 577–584. [Google Scholar] [CrossRef]

- Memmel, N.; Detzel, T. Growth, structure and stability of ultrathin iron films on Cu(001). Surf. Sci. 1994, 307–309, 490–495. [Google Scholar] [CrossRef]

- Meiser, J.; Urbassek, H.M. Influence of the crystal surface on the austenitic and martensitic phase transition in pure iron. Crystals 2018, 8, 469. [Google Scholar] [CrossRef] [Green Version]

- Meyer, R.; Entel, P. Martensite-austenite transition and phonon dispersion curves of Fe1–xNix studied by molecular-dynamics simulations. Phys. Rev. B 1998, 57, 5140. [Google Scholar] [CrossRef]

- Wang, B.; Sak-Saracino, E.; Gunkelmann, N.; Urbassek, H.M. Molecular-dynamics study of the α↔γ phase transition in Fe–C. Comput. Mater. Sci. 2014, 82, 399–404. [Google Scholar]

- Cai, M.; Li, Z.; Chao, Q.; Hodgson, P.D. A novel Mo and Nb microalloyed medium Mn TRIP steel with maximal ultimate strength and moderate ductility. Metall. Mater. Trans. A 2014, 45, 5624–5634. [Google Scholar]

- Wu, X.L.; Yang, M.X.; Yuan, F.P.; Chen, L.; Zhu, Y.T. Combining gradient structure and TRIP effect to produce austenite stainless steel with high strength and ductility. Acta Mater. 2016, 112, 337–346. [Google Scholar]

- Han, X.; Zhang, H.; Li, Y.; Tang, J.J.; Wang, C.; Chen, J. Investigation of the hot stamping process for TRIP steel with high strength and high ductility. J. Mater. Eng. Perform. 2019, 28, 6125–6134. [Google Scholar]

- Engin, C.; Sandoval, L.; Urbassek, H.M. Characterization of Fe potentials with respect to the stability of the bcc and fcc phase. Model. Simul. Mater. Sci. Eng. 2008, 16, 035005. [Google Scholar] [CrossRef]

- Finnis, M.W.; Sinclair, J.E. A simple empirical N-body potential for transition metals. Philos. Mag. A 1984, 50, 45–55. [Google Scholar]

- Johnson, R.A.; Oh, D.J. Analytic embedded atom method model for bcc metals. J. Mater. Res. 1989, 4, 1195–1201. [Google Scholar]

- Karewar, S.; Sietsma, J.; Santofimia, M.J. Effect of pre-existing defects in the parent fcc phase on atomistic mechanisms during the martensitic transformation in pure Fe: A molecular dynamics study. Acta Mater. 2018, 142, 71–81. [Google Scholar]

- Müller, M.; Erhart, P.; Albe, K. Analytic bond-order potential for bcc and fcc iron—Comparison with established embedded-atom method potentials. J. Phys. Condens. Matter. 2007, 19, 326220. [Google Scholar] [CrossRef]

- Sak-Saracino, E.; Urbassek, H.M. Temperature-induced phase transformation of Fe1–xNix alloys: Molecular-dynamics approach. Eur. Phys. J. B 2015, 88, 169. [Google Scholar] [CrossRef]

- Wang, B.; Urbassek, H.M. Phase transitions in an Fe system containing a bcc/fcc phase boundary: An atomistic study. Phys. Rev. B 2013, 87, 104108. [Google Scholar]

- Kurdjumov, G.V.; Sachs, G. Über den mechanismus der stahlhärtung. Z. Phys. 1930, 64, 325–343. [Google Scholar]

- Nishiyama, Z. Mechanism of transformation from face-centred to body-centred cubic lattice. Sci. Rep. Tohoku Imp. Univ. 1934, 23, 637. [Google Scholar]

- Wang, B.; Urbassek, H.M. Molecular dynamics study of the α−γ phase transition in Fe induced by shear deformation. Acta Mater. 2013, 61, 5979–5987. [Google Scholar]

- LAMMPS. Available online: http://lammps.sandia.gov/ (accessed on 15 September 2020).

- Faken, D.; Jónsson, H. Systematic analysis of local atomic structure combined with 3D computer graphics. Comput. Mater. Sci. 1994, 2, 279–286. [Google Scholar]

- Stukowski, A. Structure identification methods for atomistic simulations of crystalline materials. Model. Simul. Mater. Sci. Eng. 2012, 20, 045021. [Google Scholar]

- Li, J. AtomEye: An efficient atomistic configuration viewer. Model. Simul. Mater. Sci. Eng. 2003, 11, 173–177. [Google Scholar]

- Wang, B.; Urbassek, H.M. Atomistic dynamics of the bcc↔fcc phase transition in iron: Competition of homo- and heterogeneous phase growth. Comput. Mater. Sci. 2014, 81, 170–177. [Google Scholar]

- Fukino, T.; Tsurekawa, S. In-situ SEM/EBSD observation of α/γ phase transformation in Fe-Ni alloy. Mater. Trans. 2008, 49, 2770–2775. [Google Scholar]

- Barcelo, F.; Bechade, J.L.; Fournier, B. Orientation relationship in various 9%Cr ferritic/martensitic steels–EBSD comparison between Nishiyama–Wassermann, Kurdjumov–Sachs and Greninger–Troiano. Phase Transit. 2010, 83, 601–614. [Google Scholar]

- Johnston, H.L.; Arnold, C.S.; Venus, D. Thickness-dependent fcc to bcc structural change in iron films: Use of a 2-ML Ni/W(110) substrate. Phys. Rev. B 1997, 55, 13221–13229. [Google Scholar]

- Shen, Y.F.; Li, X.X.; Sun, X.; Wang, Y.D.; Zuo, L. Twinning and martensite in a 304 austenitic stainless steel. Mater. Sci. Eng. A 2012, 552, 514–522. [Google Scholar]

- Dupé, B.; Amadon, B.; Pellegrini, Y.P.; Denoual, C. Mechanism for the α→ε phase transition in iron. Phys. Rev. B 2013, 87, 024103. [Google Scholar]

- Pang, W.W.; Zhang, P.; Zhang, G.C.; Xu, A.G.; Zhao, X.G. Morphology and growth speed of hcp domains during shock-induced phase transition in iron. Sci. Rep. 2014, 4, 3628. [Google Scholar] [PubMed] [Green Version]

- Sandoval, L.; Urbassek, H.M.; Entel, P. Solid-solid phase transition and phonon softening in an embedded-atom method model for iron. Phys. Rev. B 2009, 80, 214108. [Google Scholar]

- Stukowski, A.; Albe, K. Extracting dislocations and non-dislocation crystal defects from atomistic simulation data. Model. Simul. Mater. Sci. Eng. 2010, 18, 085001. [Google Scholar]

| Film | x | y | z | Δx (Å) | Δy (Å) | Δz (Å) | Crystal Structure | N |

|---|---|---|---|---|---|---|---|---|

| 1 | [0] | [11] | [] | 80.80 | 81.26 | 40.43 | fcc | 20,896 |

| 2 | [] | [] | [] | 83.00 | 81.26 | 40.40 | fcc | 22,326 |

| 3 | [] | [] | [] | 64.62 | 64.94 | 65.61 | bcc | 23,081 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ruan, T.; Wang, B.; Xu, C.; Jiang, Y. Shear Deformation Helps Phase Transition in Pure Iron Thin Films with “Inactive” Surfaces: A Molecular Dynamics Study. Crystals 2020, 10, 855. https://doi.org/10.3390/cryst10100855

Ruan T, Wang B, Xu C, Jiang Y. Shear Deformation Helps Phase Transition in Pure Iron Thin Films with “Inactive” Surfaces: A Molecular Dynamics Study. Crystals. 2020; 10(10):855. https://doi.org/10.3390/cryst10100855

Chicago/Turabian StyleRuan, Ting, Binjun Wang, Chun Xu, and Yunqiang Jiang. 2020. "Shear Deformation Helps Phase Transition in Pure Iron Thin Films with “Inactive” Surfaces: A Molecular Dynamics Study" Crystals 10, no. 10: 855. https://doi.org/10.3390/cryst10100855

APA StyleRuan, T., Wang, B., Xu, C., & Jiang, Y. (2020). Shear Deformation Helps Phase Transition in Pure Iron Thin Films with “Inactive” Surfaces: A Molecular Dynamics Study. Crystals, 10(10), 855. https://doi.org/10.3390/cryst10100855