Performance of SU-8 Membrane Suitable for Deep X-Ray Grayscale Lithography

Abstract

:1. Introduction

- (1)

- High transmittance in the X-ray energy region;

- (2)

- Dimensional stability during the X-ray exposure;

- (3)

- Durability for an extended X-ray exposure time;

- (4)

- Sufficient mechanical strength serving as a self-supporting membrane;

- (5)

- Simple film-forming method and high compatibility with other processes.

| Category | Absorber | Membrane | Coefficient of Thermal Expansion on Membrane |

|---|---|---|---|

| Stencil | Stainless steel | None | - |

| Si | None | - | |

| Polymer membrane | Au | Kapton (Polyimide) | 20 × 10−6/K [26] |

| Mylar (Polyester) | 17 × 10−6/K [27] | ||

| Built-on | Au | SU-8 | 52 × 10−6/K [28,29] |

| SiX membrane | Au, Ta, W | Si | 2.6 × 10−6/K [30] |

| SiNx | 3.3 × 10−6/K [31] | ||

| SiC | 3.8 × 10−6/K [32] | ||

| Oxidation inhibiting | TaGeN, TaBN | SiC | 3.8 × 10−6/K [32] |

| Others | Au | Graphite | 3.8 × 10−6/K [33] |

| Grayscale | Si | None | - |

| (Our product) | Si | SU-8 | 52 × 10−6/K [28,29] |

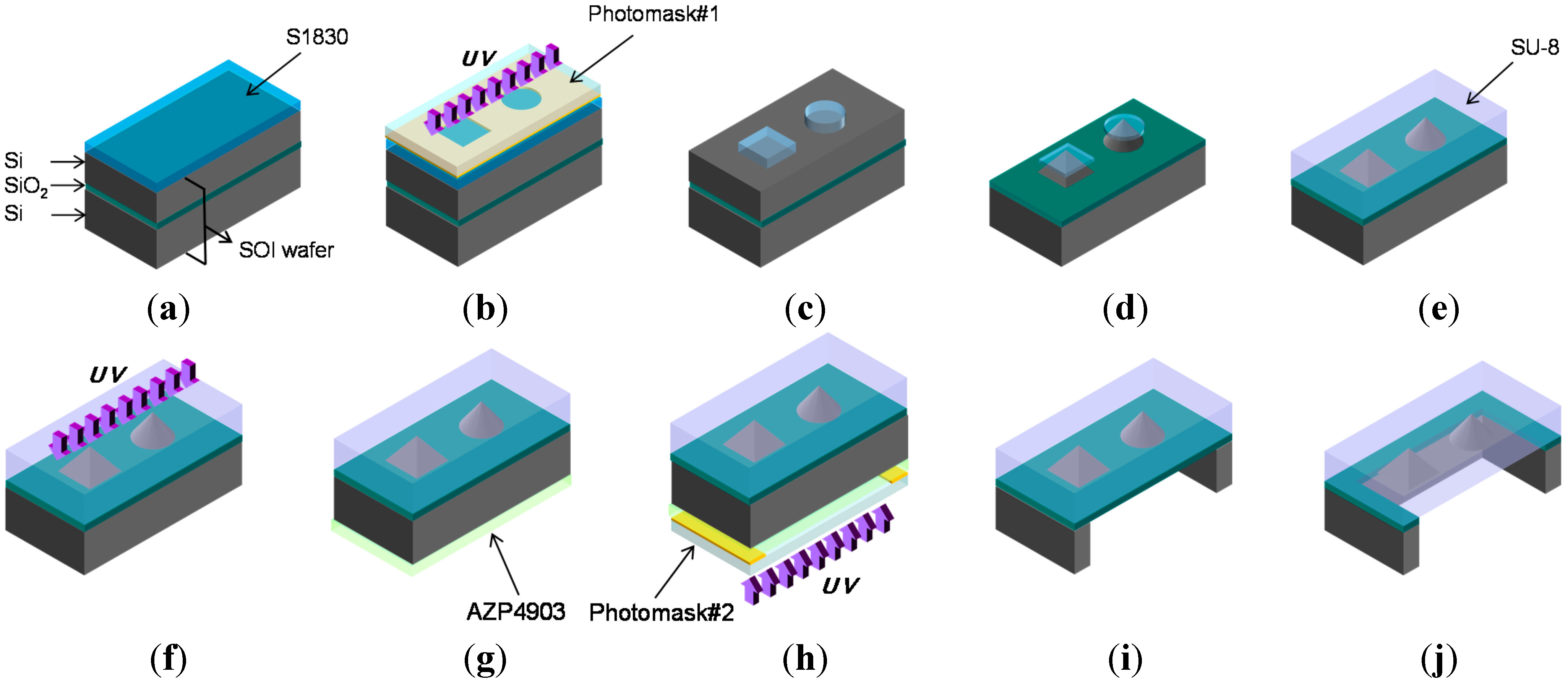

2. Experimental Section

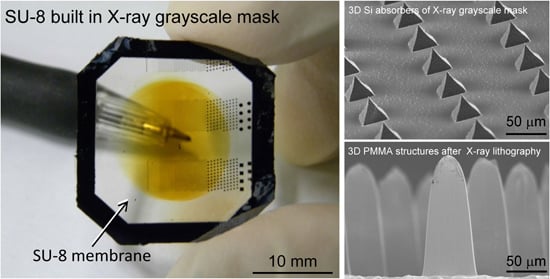

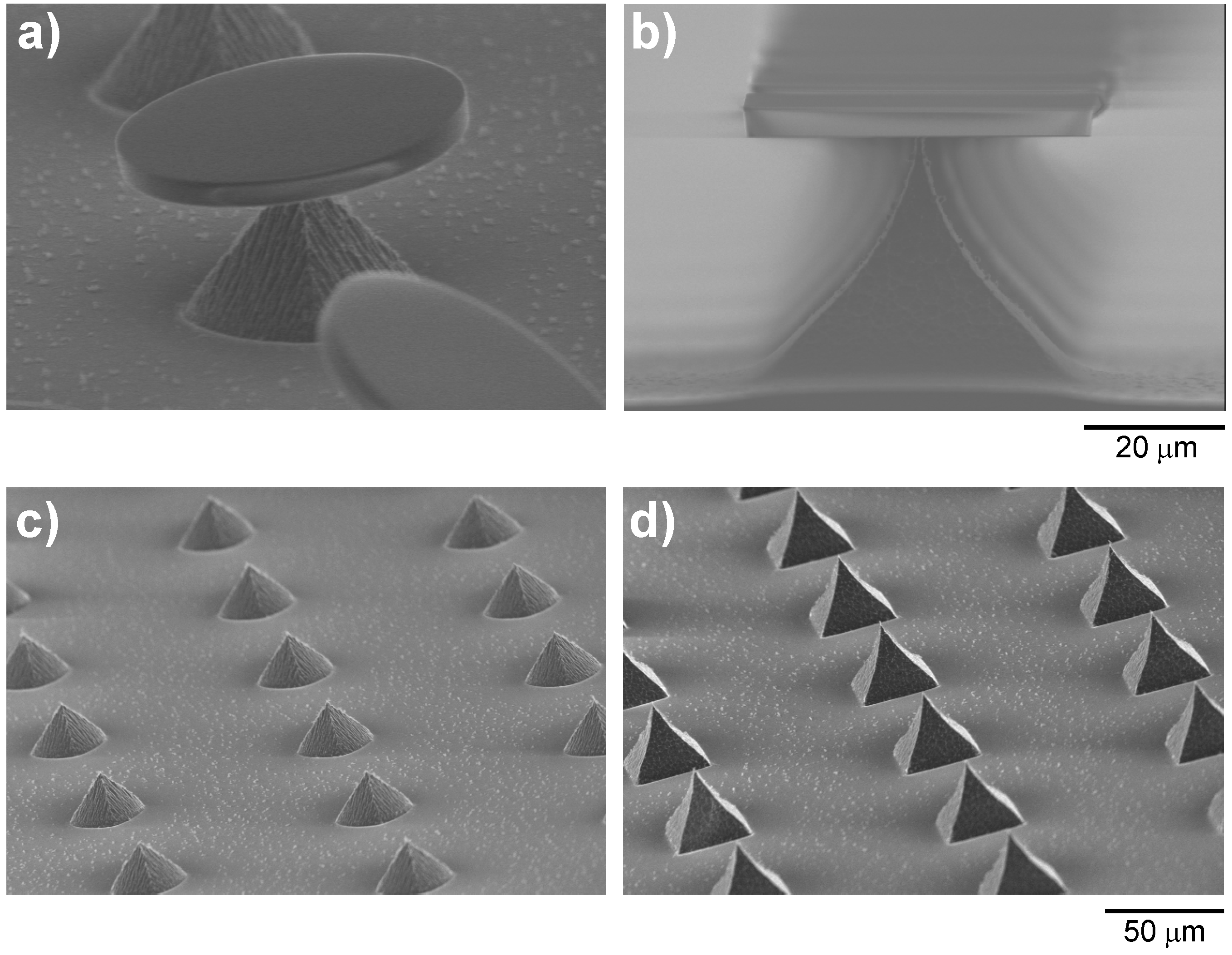

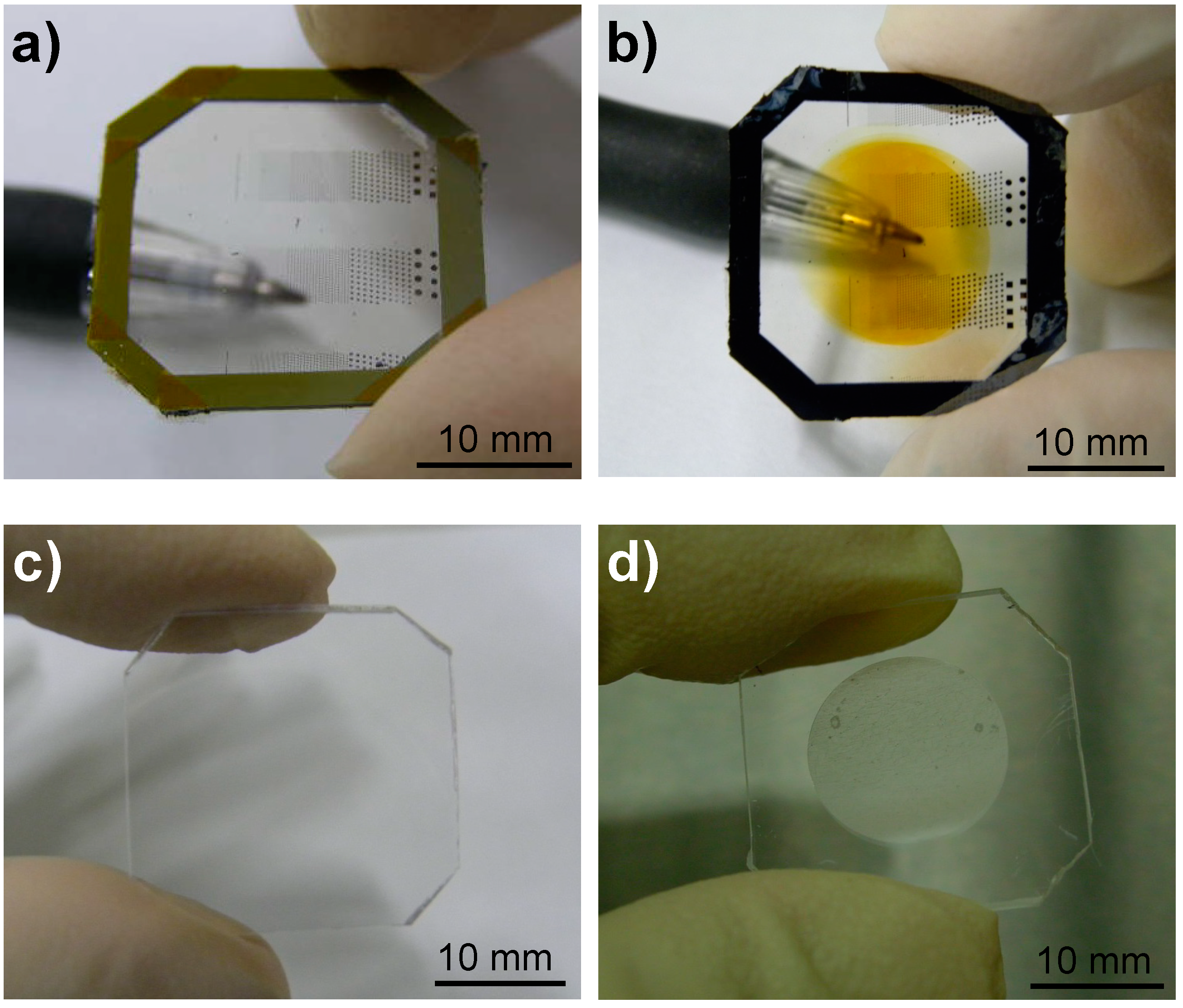

2.1. SU-8 Built-In X-Ray Mask

| Process | Material | Parameter | Condition |

|---|---|---|---|

| 1st Spin-coating | S1830 | thickness | 3 μm |

| 1st UV exposure | time | 15 s | |

| Pre-baking | temperature | 120 °C | |

| time | 20 min | ||

| 1st Development | NF-319 | temperature | Room Temperature |

| time | 5 min | ||

| Tapered trench etching | gas | SF6 + C4F8 + O2 | |

| pressure | 3.7–9.5 Pa | ||

| time | 11 s | ||

| Removal (+Ultrasonic) | Acetone | time | 10 min |

| 2nd Spin-coating | SU-8 25 | thickness | 30 μm |

| Pre-baking | temperature | 95 °C | |

| time | 10 min | ||

| 2nd UV exposure | time | 1 min | |

| Post-baking | temperature | 95 °C | |

| time | 10 min | ||

| 3rd Spin-coating | AZP4903 | thickness | 16 μm |

| 3rd UV exposure | time | 35 s | |

| 2nd Development | AZ400k + Distilled water (1:3) | temperature | Room Temperature |

| time | 5 min | ||

| Deep RIE of Si | gas | SF6 + C4F8 | |

| time | 150 min | ||

| RIE of SiO2 | gas | CHF3 | |

| time | 50 min | ||

| Ashing | gas | O2 | |

| time | 10 min | ||

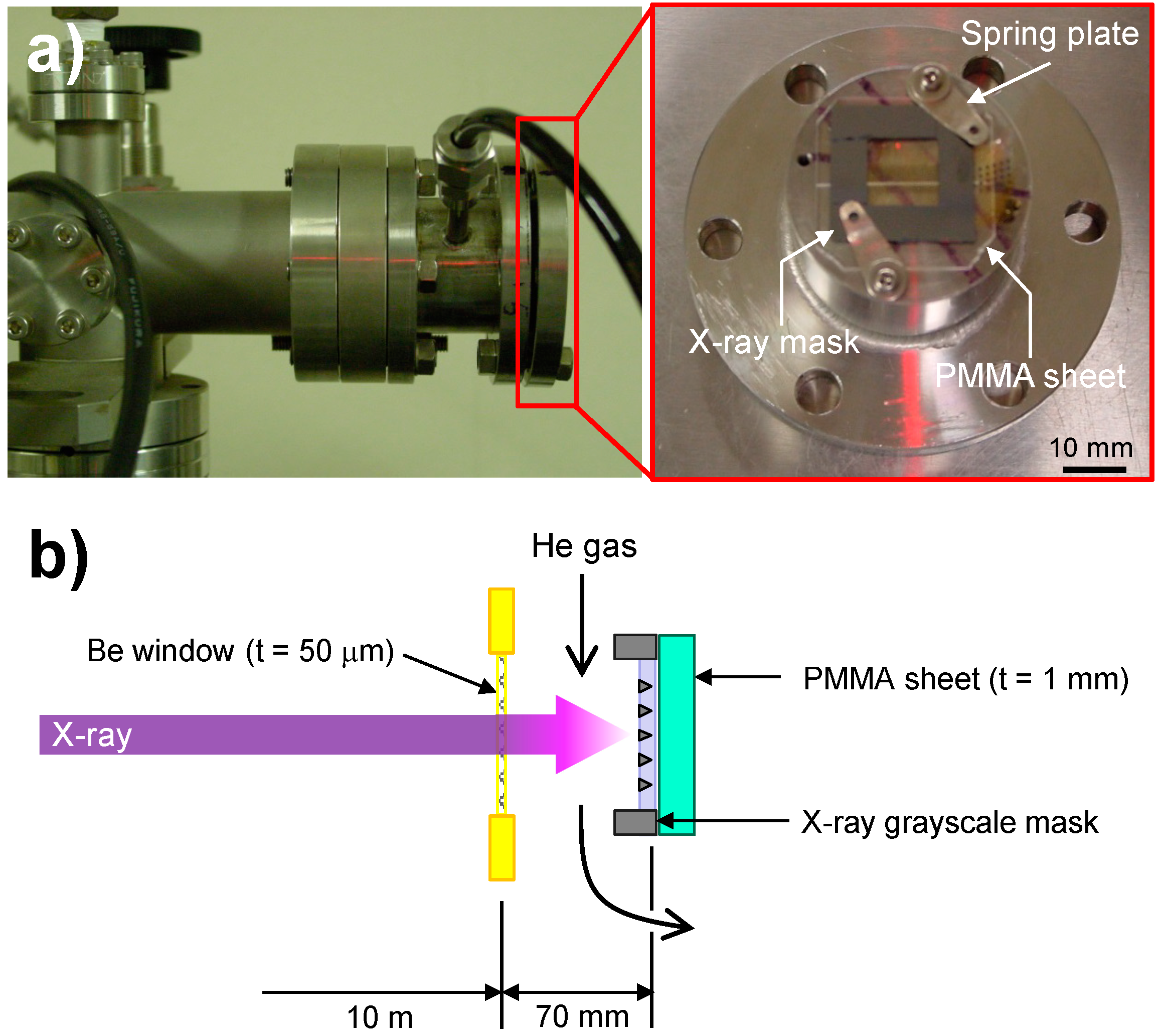

2.2. X-Ray Exposure and Development

3. Results and Discussion

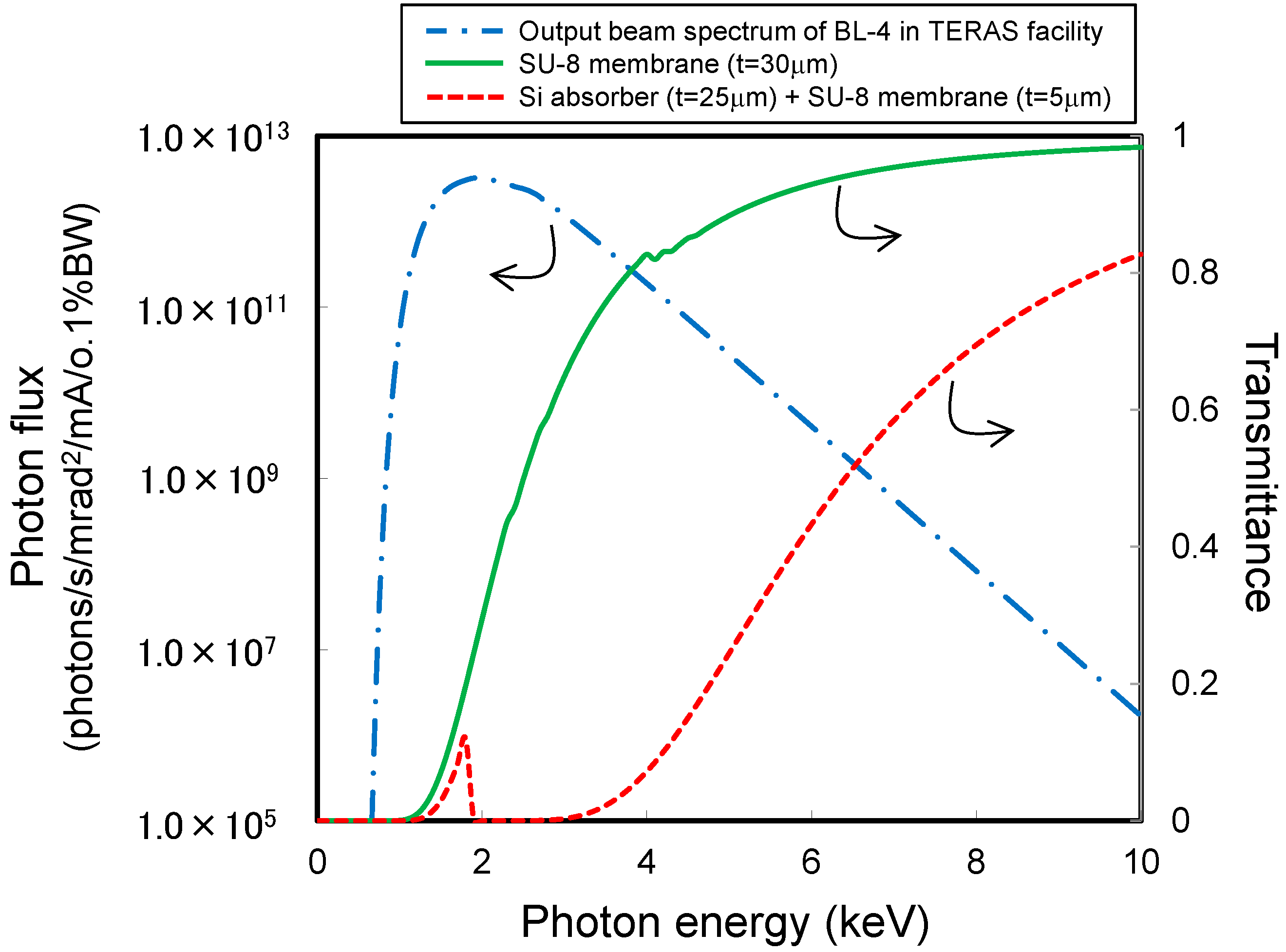

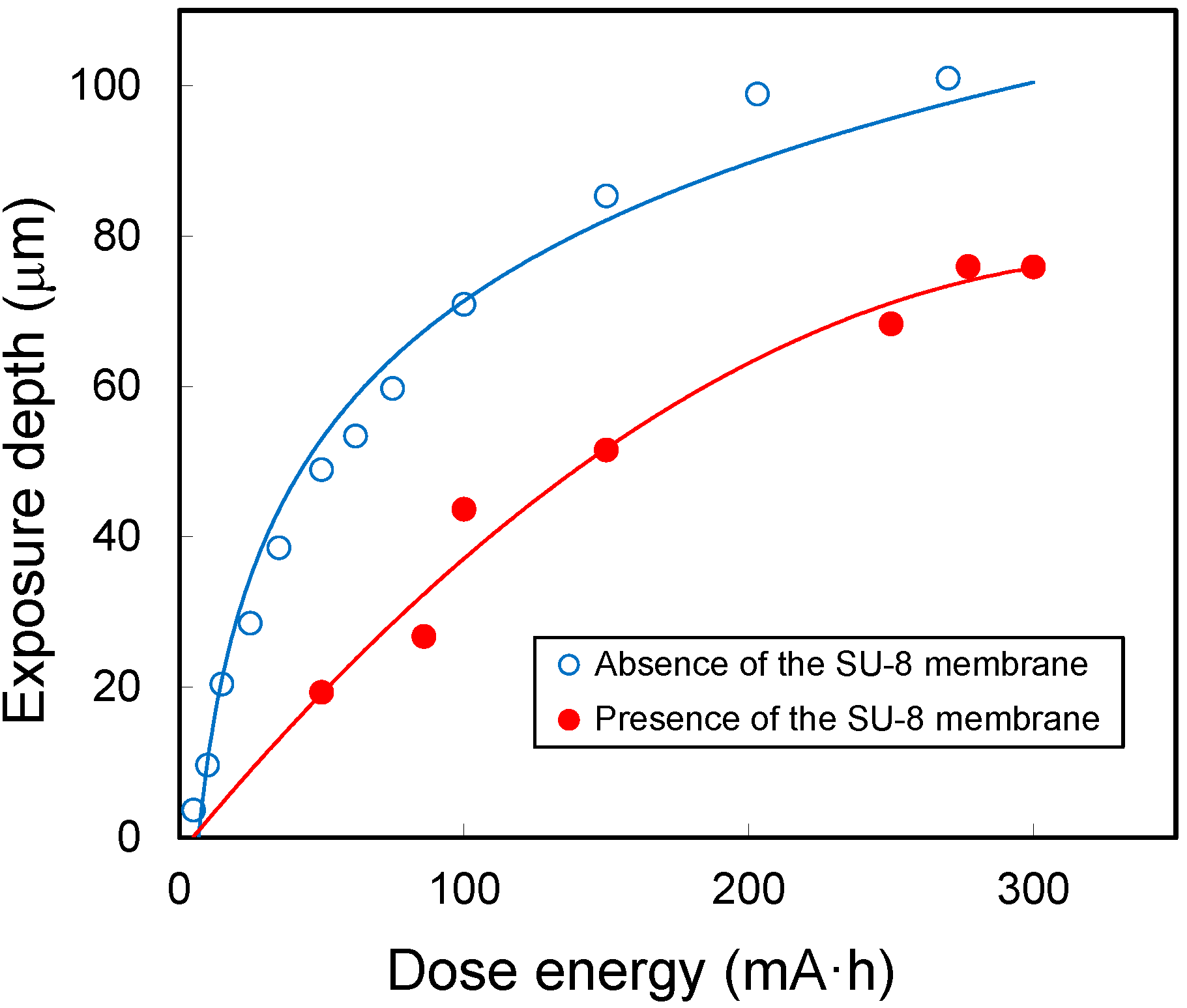

3.1. Transmission Property of SU-8 in the X-Ray Energy Region

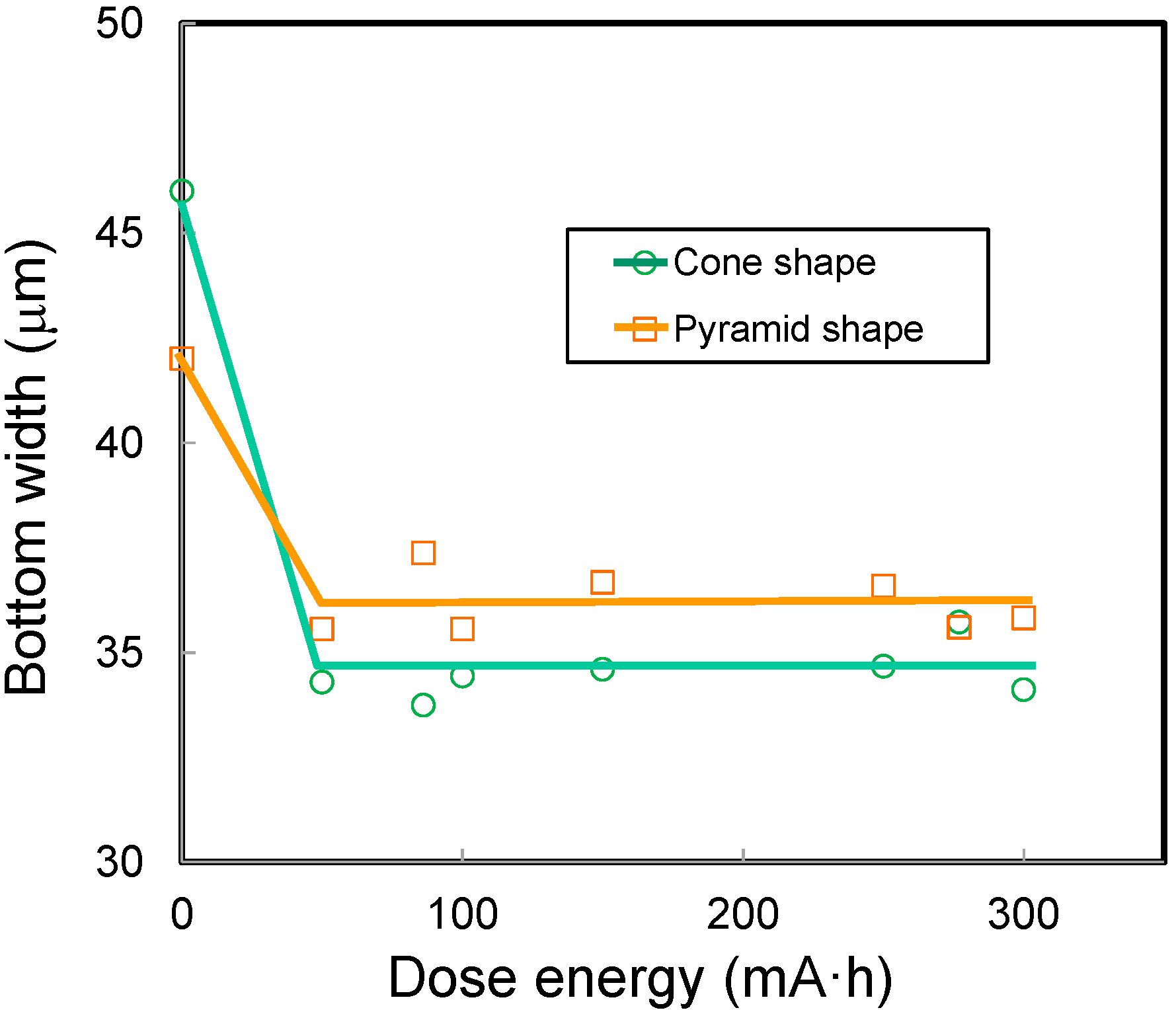

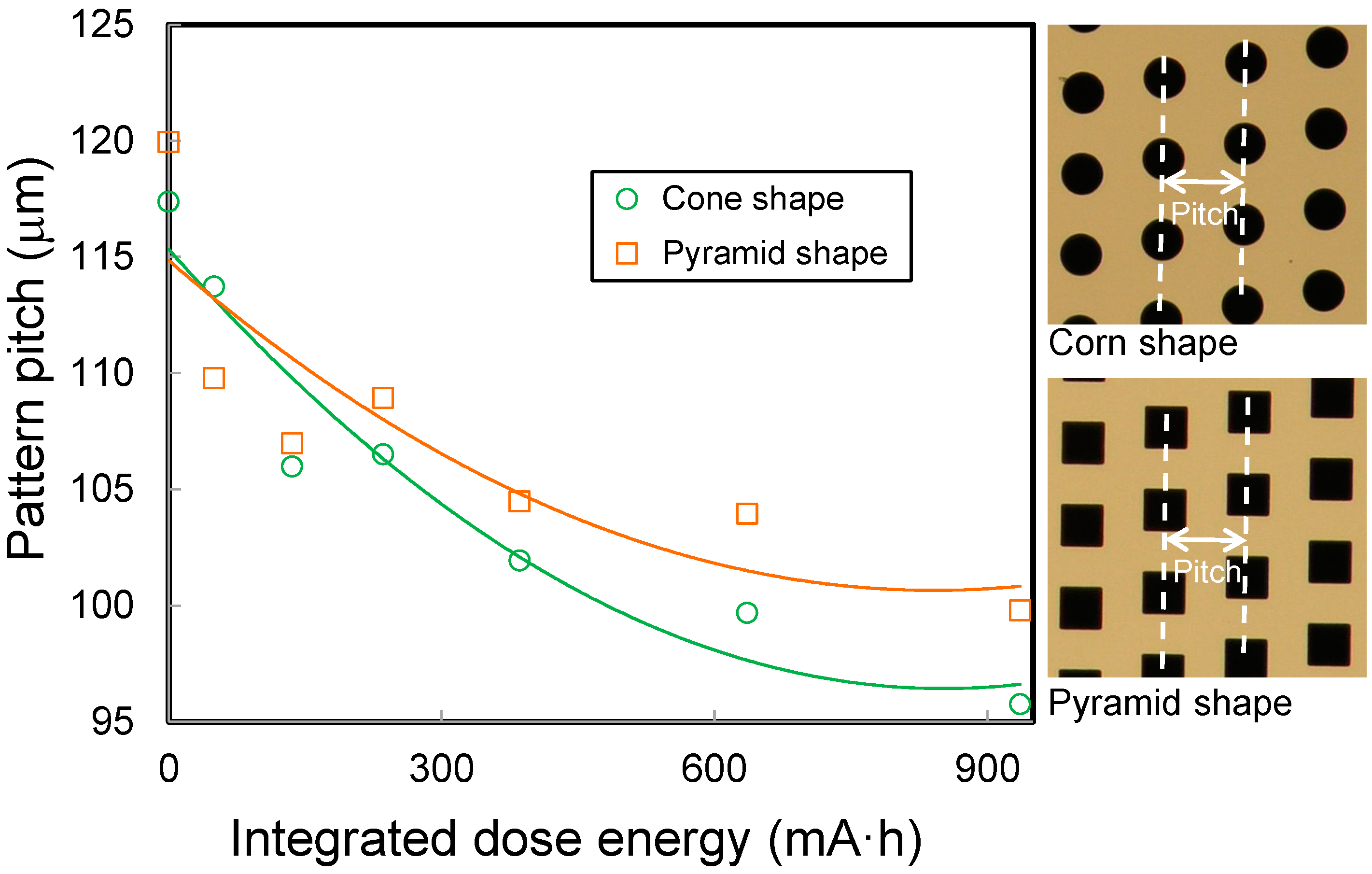

3.2. Transition of Pattern Width with SU-8 Thermal Expansion

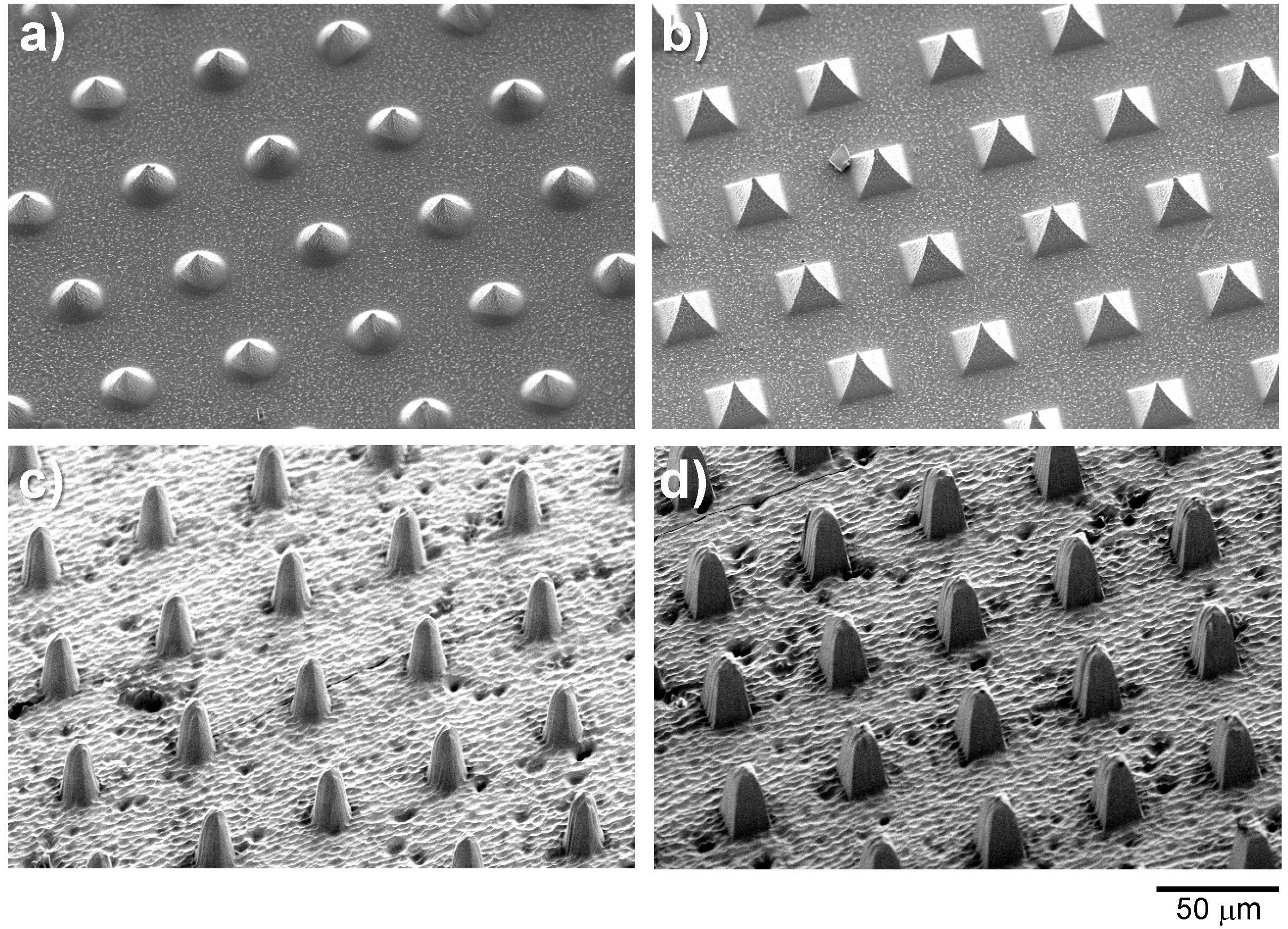

3.3. Tolerance of SU-8 to Synchrotron Radiation

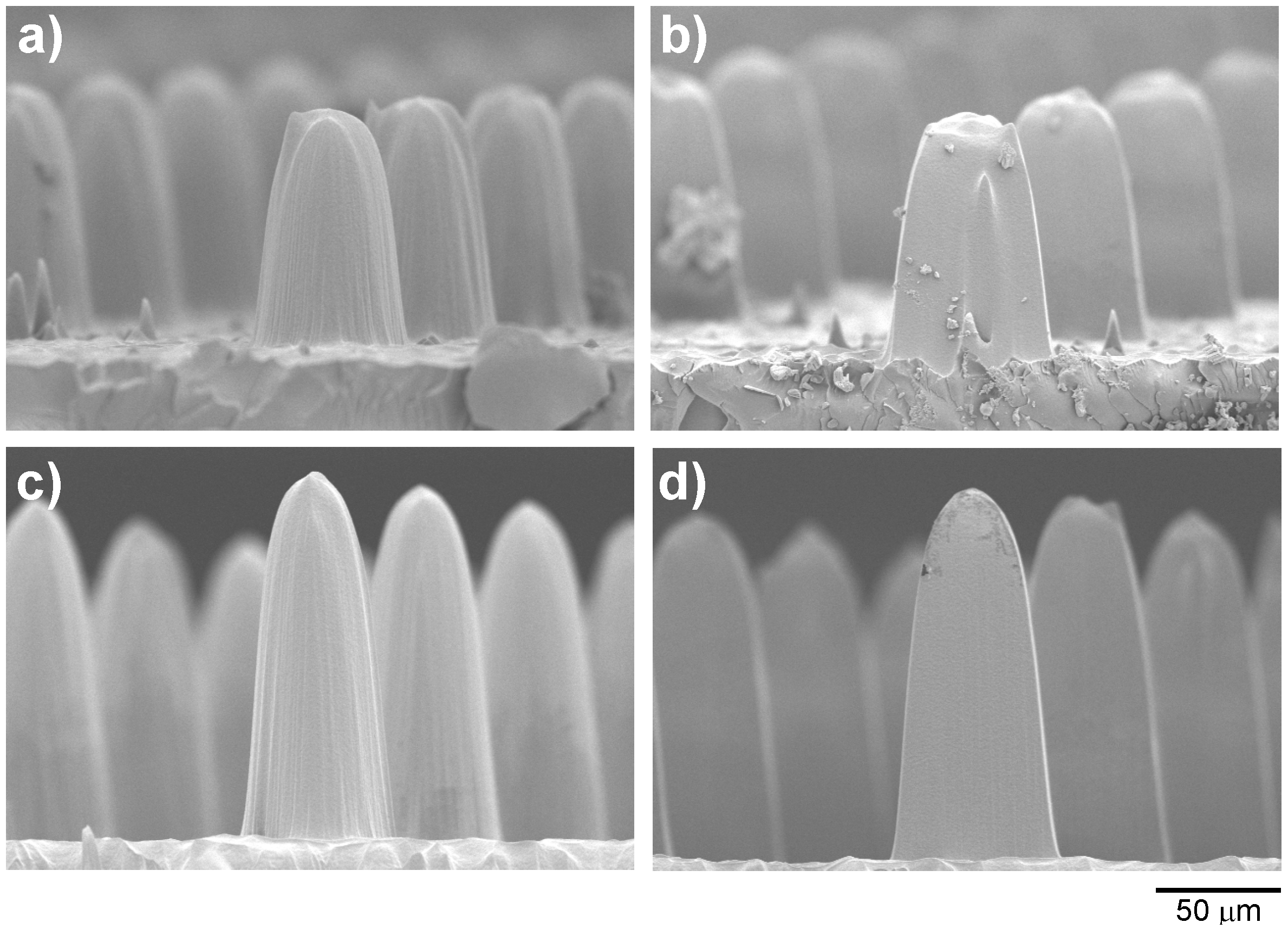

4. Conclusions

Acknowledgments

Conflicts of Interest

References and Notes

- Wu, B.; Kumar, A. Extreme ultraviolet lithography: A review. J. Vac. Sci. Technol. B 2007, 25, 1743–1761. [Google Scholar] [CrossRef]

- Kinoshita, H.; Wood, O. An Historical Perspective. In EUV Lithography; Bakshi, V., Ed.; SPIE Press: Bellingham, WA, USA, 2007; pp. 1–54. [Google Scholar]

- Malek, C.K.; Saile, V. Applications of LIGA technology to precision manufacturing of high-aspect-ratio micro-components and systems: A review. Microelectron. J. 2004, 35, 131–143. [Google Scholar] [CrossRef]

- Salker, V. Introduction: LIGA and Its Applications. In LIGA and Its Applications; Saile, V., Wallrabe, U., Tabata, O., Korvink, J.G., Eds.; Wiley-Vch: Weinheim, Germany, 2009; pp. 1–10. [Google Scholar]

- Becker, E.W.; Ehrfeld, W.; Hagmann, P.; Manwe, A.; Münchmeyer, D. Fabrication of microstructures with high aspect ratios and great structural heights by synchrotron radiation lithography, galvanoforming, and plastic moulding (LIGA process). Microelectron. Eng. 1986, 4, 35–56. [Google Scholar] [CrossRef]

- Bogdanov, A.L.; Peredlkov, S.S. Use of SU-8 photoresist for very high aspect ratio X-ray lithography. Microelectron. Eng. 2000, 53, 493–496. [Google Scholar] [CrossRef]

- Desta, Y.; Goettert, J. X-Ray Masks for LIGA Microfabrication. In LIGA and Its Applications; Saile, V., Wallrabe, U., Tabata, O., Korvink, J.G., Eds.; Wiley-Vch: Weinheim, Germany, 2009; pp. 11–50. [Google Scholar]

- Utsumi, Y.; Kishimoto, T.; Hattori, T.; Hara, H. Large-area x-ray lithography system for liga process operating in wide energy range of synchrotron radiation. Jpn. J. Appl. Phys. 2005, 44, 5500–5504. [Google Scholar] [CrossRef]

- Mekaru, H.; Takano, T.; Ukita, Y.; Utsumi, Y.; Takahashi, M. A Si stencil mask for deep X-ray lithography fabricated by MEMS technology. Microsyst. Technol. 2008, 14, 1335–1342. [Google Scholar] [CrossRef]

- Flanders, D.C.; Smith, I. Polyimide membrane X-ray lithography masks—Fabrication and distortion measurements. J. Vac. Sci. Technol. 1978, 15, 995–997. [Google Scholar] [CrossRef]

- Spiller, E.; Feder, R.; Topalian, J.; Castellani, E.; Romankiw, L.; Heritage, M. X-ray lithography for bubble devices. Solid State Technol. 1979, 19, 62–68. [Google Scholar]

- Lee, S.; Kim, D.; Jin, Y.; Han, Y.; Desta, Y.; Bryant, M.D.; Goettert, J. A Micro corona motor fabricated by a SU-8 built-on X-ray mask. Microsyst. Technol. 2004, 10, 522–526. [Google Scholar] [CrossRef]

- Schmidt, C.J.; Lenzo, P.V.; Spencer, E.G. Preparation of thin windows in silicon masks for X-ray lithography. J. Appl. Phys. 1975, 46, 4080–4082. [Google Scholar] [CrossRef]

- Watts, R.K. X-ray lithography. Solid State Technol. 1979, 22, 68–82. [Google Scholar]

- Bassous, E.; Feder, E.; Spiller, E.; Topalian, J. High transmission X-ray masks for lithographic applications. Proc. Int. Electron Devices Meet. 1975, 21, 17–19. [Google Scholar]

- Desta, Y.M.; Aigeldinger, G.; Zanca, K.J.; Coane, P.J.; Goettert, J.; Murphy, M.C. Fabrication of graphite masks for deep and ultradeep X-ray lithography. Proc. Mater. Device Charact. Micromach. III 2000, 4175, 122–130. [Google Scholar]

- Hofer, D.; Powers, J.; Grobman, W.D. X-ray lithographic patterning of magnetic bubble circuits with submicron dimensions. J. Vac. Sci. Technol. 1979, 16, 1968–1972. [Google Scholar] [CrossRef]

- Yamada, M.; Nakaishi, M.; Kudou, J.; Eshita, T.; Furumura, Y. An X-ray mask using Ta and heteroepitaxially grown SiC. Microelectron. Eng. 1989, 9, 135–138. [Google Scholar] [CrossRef]

- Lüthje, H.; Harms, H.; Matthiessen, B.; Bruns, A. X-ray lithography: Novel fabrication process for SiC/W steppermasks. Jpn. J. Appl. Phys. 1989, 28, 2342–2347. [Google Scholar] [CrossRef]

- Iba, Y.; Kumasaka, F.; Iizuka, T.; Yamabe, M. Amorphous refractory compound film material for X-ray mask absorbers. Jpn. J. Appl. Phys. 2000, 39, 5329–5333. [Google Scholar] [CrossRef]

- Mekaru, H.; Takano, T.; Awazu, K.; Takahashi, M.; Maeda, R. Fabrication and evaluation of a grayscale mask for X-ray lithography using MEMS technology. J. Micro/Nanolithogr. MEMS MOEMS 2008, 7, 013009. [Google Scholar] [CrossRef]

- Mekaru, H.; Takano, T.; Awazu, K.; Takahashi, M.; Maeda, R. Fabrication of a needle array using a Si gray mask for X-ray lithography. J. Vac. Sci. Technol. B 2007, 25, 2196–2201. [Google Scholar] [CrossRef]

- Mekaru, H.; Takano, T.; Awazu, K.; Takahashi, M.; Maeda, R. Demonstration of fabricating a needle array by the combination of X-ray grayscale mask with the lithografie, galvanoformung, abformung process. J. Micro/Nanolithogr. MEMS MOEMS 2009, 8, 033010. [Google Scholar] [CrossRef]

- Kudryashov, V.; Yuan, X.; Cheong, W.; Radhakrishnan, K. Grey scale structures formation in SU-8 with e-beam and UV. Microelectron. Eng. 2003, 67–68, 306–311. [Google Scholar] [CrossRef]

- Watt, F. Focused high energy proton beam micromachining: A perspective view. Nucl. Instrum. Methods Phys. Res. B 1999, 158, 165–172. [Google Scholar] [CrossRef]

- DuPontTM Kapton® HN, Polyimide Film. Available online: http://www.dupont.com/content/dam/assets/products-and-services/membranes-films/assets/DEC-Kapton-HN-datasheet.pdf (accessed on 5 February 2015).

- Product Information, Mular®, Polyester Film. Available online: http://usa.dupontteijinfilms.com/informationcenter/downloads/Physical_And_Thermal_Properties.pdf (accessed on 5 February 2015).

- Del Campo, A.; Greiner, C. SU-8: Aphotoresist for high-aspect-ratio and 3D submicron lithography. J. Micromech. Microeng. 2007, 17, R81–R95. [Google Scholar] [CrossRef]

- Lorenz, H.; Laudon, M.; Renaud, P. Mechanical characterization of a new high-aspect-ratio near UV-photoresist. Microelectron. Eng. 1998, 41, 371–374. [Google Scholar] [CrossRef]

- Okada, Y.; Tokumura, Y. Precise determination of lattice parameter and thermal expansion coefficient of silicon between 300 and 1500 K. J. Appl. Phys. 1984, 56, 314–320. [Google Scholar] [CrossRef]

- Tien, C.; Lin, T. Thermal expansion coefficient and thermomechanical properties of SiNx thin films prepared by plasma-enhanced chemical vapor deposition. Appl. Opt. 2012, 51, 7229–7235. [Google Scholar] [CrossRef] [PubMed]

- Goldberg, Y.; Levinshtein, M.E.; Rumyantsev, S.L. Chapter 5: Silicon Carbide (SiC). In Properties of Advanced Semiconductor Materials: GaN, AlN, InN, BN, SiC, SiGe; Levinshtein, M.E., Rumyantsev, S.L., Shur, M.S., Eds.; John Wiley & Sons: Hoboken, NJ, USA, 2001; pp. 93–148. [Google Scholar]

- The coefficient of thermal expansion on graphite was applied by Tokai Carbon Co., Ltd. (Tokyo, Japan)

- Toyokawa, H.; Awazu, K.; Hohara, S.; Koike, M.; Kuroda, R.; Morishita, Y.; Saito, N.; Saito, T.; Tanaka, M.; Watanabe, K.; et al. Present status of the electron storage ring TERAS of AIST. In Proceedings of the First Annual Meeting of Particle Accelerator Society of Japan and the 29th Linear Accelerator Meeting in Japan, Funabashi, Japan, 4–6 August 2004; pp. 203–205.

- Awazu, K.; Wang, X.; Fujimaki, M.; Kuriyama, T.; Sai, A.; Ohki, Y.; Imai, H. Fabrication of two- and three-dimensional photonic cystals of titania with submicrometer resolution by deep X-ray lithography. J. Vac. Sci. Technol. B 2005, 23, 934–939. [Google Scholar] [CrossRef]

- Tada, H.; Kumpel, A.E.; Lathrop, R.E.; Stanina, J.B.; Nieva, P.; Zavracky, P.; Miaoulis, I.N.; Wong, P.Y. Thermal expansion coefficient of polysrystalline silicon and silicon dioxide thin films at high temperatures. J. Appl. Phys. 2000, 87, 4189–4193. [Google Scholar] [CrossRef]

© 2015 by the author; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mekaru, H. Performance of SU-8 Membrane Suitable for Deep X-Ray Grayscale Lithography. Micromachines 2015, 6, 252-265. https://doi.org/10.3390/mi6020252

Mekaru H. Performance of SU-8 Membrane Suitable for Deep X-Ray Grayscale Lithography. Micromachines. 2015; 6(2):252-265. https://doi.org/10.3390/mi6020252

Chicago/Turabian StyleMekaru, Harutaka. 2015. "Performance of SU-8 Membrane Suitable for Deep X-Ray Grayscale Lithography" Micromachines 6, no. 2: 252-265. https://doi.org/10.3390/mi6020252

APA StyleMekaru, H. (2015). Performance of SU-8 Membrane Suitable for Deep X-Ray Grayscale Lithography. Micromachines, 6(2), 252-265. https://doi.org/10.3390/mi6020252