Assembly and Interconnection Technologies for 3D Plastic Circuit Carriers: An Overview of Technologies, Materials, and Applications

Abstract

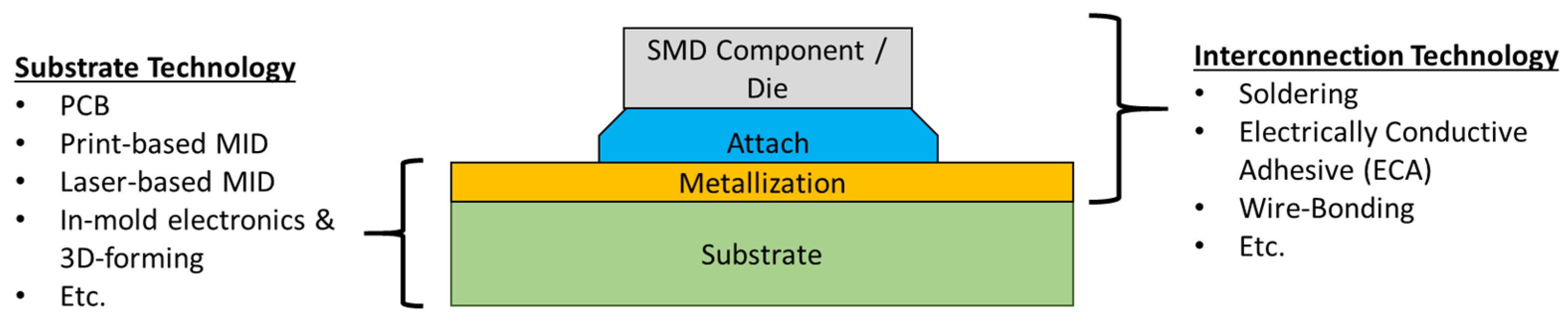

1. Introduction

2. Print-Based 3D Electronics

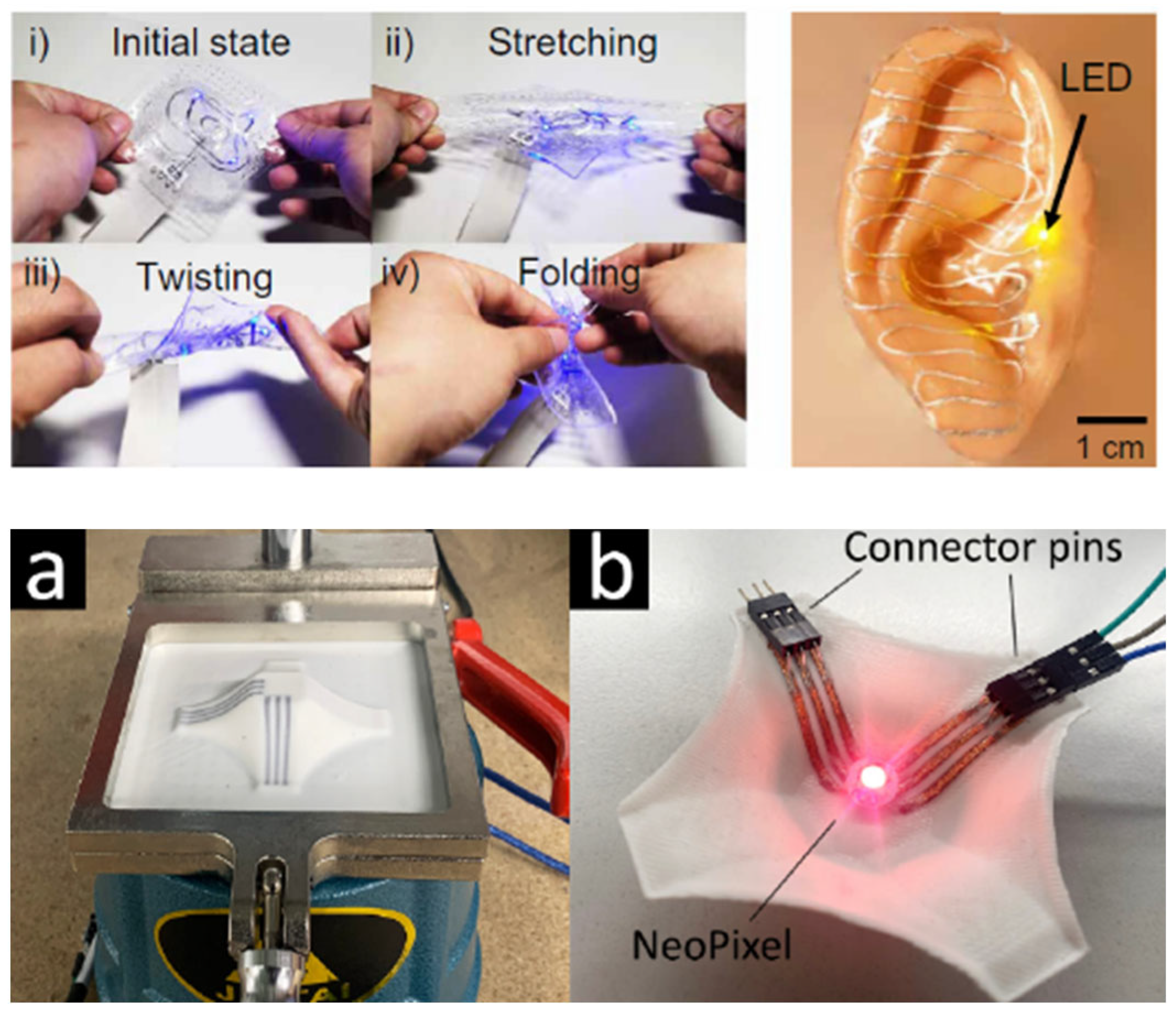

2.1. In-Mold Electronics by Means of 3D Forming

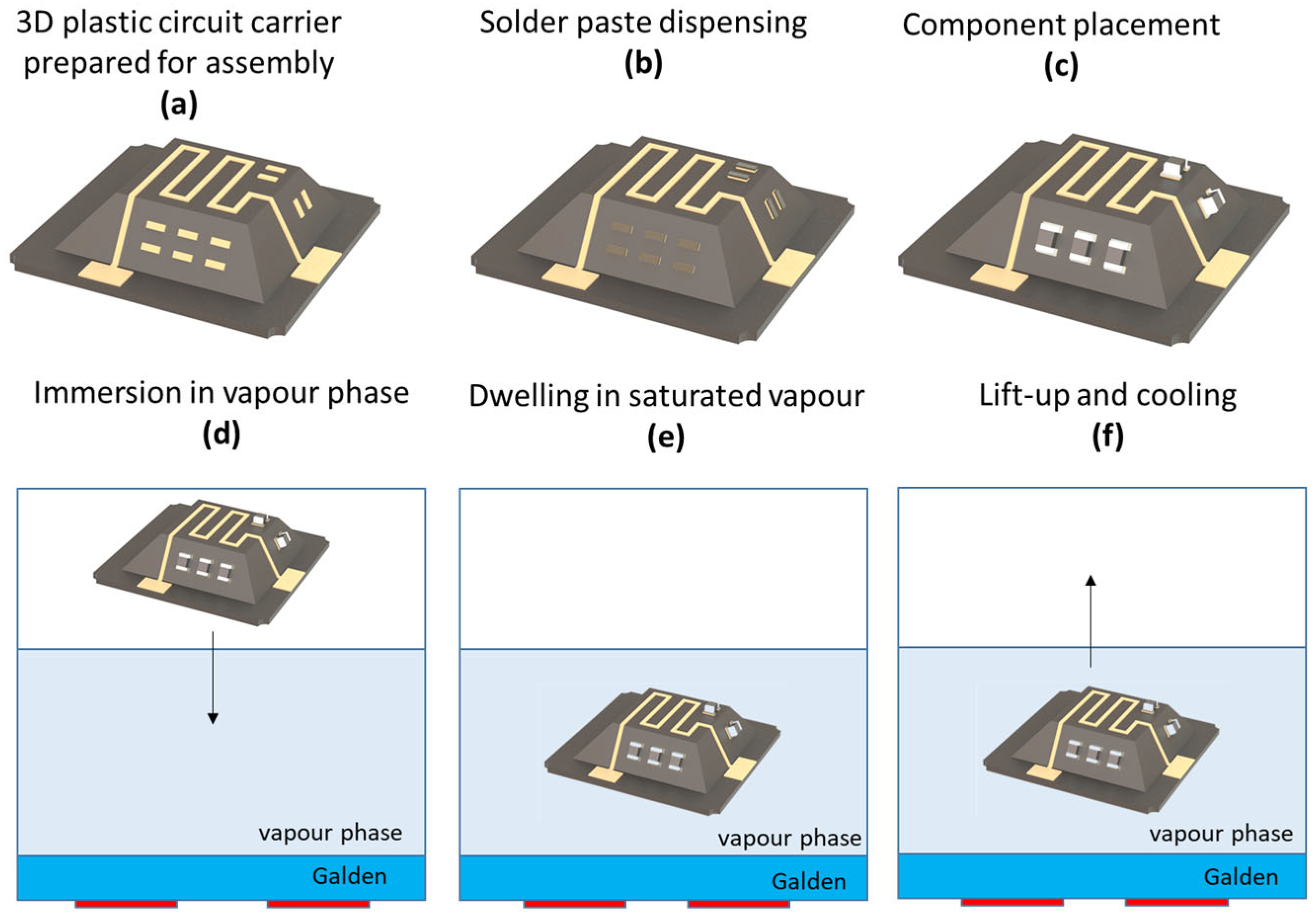

2.1.1. Introduction

2.1.2. Contact Printing by Means of Screen Printing

2.1.3. 3D Forming

2.1.4. Applications

- Most SMD packages (e.g., 0603, 0805);

- Quad-Flat-No-Lead (QFN) package;

- Land-Grid-Array (LGA) package;

- Chip-Scale-Package with few contacts.

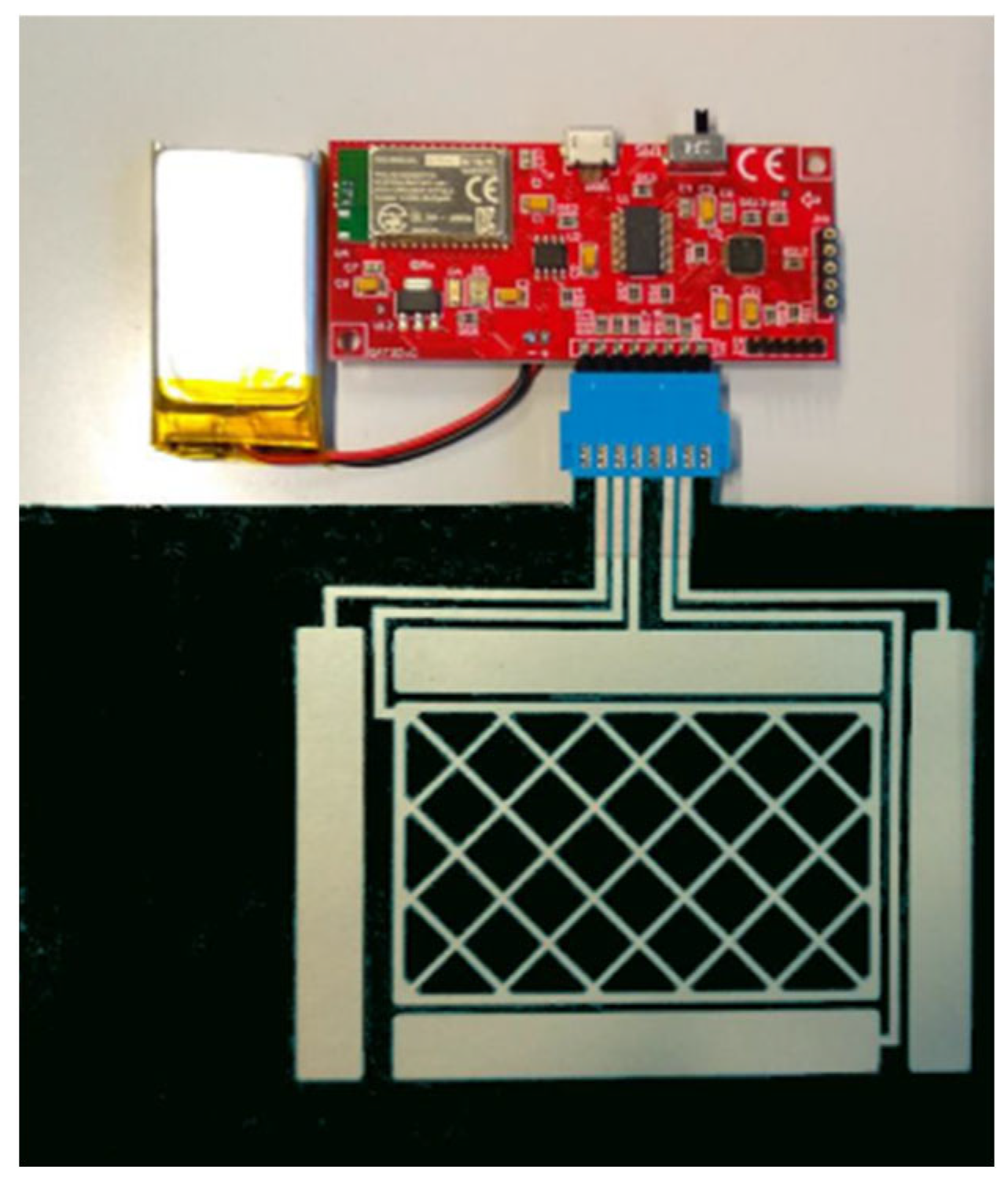

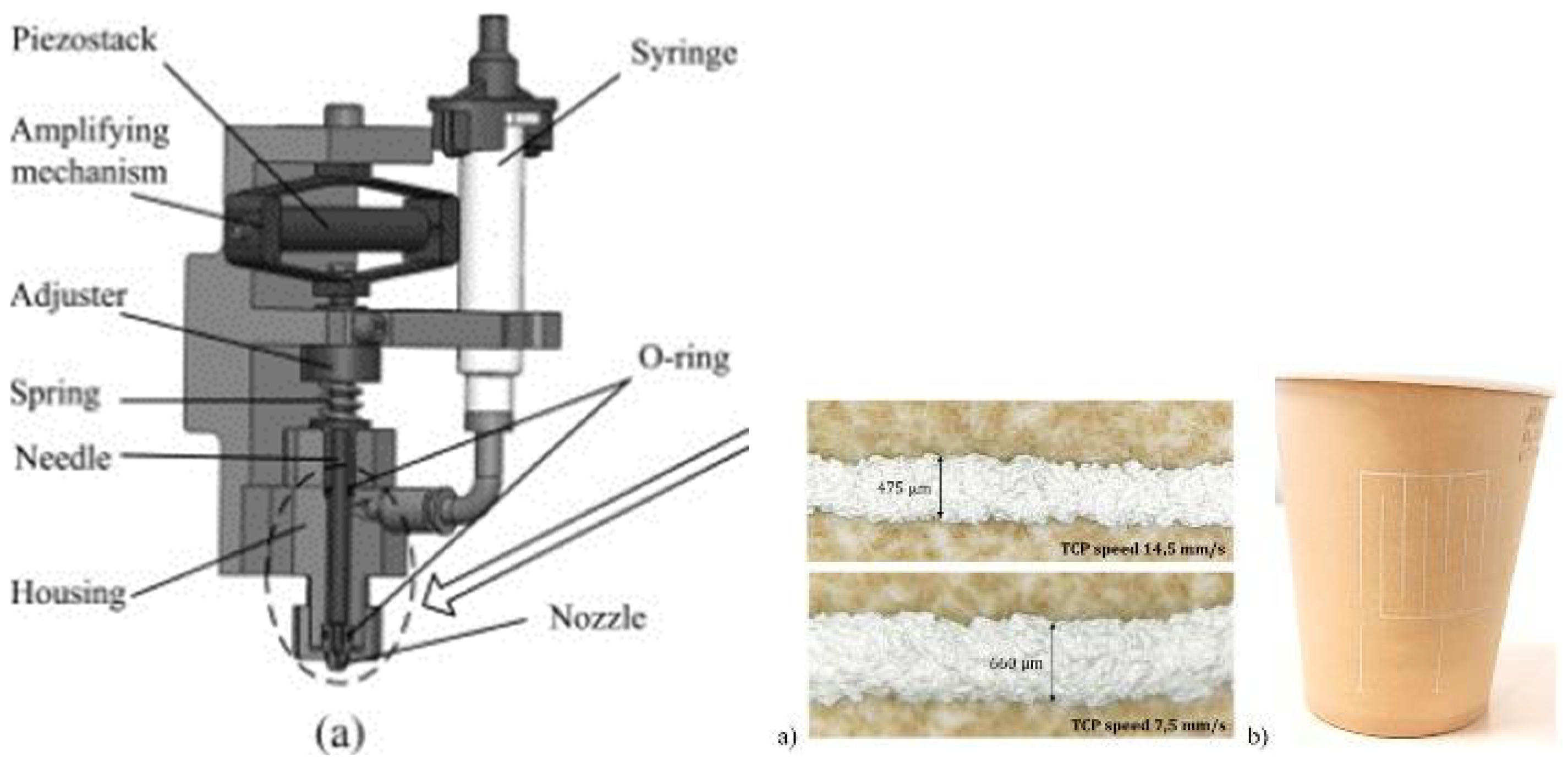

2.2. Non-Contact Printing

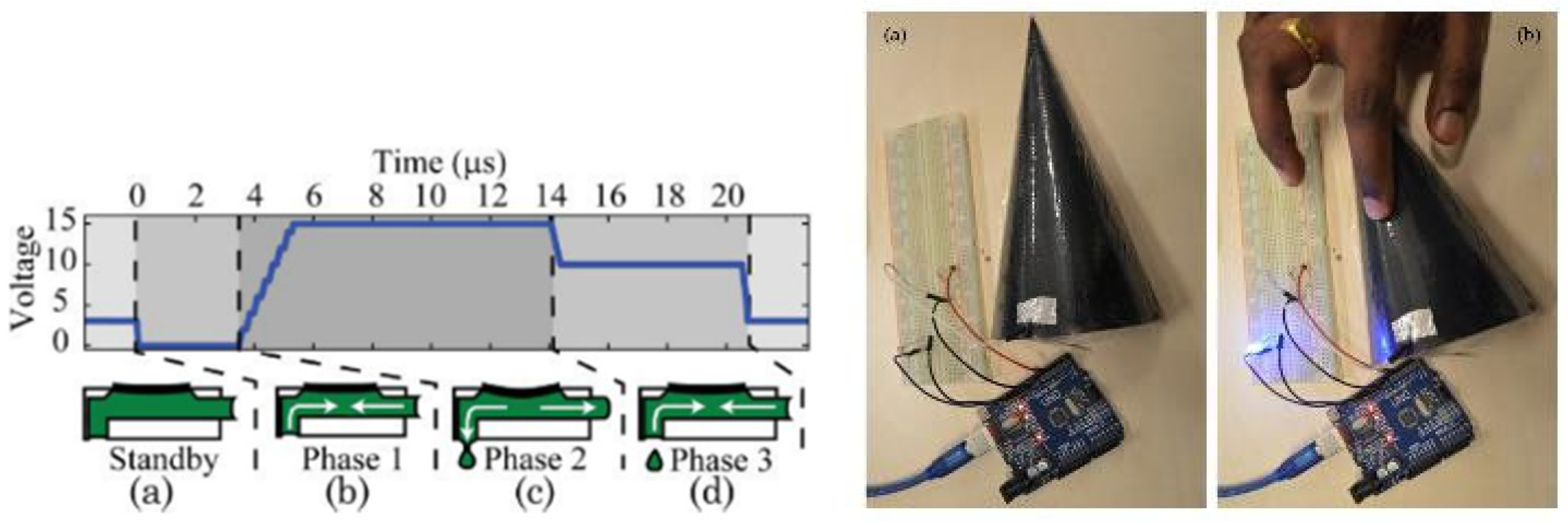

2.2.1. Valve Jetting

2.2.2. Inkjet Printing

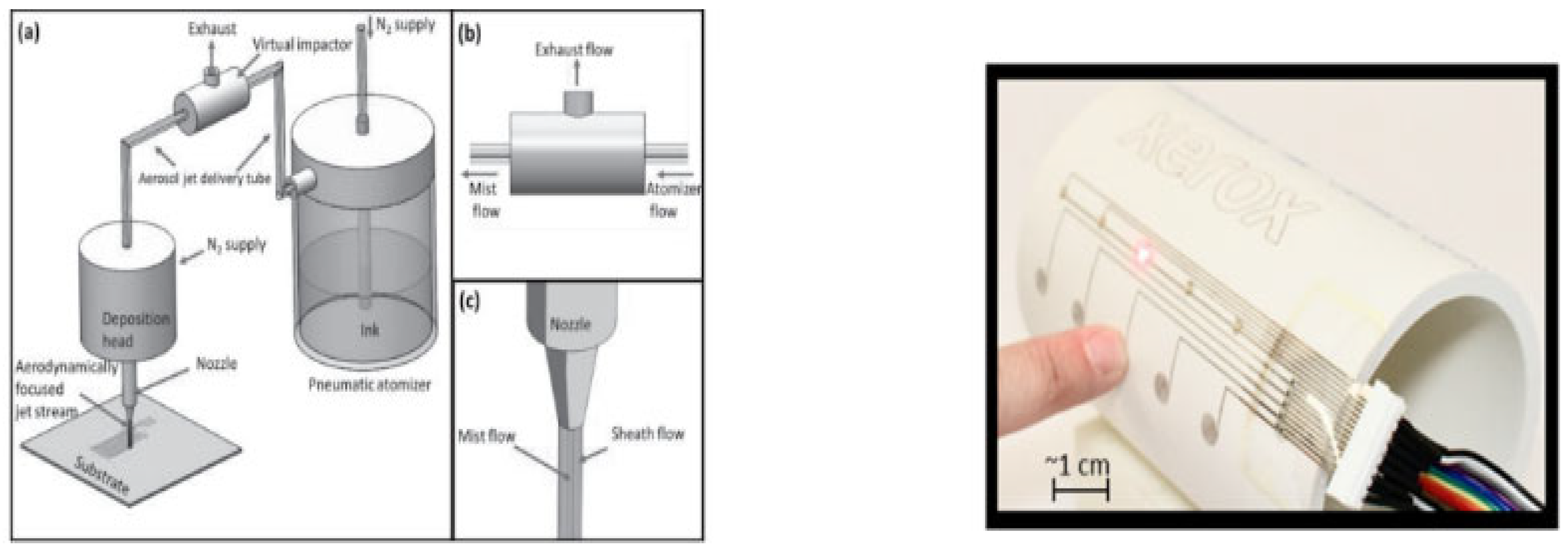

2.2.3. Aerosol Jet Printing

2.2.4. Practical Ink Related Limitations

3. Laser-Based 3D Electronics

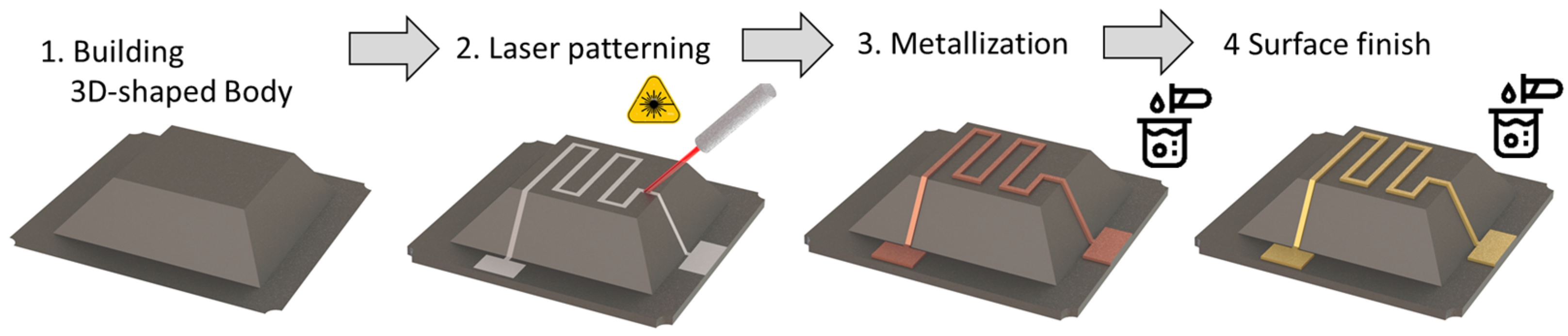

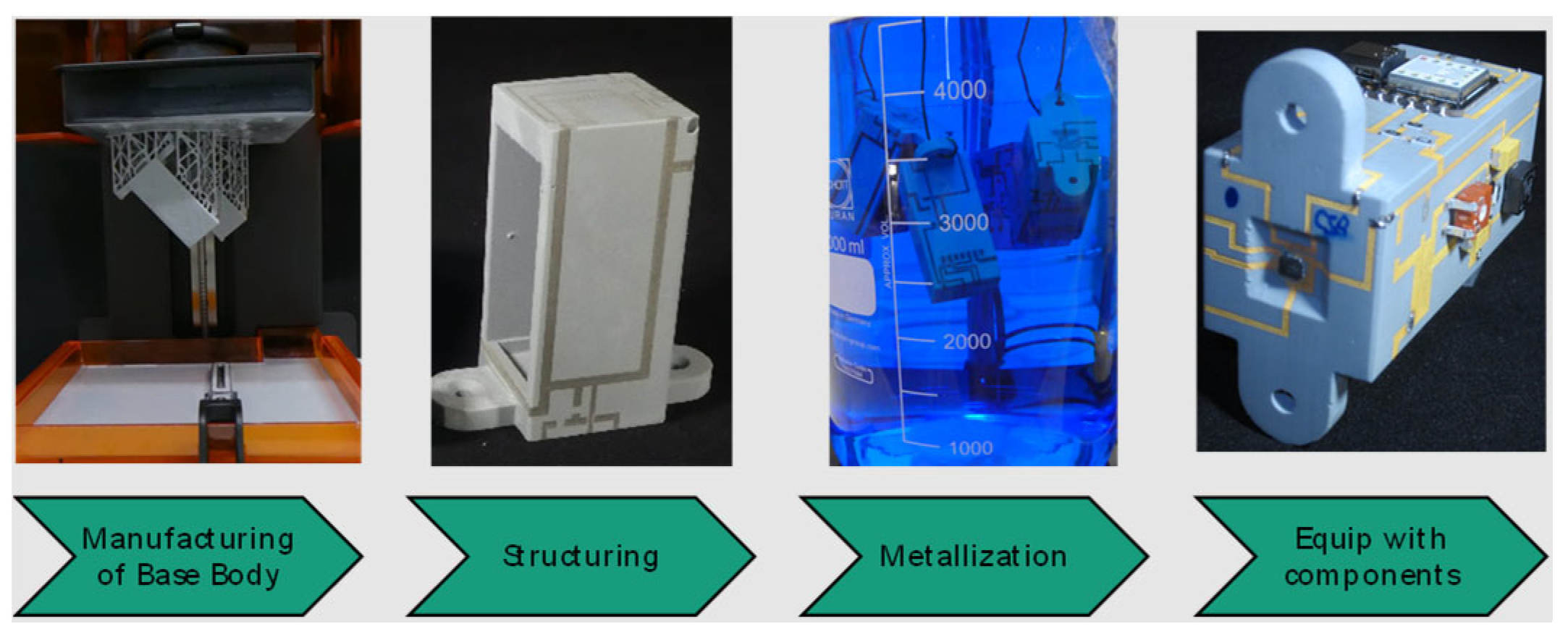

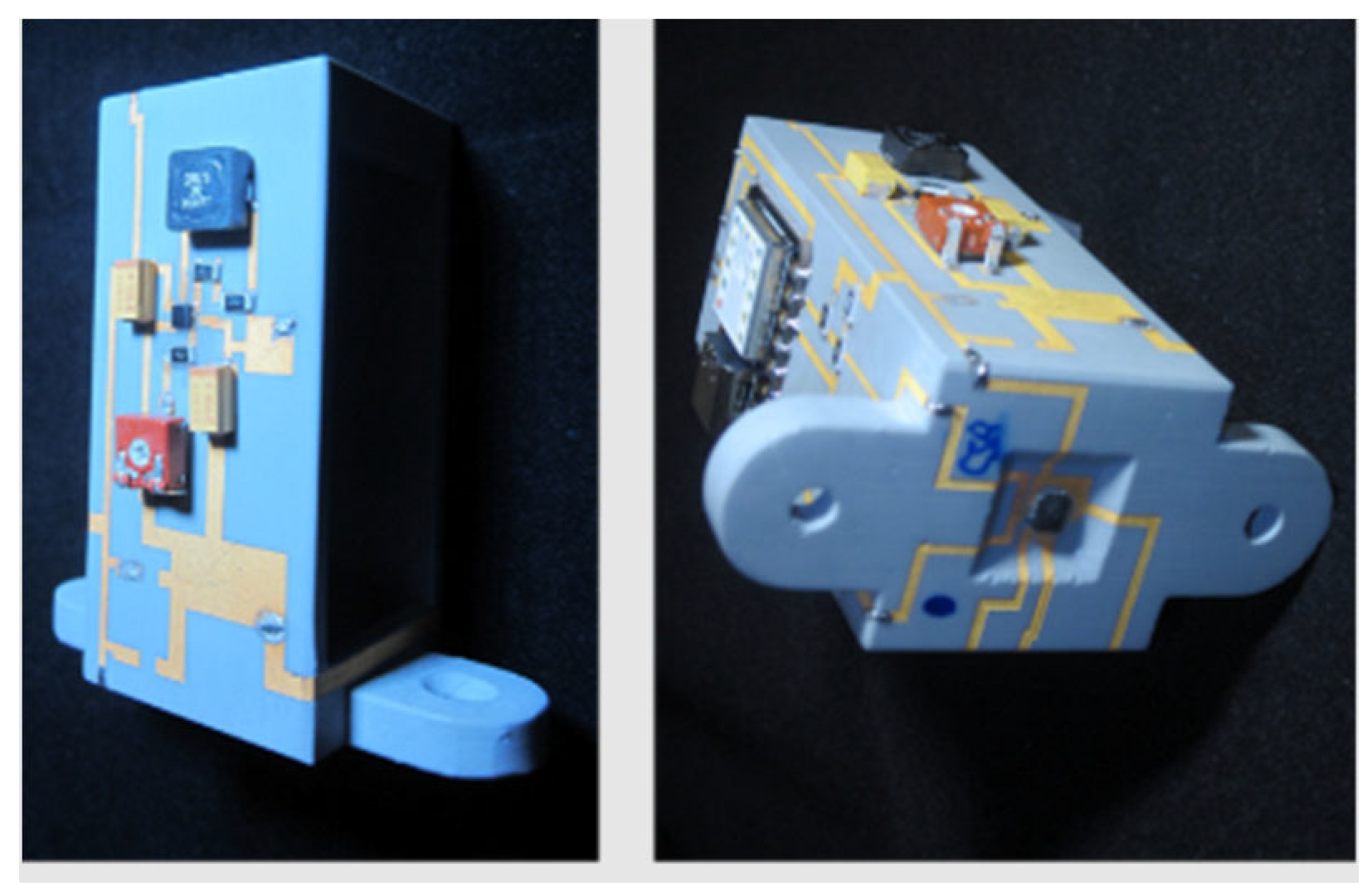

3.1. Laser Direct Structuring (LDS) on Molded Substrates

3.1.1. Introduction

3.1.2. Substrate Materials

3.1.3. Advantages and Disadvantages

3.1.4. Applications

3.2. Laser Direct Structuring (LDS) on Coated or Additive Manufactured Substrates

3.2.1. MID Lacquer

3.2.2. MID Resin and Stereolithography

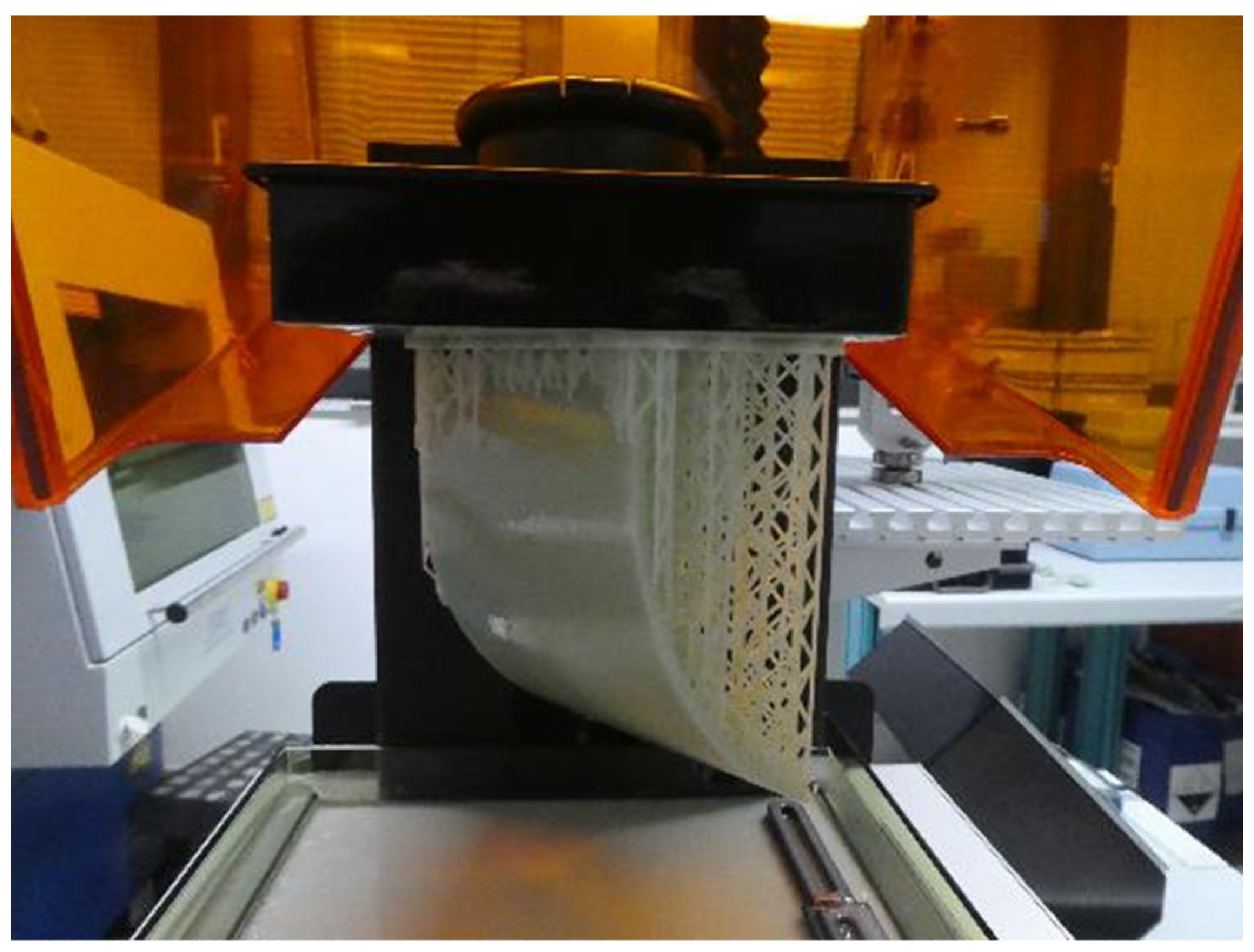

3.2.3. MID Resin and Hot Lithography

3.2.4. Fused Filament Fabrication (FFF)

3.2.5. Casting Silicone Substrates

3.2.6. Selective Laser Sintering (SLS)

3.3. Other Laser-Based Technologies

3.3.1. Semi-Additive Process

3.3.2. SANCHO Process

3.3.3. Selective Surface Activation Induced by a Laser (SSAIL) [122]

4. Alternative Structuring Processes

4.1. Two-Shot MID

4.2. Hot Embossing

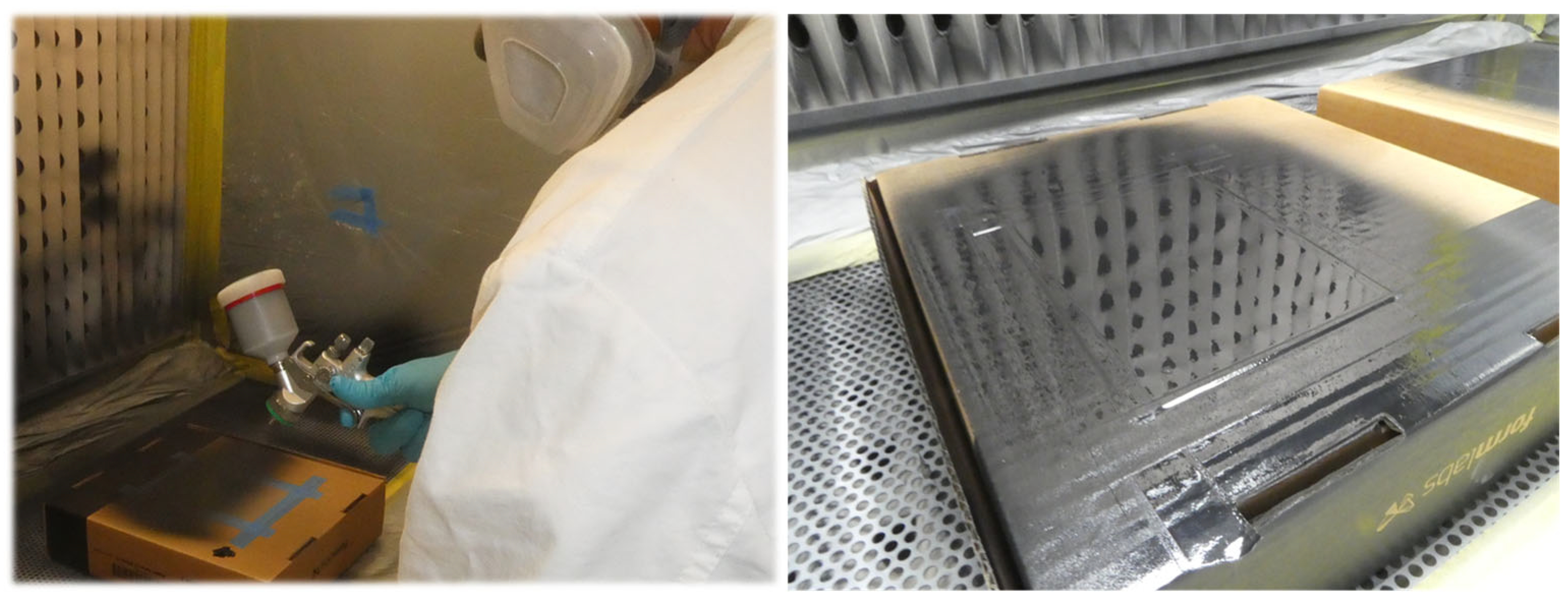

4.3. FlameCon and PlasmaDust

5. Connecting Rigid Components to a 3D Electronic Device

5.1. Soldering Technologies

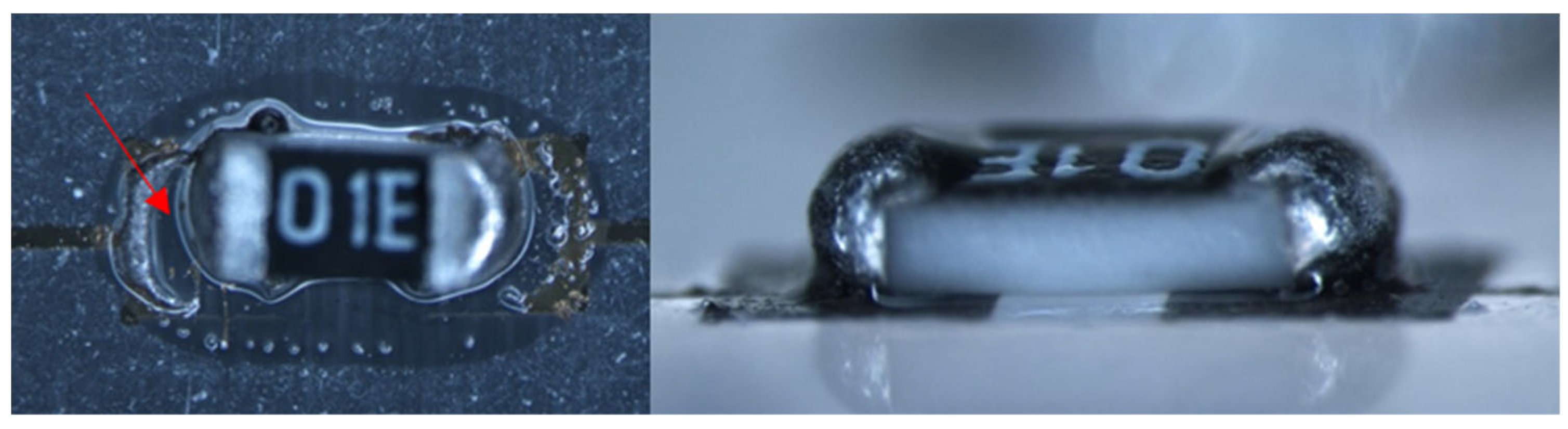

- In the case of LDS-MID, the typically rough surface topography can result in the non-uniform or wide-spread wetting behavior of solder joints.

- In printed electronics, the tin in the solder tends to alloy with the thin silver layers, leading to intermetallic compound formation and the potential degradation of the conductive structures.

5.1.1. Conveyor Oven Soldering

5.1.2. Vapor Phase Soldering

5.1.3. Laser Soldering

5.2. Conductive Bonding by Electrically Conductive Adhesive (ECA)

5.3. Chip Assembly by Wire Bonding [149,150,151]

6. Comparison on Suitable Combinations of Substrate and Interconnection Technology

6.1. Comparison and Overview of 3D Plastic Circuit Carrier Technologies

- All processes are batch capable, if the 3D geometry allows it.

- IME is best suited for large-area circuits, as the conductive pattern can be rapidly applied in 2D using screen printing of pastes. Accordingly, the associated applications typically involve large-area components.

- In laser-based and print-based MID technologies, structuring is carried out sequentially using laser or jetting technologies, respectively. As a result, the process is comparatively slow for large circuits on large surface areas.

- Laser-based MID technologies are well-suited for miniaturized 3D parts, as the electroless plating process can be carried out by barrel plating.

- The nozzle-to-surface distance in the aerosol jet process is less critical than in inkjet or valve-jet technologies. This makes it easier to follow 3D surfaces with the jetting head without multiple clamping setups.

- In 2D screen printing, valve- and inkjet printing can be very cost effective and scalable while in 3D it presents significant challenges.

6.2. Technology Combinations Considering Substrate Temperature Stability

6.3. Isotropic Conductive Adhesives (ICA) on Print-Based 3D Electronics

6.4. Soldering on Laser-Based 3D Electronics

6.5. Comparison of Reliability

6.5.1. Reliability of Print-Based Substrates

- The mechanical stress in the inkjet-printed circuit boards strongly depends on the sintering process because of its impact on density and modulus, shown, e.g., in [208,209]. During subsequent thermal cycling, the stresses in inkjet-printed structures are relatively comparable to FR4 PCB. However, inkjet-printed circuit carriers show noticeably greater deformation than FR4 PCB.

- ICA materials on inkjet-printed circuit carriers can offer a similar reliability as on traditional PCB [210]. The failure can be a crack located between the SMD component interface, which is traced back to the high CTE mismatch between the ICA and the SMD component and the mechanical stress that this induces [211].

- The authors of [212,213] showed that the SMD size and the CTE of the substrate are critical properties, which need to be considered for highly reliable connections that need to withstand thermal load. Furthermore, it was demonstrated that, for adhesively bonded SMDs, a characteristic fatigue life of approximately 3500 cycles under thermal cycling between +125 °C and −40 °C, as well as more than 1000 h under combined temperature–humidity stress at 85 °C and 85% relative humidity, can be achieved for various SMD sizes.

6.5.2. Reliability of In-Mold Electronic

6.5.3. Reliability of LDS-MID

7. Conclusions

- In the case of laser-based MID, the typically surface topography can influence the wetting behavior of solder joints.

- In printed electronics, the tin in the solder tends to alloy with the thin silver layers, resulting in the formation of intermetallic compounds and possible degradation of the conductive structures.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| 3D | Three-dimensional |

| ACA | Anisotropic conductive adhesives |

| AJP | Aerosol jet printing |

| AgNP | Ag nanoparticle |

| AgNW | Ag nanowires |

| CNT | Carbon nanotube |

| DoD | Drop-on-demand |

| ECG | Electrocardiogram |

| ECA | Electrically conductive adhesives |

| EGaIn | Eutectic gallium indium |

| EL | Electroluminescent |

| EMST | Ensinger Microsystems Technology |

| ESA | European Space Agency |

| FDM | Fused deposition modeling |

| FFF | Fused filament fabrication |

| HTOL | High-temperature operating life |

| HVLP | High-volume low-pressure |

| ICA | Isotropic conductive adhesives |

| IME | In-mold electronics |

| ITO | Indium tin oxide |

| LED | Light-emitting diode |

| LDS | Laser direct structuring |

| MID | Mechatronic-integrated devices |

| MIPTEC | Microscopic-integrated processing technology |

| MOD | Metal–organic decomposition |

| OLED | Organic light-emitting diode |

| OSC | Organic semiconductor |

| P3HT | Poly(3-hexylthiophen-2,5-diyl) |

| PBT | Polybutylene terephthalate |

| PC | Polycarbonate |

| PCB | Printed circuit board |

| PE | Printed electronics |

| PEDOT:PSS | Poly(3,4-ethylenedioxythiophene) polystyrene sulfonate |

| PEEK | Polyether ether ketone |

| PET | Polyethylene terephthalate |

| PLA | Polylactide |

| PMMA | Polymethyl methacrylate |

| PP | Polypropylene |

| PS | Polystyrene |

| PQT | Poly quarter thiophene |

| PVA | Polyvinyl acetate |

| PVP | Polyvinylpyrrolidone |

| PZT | Piezo-electric |

| RFID | Radio-frequency identification |

| SE | Structural electronics |

| SEBS | Styrene-ethylene-butylene-styrene |

| SiO2 | Silicon dioxide |

| SLA | Stereolithography |

| SLS | Selective laser sintering |

| SMT | Surface mount technology |

| SMD | Surface mount devices |

| SSAIL | Selective surface activation induced by a laser |

| TFT | Thin-film transistors |

| TPU | Thermoplastic polyurethane |

| UV | Ultraviolet |

References

- Sensor Trends 2030, Study by AMA Association for Sensors and Measurement in Co-Operation with VDI. 2025. Available online: https://www.vdi.de/ueber-uns/presse/publikationen/details/sensor-trends-2030 (accessed on 19 August 2025).

- Datenblatt_MID.cdr. Available online: https://www.flowcad.de/datasheets/NEXTRA_MID_Datasheet.pdf (accessed on 24 July 2025).

- 3D-MID Design. Altium Documentation. Available online: https://www.altium.com/documentation/altium-designer/3d-mid-design (accessed on 24 July 2025).

- Wie Elektroingenieure In-Mold-Elektronik Nutzen, um Schaltkreise Direkt in Funktionale Oberflächen zu Integrieren. Altium. Available online: https://resources.altium.com/de/p/in-mold-electronics-functional-surfaces (accessed on 24 July 2025).

- Designing for Printed Electronics. Altium Documentation. Available online: https://www.altium.com/documentation/altium-designer/designing-for-printed-electronics (accessed on 24 July 2025).

- TARGET 3001. Leiterplatten CAD Software. IB Friedrich. Available online: https://ibfriedrich.com/ (accessed on 24 July 2025).

- IGF-Vorhaben-Nr. 20975. N: Prozesssichere Herstellung von keramischen 3D Schaltungsträgern (Prokeram3D), Stuttgart, Germany. 2021. Available online: https://www.hahn-schickard.de/fileadmin/media/Metanavigation/Mediathek/Publikationen_-_wissenschaftlich/PDF_Abschlussberichte/S/2022_Abschlussbericht_Prokeram3D_final.pdf (accessed on 19 August 2025).

- IGF-Vorhaben-Nr. 22459. N: Flexible, Digitale Fertigungsprozessketten zur Herstellung Zuverlässiger 3D-Schaltungsträger auf Basis Kera- Mischer Substrate (FlexiKer3D), Stuttgart, Germany. 2025. Available online: https://www.hahn-schickard.de/fileadmin/media/Metanavigation/Mediathek/Publikationen_-_wissenschaftlich/PDF_Abschlussberichte/S/2025_Abschlussbericht_FlexiKer3D_final.pdf (accessed on 19 August 2025).

- Krause-Widjaja, C. Active Mold Packaging (AMP) Realisiert Package- Und SiP-Basierte Planare Antennen. LPKF Laser & Electronics AG, Pressemiteilung. 2021. Available online: https://www.lpkf.com/fileadmin/mediafiles/LPKF_PI_2102_EQ_AMP_Antenna_DE.pdf (accessed on 19 August 2025).

- IGF-Vorhaben-Nr. 19758 N: Selektive Laserbasierte Metallisierung zur Direktkontaktierung von Elektronischen Komponenten in Duroplastischen 3D-Packages (Slimdup), Stuttgart, Germany. 2020. Available online: https://www.hahn-schickard.de/fileadmin/media/Metanavigation/Mediathek/Publikationen_-_wissenschaftlich/PDF_Abschlussberichte/S/2021_Abschlussbericht_Slimdup.pdf (accessed on 19 August 2025).

- Mager, T.; Jürgenhake, C.; Dumitrescu, R. Efficient method for determining substrate parameters of additive manufactured spatial circuit carriers. In Proceedings of the 2022 14th German Microwave Conference (GeMiC), Ulm, Germany, 16–18 May 2022; pp. 224–227. [Google Scholar]

- Khan, S.; Lorenzelli, L.; Dahiya, R.S. Technologies for Printing Sensors and Electronics Over Large Flexible Substrates: A Review. IEEE Sens. J. 2015, 15, 3164–3185. [Google Scholar] [CrossRef]

- Simula, T.; Niskala, P.; Heikkinen, M.; Rusanen, O. Component Packages for IMSETM (Injection Molded Structural Electronics). In Proceedings of the 2018 IMAPS Nordic Conference on Microelectronics Packaging (NordPac), Oulu, Finland, 12–14 June 2018; pp. 50–54. [Google Scholar] [CrossRef]

- Brasse, Y.; Moreno, M.L.; Blum, S.; Horter, T.; Janek, F.; Gläser, K.; Emmerechts, C.; Clanet, J.-M.; Verhaert, M.; Grymonprez, B.; et al. Recyclable in-mold and printed electronics with polymer separation layers. RSC Sustain. 2024, 2, 1883–1894. [Google Scholar] [CrossRef]

- Liu, X.; Li, D.; Fukutani, H.; Trudeau, P.; Khoun, L.; Mozenson, O.; Sampson, K.L.; Gallerneault, M.; Paquet, C.; Lacelle, T.; et al. UV-Sinterable Silver Oxalate-Based Molecular Inks and Their Application for In-Mold Electronics. Adv. Electron. Mater. 2021, 7, 2100194. [Google Scholar] [CrossRef]

- Ferri, J.; Llinares Llopis, R.; Moreno, J.; Ibañez Civera, J.; Garcia-Breijo, E. A Wearable Textile 3D Gesture Recognition Sensor Based on Screen-Printing Technology. Sensors 2019, 19, 5068. [Google Scholar] [CrossRef]

- Moldenhauer, D.; Nguyen, D.C.Y.; Jescheck, L.; Hack, F.; Fischer, D.; Schneeberger, A. 3D screen printing—An innovative technology for large-scale manufacturing of pharmaceutical dosage forms. Int. J. Pharm. 2021, 592, 120096. [Google Scholar] [CrossRef]

- Javed Beg, A. Market Data Insights: In-Mold Technology in labeling, Decoration, and electronics. In Proceedings of the IPI Conference, Düsseldorf, Germany, 21 November 2023. [Google Scholar]

- Kunststoff Tiefziehen-So Geht’s. S-Polytec. Available online: https://www.s-polytec.de/blog/kunststoff-tiefziehen-thermoforming.html (accessed on 21 July 2025).

- Temperature for Thick Thermoforming Materials. Blister Packaging Machine Challenger—CN Thermoforming Machine. Available online: https://www.cn-thermoforming.com/ideal-softening-temperature-for-thick-thermoforming-materials/ (accessed on 21 July 2025).

- Zhang, Y.; Zhu, Y.; Zheng, S.; Zhang, L.; Shi, X.; He, J.; Chou, X.; Wu, Z.-S. Ink formulation, scalable applications and challenging perspectives of screen printing for emerging printed microelectronics. J. Energy Chem. 2021, 63, 498–513. [Google Scholar] [CrossRef]

- Zavanelli, N.; Yeo, W.-H. Advances in Screen Printing of Conductive Nanomaterials for Stretchable Electronics. ACS Omega 2021, 6, 9344–9351. [Google Scholar] [CrossRef]

- Beltrão, M.; Duarte, F.M.; Viana, J.C.; Paulo, V. A review on in-mold electronics technology. Polym. Eng. Sci. 2022, 62, 967–990. [Google Scholar] [CrossRef]

- Lee, S.Y.; Jang, S.H.; Lee, H.K.; Kim, J.S.; Lee, S.; Song, H.J.; Jung, J.W.; Yoo, E.S.; Choi, J. The development and investigation of highly stretchable conductive inks for 3-dimensional printed in-mold electronics. Org. Electron. 2020, 85, 105881. [Google Scholar] [CrossRef]

- Nagels, S.; Deferme, W. Fabrication Approaches to Interconnect Based Devices for Stretchable Electronics: A Review. Materials 2018, 11, 375. [Google Scholar] [CrossRef]

- de Vos, M.; Torah, R.; Beeby, S.; Tudor, J. Functional Electronic Screen-printing—Electroluminescent Lamps on Fabric. Procedia Eng. 2014, 87, 1513–1516. [Google Scholar] [CrossRef]

- Hong, F.; Tendera, L.; Myant, C.; Boyle, D. Vacuum-Formed 3D Printed Electronics: Fabrication of Thin, Rigid and Free-Form Interactive Surfaces. SN Comput. Sci. 2022, 3, 275. [Google Scholar] [CrossRef]

- Choi, J.; Han, C.; Cho, S.; Kim, K.; Ahn, J.; Orbe, D.D.; Cho, I.; Zhao, Z.-J.; Oh, Y.S.; Hong, H.; et al. Customizable, conformal, and stretchable 3D electronics via predistorted pattern generation and thermoforming. Sci. Adv. 2021, 7, eabj0694. [Google Scholar] [CrossRef]

- Basak, I.; Nowicki, G.; Ruttens, B.; Desta, D.; Prooth, J.; Jose, M.; Nagels, S.; Boyen, H.-G.; D’Haen, J.; Buntinx, M.; et al. Inkjet Printing of PEDOT:PSS Based Conductive Patterns for 3D Forming Applications. Polymers 2020, 12, 2915. [Google Scholar] [CrossRef]

- Jose, M.; Bronckaers, A.; Kumar, R.S.N.; Reenaers, D.; Vandenryt, T.; Thoelen, R.; Deferme, W. Stretchable printed device for the simultaneous sensing of temperature and strain validated in a mouse wound healing model. Sci. Rep. 2022, 12, 10138. [Google Scholar] [CrossRef]

- Outi, R. White Paper: Reliable smart molded structures. In Proceedings of the European Microelectronics Packaging Conference, Gothenburg, Sweden, 13–16 September 2021. [Google Scholar]

- IMSE® Enabling Innovative Automotive Applications. Available online: https://www.tactotek.com/resources/imse-enabling-innovative-automotive-applications (accessed on 15 July 2025).

- The Possibilities and the Diversity of Printed Electronics in the Automotive Industry. Quad Industries. Available online: https://www.quad-ind.com/the-possibilities-and-the-diversity-of-printed-electronics-in-the-automotive-industry/ (accessed on 15 July 2025).

- Petersen, I.; Hübner, G.; Pfletschinger, M. Integration of screen-printed antennas in plastic body parts using in-mould technology. In Proceedings of the 35th International Research Conference of iarigai, in Advances in Printing and Media Technology, Valencia, Spain, 7–10 September 2008; Volume 35, pp. 313–320. Available online: https://jpmtr.org/Advances-Vol-35(2008)_online.pdf (accessed on 19 August 2025).

- Huebner, G.; Mayer, K.; Kaefer, W.; Schmidt, K. Development of a 3D-formed and thin-film backlit HMI. J. Print Media Technol. Res. 2024, 13, 181–188. [Google Scholar]

- Taleat, Z.; Khoshroo, A.; Mazloum-Ardakani, M. Screen-printed electrodes for biosensing: A review (2008–2013). Microchim. Acta 2014, 181, 865–891. [Google Scholar] [CrossRef]

- Next-Gen ECG Patch for Smart Healthcare with Platilon®. Covestro AG. Available online: https://solutions.covestro.com/en/highlights/articles/cases/2025/tpu-films-in-wearables-and-smart-healthcare (accessed on 15 July 2025).

- Bakr, M.; Su, Y.; Bossuyt, F.; Vanfleteren, J. Effect of overmolding process on the integrity of electronic circuits. In Proceedings of the 2019 22nd European Microelectronics and Packaging Conference & Exhibition (EMPC), Pisa, Italy, 16–19 September 2019; pp. 1–8. [Google Scholar] [CrossRef]

- Pascual Cuenca, E.; Sánchez-Soto, M.; Fontdecaba Baig, E.; De la Cruz, L.G. Study of the conductive ink wash-out during overmolding. Int. J. Adv. Manuf. Technol. 2025, 136, 3407–3420. [Google Scholar] [CrossRef]

- Hubmann, M.; Bakr, M.; Groten, J.; Pletz, M.; Vanfleteren, J.; Bossuyt, F.; Madadnia, B.; Stadlober, B. Parameter Study on Force Curves of Assembled Electronic Components on Foils during Injection Overmolding Using Simulation. Micromachines 2023, 14, 876. [Google Scholar] [CrossRef]

- Yeomans, S. What Is a Jetting Valve and When Should I Use It? Intertronics. 2021. Available online: https://www.intertronics.co.uk/2021/01/what-is-a-jetting-valve-and-when-should-i-use-it/ (accessed on 15 July 2025).

- Kwon, K.-S.; Rahman, M.K.; Phung, T.H.; Hoath, S.D.; Jeong, S.; Kim, J.S. Review of digital printing technologies for electronic materials. Flex. Print. Electron. 2020, 5, 043003. [Google Scholar] [CrossRef]

- Furia, G.; Tricot, F.; Chaussy, D.; Marin, P.; Graziano, A.; Beneventi, D. Use of a 6-axis robot and ink pie-zo-jetting to print conductive paths on 3D objects. Printed circuit geometry, and conductivity predictive model. CIRP J. Manuf. Sci. Technol. 2021, 35, 855–863. [Google Scholar] [CrossRef]

- Singh, M.; Haverinen, H.M.; Dhagat, P.; Jabbour, G.E. Inkjet Printing—Process and Its Applications. Adv. Mater. 2010, 22, 673–685. [Google Scholar] [CrossRef]

- Kvavle, J.; Schultz, S.; Selfridge, R. Ink-jetting AJL8/APC for D-fiber electric field sensors. Appl. Opt. 2009, 48, 5280–5286. [Google Scholar] [CrossRef] [PubMed]

- Verboven, I.; Deferme, W. Printing of flexible light emitting devices: A review on different technologies and devices, printing technologies and state-of-the-art applications and future prospects. Prog. Mater. Sci. 2020, 118, 100760. [Google Scholar] [CrossRef]

- Reenaers, D.; Marchal, W.; Biesmans, I.; Nivelle, P.; D’Haen, J.; Deferme, W. Layer Morphology and Ink Compatibility of Silver Nanoparticle Inkjet Inks for Near-Infrared Sintering. Nanomaterials 2020, 10, 892. [Google Scholar] [CrossRef]

- Chen, S.-P.; Chiu, H.-L.; Wang, P.-H.; Liao, Y.-C. Inkjet Printed Conductive Tracks for Printed Electronics. ECS J. Solid State Sci. Technol. 2015, 4, P3026. [Google Scholar] [CrossRef]

- Marchal, W.; Mattelaer, F.; Van Hecke, K.; Briois, V.; Longo, A.; Reenaers, D.; Elen, K.; Detavernier, C.; Deferme, W.; Van Bael, M.K.; et al. Effectiveness of Ligand Denticity-Dependent Oxidation Protection in Copper MOD Inks. Langmuir 2019, 35, 16101–16110. [Google Scholar] [CrossRef]

- Shen, W.; Zhang, X.; Huang, Q.; Xu, Q.; Song, W. Preparation of solid silver nanoparticles for inkjet printed flexible electronics with high conductivity. Nanoscale 2014, 6, 1622–1628. [Google Scholar] [CrossRef]

- Hengge, M.; Livanov, K.; Zamoshchik, N.; Hermerschmidt, F.; List-Kratochvil, E.J.W. ITO-free OLEDs utilizing inkjet-printed and low temperature plasma-sintered Ag electrodes. Flex. Print. Electron. 2021, 6, 015009. [Google Scholar] [CrossRef]

- Smith, M.; Choi, Y.S.; Boughey, C.; Kar-Narayan, S. Controlling and assessing the quality of aerosol jet printed features for large area and flexible electronics. Flex. Print. Electron. 2017, 2, 015004. [Google Scholar] [CrossRef]

- Agarwala, S.; Guo Liang, G.; Yeong, W.Y. High resolution aerosol jet printing of conductive ink for stretchable electronics. In Proceedings of the 3rd International Conference on Progress in Additive Manufacturing (Pro-AM 2018), Singapore, 14–17 May 2018. [Google Scholar] [CrossRef]

- Vella, S.; Smithson, C.; Halfyard, K.; Shen, E.; Chrétien, M. Integrated capacitive sensor devices aerosol jet printed on 3D objects. Flex. Print. Electron. 2019, 4, 045005. [Google Scholar] [CrossRef]

- Alvarado, M.; La Flor, S.D.; Llobet, E.; Romero, A.; Ramírez, J.L. Performance of Flexible Chemoresistive Gas Sensors after Having Undergone Automated Bending Tests. Sensors 2019, 19, 5190. [Google Scholar] [CrossRef]

- Perelaer, J.; Smith, P.J.; Mager, D.; Soltman, D.; Volkman, S.K.; Subramanian, V.; Korvink, J.G.; Schubert, U.S. Printed electronics: The challenges involved in printing devices, interconnects, and contacts based on inorganic materials. J. Mater. Chem. 2010, 20, 8446. [Google Scholar] [CrossRef]

- Dybowska-Sarapuk, Ł.; Szałapak, J.; Wróblewski, G.; Wyżkiewicz, I.; Słoma, M.; Jakubowska, M. Rheology of inks for various techniques of printed electronics. In Advanced Mechatronics Solutions; Jabłoński, R., Brezina, T., Eds.; Advances in Intelligent Systems and Computing; Springer International Publishing: Cham, Switzerland, 2016; Volume 393, pp. 447–451. [Google Scholar] [CrossRef]

- Tian, L.; Liu, J.; Chen, X.; Branicio, P.S.; Lei, Q. Mechanisms and Strategies to Achieve Stability in Inkjet Printed 2D Materials Electronics. Adv. Electron. Mater. 2025, 11, 2400143. [Google Scholar] [CrossRef]

- Hoerber, J.; Goth, C.; Franke, J.; Hedges, M. Electrical functionalization of thermoplastic materials by Aerosol Jet Printing. In Proceedings of the 2011 IEEE 13th Electronics Packaging Technology Conference, Singapore, 7–9 December 2011; pp. 813–818. [Google Scholar] [CrossRef]

- 3D Electronics: Empowering Markets with Greater Integration. IDTechEx. Available online: https://www.idtechex.com/en/research-article/3d-electronics-empowering-markets-with-greater-integration/30908 (accessed on 15 July 2025).

- Wolf, M.; Werum, K.; Eberhardt, W.; Günther, T.; Zimmermann, A. Injection Compression Molding of LDS-MID for Millimeter Wave Applications. J. Manuf. Mater. Process. 2023, 7, 184. [Google Scholar] [CrossRef]

- He, C.; DeWit, R.; Chao, J.; Champagne, T.; Guino, R.; Winster, T.; Trichur, R.; Saliba, M.; Song, F.; Roick, F.; et al. Laser Direct Structuring of Semiconductor Liquid Encapsulants for Active Mold Packaging. In Proceedings of the 2022 IEEE 72nd Electronic Components and Technology Conference (ECTC), San Diego, CA, USA, 31 May–3 June 2022; pp. 1277–1281. [Google Scholar] [CrossRef]

- LPKF Laser & Electronics AG. Approved THERMO-PLASTIC LDS Materials. March 2024. Available online: https://www.lpkf.com/fileadmin/mediafiles/user_upload/LPKF_LDS_Polymers_Approval_List_2023-04.pdf (accessed on 15 July 2025).

- Franke, J. Three-Dimensional Molded Interconnect Devices (3D-MID)—Materials, Manufacturing, Assembly and Applications for Injection Molded Circuit Carriers; Carl Hanser Verlag: Munich, Germany, 2014. [Google Scholar]

- Mueller, H.; Weser, S.; Eberhardt, W.; Kück, H. Fine Pitch Metal Deposition on LDS Materials. In Proceedings of the 4M/ICOMM 2015 Conference, Milan, Italy, 31 March–2 April 2015. [Google Scholar] [CrossRef]

- Deckert, C.A. Electroless Copper Plating—A Review: Part I. Plat. Surf. Finish. 1995, 82, 48–55. [Google Scholar]

- Kordass, T.; Franke, J. Galvanic plating for 3D-MID applications. In Proceedings of the 2014 37th International Spring Seminar on Electronics Technology, Dresden, Germany, 7–11 May 2014; pp. 491–495. [Google Scholar] [CrossRef]

- MID/LDS Technology from MOLEX 2018. Available online: https://www.content.molex.com/dxdam/literature/987651-9286.pdf (accessed on 15 July 2025).

- LPKF Laser & Electronics AG. LDS MID Designregeln Designregeln für Laserdirektstrukturierte MID-Komponenten. Available online: https://www.2e-mechatronic.de/wp-content/uploads/2021/09/Download_LDS-MID_Designregeln_EX_V2.1_2011_DEU.pdf (accessed on 15 July 2025).

- LPKF Laser & Electronics AG. Three-Dimensional Circuits LPKF LDS: Laser Direct Structuring for 3D Molded Interconnect Devices. 2022. Available online: https://www.lpkf.com/fileadmin/mediafiles/user_upload/products/pdf/EQ/3D-MID-LDS/brochure_lpkf_laser_direct_structuring_en.pdf (accessed on 15 July 2025).

- Tengsuthiwat, J.; Sanjay, M.R.; Siengchin, S.; Pruncu, C.I. 3D-MID Technology for Surface Modification of Polymer-Based Composites: A Comprehensive Review. Polymers 2020, 12, 1408. [Google Scholar] [CrossRef]

- LPKF Laser & Electronics AG. Approved THERMO-SET LDS Materials. June 2021. Available online: https://en.lpkf.com/_mediafiles/2074-approved-plastics-lpkf-lds.pdf (accessed on 15 July 2025).

- Gottardo, A.M.; Zafferoni, C.; Villa, R. Direct Copper Interconnection: Laser Direct Structuring and Morphological Characterization of Copper Plated Vias. In Proceedings of the 2024 IMAPS Nordic Conference on Microelectronics Packaging (NordPac), Tampere, Finland, 11–13 June 2024; pp. 1–5. [Google Scholar]

- Catalano, G.; Cecchetto, L.; Sanna, A.; Verardi, E.; Villa, R.; Vitello, D. Laser Direct Structuring (LDS) for enhanced QFN package. In Proceedings of the 2023 IEEE 25th Electronics Packaging Technology Conference (EPTC), Singapore, 5–8 December 2023; pp. 478–483. [Google Scholar]

- Shepherd Technologies. High Performance LDS Additives. Available online: www.shepherdtechnologies.com (accessed on 17 July 2025).

- Laser Marking Additives for Best Results. Keeling & Walker. Available online: https://www.keelingwalker.co.uk/products-applications/laser-marking-additives/ (accessed on 15 July 2025).

- Yang, J.; Cho, J.H.; Yoo, M.J. Selective metallization on copper aluminate composite via laser direct structuring technology. Compos. Part B Eng. 2017, 110, 361–367. [Google Scholar] [CrossRef]

- Hemmelgarn, F.; Ehlert, P.; Mager, T.; Jürgenhake, C.; Dumitrescu, R.; Springer, A. Evaluation of different additive manufacturing technologies for MIDs in the context of smart sensor systems for retrofit applications. In Proceedings of the 2021 14th International Congress Molded Interconnect Devices (MID), Amberg, Germany, 8–11 February 2021; pp. 1–8. [Google Scholar]

- Rastikian, S.; Eberhardt, W.; Kück, H.; Fuchs, S.; Karamuk, E.; Dessors, S.; Fond, E.; Legrand, J.; Boubtane, M.; Mbaye, M.; et al. 3D-HiPMAS—Pilot factory for 3D high precision MID assemblies. In Proceedings of the 4M/ICOMM 2015 Conference, Milan, Italy, 31 March–2 April 2015. [Google Scholar] [CrossRef]

- LPKF. 3D-MIDs with Laser Direct Structuring (LDS). Available online: https://www.lpkf.com/en/industries-technologies/electronics-manufacturing/3d-mids-with-laser-direct-structuring-lds (accessed on 17 July 2025).

- Fischer, A. Untersuchungen zur Serienfertigung von Mechatronischen Mikrosystemen auf Basis Spritzgegossener Schaltungsträger am Beispiel von Braille-Modulen; Dr. Hut Verlag: Munich, Germany, 2017. [Google Scholar]

- Mross, M. HARTING PCB-Stack: Increased placement density under limited space conditions. In Proceedings of the 15th International Congress Mechatronic Integrated Discourse, Amberg, Germany, 21–22 June 2023. [Google Scholar]

- Burger, F.; Keßler, U.; Schober, M.; Eberhardt, W.; Grözinger, T.; Kück, H. Optimized contact elements for soldering MID (Moulded Interconnect Devices) on PCB. In Proceedings of the SMART SYSTEMS INTEGRATION 2011, Dresden, Germany, 22–23 March 2011; VDE Verlag GmbH: Dresden, Germany, 2011. [Google Scholar]

- Hess, T. Propriertary 3D-MIDs—How a component carrier replaces flexible PCB. In Proceedings of the 14th International Congress Molded Interconnect Devices, Amberg, Germany, 8–11 February 2021. [Google Scholar]

- Remer, U. Smart series application in 3D shape. In Proceedings of the 12th International Congress Molded Interconnect Devices, Würzburg, Germany, 28–29 September 2016. [Google Scholar]

- Palin, U. 3D-MID Antenna challenges and learnings. In Proceedings of the 14th International Congress Molded Interconnect Devices, Amberg, Germany, 8–11 February 2021. [Google Scholar]

- Obermaier, J. MID in communication system. In Proceedings of the 13th International Congress Molded Interconnect Devices, Würzburg, Germany, 25–26 September 2018. [Google Scholar]

- 4 and 2.4, 5 GHz Ceramic and MID Chip Antennas. 2019. Available online: https://www.molex.com/content/dam/molex/molex-dot-com/en_us/pdf/datasheets/987650-5702.pdf?inline (accessed on 15 July 2025).

- 3D MID Technologie Entdecke die Möglichkeiten. 2E Mechatronic. Available online: https://www.2e-mechatronic.de/mid/ (accessed on 15 July 2025).

- HARTING 3D-Circuits. Available online: https://3d-circuits.com/ (accessed on 15 July 2025).

- S-2P. Available online: https://s-2p.com/ (accessed on 15 July 2025).

- Laser Direct Structuring (LDS) Technology. KYOCERA AVX. Available online: https://www.kyocera-avx.com/products/antennas/laser-direct-structuring-lds/ (accessed on 15 July 2025).

- Pilot Factory for 3D High Precision MID Assemblies. CORDIS. European Commission. Available online: https://cordis.europa.eu/project/id/314293 (accessed on 15 July 2025).

- Hirt, E.; Ruzicka, K.; Wigger, B.; Barth, M.; Saleh, R.; Janek, F.; Müller, E. 3D-MID Evaluation and Validation for Space Applications. In Proceedings of the 2019 IEEE 69th Electronic Components and Technology Conference (ECTC), Las Vegas, NV, USA, 28–31 May 2019; pp. 868–877. [Google Scholar]

- Cihangir, A.; Sonnerat, F.; Gianesello, F.; Gloria, D.; Luxey, C. Antenna Solutions for 4G Smartphones in Laser Direct Structuring Technology. Radioengineering 2016, 25, 419–428. [Google Scholar] [CrossRef]

- MID/LDS Custom Capabilities. AVNET Abacus. Available online: https://my.avnet.com/abacus/manufacturers/m/molex/products/mid-lds-technology/ (accessed on 15 July 2025).

- 3D-MID for Wireless Automotive Applications. MID4Automotive. Available online: https://www.mid4automotive.de/en/ (accessed on 15 July 2025).

- Friedrich, A.; Geck, B.; Fengler, M. LDS manufacturing technology for next generation radio frequency applications. In Proceedings of the 2016 12th International Congress Molded Interconnect Devices (MID), Würzburg, Germany, 28–29 September 2016; pp. 1–6. [Google Scholar]

- Glise, A.; Quéré, Y.; Maalouf, A.; Rius, E.; Castel, V.; Laur, V.; Sauvage, R.M. LDS Realization of High-Q SIW Millimeter Wave Filters with Cyclo-Olefin Polymers. Appl. Sci. 2018, 8, 2230. [Google Scholar] [CrossRef]

- Geneiß, V.; Lüke, T.; Hedayat, C.; Wolf, M.; Janek, F.; Meissner, T.; Barth, M.; Eberhardt, W.; Zimmermann, A.; Otto, T. Impedance-Controlled Design and Connection Technology for Micromounting and Hybrid Integration of High-Frequency and Mixed-Signal Systems with MID Technology. In Proceedings of the Smart Systems Integration, Dresden, Germany, 11–12 April 2018. [Google Scholar]

- Sonnerat, F.; Pilard, R.; Gianesello, F.; Le Pennec, F.; Person, C.; Gloria, D. Innovative LDS Antenna for 4G Applications. In Proceedings of the 7th European Conference on Antennas and Propagation (EuCAP), Gothenburg, Sweden, 8–12 April 2013; p. 2776. [Google Scholar]

- Seewald, S.; Manteuffel, D.; Wolf, M.; Barth, M.; Eberhardt, W.; Zimmermann, A. Low-Loss 3D-Coplanar Line Structure for Millimeter Wave Applications Using Laser Direct Structuring Technology. In Proceedings of the 2021 International Conference on Electromagnetics in Advanced Applications (ICEAA), Honolulu, HI, USA, 9–13 August 2021; p. 085. [Google Scholar]

- Scherzer, T.; Wolf, M.; Werum, K.; Ruckdäschel, H.; Eberhardt, W.; Zimmermann, A. Dielectric Properties of PEEK/PEI Blends as Substrate Material in High-Frequency Circuit Board Applications. Micromachines 2024, 15, 801. [Google Scholar] [CrossRef]

- Wolf, M.; Werum, K.; Guenther, T.; Schleeh, L.; Eberhardt, W.; Zimmermann, A. Analysis of Tempering Effects on LDS-MID and PCB Substrates for HF Applications. J. Manuf. Mater. Process. 2023, 7, 139. [Google Scholar] [CrossRef]

- Wurz, M.C.; Bengsch, S.; Roesener, B.; Beringer, S. Concept for Using MID Technology for Advanced Packaging. In Proceedings of the 2018 IEEE 68th Electronic Components and Technology Conference (ECTC), San Diego, CA, USA, 29 May–1 June 2018; pp. 932–939. [Google Scholar]

- Bierwirth, T.N.; Bengsch, S.; Werner, M.; Wachs, R.; Henne, C.; Bur, S.; Dencker, F.; Wurz, M.C. Manufacturing and Characterization of Planar Transformers as Molded Interconnect Device Technology Component for an Industrial Production. In Proceedings of the 2024 IEEE 74th Electronic Components and Technology Conference (ECTC), Denver, CO, USA, 28–31 May 2024; pp. 2172–2177. [Google Scholar]

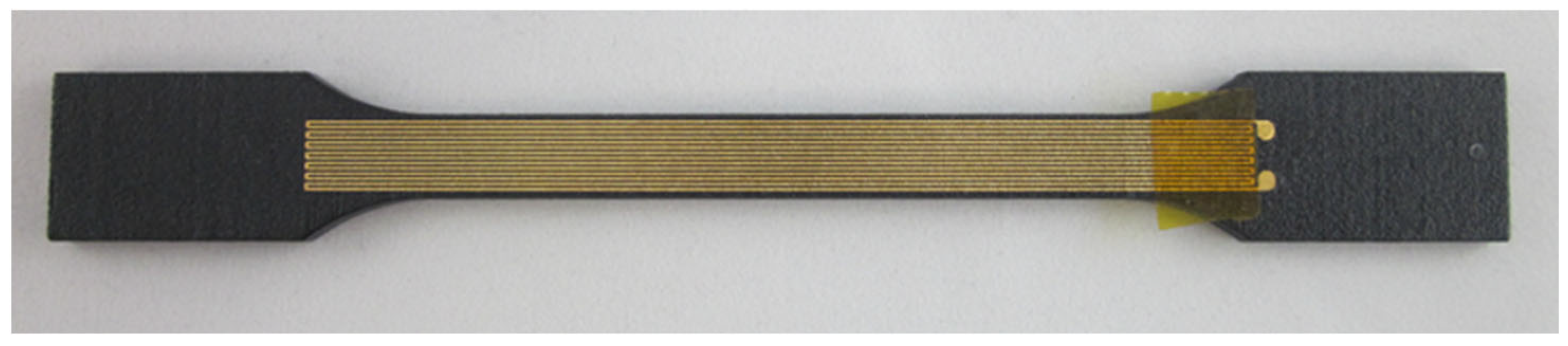

- Bengsch, S.; Bur, S.; Werner, M.; Henne, C.; Wochele, M.; Buelau, A.; Knöller, A.; Kible, V.; Walter, D.; Helm, D.; et al. Development of a Thermal Flow Sensor Based on the Ensinger Microsystems Technology. In Proceedings of the MikroSystemTechnik Kongress 2023, Dresden, Deutschland, 25 October 2023; VDE Publishing House: Dresden, Germany, 2023. Available online: https://www.vde-verlag.de/proceedings-en/456203171.html (accessed on 15 July 2025).

- MEMS und Mikrosysteme mit EMST. Available online: https://www.ensingerplastics.com/de-de/microsystems (accessed on 15 July 2025).

- Mager, T.; Jürgenhake, C.; Dumitrescu, R. Functionalization of additive manufactures components with laser direct structurable lacquer. In Proceedings of the 2018 13th International Congress Molded Interconnect Devices (MID), Würzburg, Germany, 25–26 September 2018; pp. 1–9. [Google Scholar]

- LPKF Laser & Electronics AG. Leiterbahnen aus der Sprühdose. LDS-Beschichtung von 3D-Schaltungsträgern mit LPKF ProtoPaint LDS. Available online: https://de.lpkf.com/_mediafiles/3022-brochure-lpkf-protopaint-lds-de.pdf (accessed on 15 July 2025).

- Mager, T.; Kruse, S.; Dumitrescu, R.; Diri, J. MID as an enabler for the integration of 77 GHz automotive radar systems onto plastic surfaces. In Proceedings of the 16th International MID Congress—Mechatronic Integration Discourse, Conference, Amberg, Germany, 2–3 July 2025. [Google Scholar]

- Piechulek, N.; Xu, L.; Fröhlich, J.; Bründl, P.; Franke, J. Miniaturization Potential of Additive-Manufactured 3D Mechatronic Integrated Device Components Produced by Stereolithography. Micromachines 2025, 16, 16. [Google Scholar] [CrossRef]

- Mohrmann, M. Rapid Prototyping of MID by Stereolithographic Printing. In Proceedings of the MIDSummit and MID Workshop 2022, Böblingen, Germany, 21–22 September 2022. [Google Scholar]

- Zenker, M. New Materials for the Realization of Product-Related Prototypes. In Proceedings of the 16th International MID Congress, Amberg, Germany, 2–3 July 2025. [Google Scholar]

- HARTING Revolutioniert den 3D-Druck von LDS-Materialien Mittels Hot Lithography. HARTING 3D-Circuits. Available online: https://3d-circuits.com/harting-revolutioniert-den-3d-druck-von-lds-materialien-mittels-hot-lithography/ (accessed on 15 July 2025).

- LDS-Filamente für 3D-Druck—MIDs Rationell Herstellen—Kunststoff Magazin. Available online: https://www.kunststoff-magazin.de/3d-druck/lds-filamente-fuer-3d-druck---mids-rationell-herstellen.htm (accessed on 18 July 2025).

- Berix, M. Rapid Prototyping Made Easy Through 3DPrinted Xantar® LDS Materials. In Proceedings of the 13th International Congress MID 2018, Würzberg, Germany, 27 September 2018. [Google Scholar]

- Yoo, B.; Bowen, D.; Lazarus, N.; Pines, D. Laser Direct Structured 3D Circuits on Silicone. ACS Appl. Mater. Interfaces 2022, 14, 18854–18865. [Google Scholar] [CrossRef]

- Balzereit, S.; Proes, F.; Altstädt, V.; Emmelmann, C. Properties of copper modified polyamide 12-powders and their potential for the use as laser direct structurable electronic circuit carriers. Addit. Manuf. 2018, 23, 347–354. [Google Scholar] [CrossRef]

- Zinger, S.; Yuri, K. 3D MID Circuits Enable Device Miniaturization—Panasonic Electric Works. Semiconductor Digest. Available online: https://sst.semiconductor-digest.com/2007/03/3d-mid-circuits-enable-device-miniaturization/ (accessed on 18 July 2025).

- Vieten, T.; Weser, S.; Schilling, A.; Gläser, K.; Zimmermann, A. Integration of Mechatronic Functions on Additively Manufactured Components via Laser-Assisted Selective Metal Deposition. Adv. Funct. Mater. 2024, 34, 2312833. [Google Scholar] [CrossRef]

- Sadauskas, M.; Vrubliauskaitė, V.; Kvietkauskas, E.; Stankevičienė, I.; Balkauskas, D.; Trusovas, R.; Belosludtsev, A.; Ratautas, K. Laser-induced microscale copper trace deposition on glass and PET substrates. Opt. Laser Technol. 2025, 183, 112355. [Google Scholar] [CrossRef]

- Richter, H.; Kappl, H.; T, B.; S, L.; K, P.; Eberhardt, W.; Fenker, M.; H, K. New Developments in Hot Embossing MID Technology. In Proceedings of the 7th International Conference on Multi-Material Micro Manufacture, Bourg en Bresse, France, 17–19 November 2010; pp. 117–120. [Google Scholar]

- Graunitz, B. Leoni: Innovationspreis für Metallisierungsverfahren. Elektroniknet.de. Available online: https://www.elektroniknet.de/automation/leoni-innovationspreis-fuer-metallisierungsverfahren.15605.html (accessed on 15 July 2025).

- Süß-Wolf, R. Thermokinetic Process Flamecon® for Large Scale MID. In Proceedings of the 9th Congress 3-D MID e.V., Fürth, Germany, 28–29 September 2010. [Google Scholar]

- Suess-Wolf, R.; Paolis, M. Leoni Flamecon—Ein neues Metallisierungsverfahren stellt sich vor. Metall 2007, 61, 739–741. Available online: https://kupfer.de/wp-content/uploads/2020/01/739-Cu-Suess-Wolf.indd_.pdf (accessed on 15 July 2025).

- Reinhausen Plasma: Schichtabscheidung aus Kalt-Aktivem Plasma Direkt auf Kunststoffen. Available online: https://www.k-online.de/de/Media_News/News/Reinhausen_Plasma_Schichtabscheidung_aus_kalt-aktivem_Plasma_direkt_auf_Kunststoffen (accessed on 15 July 2025).

- Plasmadust—Forschungsvereinigung Räumliche Elektronische Baugruppen 3-D MID e.V. Available online: https://www.3d-mid.de/technologie/herstellungsverfahren/plasmadust/ (accessed on 3 November 2022).

- Smarte Hochflexible SMT Lösungen. Essemtec AG. Available online: https://essemtec.com/ (accessed on 15 July 2025).

- Fertigungsanlagen für die Automatisierte Mikromontage. Haecker Automation GmbH. Available online: https://haecker-automation.de/ (accessed on 15 July 2025).

- Produktportfolio. Kronos-MCT. Available online: https://kronos-mct.com/produktportfolio/ (accessed on 24 July 2025).

- Nowottnick, M.; Diehm, R. Soldering Technology for 3D PCB Assemblies with Microwave Heating. In Proceedings of the 2007 IEEE International Symposium on Industrial Electronics, Vigo, Spain, 4–7 July 2007; pp. 3273–3277. [Google Scholar] [CrossRef]

- Brand, A. Prozesse und Systeme zur Bestückung Räumlicher Elektronischer Baugruppen (3D-MID); Meisenbach: Haunetal, Germany, 1997. [Google Scholar]

- Cheng, S.; Huang, C.-M.; Pecht, M. A review of lead-free solders for electronics applications. Microelectron. Reliab. 2017, 75, 77–95. [Google Scholar] [CrossRef]

- Solder Market Size, Competitive Dynamics & Forecast. Verified Market Reports. Available online: https://www.verifiedmarketreports.com/product/global-solder-market-growth-2019-2024/ (accessed on 15 July 2025).

- Humpston, G.; Jacobson, D.M. Indium Solders. Adv. Mater. Process. 2005, 163, 45–47. [Google Scholar]

- Cryogenic and Hermetic Sealing, Indiumcorporation. Available online: https://www.indium.com/applications/sealing/ (accessed on 15 July 2025).

- Kang, H.; Rajendran, S.H.; Jung, J.P. Low Melting Temperature Sn-Bi Solder: Effect of Alloying and Nanoparticle Addition on the Microstructural, Thermal, Interfacial Bonding, and Mechanical Characteristics. Metals 2021, 11, 364. [Google Scholar] [CrossRef]

- Podsiadły, B.; Skalski, A.; Słoma, M. Soldering of Electronics Components on 3D-Printed Conductive Substrates. Materials 2021, 14, 3850. [Google Scholar] [CrossRef]

- Poole, I. Reflow Soldering for PCB Assembly. Electronics Notes. Available online: https://www.electronics-notes.com/articles/constructional_techniques/soldering/reflow-soldering.php (accessed on 15 July 2025).

- Illés, B.; Géczy, A.; Medgyes, B.; Harsanyi, G. Vapour phase soldering (VPS) technology: A review. Solder. Surf. Mt. Technol. 2018, 31, 146–156. [Google Scholar] [CrossRef]

- Jaya, N.T.; Idris, S.R.A.; Ishak, M. A Review on Mechanical Properties of SnAgCu/Cu Joint Using Laser Soldering. In Advances in Joining Technology; Awang, M., Ed.; Springer: Singapore, 2019; pp. 97–107. [Google Scholar] [CrossRef]

- Illyefalvi-Vitez, Z.; Balogh, B.; Baranyay, Z.; Farmer, G.; Harvey, T.; Kirkpatrik, D.; Kotora, G.; Ruzsics, N. Laser Soldering for Lead-free Assembly. In Proceedings of the 2007 30th International Spring Seminar on Electronics Technology (ISSE), Cluj-Napoca, Romania, 9–13 May 2007; pp. 471–476. [Google Scholar] [CrossRef]

- Suhir, E.; Lee, Y.C.; Wong, C.P. Micro- and Opto-Electronic Materials and Structures: Physics, Mechanics, Design, Reliability, Packaging; Springer: New York, NY, USA, 2007. [Google Scholar]

- Licari, J.J.; Swanson, D.W. 2—Functions and Theory of Adhesives. In Adhesives Technology for Electronic Applications; Licari, J.J., Swanson, D.W., Eds.; Materials and Processes for Electronic Applications; William Andrew Publishing: Norwich, NY, USA, 2005; pp. 39–94. [Google Scholar] [CrossRef]

- Morris, J.E.; Lee, J.; Liu, J. Isotropic Conductive Adhesive Interconnect Technology in Electronics Packaging Applications. In Proceedings of the Polytronic 2005—5th International Conference on Polymers and Adhesives in Microelectronics and Photonics, Warsaw, Poland, 23–26 October 2005; pp. 45–52. [Google Scholar] [CrossRef]

- Alam, M.O.; Bailey, C. Advanced Adhesives in Electronics; Woodhead Publishing: Cambridge, UK, 2011; Available online: https://shop.elsevier.com/books/advanced-adhesives-in-electronics/alam/978-1-84569-576-7 (accessed on 15 July 2025).

- Anisotropic Adhesives. Creative Materials. Available online: https://www.creativematerials.com/products/anisotropic-adhesives/ (accessed on 15 July 2025).

- Zhou, H.; Zhang, Y.; Cao, J.; Su, C.; Li, C.; Chang, A.; An, B. Research Progress on Bonding Wire for Microelectronic Packaging. Micromachines 2023, 14, 432. [Google Scholar] [CrossRef]

- Harman, G.G.; Harman, G.G. Wire Bonding in Microelectronics, 3rd ed.; McGraw-Hill: New York, NY, USA, 2010. [Google Scholar]

- Prasad, S.K. Advanced Wirebond Interconnection Technology; Kluwer Academic Publishers: Boston, MA, USA, 2004. [Google Scholar]

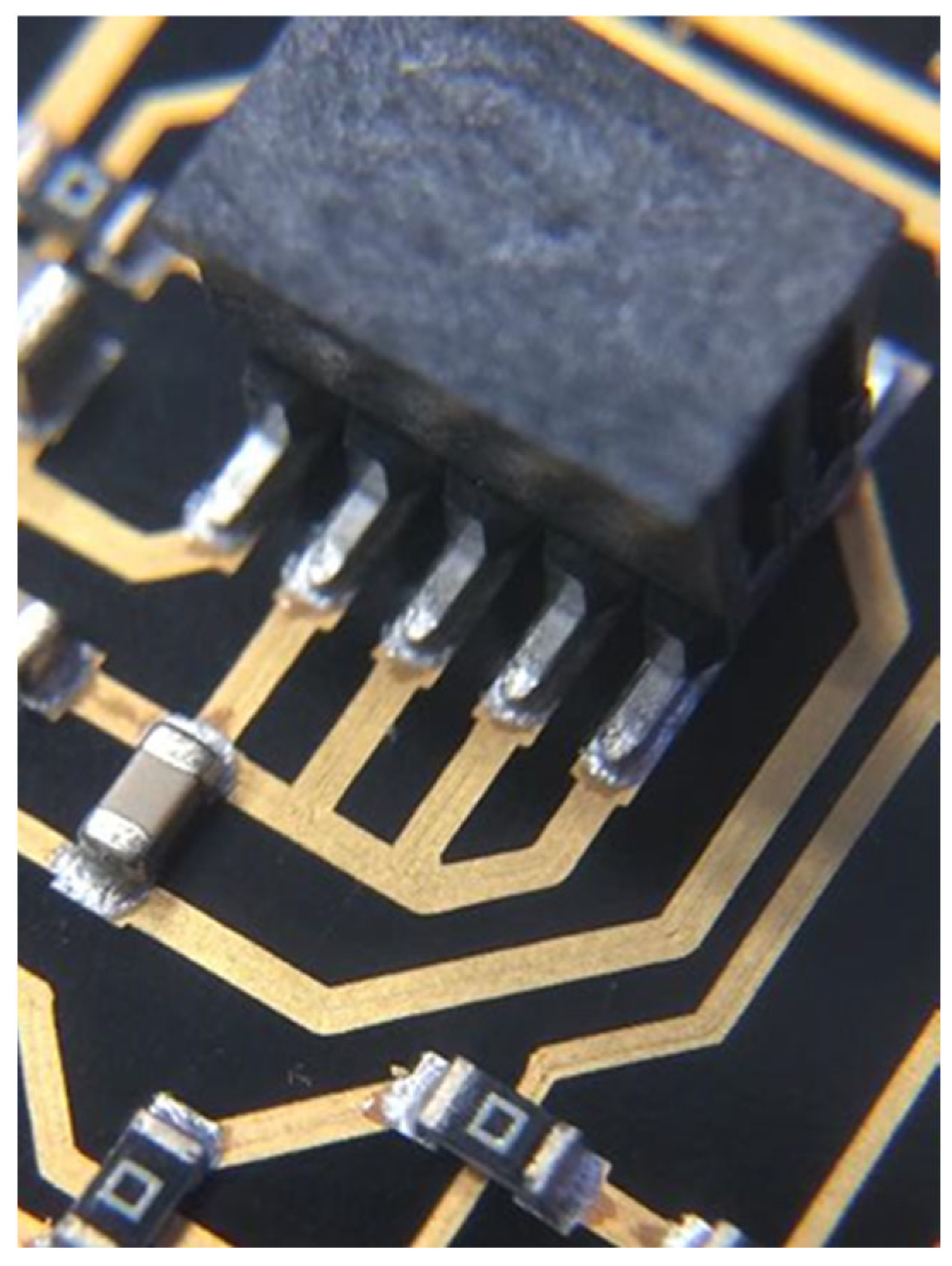

- Buckmüller, P.; Eberhardt, W.; Keßler, U.; Willeck, H.; Kück, H. Aluminium wedge-wedge wire bonding on thermoplastic substrates made by LPKF-LDS® technology. In Proceedings of the 3rd Electronics System Integration Technology Conference ESTC, Berlin, Germany, 13–16 September 2010; pp. 1–5. [Google Scholar] [CrossRef]

- Guenther, T.; Werum, K.; Müller, E.; Wolf, M.; Zimmermann, A. Characterization of Wire-Bonding on LDS Materials and HF-PCBs for High-Frequency Applications. J. Manuf. Mater. Process. 2022, 6, 9. [Google Scholar] [CrossRef]

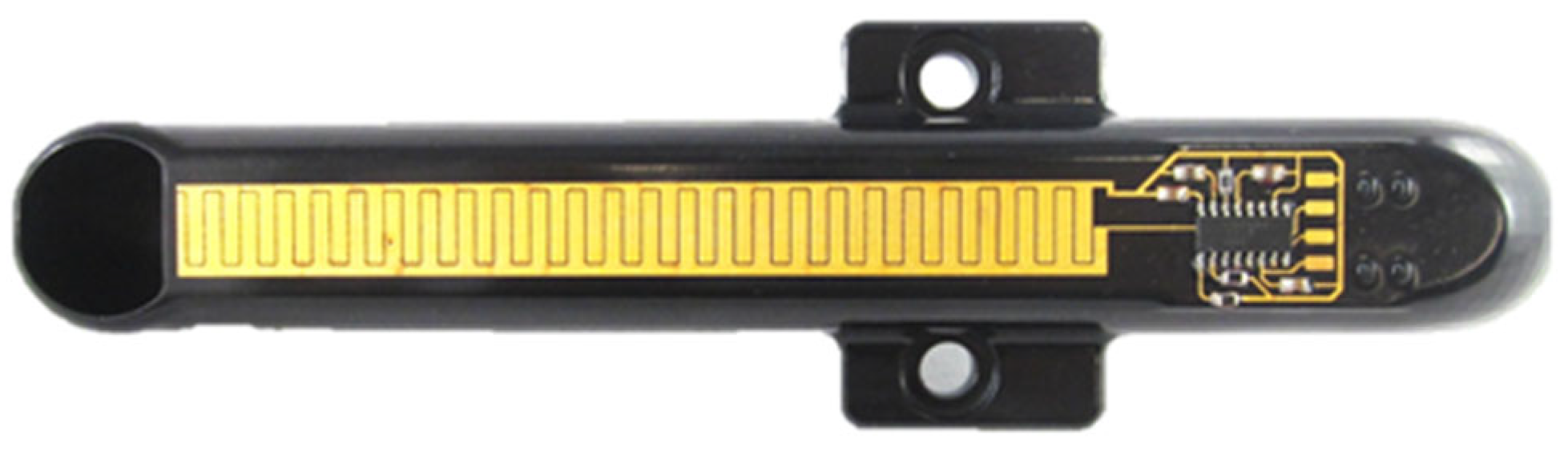

- LDS Product Sample (Flow Sensor). 2E Mechatronic. Available online: https://www.2e-mechatronic.de/en/mid/lds-product-sample-flow-sensor/ (accessed on 15 July 2025).

- Andersson, H.; Siden, J.; Skerved, V.; Li, X.; Gyllner, L. Soldering Surface Mount Components Onto Inkjet Printed Conductors on Paper Substrate Using Industrial Processes. IEEE Trans. Compon. Packag. Manuf. Technol. 2016, 6, 478–485. [Google Scholar] [CrossRef]

- Franke, J. Räumliche Elektronische Baugruppen (3D-MID): Werkstoffe, Herstellung, Montage und Anwendungen für Spritzgegossene Schaltungsträger; Hanser: München, Germany, 2013. [Google Scholar]

- Meier, H.; Löffelmann, U.; Mager, D.; Smith, P.J.; Korvink, J.G. Inkjet printed, conductive, 25 μm wide silver tracks on unstructured polyimide. Phys. Status Solidi A 2009, 206, 1626–1630. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, X.; Xin, Z.; Deng, M.; Wen, Y.; Song, Y. Controlled Inkjetting of a Conductive Pattern of Silver Nanoparticles Based on the Coffee-Ring Effect. Adv. Mater. 2013, 25, 6714–6718. [Google Scholar] [CrossRef]

- Jaiswar, R.; Mederos-Henry, F.; Dupont, V.; Hermans, S.; Raskin, J.-P.; Huynen, I. Inkjet-printed frequency-selective surfaces based on carbon nanotubes for ultra-wideband thin microwave absorbers. J. Mater. Sci. Mater. Electron. 2020, 31, 2190–2201. [Google Scholar] [CrossRef]

- Banquart, A.; Callé, S.; Levassort, F.; Fritsch, L.; Ossant, F.; Toffessi Siewe, S.; Chevalliot, S.; Capri, A.; Grégoire, J.-M. Piezoelectric P(VDF-TrFE) film inkjet printed on silicon for high-frequency ultrasound applications. J. Appl. Phys. 2021, 129, 195107. [Google Scholar] [CrossRef]

- Zikulnig, J.; Chang, S.; Bito, J.; Rauter, L.; Roshanghias, A.; Carrara, S.; Kosel, J. Printed Electronics Technologies for Additive Manufacturing of Hybrid Electronic Sensor Systems. Adv. Sens. Res. 2023, 2. [Google Scholar] [CrossRef] [PubMed]

- Ultrafine Printed Electronics: Technologies for Reaching Sub-Micron Feature Sizes. TechBlick. Available online: https://www.techblick.com/post/ultrafine-printed-electronics-technologies-for-reaching-sub-micron-feature-sizes (accessed on 22 July 2025).

- Furia, G. Development of a Robotic Cell for the Printing of Electronic Circuits on Free Form Surfaces and Industrial Applications. Phdthesis, Université Grenoble Alpes [2020–…]. 2021. Available online: https://theses.hal.science/tel-03228497 (accessed on 24 July 2025).

- Borghetti, M.; Nicolosi, V.; Sardini, E.; Serpelloni, M.; Spurling, D. Optimization of Piezo-Driven Jet Valve Dispensing Process for the Geometrical Control of Printed Sensors Based on Silver and MXene Inks. IEEE Trans. Instrum. Meas. 2024, 73, 1–11. [Google Scholar] [CrossRef]

- Wilkinson, N.J.; Smith, M.A.A.; Kay, R.W.; Harris, R.A. A review of aerosol jet printing—A non-traditional hybrid process for micro-manufacturing. Int. J. Adv. Manuf. Technol. 2019, 105, 4599–4619. [Google Scholar] [CrossRef]

- Abdolmaleki, H.; Kidmose, P.; Agarwala, S. Droplet-Based Techniques for Printing of Functional Inks for Flexible Physical Sensors. Adv. Mater. 2021, 33, 2006792. [Google Scholar] [CrossRef]

- Eberhardt, W.; Müller, H.; Weser, S.; Zimmermann, A. 3D-HiPMAS—Pilot factory for 3D high precision MID assemblies. In Proceedings of the 12th International Congress Molded Interconnect Devices MID 2016, Würzburg, Germany, 28–29 September 2016. [Google Scholar]

- Arnold, H. LPKF-Prozess Spart 30 Prozent Kosten. Elektroniknet. Available online: https://www.elektroniknet.de/halbleiter/lpkf-prozess-spart-30-prozent-kosten.181285.html (accessed on 22 July 2025).

- Koscielski, M.; Stobbe, L.; Mager, T.; Jokinen, T.; Schulz, A.; Kiernich, A. ALU4CED—New Concept for Circular Electronic Design Based on Aluminium. In Proceedings of the 2024 Electronics Goes Green 2024+ (EGG), Berlin, Germany, 18–20 June 2024; pp. 1–7. [Google Scholar] [CrossRef]

- Mager, T.; Diri, J.; Kneuper, P.; Kruse, S.; Scheytt, C. Integration of a 77GHz automotive radar system into plastic surfaces using MID-technology. In Proceedings of the AmEC 2024—Automotive meets Electronics & Control; 14. GMM Symposium, Dortmund, Germany, 14–15 March 2024; pp. 89–94. Available online: https://ieeexplore.ieee.org/document/10564559 (accessed on 22 July 2025).

- Mager, T.; Dumitrescu, R. Hybrid design approach for the design of high-frequency components in MID technology. In Proceedings of the 2023 15th International Congress Mechatronic Integration Discourse (MID), Amberg, Germany, June 2023; pp. 1–6. [Google Scholar] [CrossRef]

- Khuntontong, P.; Blaser, T.; Schomburg, W.K. Fabrication of Molded Interconnection Devices by Ultrasonic Hot Embossing on Thin Polymer Films. IEEE Trans. Electron. Packag. Manuf. 2009, 32, 152–156. [Google Scholar] [CrossRef]

- Chen, J.Y.; Young, W.B. Two-Component Injection Molding of Molded Interconnect Devices. Adv. Mater. Res. 2013, 628, 78–82. [Google Scholar] [CrossRef]

- Serie Dreidimensionaler Elektronikbauteile aus zwei Kunststoffen (2K-3D-MID). Available online: https://www.kunststoffe.de/a/produktmeldung/serie-dreidimensionaler-elektronikbautei-249867 (accessed on 22 July 2025).

- 2K-Spritzguss. Forschungsvereinigung Räumliche Elektronische Baugruppen 3-D MID e.V. Available online: https://www.3d-mid.de/technologie/herstellungsverfahren/2k-spritzguss/ (accessed on 22 July 2025).

- Flamecon. Forschungsvereinigung Räumliche Elektronische Baugruppen 3-D MID e.V. Available online: https://www.3d-mid.de/technologie/herstellungsverfahren/flamecon/ (accessed on 3 November 2022).

- Deferme, W. ACT 3D—Screen printing and thermoforming results. In Proceedings of the Industrial Print Integration (IPI), Düsseldorf, Germany, 28 November 2023. [Google Scholar]

- Cinquino, M.; Pugliese, M.; Prontera, C.T.; Mariano, F.; Zizzari, A.; Maiorano, G.; Maggiore, A.; Manfredi, R.; Mello, C.; Tarantini, I.; et al. Inkjet-printed multilayer structure for low-cost and efficient OLEDs. J. Sci. Adv. Mater. Devices 2024, 9, 100707. [Google Scholar] [CrossRef]

- Willert, A.; Tabary, F.Z.; Zubkova, T.; Santangelo, P.E.; Romagnoli, M.; Baumann, R.R. Multilayer additive manufacturing of catalyst-coated membranes for polymer electrolyte membrane fuel cells by inkjet printing. Int. J. Hydrogen Energy 2022, 47, 20973–20986. [Google Scholar] [CrossRef]

- Calvert, P.; Yoshioka, Y.; Jabbour, G. Inkjet printing for building multilayer devices. In Frontiers in Optics (2003), Paper WR2; Optica Publishing Group: Washington, DC, USA, 2003; p. WR2. [Google Scholar] [CrossRef]

- Jeschke, D.; Ahlfs, E.; Krüger, K. Inkjet Printing of Multilayer Capacitors. J. Microelectron. Electron. Packag. 2012, 9, 126–132. [Google Scholar] [CrossRef]

- Technical Data Sheet ABS Sheets. S-Polytec. Available online: https://www.s-polytec.com/media/attachment/file/d/a/data_sheet_abs-sheets.pdf (accessed on 15 July 2025).

- Franck, A. Kunststoff-Kompendium, 1st ed.; Vogel Communications Group GmbH & Co. KG: Würzburg, Germany, 2006. [Google Scholar]

- Kaiser, W. Kunststoffchemie für Ingenieure: Von der Synthese bis zur Anwendung, 3rd ed.; Hanser eLibrary; Hanser Verlag: München, Germany, 2011. [Google Scholar] [CrossRef]

- Liquid Crystal LCP Compound—TECACOMP LCP LDS Black 1014978. Ensinger. Available online: https://www.ensingerplastics.com/en/compounds/-lcp-compound-tecacomp-lcp-lds-black-1049426 (accessed on 15 July 2025).

- Datenblatt VECTRA® E840i LDS. Material Data Center. Available online: https://www.materialdatacenter.com/ms/de/Vectra/Celanese/VECTRA+E840i+LDS/d26150b8/2442 (accessed on 15 July 2025).

- LEXANTM 9030 AND 9030TG SHEET. Sabic Corporation. 2021. Available online: https://www.kapoorplastics.com/download/lexan%E2%84%A2-9030-and-lexan%E2%84%A2-9030-tg-sheet-datasheet.pdf (accessed on 15 July 2025).

- Datasheet XANTARTM LDS 3760. CAMPUSplastics. Available online: https://www.campusplastics.com/campus/en/datasheet/XANTAR%E2%84%A2+LDS+3760/Mitsubishi+Chemical+Group/107/83e9cba2 (accessed on 15 July 2025).

- Datasheet EMERGETM PC 8900. Available online: https://www.materialdatacenter.com/ms/en/tradenames/Emerge/Trinseo/EMERGE%E2%84%A2+PC+8900/a41440a6/703 (accessed on 15 July 2025).

- Plazcryl Plazcast Solid PMMA Sheets. PLAZIT POLYGAL. Available online: https://trekz.de/img/products/laser/specs/acrylat-weiss-datenblatt-de.pdf (accessed on 15 July 2025).

- PEEK LDS Compound—TECACOMP PEEK LDS Black. Ensinger. Available online: https://www.ensingerplastics.com/en/compounds/tecacomp-peek-lds-black (accessed on 15 July 2025).

- PPA Compound—TECACOMP PPA TRM XS Black. Ensinger. Available online: https://www.ensingerplastics.com/de-de/compounds/tecacomp-ppa-trm-xs-mod-black (accessed on 21 July 2025).

- Datasheet ForTii® LDS51B. CAMPUSplastics. Available online: https://www.campusplastics.com/campus/en/datasheet/ForTii%C2%AE+LDS51B/Envalior/50/b2ce808d (accessed on 15 July 2025).

- Juric, D.; Hämmerle, S.; Gläser, K.; Eberhardt, W.; Zimmermann, A. Assembly of Components on Inkjet-Printed Silver Structures by Soldering. IEEE Trans. Compon. Packag. Manuf. Technol. 2019, 9, 156–162. [Google Scholar] [CrossRef]

- Liang, J.; Dariavach, N.; Kelly, V.; Callahan, P.; Barr, G.; Shangguan, D. A study on copper dissolution in liquid lead free solders under static and dynamic conditions. In Proceedings of the IPC APEX Expo 2009; Volume 2, pp. 654–663.

- Berg, H.; Hall, E.L. Dissolution Rates and Reliability Effects of Au, Ag, Ni and Cu in Lead Base Solders. In Proceedings of the 11th Reliability Physics Symposium, April 1973; pp. 10–20. [Google Scholar] [CrossRef]

- Di Maio, D.; Hunt, C.P.; Willis, B. Reduce Copper Dissolution in Lead-Free Assembly; A National Measurement No.110; National Physical Laboratory: London, UK, 2018. [Google Scholar]

- Yeh, P.-Y.; Song, J.-M.; Lin, K.-L. Dissolution behavior of Cu and Ag substrates in molten solders. J. Electron. Mater. 2006, 35, 978–987. [Google Scholar] [CrossRef]

- „Mikroelektronik für Permanente, Nichtinvasice Blutdruckmessung im Ohr“: OLA „An Leiterbahndruck Angepasster Lei-Terbahndruck und AVT-Prozesse“; BMBF-FKZ: 16ES0767K. Hahn-Schickard: Stuttgart, Germany, 2021.

- Werum, K.; Mueller, E.; Keck, J.; Jaeger, J.; Horter, T.; Glaeser, K.; Buschkamp, S.; Barth, M.; Eberhardt, W.; Zimmermann, A. Aerosol Jet Printing and Interconnection Technologies on Additive Manufactured Substrates. J. Manuf. Mater. Process. 2022, 6, 119. [Google Scholar] [CrossRef]

- Nassiet, V.; Hassoune-Rhabbour, B.; Tramis, O.; Petit, J.-A. 22—Electrical and electronics. In Adhesive Bonding, 2nd ed.; Adams, R.D., Ed.; Woodhead Publishing Series in Welding and Other Joining Technologies; Woodhead Publishing: Cambridge, UK, 2021; pp. 719–761. [Google Scholar] [CrossRef]

- Yang, M.; Liu, Y.; Zhang, D.; Cao, C.; Zhao, X.; Huo, Y. Size-Controlled Low-Melting-Point-Alloy Particle-Incorporated Transient Liquid-Phase Epoxy Composite Conductive Adhesive with High Performances. ACS Appl. Polym. Mater. 2023, 5, 2760–2773. [Google Scholar] [CrossRef]

- Lall, P.; Sarwar, M.G.; Miller, S. Reliability of Direct Write Additively Printed Sustainable Flexible Circuitry With ECA Under Sustained High-Temperature Operation. In Proceedings of the ASME 2024 International Technical Conference and Exhibition on Packaging and Integration of Electronic and Photonic Microsystems, San Jose, CA, USA, 8–10 October 2024. [Google Scholar] [CrossRef]

- Lall, P.; Kulkarni, S.; Miller, S. Performance Analysis of Screen-Printed Functional Circuits on Biodegradable PET Substrates Using Low-Temperature ECA for SMD Component Attachment. In Proceedings of the 2024 23rd IEEE Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems (ITherm), Aurora, CO, USA, 28–31 May 2024; pp. 1–10. [Google Scholar] [CrossRef]

- Grözinger, T. Untersuchungen zu Zuverlässigkeit und Lebensdauermodellen für Gelötete SMD auf Spritzgegossenen Schaltungsträgern; Dr. Hut Verlag: Stuttgart, Germany, 2015. [Google Scholar]

- Kim, K.-Y.; Jeong, H.; Myung, W.-R.; Jung, S.-B. Microstructures and Drop Impact Test of SAC305, Sn58%Bi and Epoxy Sn58%Bi Solder Joint on the OSP Surface Finished PCB Substrate. J. Weld. Join. 2018, 36, 14–20. [Google Scholar] [CrossRef]

- Der Heilige Gral des Lötens: Niedertemperatur-Reflowlöten für den Hochtemperatur-Einsatz. Indium Corporation. Available online: https://www.indium.com/blog/the-holy-grail-of-soldering-low-temperature-reflow-high-temperature-use/ (accessed on 15 July 2025).

- Tilford, T.; Stoyanov, S.; Birch, R.; Bailey, C. Numerical Analysis of the Design and Manufacture of Inkjet Printed Electronics Packaging. In Proceedings of the 2018 IEEE 20th Electronics Packaging Technology Conference (EPTC), Singapore, 4–7 December 2018; pp. 167–172. [Google Scholar] [CrossRef]

- Tilford, T.; Stoyanov, S.; Braun, J.; Janhsen, J.C.; Patel, M.K.; Bailey, C. Comparative Reliability of Inkjet-Printed Electronics Packaging. IEEE Trans. Compon. Packag. Manuf. Technol. 2021, 11, 351–362. [Google Scholar] [CrossRef]

- Niittynen, J.; Kiilunen, J.; Putaala, J.; Pekkanen, V.; Mäntysalo, M.; Jantunen, H.; Lupo, D. Reliability of ICA attachment of SMDs on inkjet-printed substrates. Microelectron. Reliab. 2012, 52, 2709–2715. [Google Scholar] [CrossRef]

- Putaala, J.; Hannu, J.; Kunnari, E.; Mäntysalo, M.; Nousiainen, O.; Jantunen, H. Reliability of SMD interconnections on flexible low-temperature substrates with inkjet-printed conductors. Microelectron. Reliab. 2014, 54, 272–280. [Google Scholar] [CrossRef]

- IGF-Vorhaben-Nr. 20337 N: Kontaktierung Gedruckter Leitfähiger Strukturen (KonsDruckt); Abschlussbericht IGF-Vorhaben-Nr. 20337 N, Stuttgart, Germany. 2021. Available online: https://www.hahn-schickard.de/fileadmin/media/Metanavigation/Mediathek/Publikationen_-_wissenschaftlich/PDF_Abschlussberichte/S/2022_Schlussbericht_AiF_KonsDruckt.pdf (accessed on 19 August 2025).

- Jäger, J.; Buschkamp, S.; Werum, K.; Gläser, K.; Grözinger, T.; Eberhardt, W.; Zimmermann, A. Contacting Inkjet-Printed Silver Structures and SMD by ICA and Solder. IEEE Trans. Compon. Packag. Manuf. Technol. 2022, 12, 1232–1240. [Google Scholar] [CrossRef]

- Wankhede, S.P.; Alshehri, A.H.; Du, X. Encapsulating and inkjet-printing flexible conductive patterns on a fluoroelastomer for harsh hydrocarbon fluid environments. J. Mater. Chem. C 2023, 11, 3964–3980. [Google Scholar] [CrossRef]

- TactoTek’s IMSE® Technology. Available online: https://www.tactotek.com/technology (accessed on 14 August 2025).

- KURZ Automotive: IME Sensorintegration. KURZ Automotive. Available online: https://www.kurz-automotive.com/verfahren/ime-in-mold-electronics (accessed on 14 August 2025).

- Lall, P.; Kulkarni, S.; Miller, S. Screen-Printed Thermoformed Circuits Performance and Reliability under Sustained High Temperatures for In-Mold Electronics. In Proceedings of the 2024 23rd IEEE Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems (ITherm), Aurora, CO, USA, 28–31 May 2024; pp. 1–12. [Google Scholar] [CrossRef]

- Kulkarni, S.; Harsha, A.; Sarwar, M.G.; Lall, P.; Miller, S. Additively Manufactured in-Mold Electronics Reliability Under Thermal Cycling and Sustained High Temperature. In Proceedings of the 2025 IEEE 75th Electronic Components and Technology Conference (ECTC), Dallas, TX, USA, 27–30 May 2025; pp. 718–725. [Google Scholar] [CrossRef]

- Lall, P.; Sarwar, M.G.; Miller, S. Reliability of Additively Printed In-Mold Electronics Using ECA in Sustained High-Temperature Operation. In Proceedings of the 2024 23rd IEEE Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems (ITherm), Aurora, CO, USA, 28–31 May 2024; pp. 1–6. [Google Scholar] [CrossRef]

- Fechtelpeter, C.; Jurgenhake, C.; Mager, T.; Dumitrescu, R.; Fritz, K.-P.; Grozinger, T.; Wild, P.; Muller, H.; Zimmermann, A. Reliability in MID. In Proceedings of the 2016 12th International Congress Molded Interconnect Devices (MID), Wuerzburg, Germany, 28–29 September 2016; pp. 1–6. [Google Scholar] [CrossRef]

- Goth, C.; Putzo, S.; Franke, J. Aerosol Jet printing on rapid prototyping materials for fine pitch electronic applications. In Proceedings of the 2011 IEEE 61st Electronic Components and Technology Conference (ECTC), Lake Buena Vista, FL, USA, 31 May–3 June 2011; pp. 1211–1216. [Google Scholar] [CrossRef]

- Kuhn, T.; Franke, J. Influences on crack initiation in conductor tracks on three-dimensional thermoplastic substrates. In Proceedings of the 2017 Pan Pacific Microelectronics Symposium (Pan Pacific), Kauai, HI, USA, 6–9 February 2017; pp. 1–7. Available online: https://ieeexplore.ieee.org/document/7859562 (accessed on 14 August 2025).

- Braeuer, P.; Wurzer, L.; Kuhn, T.; Knoeller, A.; Mueller, H.; Eberhardt, W.; Zimmermann, A.; Franke, J. Reliability of Mechatronic Integrated Devices Regarding Failure Mechanisms. In Proceedings of the 2020 43rd International Spring Seminar on Electronics Technology (ISSE), Demanovska Valley, Slovakia, 14–15 May 2020; pp. 1–6. [Google Scholar] [CrossRef]

- lds_mid_designrules_en.pdf. Available online: https://www.lpkf.com/fileadmin/mediafiles/user_upload/products/pdf/EQ/3D-MID-LDS/lds_mid_designrules_en.pdf (accessed on 14 August 2025).

- Zimmermann, A. Aufbau- und Verbindungstechnik auf LDS-MID. In PLUS—Produktion von Leiterplatten und Systemen; Leuze Verlag Saulgau: Bad Saulgau, Germany, 2009; pp. 621–632. [Google Scholar]

- Reinhardt, A.; Franke, J.; Goth, C. Reliability of micromechatronic systems with chip on molded interconnected devices and flexible substrates. In Proceedings of the 2010 12th Electronics Packaging Technology Conference, Singapore, 8–10 December 2010; pp. 79–83. [Google Scholar] [CrossRef]

- Braeurer, P.; Kuhn, T.; Mueller, M.; Franke, J. Reliability of Molded Interconnect Devices Regarding Crack Initiation and Overmolding. In Proceedings of the 2019 42nd International Spring Seminar on Electronics Technology (ISSE), Wroclaw, Poland, 15–19 May 2019; pp. 1–6. [Google Scholar]

- IGF-Vorhaben-Nr. 19754 N: Metallisierungssysteme für Leiterbahnen auf Polymerbasierten 3D-Schaltungsträgern mit erhöhter Zuverlässigkeit (MetaZu), Stuttgart, Germany. 2020. Available online: https://www.hahn-schickard.de/fileadmin/media/Metanavigation/Mediathek/Publikationen_-_wissenschaftlich/PDF_Abschlussberichte/S/2020_MetaZu_Schlussbericht.pdf (accessed on 19 August 2025).

- IGF-Vorhaben-Nr. 21862 N/2: Nickelfreie Metallisierungssysteme auf 3D MID Substratwerkstoffen (NiMm3), Stuttgart, Germany. 2023. Available online: https://www.hahn-schickard.de/fileadmin/media/Metanavigation/Mediathek/Publikationen_-_wissenschaftlich/PDF_Abschlussberichte/S/2025_Schlussbericht_NiMm3_HS_FAPS_final.pdf (accessed on 19 August 2025).

| Polymer Type | Typical Molding Temperatures |

|---|---|

| PP (polypropylene) | 190–220 °C |

| PC (polycarbonate) | 260–340 °C |

| PET (polyethylene terephthalate) | 250–260 °C |

| PMMA (polymethyl methacrylate) | 240–280 °C |

| TPU (thermoplastic polyurethane) | 190–210 °C |

| Conductive | Semiconductive | Dielectric |

|---|---|---|

| Ag, Cu, Ni | OSC | SiO2 |

| PEDOT:PSS | P3HT | PVA |

| CNT | PQT | PVP |

| Graphene | PMMA | |

| ITO | Epoxy |

| Parameter | Scale |

|---|---|

| Print resolution | 30–100 µm |

| Print thickness | 3–30 µm |

| Printing speed | 9.96–1660 mm/s |

| Solution viscosity | 0.500–5 Pa·s |

| Solution surface tension | 38–47 mN/m |

| Parameter | Scale |

|---|---|

| Print resolution | 5–100 µm |

| Print thickness | >100 µm |

| Printing speed | 100 dots/s |

| Solution viscosity | 100 Pa·s |

| Solution surface tension | 20–40 mN/m |

| Parameter | Scale |

|---|---|

| Print resolution | 15–100 µm |

| Print thickness | 0.01–0.5 µm |

| Printing speed | 5.48–1377.8 mm/s |

| Solution viscosity | 0.001–0.10 Pa⋅s |

| Solution surface tension | 15–25 mN/m |

| Parameter | Scale |

|---|---|

| Print resolution | >85 nm |

| Print thickness | 10 nm–5 µm |

| Printing speed | 200 mm/s |

| Solution viscosity | 0.001–2.5 Pa·s |

| Solution surface tension | 10–20 mN/m |

| Solder Type | Composition | Melting Point |

|---|---|---|

| SAC305 | 96.5Sn/3Ag/0.5Cu | 217 °C |

| SnBi (Ag) | 42Sn/57Bi/1Ag | 138 °C |

| Indium | 52In/48Sn | 118 °C |

| Minimum Pitch [µm] | Minimum Line Width [µm] | 3D Capability | Layout Changes | Ampacity | Vias | Source | ||

|---|---|---|---|---|---|---|---|---|

| IME | Inkjet printing | 20 | 10 | −/+ | ++ | − | − | [12,157,158,159,160,161] |

| Screen printing | 50 | 30 | + * | − | −/+ | + | [12,53,161,162] | |

| Print-based MID | Valve jetting | n/a | 400 | − | ++ | ++ | + | [163,164] |

| Inkjet printing | 20 | 10 | −/+ | ++ | − | − | [157,158,159,160] | |

| Aerosol jet printing | 20 | 10 | ++ | ++ | −− | − | [161,165,166] | |

| Laser-based MID | LDS | 70 | 50 | ++ | ++ | −/+ | + | [79,93,167] |

| LDS thermoset | 60 | 30 | ++ | ++ | −/+ | + | [10,168] | |

| MID resin | 100 | 100 | ++ | ++ | −/+ | + | [11] | |

| MID lacquer | 60 | 60 | + | ++ | −/+ | −/+ | [169,170,171] | |

| Alternative MID | Hot embossing | 300 | 400 | − | +/− | ++ | − | [64,172] |

| 2-Shot MID | 150–250 | 150–250 | +/− | −− | −/+ | + | [173,174,175] | |

| FlameCon and PlasmaDust | >200 | n/a | + | + | + | − | [64,125,126,128,176] | |

| Substrate Material | Shape Resistance/DTUL HDT A (@1,8 MPa) [°C] | Tmelt [°C] | Source | Compatible with SnBi Soldering | Compatible with SAC Soldering |

|---|---|---|---|---|---|

| ABS | 80–105 | 130 | [182,183,184] | x | x |

| ABS (TF) | 101 | - | [182] | x | x |

| LCP | <250 | 320–325 | [183] | ✔ | ✔ |

| LCP (LDS) | 221–274 | 310–335 | [185,186] | ✔ | ✔ |

| PC | 120–135 | 148–230 | [183,184] | o | x |

| PC (TF) | 127 | - | [187] | o | x |

| PC (LDS) | 86–103 | - | [188,189] | o | x |

| PMMA | 75–105 | 110 | [183,184] | x | x |

| PMMA (TF) | 83–105 | - | [190] | x | x |

| PETG | 65 | 100 | [183,184] | x | x |

| PEEK | 152–280 | 340–345 | [183,184] | ✔ | ✔ |

| PEEK (LDS) | 255 | 343 | [191] | ✔ | ✔ |

| PPA | 307 | 315 | [192] | ✔ | o |

| PPA (LDS) | 290 | - | [193] | ✔ | o |

| PBT | 50–65 | 220–225 | [183,184] | o | x |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Werum, K.; Eberhardt, W.; Reenaers, D.; Mager, T.; Endl, M.; Zimmermann, A.; Deferme, W. Assembly and Interconnection Technologies for 3D Plastic Circuit Carriers: An Overview of Technologies, Materials, and Applications. Micromachines 2025, 16, 980. https://doi.org/10.3390/mi16090980

Werum K, Eberhardt W, Reenaers D, Mager T, Endl M, Zimmermann A, Deferme W. Assembly and Interconnection Technologies for 3D Plastic Circuit Carriers: An Overview of Technologies, Materials, and Applications. Micromachines. 2025; 16(9):980. https://doi.org/10.3390/mi16090980

Chicago/Turabian StyleWerum, Kai, Wolfgang Eberhardt, Dieter Reenaers, Thomas Mager, Mika Endl, André Zimmermann, and Wim Deferme. 2025. "Assembly and Interconnection Technologies for 3D Plastic Circuit Carriers: An Overview of Technologies, Materials, and Applications" Micromachines 16, no. 9: 980. https://doi.org/10.3390/mi16090980

APA StyleWerum, K., Eberhardt, W., Reenaers, D., Mager, T., Endl, M., Zimmermann, A., & Deferme, W. (2025). Assembly and Interconnection Technologies for 3D Plastic Circuit Carriers: An Overview of Technologies, Materials, and Applications. Micromachines, 16(9), 980. https://doi.org/10.3390/mi16090980