Hybrid Actuation MEMS Micromirror with Decoupled Piezoelectric Fast Axis and Electromagnetic Slow Axis for Crosstalk Suppression

Abstract

1. Introduction

2. Principle and Design

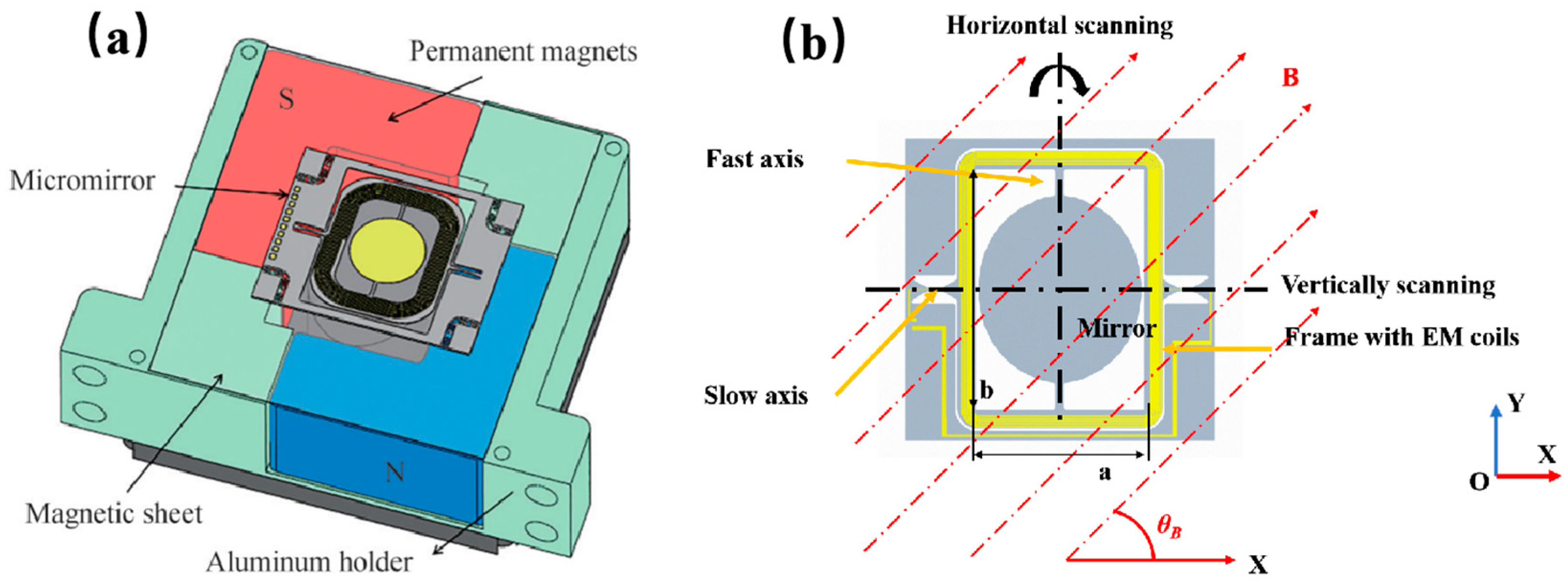

2.1. Electromagnetic Micromirror

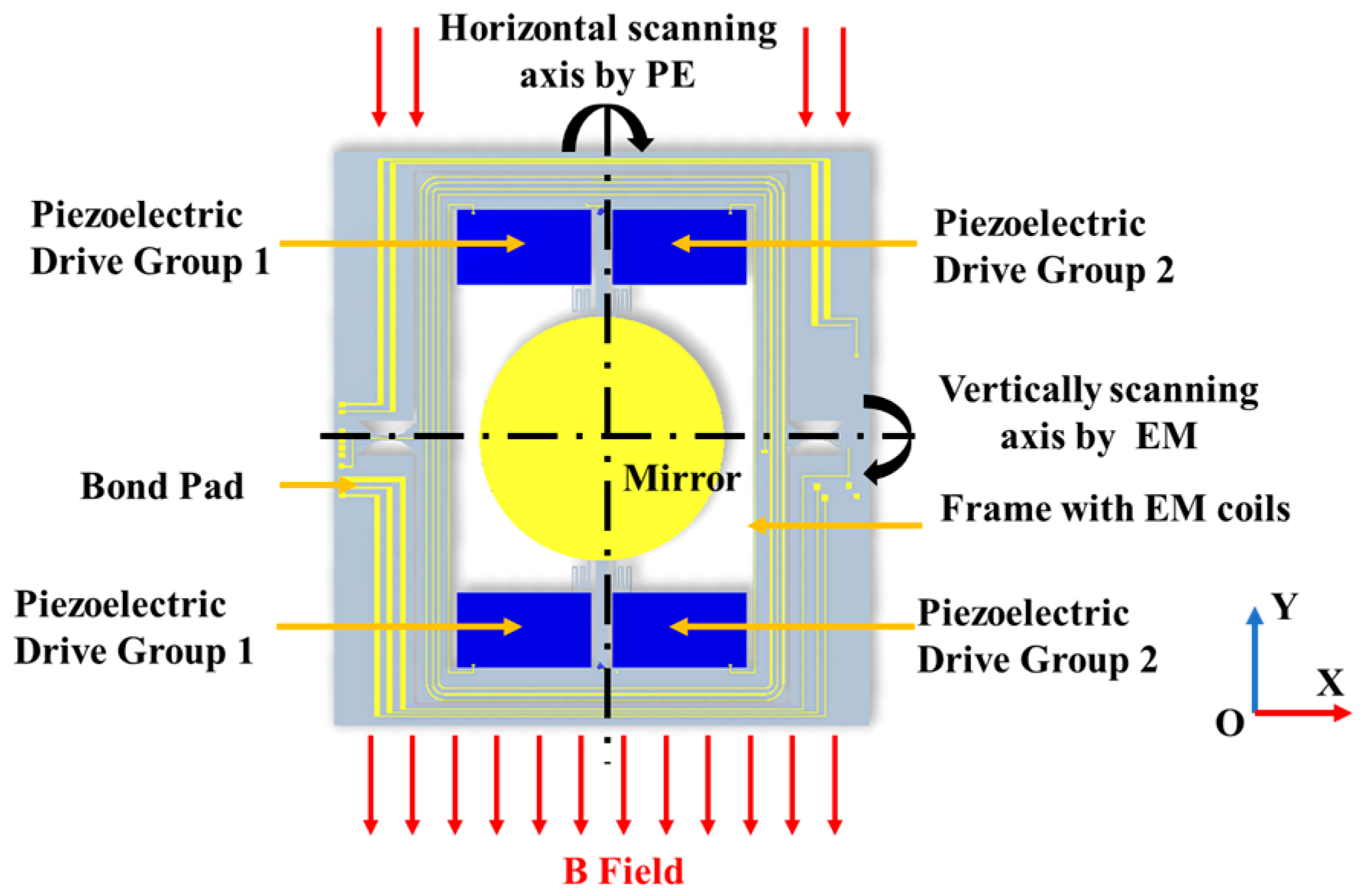

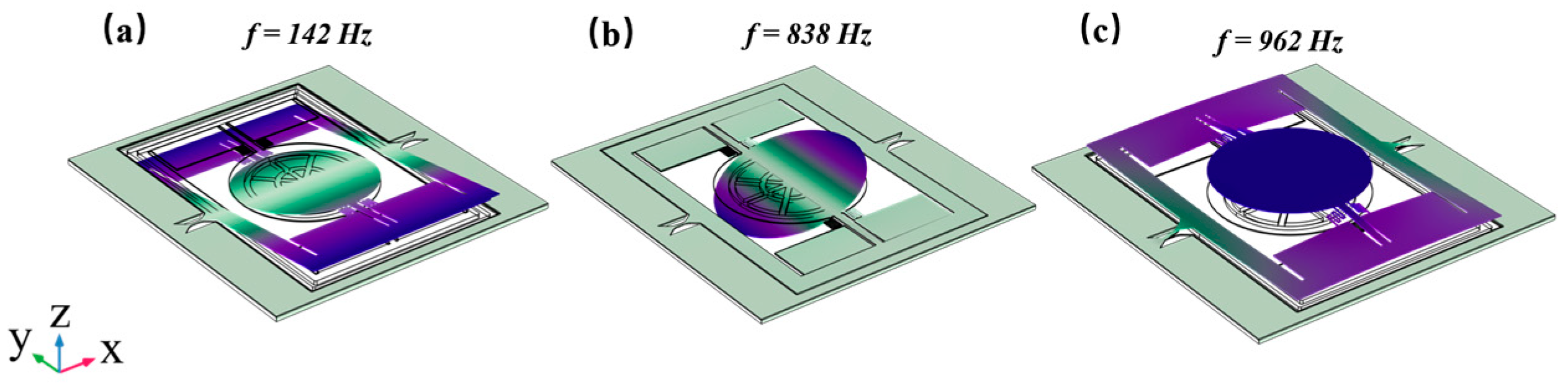

2.2. Hybrid-Driven Micromirror

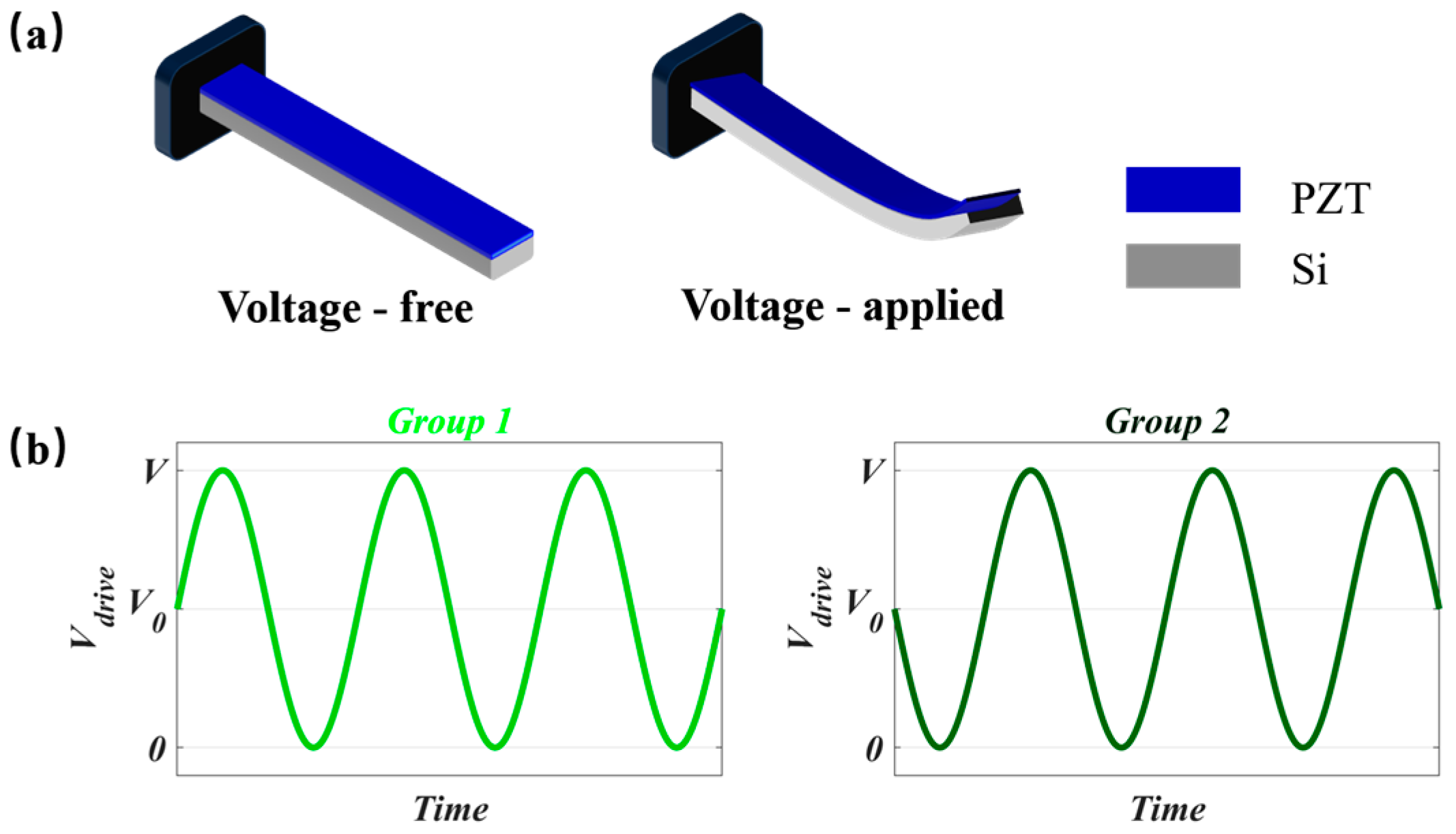

2.2.1. Piezoelectric Drive

2.2.2. EM Drive

3. Device Fabrication

4. Discussion

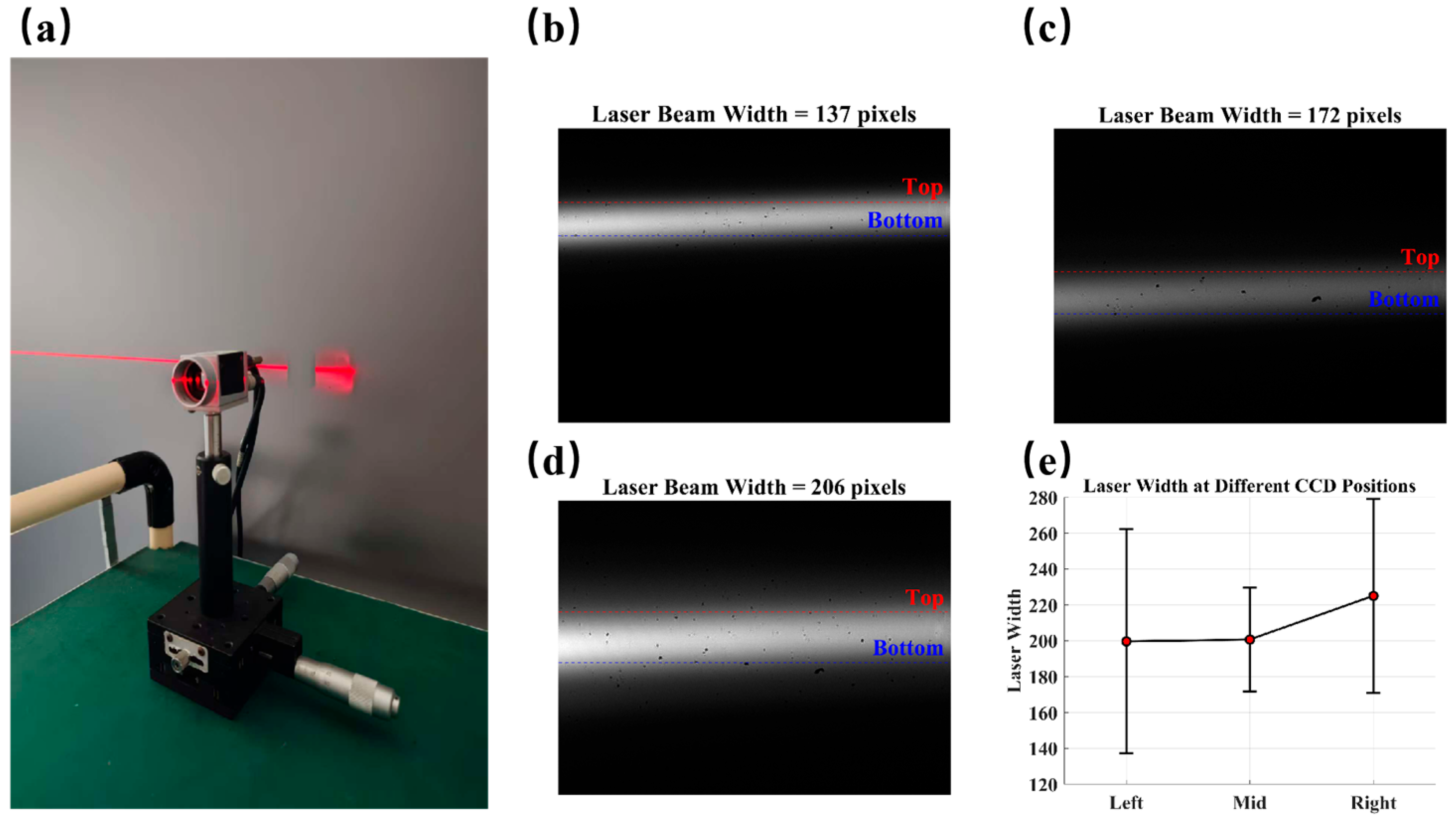

4.1. Experimental Setup

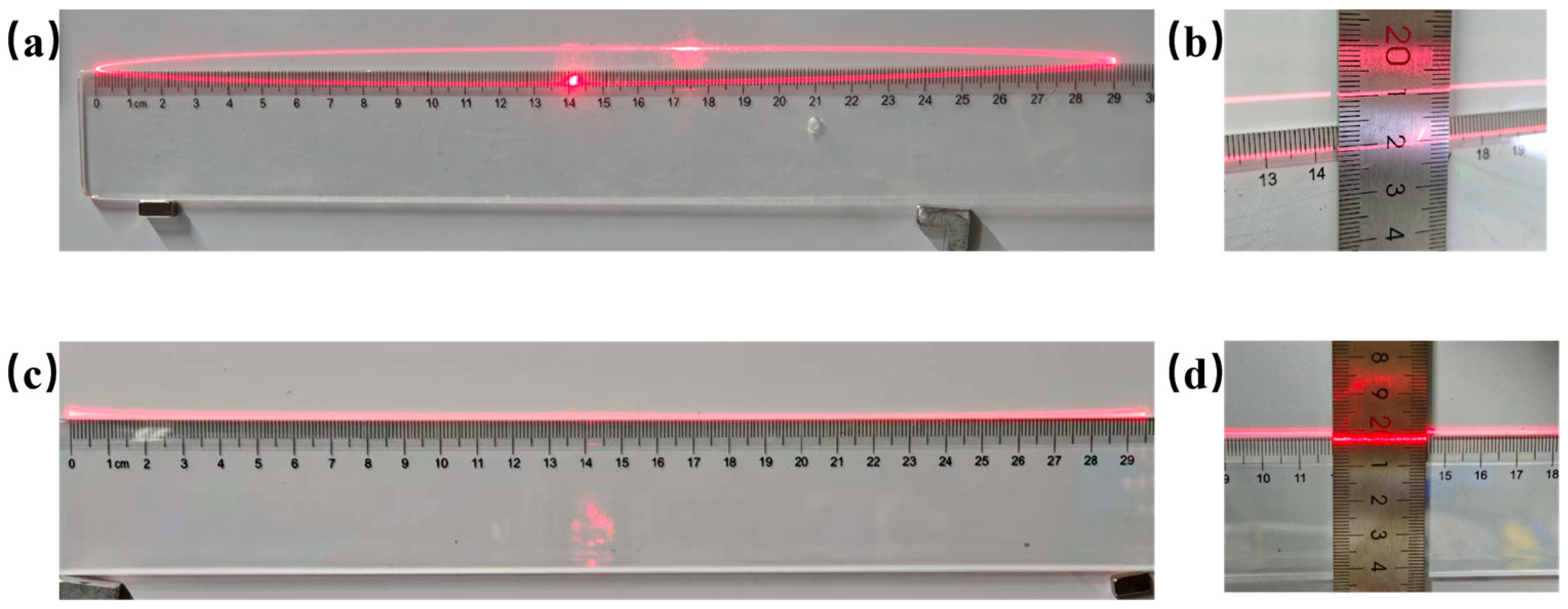

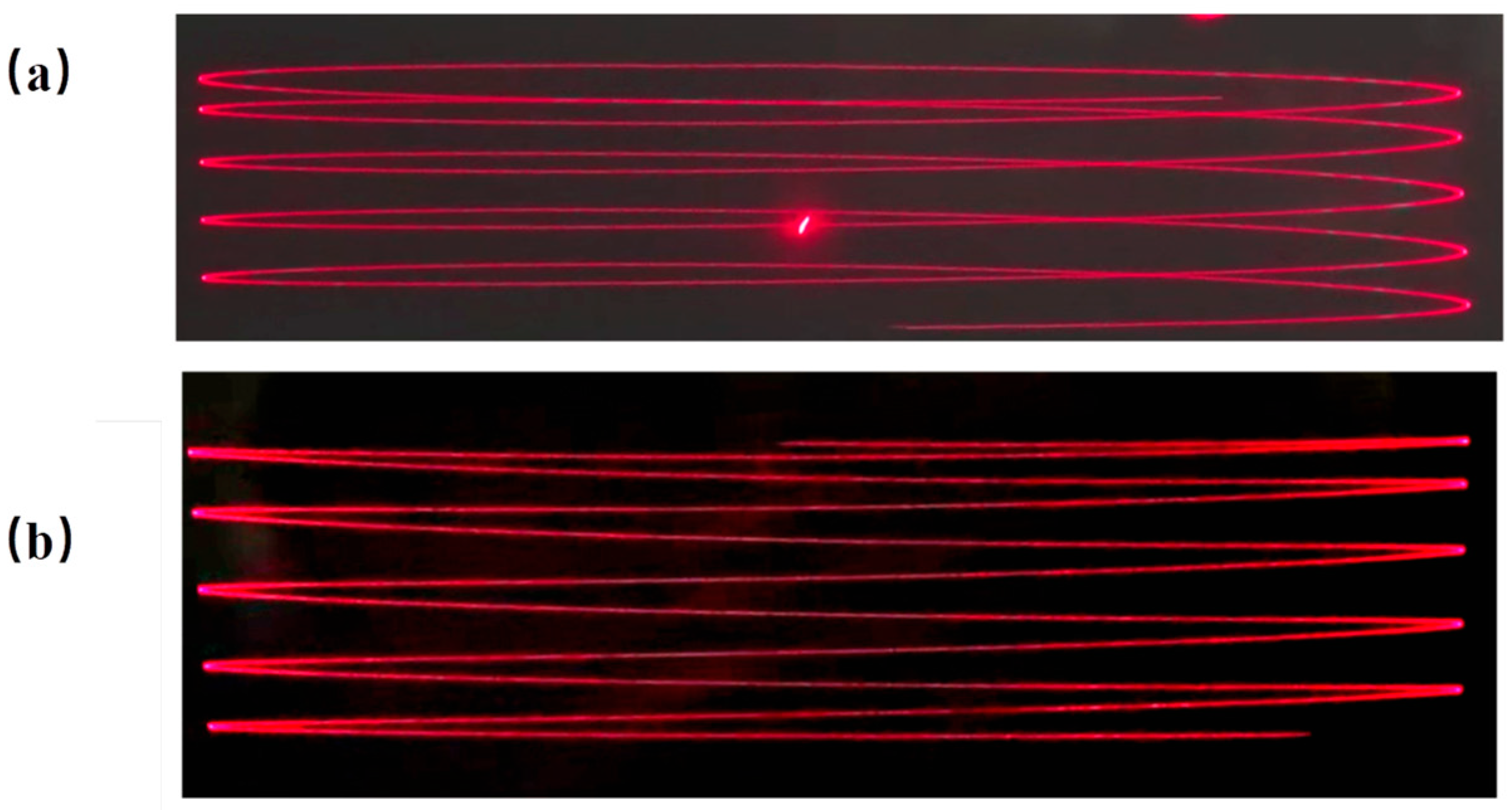

4.2. Scan Line Test

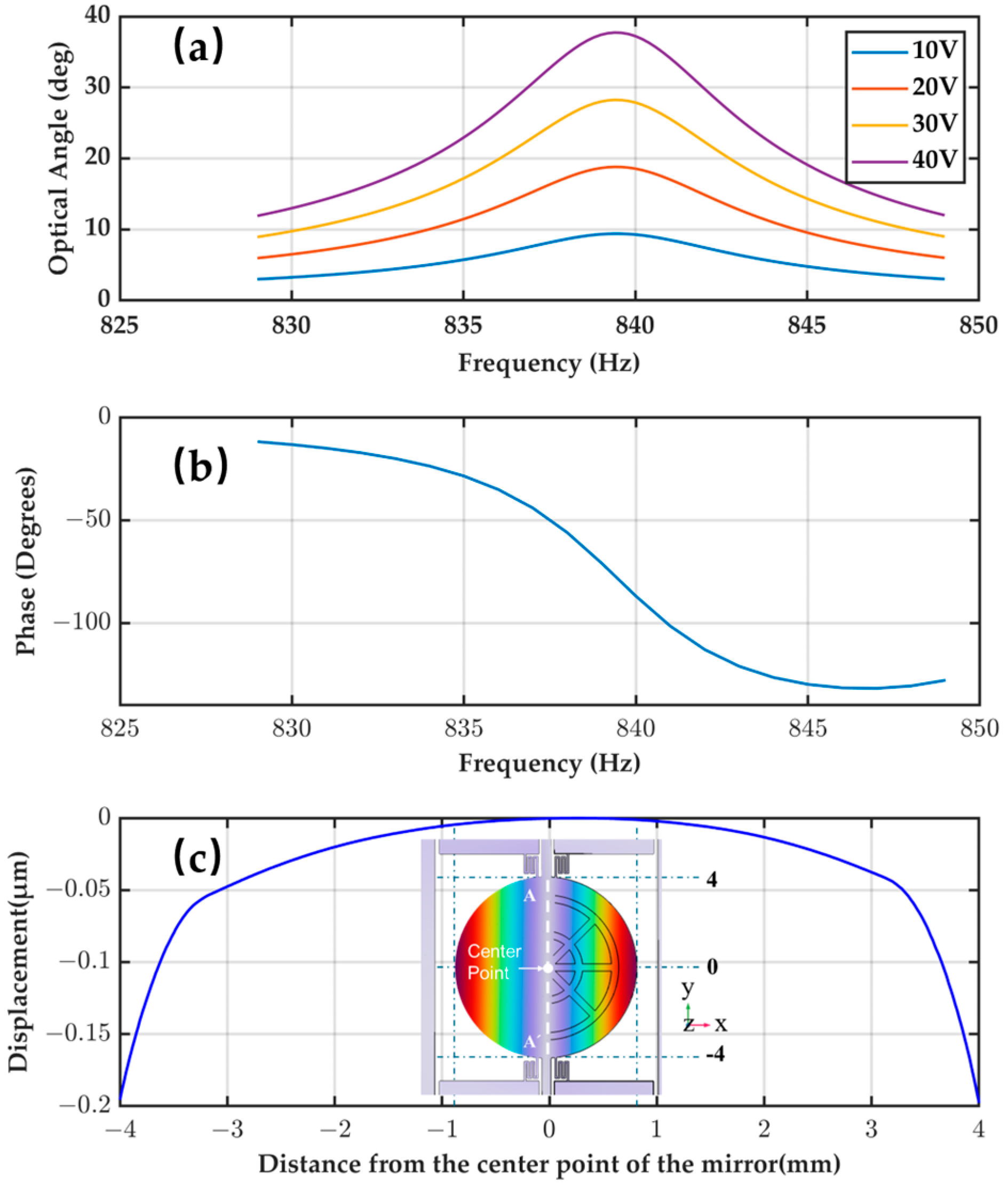

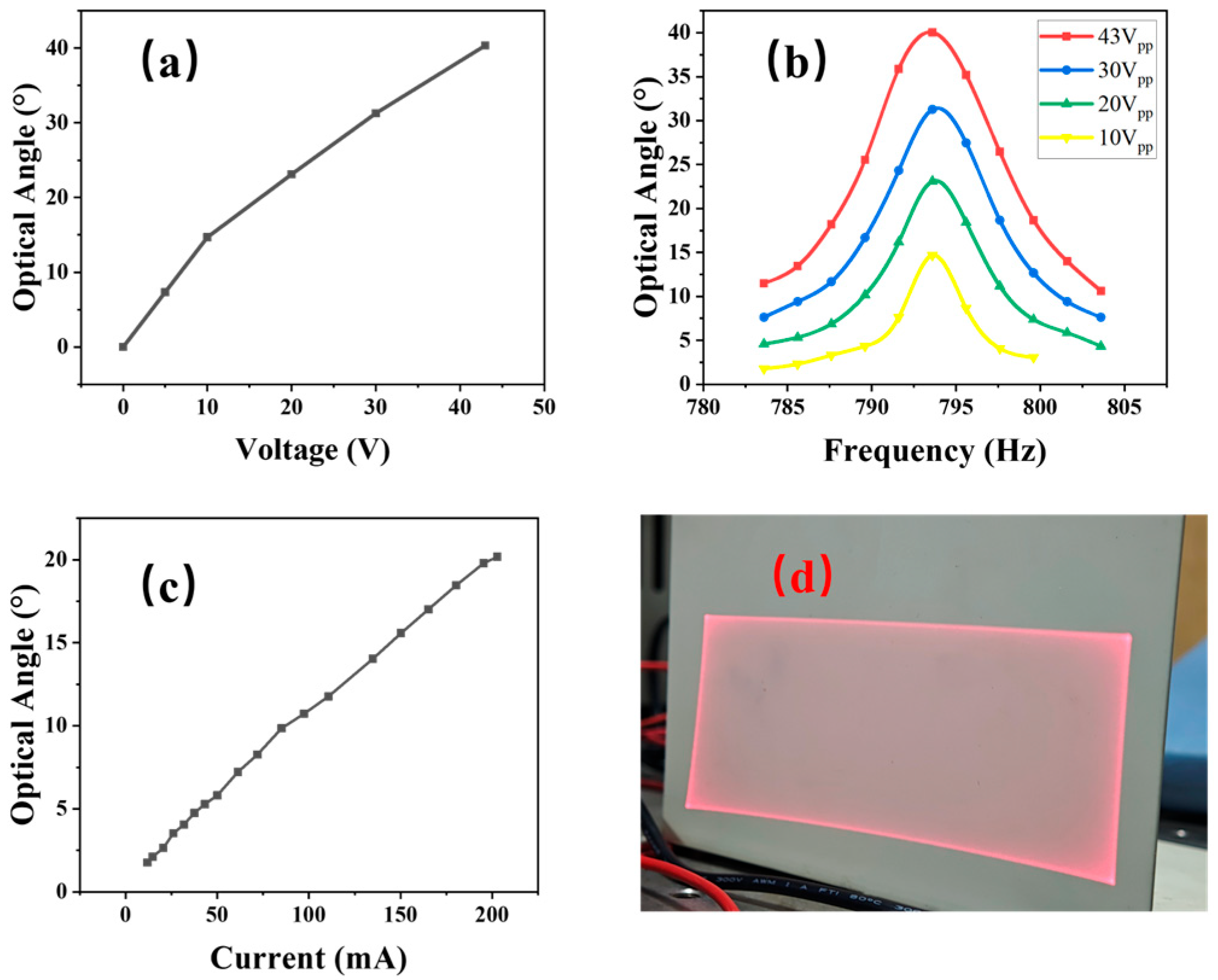

4.3. Micromirror Characterization

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, D.; Watkins, C.; Xie, H. MEMS mirrors for LiDAR: A review. Micromachines 2020, 11, 456. [Google Scholar] [CrossRef] [PubMed]

- An, Y.; Sun, B.; Wang, P.; Xiao, L.; Liu, H.; Xie, H. A 1× 20 MEMS mirror array with large scan angle and low driving voltage for optical wavelength-selective switches. Sens. Actuators A Phys. 2021, 324, 112689. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, G.; You, Z. Design rules for dense and rapid Lissajous scanning. Microsyst. Nanoeng. 2020, 6, 101. [Google Scholar] [CrossRef] [PubMed]

- Ahmad, M.; Bahri, M.; Sawan, M. MEMS Micromirror Actuation Techniques: A Comprehensive Review of Trends, Innovations, and Future Prospects. Micromachines 2024, 15, 1233. [Google Scholar] [CrossRef] [PubMed]

- Naono, T.; Fujii, T.; Esashi, M.; Tanaka, S. Non-resonant 2-D piezoelectric MEMS optical scanner actuated by Nb doped PZT thin film. Sens. Actuators A Phys. 2015, 233, 147–157. [Google Scholar] [CrossRef]

- Baran, U.; Brown, D.; Holmstrom, S.; Balma, D.; Davis, W.O.; Muralt, P.; Urey, H. Resonant PZT MEMS scanner for high-resolution displays. J. Microelectromech. Syst. 2012, 21, 1303–1310. [Google Scholar] [CrossRef]

- Merli, M.; Mendicino, G.; Carminati, R.; Boni, N. Modeling and experimental validation of hysteretic scan behavior of quasi-static piezoelectric micromirror. In Proceedings of the MOEMS and Miniaturized Systems XXI, San Francisco, CA, USA, 22 January–28 February 2022; pp. 167–178. [Google Scholar]

- Shan, Y.; Qian, L.; He, K.; Chen, B.; Wang, K.; Li, W.; Shen, W. Electrostatic mems two-dimensional scanning micromirrors integrated with piezoresistive sensors. Micromachines 2024, 15, 1421. [Google Scholar] [CrossRef] [PubMed]

- Hou, J.; Li, H.; Qian, L.; Yu, H.; Shen, W. Control of a Micro-Electro-Mechanical System Fast Steering Mirror with an Input Shaping Algorithm. Micromachines 2024, 15, 1215. [Google Scholar] [CrossRef] [PubMed]

- Tanguy, Q.A.; Gaiffe, O.; Passilly, N.; Cote, J.-M.; Cabodevila, G.; Bargiel, S.; Lutz, P.; Xie, H.; Gorecki, C. Real-time Lissajous imaging with a low-voltage 2-axis MEMS scanner based on electrothermal actuation. Opt. Express 2020, 28, 8512–8527. [Google Scholar] [CrossRef] [PubMed]

- Li, L.; Bauer, R.; Brown, G.; Uttamchandani, D. A symmetric hybrid MEMS scanner with electrothermal and electrostatic actuators. In Proceedings of the 16th International Conference on Optical MEMS and Nanophotonics, Istanbul, Turkey, 8–11 August 2011; pp. 163–164. [Google Scholar]

- Koh, K.H.; Lee, C. A two-dimensional MEMS scanning mirror using hybrid actuation mechanisms with low operation voltage. J. Microelectromech. Syst. 2012, 21, 1124–1135. [Google Scholar] [CrossRef]

- Eun, Y.; Na, H.; Jeong, B.; Lee, J.-i.; Kim, J. Bidirectional electrothermal electromagnetic torsional microactuators for large angular motion at dc mode and high frequency resonance mode operation. J. Micromech. Microeng. 2009, 19, 065023. [Google Scholar] [CrossRef]

- Alneamy, A.; Khater, M.; Al-Ghamdi, M.; Park, S.; Heppler, G.R.; Abdel-Rahman, E.M. Dual actuation micro-mirrors. J. Micromech. Microeng. 2018, 28, 075014. [Google Scholar] [CrossRef]

- Hwang, J.-Y.; Ji, C.-H. Bulk PZT actuator based scanning micromirror with integrated deflection angle sensor. In Proceedings of the 2019 20th International Conference on Solid-State Sensors, Actuators and Microsystems & Eurosensors XXXIII (TRANSDUCERS & EUROSENSORS XXXIII), Berlin, Germany, 23–27 June 2019; pp. 1537–1540. [Google Scholar]

- Gu-Stoppel, S.; Janes, J.; Quenzer, H.; Hofmann, U.; Kaden, D.; Wagner, B.; Benecke, W. Design, fabrication and characterization of low-voltage piezoelectric two-axis gimbal-less microscanners. In Proceedings of the 2013 Transducers & Eurosensors XXVII: The 17th International Conference on Solid-State Sensors, Actuators and Microsystems (TRANSDUCERS & EUROSENSORS XXVII), Barcelona, Spain, 16–20 June 2013; pp. 2489–2492. [Google Scholar]

- Liu, Y.; Wang, L.; Su, Y.; Zhang, Y.; Wang, Y.; Wu, Z. AlScN piezoelectric MEMS mirrors with large field of view for LiDAR application. Micromachines 2022, 13, 1550. [Google Scholar] [CrossRef]

- Park, Y.; Moon, S.; Lee, J.; Kim, K.; Lee, S.-J.; Lee, J.-H. Gimbal-less two-axis electromagnetic microscanner with twist mechanism. Micromachines 2018, 9, 219. [Google Scholar] [CrossRef]

- Park, Y.; Moon, S.; Lee, J.; Kim, K.; Lee, S.-J.; Lee, J.H. Via-less two-axis electromagnetic micro scanner based on dual radial magnetic fields. IEEE Photonics Technol. Lett. 2018, 30, 443–446. [Google Scholar] [CrossRef]

- Fang, X.-Y.; Tu, E.-Q.; Zhou, J.-F.; Li, A.; Zhang, W.-M. A 2D mems crosstalk-free electromagnetic micromirror for lidar application. J. Microelectromechanical Syst. 2024, 33, 559–567. [Google Scholar] [CrossRef]

- Qian, L.; Shan, Y.; Wang, J.; Li, H.; Wang, K.; Yu, H.; Zhou, P.; Shen, W. Experimental investigation of vibration isolator for large aperture electromagnetic MEMS micromirror. Micromachines 2023, 14, 1490. [Google Scholar] [CrossRef] [PubMed]

- Cheng, H.; Ouyang, J.; Kanno, I. Probing domain switching dynamics in ferroelectric thick films by small field e31, f piezoelectric measurement. Appl. Phys. Lett. 2017, 111, 022904. [Google Scholar] [CrossRef]

- Ding, X.; Guo, H.; Qu, Z.; Wei, X.; Wang, J.; You, Z. An efficient and noticeable wet etching method for PZT and its application in scanning mirrors. Sens. Actuators A Phys. 2024, 379, 115987. [Google Scholar] [CrossRef]

| Design Parameter | Units | |

|---|---|---|

| Mirror diameter | 8 | mm |

| Fast-axis width | 400 | μm |

| Fast-axis length | 3500 | μm |

| Piezoelectric width | 4.3 | mm |

| Piezoelectric length | 2.4 | mm |

| e31 | 15 | C/m2 |

| Slow-axis width | 145 | μm |

| Slow-axis length | 1500 | μm |

| References | Gu-Stoppel [16] | Liu [17] | Park [18] | Park [19] | Fang [20] | This study |

|---|---|---|---|---|---|---|

| Mirror diameter | 1 mm | 3 mm | 3 mm | 3 mm | 7.2 mm | 8 mm |

| Scan method | Lissajous | Lissajous | Raster | Raster | Raster | Raster |

| Principle | PE | PE | EM | EM | EM | PE |

| Drive signal | 4 V | 30 V | 353 mA | 188 mA | 84.9 mA | 43 V |

| Frequency | 27 kHz | 2061 Hz | 902 Hz | 1635 Hz | 712 Hz | 792 Hz |

| Angle | 3.4° | 32.8° | 22° | 50.6° | 35.2° | 40° |

| Decoupling effect | No coupling observed at 3.4° | No coupling observed at 32.8° | Reduced to 0.97% | Reduced to 0.45% | No coupling observed at 20° | No coupling observed at 40° |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, H.; Hou, J.; Gong, Z.; Yu, H.; Liu, Y.; Shen, W. Hybrid Actuation MEMS Micromirror with Decoupled Piezoelectric Fast Axis and Electromagnetic Slow Axis for Crosstalk Suppression. Micromachines 2025, 16, 1072. https://doi.org/10.3390/mi16091072

Li H, Hou J, Gong Z, Yu H, Liu Y, Shen W. Hybrid Actuation MEMS Micromirror with Decoupled Piezoelectric Fast Axis and Electromagnetic Slow Axis for Crosstalk Suppression. Micromachines. 2025; 16(9):1072. https://doi.org/10.3390/mi16091072

Chicago/Turabian StyleLi, Haoxiang, Jiapeng Hou, Zheng Gong, Huijun Yu, Yue Liu, and Wenjiang Shen. 2025. "Hybrid Actuation MEMS Micromirror with Decoupled Piezoelectric Fast Axis and Electromagnetic Slow Axis for Crosstalk Suppression" Micromachines 16, no. 9: 1072. https://doi.org/10.3390/mi16091072

APA StyleLi, H., Hou, J., Gong, Z., Yu, H., Liu, Y., & Shen, W. (2025). Hybrid Actuation MEMS Micromirror with Decoupled Piezoelectric Fast Axis and Electromagnetic Slow Axis for Crosstalk Suppression. Micromachines, 16(9), 1072. https://doi.org/10.3390/mi16091072