Reduction of Visual Artifacts in Laser Beam Scanning Displays

Abstract

1. Introduction

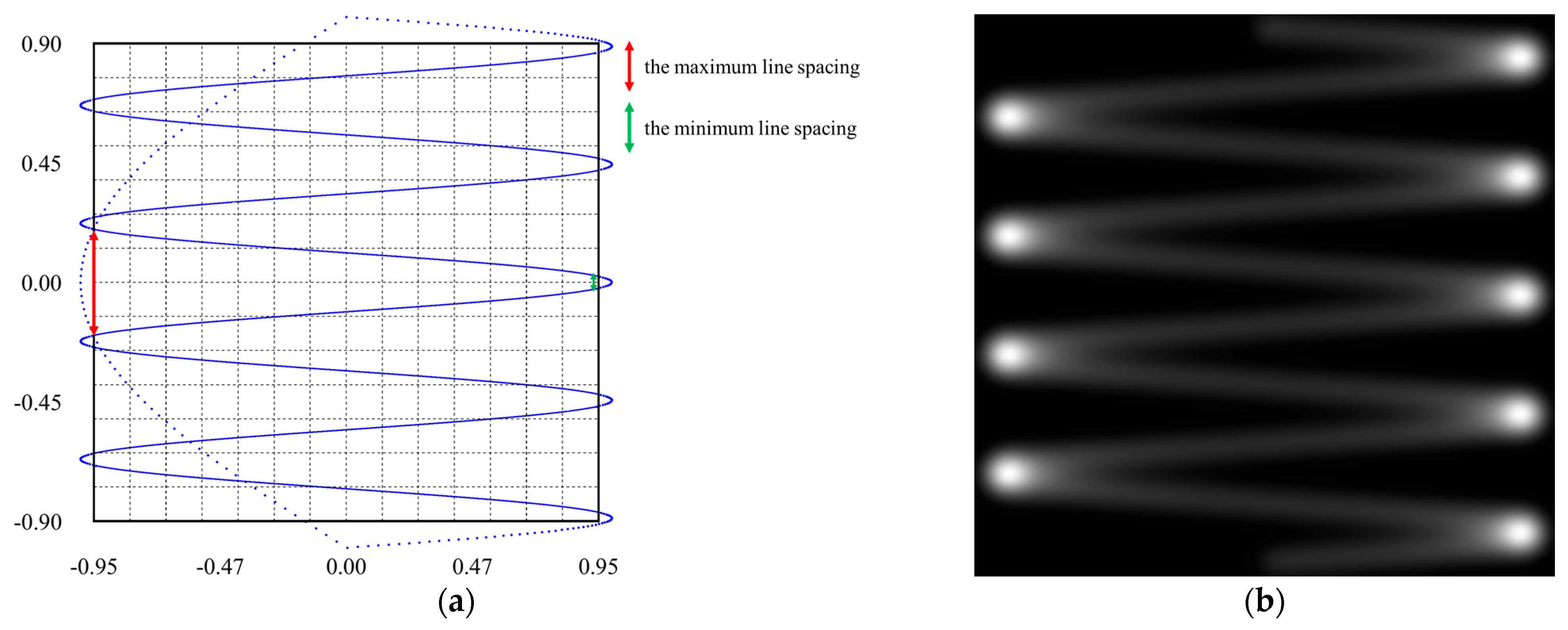

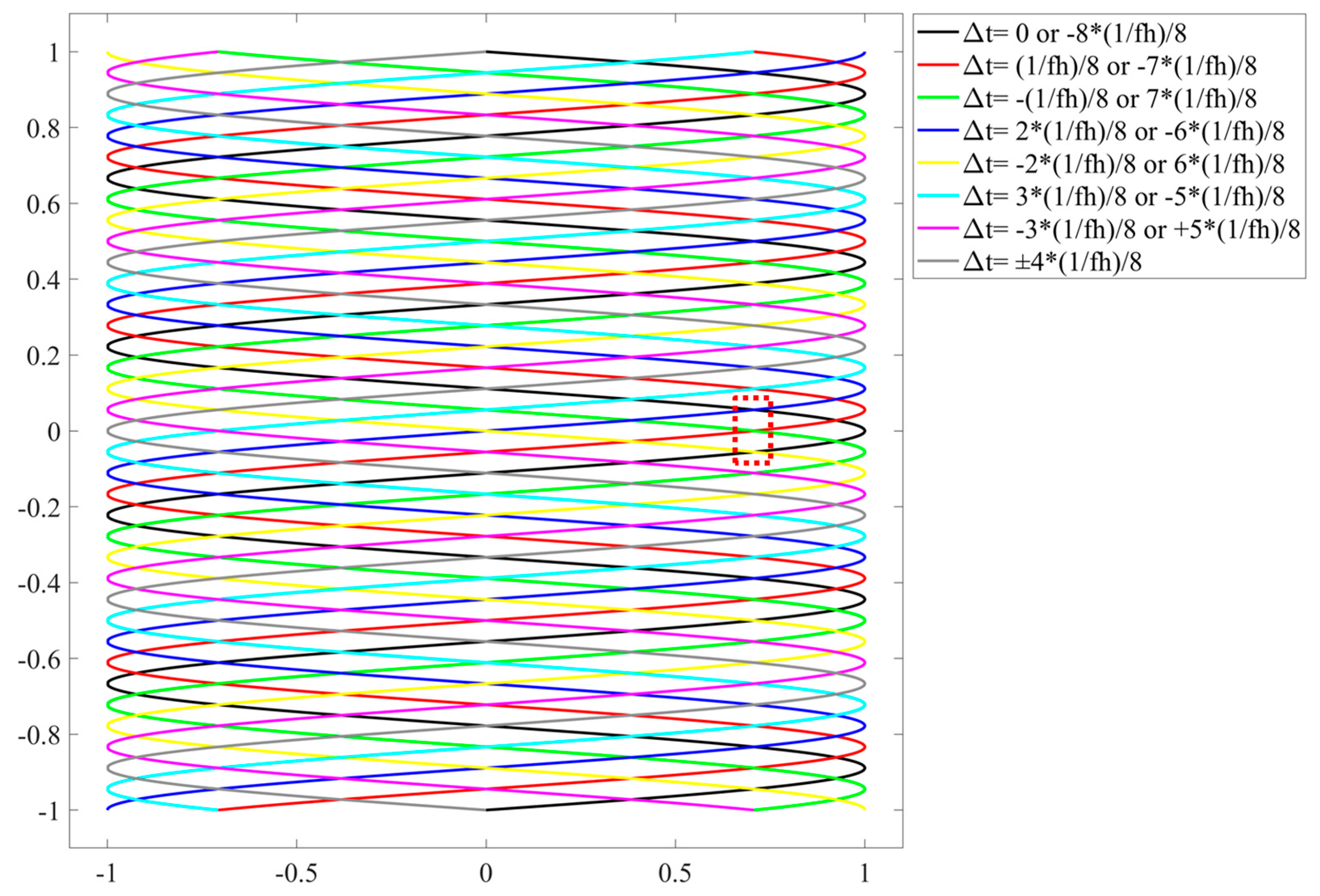

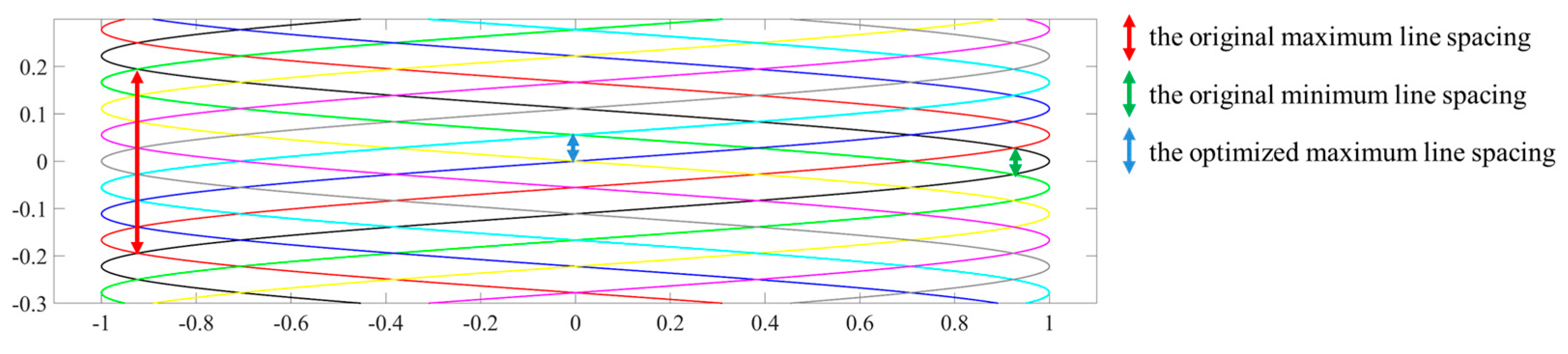

2. Raster Pinch Effect and Banding Artifacts

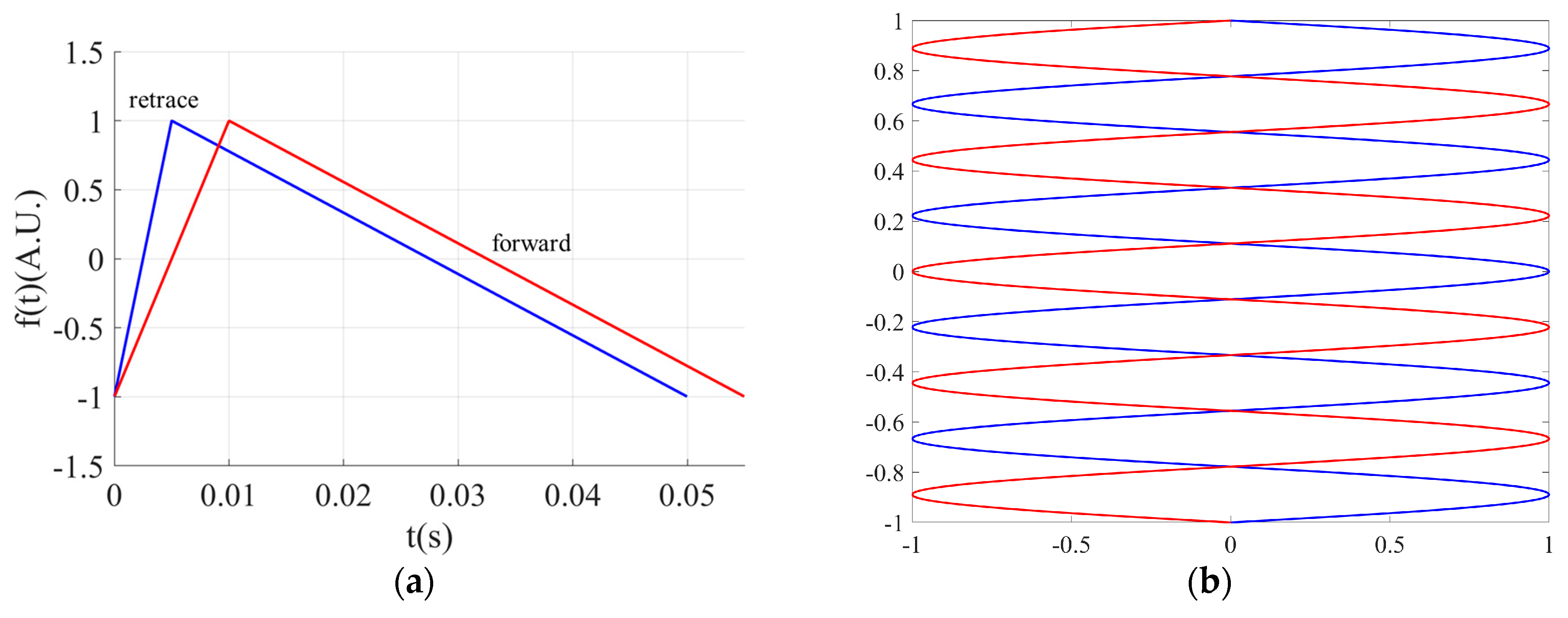

2.1. Raster Pinch Effect

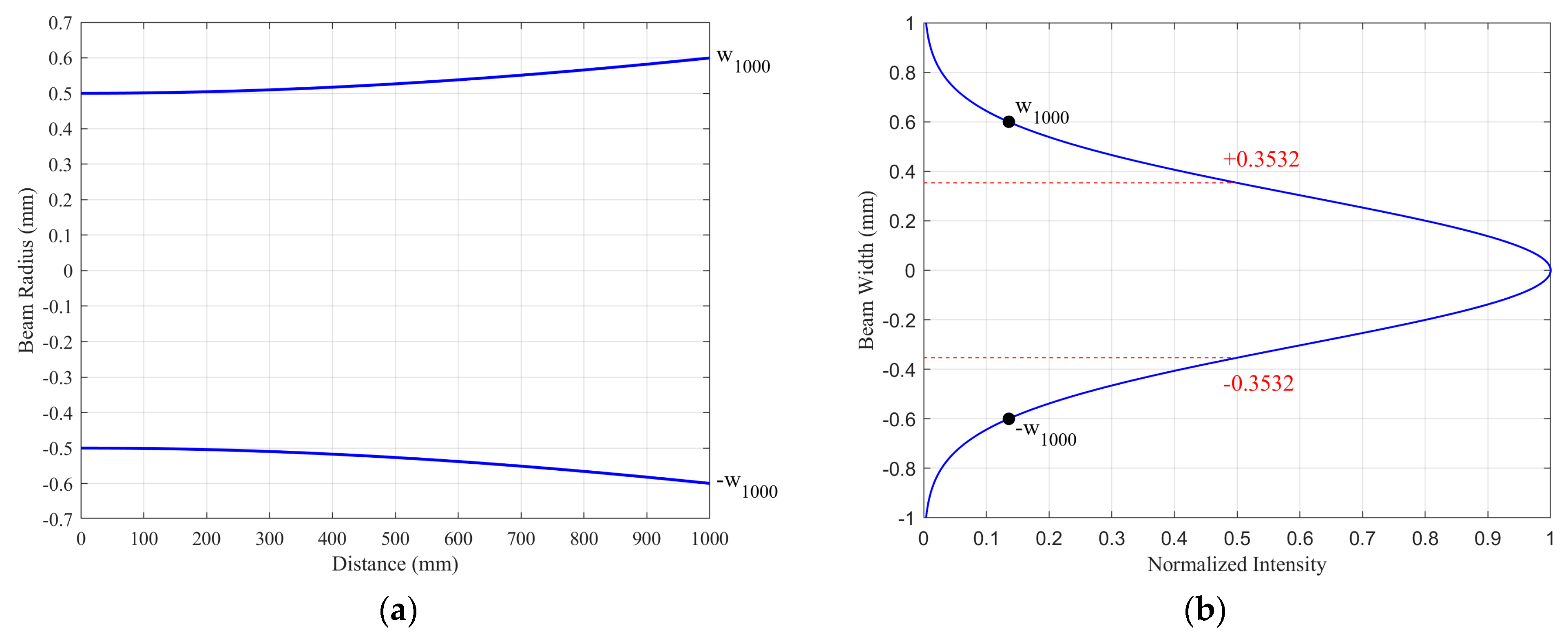

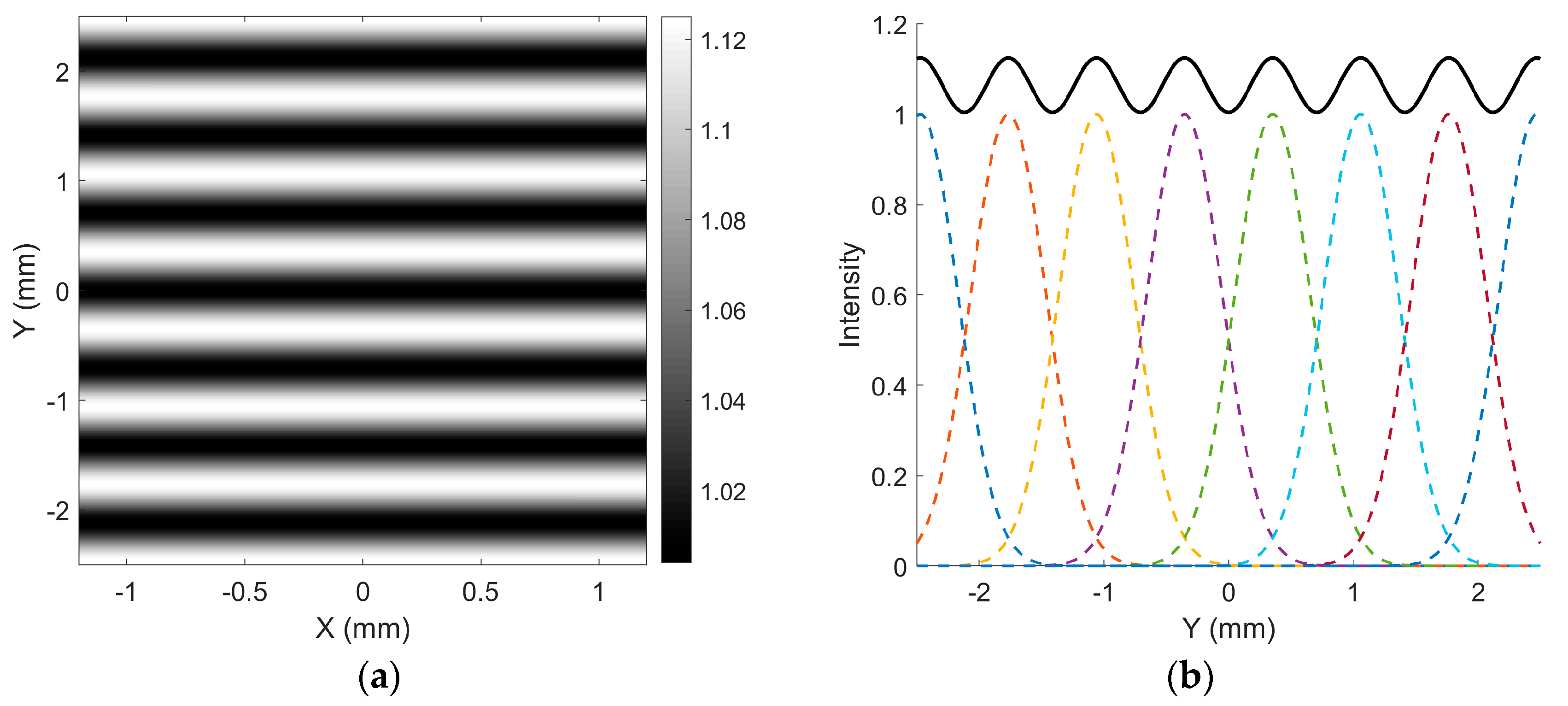

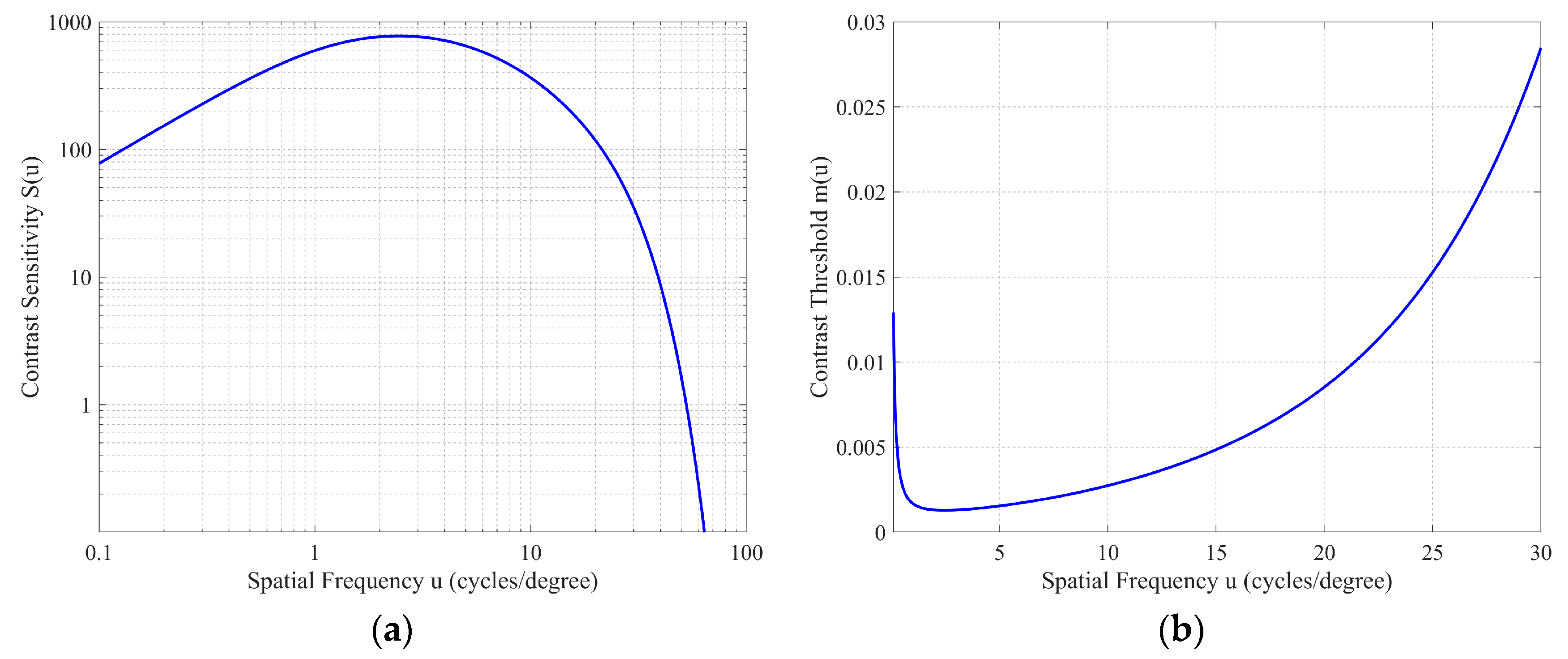

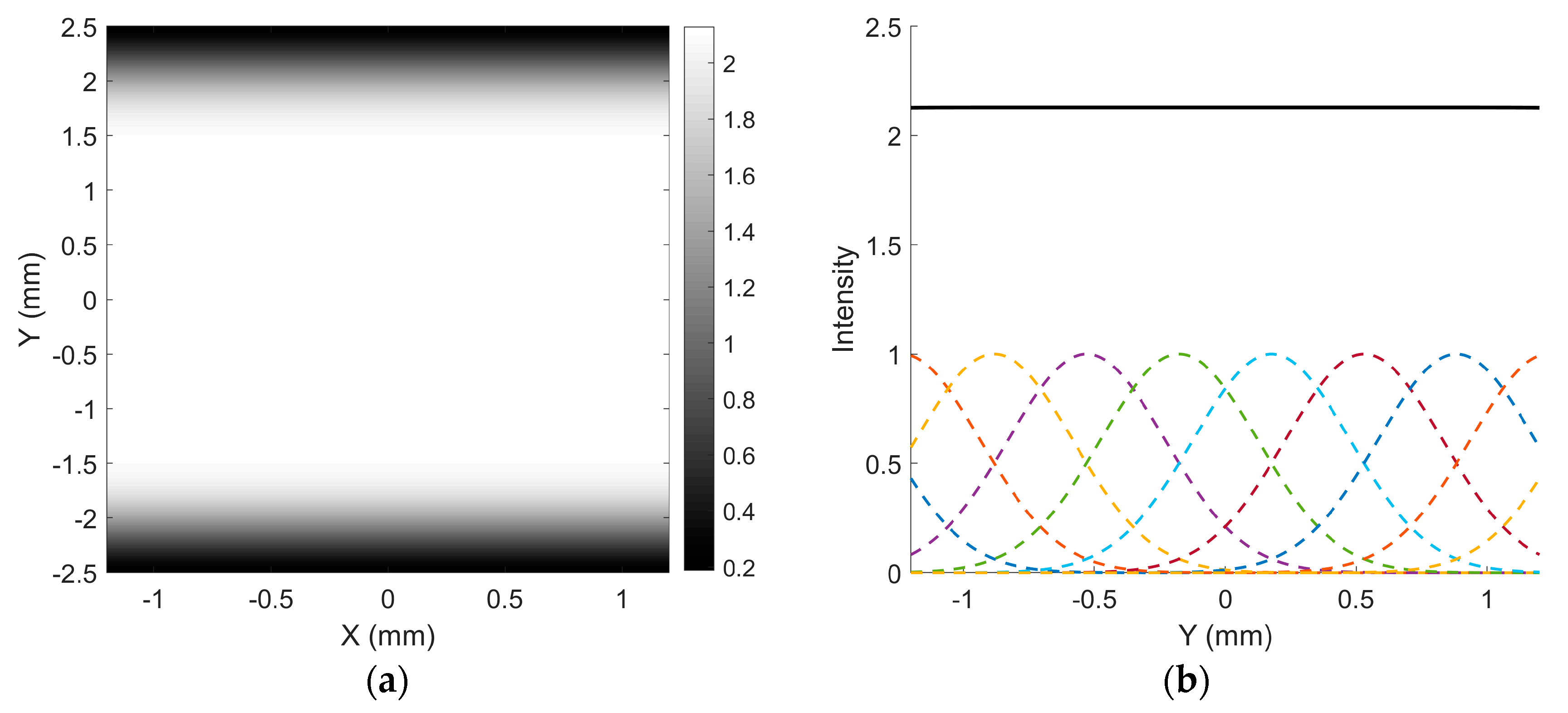

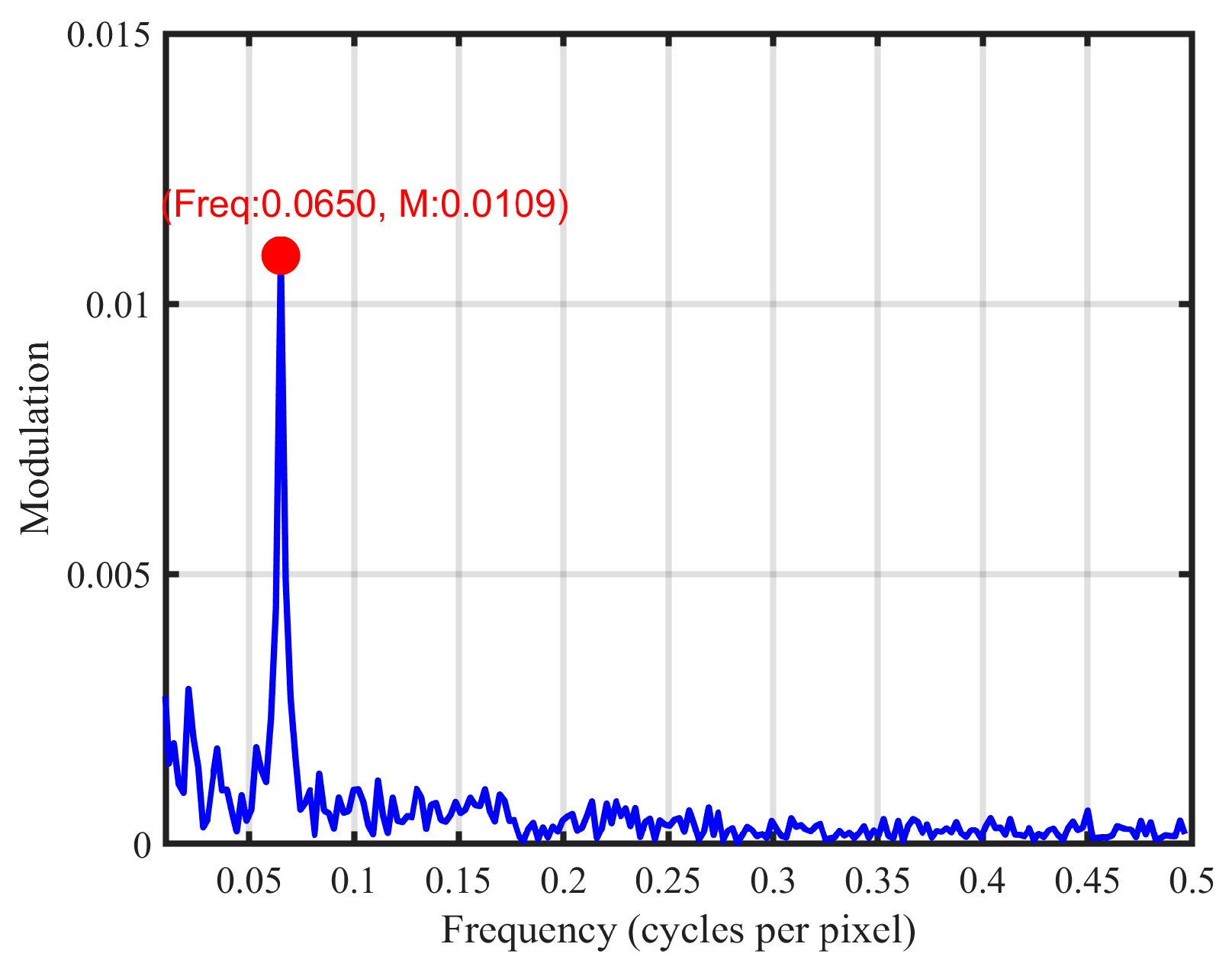

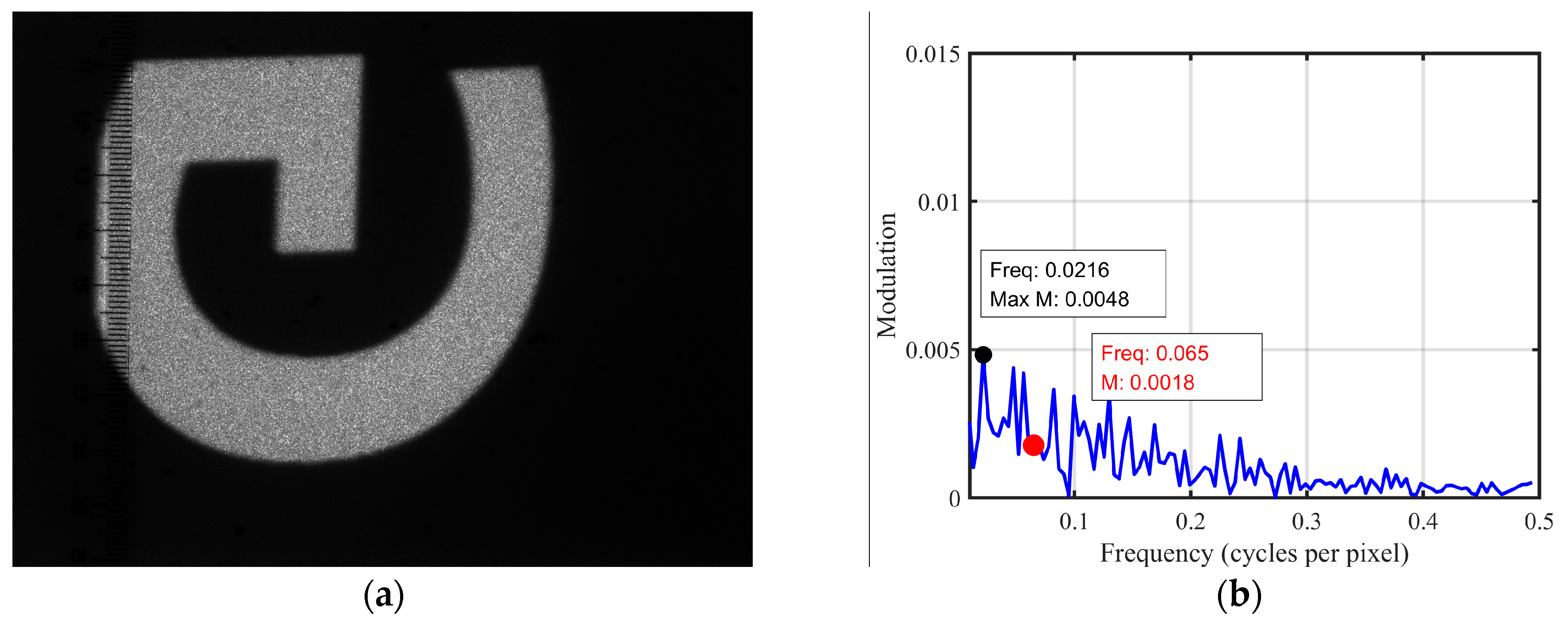

2.2. Banding Artifacts

3. Optimization Strategies

- ±1/8 of the horizontal scanning period (1/fh);

- ±2/8 of the horizontal scanning period (1/fh);

- ±3/8 of the horizontal scanning period (1/fh);

- ±4/8 of the horizontal scanning period (1/fh);

- ±5/8 of the horizontal scanning period (1/fh);

- ±6/8 of the horizontal scanning period (1/fh);

- ±7/8 of the horizontal scanning period (1/fh);

- 0 and −8/8 of the horizontal scanning period (1/fh).

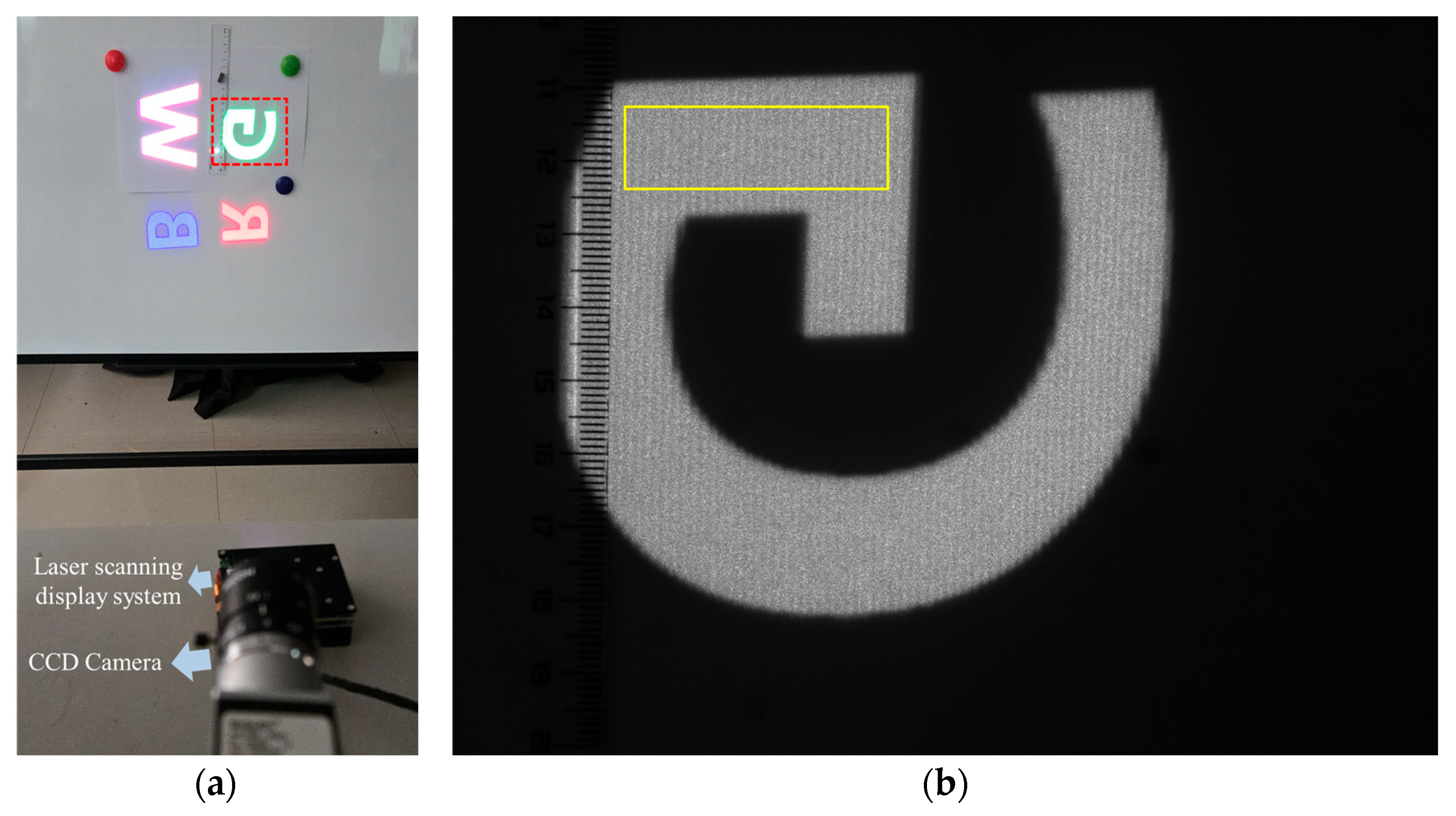

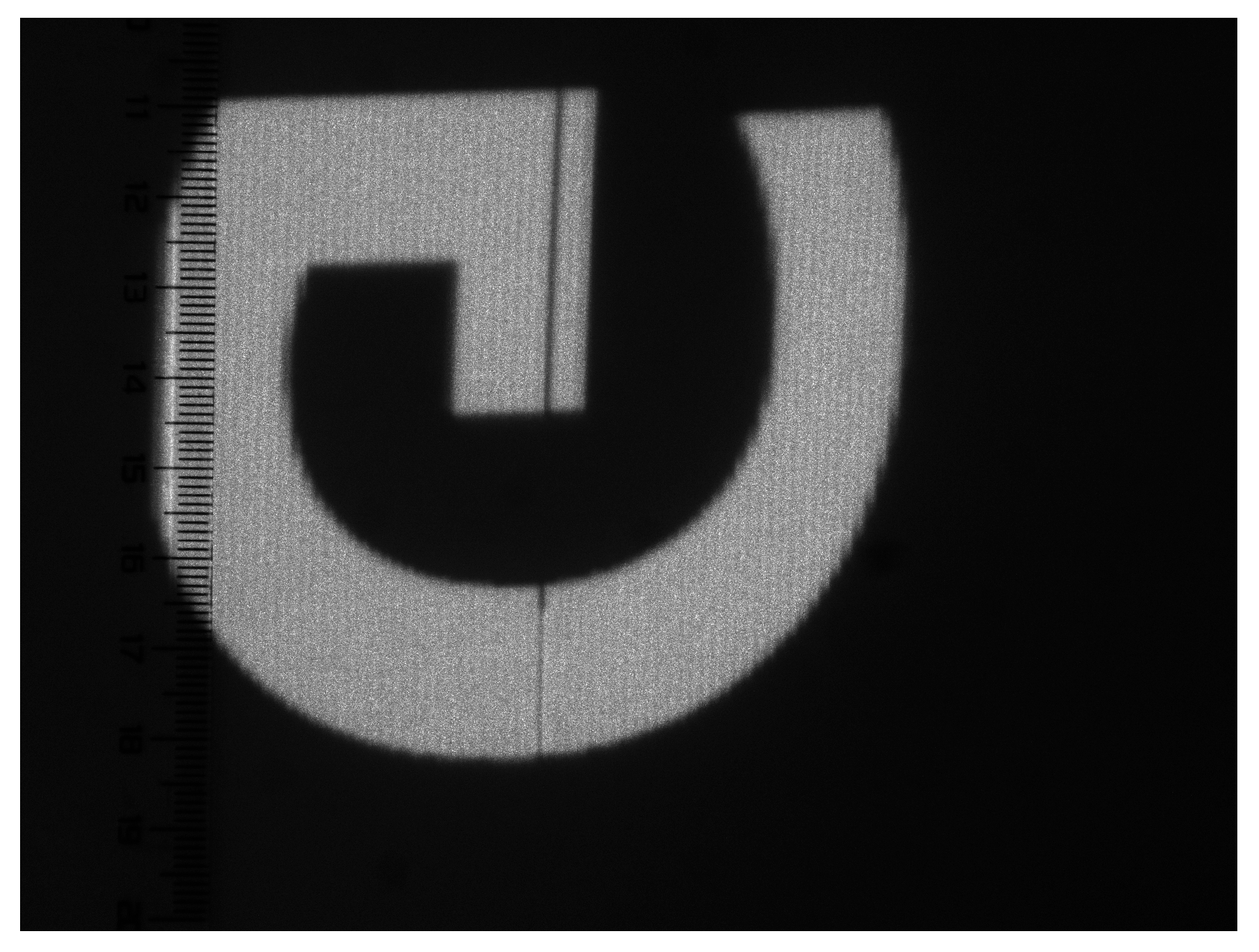

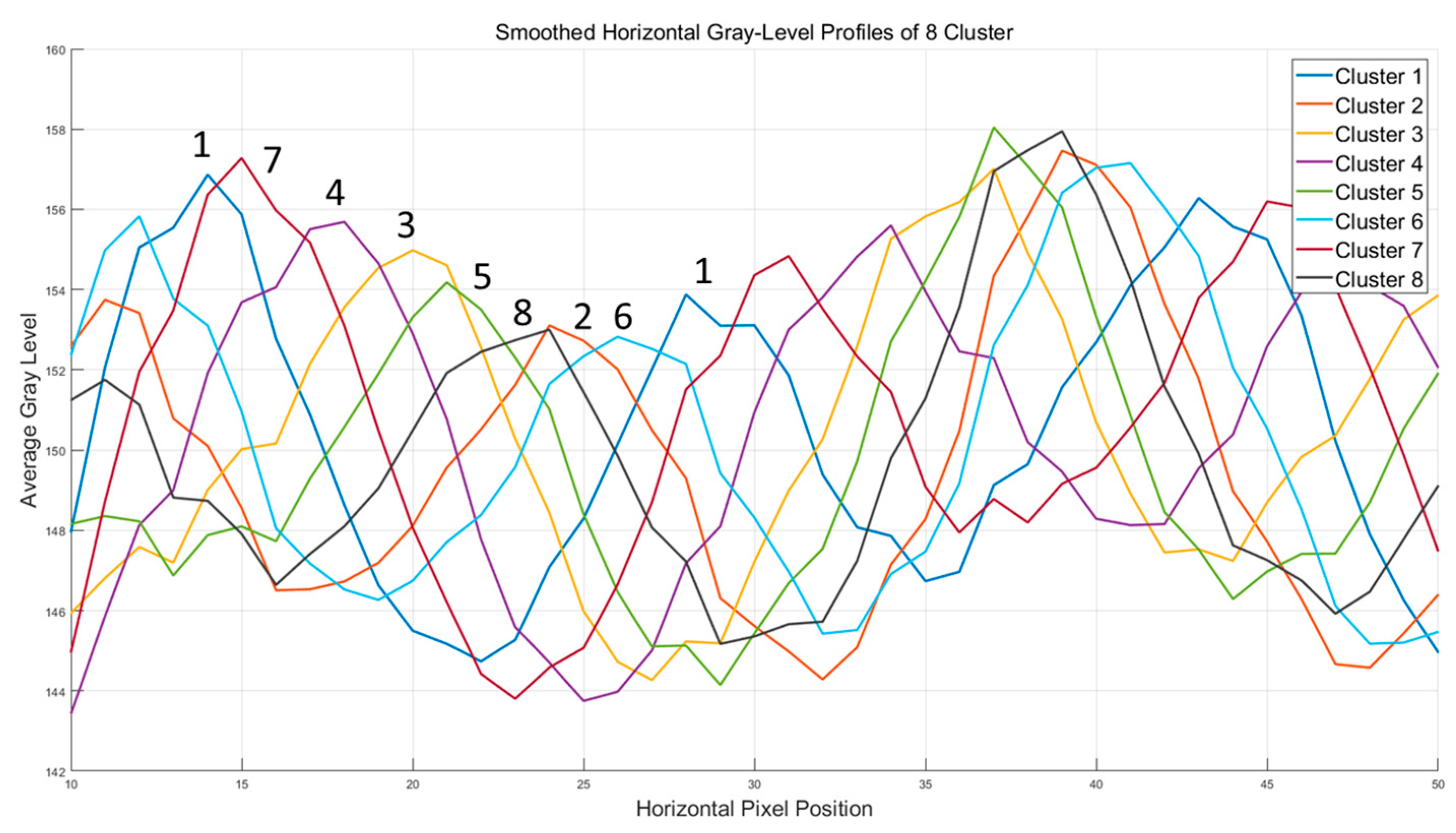

4. Experimental Validation

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Petersen, K.E. Silicon torsional scanning mirror. IBM J. Res. Dev. 1980, 24, 631–637. [Google Scholar] [CrossRef]

- Holmström, S.T.S.; Baran, U.; Urey, H. MEMS laser scanners: A review. J. Microelectromech. Syst. 2014, 23, 259–275. [Google Scholar] [CrossRef]

- Boni, N.; Carminati, R.; Mendicino, G.; Merli, M.; Terzi, D.; Lazarova, B.; Fusi, M. Piezoelectric MEMS mirrors for the next generation of small form factor AR glasses. In Proceedings of the SPIE MOEMS and Miniaturized Systems XXI, San Francisco, CA, USA, 23–27 January 2022; Volume 12013, pp. 30–46. [Google Scholar]

- Wolter, A.; Schenk, H.; Gaumont, E.; Lakner, H. MEMS microscanning mirror for barcode reading: From development to production. MOEMS Disp. Imaging Syst. II 2004, 5348, 32–39. [Google Scholar]

- Davis, W.O.; Brown, D.; Helsel, M.; Sprague, R.; Gibson, G.; Yalcinkaya, A.; Urey, H. High-performance silicon scanning mirror for laser printing. In Proceedings of the SPIE MOEMS and Miniaturized Systems VI, San Jose, CA, USA, 23–25 January 2007; Volume 6466, pp. 127–133. [Google Scholar]

- Wang, D.; Watkins, C.; Xie, H. MEMS mirrors for LiDAR: A review. Micromachines 2020, 11, 456. [Google Scholar] [CrossRef] [PubMed]

- Raj, T.; Hashim, F.H.; Huddin, A.B.; Ibrahim, M.F.; Hussain, A. A survey on LiDAR scanning mechanisms. Electronics 2020, 9, 741. [Google Scholar] [CrossRef]

- Xu, F.; Qiao, D.; Xia, C.; Song, X.; Zheng, W.; He, Y.; Fan, Q. A semi-coaxial MEMS LiDAR design with independently adjustable detection range and angular resolution. Sens. Actuators A Phys. 2021, 326, 112715. [Google Scholar] [CrossRef]

- Davis, W.O.; Beard, M.; Jackson, R. Trajectory precision of micromachined scanning mirrors for laser beam scanning pico-projector displays. In Proceedings of the SPIE MOEMS and Miniaturized Systems XI, San Francisco, CA, USA, 24–26 January 2012; Volume 8252. [Google Scholar]

- Conant, R.A.; Hagelin, P.M.; Krishnamoorthy, U.; Hart, M.; Solgaard, O.; Lau, K.Y.; Muller, R.S. A raster-scanning full-motion video display using polysilicon micromachined mirrors. Sens. Actuators A Phys. 2000, 83, 291–296. [Google Scholar] [CrossRef]

- Hagelin, P.M.; Solgaard, O. Optical raster-scanning displays based on surface-micromachined polysilicon mirrors. IEEE J. Sel. Top. Quantum Electron. 2002, 5, 67–74. [Google Scholar] [CrossRef]

- Wang, D.; Koppal, S.J.; Xie, H. A monolithic forward-view MEMS laser scanner with decoupled raster scanning and enlarged scanning angle for micro LiDAR applications. J. Microelectromech. Syst. 2020, 29, 996–1001. [Google Scholar] [CrossRef]

- Urey, H.; DeWitt IV, F.A.; Powell, K.D.; Bayer, M.M. High-frequency raster pinch correction scanner for retinal scanning displays. In Proceedings of the SPIE MOEMS and Miniaturized Systems II, San Jose, CA, USA, 23–25 January 2001; Volume 4561, pp. 45–54. [Google Scholar]

- Powell, K.D.; Urey, H.; Bayer, M.M. Multibeam Bidirectional Raster Scanning in Retinal Scanning Displays. In Proceedings of the Helmet-and Head-Mounted Displays VI, Orlando, FL, USA, 16–17 April 2001; Volume 4361, pp. 77–88. [Google Scholar]

- Urey, H.; DeWitt IV, F.A.; Lopez, P.A.; Tauscher, J. MEMS raster correction scanner for SXGA resolution retinal scanning display. In Proceedings of the SPIE MOEMS Display and Imaging Systems, San Jose, CA, USA, 27–29 January 2003; Volume 4985, pp. 106–114. [Google Scholar]

- Teo, Y.R.; Yong, Y.K.; Fleming, A.J. A review of scanning methods and control implications for scanning probe microscopy. In Proceedings of the 2016 American Control Conference (ACC), Boston, MA, USA, 6–8 July 2016; pp. 7377–7383. [Google Scholar]

- Schubert, P.C. Periodic image artifacts from continuous-tone laser scanners. Appl. Opt. 1986, 25, 3880–3884. [Google Scholar] [CrossRef] [PubMed]

- Stutz, G.E. Eliminating laser scanner artifacts in binary and continuous-tone printing. In Proceedings of the SPIE Micro-Optics/Micromechanics and Laser Scanning and Shaping, San Diego, CA, USA, 20 July 1995; Volume 2383, pp. 427–433. [Google Scholar]

- Yalcinkaya, A.D.; Urey, H.; Brown, D.; Montague, T.; Sprague, R. Two-axis electromagnetic microscanner for high resolution displays. J. Microelectromech. Syst. 2006, 15, 786–794. [Google Scholar] [CrossRef]

- Urey, H.; Wine, D.W.; Osborn, T.D. Optical performance requirements for MEMS-scanner-based microdisplays. In Proceedings of the SPIE MOEMS and Miniaturized Systems, San Jose, CA, USA, 23–25 January 2000; Volume 4178, pp. 176–185. [Google Scholar]

- Wallhead, I.; Ocaña, R.; Quinzá, P. Designing a laser scanning picoprojector. Part 1: Characteristics of the optical displaying system and color-management-related issues. Appl. Opt. 2012, 51, 4803–4809. [Google Scholar] [CrossRef] [PubMed]

- Self, S.A. Focusing of Spherical Gaussian Beams. Appl. Opt. 1983, 22, 658–661. [Google Scholar] [CrossRef] [PubMed]

- Barten, P.G.J. Contrast Sensitivity of the Human Eye and Its Effects on Image Quality; SPIE Press: Bellingham, WA, USA, 1999; pp. 1–200. [Google Scholar]

- Barten, P.G.J. Formula for the contrast sensitivity of the human eye. In Proceedings Volume 5294, Image Quality and System Performance; SPIE: San Jose, CA, USA, 2003. [Google Scholar]

- Campbell, F.W.; Robson, J.G. Application of Fourier analysis to the visibility of gratings. J. Physiol. 1968, 197, 551–566. [Google Scholar] [CrossRef] [PubMed]

| Cluster 1 | Cluster 2 | Cluster 3 | Cluster 4 | Cluster 5 | Cluster 6 | Cluster 7 | Cluster 8 | Discarded | |

|---|---|---|---|---|---|---|---|---|---|

| Number | 07, 08, 17, 26, 27, 36, 45, 54 | 05, 12, 22, 30, 31, 39, 41, 42, 51, 60 | 15, 24, 33, 43, 62 | 11, 21, 40, 49, 50, 59 | 09, 16, 25, 34, 35, 44, 55, 63 | 01, 02, 03, 18, 28, 37, 46, 48, 57, 58 | 04, 29, 38, 47, 56 | 06, 13, 14, 23, 32, 52, 61 | 10, 19, 20, 53 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, P.; Yu, H.; Li, X.; Shen, W.; Wu, D. Reduction of Visual Artifacts in Laser Beam Scanning Displays. Micromachines 2025, 16, 949. https://doi.org/10.3390/mi16080949

Zhou P, Yu H, Li X, Shen W, Wu D. Reduction of Visual Artifacts in Laser Beam Scanning Displays. Micromachines. 2025; 16(8):949. https://doi.org/10.3390/mi16080949

Chicago/Turabian StyleZhou, Peng, Huijun Yu, Xiaoguang Li, Wenjiang Shen, and Dongmin Wu. 2025. "Reduction of Visual Artifacts in Laser Beam Scanning Displays" Micromachines 16, no. 8: 949. https://doi.org/10.3390/mi16080949

APA StyleZhou, P., Yu, H., Li, X., Shen, W., & Wu, D. (2025). Reduction of Visual Artifacts in Laser Beam Scanning Displays. Micromachines, 16(8), 949. https://doi.org/10.3390/mi16080949