Total Ionizing Dose Effect Simulation Modeling and Analysis for a DCAP Power Chip

Abstract

1. Introduction

2. Device-Level Simulation and Modeling

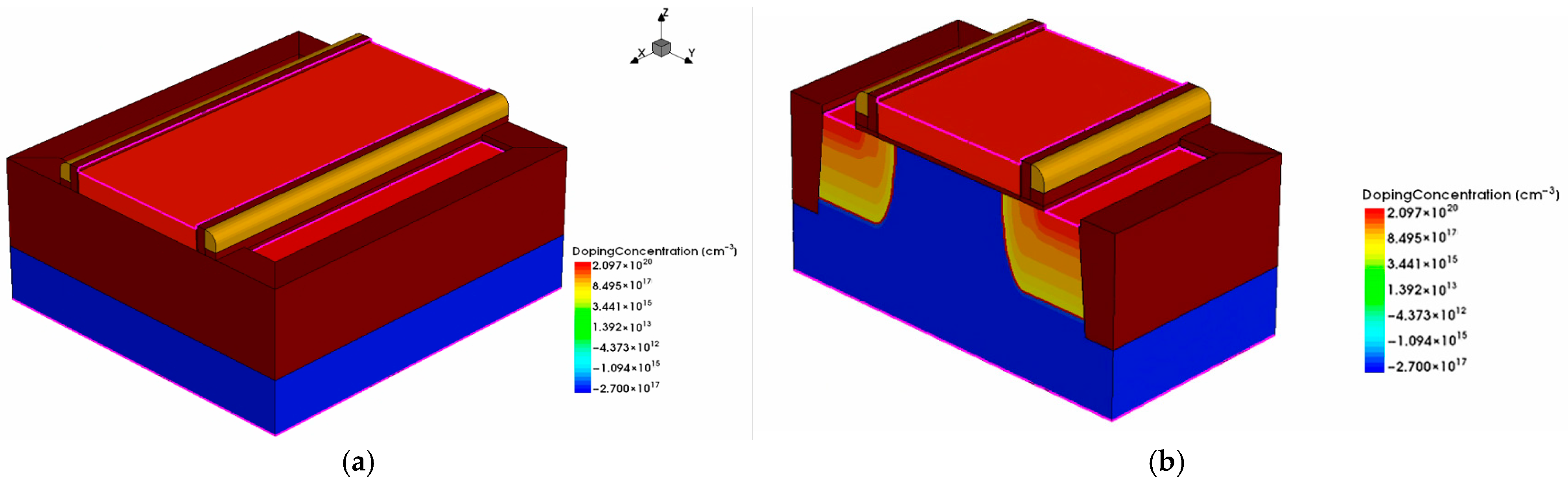

2.1. MOS Device Total Ionizing Dose Effect Simulation

2.2. MOS Device Fault Injection Modeling

3. DCAP Power Chip Simulation and Discussion

3.1. System Performance Simulation

3.2. Sensitivity Analysis for Key Modules

3.3. Bandgap Reference Module

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| BCD | Bipolar-CMOS-DMOS |

| DCAP | Direct connection to the output CAPacitor |

| NASA | National Aeronautics and Space Administration |

| NMOS | N-Metal-Oxide-Semiconductor |

| TID | Total Ionizing Dose |

| TCAD | Technology Computer-Aided Design |

| SPICE | Simulation Program with Integrated Circuit Emphasis |

| STI | Shallow Trench Isolation |

| TT | Typical Typical |

References

- Bazilevskaya, G.A. Solar cosmic rays in the near Earth space and the atmosphere. Adv. Space Res. 2005, 35, 458–464. [Google Scholar] [CrossRef]

- Tong, Q.; Zhang, D. Research on a High Output Current DC/DC Converter with Wide Input Voltage Range for Space Applications. In Proceedings of the 2016 International Conference on Integrated Circuits and Microsystems (ICICM), Chengdu, China, 23–25 November 2016; pp. 205–209. [Google Scholar]

- Ristic, G.S.; Ilic, S.D.; Duane, R.; Andjelkovic, M.S.; Palma, A.J.; Lallena, A.M.; Krstic, M.D.; Stankovic, S.J.; Jaksic, A.B. Radiation sensitive MOSFETs irradiated with various positive gate biases. J. Radiat. Res. Appl. Sci. 2021, 14, 353–357. [Google Scholar] [CrossRef]

- Marjanović, M.; Ilić, S.D.; Veljković, S.; Mitrović, N.; Gurer, U.; Yilmaz, O.; Kahraman, A.; Aktag, A.; Karacali, H.; Budak, E.; et al. The SPICE Modeling of a Radiation Sensor Based on a MOSFET with a Dielectric HfO2/SiO2 Double-Layer. Sensors 2025, 25, 546. [Google Scholar] [CrossRef]

- Metreveli, A.; Cuong, V.V.; Kuroki, S.-I.; Tanaka, K.; Zetterling, C.-M. Impact of interface oxide type on the gamma radiation response of Sic TTL ICS. Facta Univ. 2024, 37, 599–607. [Google Scholar] [CrossRef]

- Chancellor, J.C.; Scott, G.B.I.; Sutton, J.P. Space radiation: The number one risk to astronaut health beyond low earth orbit. Life 2014, 4, 491–510. [Google Scholar] [CrossRef]

- Kim, S.Y.; Castet, J.; Saleh, J.H. Spacecraft electrical power subsystem: Failure behavior, reliability, and multi-state failure analyses. Reliab. Eng. Syst. Saf. 2012, 98, 55–56. [Google Scholar] [CrossRef]

- Stassinopoulos, E.G.; Brucker, G.J.; Nakamura, D.W.; Stauffer, C.A.; Barth, J.L. Solar flare proton evaluation at geostationary orbits for engineering applications. IEEE Trans. Nucl. Sci. 1996, 43, 369–382. [Google Scholar] [CrossRef]

- Saks, N.S.; Ancona, M.G. Generation of interface states by ionizing radiation at 80K measured by charge pumping and subthreshold slope techniques. IEEE Trans. Nucl. Sci. 1987, 34, 1347–1354. [Google Scholar] [CrossRef]

- Adell, P.C.; Johnston, A.H.; Irom, F.; Galloway, K.F. Total-dose and single-event effects in DC/DC converter control circuitry. IEEE Trans. Nucl. Sci. 2003, 50, 1867–1872. [Google Scholar] [CrossRef]

- Martin, E.; Gilard, O.; Nuns, T.; David, J.; Virmontois, C. Prediction of CMOS image sensor dark current distribution and noise in a space radiation environment. IEEE Trans. Nucl. Sci. 2013, 60, 2280–2287. [Google Scholar] [CrossRef]

- Lee, M.; Cho, S.; Lee, N.; Kim, J. Design for high reliability of CMOS IC with tolerance on total ionizing dose effect. IEEE Trans. Device Mat. Rel. 2020, 20, 459–467. [Google Scholar] [CrossRef]

- Gorbunov, M.S.; Zhidkov, N.M.; Sotskov, D.I.; Kuznetsov, A.G.; Kotov, V.N.; Elesin, V.V. Total Ionizing Dose Sensitivity of 180 nm Silicon-on-Insulator Microwave Low-Noise Amplifier. In Proceedings of the 2021 IEEE 32nd International Conference on Microelectronics (MIEL), Nis, Serbia, 12–14 September 2021. [Google Scholar]

- Jiang, Y.; Kong, Q.; Qiao, M.; Zheng, Z.; Tang, Y.; Zhang, B. Compact SPICE Modeling of Total Ionizing Dose for Shield Gate Trench MOSFET. In Proceedings of the 2024 36th International Symposium on Power Semiconductor Devices and ICs (ISPSD), Bremen, Germany, 2–6 June 2024. [Google Scholar]

- Mikkola, E.O.; Vermeire, B.; Parks, H.G.; Graves, R. VHDL-AMS modeling of total ionizing dose radiation effects on CMOS mixed signal circuits. IEEE Trans. Nucl. Sci. 2007, 54, 929–934. [Google Scholar] [CrossRef]

- Jagannathan, S.; Herbison, D.R.; Holman, W.T.; Massengill, L.W. Behavioral modeling technique for TID degradation of complex analog circuits. IEEE Trans. Nucl. Sci. 2010, 57, 3708–3715. [Google Scholar] [CrossRef]

- Seiler, J.E.; Platteter, D.G.; Dunham, G.W.; Pease, R.L.; Maher, M.C.; Shaneyfelt, M.R. Effect of passivation on the enhanced low dose rate sensitivity of National LM124 operational amplifiers. In Proceedings of the 2004 IEEE Radiation Effects Data Workshop (IEEE Cat. No.04TH8774), Atlanta, GA, USA, 22 July 2004; pp. 42–46. [Google Scholar]

- Li, T.; Yang, Y.; Liu, T. Modeling of 0.18 μm NMOSFETs for TID effect. In Proceedings of the 2016 IEEE International Nanoelectronics Conference (INEC), Chengdu, China, 9–11 May 2016. [Google Scholar]

- Esqueda, I.S.; Barnaby, H.J.; King, M.P. Compact Modeling of Total Ionizing Dose and Aging Effects in MOS Technologies. IEEE Trans. Nucl. Sci. 2015, 64, 1501–1515. [Google Scholar] [CrossRef]

- Schwank, J.R.; Shaneyfelt, M.R.; Fleetwood, D.M.; Felix, J.A.; Dodd, P.E.; Paillet, P. Radiation effects in MOS oxides. IEEE Trans. Nucl. Sci. 2008, 55, 1833–1853. [Google Scholar] [CrossRef]

- Tuttle, B.R.; Hughart, D.R.; Schrimpf, R.D.; Fleetwood, D.M.; Pantelides, S.T. Defect Interactions of H2 in SiO2: Implications for ELDRS and Latent Interface Trap Buildup. IEEE Trans. Nucl. Sci. 2010, 57, 3046–3053. [Google Scholar]

- Esqueda, S.I. Modeling of Total Ionizing Dose Effects in Advanced Complementary Metal-Oxide-Semiconductor Technologies. Ph.D. Thesis, University of Arizona, Tucson, AZ, USA, 2011. [Google Scholar]

- Hu, V.P.H.; Fan, M.L.; Su, P.; Chuang, C.T. Threshold Voltage Design of UTB SOI SRAM With Improved Stability/Variability for Ultralow Voltage Near Subthreshold Operation. IEEE Trans. Nanotechnol. 2013, 12, 524–531. [Google Scholar] [CrossRef]

- Wang, S.; Li, X.; Cai, X.; Li, D.; Jin, M.; Lu, P. TID effect of MOSFETs in SOI BCD process and its hardening technique. IEEE Trans. Nucl. Sci. 2023, 70, 1995–2001. [Google Scholar] [CrossRef]

- Barnaby, H.J.; McLain, M.L.; Esqueda, I.S.; Chen, X.J. Modeling Ionizing Radiation Effects in Solid State Materials and CMOS Devices. IEEE TCAS-I Regul. Pap. 2009, 56, 1870–1883. [Google Scholar] [CrossRef]

- Liu, F.; Yang, F.; Wang, H.; Xiang, X.; Zhou, X.; Hu, S. Radiation-Hardened CMOS Negative Voltage Reference for Aerospace Application. IEEE Trans. Nucl. Sci. 2017, 64, 2505–2510. [Google Scholar] [CrossRef]

- İlik, S.; Yelten, M.B. Total ionizing dose (TID) impact on basic amplifier stages. IEEE Trans. Device Mat. Rel. 2022, 23, 51–57. [Google Scholar] [CrossRef]

- Liu, Y.; Wei, C.; Yang, S.; Jin, X.; He, C. Synergistic effect of mixed neutron and gamma irradiation in bipolar operational amplifier OP07. Nucl. Instrum. Meth. A 2016, 831, 334–338. [Google Scholar]

- Traversi, G.; Canio, F.D.; Gaioni, L.; Manghisoni, M.; Mattiazzo, S.; Ratti, L.; Re, V.; Riceputi, E. Characterization of bandgap reference circuits designed for high energy physics applications. Nucl. Instrum. Meth. A 2016, 824, 371–373. [Google Scholar] [CrossRef]

| /V | /V (Pre-Irradiation) | /V (500 krad) | Ripple Amplitude/mV (Pre-Irradiation) | Ripple Amplitude/mV (500 krad) | Output Accuracy (Pre-Irradiation) | Output Accuracy (500 krad) |

|---|---|---|---|---|---|---|

| 5 | 1.7974 | 2.1632 | ±2.996 | ±2.668 | −0.144% | +20.18% |

| 7 | 1.7986 | 2.1938 | ±4.034 | ±3.666 | −0.078% | +21.88% |

| 9 | 1.8004 | 2.2214 | ±4.750 | ±4.595 | +0.022% | +23.41% |

| 12 | 1.8014 | 2.2438 | ±5.456 | ±5.599 | +0.078% | +24.66% |

| 15 | 1.8021 | 2.2486 | ±5.975 | ±6.345 | +0.117% | +24.92% |

| 18 | 1.8020 | 2.2426 | ±6.331 | ±6.906 | +0.111% | +24.59% |

| /V | /kHz (Pre-Irradiation) | /kHz (500 krad) |

|---|---|---|

| 5 | 902.6 | 968.6 |

| 7 | 896.7 | 1027.3 |

| 9 | 877.7 | 990.1 |

| 12 | 858.9 | 947.3 |

| 15 | 847.1 | 916.3 |

| 18 | 835.3 | 892.3 |

| /V | /V (Bandgap Reference Module) | /V (Adaptive Constant On-Time Module) | /V (Ripple Compensation Module) | Output Accuracy (Bandgap Reference Module) | Output Accuracy (Adaptive Constant On-Time Module) | Output Accuracy (Ripple Compensation Module) |

|---|---|---|---|---|---|---|

| 5 | 2.0373 | 1.7974 | 1.7967 | +13.18% | −0.144% | −0.183% |

| 7 | 2.0458 | 1.7987 | 1.7998 | +13.66% | −0.072% | −0.011% |

| 9 | 2.0465 | 1.8005 | 1.8022 | +13.69% | +0.028% | +0.122% |

| 12 | 2.0478 | 1.8014 | 1.8039 | +13.77% | +0.078% | +0.217% |

| 15 | 2.0487 | 1.8019 | 1.8048 | +13.82% | +0.106% | +0.267% |

| 18 | 2.0493 | 1.8023 | 1.8054 | +13.85% | +0.128% | +0.300% |

| /V | /kHz (Pre-Irradiation) | /kHz (Bandgap Reference Module) | /kHz (Adaptive Constant On-Time Module) | /kHz (Ripple Compensation Module) |

|---|---|---|---|---|

| 5 | 902.7 | 900.6 | 895.7 | 900.5 |

| 7 | 897.1 | 962.3 | 889.7 | 895.8 |

| 9 | 880.1 | 930.4 | 872.2 | 876.3 |

| 12 | 858.5 | 895.7 | 853.7 | 858.1 |

| 15 | 847.2 | 871.5 | 840.8 | 844.2 |

| 18 | 834.9 | 852.7 | 830.8 | 834.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liao, X.; Lei, D.; Fu, Y.; Liu, Y.; Huang, K.; Wei, Y.; Zuo, Y.; Ying, Y.; Liu, Y.; Xu, C.; et al. Total Ionizing Dose Effect Simulation Modeling and Analysis for a DCAP Power Chip. Micromachines 2025, 16, 917. https://doi.org/10.3390/mi16080917

Liao X, Lei D, Fu Y, Liu Y, Huang K, Wei Y, Zuo Y, Ying Y, Liu Y, Xu C, et al. Total Ionizing Dose Effect Simulation Modeling and Analysis for a DCAP Power Chip. Micromachines. 2025; 16(8):917. https://doi.org/10.3390/mi16080917

Chicago/Turabian StyleLiao, Xinfang, Danyang Lei, Yanjun Fu, Yuchen Liu, Kangqi Huang, Yuan Wei, Yinghong Zuo, Yashi Ying, Yi Liu, Changqing Xu, and et al. 2025. "Total Ionizing Dose Effect Simulation Modeling and Analysis for a DCAP Power Chip" Micromachines 16, no. 8: 917. https://doi.org/10.3390/mi16080917

APA StyleLiao, X., Lei, D., Fu, Y., Liu, Y., Huang, K., Wei, Y., Zuo, Y., Ying, Y., Liu, Y., Xu, C., & Yang, Y. (2025). Total Ionizing Dose Effect Simulation Modeling and Analysis for a DCAP Power Chip. Micromachines, 16(8), 917. https://doi.org/10.3390/mi16080917