Improved DC and RF Characteristics of GaN HEMT Using a Back-Barrier and Locally Doped Barrier Layer

Abstract

1. Introduction

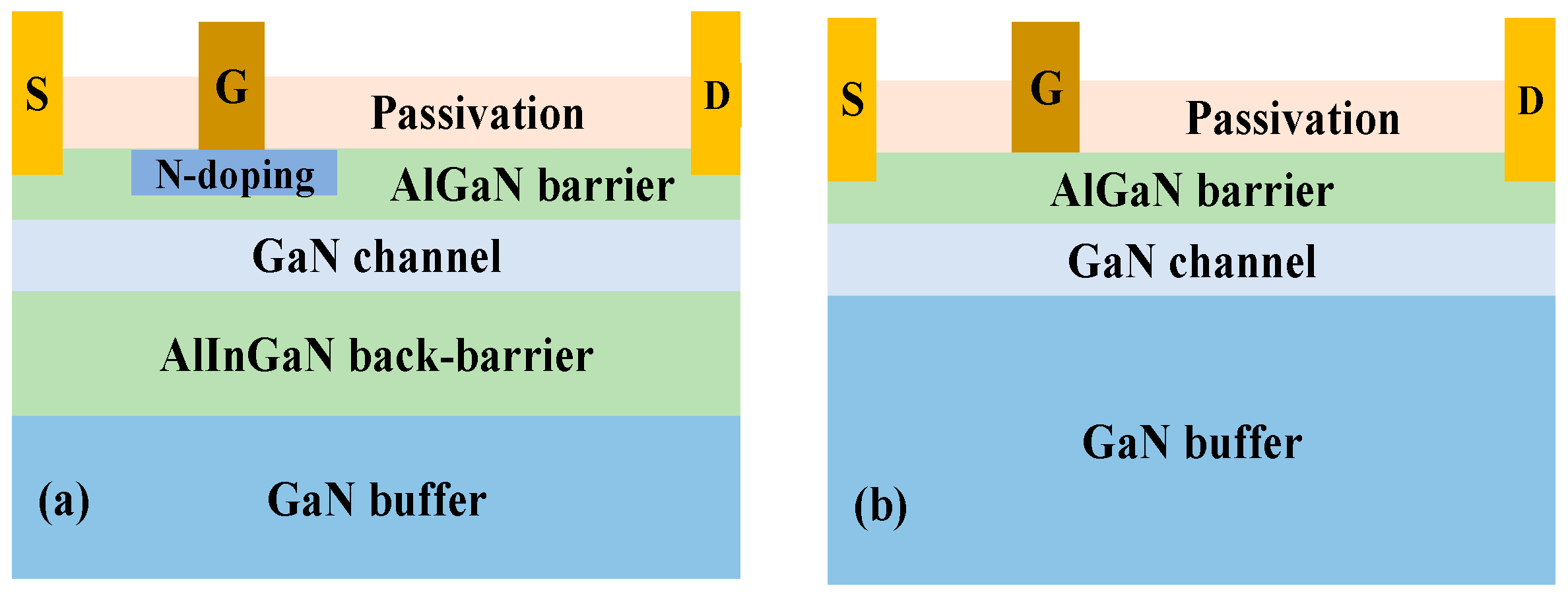

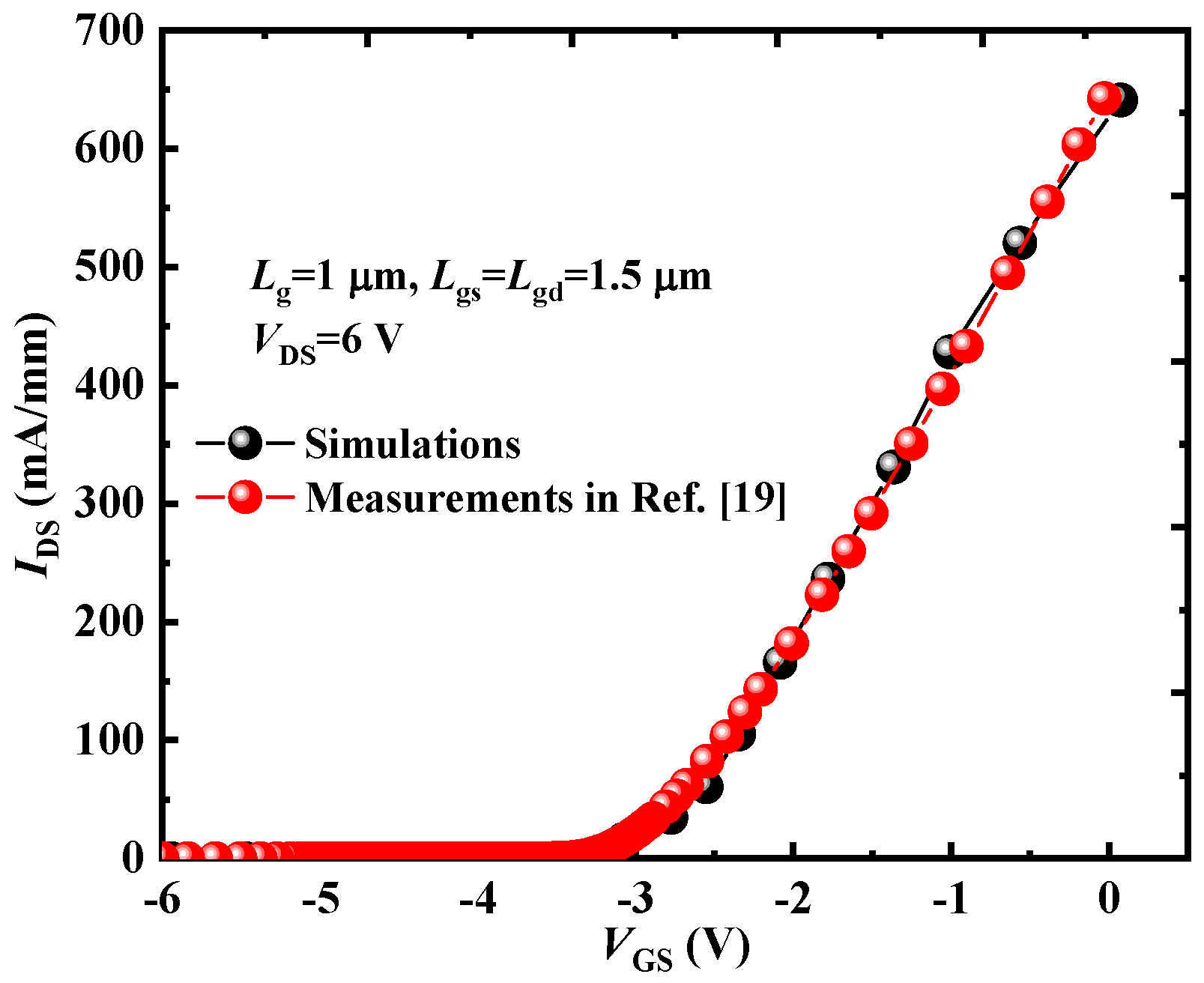

2. Structure and Simulation Models

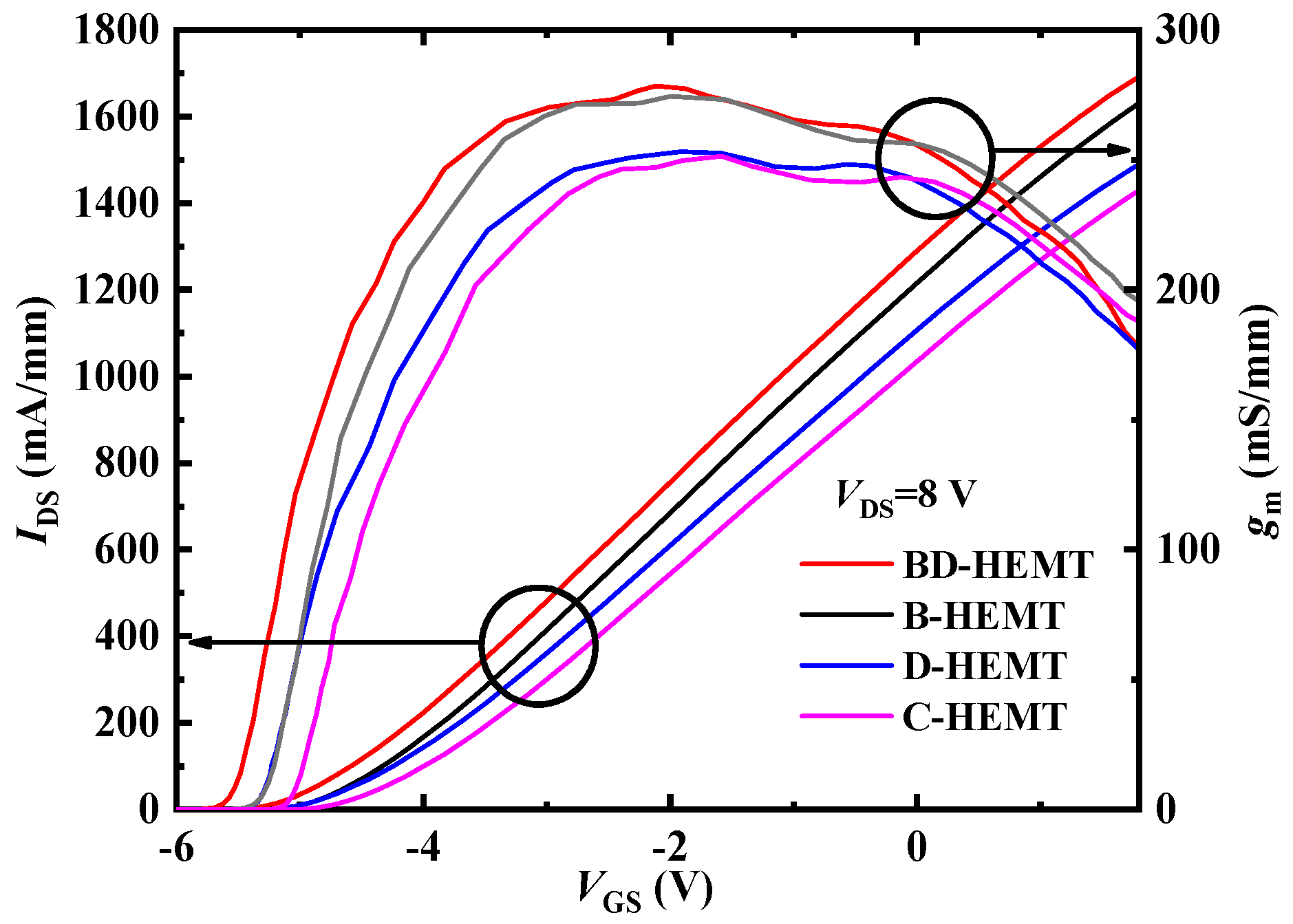

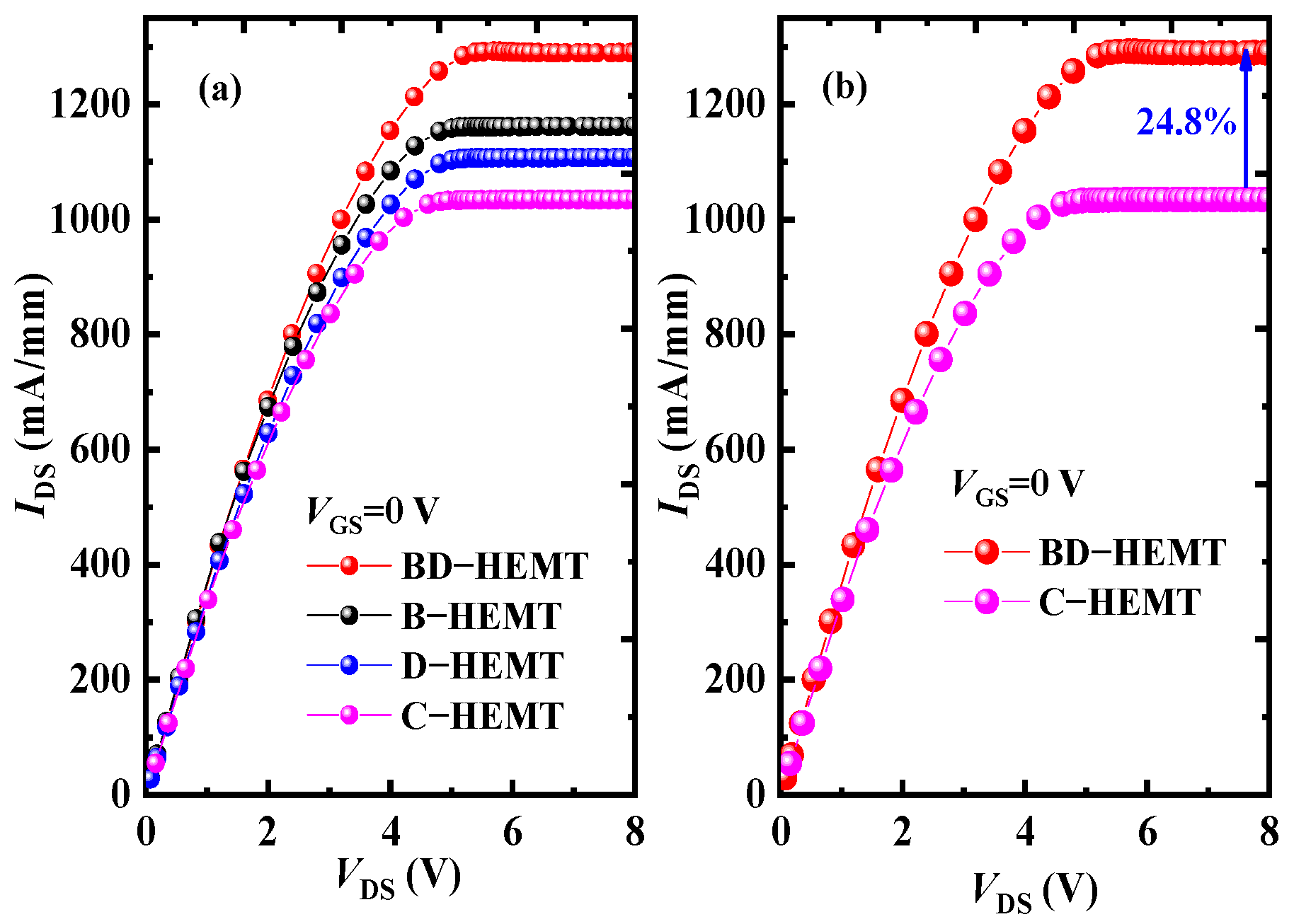

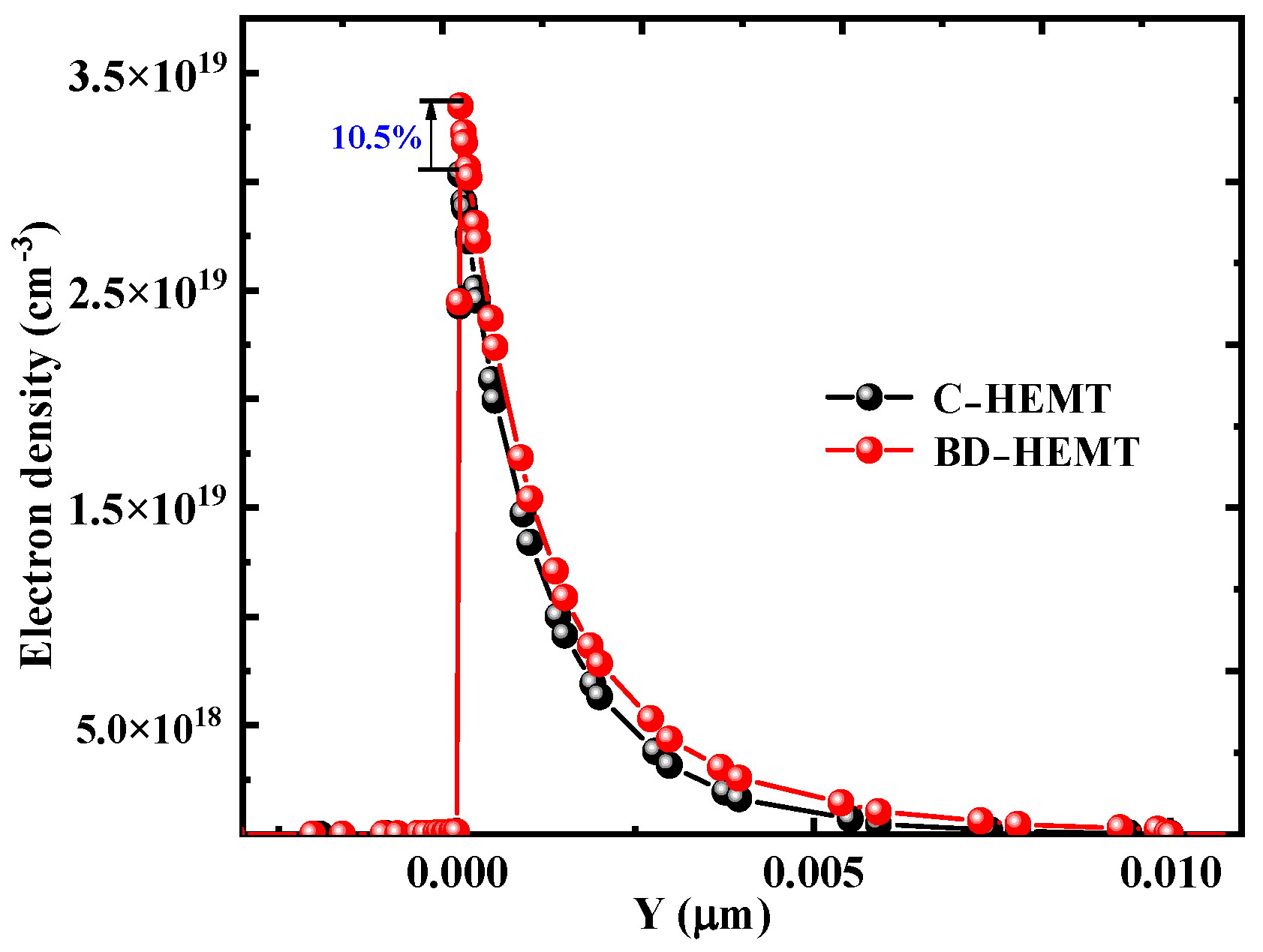

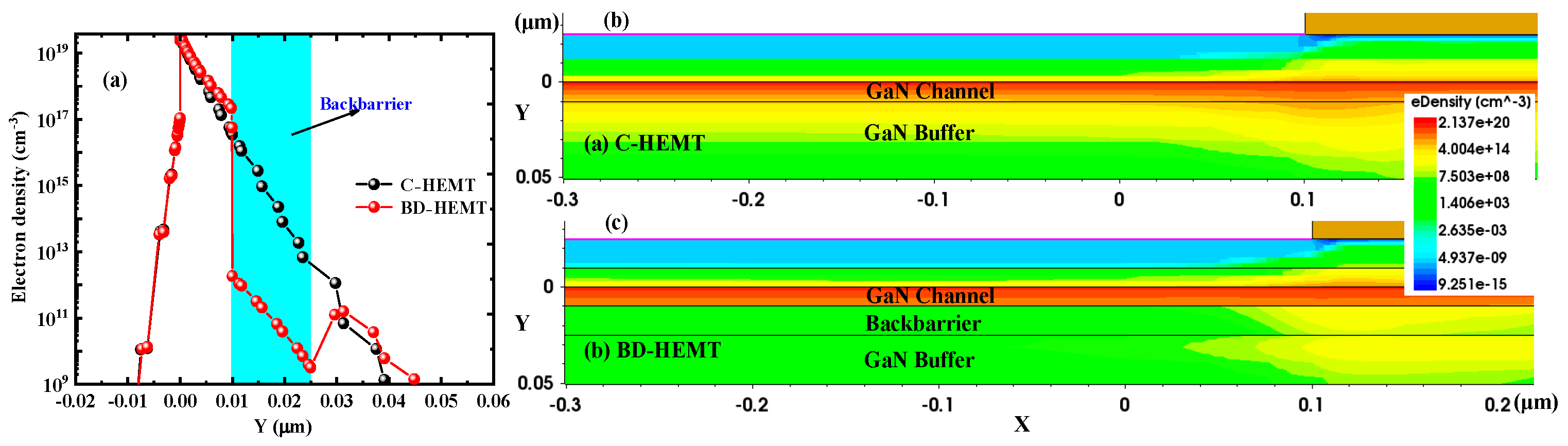

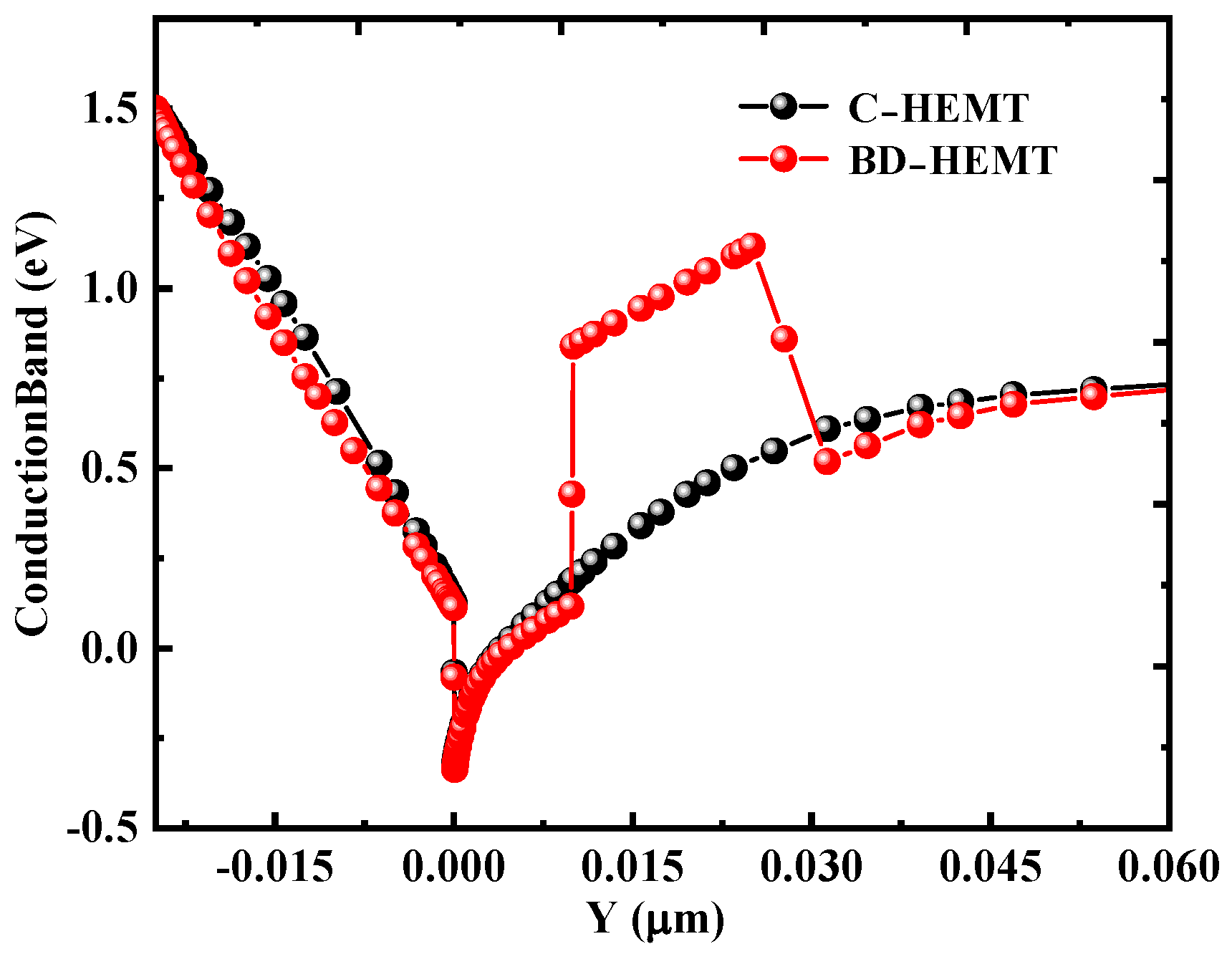

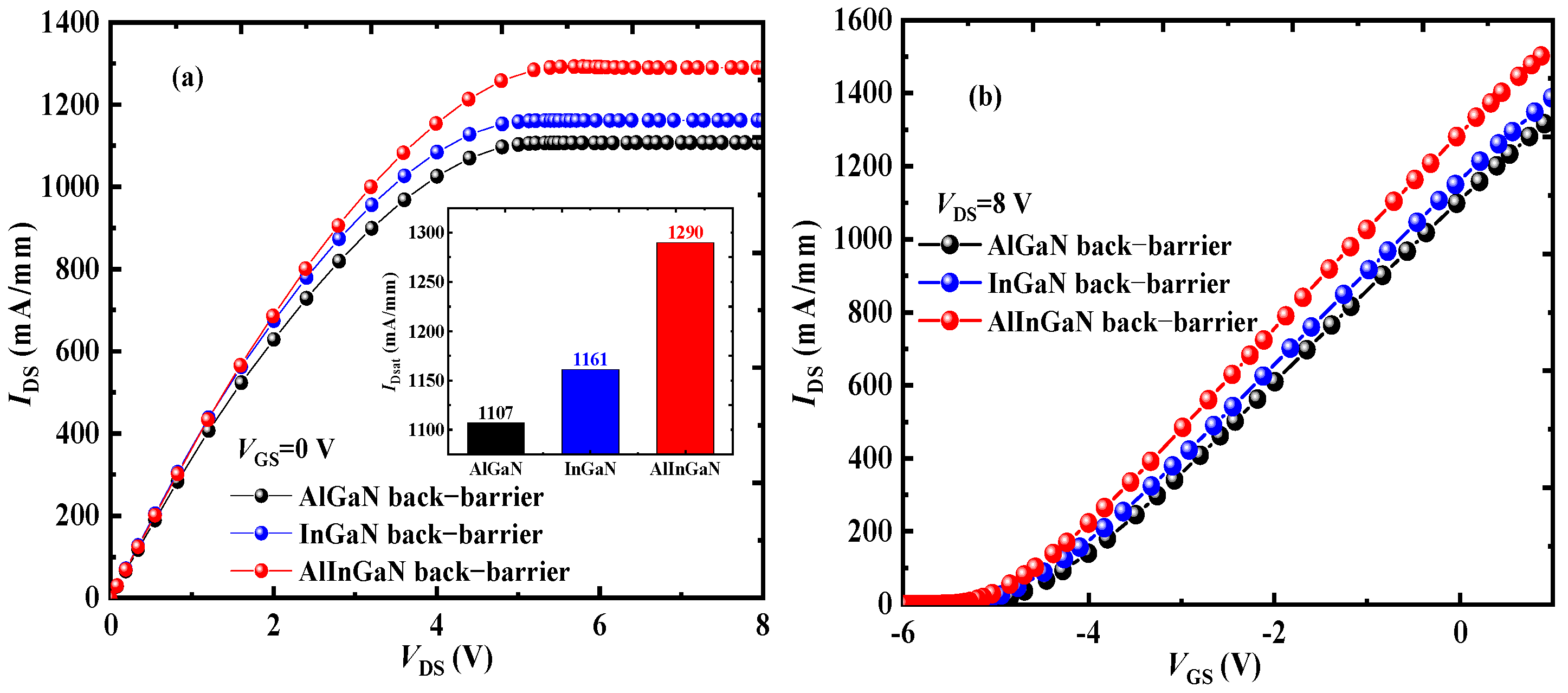

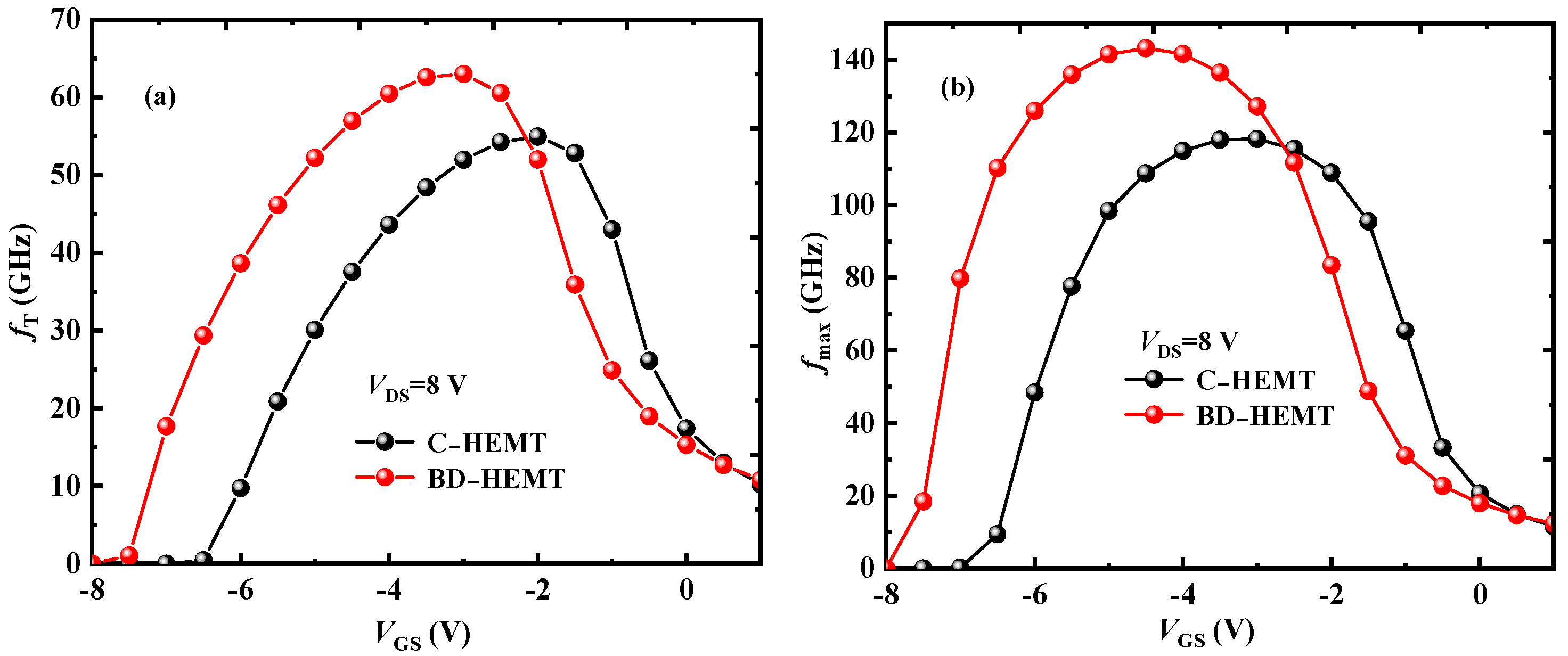

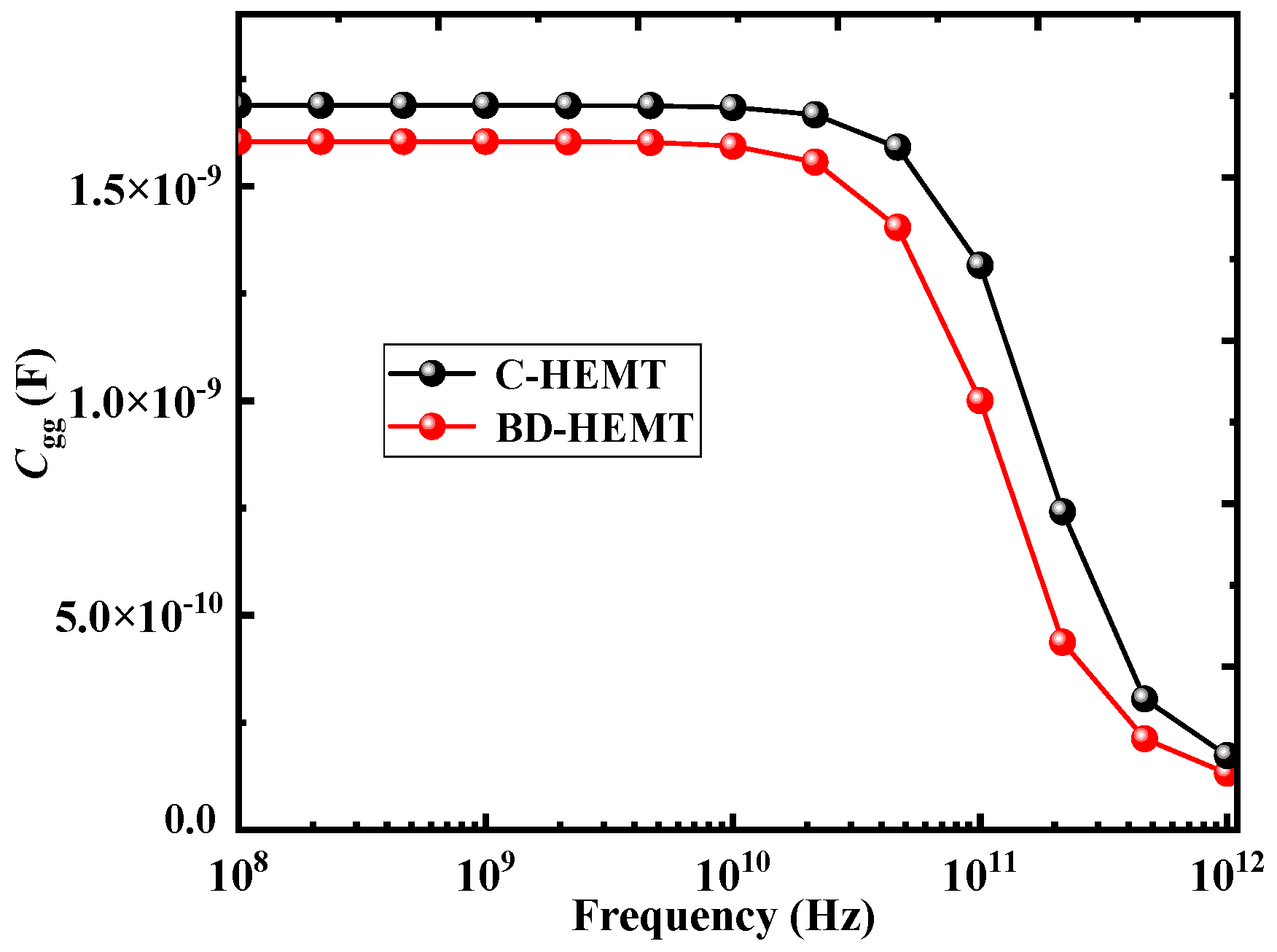

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Mounika, B.; Ajayan, J.; Bhattacharya, S.; Nirmal, D.; Dwivedi, A.K. LG = 50 nm T-gated and Fe-doped double quantum well GaN–HEMT on SiC wafer with graded AlGaN barrier for future power electronics applications. J. Sci. Adv. Mater. Devices 2024, 9, 100795. [Google Scholar] [CrossRef]

- Sun, S.X.; Zhang, Y.J.; Si, Y.H.; Xiong, J.; Luo, X.R. Improvement of Breakdown Characteristic for a Novel GaN HEMT with Enhanced Resistance Single-Event Transient Effect. J. Electron. Mater. 2025, 54, 784–791. [Google Scholar] [CrossRef]

- Mounika, B.; Ajayan, J.; Bhattacharya, S. Investigation on impact of AlxGa1-xN and InGaN back barriers and source-drain spacing on the DC/RF performance of Fe-doped recessed T-gated AlN/GaN HEMT on SiC wafer for future RF power applications. Micro Nanostruct. 2023, 175, 207504. [Google Scholar] [CrossRef]

- Haziq, M.; Falina, S.; Manaf, A.A.; Kawarada, H.; Syamsul, M. Challenges and Opportunities for High-Power and High-Frequency AlGaN/GaN High-Electron-Mobility Transistor (HEMT) Applications: A Review. Micromachines 2022, 13, 2133. [Google Scholar] [CrossRef]

- Wu, N.T.; Xing, Z.H.; Li, S.J.; Luo, L.; Zeng, F.Y.; Li, G.Q. GaN-based power high-electron-mobility transistors on Si substrates: From materials to devices. Semicond. Sci. Technol. 2023, 38, 063002. [Google Scholar] [CrossRef]

- Han, L.; Tang, X.; Wang, Z.; Gong, W.; Zhai, R.; Jia, Z.; Zhang, W. Research Progress and Development Prospects of Enhanced GaN HEMTs. Crystals 2023, 13, 911. [Google Scholar] [CrossRef]

- Zhang, H.C.; Wang, H.; Zhang, M.S.; Zuo, C.J.; Yang, L.; Yang, Y.S.; Ye, Y.K.; Qian, H.T.; Zhang, X.C.; Pei, Y.; et al. 2DEG-Concentration-Modulated High-Power-Density AlGaN/GaN RF HEMTs. IEEE Electron. Device Lett. 2024, 45, 1157–1160. [Google Scholar] [CrossRef]

- Sinha, K.; Dubey, S.K.; Islam, A. Study of high Al fraction in AlGaN barrier HEMT and GaN and InGaN channel HEMT with In0.17Al0.83N barrier. Microsyst. Technol. 2020, 26, 2145–2158. [Google Scholar] [CrossRef]

- Purnachandra Rao, G.; Lenka, T.R.; Boukortt, N.E.I.; Sadaf, S.M.; Nguyen, H.P.T. Investigation of performance enhancement of a recessed gate field-plated AlGaN/AlN/GaN nano-HEMT on β-Ga2O3 substrate with variation of AlN spacer layer thickness. J. Mater. Sci. Mater. Electron. 2023, 34, 1442. [Google Scholar]

- Liu, H.X.; Huang, H.M.; Wang, K.; Xie, Z.J.; Wang, H. Impact of composition and thickness of step-graded AlGaN barrier in AlGaN/GaN heterostructures. Mater. Sci. Eng. B 2024, 178, 108460. [Google Scholar] [CrossRef]

- Wang, H.L.; Yang, P.; Xu, K.; Duan, X.Y.; Sun, S.X. The AlInGaN back barrier effect on DC characteristics of AlGaN/GaN high electron mobility transistor. Int. J. Mod. Phys. B 2019, 33, 1950190. [Google Scholar] [CrossRef]

- Xiong, J.; Xie, X.T.; Wei, J.; Sun, S.X.; Luo, X.R. Improvement of Single Event Transient Effects for a Novel AlGaN/GaN High Electron-Mobility Transistor with a P-GaN Buried Layer and a Locally Doped Barrier Layer. Micromachines 2024, 15, 1158. [Google Scholar] [CrossRef]

- Fu, W.L.; Xu, Y.H.; Yan, B.; Zhang, B.; Xu, R.M. Numerical simulation of local doped barrier layer AlGaN/GaN HEMTs. Superlattices Microstruct. 2013, 60, 443–452. [Google Scholar] [CrossRef]

- Jia, Y.; Wang, Q.; Chen, C.; Feng, C.; Li, W.; Jiang, L.; Xiao, H.; Wang, Q.; Xu, X.; Wang, X. Simulation of a Parallel Dual-Metal-Gate Structure forAlGaN/GaN High-Electron-Mobility Transistor High-Linearity Applications. Phys. Status Solidi A 2021, 218, 2100151. [Google Scholar] [CrossRef]

- Bindhu, S.K.H.; Verma, Y.K.; Dheep, G.R. DC and RF performance analysis of scaled AlInN/GaN HEMTs with single and double-gate structures. Micro Nanostruct. 2025, 205, 208173. [Google Scholar] [CrossRef]

- Akshaykranth, A.; Ajayan, J.; Bhattacharya, S.; Nirmal, D.; Paramasivam, S.; Gatto, G.; Kumar, A. Aggressively scaled T-Gated GaN-on-silicon RF power HEMT featuring step graded SRL-AlGaN buffer for next generation broad band power amplifiers. Results Eng. 2025, 25, 104151. [Google Scholar] [CrossRef]

- Feng, B.M.; Wang, Y.; Yu, C.H.; Guo, H.M. A novel p-GaN HEMT with superjunction silicon substrate for improved current collapse. Micro Nanostruct. 2025, 201, 208102. [Google Scholar] [CrossRef]

- Sun, S.X.; Xie, X.T.; Zhang, P.F.; Zhao, Z.J.; Wei, J.; Luo, X.R. Improvement of single event transients effect for a novel AlGaN/GaN HEMT with enhanced breakdown voltage. J. Sci. Adv. Mater. Devices 2024, 9, 100692. [Google Scholar] [CrossRef]

- Huang, J.; Li, M.; Tang, C.W.; Lau, K.M. Lg = 100 nm T-shaped gate AlGaN/GaN HEMTs on Si substrates with non-planar source/drain regrowth of highly-doped n+-GaN layer by MOCVD. Chin. Phys. B 2014, 23, 128102. [Google Scholar] [CrossRef]

- Mojaver, H.R.; Gosselin, J.L.; Valizadeh, P. Use of a bilayer lattice-matched AlInGaN barrier for improving the channel carrier confinement of enhancement-mode AlInGaN/GaN hetero-structure field-effect transistors. J. Appl. Phys. 2017, 121, 244502. [Google Scholar] [CrossRef]

- Adak, S.; Sarkar, A.; Swain, S.; Pardeshi, H.; Pat, S.K.; Sarkar, C.K. High performance AlInN/AlN/GaN p-GaN back barrier Gate-Recessed Enhancement-Mode HEMT. Superlattices Microstruct. 2014, 75, 347–357. [Google Scholar] [CrossRef]

| Layer | Value |

|---|---|

| Passivation layer | 50 nm |

| N-type locally doped barrier layer | 20 nm |

| Al0.3Ga0.7N barrier layer | 25 nm |

| GaN channel layer | 10 nm |

| Al0.7In0.15Ga0.15N back-barrier layer | 15 nm |

| GaN buffer layer | 1.5 μm |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, S.; Liu, L.; Qu, G.; Xie, X.; Ajayan, J. Improved DC and RF Characteristics of GaN HEMT Using a Back-Barrier and Locally Doped Barrier Layer. Micromachines 2025, 16, 779. https://doi.org/10.3390/mi16070779

Sun S, Liu L, Qu G, Xie X, Ajayan J. Improved DC and RF Characteristics of GaN HEMT Using a Back-Barrier and Locally Doped Barrier Layer. Micromachines. 2025; 16(7):779. https://doi.org/10.3390/mi16070779

Chicago/Turabian StyleSun, Shuxiang, Lulu Liu, Gangchuan Qu, Xintong Xie, and J. Ajayan. 2025. "Improved DC and RF Characteristics of GaN HEMT Using a Back-Barrier and Locally Doped Barrier Layer" Micromachines 16, no. 7: 779. https://doi.org/10.3390/mi16070779

APA StyleSun, S., Liu, L., Qu, G., Xie, X., & Ajayan, J. (2025). Improved DC and RF Characteristics of GaN HEMT Using a Back-Barrier and Locally Doped Barrier Layer. Micromachines, 16(7), 779. https://doi.org/10.3390/mi16070779