From Indoor to Daylight Electroluminescence Imaging for PV Module Diagnostics: A Comprehensive Review of Techniques, Challenges, and AI-Driven Advancements

Abstract

1. Introduction

1.1. Overview of Electroluminescence (EL) Imaging

1.2. Importance of EL Imaging in Photovoltaic Systems

1.3. Scope and Objectives of the Review

2. Key Requirements for Electroluminescence Imaging

2.1. Physical and Operational Requirements for EL Imaging

2.2. Instrumentation and Imaging Equipment Essentials for Indoor EL

- Module Stand: For indoor EL imaging, a stable setup that ensures a consistent module position is essential. Figure 6 illustrates an example of a wall-mounted frame used to secure the test modules, ensuring a perpendicular module-to-camera perspective. The rail is adjustable to accommodate different module sizes.

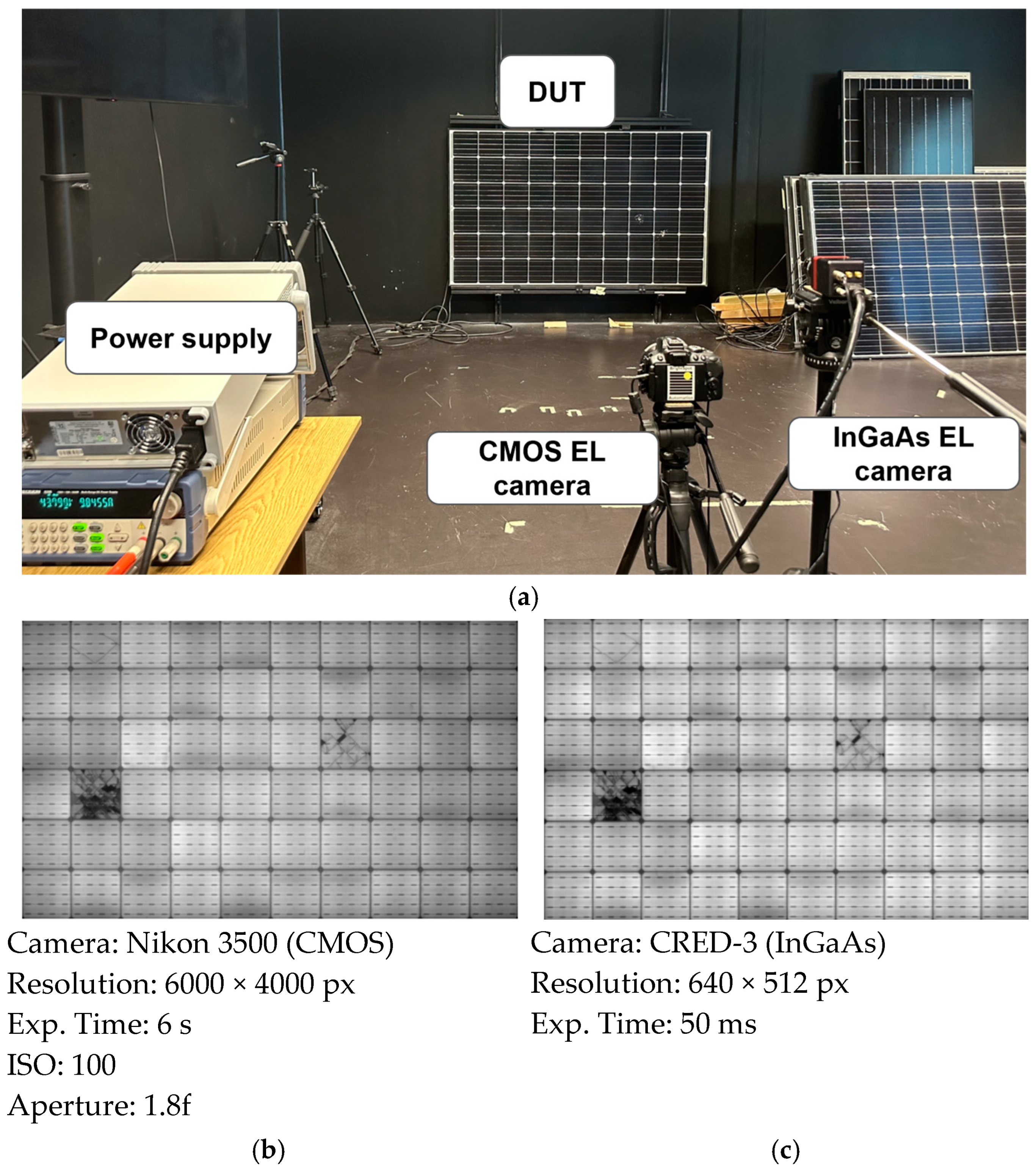

- Camera: The camera setup, as shown in Figure 6, consists of an EL-compatible camera mounted on a tripod. The camera should be positioned as perpendicularly as possible to the module, with the tripod allowing adjustments to different heights. The focus must be set to achieve sharp image quality for defect visualization. Two types of cameras are commonly used for EL imaging:

- ○

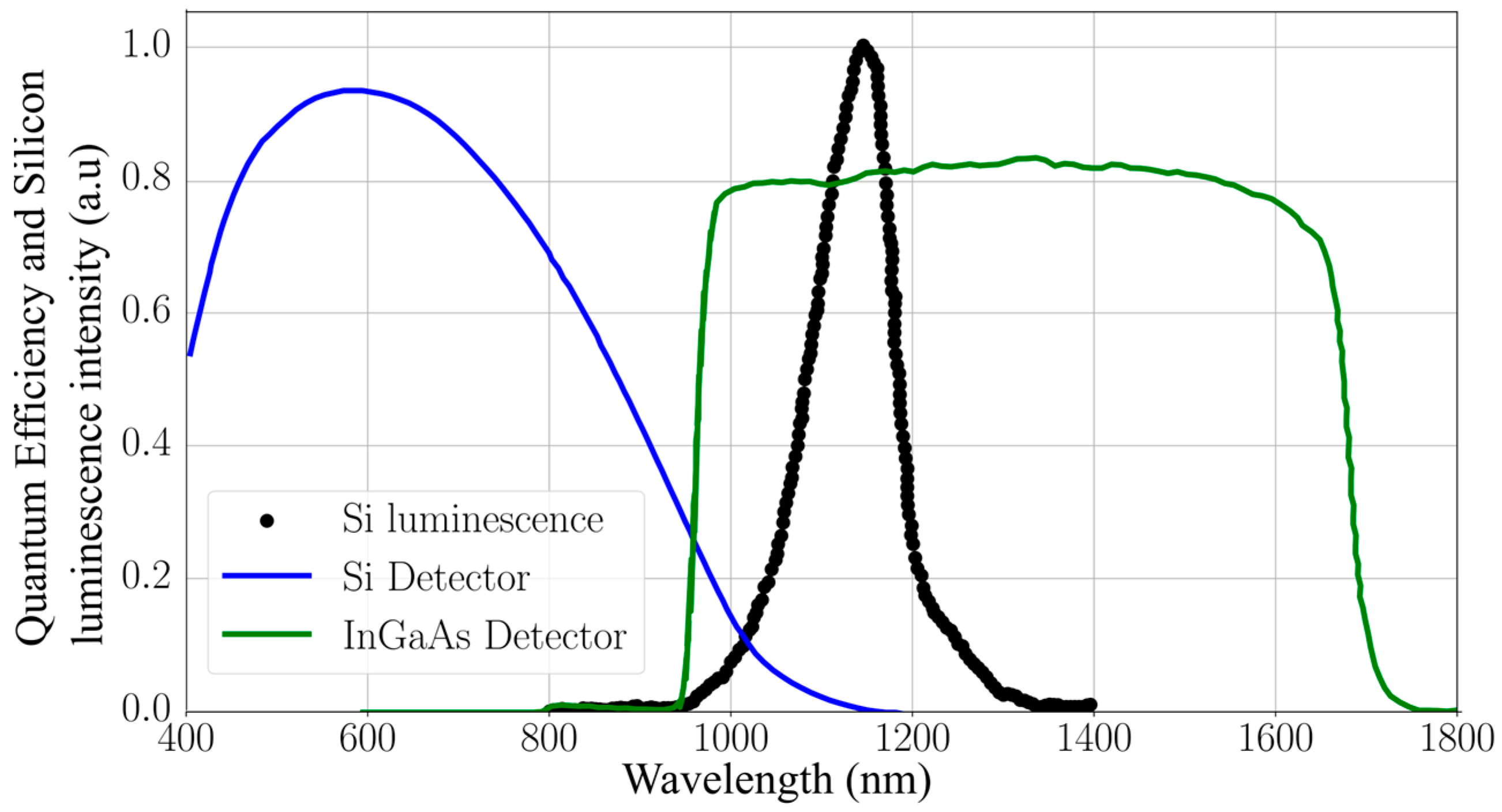

- CMOS Cameras (with the IR filter removed): These cameras capture EL emissions up to 1100 nm and typically offer high resolution. They require longer exposure times (several seconds), depending on the module technology, as well as tunable ISO and aperture settings.

- ○

- InGaAs Cameras: These cameras operate within the 950–1300 nm range, which perfectly overlaps with the emission spectrum of crystalline silicon. As a result, they require shorter exposure times for EL imaging. However, they generally have lower resolution compared to CMOS cameras.

- Power Supply Unit (PSU): A DC power supply is used to forward bias the PV module, generating the EL signal necessary for imaging.

- Camera Remote Control: Software control of the camera allows for the precise adjustment of ISO, exposure time, and aperture settings, ensuring high-quality EL image acquisition.

2.3. Challenges in Indoor and Outdoor EL Imaging

3. Recent Advancements in Electroluminescence Imaging: Innovations of Outdoor Daylight EL Imaging

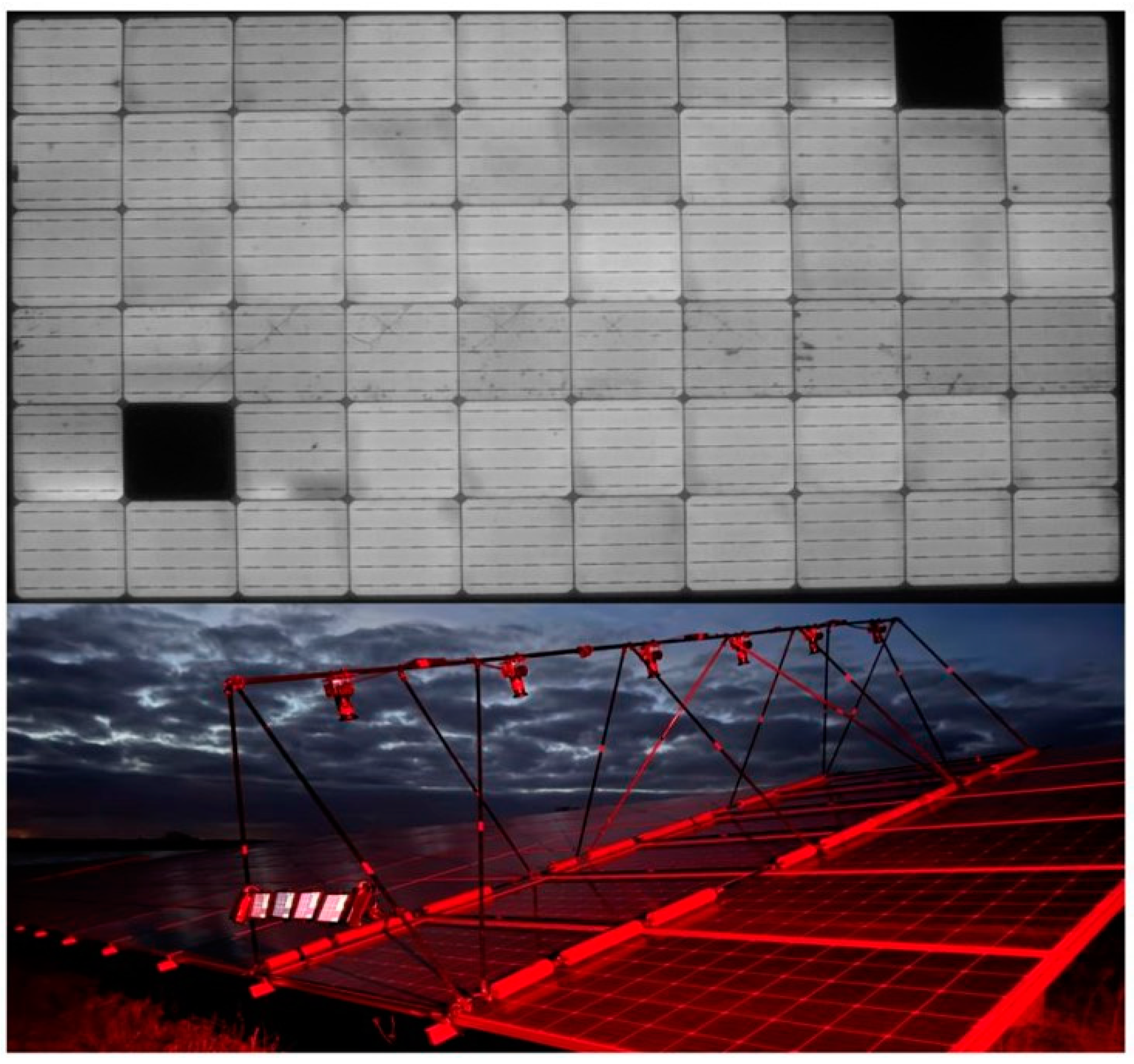

3.1. Hardware Innovations for Daylight EL Imaging

- Connection step (1): The InGaAs camera directly captures EL emissions under ambient sunlight, highlighting the versatility of the setup in adapting to varying outdoor lighting conditions.

- Connection step (2): A secondary connection from the PSU to the PV module ensures stable current injection when producing the EL signal. Present-day PSU’s have built-in sequencers or function generators that can be used to program a modulated current signal to the PV string. Alternatively, oscilloscopes or switching boxes can be used to create the modulated current sequence.

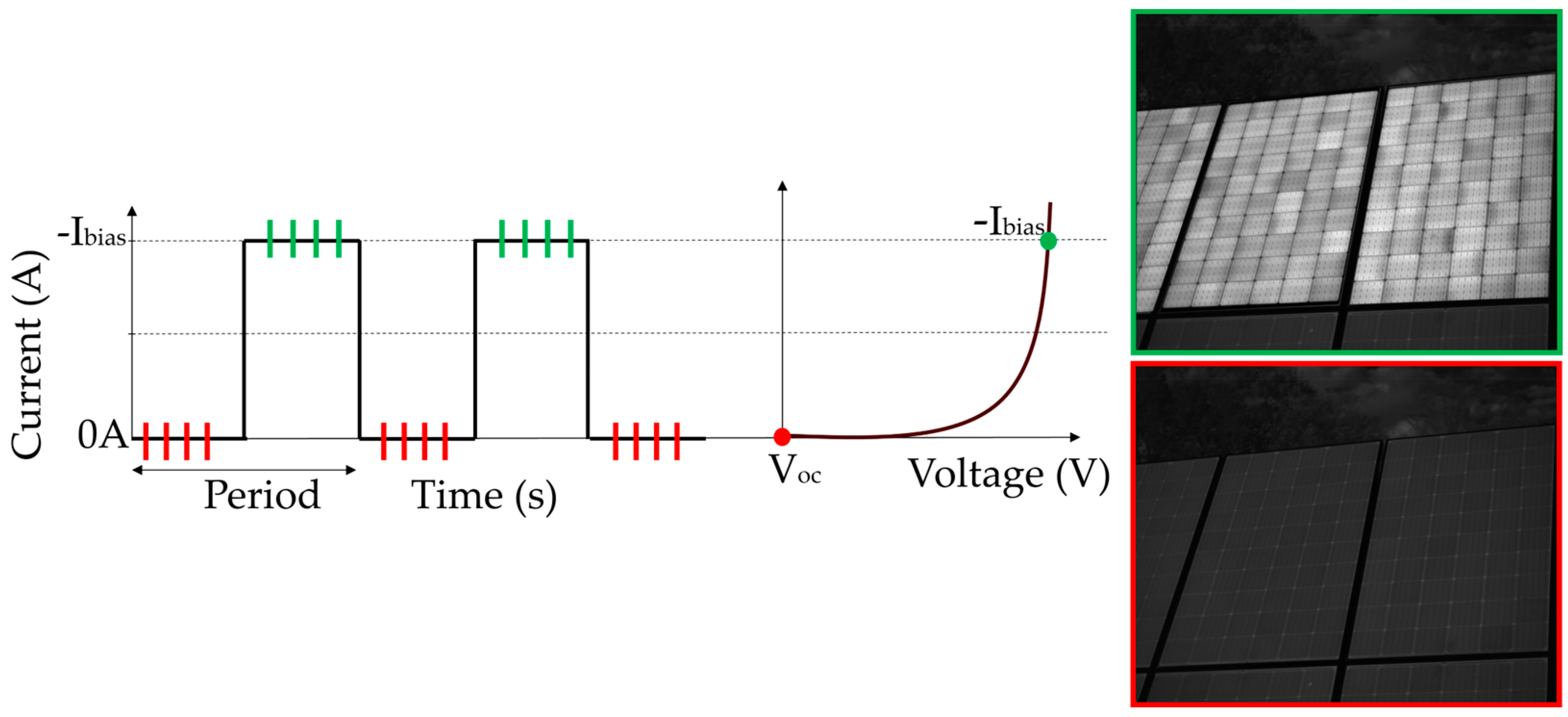

- Periodic Current Injection for Modulation: Daylight EL imaging techniques commonly utilize a periodic current waveform, typically in the range of 20–50 Hz, with 30 Hz being a frequently cited value in the literature. This waveform ensures that the EL signal can be effectively distinguished from the ambient light background. The alternating ON and OFF states of the current allow clear separation between EL-active images and background-only images [3,4,61].

- Simultaneous Acquisition of EL and Background Images: Advanced imaging systems, often equipped with InGaAs cameras, capture both EL and background images during the modulation process. During the ON phase of the current, the camera captures the EL emission from the PV module, while during the OFF phase, it records only the ambient background. This dual-image acquisition facilitates robust background subtraction in subsequent processing stages.

- Signal Averaging to Enhance SNR: To mitigate noise and improve the clarity of EL images, several studies recommend averaging multiple frames of both the ON and OFF states of sequential frames in the same modulation period. This averaging process reduces random noise and significantly enhances the SNR, a critical factor for accurate defect detection under high ambient light conditions.

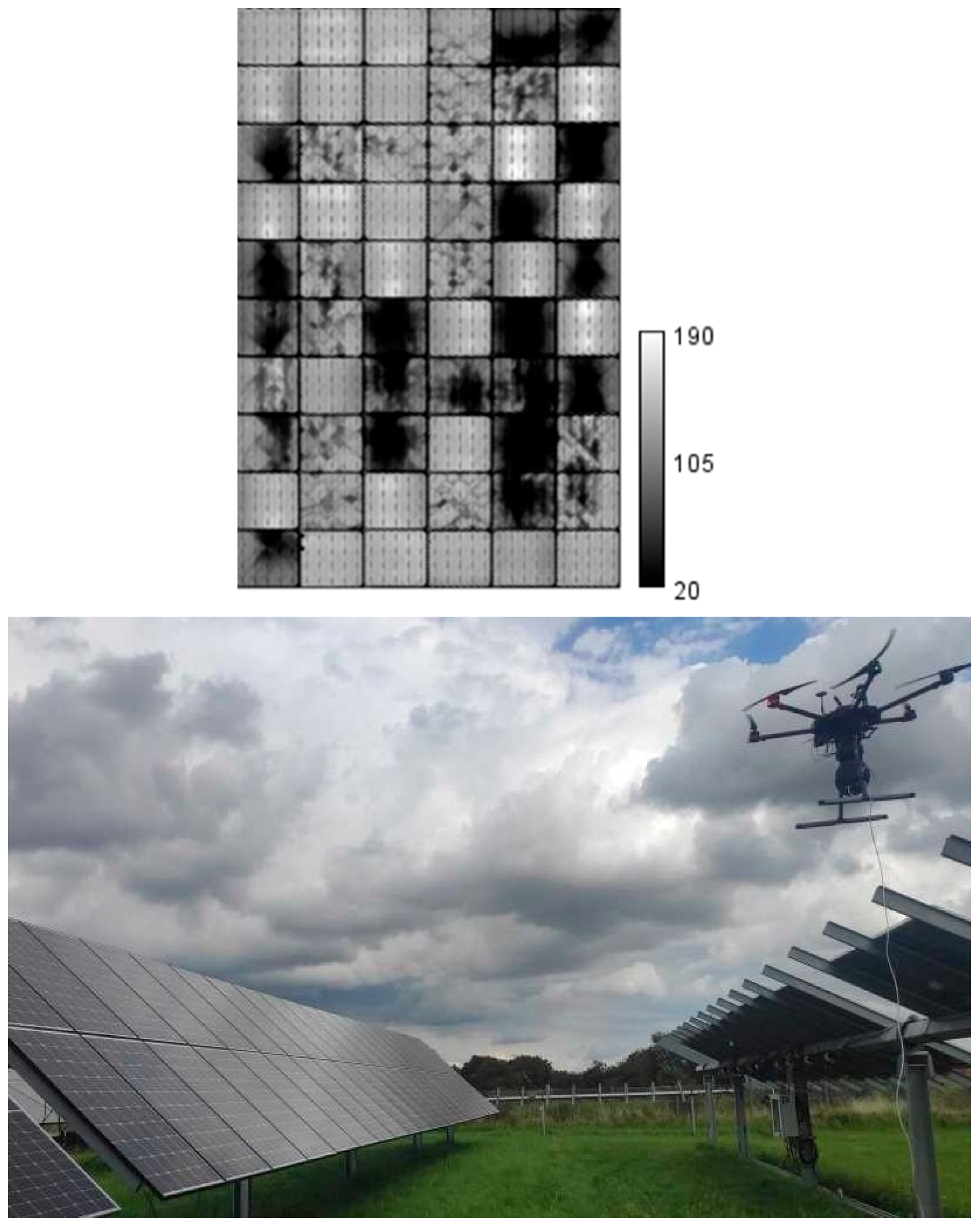

- Processed Output for Defect Identification: The processed output, obtained by subtracting the averaged background image from the averaged EL image, results in a clean and high contrast EL image. As shown in the example of Figure 8, this method effectively highlights module defects, such as microcracks, inactive areas, and degradation patterns, even in challenging daylight environments.

3.2. Why InGaAs Cameras Are Most Suitable for Outdoor EL Imaging

3.3. The Use of Optical Filters in Daylight Luminescence Imaging

3.4. Field Application of Daylight EL: Case Study

4. AI-Driven Perspectives in EL Imaging

4.1. Introduction to AI in EL Imaging

4.2. Advancements in AI for Solar PV Defect Detection and Segmentation (2022)

4.3. Advancements in AI for Solar PV Defect Detection and Segmentation (2023)

4.4. Advancements in AI for Solar PV Crack Detection and Segmentation (2024)

5. Future Perspectives and Research Directions

5.1. Challenges in Scaling Outdoor Daylight EL Imaging

5.2. Role of AI in Enhancing EL Imaging Techniques

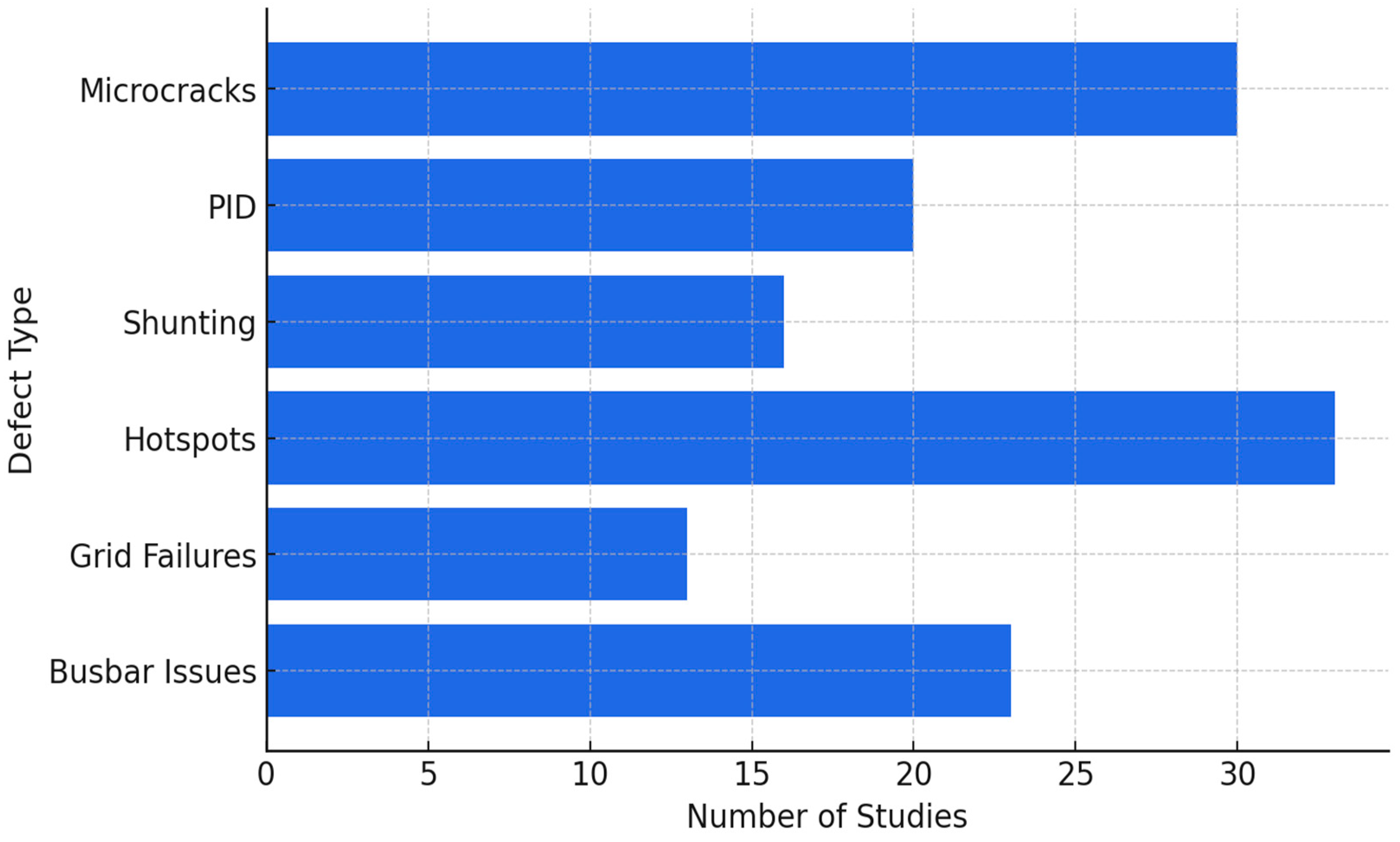

- Cell-Level Focus: most studies concentrate on cell-level defect detection and segmentation, often overlooking the complexities of module-level analysis. Real-world industrial systems comprise interconnected cells within larger modules, where defects can propagate and interact in ways that cell-level models cannot capture. Developing EL module-level datasets and algorithms is essential for industrial-scale deployment, as these tools must address challenges such as inter-cell electrical interactions, shading effects, and module-wide fault patterns.

- Dataset Diversity: current datasets, such as PVEL-AD and ELPV, while foundational to the field, fail to encompass the wide variability of PV module designs and configurations. For instance, there is a lack of representation of diverse PV cell layouts, including monocrystalline, polycrystalline, full cells, and half-cut cells, which are increasingly common in modern PV systems. Additionally, module-level EL imaging datasets are severely underrepresented, limiting the ability of AI models to generalize effectively from cell-level to module-level defect detection. Furthermore, the datasets currently available do not include bifacial PV panels (cell- or module-level EL data), which are considered the next generation of PV panels, being increasingly installed in the field. This lack of diversity in dataset types restricts the adaptability and reliability of AI-driven defect detection models in addressing real-world scenarios and evolving PV technologies.

- Single-Modality Approaches: the dominance of EL imaging limits the scope of defect detection. Non-electrical defects, such as discoloration or soiling, remain challenging to identify without incorporating visual or thermal imaging.

- Scalability of Lightweight Models: lightweight architectures have shown promise in resource-constrained environments, offering low computational overhead. However, their scalability remains questionable when applied to complex defects or large-scale industrial PV systems. Current models often lack the robustness needed to handle diverse defect types, varying imaging modalities, or the data volume associated with operational plants, posing a barrier to their widespread deployment.

- Integration into Industrial Pipelines: transitioning from laboratory-scale studies to industrial applications presents significant challenges. Many AI models lack real-world validation and fail to account for the complexities of operational PV plants, such as varying lighting conditions, module orientations, and degradation over time. The absence of standardized metrics and protocols for industrial-scale validation further hinders their adoption.

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

- Mean Average Precision (mAP). mAP@0.5: The average precision calculated at a single Intersection over Union (IoU) threshold of 0.5 (50%). It measures how well the model identifies defects while considering overlap accuracy between the predicted and ground truth bounding boxes. mAP@0.5–0.95: The average precision calculated over multiple IoU thresholds (from 0.5 to 0.95 in 0.05 increments). It provides a more comprehensive evaluation of the model’s detection performance, especially for nuanced and smaller defects. Significance: mAP is a standard metric for object detection tasks, balancing precision and recall across multiple thresholds.

- Detection Accuracy. Definition: The ratio of correctly identified defects (true positives) to the total number of predictions. It is predominantly used in classification models where the model assigns a defect type to a given input. Significance: Provides an overview of the model’s performance in distinguishing defective versus non-defective instances.

- 3.

- Average Precision (AP). Definition: The area under the precision–recall (PR) curve for a specific class or defect type. It quantifies how well a model balances precision and recall (where is Recall). Significance: AP is used for evaluating object detection and segmentation models, offering insights into the model’s capability to detect a particular defect.

- 4.

- Recall. Definition: The ratio of correctly identified positive cases (true positives) to the total actual positives (true positives + false negatives). Significance: Recall emphasizes the model’s ability to identify all instances of a defect, even at the cost of some false positives.

- 5.

- Precision. Definition: The ratio of correctly identified positive cases (true positives) to the total predicted positives (true positives + false positives). Significance: Precision evaluates the model’s ability to avoid false alarms, ensuring the detected defects are accurate.

- 6.

- F1-Score. Definition: The harmonic mean of Precision and Recall, providing a single metric that balances both. Significance: Particularly useful when there is an imbalance between classes or when both false positives and false negatives need to be equally minimized.

- 7.

- Intersection over Union (IoU). Definition: A measure of overlap between the predicted bounding box and the ground truth bounding box. Significance: IoU evaluates the spatial accuracy of object detection models.

- 8.

- Area Under the Receiver Operating Characteristic Curve (AUROC). Definition: Represents the trade-off between true positive rate (sensitivity) and false positive rate (1-specificity) across different thresholds. Significance: Higher AUROC scores indicate better model discrimination capability.

References

- Jahn, U.; Herz, M.; Köntges, M.; Parlevliet, D.; Paggi, M.; Tsanakas, I.; Stein, J.S.; Berger, K.A.; Ranta, S.; French, R.H.; et al. Review on Infrared and Electroluminescence Imaging for PV Field Applications; International Energy Agency: Paris, France, 2018. [Google Scholar]

- Rahman, M.M.; Khan, I.; Alameh, K. Potential Measurement Techniques for Photovoltaic Module Failure Diagnosis: A Review. Renew. Sustain. Energy Rev. 2021, 151, 111532. [Google Scholar] [CrossRef]

- Alves dos Reis Benatto, G.; Mantel, C.; Spataru, S.; Santamaria Lancia, A.A.; Riedel, N.; Thorsteinsson, S.; Poulsen, P.B.; Parikh, H.; Forchhammer, S.; Sera, D. Drone-Based Daylight Electroluminescence Imaging of PV Modules. IEEE J. Photovolt. 2020, 10, 872–877. [Google Scholar] [CrossRef]

- Guada, M.; Moretón, Á.; Rodríguez-Conde, S.; Sánchez, L.A.; Martínez, M.; González, M.Á.; Jiménez, J.; Pérez, L.; Parra, V.; Martínez, O. Daylight Luminescence System for Silicon Solar Panels Based on a Bias Switching Method. Energy Sci. Eng. 2020, 8, 3839–3853. [Google Scholar] [CrossRef]

- Mantel, C.; dos Reis Benatto, G.A.; Riedel, N.; Thorsteinsson, S.; Poulsen, P.B.; Parikh, H.; Spataru, S.; Sera, D.; Forchhammer, S. SNR Study of Outdoor Electroluminescence Images under High Sun Irradiation. In Proceedings of the 2018 IEEE 7th World Conference on Photovoltaic Energy Conversion (WCPEC) (A Joint Conference of 45th IEEE PVSC, 28th PVSEC & 34th EU PVSEC), Waikoloa, HI, USA, 10–15 June 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 3285–3289. [Google Scholar]

- Fuyuki, T.; Kondo, H.; Yamazaki, T.; Takahashi, Y.; Uraoka, Y. Photographic Surveying of Minority Carrier Diffusion Length in Polycrystalline Silicon Solar Cells by Electroluminescence. Appl. Phys. Lett. 2005, 86, 262108. [Google Scholar] [CrossRef]

- Köntges, M.; Kurtz, S.; Packard, C.; Jahn, U.; Berger, K.A.; Kato, K.; Friesen, T.; Liu, H.; Van Iseghem, M. Review of Failures of Photovoltaic Modules; SUPSI: Mendrisio, Switzerland, 2014. [Google Scholar]

- Jordan, D.C.; Silverman, T.J.; Wohlgemuth, J.H.; Kurtz, S.R.; VanSant, K.T. Photovoltaic Failure and Degradation Modes. Progress Photovolt. Res. Appl. 2017, 25, 318–326. [Google Scholar] [CrossRef]

- Makrides, G.; Zinsser, B.; Schubert, M.; Georghiou, G.E. Performance Loss Rate of Twelve Photovoltaic Technologies under Field Conditions Using Statistical Techniques. Sol. Energy 2014, 103, 28–42. [Google Scholar] [CrossRef]

- Deceglie, M.G.; Silverman, T.J.; Young, E.; Hobbs, W.B.; Libby, C. Field and Accelerated Aging of Cracked Solar Cells. IEEE J. Photovolt. 2023, 13, 836–841. [Google Scholar] [CrossRef]

- Kajari-Schršder, S.; Kunze, I.; Kšntges, M. Criticality of Cracks in PV Modules. Energy Procedia 2012, 27, 658–663. [Google Scholar] [CrossRef]

- Köntges, M.; Kunze, I.; Kajari-Schröder, S.; Breitenmoser, X.; Bjørneklett, B. The Risk of Power Loss in Crystalline Silicon Based Photovoltaic Modules Due to Micro-Cracks. Sol. Energy Mater. Sol. Cells 2011, 95, 1131–1137. [Google Scholar] [CrossRef]

- Luo, W.; Hacke, P.; Terwilliger, K.; Liang, T.S.; Wang, Y.; Ramakrishna, S.; Aberle, A.G.; Khoo, Y.S. Elucidating Potential-induced Degradation in Bifacial PERC Silicon Photo-voltaic Modules. Progress Photovolt. Res. Appl. 2018, 26, 859–867. [Google Scholar] [CrossRef]

- Deceglie, M.G.; Silverman, T.J.; Johnston, S.W.; Rand, J.A.; Reed, M.J.; Flottemesch, R.; Repins, I.L. Light and Elevated Temperature Induced Degradation (LeTID) in a Utility-Scale Photovoltaic System. IEEE J. Photovolt. 2020, 10, 1084–1092. [Google Scholar] [CrossRef]

- Kyranaki, N.; Smith, A.; Yendall, K.; Hutt, D.A.; Whalley, D.C.; Gottschalg, R.; Betts, T.R. Damp-heat Induced Degradation in Photovoltaic Modules Manufactured with Passivated Emitter and Rear Contact Solar Cells. Progress Photovolt. Res. Appl. 2022, 30, 1061–1071. [Google Scholar] [CrossRef]

- Trupke, T.; Kunz, O.; Weber, J.W. Daylight Photoluminescence Imaging: Quantitative Analysis of String Voltage Mismatch and Balancing Currents. Progress Photovolt. Res. Appl. 2025, 33, 435–444. [Google Scholar] [CrossRef]

- Muehleisen, W.; Eder, G.C.; Voronko, Y.; Spielberger, M.; Sonnleitner, H.; Knoebl, K.; Ebner, R.; Ujvari, G.; Hirschl, C. Outdoor Detection and Visualization of Hailstorm Damages of Photovoltaic Plants. Renew. Energy 2018, 118, 138–145. [Google Scholar] [CrossRef]

- Puranik, V.E.; Gupta, R. Analysis and Insight of Electroluminescence Imaging in the Assessment of Potential-Induced Degradation in Crystalline Silicon Photovoltaic Module. Eng. Fail. Anal. 2022, 134, 106027. [Google Scholar] [CrossRef]

- Koester, L.; Lindig, S.; Louwen, A.; Astigarraga, A.; Manzolini, G.; Moser, D. Review of Photovoltaic Module Degradation, Field Inspection Techniques and Techno-Economic Assessment. Renew. Sustain. Energy Rev. 2022, 165, 112616. [Google Scholar] [CrossRef]

- Jordan, D.C.; Kurtz, S.R. Photovoltaic Degradation Rates—An Analytical Review. Progress Photovolt. Res. Appl. 2013, 21, 12–29. [Google Scholar] [CrossRef]

- Daher, D.H.; Aghaei, M.; Quansah, D.A.; Adaramola, M.S.; Parvin, P.; Ménézo, C. Multi-pronged Degradation Analysis of a Photovoltaic Power Plant after 9.5 Years of Operation under Hot Desert Climatic Conditions. Progress Photovolt. Res. Appl. 2023, 31, 888–907. [Google Scholar] [CrossRef]

- Suleske, A.; Singh, J.; Kuitche, J.; Tamizh-Mani, G. Performance Degradation of Grid-Tied Photovoltaic Modules in a Hot-Dry Climatic Condition. In Reliability of Photovoltaic Cells, Modules, Components, and Systems IV; Dhere, N.G., Wohlgemuth, J.H., Lynn, K.W., Eds.; SPIE: Bellingham, WA, USA, 2011. [Google Scholar]

- Alimi, O.A.; Meyer, E.L.; Olayiwola, O.I. Solar Photovoltaic Modules’ Performance Re-liability and Degradation Analysis—A Review. Energies 2022, 15, 5964. [Google Scholar] [CrossRef]

- Dhimish, M.; Schofield, N.; Attya, A. Insights on the Degradation and Performance of 3000 Photovoltaic Installations of Various Technologies Across the United Kingdom. IEEE Trans Ind. Inf. 2021, 17, 5919–5926. [Google Scholar] [CrossRef]

- del Prado Santamaria, R.; Kari, T.; Alves dos Reis Benatto, G.; Ng, J.; Poulsen, P.; Spataru, S. Machine Aided Estimation of Solar Cell Crack Caused Power Loss from Electroluminescence Images. In Proceedings of the 8th World Conference on Photovoltaic Energy Conversion, Milano, Italy, 26–30 September 2022; pp. 480–487. [Google Scholar]

- Bedrich, K.G.; Luo, W.; Pravettoni, M.; Chen, D.; Chen, Y.; Wang, Z.; Verlinden, P.J.; Hacke, P.; Feng, Z.; Chai, J.; et al. Quantitative Electroluminescence Imaging Analysis for Performance Estimation of PID-Influenced PV Modules. IEEE J. Photovolt. 2018, 8, 1281–1288. [Google Scholar] [CrossRef]

- Puranik, V.E.; Gupta, R. Novel Quantitative Electroluminescence Method for Detailed Performance Analysis of PID-s Affected Crystalline Silicon PV Module. IEEE J. Photovolt. 2021, 11, 1470–1478. [Google Scholar] [CrossRef]

- Kropp, T.; Schubert, M.; Werner, J. Quantitative Prediction of Power Loss for Damaged Photovoltaic Modules Using Electroluminescence. Energies 2018, 11, 1172. [Google Scholar] [CrossRef]

- Hoffmann, M.; Buerhop-Lutz, C.; Reeb, L.; Pickel, T.; Winkler, T.; Doll, B.; Würfl, T.; Marius Peters, I.; Brabec, C.; Maier, A.; et al. Deep-learning-based Pipeline for Module Power Prediction from Electroluminescense Measurements. Progress Photovolt. Res. Appl. 2021, 29, 920–935. [Google Scholar] [CrossRef]

- Fada, J.S.; Loach, A.J.; Curran, A.J.; Braid, J.L.; Yang, S.; Peshek, T.J.; French, R.H. Correlation of I-V Curve Parameters with Module-Level Electroluminescent Image Data Over 3000 Hours Damp-Heat Exposure. In Proceedings of the 2017 IEEE 44th Photovoltaic Specialist Conference (PVSC), Washington, DC, USA, 25–30 June 2017; IEEE: Piscataway, NJ, USA, 2017; pp. 2697–2701. [Google Scholar]

- Rodrigues, S.; Buerhop, C.; Doll, B.; Hauch, J.; Brabec, C.; Peters, I.M. Predicting Modules I-V Curves from Electroluminescence Images with Deep Learning. In Proceedings of the 37th European Photovoltaic Solar Energy Conference and Exhibition, EU-PVSEC 2020, Online, 7–11 September 2020. [Google Scholar]

- Spataru, S.; Parikh, H.; Hacke, P.; Alves dos Reis Benatto, G.; Sera, D.; Poulsen, P.B. Quantification of Solar Cell Failure Signatures Based on Statistical Analysis of Electro-luminescence Images. In Proceedings of the 33rd European Photovoltaic Solar Energy Conference and Exhibition, Amsterdam, The Netherlands, 25–29 September 2017; WIP Wirtschaft und Infrastruktur GmbH & Co Planungs KG: Munich, Germany; pp. 1466–1472. [Google Scholar]

- Spataru, S.; Hacke, P.; Sera, D.; Glick, S.; Kerekes, T.; Teodorescu, R. Quantifying Solar Cell Cracks in Photovoltaic Modules by Electroluminescence Imaging. In Proceedings of the 2015 IEEE 42nd Photovoltaic Specialist Conference (PVSC), New Orleans, LA, USA, 14–19 June 2015; IEEE: Piscataway, NJ, USA, 2015; pp. 1–6. [Google Scholar]

- Drabczyk, K.; Kulesza-Matlak, G.; Drygała, A.; Szindler, M.; Lipiński, M. Electroluminescence Imaging for Determining the Influence of Metallization Parameters for Solar Cell Metal Contacts. Sol. Energy 2016, 126, 14–21. [Google Scholar] [CrossRef]

- Kumar, S.; Meena, R.; Gupta, R. Imaging and Micro-Structural Characterization of Moisture Induced Degradation in Crystalline Silicon Photovoltaic Modules. Sol. Energy 2019, 194, 903–912. [Google Scholar] [CrossRef]

- Mchedlidze, T.; Herguth, A.; Weber, J. Monitoring of Si-Solar Cell Degradation with Electroluminescence. Sol. Energy Mater. Sol. Cells 2016, 155, 38–42. [Google Scholar] [CrossRef]

- Simsek Kaya, S.; Gümüşçü, A.; Beşli, N. Efficient Busbar Slip Defects Detection in Photovoltaic Cell Electroluminescence Images. Adıyaman Üniv. Mühendis. Bilim. Derg. 2024, 11, 363–377. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, R.; Wang, F.; Zhu, D.; Gong, X.; Cheng, X. Electroluminescence as a Tool to Study the Polarization Characteristics and Generation Mechanism in Silicon PV Panels. Appl. Sci. 2023, 13, 1591. [Google Scholar] [CrossRef]

- Chowdhury, M.S.; Rahman, K.S.; Chowdhury, T.; Nuthammachot, N.; Techato, K.; Akhtaruzzaman, M.; Tiong, S.K.; Sopian, K.; Amin, N. An Overview of Solar Photo-voltaic Panels’ End-of-Life Material Recycling. Energy Strategy Rev. 2020, 27, 100431. [Google Scholar] [CrossRef]

- dos Reis Benatto, G.A.; Mayordomo, A.A.; Del Prado Santamaria, R.; Kari, T.; Poulsen, P.B.; Spataru, S.V. Analysis of Solar Cell Electroluminescence Spectra for Daylight Inspection of C-Si PV Modules. In Proceedings of the 2023 IEEE 50th Photovoltaic Specialists Conference (PVSC), San Juan, Puerto Rico, 11–16 June 2023; IEEE: Piscataway, NJ, USA, 2023; pp. 1–7. [Google Scholar]

- Dussault, D.; Hoess, P. Noise Performance Comparison of ICCD with CCD and EMCCD Cameras. In Infrared Systems and Photoelectronic Technology; Dereniak, E.L., Sampson, R.E., Johnson, C.B., Eds.; SPIE: Bellingham, WA, USA, 2004; pp. 195–204. [Google Scholar]

- dos Reis Benatto, G.A.; del Prado Santamaria, R.; Kari Hass, T.; Bartholomaus, M.; Morino, L.; Poulsen, P.B.; Spataru, S.V. Daylight Electroluminescence of PV Modules in Field Installations: When Electrical Signal Modulation Is Required? In Proceedings of the 8th World Conference on Photovoltaic Energy Conversion, Milano, Italy, 26–30 September 2022; EU PVSEC: Bilbao, Spain, 2022; pp. 735–739. [Google Scholar]

- Kari, T.; Del Prado Santamaria, R.; dos Reis Benatto, G.A.; Koelblin, P.; Stoicescu, L.; Spataru, S.V. Evaluation of Motion-Induced Noise and Pixel-Bleeding in Electroluminescence Field Inspection of PV Modules. In Proceedings of the 2023 IEEE 50th Photovoltaic Specialists Conference (PVSC), San Juan, Puerto Rico, 11–16 June 2023; IEEE: Piscataway, NJ, USA, 2023; pp. 1–5. [Google Scholar]

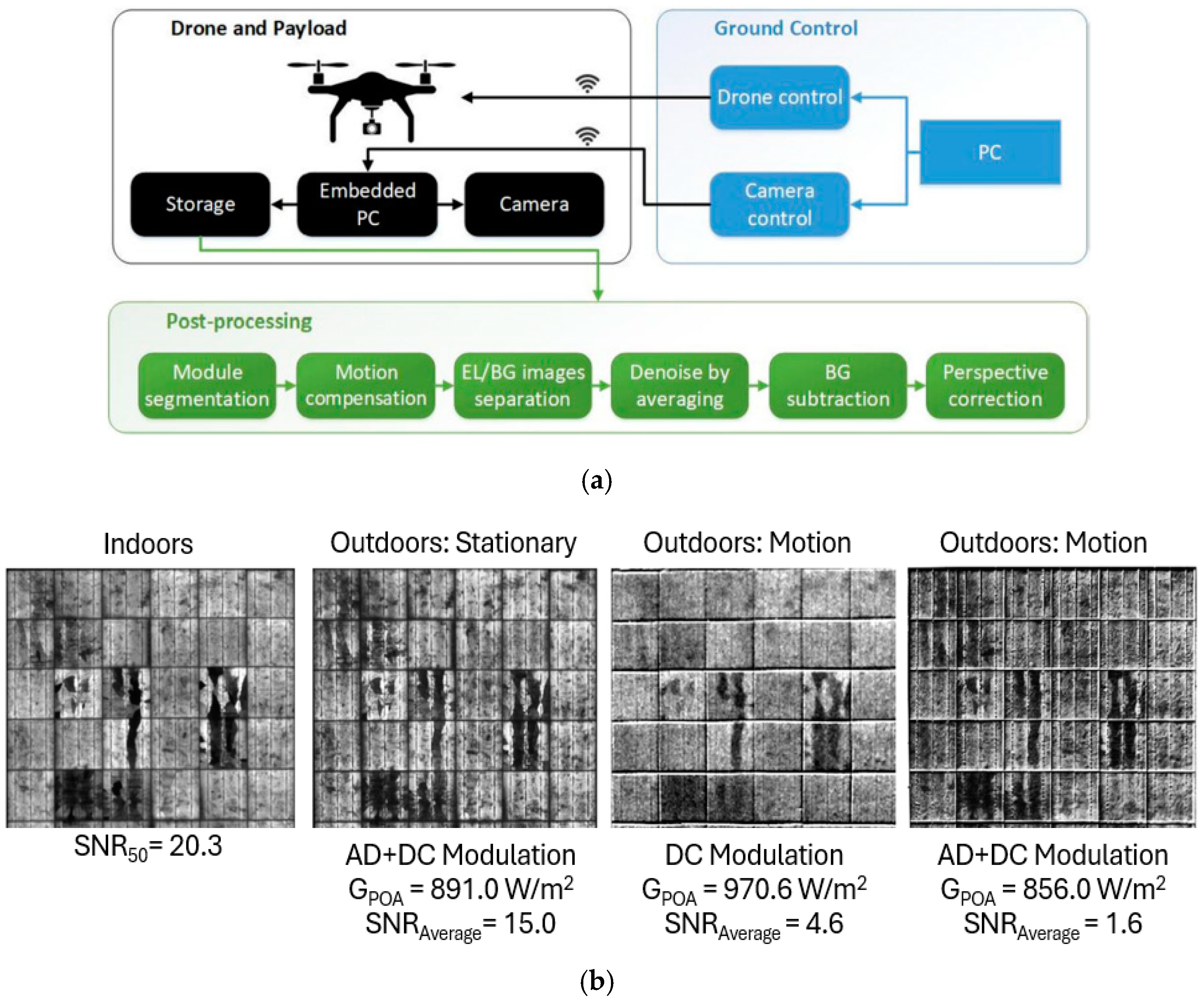

- Hass, T.K.; Spataru, S.; Santamaria Lancia, A.A.; Parikh, H.; Poulsen, P.B.; dos Reis Benatto, G.A. Computer Vision Method for Extracting an Induced Electroluminescence Signal from Photovoltaic Modules in Daylight Conditions Using Drone-Captured Images. In Proceedings of the 37th European Photovoltaic Solar Energy Conference and Exhibition, Online, 7–11 September 2020; pp. 1573–1579. [Google Scholar]

- dos Reis Benatto, G.A.; Mantel, C.; Santamaria Lancia, A.A.; Graversen, M.; Riedel, N.; Thorsteinsson, S.; Poulsen, P.B.; Forchhammer, S.; Parikh, H.; Spataru, S.; et al. Image Processing for Daylight Electroluminescence PV Imaging Acquired in Movement. In Proceedings of the 35th European Photovoltaic Solar Energy Conference and Exhibition, Brussels, Belgium, 24–28 September 2018; pp. 2005–2009. [Google Scholar]

- Parikh, H.R.; Spataru, S.; Sera, D.; Mantel, C.; Forchhammer, S.; dos Reis Benatto, G.A.; Riedel, N.; Poulsen, P.B. Enhancement of Electroluminescence Images for Fault Detection in Photovoltaic Panels. In Proceedings of the 2018 IEEE 7th World Conference on Photovoltaic Energy Conversion (WCPEC) (A Joint Conference of 45th IEEE PVSC, 28th PVSEC & 34th EU PVSEC), Waikoloa Village, HI, USA, 10–15 June 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 0447–0452. [Google Scholar]

- Bedrich, K.; Bokalic, M.; Bliss, M.; Topic, M.; Betts, T.R.; Gottschalg, R. Electroluminescence Imaging of PV Devices: Advanced Vignetting Calibration. IEEE J. Photovolt. 2018, 8, 1297–1304. [Google Scholar] [CrossRef]

- Bedrich, K.G.; Bliss, M.; Betts, T.R.; Gottschalg, R. Electroluminescence Imaging of PV Devices: Camera Calibration and Image Correction. In Proceedings of the 2016 IEEE 43rd Photovoltaic Specialists Conference (PVSC), Portland, OR, USA, 5–10 June 2016; IEEE: Piscataway, NJ, USA, 2016; pp. 1532–1537. [Google Scholar]

- Kölblin, P.; Bartler, A.; Füller, M. Image Preprocessing for Outdoor Luminescence Inspection of Large Photovoltaic Parks. Energies 2021, 14, 2508. [Google Scholar] [CrossRef]

- Sovetkin, E.; Steland, A. Automatic Processing and Solar Cell Detection in Photovoltaic Electroluminescence Images. Integr. Comput. Aided Eng. 2019, 26, 123–137. [Google Scholar] [CrossRef]

- Mantel, C.; Villebro, F.; Parikh, H.R.; Spataru, S.; dos Reis Benatto, G.A.; Sera, D.; Poulsen, P.B.; Forchhammer, S. Method for Estimation and Correction of Perspective Distortion of Electroluminescence Images of Photovoltaic Panels. IEEE J. Photovolt. 2020, 10, 1797–1802. [Google Scholar] [CrossRef]

- Wright, B.; Shakiba, A.; Sharma, R.; Hameiri, Z. Photovoltaic Module Array Luminescence Image Preprocessing: Heuristic Algorithms for Perspective Correction and Cell Segmentation. In Proceedings of the EU PVSEC, Vienna, Austria, 23–27 September 2024. [Google Scholar]

- Kurukuru, V.S.B.; Haque, A.; Khan, M.A. Fault Classification for Photovoltaic Modules Using Thermography and Image Processing. In Proceedings of the 2019 IEEE Industry Applications Society Annual Meeting, Baltimore, MD, USA, 29 September–3 October 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 1–6. [Google Scholar]

- Sovetkin, E.; Pieters, B.E.; Gerber, A.; Stoicescu, L.; Koelblin, P. Fast Cell Detection and Distortion Correction for Outdoor Electroluminescence Images. In Proceedings of the 2023 IEEE 50th Photovoltaic Specialists Conference (PVSC), San Juan, Puerto Rico, 11–16 June 2023; IEEE: Piscataway, NJ, USA, 2023; pp. 1–6. [Google Scholar]

- Mantel, C.; Spataru, S.; Parikh, H.; Sera, D.; dos Reis Benatto, G.A.; Riedel, N.; Thorsteins-son, S.; Poulsen, P.B.; Forchhammer, S. Correcting for Perspective Distortion in Electroluminescence Images of Photovoltaic Panels. In Proceedings of the 2018 IEEE 7th World Conference on Photovoltaic Energy Conversion (WCPEC) (A Joint Conference of 45th IEEE PVSC, 28th PVSEC & 34th EU PVSEC), Waikoloa Village, HI, USA, 10–15 June 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 0433–0437. [Google Scholar]

- Li, Y.; Wright, B.; Hameiri, Z. Deep Learning-Based Perspective Distortion Correction for Outdoor Photovoltaic Module Images. Sol. Energy Mater. Sol. Cells 2024, 277, 113107. [Google Scholar] [CrossRef]

- Kunz, O.; Schlipf, J.; Fladung, A.; Khoo, Y.S.; Bedrich, K.; Trupke, T.; Hameiri, Z. Outdoor Luminescence Imaging of Field-Deployed PV Modules. Progress Energy 2022, 4, 042014. [Google Scholar] [CrossRef]

- Stoicescu, L.; Reuter, M.; Werner, J.H. DaySy: Luminescence Imaging of PV Modules in Daylight. In Proceedings of the 29th European Solar Energy Conference, Amsterdam, The Netherlands, 22–26 September 2014; pp. 2553–2554. [Google Scholar]

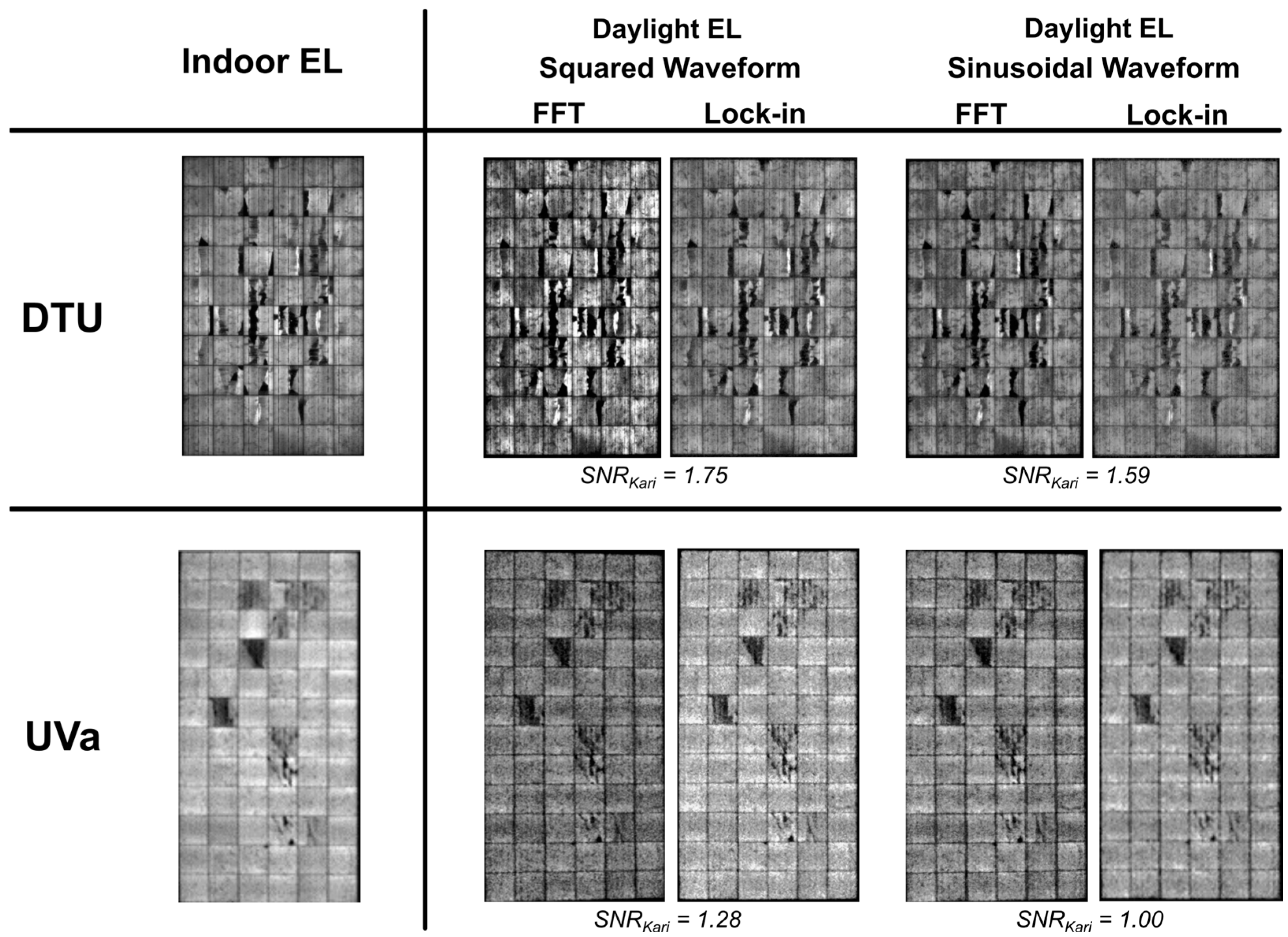

- Alves dos Reis Benatto, G.; Kari, T.; del Prado Santamaria, R.; Spataru, S.V.; Terrados, C.; Frances Gonzalez, D.; Anaya, J.; Sulca Buitron, K.P.; Gomez-Alonso, V.; Gonzalez, M.A.; et al. Daylight Electroluminescence Imaging Methodology Comparison. In Proceedings of the EU PVSEC, Lisbon, Portugal, 18–22 September 2023. [Google Scholar]

- Ballestín-Fuertes, J.; Muñoz-Cruzado-Alba, J.; Sanz-Osorio, J.F.; Hernández-Callejo, L.; Alonso-Gómez, V.; Morales-Aragones, J.I.; Gallardo-Saavedra, S.; Martínez-Sacristan, O.; Moretón-Fernández, Á. Novel Utility-Scale Photovoltaic Plant Electroluminescence Maintenance Technique by Means of Bidirectional Power Inverter Controller. Appl. Sci. 2020, 10, 3084. [Google Scholar] [CrossRef]

- Redondo-Plaza, A.; Morales-Aragonés, J.I.; Gallardo-Saavedra, S.; Mateo-Romero, H.F.; Araujo-Rendón, S.; Zorita-Lamadrid, Á.L.; Alonso-Gómez, V.; Hernández-Callejo, L. Passive Electroluminescence and Photoluminescence Imaging Acquisition of Photovoltaic Modules. Sensors 2024, 24, 1539. [Google Scholar] [CrossRef]

- Bhoopathy, R.; Kunz, O.; Juhl, M.; Trupke, T.; Hameiri, Z. Outdoor Photoluminescence Imaging of Photovoltaic Modules with Sunlight Excitation. Progress Photovolt. Res. Appl. 2018, 26, 69–73. [Google Scholar] [CrossRef]

- Kunz, O.; Weber, J.W.; Rey, G.; Juhl, M.; Trupke, T. Daylight Photoluminescence Imaging via Optical String Switching. Solar RRL 2024, 8, 2400385. [Google Scholar] [CrossRef]

- Augarten, Y.; Wrigley, A.; Gerber, A.; Pieters, B.E.; Rau, U. Quantitative Outdoor Imaging: Analysis of Solar Modules in Daylight. In Proceedings of the EU PVSEC, Munich, Germany, 20–24 June 2016; pp. 1846–1848. [Google Scholar]

- Vuković, M.; Eriksdatter Høiaas, I.; Jakovljević, M.; Svarstad Flø, A.; Olsen, E.; Burud, I. Photoluminescence Imaging of Silicon Modules in a String. Progress Photovolt. Res. Appl. 2022, 30, 436–446. [Google Scholar] [CrossRef]

- Silverman, T.J.; Deceglie, M.G.; VanSant, K.; Johnston, S.; Repins, I. Illuminated Outdoor Luminescence Imaging of Photovoltaic Modules. In Proceedings of the 2017 IEEE 44th Photovoltaic Specialist Conference (PVSC), Washington, DC, USA, 25–30 June 2017; IEEE: Piscataway, NJ, USA, 2017; pp. 3452–3455. [Google Scholar]

- Rey, G.; Kunz, O.; Green, M.; Trupke, T. Luminescence Imaging of Solar Modules in Full Sunlight Using Ultranarrow Bandpass Filters. Progress Photovolt. Res. Appl. 2022, 30, 1115–1121. [Google Scholar] [CrossRef]

- del Prado Santamaria, R.; Alves dos Reis Benatto, G.; Kari, T.; Morino, L.; Poulsen, P.; Spataru, S.V. Challenges of Aerial Drone Electroluminescence in Solar Photovoltaic Field Inspections. In Proceedings of the EU PVSEC, Lisbon, Portugal, 18–22 September 2023. [Google Scholar]

- Doll, B.; Wittmann, E.; Lüer, L.; Hepp, J.; Buerhop-Lutz, C.; Hauch, J.A.; Brabec, C.J.; Peters, I.M. Aerial Photoluminescence Imaging of Photovoltaic Modules. Phys. Status Solidi Rapid Res. Lett. 2023, 17, 2300059. [Google Scholar] [CrossRef]

- Dhimish, M.; Tyrrell, A.M. Optical Filter Design for Daylight Outdoor Electroluminescence Imaging of PV Modules. Photonics 2024, 11, 63. [Google Scholar] [CrossRef]

- Parikh, H.R.; Vedde, J.; Spataru, S.; Sera, D.; dos Reis Benatto, G.A.; Poulsen, P.B.; Mantel, C.; Forchhammer, S.; Larsen, M.; Frederiksen, K.H.B. A Photovoltaic Module Diagnostic Setup for Lock-in Electroluminescence Imaging. In Proceedings of the 2019 IEEE 46th Photovoltaic Specialists Conference (PVSC), Chicago, IL, USA, 16–21 June 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 0538–0543. [Google Scholar]

- dos Reis Benatto, G.A.; Vedde, J.; Petersen, M.; Voss, H.; Messerschmidt, M.; Parikh, H.; Spataru, S.; Sera, D.; Riedel, N.; Thorsteinsson, S.; et al. Development of Outdoor Luminescence Imaging for Drone-Based PV Array Inspection. In Proceedings of the 2017 IEEE 44th Photovoltaic Specialist Conference (PVSC), Washington, DC, USA, 25–30 June 2017; IEEE: Piscataway, NJ, USA, 2017; pp. 2682–2687. [Google Scholar]

- Koch, S.; Weber, T.; Sobottka, C.; Fladung, A.; Clemens, P.; Berghold, J. Outdoor Electroluminescence Imaging of Crystalline Photovoltaic Modules: Comparative Study between Manual Ground-Level Inspections and Drone-Based Aerial Surveys. In Proceedings of the 32nd European Photovoltaic Solar Energy Conference and Exhibition, Munich, Germany, 20–24 June 2016; pp. 1736–1740. [Google Scholar]

- Vidal de Oliveira, A.K.; Bedin, C.; de Andrade Pinto, G.X.; Mendes Ferreira Gomes, A.; Souza Reis, G.H.; Rafael do Nascimento, L.; Ruther, R. Low-Cost Aerial Electroluminescence (AEL) of PV Power Plants. In Proceedings of the 2019 IEEE 46th Photovoltaic Specialists Conference (PVSC), Chicago, IL, USA, 16–21 June 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 0532–0537. [Google Scholar]

- Su, B.; Zhou, Z.; Chen, H. PVEL-AD: A Large-Scale Open-World Dataset for Photovoltaic Cell Anomaly Detection. IEEE Trans. Ind. Inform. 2023, 19, 404–413. [Google Scholar] [CrossRef]

- Korovin, A.; Vasilyev, A.; Egorov, F.; Saykin, D.; Terukov, E.; Shakhray, I.; Zhukov, L.; Budennyy, S. Anomaly Segmentation Model for Defects Detection in Electroluminescence Images of Heterojunction Solar Cells. arXiv 2022, arXiv:2208.05994. [Google Scholar]

- Wan, Q.; Gao, L.; Li, X. Logit Inducing with Abnormality Capturing for Semi-Supervised Image Anomaly Detection. IEEE Trans. Instrum. Meas. 2022, 71, 1–12. [Google Scholar] [CrossRef]

- Wang, C.; Chen, H.; Zhao, S.; Rahman, M.R.U. Efficient and Refined Deep Convolutional Features Network for the Crack Segmentation of Solar Cell Electroluminescence Images. IEEE Trans. Semicond. Manuf. 2022, 35, 610–619. [Google Scholar] [CrossRef]

- Hussain, M.; Chen, T.; Titrenko, S.; Su, P.; Mahmud, M. A Gradient Guided Architecture Coupled with Filter Fused Representations for Micro-Crack Detection in Photovoltaic Cell Surfaces. IEEE Access 2022, 10, 58950–58964. [Google Scholar] [CrossRef]

- Jiang, Y.; Zhao, C. Attention Classification-and-Segmentation Network for Micro-Crack Anomaly Detection of Photovoltaic Module Cells. Sol. Energy 2022, 238, 291–304. [Google Scholar] [CrossRef]

- Meng, Z.; Xu, S.; Wang, L.; Gong, Y.; Zhang, X.; Zhao, Y. Defect Object Detection Algorithm for Electroluminescence Image Defects of Photovoltaic Modules Based on Deep Learning. Energy Sci. Eng. 2022, 10, 800–813. [Google Scholar] [CrossRef]

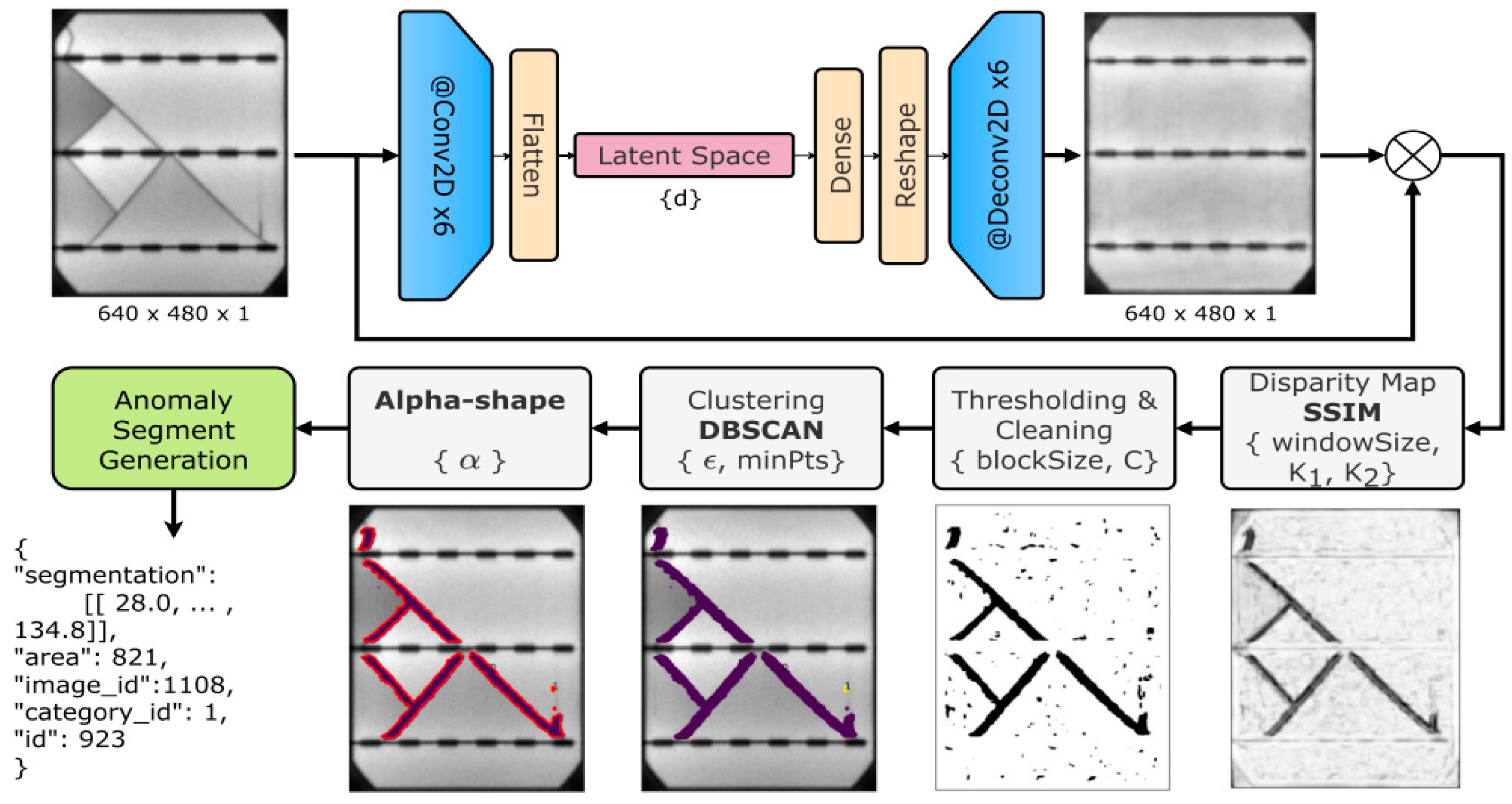

- Otamendi, U.; Martinez, I.; Olaizola, I.G.; Quartulli, M. A Scalable Framework for An-notating Photovoltaic Cell Defects in Electroluminescence Images. IEEE Trans. Ind. Inform. 2023, 19, 9361–9369. [Google Scholar] [CrossRef]

- Tella, H.; Mohandes, M.; Liu, B.; Rehman, S.; Al-Shaikhi, A. Deep Learning System for Defect Classification of Solar Panel Cells. In Proceedings of the 2022 14th International Conference on Computational Intelligence and Communication Networks (CICN), Al-Khobar, Saudi Arabia, 4–6 December 2022; IEEE: Piscataway, NJ, USA, 2022; pp. 448–453. [Google Scholar]

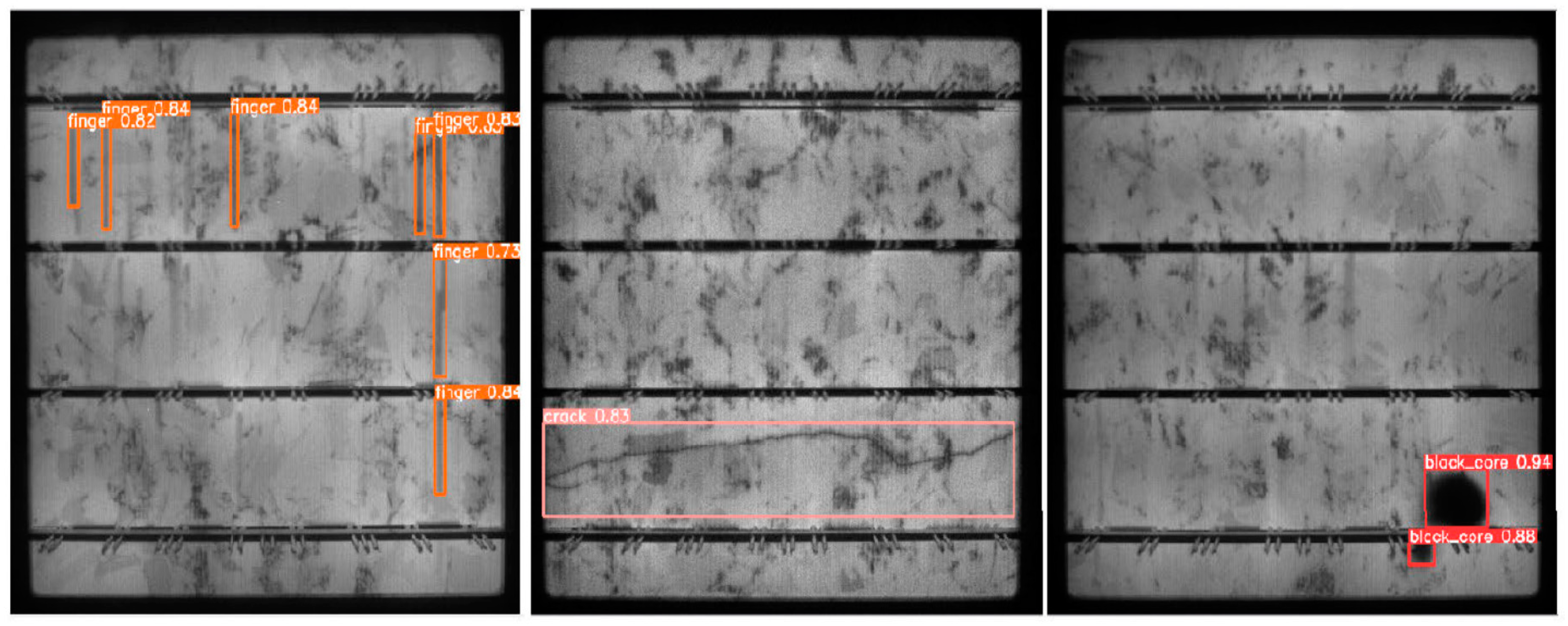

- Tang, W.; Yang, Q.; Yan, W. Deep Learning-Based Algorithm for Multi-Type Defects Detection in Solar Cells with Aerial EL Images for Photovoltaic Plants. Comput. Model. Eng. Sci. 2022, 130, 1423–1439. [Google Scholar] [CrossRef]

- Hassan, S.; Dhimish, M. Dual Spin Max Pooling Convolutional Neural Network for Solar Cell Crack Detection. Sci. Rep. 2023, 13, 11099. [Google Scholar] [CrossRef]

- Eesaar, H.; Joe, S.; Rehman, M.U.; Jang, Y.; Chong, K.T. SEiPV-Net: An Efficient Deep Learning Framework for Autonomous Multi-Defect Segmentation in Electroluminescence Images of Solar Photovoltaic Modules. Energies 2023, 16, 7726. [Google Scholar] [CrossRef]

- Xie, X.; Lai, G.; You, M.; Liang, J.; Leng, B. Effective Transfer Learning of Defect Detection for Photovoltaic Module Cells in Electroluminescence Images. Sol. Energy 2023, 250, 312–323. [Google Scholar] [CrossRef]

- Lu, S.; Wu, K.; Chen, J. Solar Cell Surface Defect Detection Based on Optimized YOLOv5. IEEE Access 2023, 11, 71026–71036. [Google Scholar] [CrossRef]

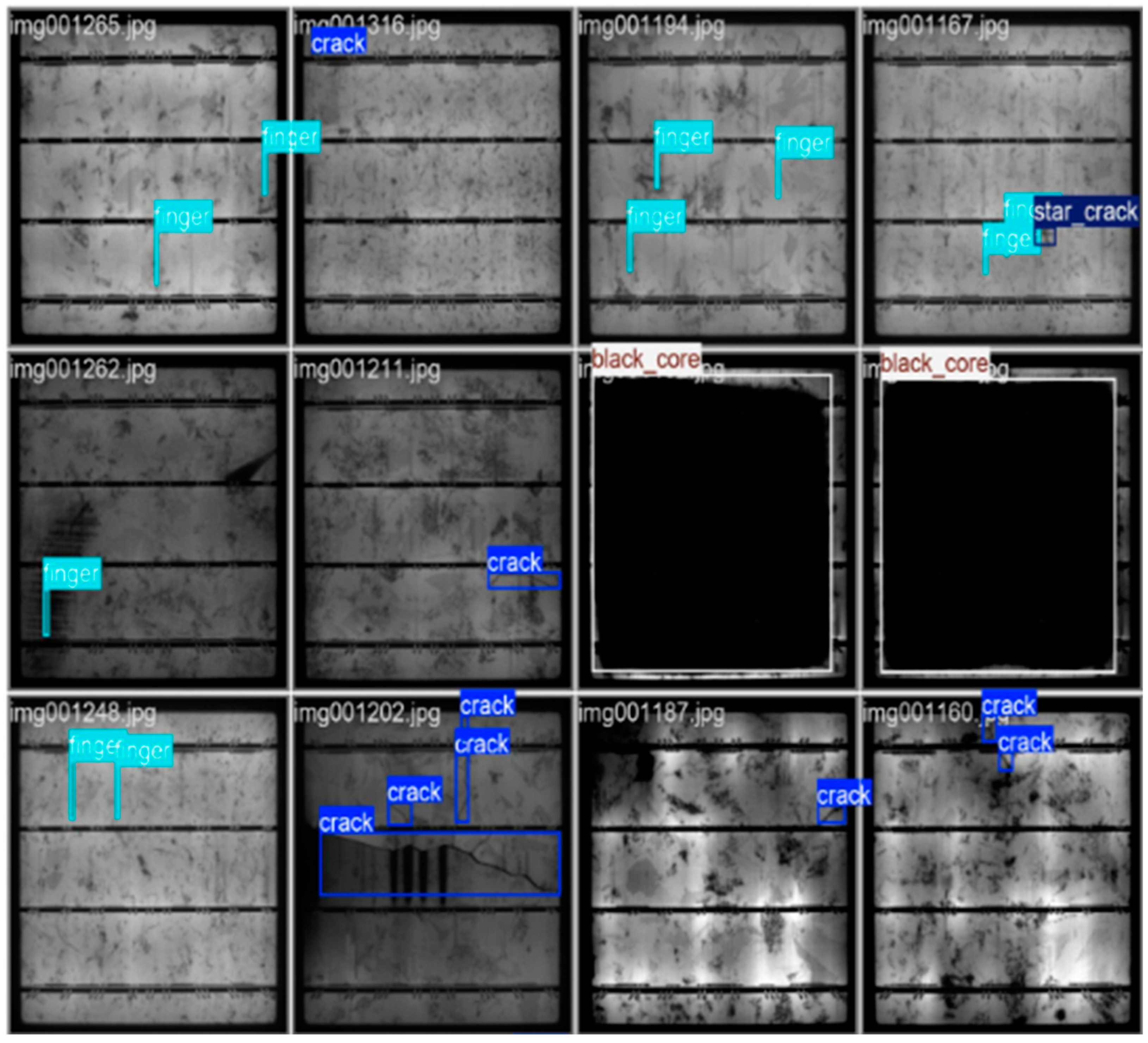

- Pratt, L.; Mattheus, J.; Klein, R. A Benchmark Dataset for Defect Detection and Classification in Electroluminescence Images of PV Modules Using Semantic Segmentation. Syst. Soft Comput. 2023, 5, 200048. [Google Scholar] [CrossRef]

- Chen, X.; Karin, T.; Libby, C.; Deceglie, M.; Hacke, P.; Silverman, T.J.; Jain, A. Automatic Crack Segmentation and Feature Extraction in Electroluminescence Images of Solar Modules. IEEE J. Photovolt. 2023, 13, 334–342. [Google Scholar] [CrossRef]

- Korovin, A.; Vasilev, A.; Egorov, F.; Saykin, D.; Terukov, E.; Shakhray, I.; Zhukov, L.; Budennyy, S. Anomaly Detection in Electroluminescence Images of Heterojunction Solar Cells. Sol. Energy 2023, 259, 130–136. [Google Scholar] [CrossRef]

- Mazen, F.M.A.; Seoud, R.A.A.; Shaker, Y.O. Deep Learning for Automatic Defect Detection in PV Modules Using Electroluminescence Images. IEEE Access 2023, 11, 57783–57795. [Google Scholar] [CrossRef]

- Animashaun, D.; Hussain, M. Automated Micro-Crack Detection within Photovoltaic Manufacturing Facility via Ground Modelling for a Regularized Convolutional Network. Sensors 2023, 23, 6235. [Google Scholar] [CrossRef] [PubMed]

- Munawer Al-Otum, H. Deep Learning-Based Automated Defect Classification in Electroluminescence Images of Solar Panels. Adv. Eng. Inform. 2023, 58, 102147. [Google Scholar] [CrossRef]

- Lang, D.; Lv, Z. A PV Cell Defect Detector Combined with Transformer and Attention Mechanism. Sci. Rep. 2024, 14, 20671. [Google Scholar] [CrossRef]

- Zhao, L.; Wu, Y.; Yuan, Y. PD-DETR: Towards Efficient Parallel Hybrid Matching with Transformer for Photovoltaic Cell Defects Detection. Complex. Intell. Syst. 2024, 10, 7421–7434. [Google Scholar] [CrossRef]

- Yang, B.; Zhang, Z.; Ma, J. Wavelet-Based Normalized Flow for Anomaly Detection in Photovoltaic Electroluminescent with Nonstationary Textures. IEEE Sens. J. 2025, 25, 891–903. [Google Scholar] [CrossRef]

- Tan, H.; Zhou, H.; Duan, C.; Zhang, T.; Zhang, L. RAFBSD: An Efficient Detector for Accurate Identification of Defects in Photovoltaic Cells. IEEE Access 2024, 12, 61512–61528. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, J.; Shu, X.; Pan, L.; Zhang, M. A Lightweight Transformer Model for Defect Detection in Electroluminescence Images of Photovoltaic Cells. IEEE Access 2024, 12, 194922–194931. [Google Scholar] [CrossRef]

- Pan, W.; Sun, X.; Wang, Y.; Cao, Y.; Lang, Y.; Qian, Y. Enhanced Photovoltaic Panel Defect Detection via Adaptive Complementary Fusion in YOLO-ACF. Sci. Rep. 2024, 14, 26425. [Google Scholar] [CrossRef]

- Yusuf Demirci, M.; Beşli, N.; Gümüşçü, A. An Improved Hybrid Solar Cell Defect Detection Approach Using Generative Adversarial Networks and Weighted Classification. Expert. Syst. Appl. 2024, 252, 124230. [Google Scholar] [CrossRef]

- Munawer Al-Otum, H. Classification of Anomalies in Electroluminescence Images of Solar PV Modules Using CNN-Based Deep Learning. Sol. Energy 2024, 278, 112803. [Google Scholar] [CrossRef]

- Bin, F.; Qiu, K.; Zheng, Z.; Lu, X.; Du, L.; Sun, Q. Investigation on a Lightweight Defect Detection Model for Photovoltaic Panel. Measurement 2024, 236, 115121. [Google Scholar] [CrossRef]

- Aktouf, L.; Shivanna, Y.; Dhimish, M. High-Precision Defect Detection in Solar Cells Using YOLOv10 Deep Learning Model. Solar 2024, 4, 639–659. [Google Scholar] [CrossRef]

- Fioresi, J.; Colvin, D.J.; Frota, R.; Gupta, R.; Li, M.; Seigneur, H.P.; Vyas, S.; Oliveira, S.; Shah, M.; Davis, K.O. Automated Defect Detection and Localization in Photovoltaic Cells Using Semantic Segmentation of Elec-troluminescence Images. IEEE J. Photovolt. 2022, 12, 53–61. [Google Scholar] [CrossRef]

- Deitsch, S.; Christlein, V.; Berger, S.; Buerhop-Lutz, C.; Maier, A.; Gallwitz, F.; Riess, C. Automatic Classification of Defective Photovoltaic Module Cells in Electroluminescence Images. Sol. Energy 2019, 185, 455–468. [Google Scholar] [CrossRef]

- Buerhop-Lutz, C.; Deitsch, S.; Maier, A.; Gallwitz, F.; Berger, S.; Doll, B.; Hauch, J.; Camus, C.; Brabec, C.J. Benchmark for Visual Identification of Defective Solar Cells in Electroluminescence Imagery. In Proceedings of the European PV Solar Energy Conference and Exhibition (EU PVSEC), Brussels, Belgium, 24–28 September 2018. [Google Scholar]

- Deitsch, S.; Buerhop-Lutz, C.; Sovetkin, E.; Steland, A.; Maier, A.; Gallwitz, F.; Riess, C. Segmentation of Photovoltaic Module Cells in Uncalibrated Electroluminescence Images. Mach. Vis. Appl. 2021, 32, 84. [Google Scholar] [CrossRef]

- Fischer, M.; Woodhouse, M.; Baliozian, P. International Technology Roadmap for Photovoltaics (ITRPV); ITRPV: Frankfurt, Germany, 2024. [Google Scholar]

- Trupke, T.; Mitchell, B.; Weber, J.W.; McMillan, W.; Bardos, R.A.; Kroeze, R. Photoluminescence Imaging for Photovoltaic Applications. Energy Procedia 2012, 15, 135–146. [Google Scholar] [CrossRef]

- Vuković, M.; Wiig, M.S.; dos Reis Benatto, G.A.; Olsen, E.; Burud, I. A Review of Imaging Methods for Detection of Photoluminescence in Field-Installed Photovoltaic Modules. Progress Energy 2024, 6, 032001. [Google Scholar] [CrossRef]

- Terrados, C.; González-Francés, D.; Alonso, V.; González, M.A.; Jiménez, J.; Martínez, O. Comparison of Outdoor and Indoor PL and EL Images in Si Solar Cells and Panels for Defect Detection and Classification. J. Electron. Mater. 2023, 52, 5189–5198. [Google Scholar] [CrossRef]

- Rajput, A.S.; Ho, J.W.; Zhang, Y.; Nalluri, S.; Aberle, A.G. Quantitative Estimation of Electrical Performance Parameters of Individual Solar Cells in Silicon Photovoltaic Modules Using Electroluminescence Imaging. Sol. Energy 2018, 173, 201–208. [Google Scholar] [CrossRef]

- Dost, G.; Höffler, H.; Greulich, J.M. Advanced Series Resistance Imaging for Silicon Solar Cells via Electroluminescence. Phys. Status Solidi 2021, 218, 2000546. [Google Scholar] [CrossRef]

- Haunschild, J.; Glatthaar, M.; Kasemann, M.; Rein, S.; Weber, E.R. Fast Series Resistance Imaging for Silicon Solar Cells Using Electroluminescence. Phys. Status Solidi Rapid Res. Lett. 2009, 3, 227–229. [Google Scholar] [CrossRef]

- Ozturk, E.; Ogliari, E.; Sakwa, M.; Dolara, A.; Blasuttigh, N.; Pavan, A.M. Photovoltaic Modules Fault Detection, Power Output, and Parameter Estimation: A Deep Learning Approach Based on Electro-luminescence Images. Energy Convers. Manag. 2024, 319, 118866. [Google Scholar] [CrossRef]

- Karimi, A.M.; Fada, J.S.; Parrilla, N.A.; Pierce, B.G.; Koyuturk, M.; French, R.H.; Braid, J.L. Generalized and Mechanistic PV Module Performance Prediction from Computer Vision and Machine Learning on Electroluminescence Images. IEEE J. Photovolt. 2020, 10, 878–887. [Google Scholar] [CrossRef]

| Environment | Challenge | Details |

|---|---|---|

| Indoor EL Imaging | Module size and handling | Large module sizes complicate positioning and handling within indoor setups. |

| Electrical connections | Corrosion or wear on contact points can lead to non-uniform current injection. | |

| Cost of setup | Expensive setup costs for high-resolution cameras and current sources. | |

| Outdoor Dark EL Imaging | Ambient light interference | Sunlight reduces contrast, requiring shielding or advanced processing. |

| Temperature fluctuations | Temperature changes alter electrical properties, impacting luminescence output. | |

| Weather dependence | Rain, wind, and humidity destabilize equipment and interfere with connections. | |

| Logistical constraints | Portable equipment is required to inspect large-scale installations quickly. | |

| Signal-to-noise ratio | Weak infrared signals are easily overwhelmed by external noise sources. | |

| Outdoor Daylight EL Imaging | High ambient light levels | Requires advanced filtering techniques or specialized sensors to isolate EL signals. |

| Exposure time constraints | Shorter exposure times are needed to prevent overexposure from daylight conditions. | |

| Equipment limitations | Daylight-compatible EL imaging systems are less mature and more expensive. | |

| Image post-processing | Extensive image correction and enhancement are required to extract meaningful data. | |

| High image volume | Typically, between 100 and 300 image frames are required per module for a good quality daylight EL image. | |

| Shared Challenges | Resolution limitations | High-resolution systems are resource-intensive and slow for large modules. |

| Electrical safety | High current injections pose safety risks, requiring rigorous protocols. |

| Reference | Optical Filter Type | Center Wavelength/Bandwidth | Application |

|---|---|---|---|

| [62] | Band-pass | ~1137 nm/25 nm | Daylight PL |

| [63] | Band-pass | ~1137 nm/25 nm | Daylight PL |

| [64] | Band-pass | 1150 nm/30 nm | Daylight PL |

| [4] | Band-pass | 1160 nm/150 nm | Daylight EL |

| [65] | Band-pass | 1125 nm/50 nm | Daylight PL |

| [66] | Long-pass | >1000 nm | Daylight EL and PL |

| [3] | Band-pass | 1150 nm/50 nm | Daylight drone-based EL |

| [67] | Band-pass | ~1135 nm/0.34 nm | Daylight PL |

| [68] | Band-pass | 1150 nm/25 nm | Daylight drone-based EL |

| [69] | Long-pass | >970 nm | Daylight PL |

| Environment | Description | Link | References |

|---|---|---|---|

| ELPV | This dataset comprises 2624 grayscale images (300 × 300 pixels) of both functional and defective solar cells, extracted from 44 different solar modules. Each image is annotated with defect probability and the type of solar module (monocrystalline or polycrystalline). | https://github.com/zae-bayern/elpv-dataset (accessed on 26 March 2025) | [106,107,108] |

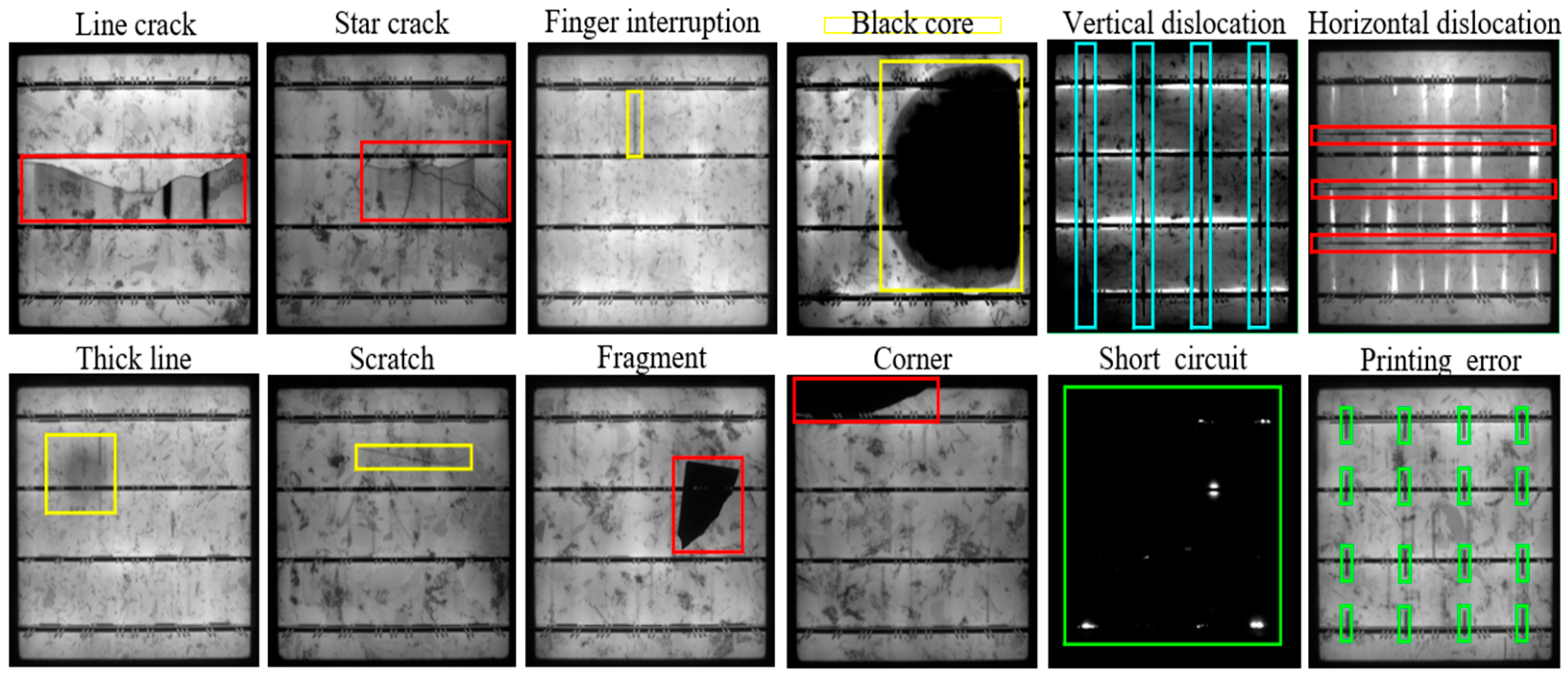

| PVEL-AD | This dataset contains 36,543 near-infrared EL images with various internal defects and heterogeneous backgrounds. It includes one class of anomaly-free images and anomalous images across twelve different categories. | https://github.com/binyisu/PVEL-AD/tree/main (accessed on 26 March 2025) | [75] |

| Benchmark EL Images | This repository hosts benchmark datasets (with over 15,000 cell-level) for the multi-class semantic segmentation of EL images of silicon wafer-based solar cells, providing both labeled and unlabeled images from multiple sources. | https://github.com/TheMakiran/BenchmarkELimages (accessed on 26 March 2025) | [89] |

| UCF EL Defect | This dataset comprises 17,064 EL images from multicrystalline and monocrystalline aluminum back-surface and monocrystalline PERC solar cells, categorized into 10 different defect classes. It also includes a segmentation tool called “DeepLabv3”. | https://github.com/ucf-photovoltaics/UCF-EL-Defect (accessed on 26 March 2025) | [105] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

del Prado Santamaría, R.; Dhimish, M.; dos Reis Benatto, G.A.; Kari, T.; Poulsen, P.B.; Spataru, S.V. From Indoor to Daylight Electroluminescence Imaging for PV Module Diagnostics: A Comprehensive Review of Techniques, Challenges, and AI-Driven Advancements. Micromachines 2025, 16, 437. https://doi.org/10.3390/mi16040437

del Prado Santamaría R, Dhimish M, dos Reis Benatto GA, Kari T, Poulsen PB, Spataru SV. From Indoor to Daylight Electroluminescence Imaging for PV Module Diagnostics: A Comprehensive Review of Techniques, Challenges, and AI-Driven Advancements. Micromachines. 2025; 16(4):437. https://doi.org/10.3390/mi16040437

Chicago/Turabian Styledel Prado Santamaría, Rodrigo, Mahmoud Dhimish, Gisele Alves dos Reis Benatto, Thøger Kari, Peter B. Poulsen, and Sergiu V. Spataru. 2025. "From Indoor to Daylight Electroluminescence Imaging for PV Module Diagnostics: A Comprehensive Review of Techniques, Challenges, and AI-Driven Advancements" Micromachines 16, no. 4: 437. https://doi.org/10.3390/mi16040437

APA Styledel Prado Santamaría, R., Dhimish, M., dos Reis Benatto, G. A., Kari, T., Poulsen, P. B., & Spataru, S. V. (2025). From Indoor to Daylight Electroluminescence Imaging for PV Module Diagnostics: A Comprehensive Review of Techniques, Challenges, and AI-Driven Advancements. Micromachines, 16(4), 437. https://doi.org/10.3390/mi16040437