A Pathway for the Integration of Novel Ferroelectric Thin Films on Non-Planar Photonic Integrated Circuits

Abstract

1. Introduction

2. Materials and Methods

3. Results

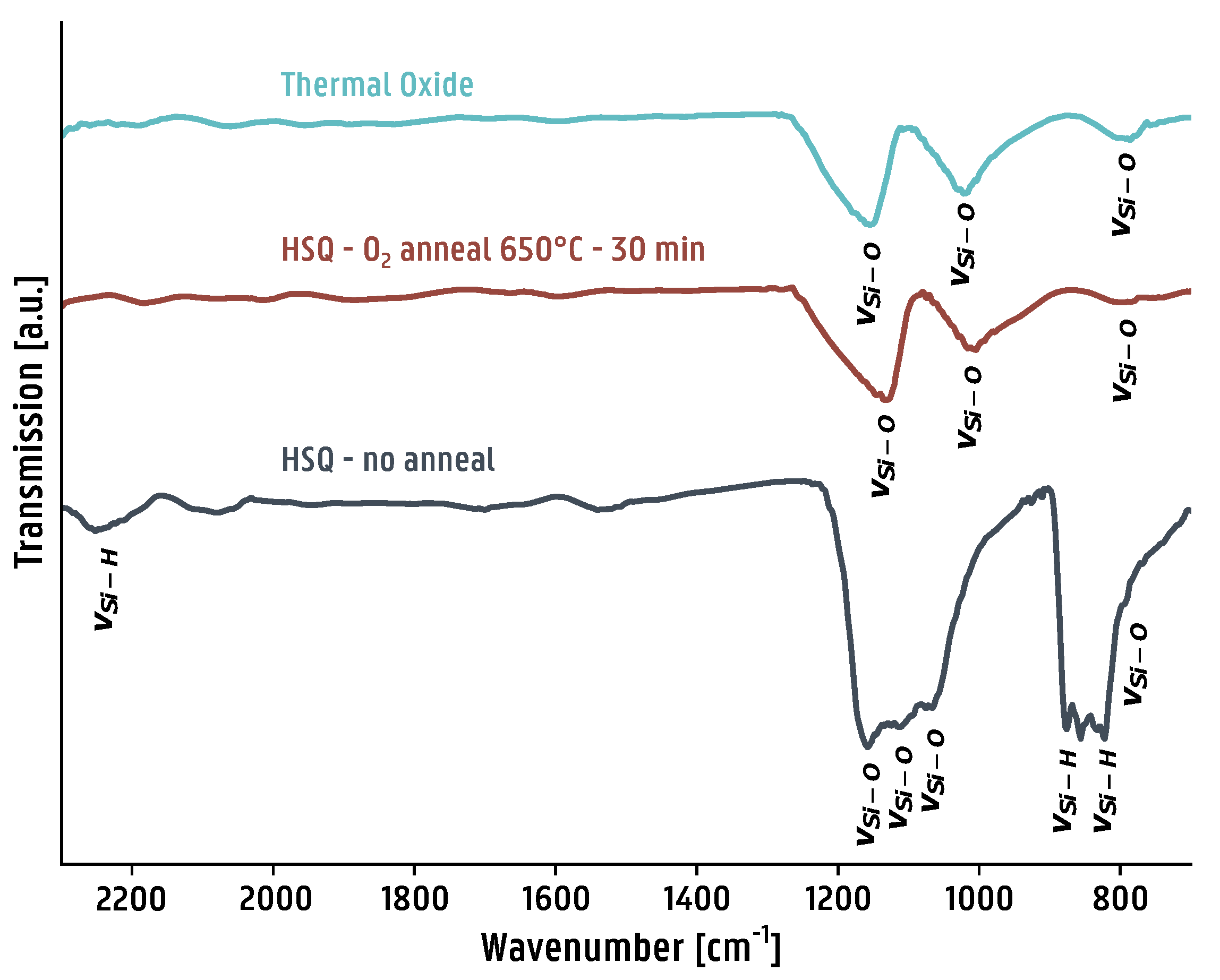

3.1. HSQ Film Characterization

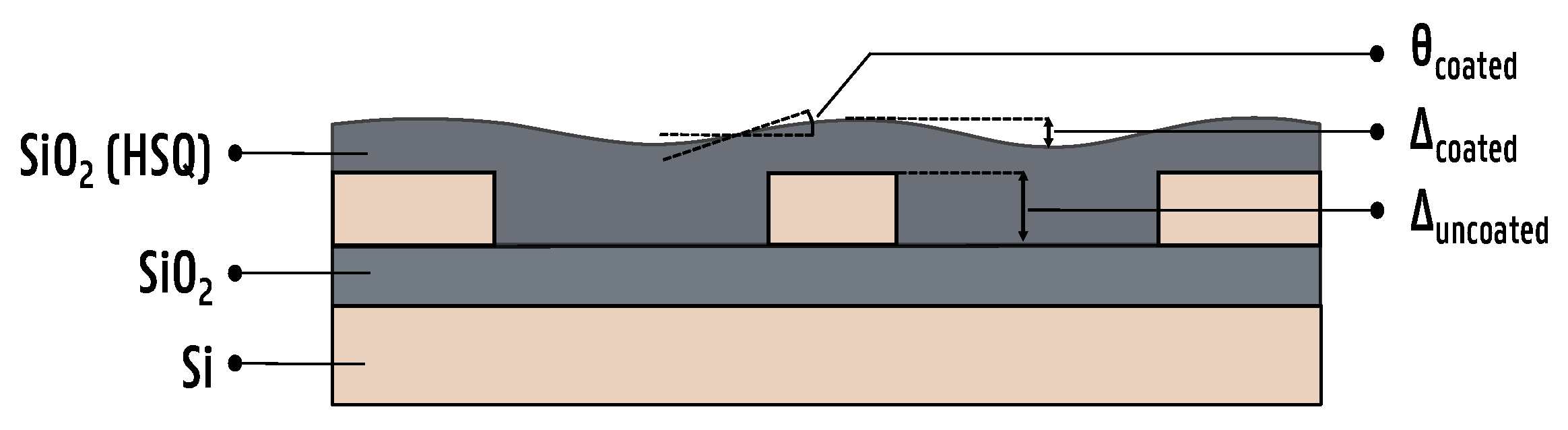

3.2. Degree of Planarization

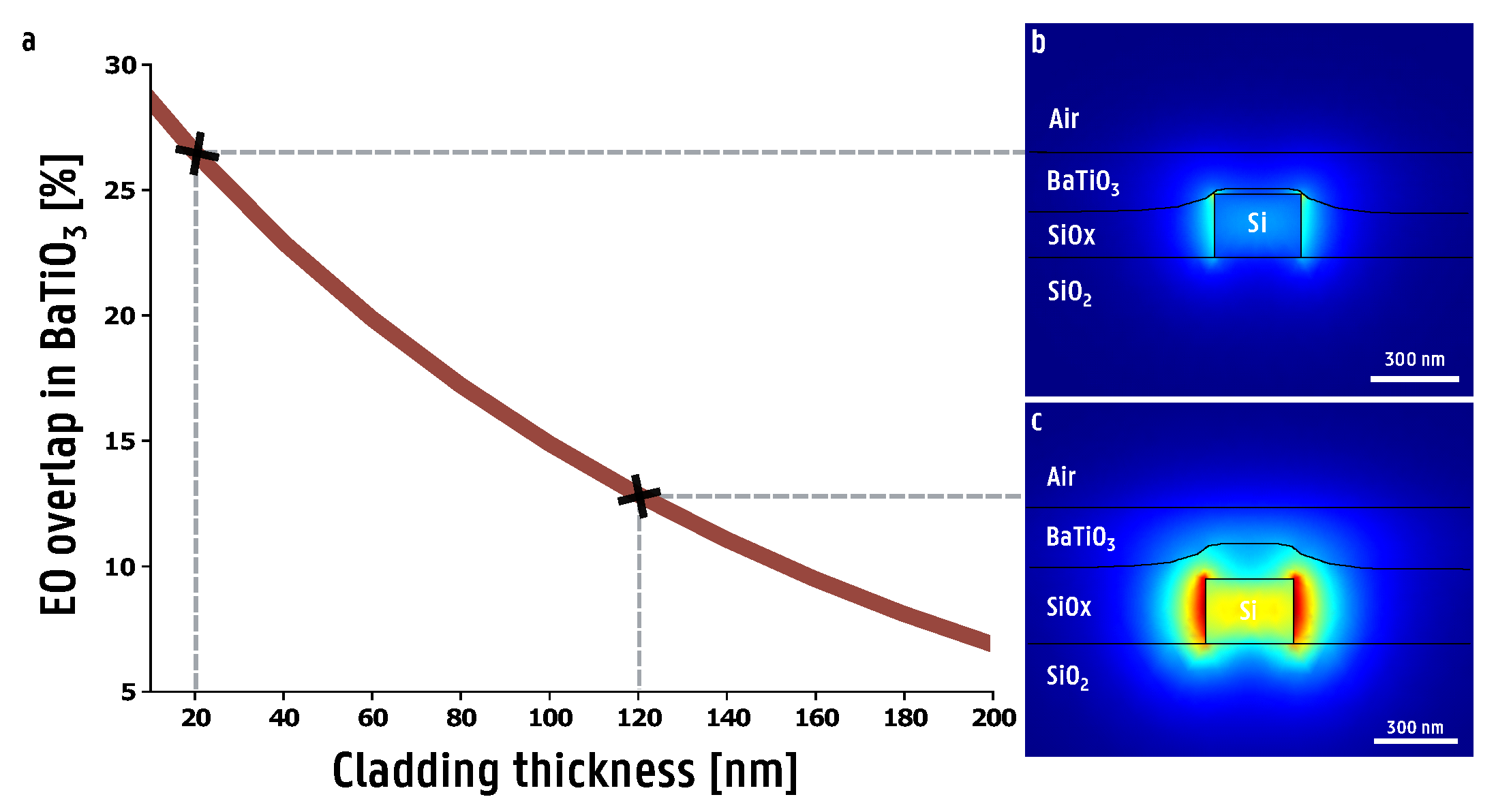

3.3. Cladding Thickness and Optical Mode Overlap

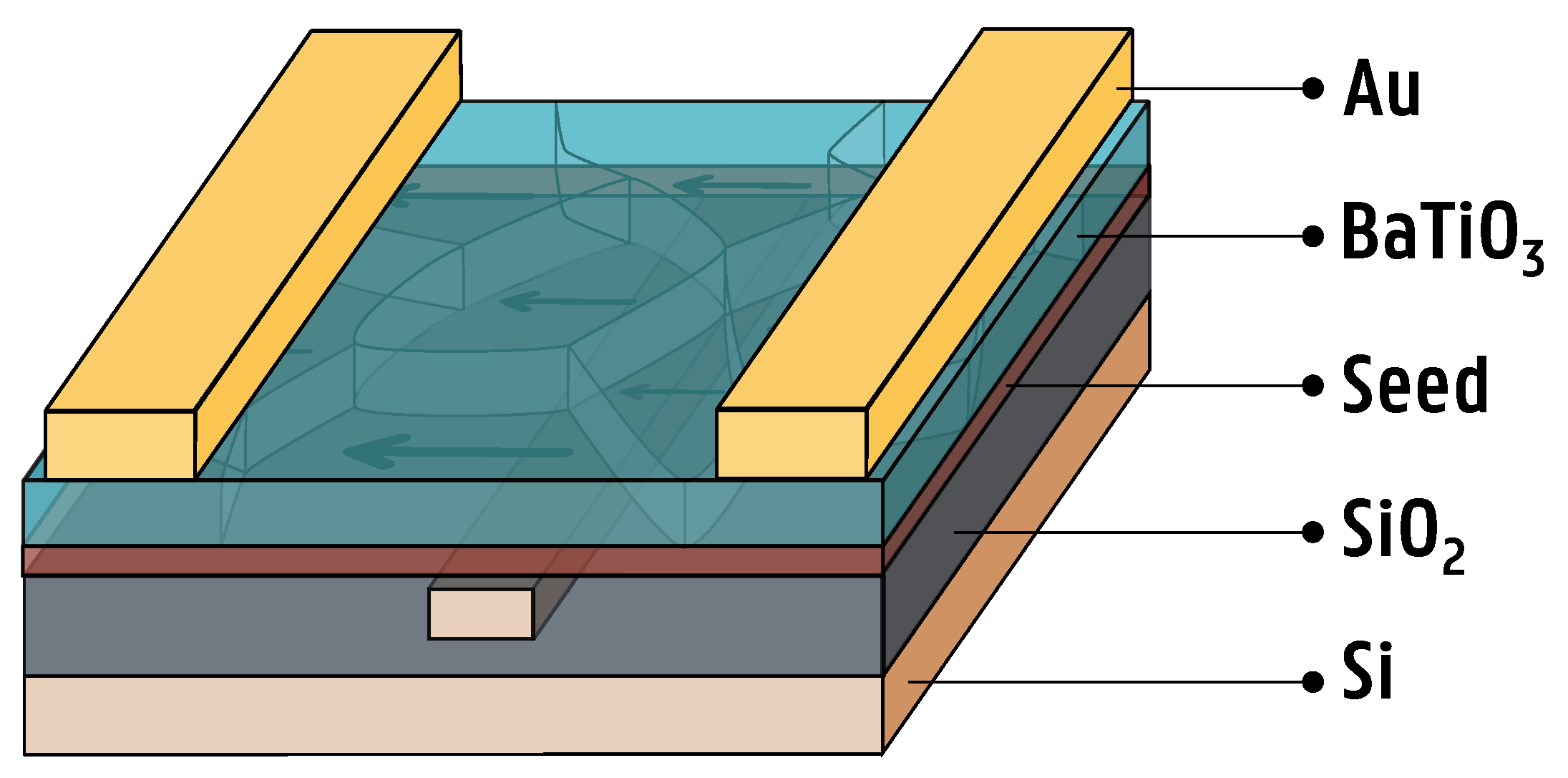

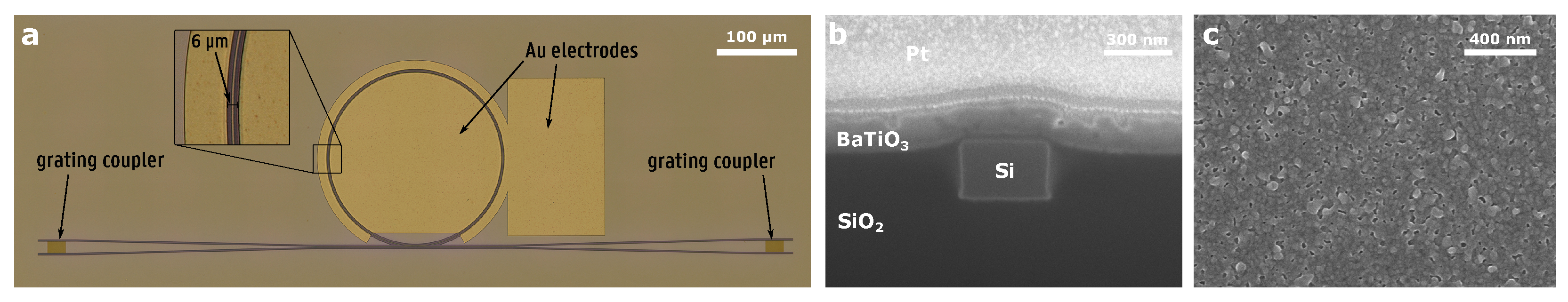

3.4. Integration of BaTiO3 into Silicon Ring Resonator

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Soci, C.; Adamo, G.; Cortecchia, D.; Wang, K.; Xiao, S.; Song, Q.; Schall-Giesecke, A.L.; Cegielski, P.J.; Lemme, M.C.; Gerace, D.; et al. Roadmap on perovskite nanophotonics. Opt. Mater. X 2023, 17, 100214. [Google Scholar]

- Wang, K.; Xing, G.; Song, Q.; Xiao, S. Micro-and nanostructured lead halide perovskites: From materials to integrations and devices. Adv. Mater. 2021, 33, 2000306. [Google Scholar] [CrossRef] [PubMed]

- Fathpour, S. Emerging heterogeneous integrated photonic platforms on silicon. Nanophotonics 2015, 4, 143–164. [Google Scholar] [CrossRef]

- Wen, Y.; Chen, H.; Wu, Z.; Li, W.; Zhang, Y. Fabrication and photonic applications of Si-integrated LiNbO3 and BaTiO3 ferroelectric thin films. APL Mater. 2024, 12, 020601. [Google Scholar] [CrossRef]

- Abe, S.; Joichi, T.; Uekusa, K.; Hara, H.; Masuda, S. Photonic integration based on a ferroelectric thin-film platform. Sci. Rep. 2019, 9, 16548. [Google Scholar] [CrossRef]

- Xiang, C.; Jin, W.; Huang, D.; Tran, M.A.; Guo, J.; Wan, Y.; Xie, W.; Kurczveil, G.; Netherton, A.M.; Liang, D.; et al. High-Performance Silicon Photonics Using Heterogeneous Integration. IEEE J. Sel. Top. Quantum Electron. 2022, 28, 8200515. [Google Scholar] [CrossRef]

- Marshall, O.; Hsu, M.; Wang, Z.; Kunert, B.; Koos, C.; Thourhout, D.V. Heterogeneous Integration on Silicon Photonics. Proc. IEEE 2018, 106, 2258–2269. [Google Scholar] [CrossRef]

- Baets, R.; Rahim, A. Heterogeneous integration in silicon photonics: Opportunities and challenges: Opinion. Opt. Mater. Express 2023, 13, 3439–3444. [Google Scholar] [CrossRef]

- Shekhar, S.; Bogaerts, W.; Chrostowski, L.; Bowers, J.E.; Hochberg, M.; Soref, R.; Shastri, B.J. Roadmapping the next generation of silicon photonics. Nat. Commun. 2024, 15, 751. [Google Scholar] [CrossRef]

- Picavet, E.; Rijckaert, H.; Solano, E.; Bikondoa, O.; Gutierrez Fernandez, E.; Paturi, P.; Van Bossele, L.; Vrielinck, H.; Beeckman, J.; De Buysser, K. The self out-of-plane oriented La2O2CO3 film: An integration tool for fiber textured ferroelectric thin films. J. Mater. Chem. C 2023, 11, 7705–7713. [Google Scholar] [CrossRef]

- Picavet, E.; Lievens, E.; De Geest, K.; Rijckaert, H.; Fernandez, E.G.; Bikondoa, O.; Solano, E.; Paturi, P.; Singh, N.; Pannier, T.; et al. Integration Of Solution-Processed BaTiO3 Thin Films with High Pockels Coefficient on Photonic Platforms. Adv. Funct. Mater. 2024, 34, 2403024. [Google Scholar] [CrossRef]

- Picavet, E.; De Geest, K.; Lievens, E.; Rijckaert, H.; Vandekerckhove, T.; Solano, E.; Deduytsche, D.; Van Bossele, L.; Van Thourhout, D.; De Buysser, K.; et al. Solution-Processed Pb(Zr,Ti)O3 Thin Films with Strong Remnant Pockels Coefficient. ACS Appl. Mater. Interfaces 2024, 16, 41134–41144. [Google Scholar] [CrossRef] [PubMed]

- Wooten, E.L.; Kissa, K.M.; Yi-Yan, A.; Murphy, E.J.; Lafaw, D.A.; Hallemeier, P.F.; Maack, D.; Attanasio, D.V.; Fritz, D.J.; McBrien, G.J.; et al. A review of lithium niobate modulators for fiber-optic communications systems. IEEE J. Sel. Top. Quantum Electron. 2000, 6, 69–82. [Google Scholar] [CrossRef]

- Vanackere, T.; Vandekerckhove, T.; Bogaert, L.; Billet, M.; Poelman, S.; Cuyvers, S.; Van Kerrebrouck, J.; Moerman, A.; Caytan, O.; Singh, N.; et al. Heterogeneous integration of a high-speed lithium niobate modulator on silicon nitride using micro-transfer printing. APL Photonics 2023, 8, 086102. [Google Scholar] [CrossRef]

- Abel, S.; Eltes, F.; Ortmann, J.E.; Messner, A.; Castera, P.; Wagner, T.; Urbonas, D.; Rosa, A.; Gutierrez, A.M.; Tulli, D.; et al. Large Pockels effect in micro-and nanostructured barium titanate integrated on silicon. Nat. Mater. 2019, 18, 42–47. [Google Scholar] [CrossRef]

- Jin, T.; Lin, P.T. Efficient mid-infrared electro-optical waveguide modulators using ferroelectric barium titanate. IEEE J. Sel. Top. Quantum Electron. 2020, 26, 3400107. [Google Scholar] [CrossRef]

- Alexander, K.; George, J.P.; Verbist, J.; Neyts, K.; Kuyken, B.; Van Thourhout, D.; Beeckman, J. Nanophotonic Pockels modulators on a silicon nitride platform. Nat. Commun. 2018, 9, 3444. [Google Scholar] [CrossRef]

- Feutmba, G.F.; Da Silva, L.; Singh, N.; Breyne, L.; De Geest, K.; George, J.P.; Bauwelinck, J.; Van Thourhout, D.; Yin, X.; Beeckman, J. High frequency characterization of PZT thin-films deposited by chemical solution deposition on SOI for integrated high speed electro-optic modulators. Opt. Mater. Express 2023, 13, 2120–2134. [Google Scholar] [CrossRef]

- Eltes, F.; Kroh, M.; Caimi, D.; Mai, C.; Popoff, Y.; Winzer, G.; Petousi, D.; Lischke, S.; Ortmann, J.E.; Czornomaz, L.; et al. A novel 25 Gbps electro-optic Pockels modulator integrated on an advanced Si photonic platform. In Proceedings of the 2017 IEEE International Electron Devices Meeting (IEDM), San Francisco, CA, USA, 2–6 December 2017; pp. 24–25. [Google Scholar]

- Guo, W.; Posadas, A.B.; Demkov, A.A. Epitaxial integration of BaTiO3 on Si for electro-optic applications. J. Vac. Sci. Technol. A 2021, 39, 030804. [Google Scholar] [CrossRef]

- Posadas, A.B.; Park, H.; Reynaud, M.; Cao, W.; Reynolds, J.D.; Guo, W.; Jeyaselvan, V.; Beskin, I.; Mashanovich, G.Z.; Warner, J.H.; et al. Thick BaTiO3 Epitaxial Films Integrated on Si by RF Sputtering for Electro-Optic Modulators in Si Photonics. ACS Appl. Mater. Interfaces 2021, 13, 51230–51244. [Google Scholar] [CrossRef]

- Bremmer, J.N.; Gray, D.; Liu, Y.; Gruszynski, K.; Marcus, S. Rapid Thermal Processing of Hydrogen Silsesquioxane for Low Dielectric Constant Performance. MRS Online Proc. Libr. 1999, 565, 273–278. [Google Scholar] [CrossRef]

- Liou, H.C.; Dehate, E.; Duel, J.; Dall, F. Curing Study of Hydrogen Silsesquioxane Under H2/N2 Ambient. MRS Online Proc. Libr. 2000, 612, 5121. [Google Scholar] [CrossRef]

- Chen, Y. Nanofabrication by electron beam lithography and its applications: A review. Microelectron. Eng. 2015, 135, 57–72. [Google Scholar] [CrossRef]

- Vieu, C.; Carcenac, F.; Pepin, A.; Chen, Y.; Mejias, M.; Lebib, A.; Manin-Ferlazzo, L.; Couraud, L.; Launois, H. Electron beam lithography: Resolution limits and applications. Appl. Surf. Sci. 2000, 164, 111–117. [Google Scholar] [CrossRef]

- Tseng, A.A.; Chen, K.; Chen, C.D.; Ma, K.J. Electron beam lithography in nanoscale fabrication: Recent development. IEEE Trans. Electron. Packag. Manuf. 2003, 26, 141–149. [Google Scholar] [CrossRef]

- Bornside, D.E. Mechanism for the Local Planarization of Microscopically Rough Surfaces by Drying Thin Films of Spin-Coated Polymer/Solvent Solutions. J. Electrochem. Soc. 1990, 137, 2589. [Google Scholar] [CrossRef]

- Bornside, D.E.; Macosko, C.W.; Scriven, L.E. Spin coating: One-dimensional model. J. Appl. Phys. 1989, 66, 5185–5193. [Google Scholar] [CrossRef]

- Maddalon, C.; Barla, K.; Denis, E.; Lous, E.; Perrin, E.; Lis, S.; Lair, C.; Dehan, E. Planarization properties of hydrogen silsesquioxane (HSQ) influence on CMP. Microelectron. Eng. 2000, 50, 33–40. [Google Scholar] [CrossRef]

- Bremmer, J.; Liu, Y.; Gruszynski, K.; Dall, F. Cure of Hydrogen Silsesquioxane for Intermetal Dielectric Applications. MRS Online Proc. Libr. 1997, 476, 37–41. [Google Scholar] [CrossRef]

- Liou, H.C.; Pretzer, J. Effect of curing temperature on the mechanical properties of hydrogen silsesquioxane thin films. Thin Solid Film 1998, 335, 186–191. [Google Scholar] [CrossRef]

- Loboda, M.J.; Grove, C.M.; Schneider, R.F. Properties of a-SiOx:H Thin Films Deposited from Hydrogen Silsesquioxane Resins. J. Electrochem. Soc. 1998, 145, 2861. [Google Scholar] [CrossRef]

- Yang, C.C.; Chen, W.C. The structures and properties of hydrogen silsesquioxane (HSQ) films produced by thermal curing. J. Mater. Chem. 2002, 12, 1138–1141. [Google Scholar] [CrossRef]

- Smith, A. Infrared spectra-structure correlations for organosilicon compounds. Spectrochim. Acta 1960, 16, 87–105. [Google Scholar] [CrossRef]

- Petraru, A.; Schubert, J.; Schmid, M.; Trithaveesak, O.; Buchal, C. Integrated optical Mach Zehnder modulator based on polycrystalline BaTiO3. Opt. Lett. 2003, 28, 2527–2529. [Google Scholar] [CrossRef] [PubMed]

- Xiong, C.; Pernice, W.H.P.; Ngai, J.H.; Reiner, J.W.; Kumah, D.; Walker, F.J.; Ahn, C.H.; Tang, H.X. Active Silicon Integrated Nanophotonics: Ferroelectric BaTiO3 Devices. Nano Lett. 2014, 14, 1419–1425. [Google Scholar] [CrossRef]

- Eltes, F.; Mai, C.; Caimi, D.; Kroh, M.; Popoff, Y.; Winzer, G.; Petousi, D.; Lischke, S.; Ortmann, J.E.; Czornomaz, L.; et al. A BaTiO3-Based Electro-Optic Pockels Modulator Monolithically Integrated on an Advanced Silicon Photonics Platform. J. Light Technol. 2019, 37, 1456–1462. [Google Scholar] [CrossRef]

- Ortmann, J.E.; Eltes, F.; Caimi, D.; Meier, N.; Demkov, A.A.; Czornomaz, L.; Fompeyrine, J.; Abel, S. Ultra-Low-Power Tuning in Hybrid Barium Titanate–Silicon Nitride Electro-optic Devices on Silicon. ACS Photonics 2019, 6, 2677–2684. [Google Scholar] [CrossRef]

- Abel, S.; Stöferle, T.; Marchiori, C.; Caimi, D.; Czornomaz, L.; Stuckelberger, M.; Sousa, M.; Offrein, B.J.; Fompeyrine, J. A Hybrid Barium Titanate–Silicon Photonics Platform for Ultraefficient Electro-Optic Tuning. J. Light Technol. 2016, 34, 1688–1693. [Google Scholar] [CrossRef]

- Bogaerts, W.; De Heyn, P.; Van Vaerenbergh, T.; De Vos, K.; Kumar Selvaraja, S.; Claes, T.; Dumon, P.; Bienstman, P.; Van Thourhout, D.; Baets, R. Silicon microring resonators. Laser Photonics Rev. 2012, 6, 47–73. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lievens, E.; De Geest, K.; Picavet, E.; Van Landschoot, L.; Vrielinck, H.; Feutmba, G.F.; Rijckaert, H.; De Buysser, K.; Van Thourhout, D.; Bienstman, P.; et al. A Pathway for the Integration of Novel Ferroelectric Thin Films on Non-Planar Photonic Integrated Circuits. Micromachines 2025, 16, 334. https://doi.org/10.3390/mi16030334

Lievens E, De Geest K, Picavet E, Van Landschoot L, Vrielinck H, Feutmba GF, Rijckaert H, De Buysser K, Van Thourhout D, Bienstman P, et al. A Pathway for the Integration of Novel Ferroelectric Thin Films on Non-Planar Photonic Integrated Circuits. Micromachines. 2025; 16(3):334. https://doi.org/10.3390/mi16030334

Chicago/Turabian StyleLievens, Enes, Kobe De Geest, Ewout Picavet, Liesbet Van Landschoot, Henk Vrielinck, Gilles Freddy Feutmba, Hannes Rijckaert, Klaartje De Buysser, Dries Van Thourhout, Peter Bienstman, and et al. 2025. "A Pathway for the Integration of Novel Ferroelectric Thin Films on Non-Planar Photonic Integrated Circuits" Micromachines 16, no. 3: 334. https://doi.org/10.3390/mi16030334

APA StyleLievens, E., De Geest, K., Picavet, E., Van Landschoot, L., Vrielinck, H., Feutmba, G. F., Rijckaert, H., De Buysser, K., Van Thourhout, D., Bienstman, P., & Beeckman, J. (2025). A Pathway for the Integration of Novel Ferroelectric Thin Films on Non-Planar Photonic Integrated Circuits. Micromachines, 16(3), 334. https://doi.org/10.3390/mi16030334