Application Characteristics of Ultra-Fine 15 μm Stainless Steel Wires: Microstructures, Electrical Fatigue, and Ball Formation Mechanisms

Abstract

1. Introduction

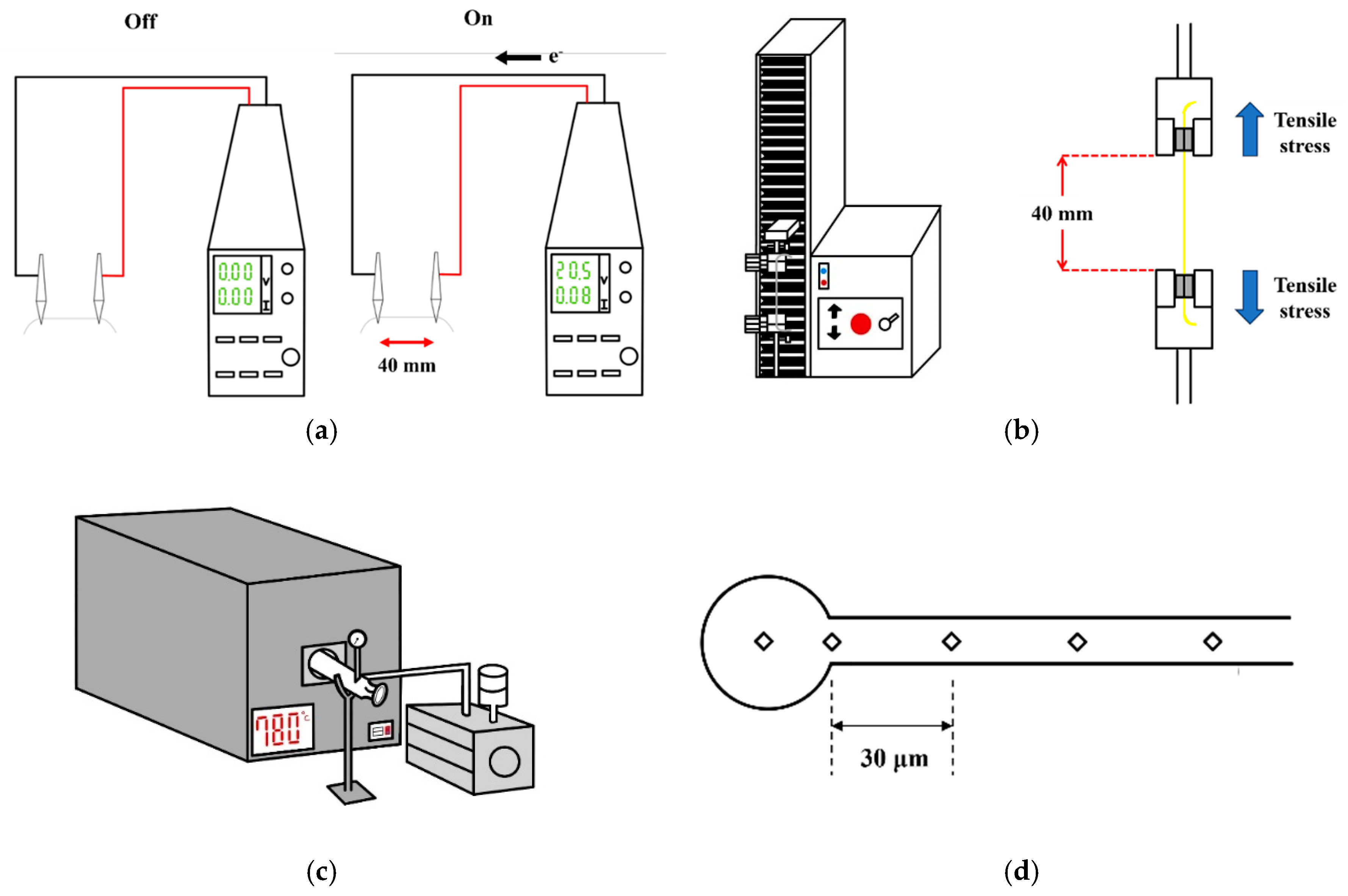

2. Experimental Procedures

3. Results and Discussion

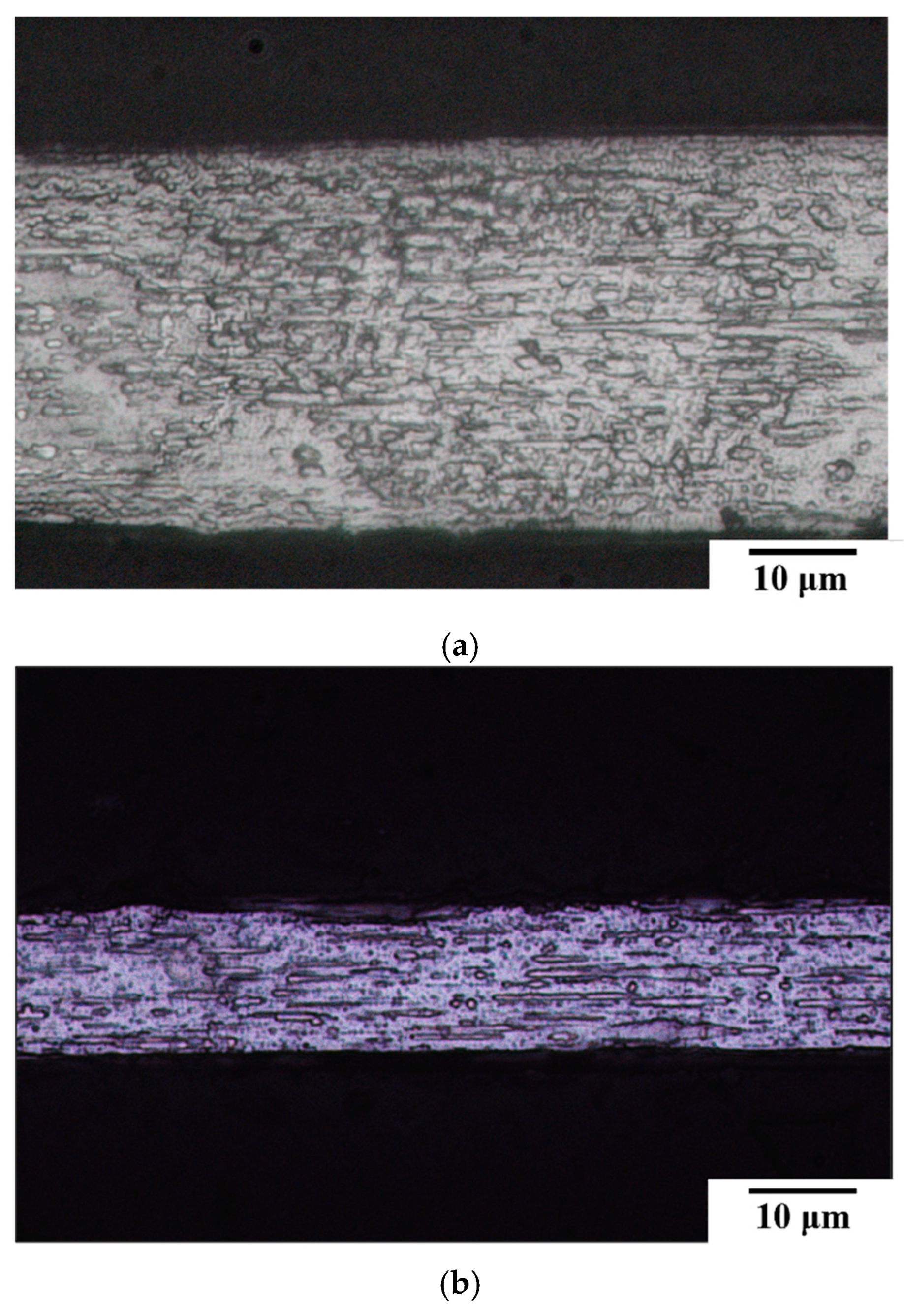

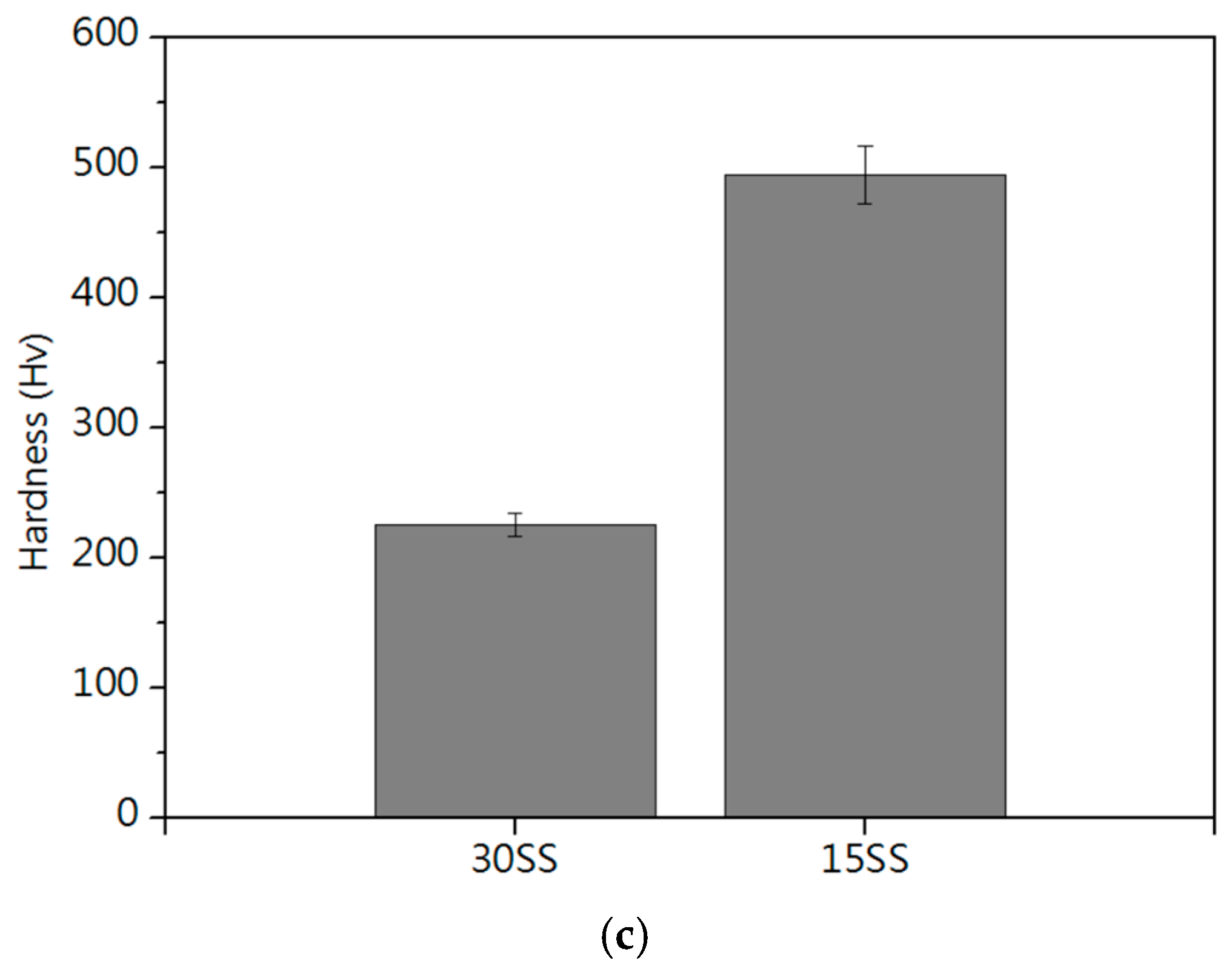

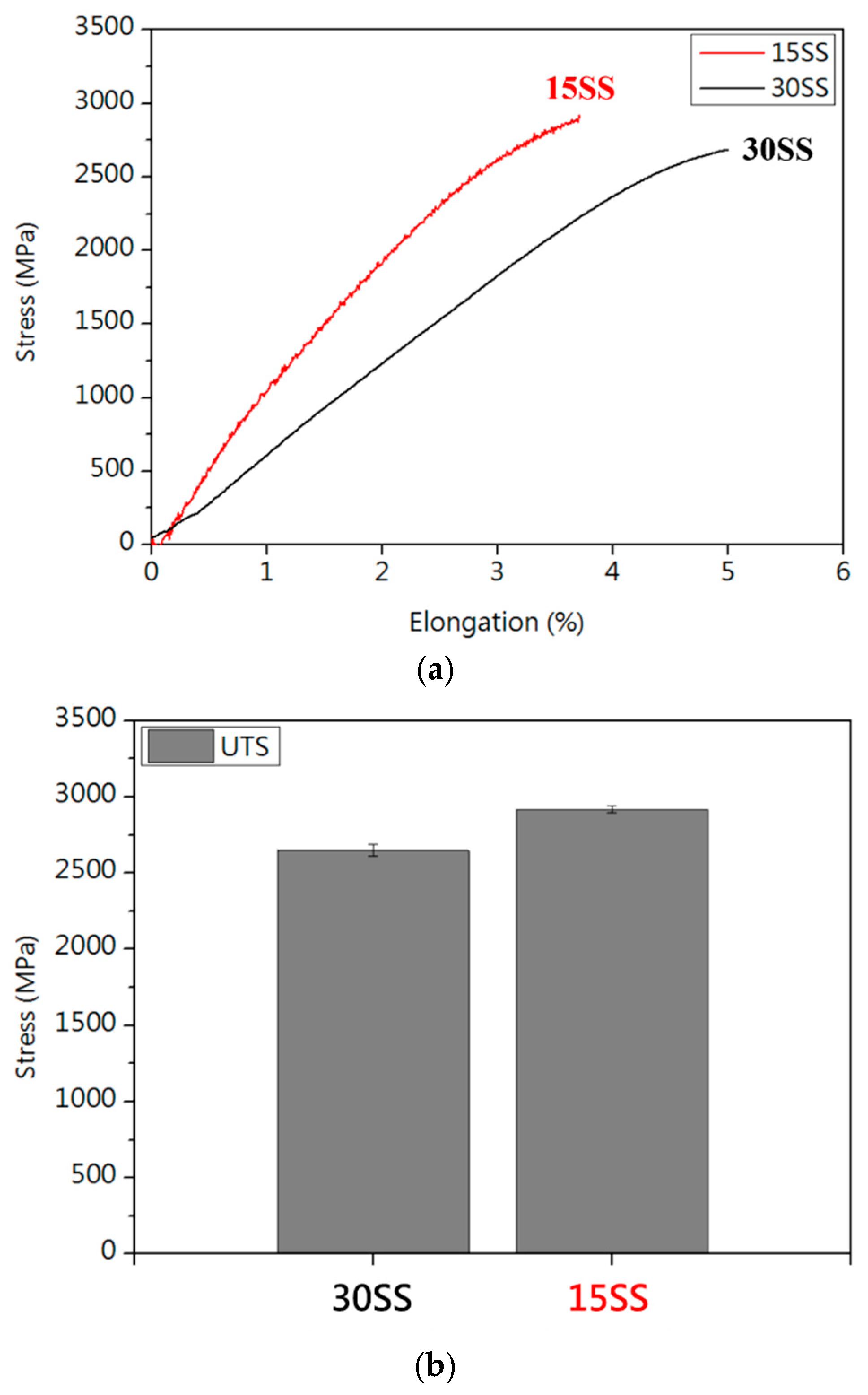

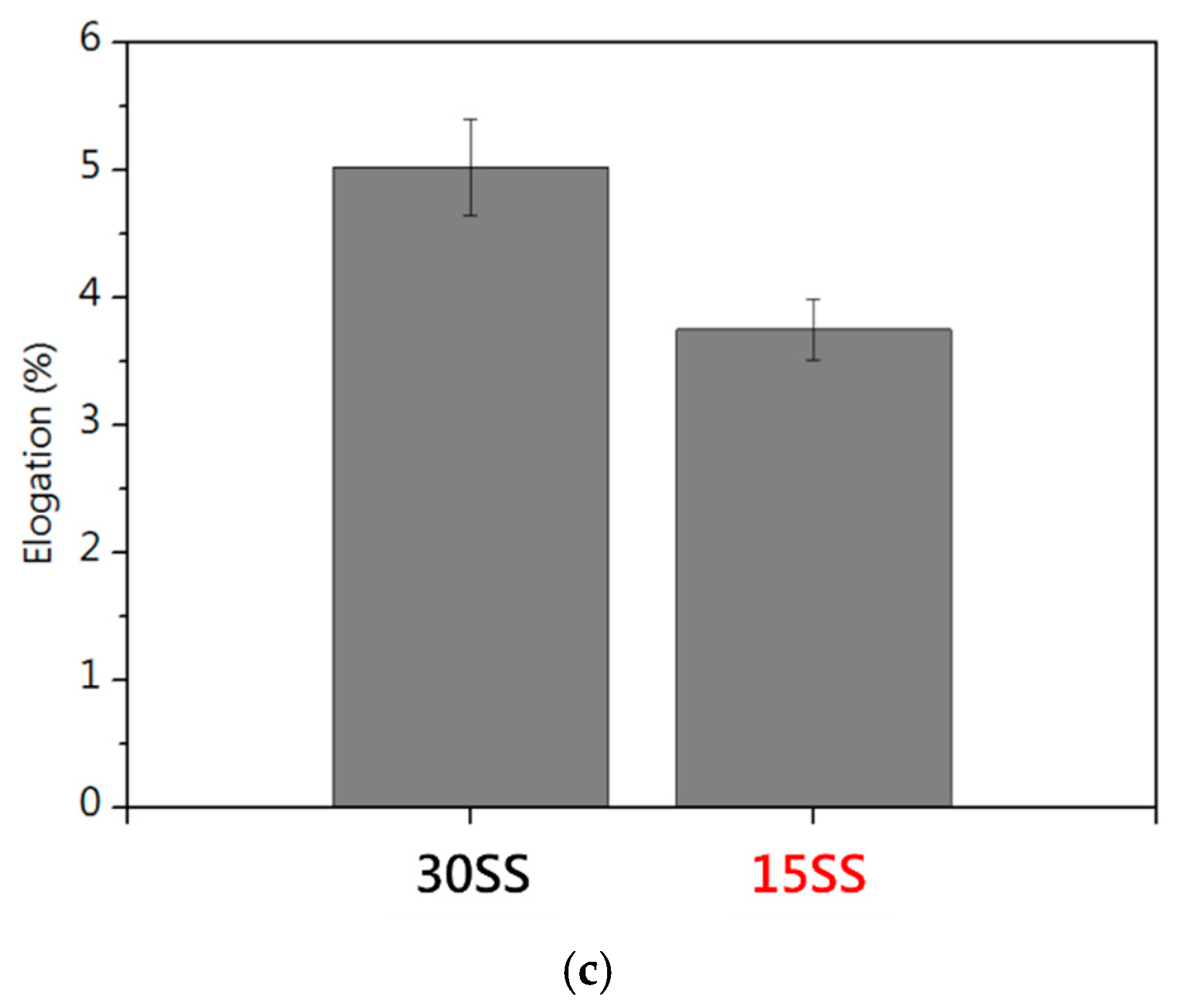

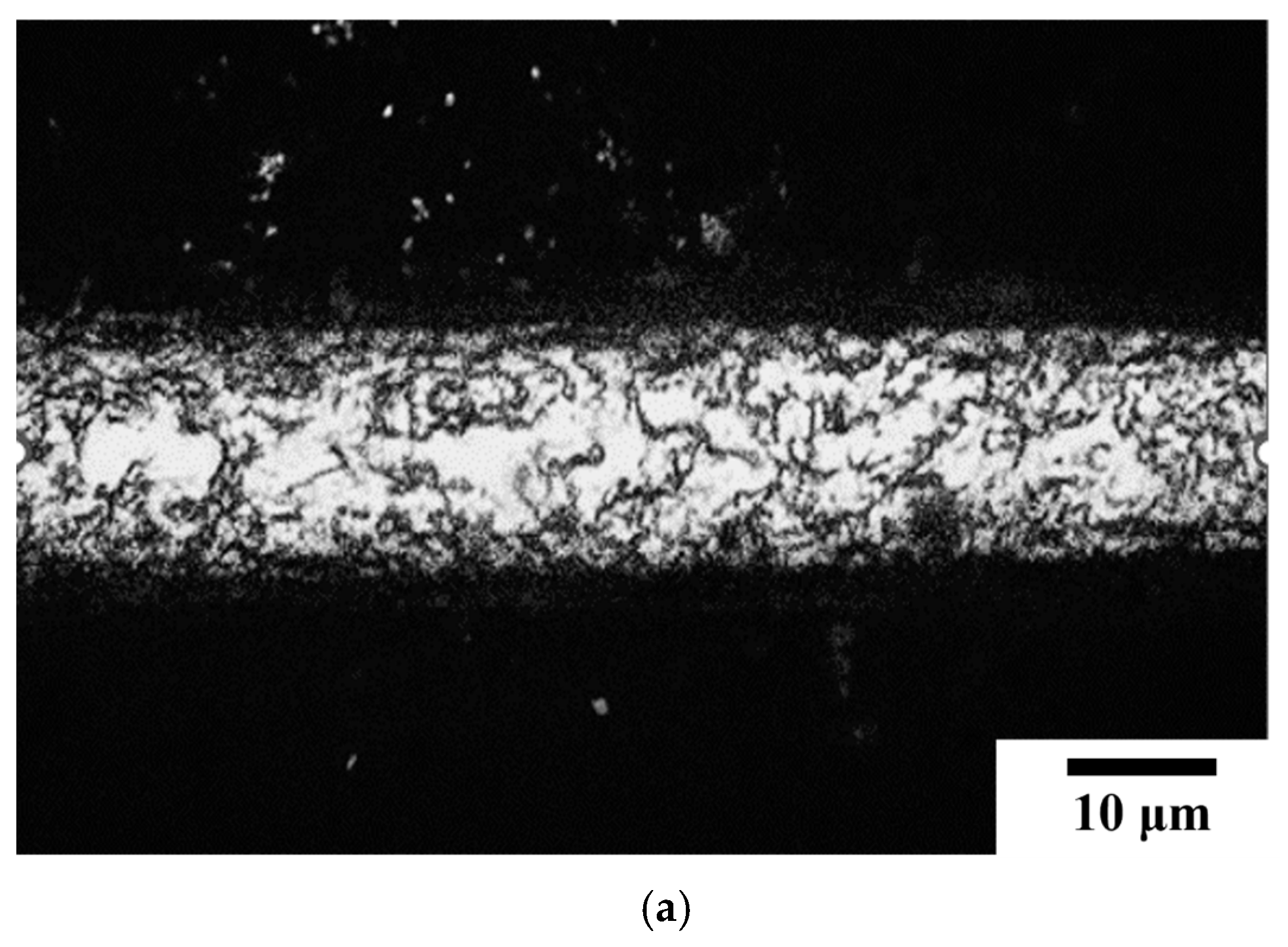

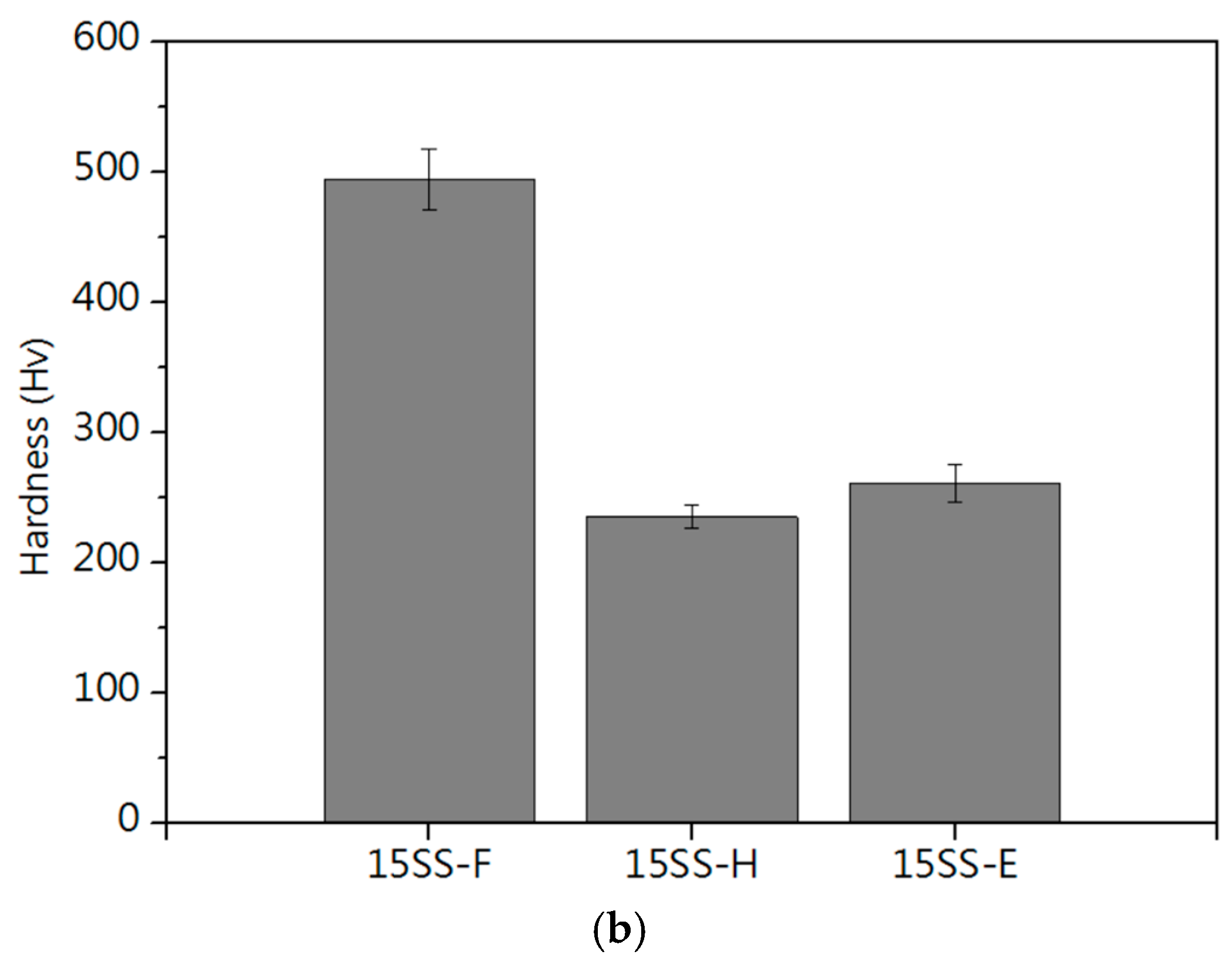

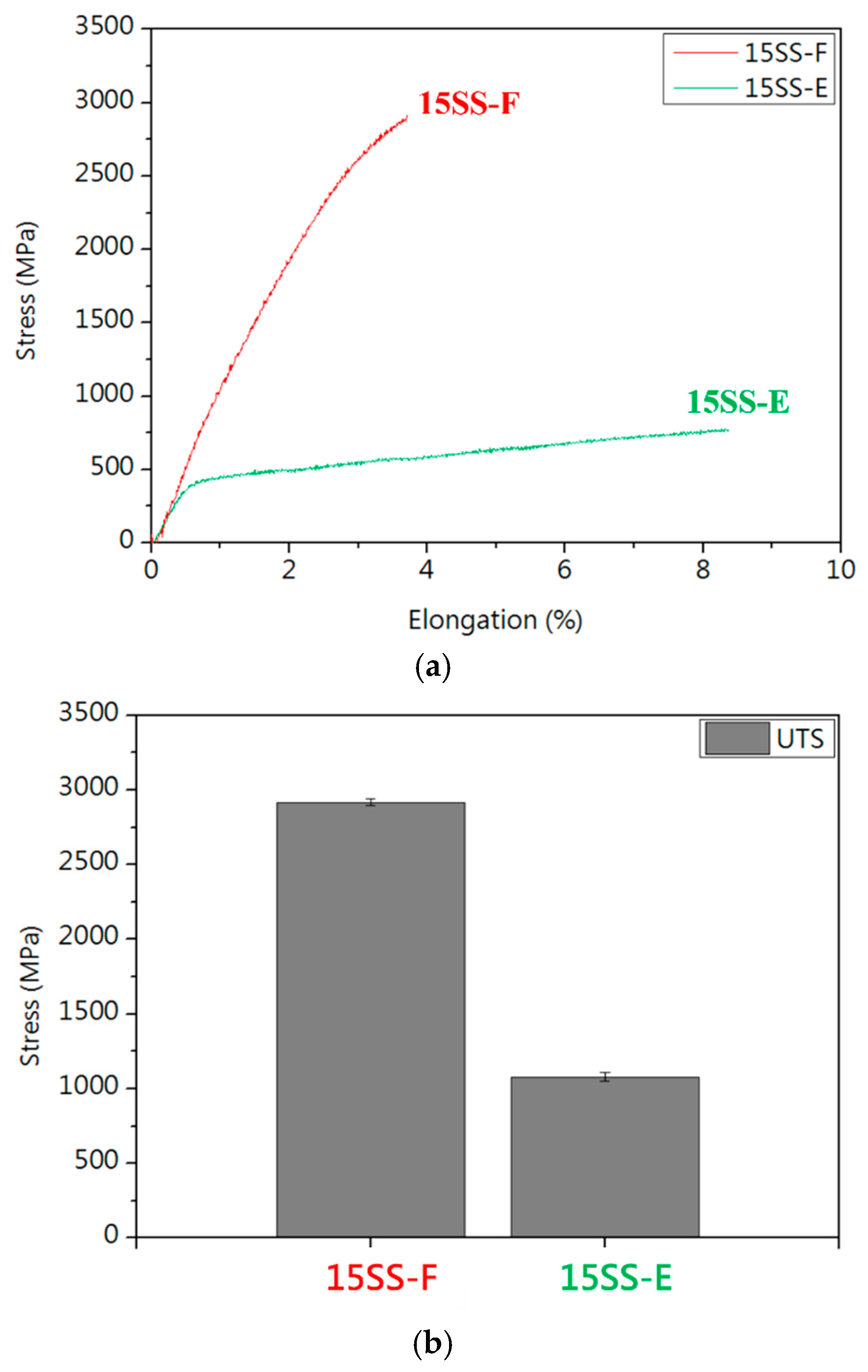

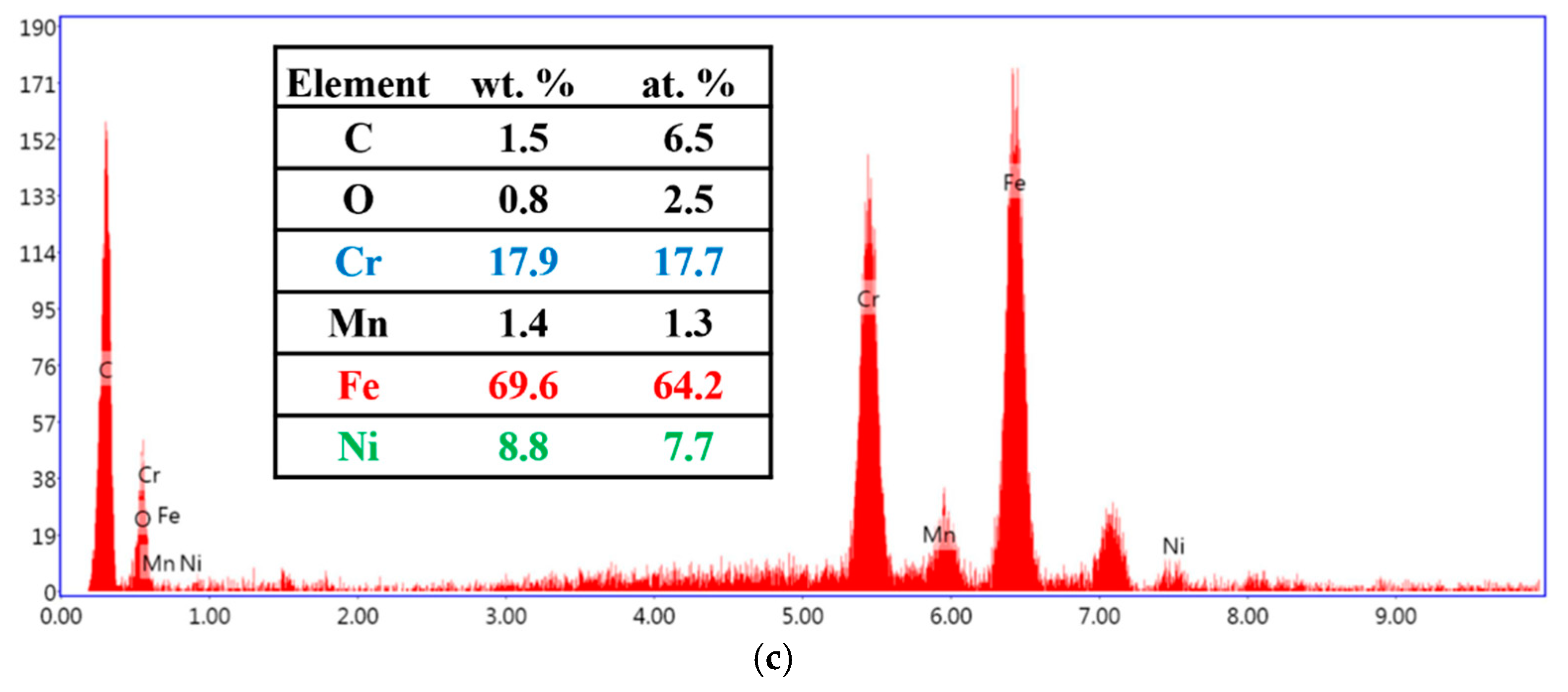

3.1. Microstructure and Mechanical Properties

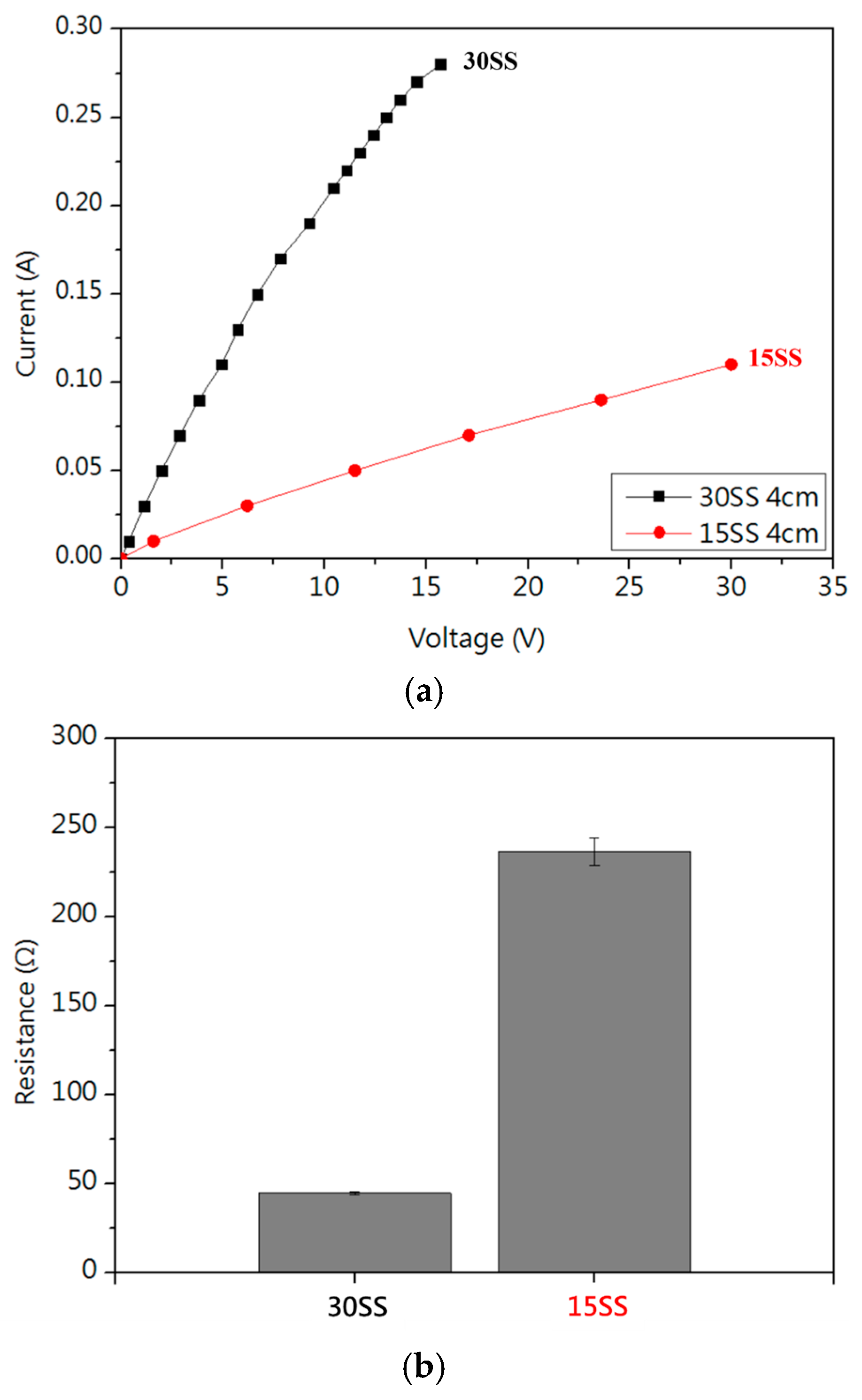

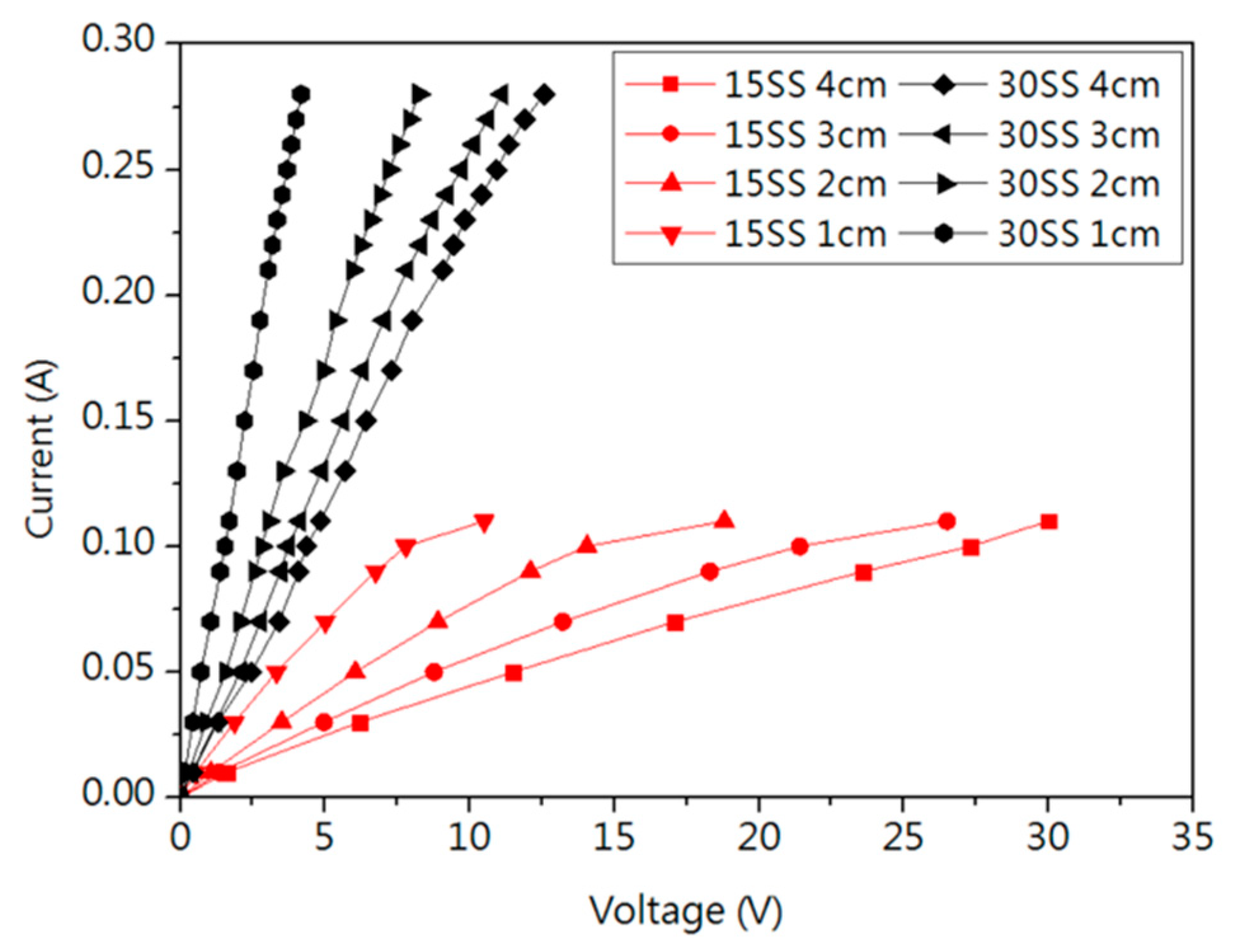

3.2. IV Curve and Electrical Fatigue Test

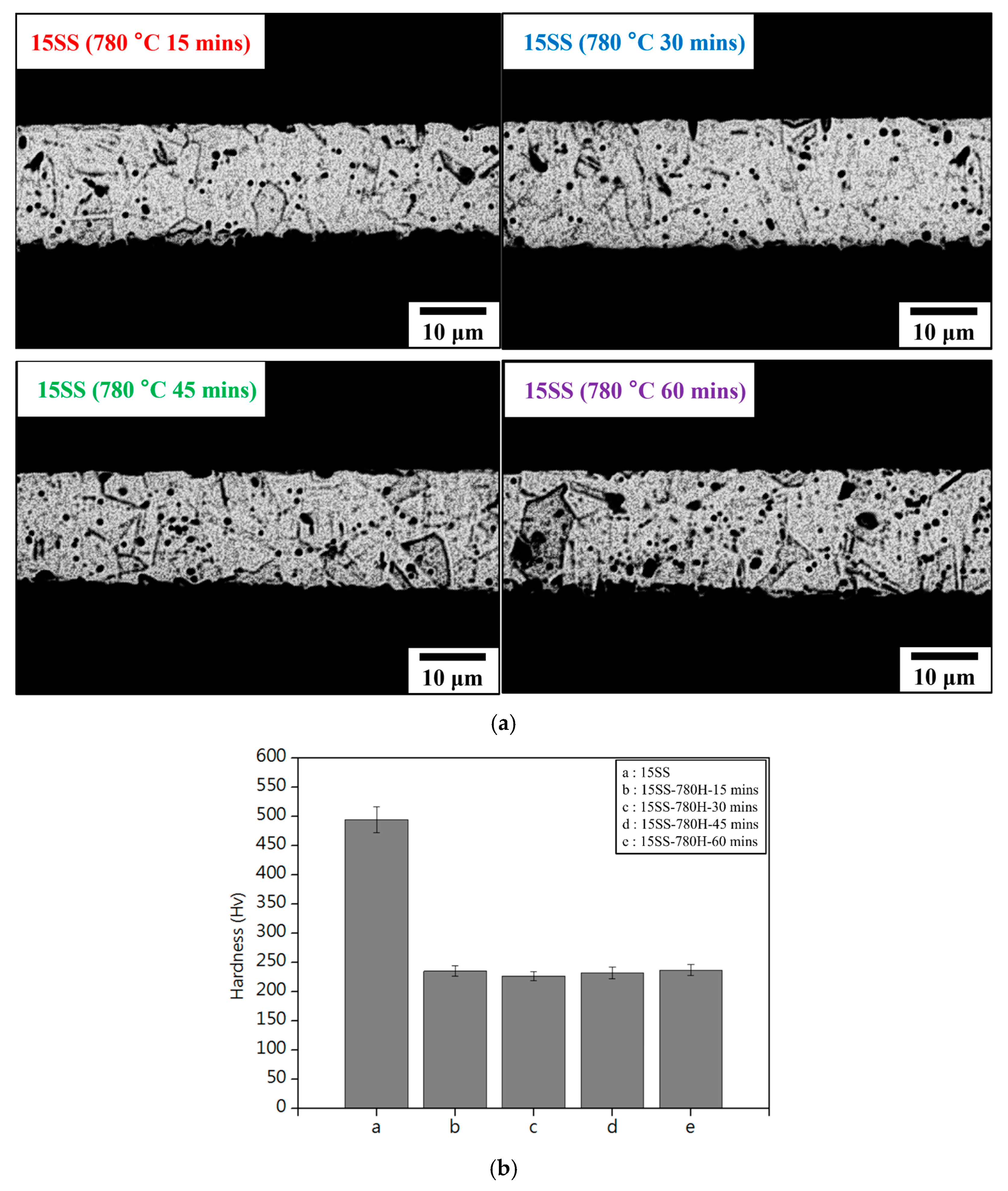

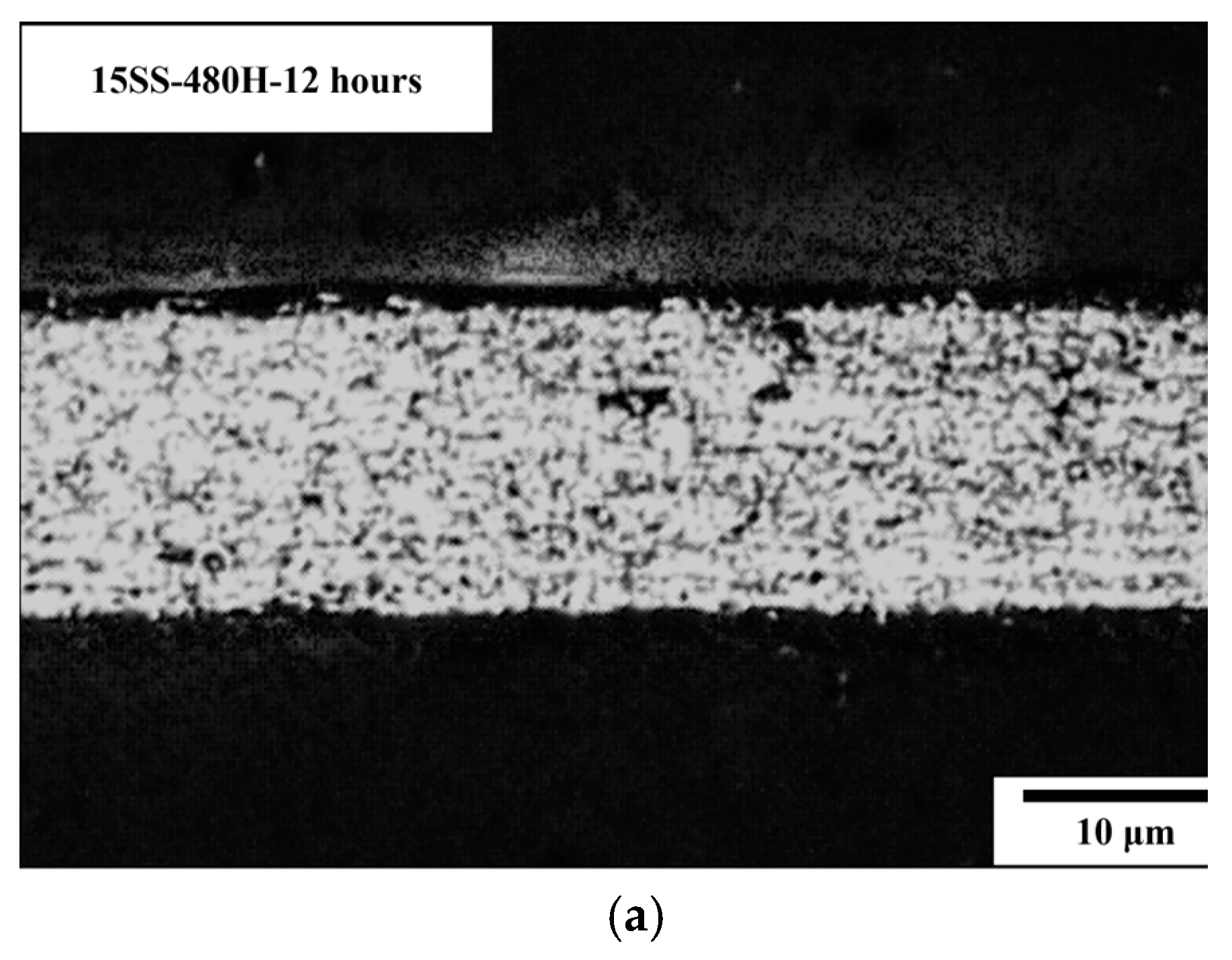

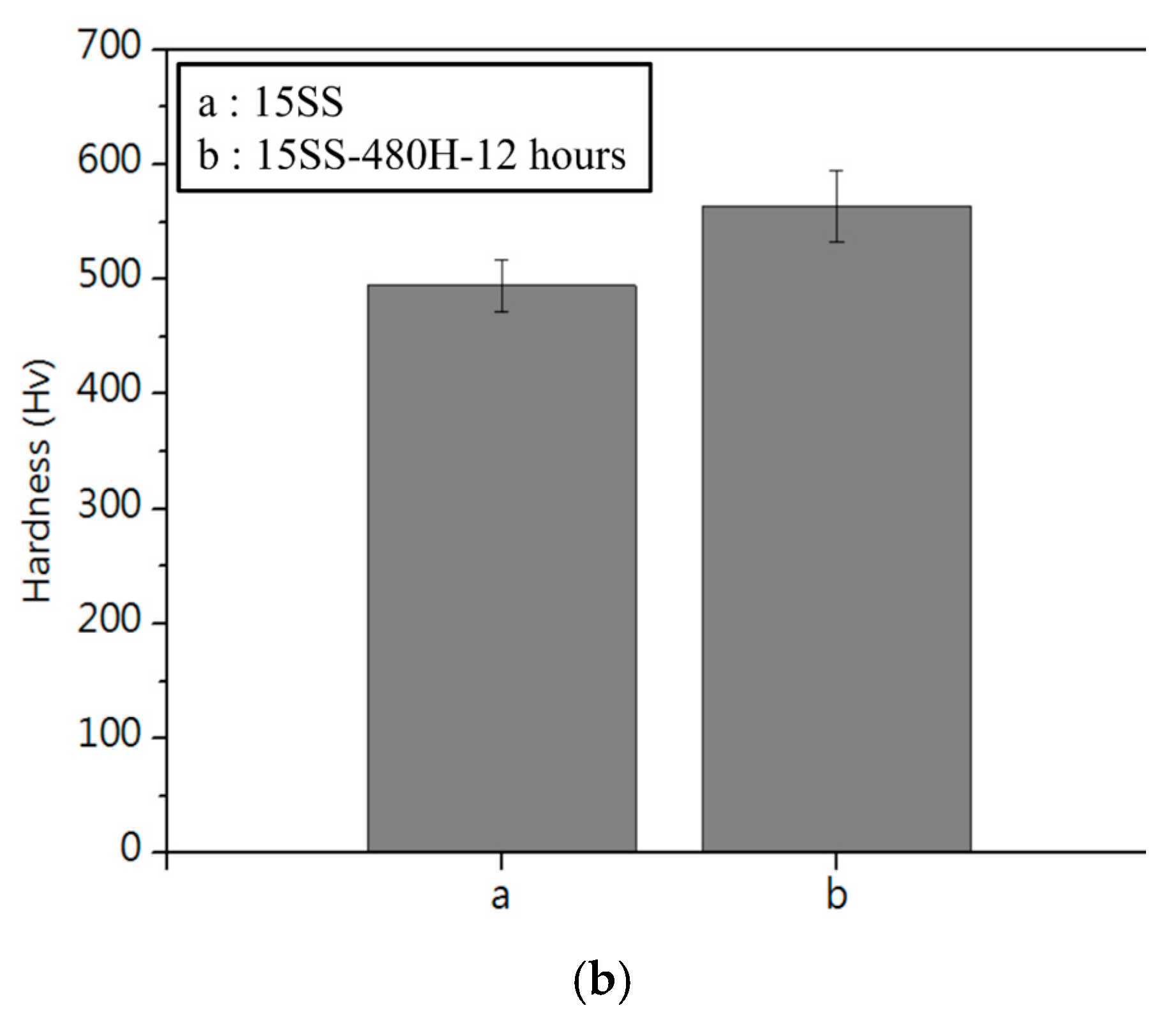

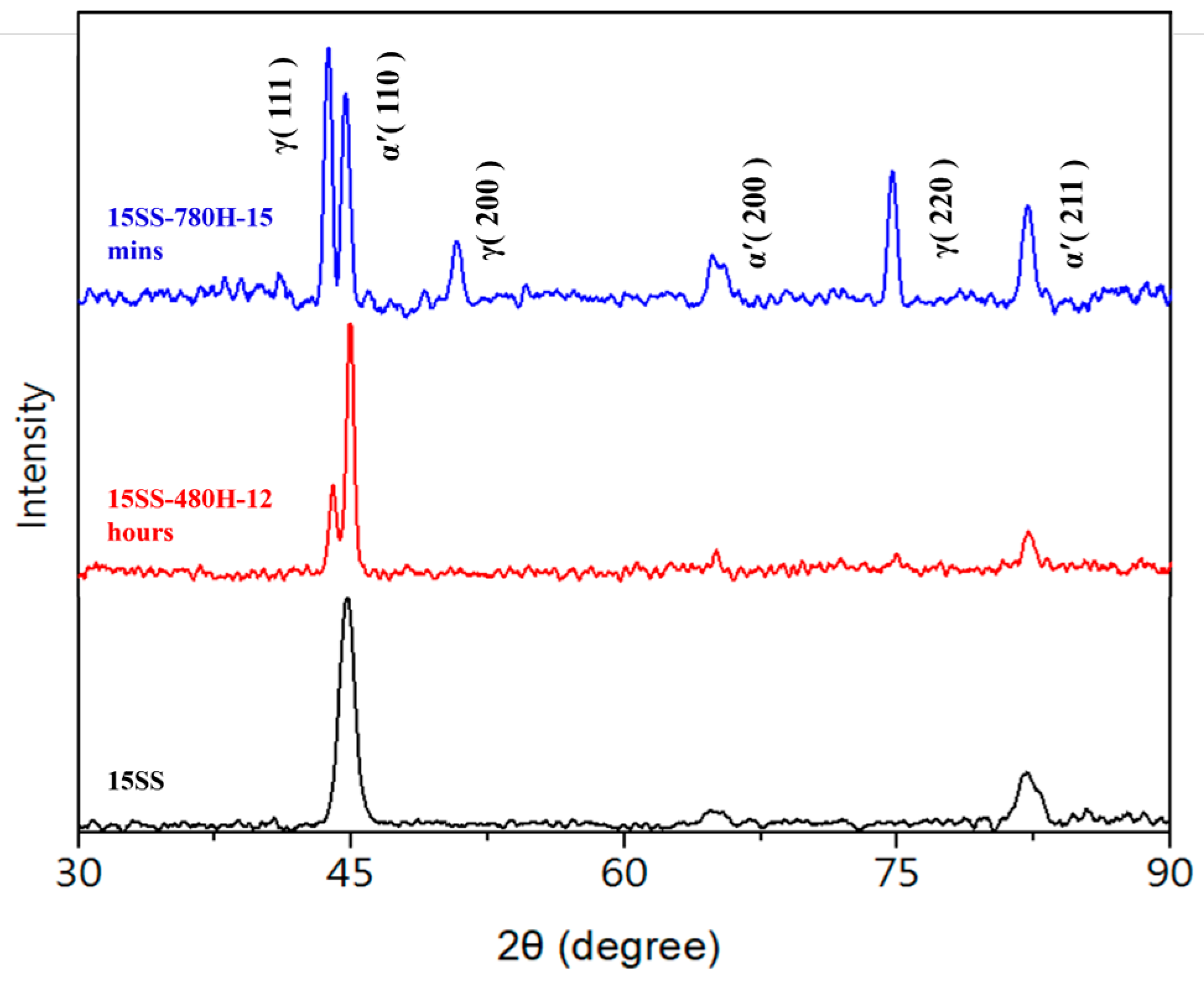

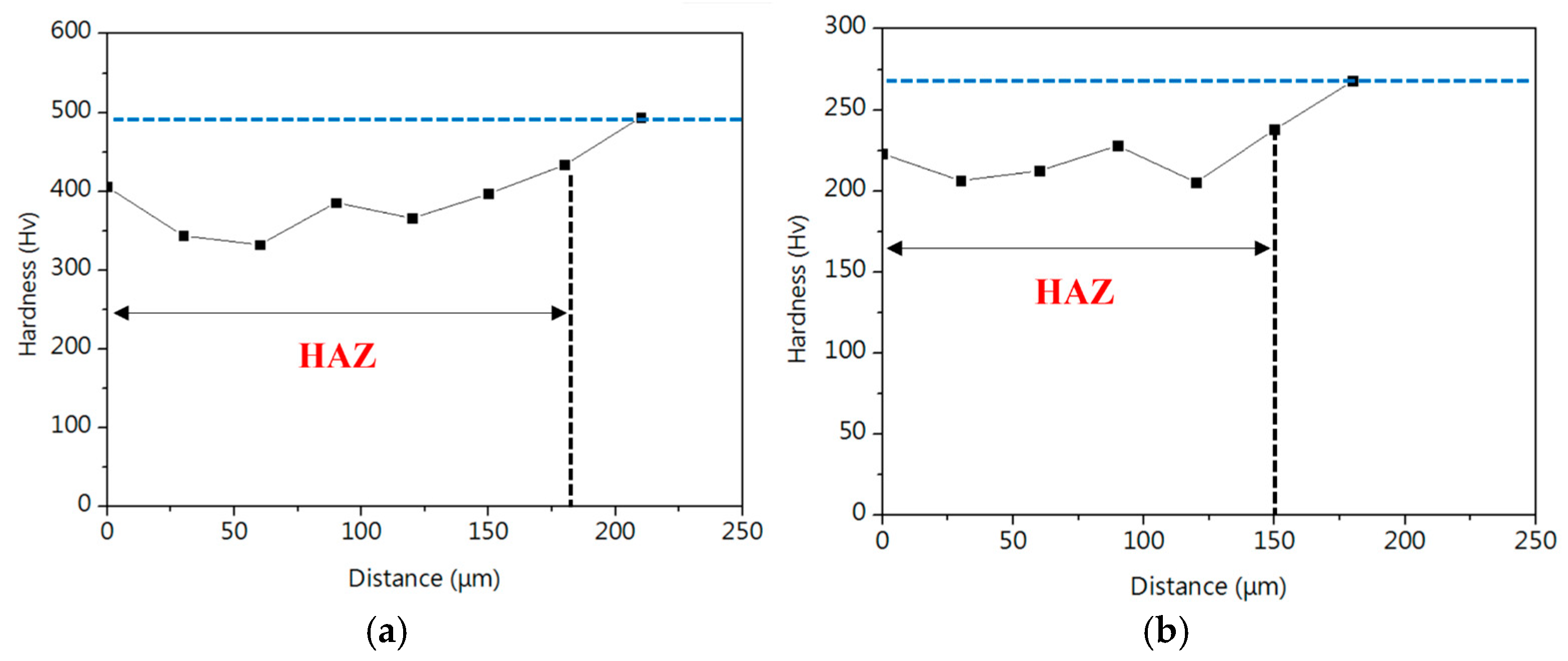

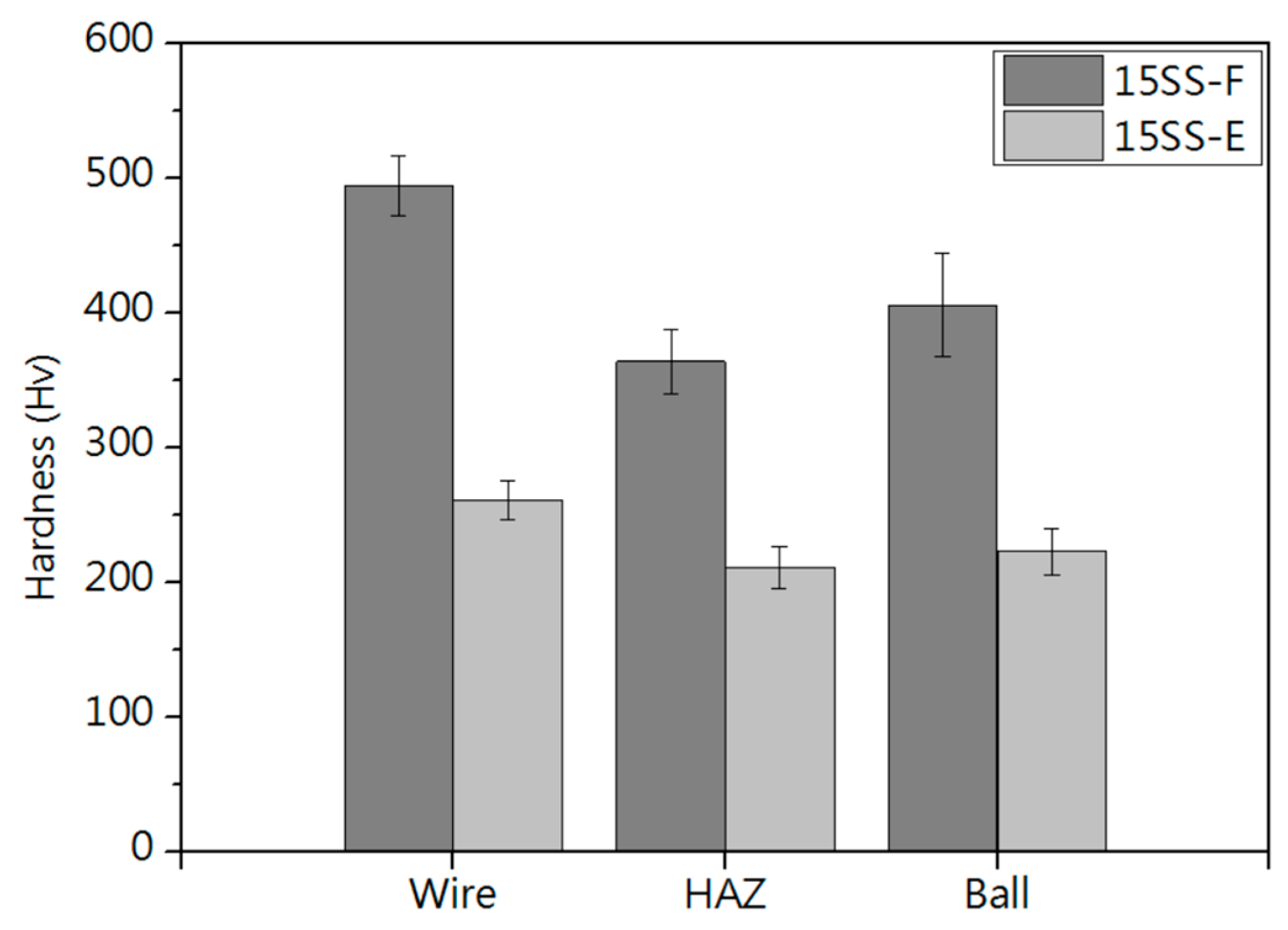

3.3. Microstructure and Micro-Hardness of Vacuum-Annealed Wires

3.4. Electrical-Induced Temperature [19]

3.5. Microstructure and Mechanical Properties of Electrically Annealed Wires

3.6. Electrical Properties of Electrically Annealed Wires

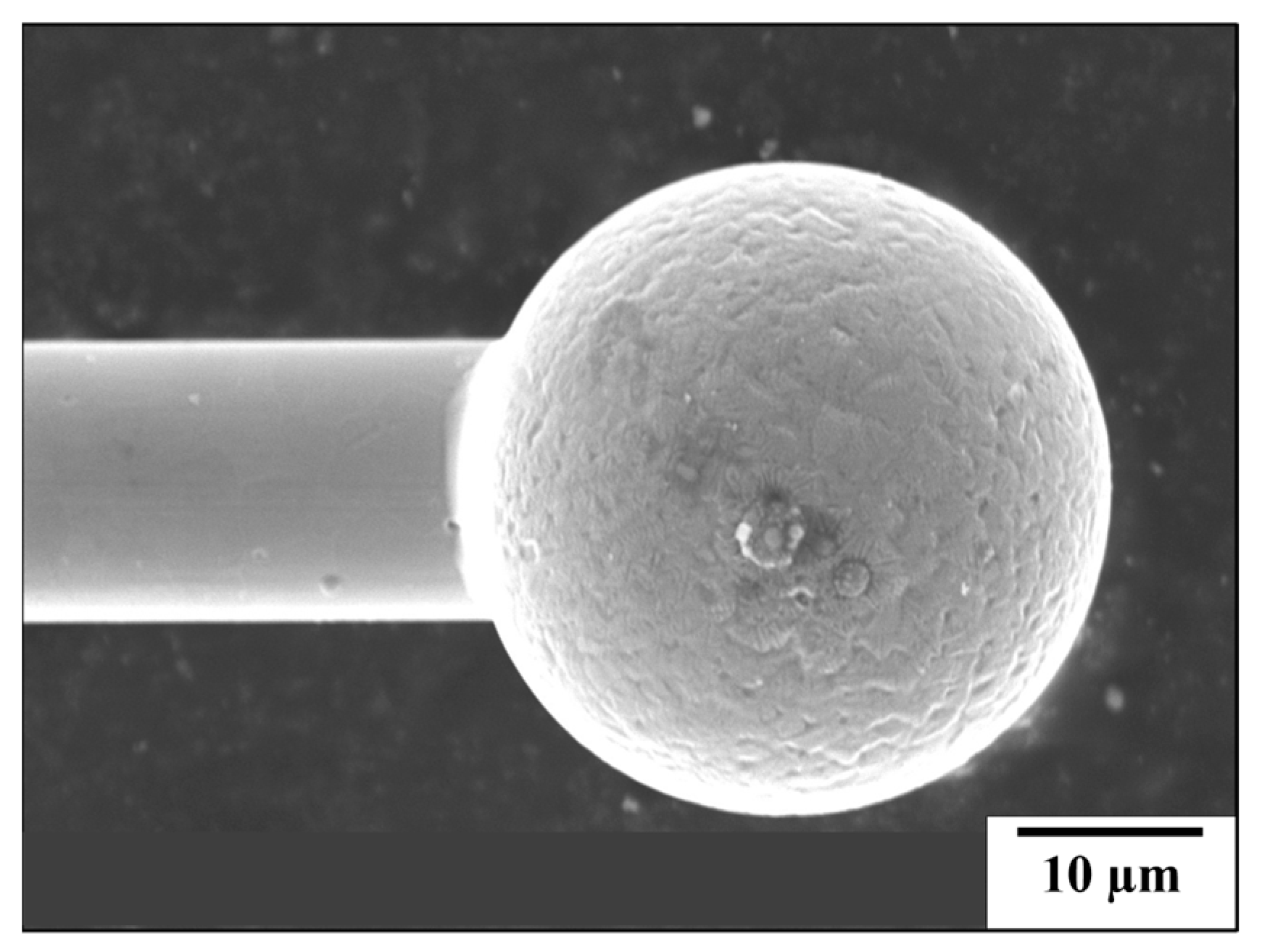

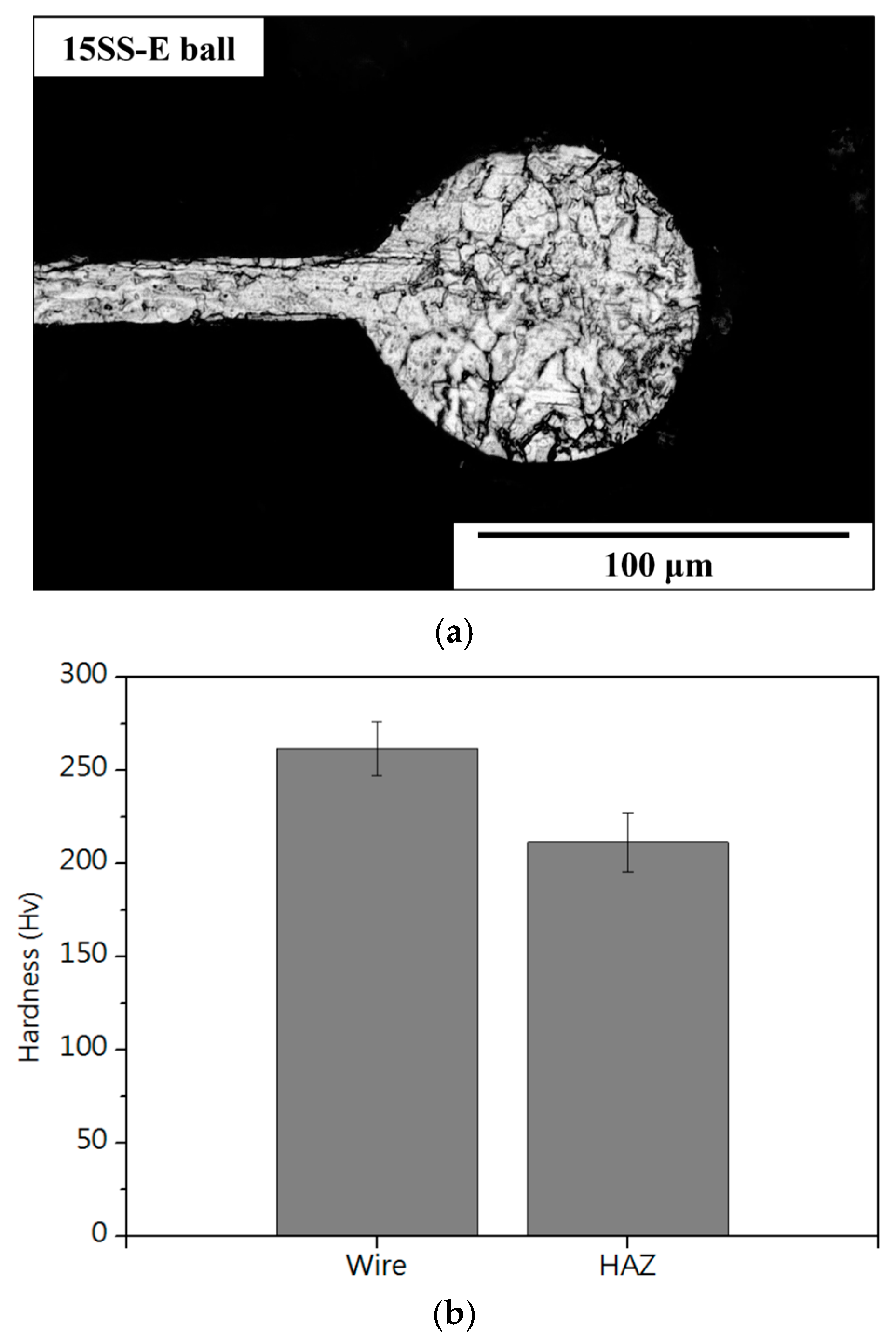

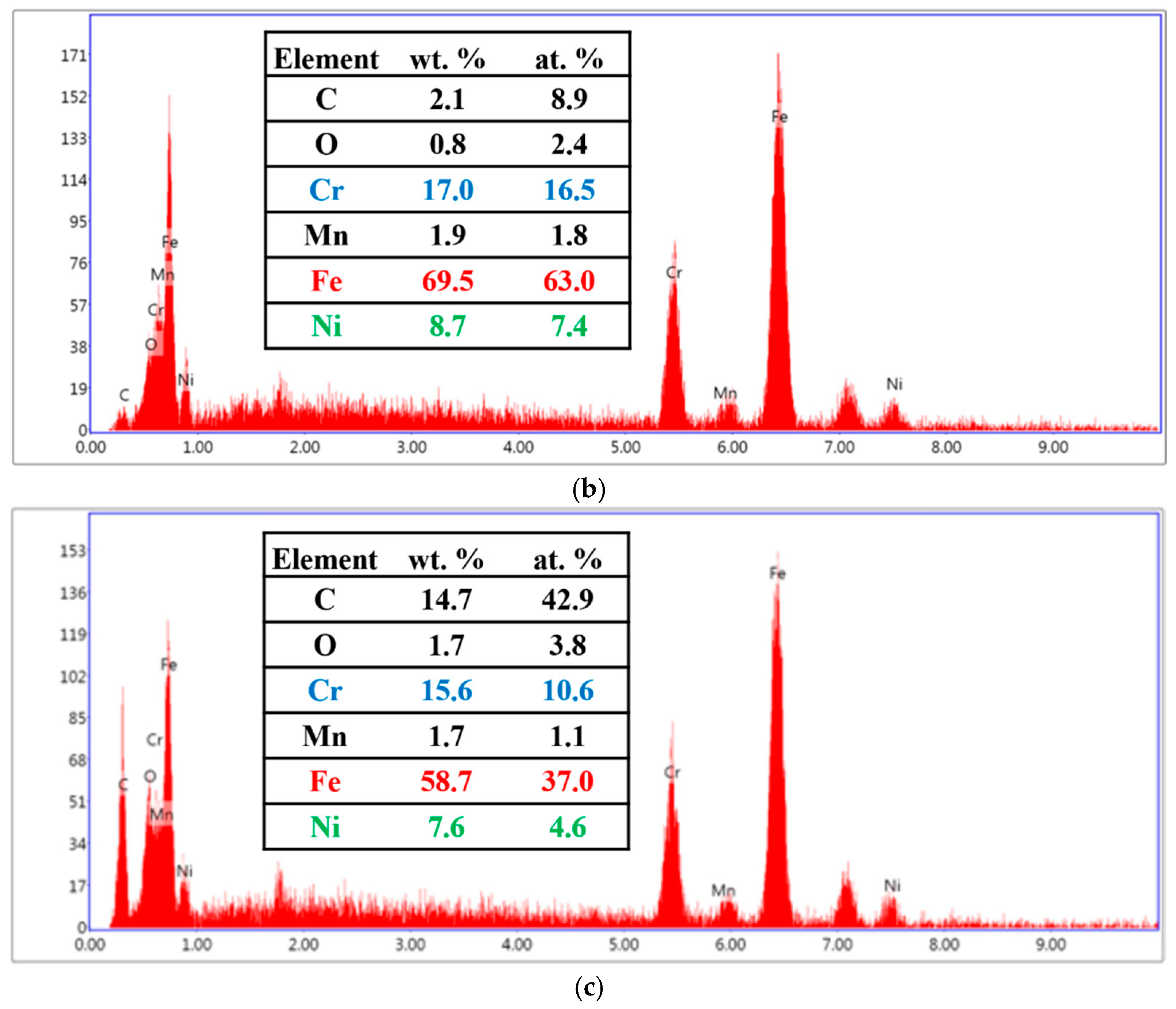

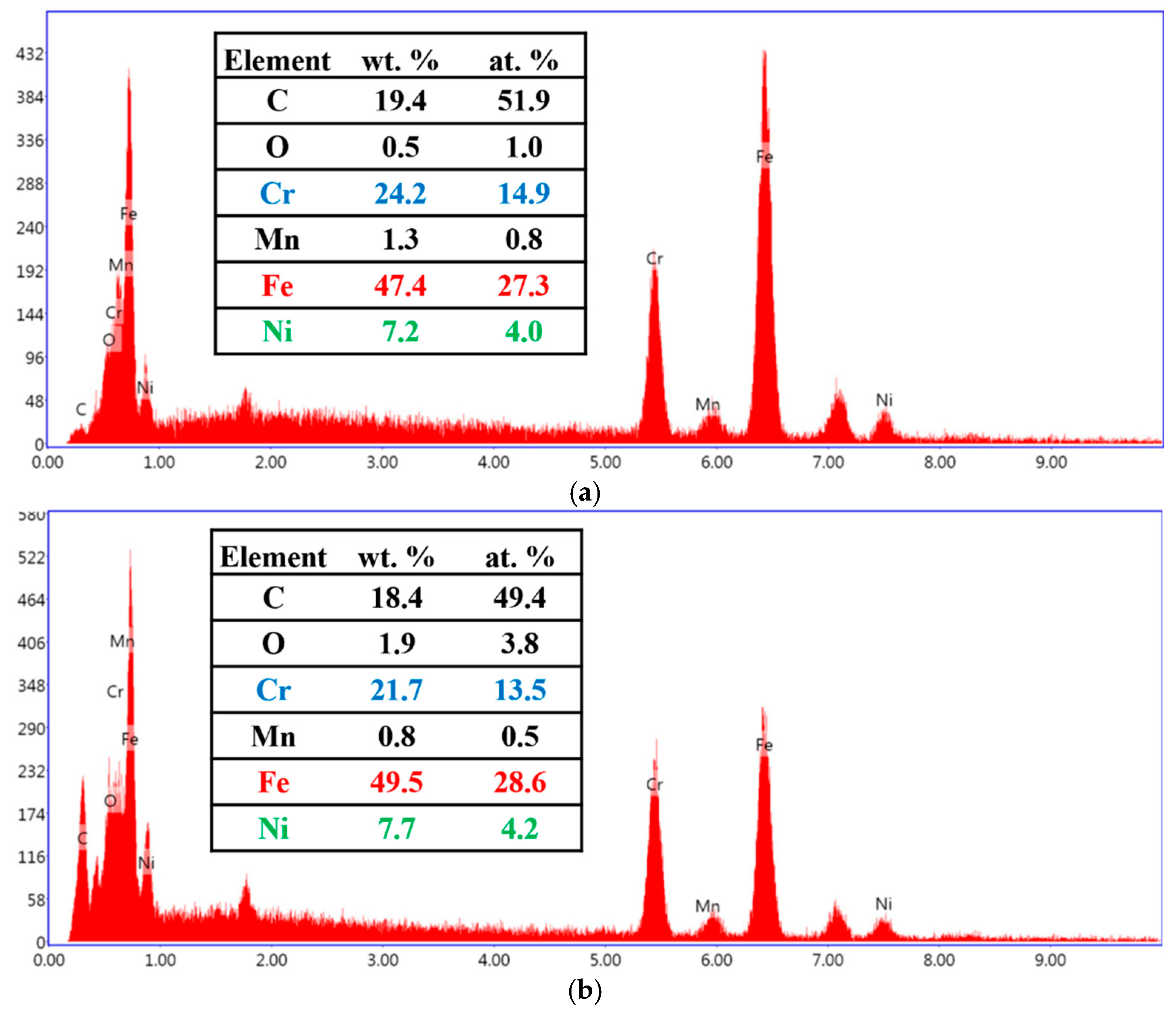

3.7. Electronic Flame-Off (EFO) Test

4. Conclusions

- (1)

- Due to the cold drawing process, the grains of the 304L stainless steel fine wire are elongated along the drawing direction, forming an elongated grain structure. The material exhibits a dense, defect-free internal structure with significant work hardening effects, resulting in excellent strength (2916 MPa) and hardness (494 Hv).

- (2)

- Both 30 µm and 15 µm 304L stainless steel fine wires exhibit excellent electrical fatigue resistance and successfully undergo the EFO process, reaching the requirements for wire bonding applications.

- (3)

- Vacuum annealing at 480 °C was ineffective in reversing the SIMT-induced martensite back to austenite in the wire, resulting in no reduction in hardness. In contrast, annealing at 780 °C successfully facilitated the reverse transformation of martensite in 304L stainless steel wire, decreasing strength and hardness. By converting the 780 °C condition to an equivalent electrical annealing current of 0.08 A, the electrically annealed wire exhibited softening and enhanced ductility, making it more suitable for wire bonding applications.

- (4)

- Cold-drawn 304L stainless steel fine wires develop a dendritic crystal structure after the EFO process. In contrast, electrified annealing reduces solidification segregation in the ball microstructure, minimizes the heat-affected zone, and decreases the number of dendritic structures, enhancing their suitability for wire bonding applications.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chen, W.T.; Chang, C.S.; Charsky, R.S. An overview of electrical and mechanical aspects of electronic packaging. In Proceedings of the 1990 IEEE International Symposium on Circuits and Systems (ISCAS), New Orleans, LA, USA, 1–3 May 1990; pp. 2085–2094. [Google Scholar]

- Hu, G. Comparison of copper, silver and gold wire bonding on interconnect metallization. In Proceedings of the 2012 13th International Conference on Electronic Packaging Technology & High Density Packaging, Guilin, China, 13–16 August 2012; pp. 529–533. [Google Scholar]

- Zhou, H.; Zhang, Y.; Cao, J.; Su, C.; Li, C.; Chang, A.; An, B. Research progress on bonding wire for microelectronic packaging. Micromachines 2023, 14, 432. [Google Scholar] [CrossRef] [PubMed]

- Jaafar, N.B.; Ching, E.W.L. Comparison of Au/Al, Cu/Al and Ag/Al in wirebonding assembly and IMC growth behavior. In Proceedings of the 2016 IEEE 18th Electronics Packaging Technology Conference (EPTC), Singapore, 30 November–3 December 2016; pp. 10–12. [Google Scholar]

- Lu, C.T. The challenges of copper wire bonding. In Proceedings of the 2010 5th International Microsystems Packaging Assembly and Circuits Technology Conference, Taipei, Taiwan, 20–22 October 2010; pp. 1–4. [Google Scholar]

- George, G.; Shaikh, H. Introduction to austenitic stainless steels. In Corrosion of Austenitic Stainless Steels; Elsevier: Amsterdam, The Netherlands, 2002; pp. 1–36. [Google Scholar]

- Tuthill, A.H.; Covert, R.A. Stainless steels: An introduction to their metallurgy and corrosion resistance. Dairy Food Environ. Sanit. 2000, 20, 506–517. [Google Scholar]

- Xu, Q.; Zhu, J.; Zong, Y.; Liu, L.; Zhu, X.; Zhang, F.; Luan, B. Effect of drawing and annealing on the microstructure and mechanical properties of 304 austenitic stainless steel wire. Mater. Res. Express 2021, 8, 126530. [Google Scholar] [CrossRef]

- Milad, M.; Zreiba, N.; Elhalouani, F.; Baradai, C. The effect of cold work on structure and properties of AISI 304 stainless steel. J. Mater. Process. Technol. 2008, 203, 80–85. [Google Scholar] [CrossRef]

- Pham, H.T.; Iwamoto, T. An evaluation of fracture properties of type-304 austenitic stainless steel at high deformation rate using the small punch test. Int. J. Mech. Sci. 2018, 144, 249–261. [Google Scholar] [CrossRef]

- Prasad, K.S.; Rao, C.S.; Rao, D.N. A review on welding of AISI 304L austenitic stainless steel. J. Manuf. Sci. Prod. 2014, 14, 1–11. [Google Scholar] [CrossRef]

- Chuang, H.C.; Hung, F.Y.; Lui, T.S.; Chen, L.H. Effect of the twins on mechanical properties of AISI 304 stainless steel wire using electrical current method. Mater. Trans. 2011, 52, 25–30. [Google Scholar] [CrossRef]

- Panov, D.; Kudryavtsev, E.; Chernichenko, R.; Smirnov, A.; Stepanov, N.; Simonov, Y.; Zherebtsov, S.; Salishchev, G. Mechanisms of the reverse martensite-to-austenite transformation in a metastable austenitic stainless steel. Metals 2021, 11, 599. [Google Scholar] [CrossRef]

- Chang, Y.T.; Hung, F.Y.; Wu, B.D. Comparison of the Microstructural Characteristics and the Electrothermal Fracture Mechanism of Au-Pd-Coated Copper Wire and Cu-Ti Micro-alloyed Wire. J. Electron. Mater. 2024, 53, 1695–1707. [Google Scholar] [CrossRef]

- Choi, J.Y.; Jin, W. Strain induced martensite formation and its effect on strain hardening behavior in the cold drawn 304 austenitic stainless steels. Scr. Mater. 1997, 36, 99–104. [Google Scholar] [CrossRef]

- Lee, S.H.; Lee, J.C.; Choi, J.Y.; Nam, W.J. Effects of deformation strain and aging temperature on strain aging behavior in a 304 stainless steel. Met. Mater. Int. 2010, 16, 21–26. [Google Scholar] [CrossRef]

- Salgado, J.; Fava, J.; Spinosa, C. A study of the reverse martensitic transformations in austenitic stainless steels by calorimetry and isothermal heat treatments. Matéria 2024, 29, e20230221. [Google Scholar] [CrossRef]

- Sohrabi, M.J.; Naghizadeh, M.; Mirzadeh, H. Deformation-induced martensite in austenitic stainless steels: A review. Arch. Civ. Mech. Eng. 2020, 20, 124. [Google Scholar] [CrossRef]

- Balluffi, R.W.; Allen, S.M.; Carter, W.C. Kinetics of Materials; John Wiley & Sons: Hoboken, NJ, USA, 2005. [Google Scholar]

- Wu, B.D.; Hsu, C.K.; Huang, B.C.; Hung, F.Y. Effect of electro-thermal diffusion induced deterioration on the failure mechanism of Pd-Au-coated Cu wires. J. Mater. Sci. Mater. Electron. 2024, 35, 2024. [Google Scholar] [CrossRef]

- Hou, J.; Sun, P.; Wang, Q.; Zhang, Z.; Zhang, Z. Breaking the trade-off relation between strength and electrical conductivity: Heterogeneous grain design. Acta Metall. Sin. 2022, 58, 1467–1477. [Google Scholar]

- Fu, J.W.; Yang, Y.S.; Guo, J.J.; Tong, W.H. Effect of cooling rate on solidification microstructures in AISI 304 stainless steel. Mater. Sci. Technol. 2008, 24, 941–944. [Google Scholar] [CrossRef]

- Ma, J.C.; Yang, Y.S.; Tong, W.H.; Fang, Y.; Yu, Y.; Hu, Z.Q. Microstructural evolution in AISI 304 stainless steel during directional solidification and subsequent solid-state transformation. Mater. Sci. Eng. A 2007, 444, 64–68. [Google Scholar] [CrossRef]

- Fu, J.W.; Yang, Y.S.; Guo, J.J.; Ma, J.C.; Tong, W.H. Microstructure evolution in AISI 304 stainless steel during near rapid directional solidification. Mater. Sci. Technol. 2009, 25, 1013–1016. [Google Scholar] [CrossRef]

- Huang, F.; Wang, X.; Zhang, J.; Ji, C.; Yuan, F.; Yan, Y.U. In situ observation of solidification process of AISI 304 austenitic stainless steel. J. Iron Steel Res. Int. 2008, 15, 78–82. [Google Scholar] [CrossRef]

| 15SS | 30SS | |

|---|---|---|

| FC at 4 cm (A) | 0.11 | 0.28 |

| Resistance at 4 cm (Ω) | 236.46 | 44.85 |

| Resistance at 3 cm (Ω) | 177.17 | 40.83 |

| Resistance at 2 cm (Ω) | 120.72 | 30.16 |

| Resistance at 1 cm (Ω) | 66.77 | 14.75 |

| Resistance at 100 µm (Ω) | 0.61 | 0.14 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, H.-C.; Hung, F.-Y.; Wu, B.-D.; Chang, Y.-T. Application Characteristics of Ultra-Fine 15 μm Stainless Steel Wires: Microstructures, Electrical Fatigue, and Ball Formation Mechanisms. Micromachines 2025, 16, 326. https://doi.org/10.3390/mi16030326

Yang H-C, Hung F-Y, Wu B-D, Chang Y-T. Application Characteristics of Ultra-Fine 15 μm Stainless Steel Wires: Microstructures, Electrical Fatigue, and Ball Formation Mechanisms. Micromachines. 2025; 16(3):326. https://doi.org/10.3390/mi16030326

Chicago/Turabian StyleYang, Hsiang-Chi, Fei-Yi Hung, Bo-Ding Wu, and Yi-Tze Chang. 2025. "Application Characteristics of Ultra-Fine 15 μm Stainless Steel Wires: Microstructures, Electrical Fatigue, and Ball Formation Mechanisms" Micromachines 16, no. 3: 326. https://doi.org/10.3390/mi16030326

APA StyleYang, H.-C., Hung, F.-Y., Wu, B.-D., & Chang, Y.-T. (2025). Application Characteristics of Ultra-Fine 15 μm Stainless Steel Wires: Microstructures, Electrical Fatigue, and Ball Formation Mechanisms. Micromachines, 16(3), 326. https://doi.org/10.3390/mi16030326