Impact of Bonding Pressure on the Reactive Bonding of LTCC Substrates

Abstract

1. Introduction

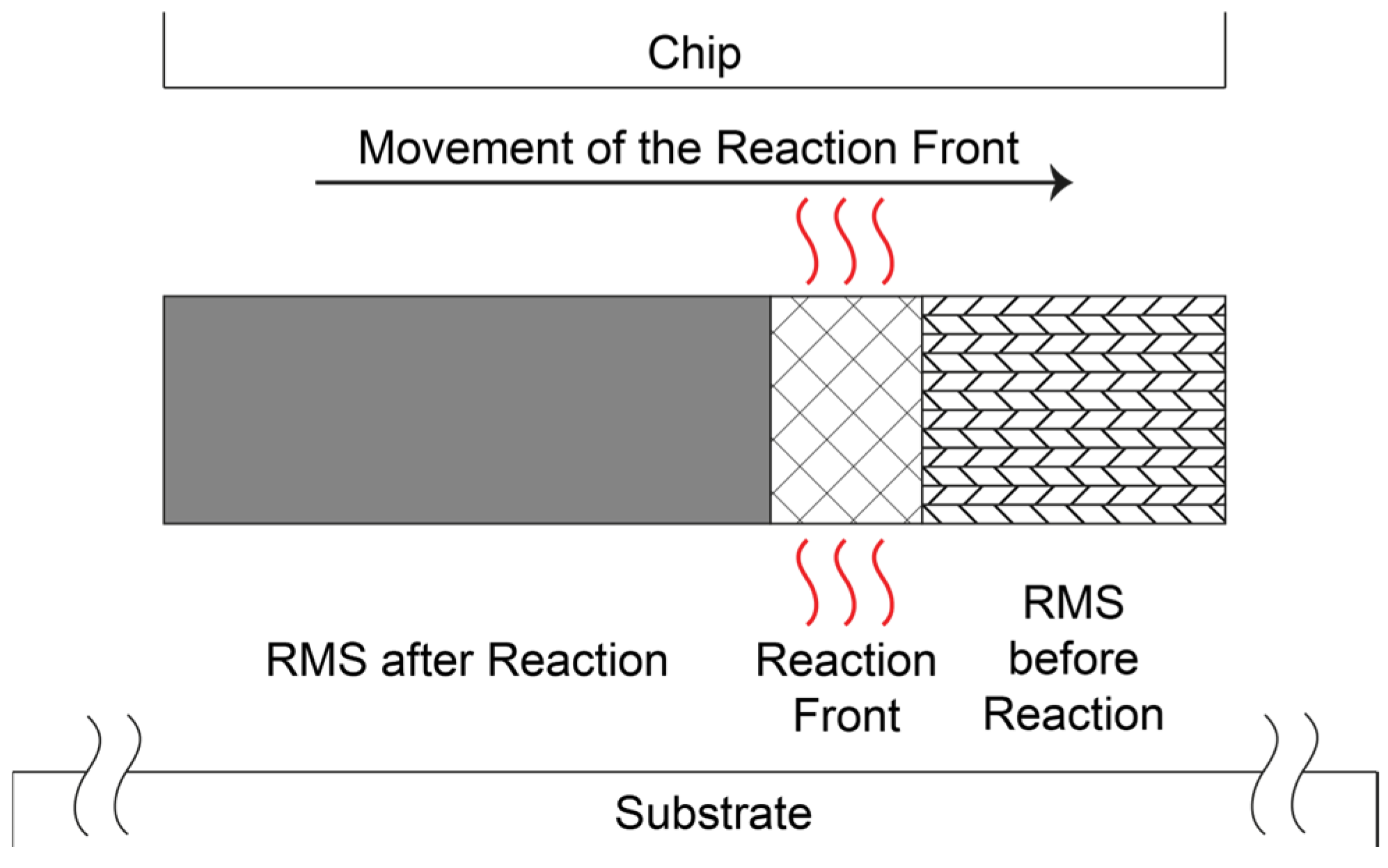

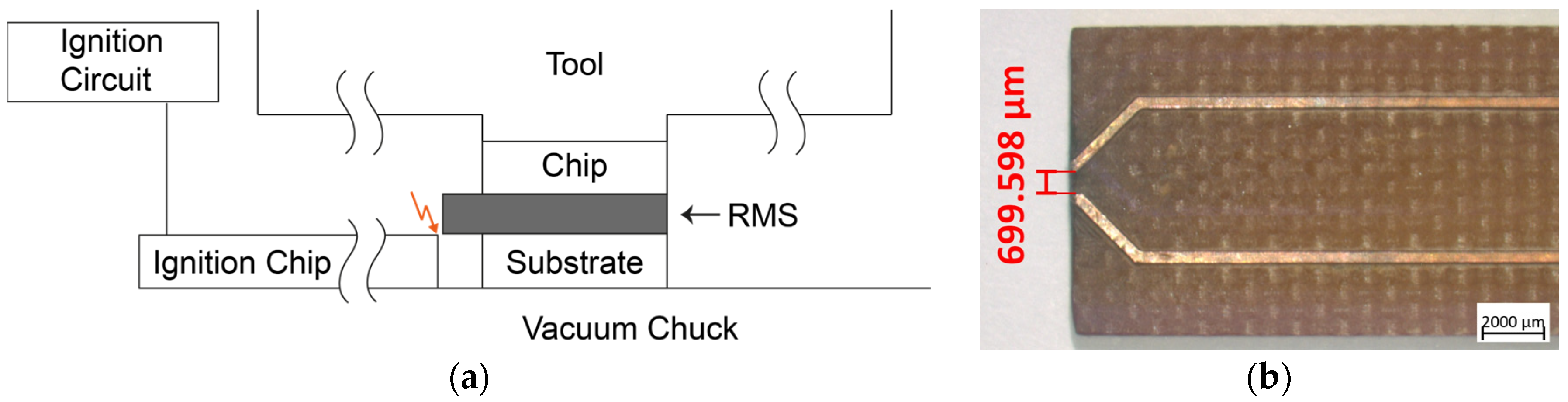

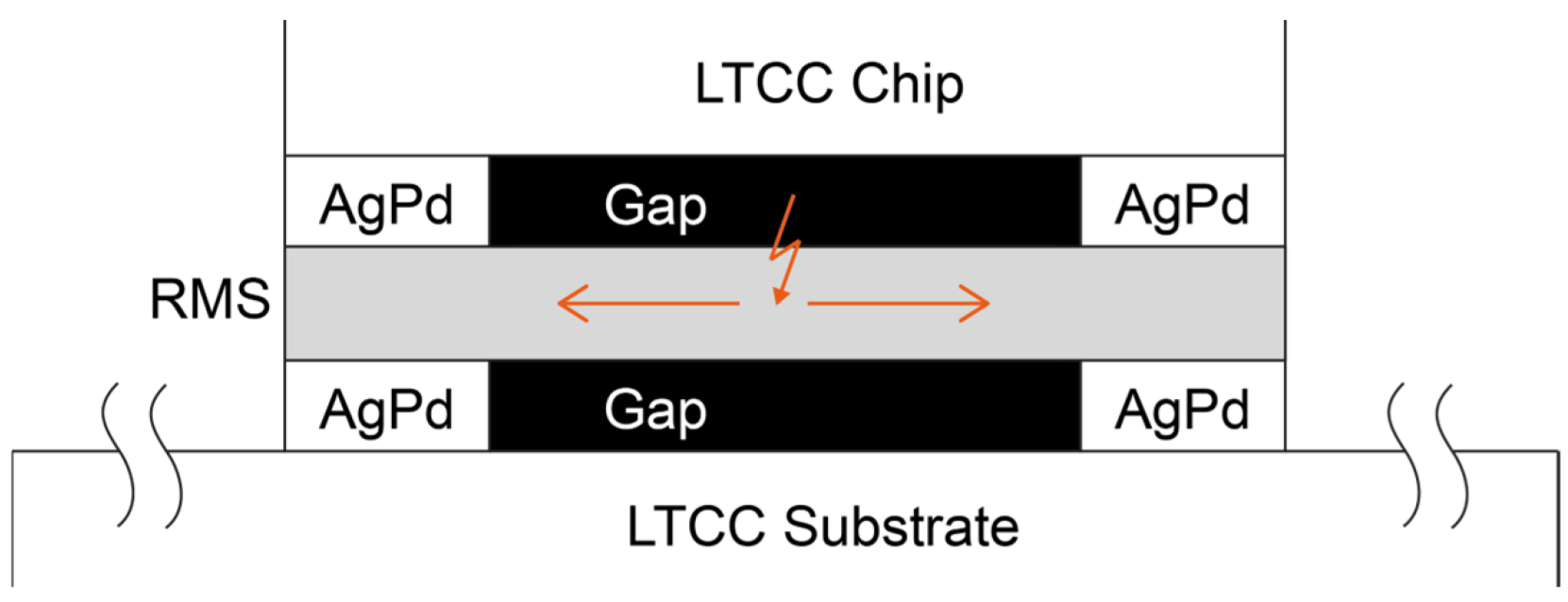

2. Materials and Methods

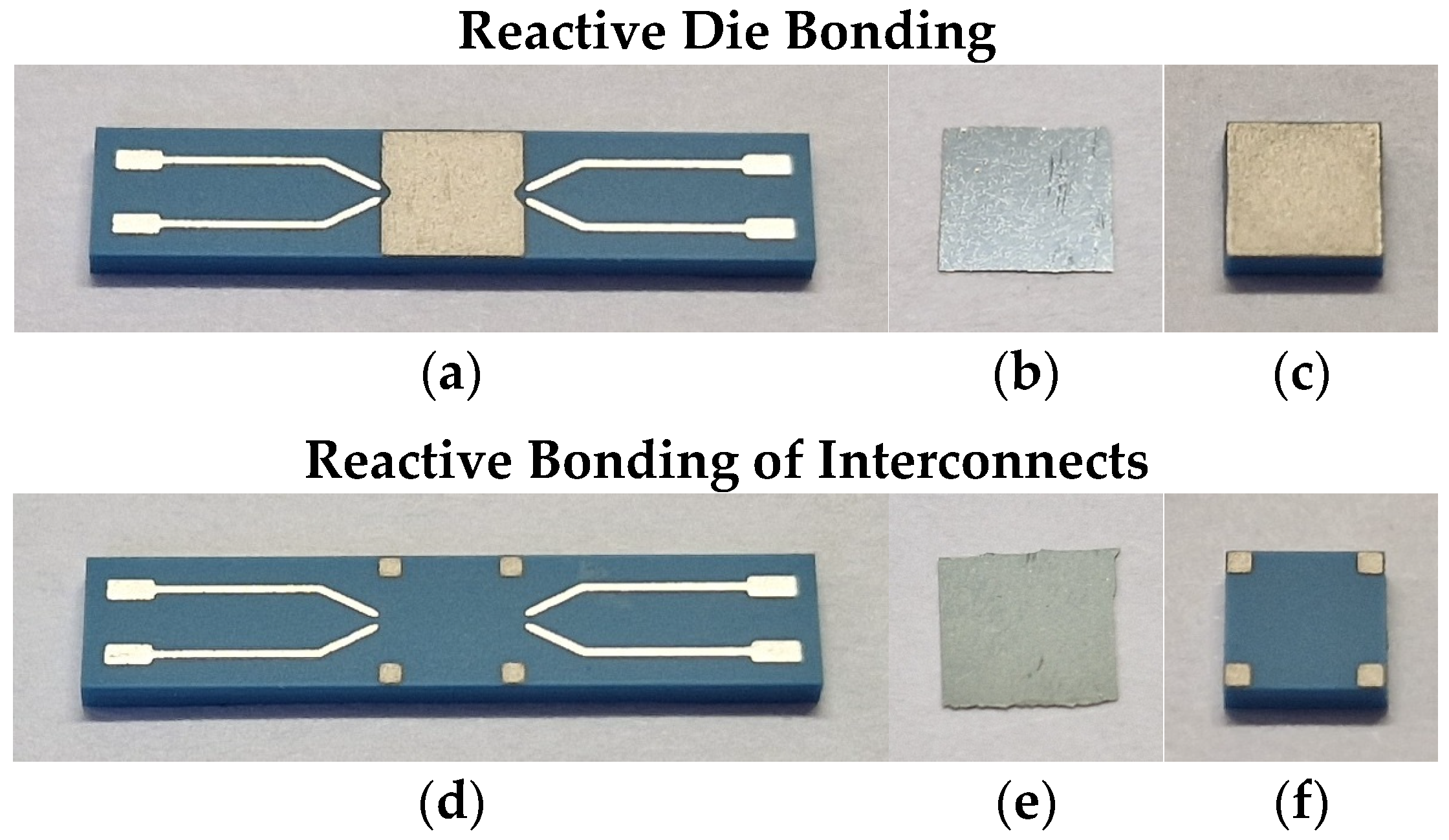

2.1. Sample Preparation

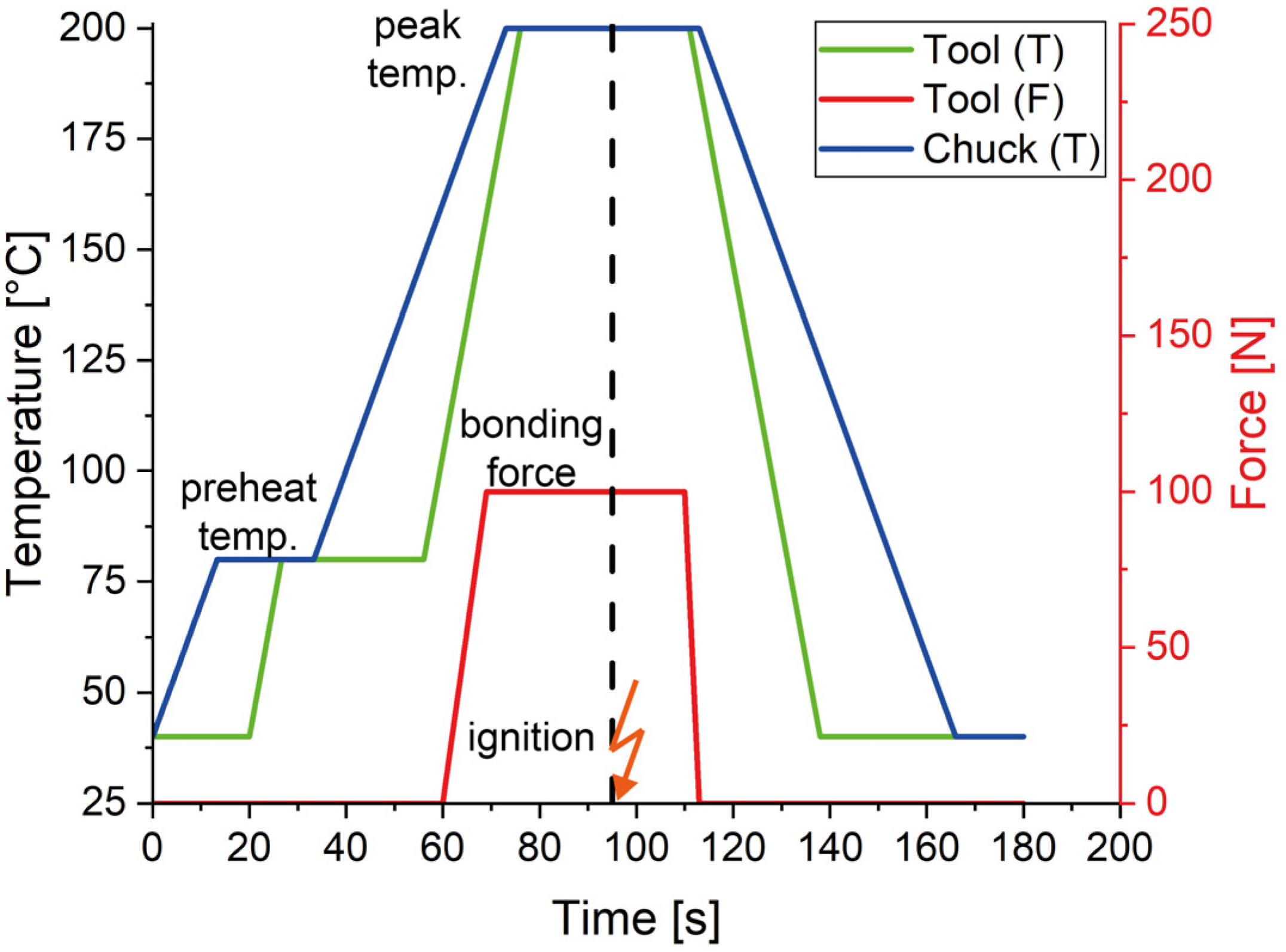

2.2. Bonding Process

2.3. Microscopical Analysis

3. Results

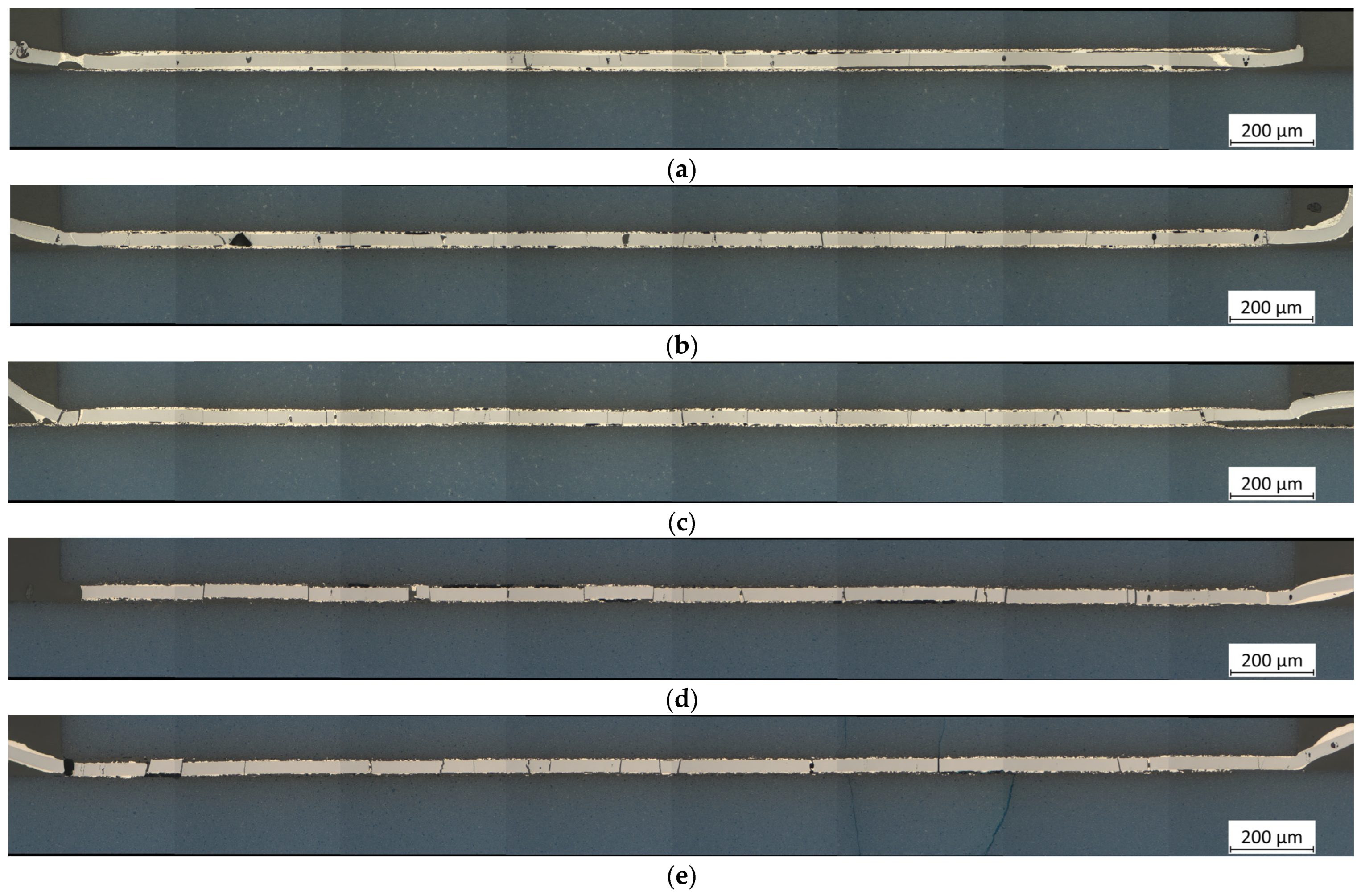

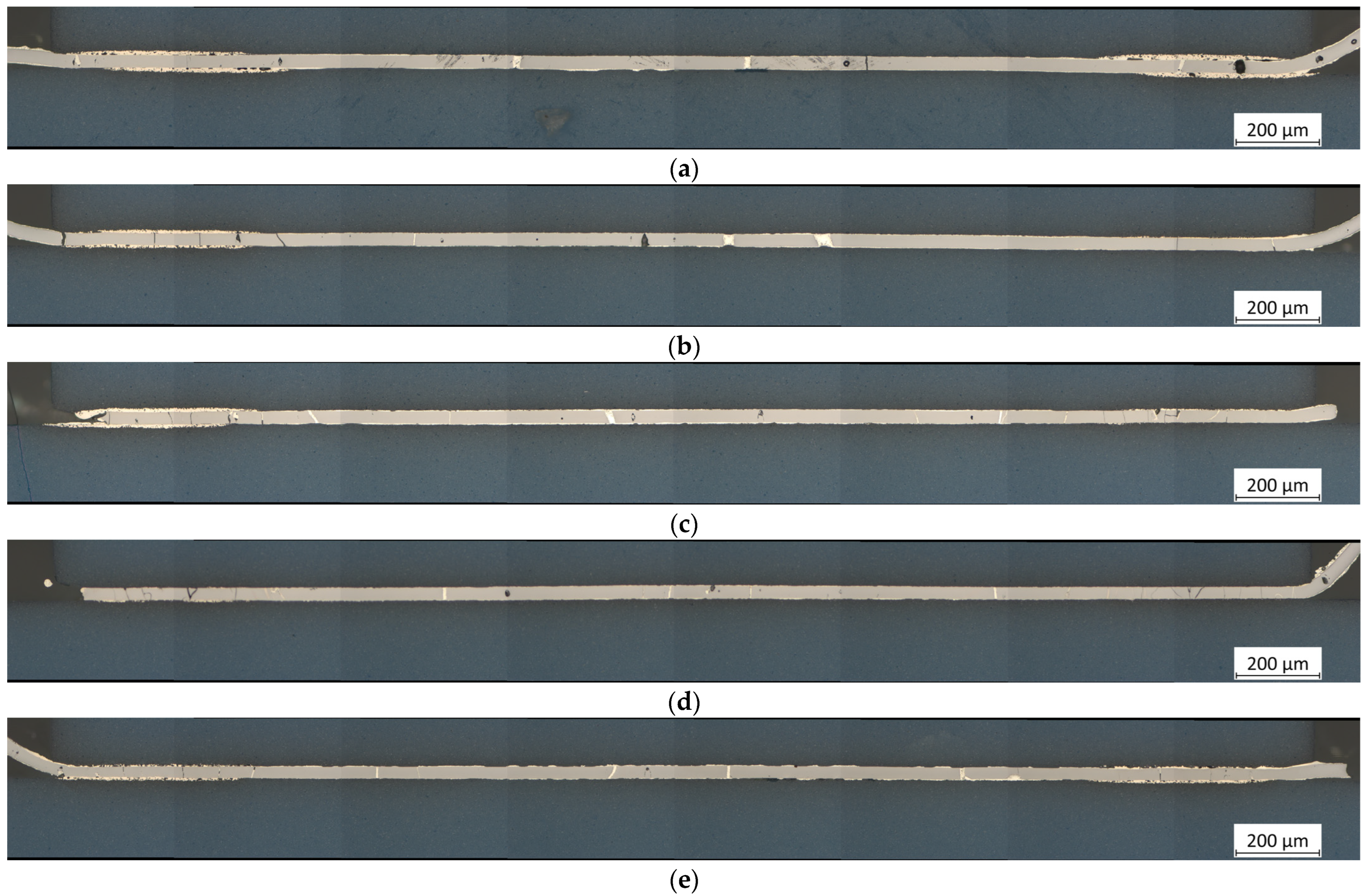

3.1. Light Microscopy

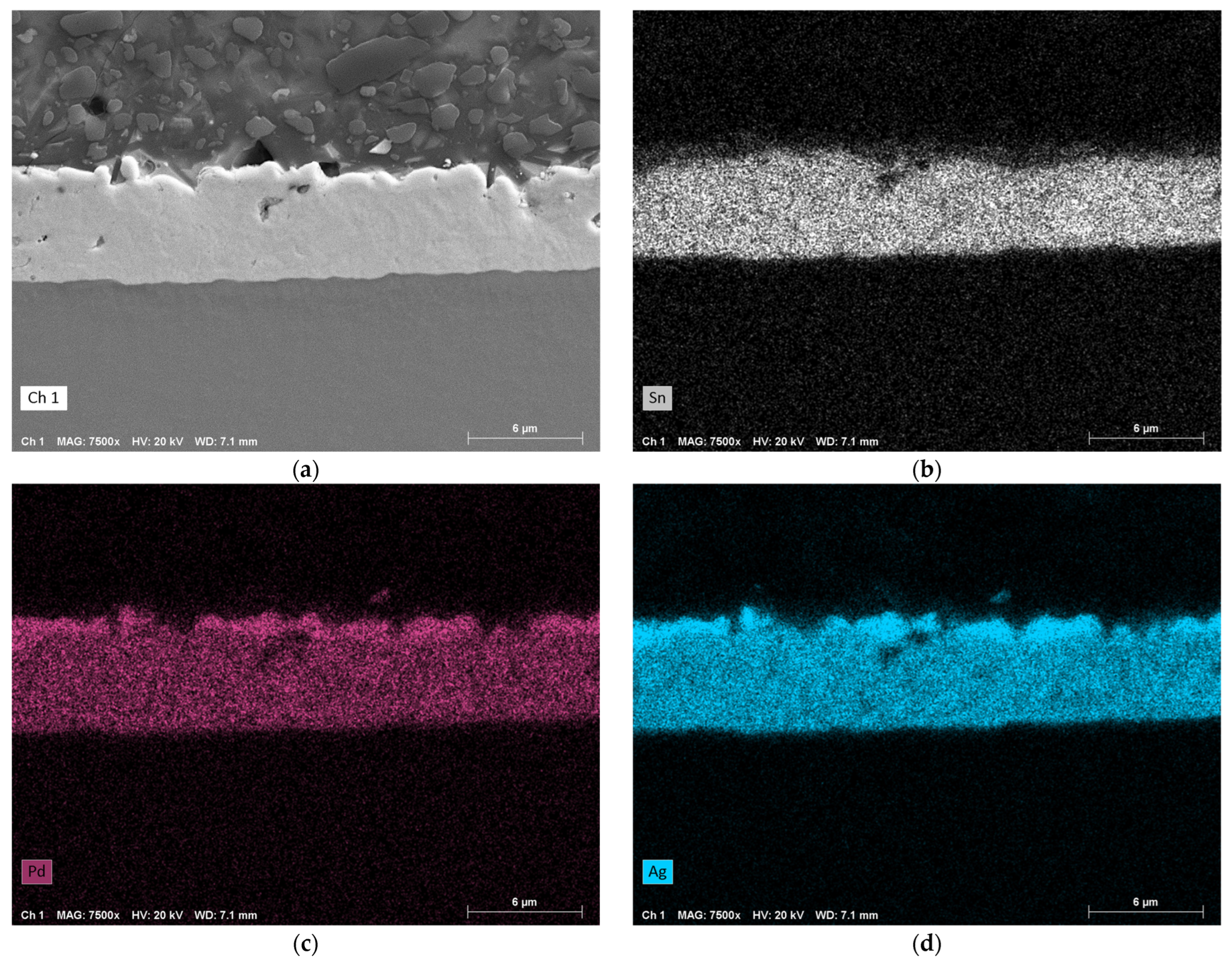

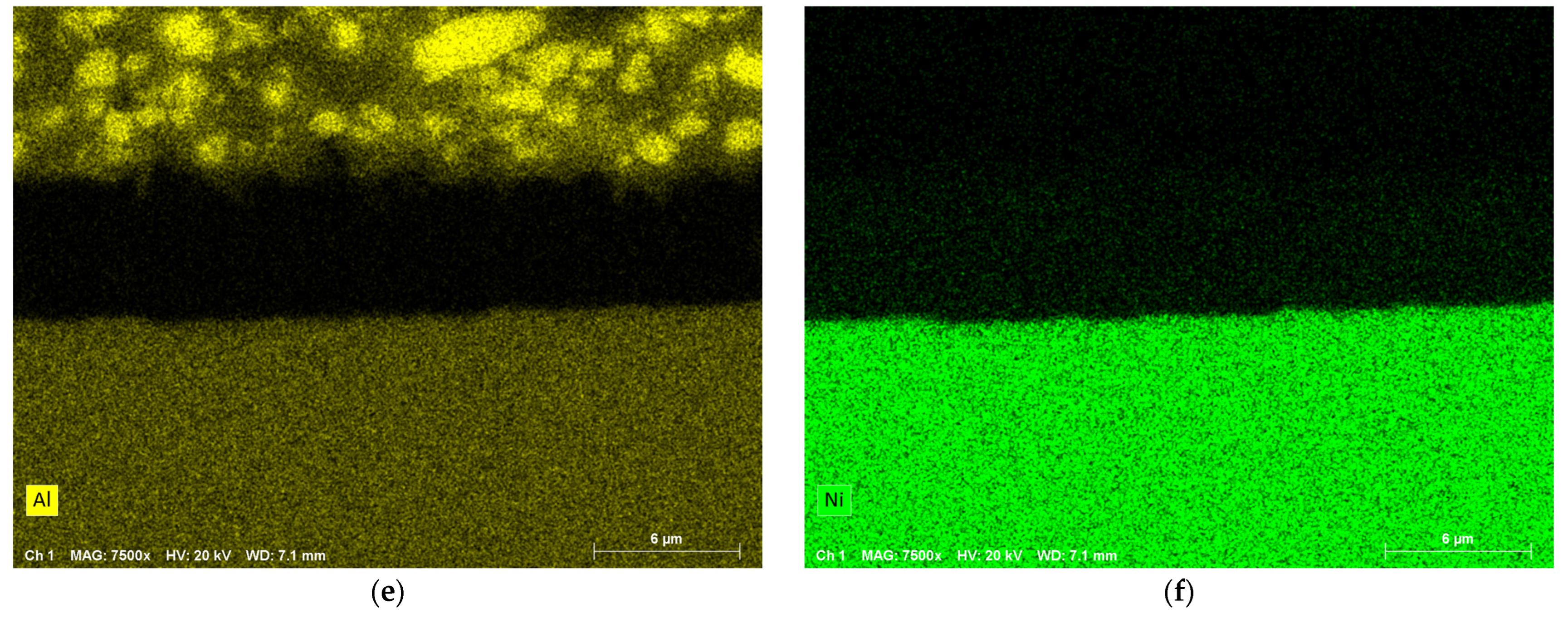

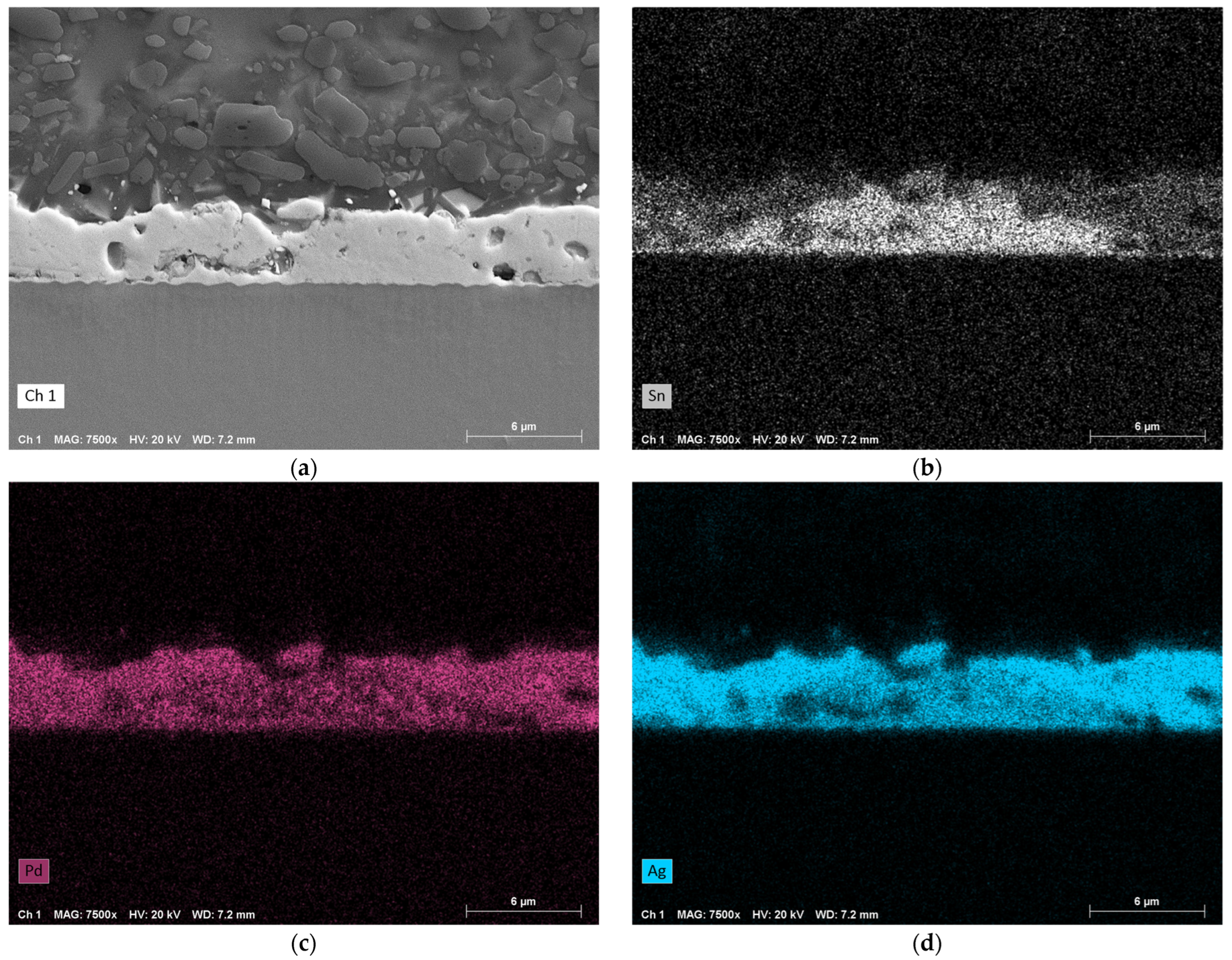

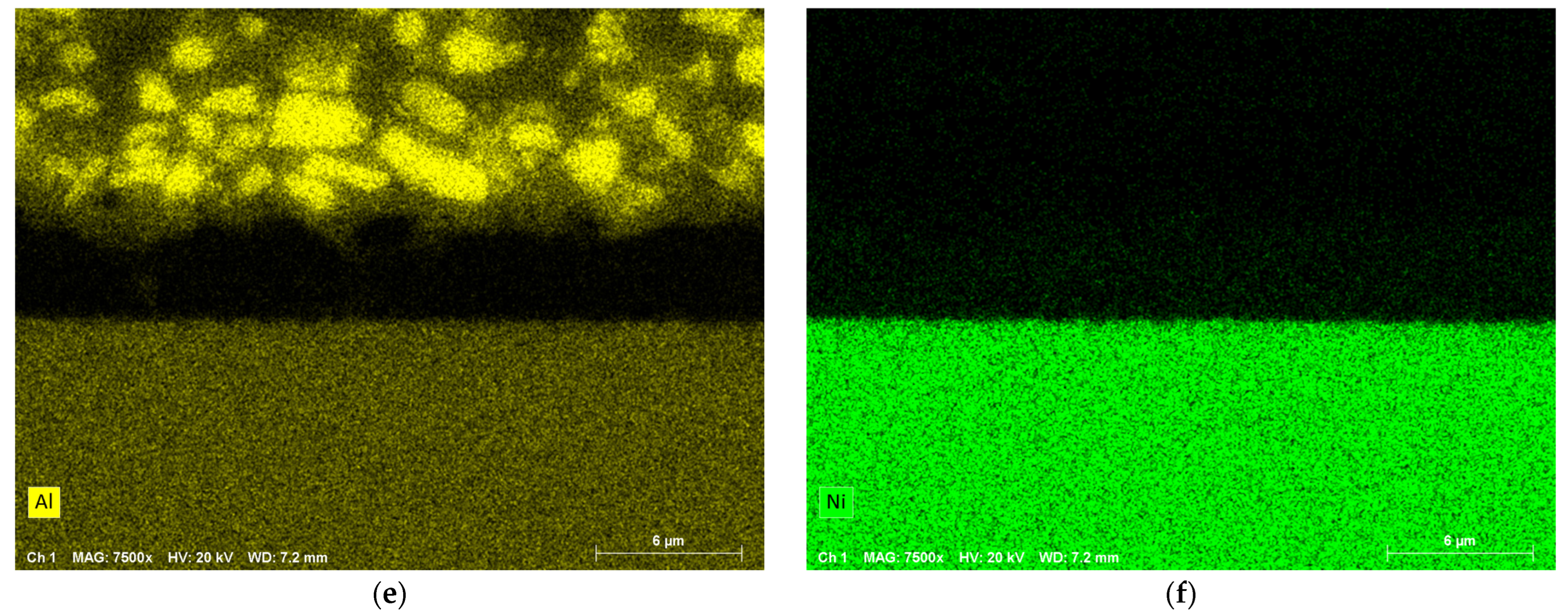

3.2. EDX Analysis

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, J.; Wu, F.S.; Zou, J.; An, B.; Liu, H. Al/Ni Multilayer Used as a Local Heat Source for Mounting Microelectronic Components. In Proceedings of the 2009 International Conference on Electronic Packaging Technology & High Density Packaging (IEEE), Beijing, China, 10–13 August 2009. [Google Scholar]

- Levin, J.P.; Rude, T.R.; Subramanian, J.; Besnoin, E.; Weihs, T.P.; Knio, O.M.; Van Heerden, D. Room Temperature Lead-Free Soldering of Microelectronic Components using a Local Heat Source. In Proceedings of the ASM Materials Solutions Conference & Exposition, Columbus, OH, USA, 18–21 October 2004. [Google Scholar]

- Boettge, B.; Braeuer, J.; Wiemer, M.; Petzold, M.; Bagdahn, J.; Gessner, T. Fabrication and characterization of reactive multilayer systems for low-temperature bonding in microsystem technology. J. Micromech. Microeng. 2010, 20, 064018. [Google Scholar] [CrossRef]

- Sen, S.; Lake, M.; Kroppen, N.; Farber, P.; Wilden, J.; Schaaf, P. Self-propagating exothermic reaction analysis in Ti/Al reactive films using experiments and computational fluid dynamics simulation. Appl. Surf. Sci. 2017, 396, 1490–1498. [Google Scholar] [CrossRef]

- Adams, D.P. Reactive multilayers fabricated by vapor deposition: A critical review. Thin Solid Film. 2015, 576, 98–128. [Google Scholar] [CrossRef]

- Gavens, A.J.; Van Heerden, D.; Mann, A.B.; Reiss, E.; Weihs, T.P. Effect of intermixing on self-propagating exothermic reactions in Al/Ni nanolaminate foils. J. Appl. Phys. 2000, 87, 1255–1263. [Google Scholar] [CrossRef]

- Grigoryan, A.E.; Elistratov, N.G.; Kovalev, D.Y.; Merzhanov, A.G.; Nosyrev, A.N.; Ponomarev, V.I.; Rogachev, A.S.; Khvesyuk, V.I.; Tsygankov, P.A. Autowave Propagation of Exothermic Reactions in Ti-Al Thin Multilayer Films. Dokl. Phys. Chem. 2001, 381, 283–287. [Google Scholar] [CrossRef]

- Reiss, M.E.; Esber, C.M.; Van Heerden, D.; Gavens, A.J.; Williams, M.E.; Weihs, T.P. Self-propagating formation reactions in Nb/Si multilayers. Mater. Sci. Eng. A 1999, 261, 217–222. [Google Scholar] [CrossRef]

- Tanaka, S.; Kondo, K.; Habu, H.; Itoh, A.; Watanabe, M.; Hori, K.; Esashi, M. B/Ti multilayer reactive igniter for micro solid rocket array thruster. In Proceedings of the 2017 IEEE 20th International Conference on Micro Electro Mechanical Systems (MEMS), Hyogo, Japan, 21–25 January 2007. [Google Scholar]

- Rzyman, K.; Moser, Z. Enthalpies of Formation of AlNi: Experiment Versus Theory. J. Phase Equilibria 1998, 19, 106–111. [Google Scholar] [CrossRef]

- Qiu, X.; Wang, J. Bonding silicon wafers with reactive multilayer foils. Sens. Actuators A Phys. 2008, 141, 476–481. [Google Scholar] [CrossRef]

- Qiu, X.; Wang, J. Reactive Multilayer Foils for Silicon Wafer Bonding. Mater. Res. Soc. Symp. Proc. 2006, 968, 206. [Google Scholar] [CrossRef]

- Simões, S.; Ramos, A.S.; Viana, F.; Vieria, M.T.; Vieria, M.F. Joining of TiAl to Steel by Diffusion Bonding with Ni/Ti Reactive Multilayers. Metals 2016, 6, 96. [Google Scholar] [CrossRef]

- Jantunen, H.; Kangasvieri, T.; Vähäkangas, J.; Leppävuori, S. Design aspects of microwave components with LTCC technique. J. Eur. Ceram. 2003, 23, 2541–2548. [Google Scholar] [CrossRef]

- Matters-Kammerer, M.; Mackens, U.; Reimann, K.; Pietig, R.; Hennings, D.; Schreinemacher, B.; Mauczok, R.; Gruhlke, S.; Martiny, C. Material properties and RF applications of high k and ferrite LTCC ceramics. Microelectron. Reliab. 2006, 46, 134–143. [Google Scholar] [CrossRef]

- Schulz, A.; Bartsch, H.; Gutzeit, N.; Matthes, S.; Glaser, M.; Ruh, A.; Müller, J.; Schaaf, P.; Bergmann, J.P.; Wiese, S. Characterization of Reactive Multilayer Systems deposited on LTCC featuring different surface morphologies. In Proceedings of the MikroSystemTechnik Congress 2021, Ludwigsburg, Germany, 8–10 November 2021. [Google Scholar]

- Schulz, A.; Ruh, A.; Wiese, S.; Müller, J. Characterization of Reactive Multilayer Systems deposited on LTCC screen printing pastes featuring different surface morphologies suitable for reactive joining applications. In Proceedings of the Ceramic Interconnect and Ceramic Microsystems Technologies (CICMT) 2022, Wien, Austria, 13–15 July 2022. [Google Scholar]

- Wiss, E.; Schulz, A.; Ruh, A.; Jaekel, K.; Müller, J.; Wiese, S. Morphologies of Reactive Nanolayer Stacks Sputtered on Ceramic Low-Temperature Cofired Ceramic Substrates Having a Micrometer-Scale Surface Roughness. Adv. Eng. Mater. 2024, 27, 2302284. [Google Scholar] [CrossRef]

- Yuile, A.; Schulz, A.; Wiss, E.; Müller, J.; Wiese, S. The Simulated Effect of Adding Solder Layers on Reactive Multilayer Films Used for Joining Processes. Appl. Sci. 2022, 12, 2397. [Google Scholar] [CrossRef]

- Wang, J.; Besnoin, E.; Knio, O.M.; Weihs, T.P. Investigating the effect of applied pressure on reactive multilayer foil joining. Acta Mater. 2004, 52, 5265–5274. [Google Scholar] [CrossRef]

- Kanetsuki, S.; Miyake, S.; Kuwahara, K.; Namazu, T. Influence of bonding pressure on thermal resistance in reactively-bonded solder joints. Jpn. J. Appl. Phys. 2016, 55, 06GP17. [Google Scholar] [CrossRef]

- Schumacher, A.; Gaiß, U.; Knappmann, S.; Braun, S.; Pflug, E.; Roscher, F.; Vogel, K.; Hertel, S.; Kähler, D.; Reinert, W. Assembly and Packaging of Micro Systems by Using Reactive Bonding Processes. In Proceedings of the 2015 European Microelectronics Packaging Conference (EMPC), Friedrichshafen, Germany, 14–16 September 2015. [Google Scholar]

- Wiss, E.; Jaziri, N.; Yuile, A.; Müller, J.; Wiese, S. Experimental Study on Reactive Joining Processes on LTCC Substrates. In Proceedings of the 2024 IEEE 10th Electronics System-Integration Technology Conference (ESTC), Berlin, Germany, 11–13 September 2024. [Google Scholar]

- Namazu, T.; Ohtani, K.; Yoshiki, K.; Inoue, S. Crack propagation direction control for crack-less solder bonding using Al/Ni flash heating technique. In Proceedings of the 2011 16th International Solid-State Sensors, Actuators and Microsystems Conference (IEEE), Beijing, China, 5–9 June 2011. [Google Scholar]

| Configuration | Base Material | Substrate Size [mm2] | Chip Size [mm2] | Type of Metallization | Effective Bonding Area [mm2] |

|---|---|---|---|---|---|

| L1–L5 | LTCC | 15 × 3 | 3 × 3 | Pd/Ag | 3 × 3 |

| L6–L10 | LTCC | 15 × 3 | 3 × 3 | Pd/Ag | 4 × 0.5 × 0.5 |

| Configuration | Preheat Temperature [°C] | Peak Temperature [°C] | Force [N] | Metallization Area [mm2] | Bonding Pressure [MPa] |

|---|---|---|---|---|---|

| L1 | 80 | 200 | 20 | 3 × 3 | 2 |

| L2 | 80 | 200 | 100 | 3 × 3 | 11 |

| L3 | 80 | 200 | 200 | 3 × 3 | 22 |

| L4 | 80 | 200 | 300 | 3 × 3 | 33 |

| L5 | 80 | 200 | 400 | 3 × 3 | 44 |

| L6 | 80 | 200 | 20 | 4 × 0.5 × 0.5 | 20 |

| L7 | 80 | 200 | 100 | 4 × 0.5 × 0.5 | 100 |

| L8 | 80 | 200 | 200 | 4 × 0.5 × 0.5 | 200 |

| L9 | 80 | 200 | 300 | 4 × 0.5 × 0.5 | 300 |

| L10 | 80 | 200 | 400 | 4 × 0.5 × 0.5 | 400 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wiss, E.; Jaziri, N.; Müller, J.; Wiese, S. Impact of Bonding Pressure on the Reactive Bonding of LTCC Substrates. Micromachines 2025, 16, 321. https://doi.org/10.3390/mi16030321

Wiss E, Jaziri N, Müller J, Wiese S. Impact of Bonding Pressure on the Reactive Bonding of LTCC Substrates. Micromachines. 2025; 16(3):321. https://doi.org/10.3390/mi16030321

Chicago/Turabian StyleWiss, Erik, Nesrine Jaziri, Jens Müller, and Steffen Wiese. 2025. "Impact of Bonding Pressure on the Reactive Bonding of LTCC Substrates" Micromachines 16, no. 3: 321. https://doi.org/10.3390/mi16030321

APA StyleWiss, E., Jaziri, N., Müller, J., & Wiese, S. (2025). Impact of Bonding Pressure on the Reactive Bonding of LTCC Substrates. Micromachines, 16(3), 321. https://doi.org/10.3390/mi16030321