Improving the High-Temperature Gate Bias Instabilities by a Low Thermal Budget Gate-First Process in p-GaN Gate HEMTs

Abstract

1. Introduction

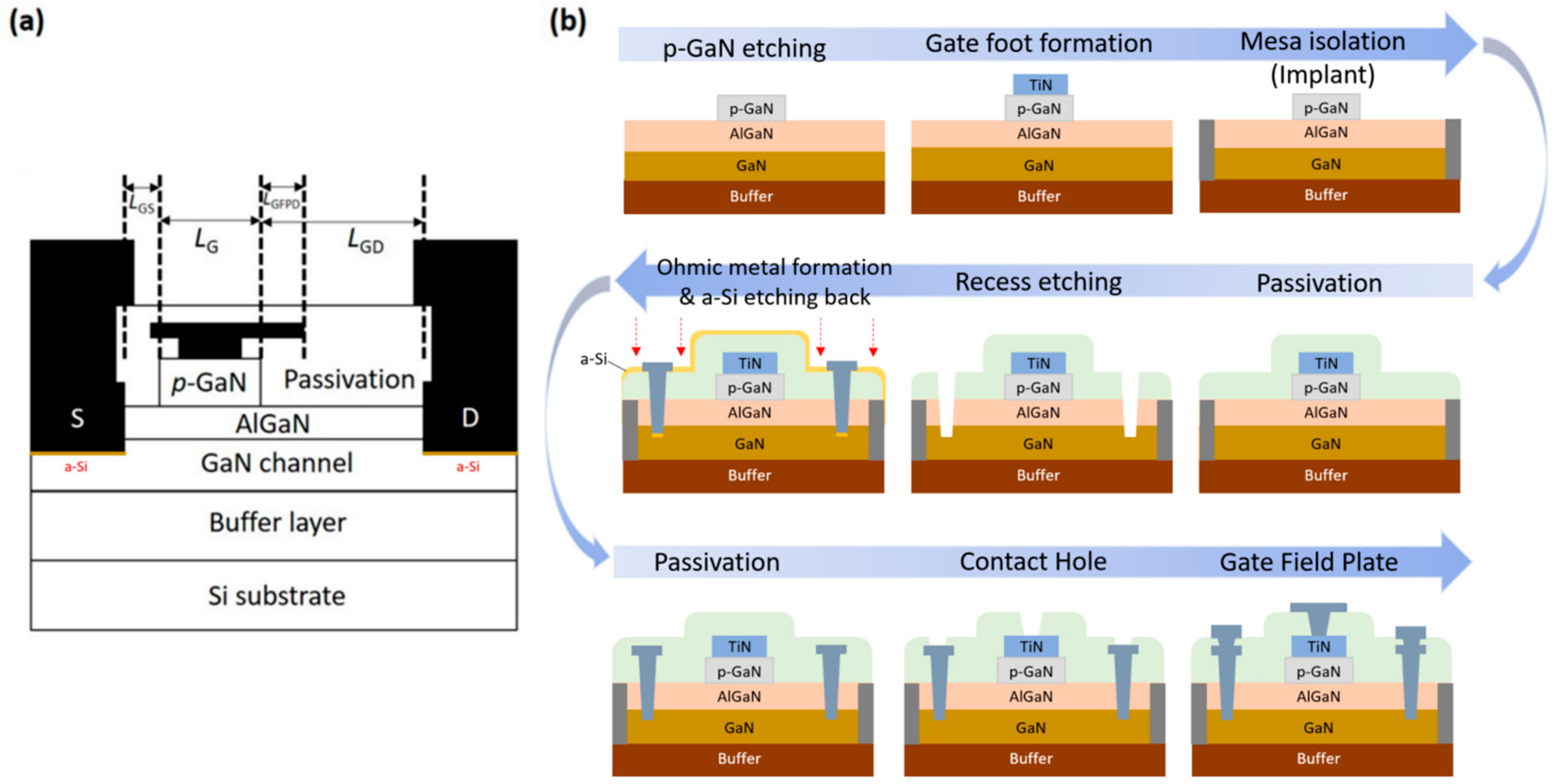

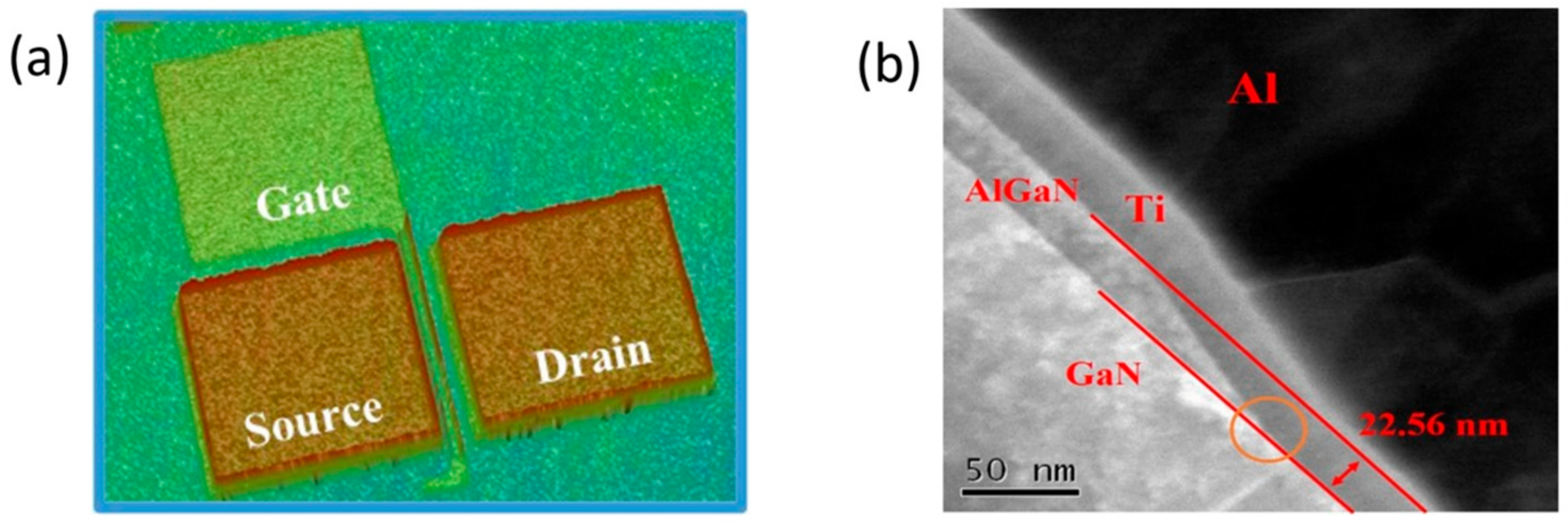

2. Device Structure and Fabrication

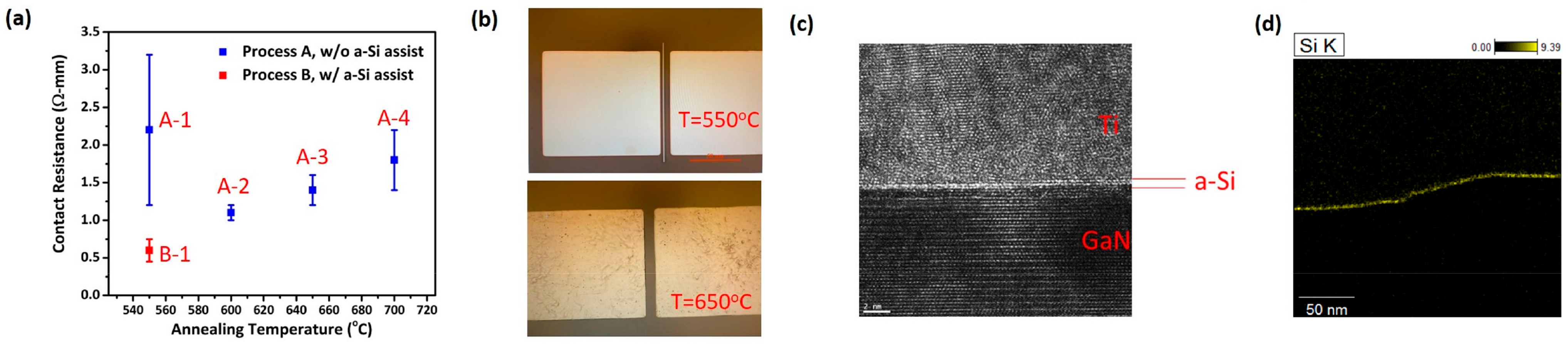

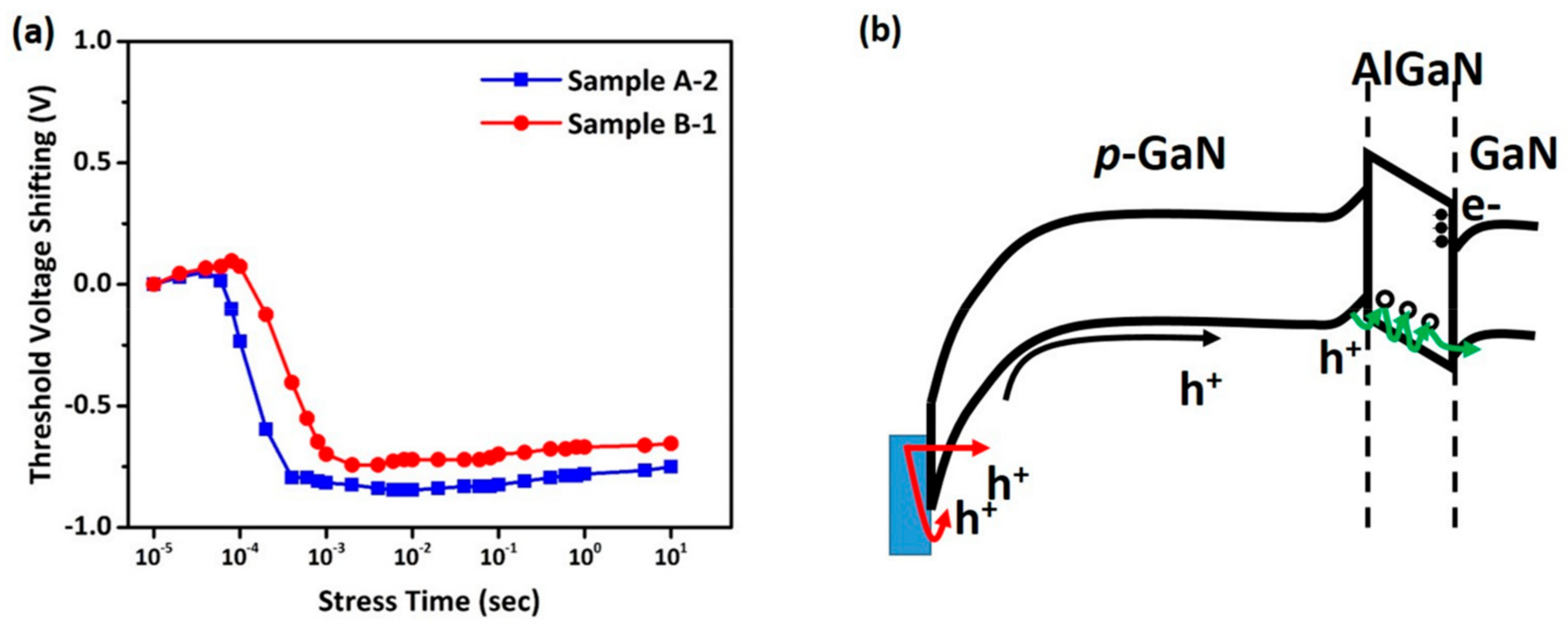

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Dora, Y.; Chakraborty, A.; Mccarthy, L.; Keller, S.; DenBaars, S.; Mishra, U.K. High breakdown voltage achieved on AlGaN/GaN HEMTs with integrated slant field plates. IEEE Electron Device Lett. 2006, 27, 713–715. [Google Scholar] [CrossRef]

- Uemoto, Y.; Hikita, M.; Ueno, H.; Matsuo, H.; Ishida, H.; Yanagihara, M.; Ueda, T.; Tanaka, T.; Ueda, D. Gate injection transistor (GIT)—A normally-off AlGaN/GaN power transistor using conductivity modulation. IEEE Trans. Electron Devices 2007, 54, 3393–3399. [Google Scholar] [CrossRef]

- Kuzuhara, M.; Tokuda, H. Low-loss and high-voltage III-nitride transistors for power switching applications. IEEE Trans. Electron Devices 2014, 62, 405–413. [Google Scholar] [CrossRef]

- He, J.; Tang, G.; Chen, K.J. VTH Instability of p-GaN Gate HEMTs Under Static and Dynamic Gate Stress. IEEE Electron Device Lett. 2018, 39, 1576–1579. [Google Scholar] [CrossRef]

- Lee, F.; Su, L.-Y.; Wang, C.-H.; Wu, Y.-R.; Huang, J. Impact of gate metal on the performance of p-GaN/AlGaN/GaN high electron mobility transistors. IEEE Electron Device Lett. 2015, 36, 232–234. [Google Scholar] [CrossRef]

- Jiang, H.; Lyu, Q.; Zhu, R.; Xiang, P.; Cheng, K.; Lau, K.M. 1300 V normally-OFF p-GaN gate HEMTs on Si with high ON-state drain current. IEEE Trans. Electron Devices 2020, 68, 653–657. [Google Scholar] [CrossRef]

- Tang, X.; Li, B.; Moghadam, H.A.; Tanner, P.; Han, J.; Dimitrijev, S. Mechanism of Threshold Voltage Shift in p-GaN Gate AlGaN/GaN Transistors. IEEE Electron Device Lett. 2018, 39, 1145–1148. [Google Scholar] [CrossRef]

- Sayadi, L.; Iannaccone, G.; Sicre, S.; Häberlen, O.; Curatola, G. Threshold voltage instability in p-GaN gate AlGaN/GaN HFETs. IEEE Trans. Electron Devices 2018, 65, 2454–2460. [Google Scholar] [CrossRef]

- Shi, Y.; Zhou, Q.; Cheng, Q.; Wei, P.; Zhu, L.; Wei, D.; Zhang, A.; Chen, W.; Zhang, B. Carrier Transport Mechanisms Underlying the Bidirectional VTH Shift in p-GaN Gate HEMTs Under Forward Gate Stress. IEEE Trans. Electron Devices 2018, 66, 876–882. [Google Scholar] [CrossRef]

- Del Alamo, J.A.; Lee, E.S. Stability and reliability of lateral GaN power field-effect transistors. IEEE Trans. Electron Devices 2019, 66, 4578–4590. [Google Scholar] [CrossRef]

- Wang, H.; Wei, J.; Xie, R.; Liu, C.; Tang, G.; Chen, K.J. Maximizing the performance of 650-V p-GaN gate HEMTs: Dynamic RON characterization and circuit design considerations. IEEE Trans. Power Electron. 2016, 32, 5539–5549. [Google Scholar] [CrossRef]

- Tajalli, A.; Canato, E.; Nardo, A.; Meneghini, M.; Stockman, A.; Moens, P.; Zanoni, E.; Meneghesso, G. Impact of sidewall etching on the dynamic performance of GaN-on-Si E-mode transistors. Microelectron. Reliab. 2018, 88, 572–576. [Google Scholar] [CrossRef]

- Wang, R.; Lei, J.-M.; Guo, H.; Li, R.; Chen, D.-J.; Lu, H.; Zhang, R.; Zheng, Y.-D. VT Shift and Recovery Mechanisms of p-GaN Gate HEMTs Under DC/AC Gate Stress Investigated by Fast Sweeping Characterization. IEEE Electron Device Lett. 2021, 42, 1508–1511. [Google Scholar] [CrossRef]

- Stockman, A.; Canato, E.; Meneghini, M.; Meneghesso, G.; Moens, P.; Bakeroot, B.; Reliability, M. Schottky gate induced threshold voltage instabilities in p-GaN gate AlGaN/GaN HEMTs. IEEE Trans. Device Mater. Reliab. 2021, 21, 169–175. [Google Scholar] [CrossRef]

- Tallarico, A.N.; Stoffels, S.; Posthuma, N.; Magnone, P.; Marcon, D.; Decoutere, S.; Sangiorgi, E.; Fiegna, C. PBTI in GaN-HEMTs with p-Type Gate: Role of the Aluminum Content on ΔVTH and Underlying Degradation Mechanisms. IEEE Trans. Electron Devices 2017, 65, 38–44. [Google Scholar] [CrossRef]

- Ruzzarin, M.; Meneghini, M.; Barbato, A.; Padovan, V.; Haeberlen, O.; Silvestri, M.; Detzel, T.; Meneghesso, G.; Zanoni, E. Degradation mechanisms of GaN HEMTs with p-type gate under forward gate bias overstress. IEEE Trans. Electron Devices 2018, 65, 2778–2783. [Google Scholar] [CrossRef]

- Tallarico, A.N.; Stoffels, S.; Posthuma, N.; Decoutere, S.; Sangiorgi, E.; Fiegna, C. Threshold voltage instability in GaN HEMTs with p-type gate: Mg doping compensation. IEEE Electron Device Lett. 2019, 40, 518–521. [Google Scholar] [CrossRef]

- Li, S.; He, Z.; Gao, R.; Chen, Y.; Chen, Y.; Liu, C.; Huang, Y.; Li, G. Time-dependent threshold voltage instability mechanisms of p-GaN gate AlGaN/GaN HEMTs under high reverse bias conditions. IEEE Trans. Electron Devices 2020, 68, 443–446. [Google Scholar] [CrossRef]

- Wu, H.; Fu, X.; Guo, J.; Wang, Y.; Liu, T.; Hu, S. Time-Resolved Threshold Voltage Instability of 650-V Schottky Type p-GaN Gate HEMT Under Temperature-Dependent Forward and Reverse Gate Bias Conditions. IEEE Trans. Electron Devices 2022, 69, 531–535. [Google Scholar] [CrossRef]

- Savadi, L.; Iannaccone, G.; Sicre, S.; Lavanza, S.; Fiori, G.; Haberlen, O.; Curatola, G. Charge injection in normally-off p-GaN gate AlGaN/GaN-on-Si HFETs. In Proceedings of the 2018 48th European Solid-State Device Research Conference (ESSDERC), Dresden, Germany, 3–6 September 2018; pp. 18–21. [Google Scholar]

- Chihani, O.; Theolier, L.; Deletage, J.-Y.; Woirgard, E.; Bensoussan, A.; Durier, A. Temperature and voltage effects on HTRB and HTGB stresses for AlGaN/GaN HEMTs. In Proceedings of the 2018 IEEE International Reliability Physics Symposium (IRPS), Burlingame, CA, USA, 11–15 March 2018; pp. P-RT.2-1–P-RT.2-6. [Google Scholar]

- Lu, C.; Davydov, A.; Josell, D.; Bendersky, L.A. Interfacial reactions of Ti/n-GaN contacts at elevated temperature. J. Appl. Phys. 2003, 94, 245–253. [Google Scholar] [CrossRef]

- Lin, Y.-S.; Wu, J.-Y.; Chan, C.-Y.; Hsu, S.S.; Huang, C.-F.; Lee, T.-C. Square-gate AlGaN/GaN HEMTs with improved trap-related characteristics. IEEE Trans. Electron Devices 2009, 56, 3207–3211. [Google Scholar] [CrossRef]

- Bakeroot, B.; Stockman, A.; Posthuma, N.; Stoffels, S.; Decoutere, S. Analytical Model for the Threshold Voltage of p-(Al) GaN High-Electron-Mobility Transistors. IEEE Trans. Electron Devices 2017, 65, 79–86. [Google Scholar] [CrossRef]

- Tang, X.; Li, B.; Zhang, J.; Li, H.; Han, J.; Nguyen, N.-T.; Dimitrijev, S.; Wang, J. Demonstration of Electron/Hole Injections in the Gate of p-GaN/AlGaN/GaN Power Transistors and Their Effect on Device Dynamic Performance. In Proceedings of the 2019 31st International Symposium on Power Semiconductor Devices and ICs (ISPSD), Shanghai, China, 19–23 May 2019; pp. 415–418. [Google Scholar]

- Narita, T.; Yoshida, H.; Tomita, K.; Kataoka, K.; Sakurai, H.; Horita, M.; Bockowski, M.; Ikarashi, N.; Suda, J.; Kachi, T.; et al. Progress on and challenges of p-type formation for GaN power devices. J. Appl. Phys. 2020, 128, 090901. [Google Scholar] [CrossRef]

- Kachi, T.; Narita, T.; Sakurai, H.; Matys, M.; Kataoka, K.; Hirukawa, K.; Sumida, K.; Horita, M.; Ikarashi, N.; Sierakowski, K.; et al. Process engineering of GaN power devices via selective-area p-type doping with ion implantation and ultra-high-pressure annealing. J. Appl. Phys. 2022, 132, 130901. [Google Scholar] [CrossRef]

- Stoffels, S.; Bakeroot, B.; Wu, T.-L.; Marcon, D.; Posthuma, N.; Decoutere, S.; Tallarico, A.; Fiegna, C. Failure mode for p-GaN gates under forward gate stress with varying Mg concentration. In Proceedings of the 2017 IEEE International Reliability Physics Symposium (IRPS), Monterey, CA, USA, 2–6 April 2017; pp. 4B-4.1–4B-4.9. [Google Scholar]

| Sample | S/D Etching Depth (nm) | a-Si Thickness (nm) | S/D Metal Stack Ti/Al/Ti (nm) | Annealing Temperature (°C) |

|---|---|---|---|---|

| A-1 | 16 + 2 | NA | 25/500/5 | 550 |

| A-2 | NA | 25/500/5 | 600 | |

| A-3 | NA | 25/500/5 | 650 | |

| A-4 | NA | 25/500/5 | 700 | |

| B-1 | 1 | 50/500/5 | 550 |

| Sample | 2 Rc | RChannel | RD + RS | Ron |

|---|---|---|---|---|

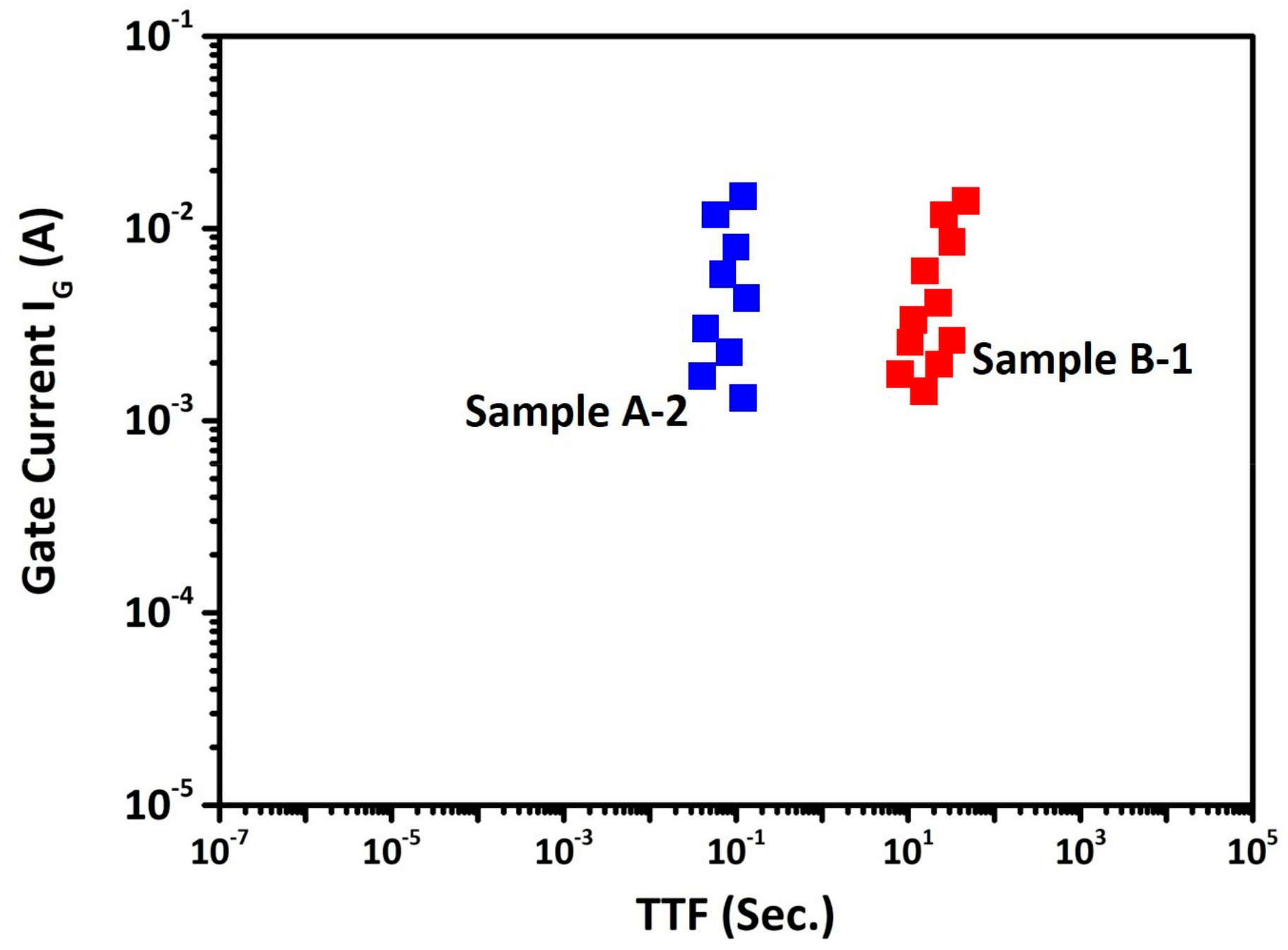

| Sample A-2 | 2.2 | 1.8 | 10.4 | 14.4 |

| Sample B-1 | 1.2 | 1.8 | 10.0 | 13.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Langpoklakpam, C.; Liu, A.-C.; You, N.-J.; Kao, M.-H.; Huang, W.-H.; Shen, C.-H.; Tzou, J.; Kuo, H.-C.; Shieh, J.-M. Improving the High-Temperature Gate Bias Instabilities by a Low Thermal Budget Gate-First Process in p-GaN Gate HEMTs. Micromachines 2023, 14, 576. https://doi.org/10.3390/mi14030576

Langpoklakpam C, Liu A-C, You N-J, Kao M-H, Huang W-H, Shen C-H, Tzou J, Kuo H-C, Shieh J-M. Improving the High-Temperature Gate Bias Instabilities by a Low Thermal Budget Gate-First Process in p-GaN Gate HEMTs. Micromachines. 2023; 14(3):576. https://doi.org/10.3390/mi14030576

Chicago/Turabian StyleLangpoklakpam, Catherine, An-Chen Liu, Neng-Jie You, Ming-Hsuan Kao, Wen-Hsien Huang, Chang-Hong Shen, Jerry Tzou, Hao-Chung Kuo, and Jia-Min Shieh. 2023. "Improving the High-Temperature Gate Bias Instabilities by a Low Thermal Budget Gate-First Process in p-GaN Gate HEMTs" Micromachines 14, no. 3: 576. https://doi.org/10.3390/mi14030576

APA StyleLangpoklakpam, C., Liu, A.-C., You, N.-J., Kao, M.-H., Huang, W.-H., Shen, C.-H., Tzou, J., Kuo, H.-C., & Shieh, J.-M. (2023). Improving the High-Temperature Gate Bias Instabilities by a Low Thermal Budget Gate-First Process in p-GaN Gate HEMTs. Micromachines, 14(3), 576. https://doi.org/10.3390/mi14030576