Screw Analysis, Modeling and Experiment on the Mechanics of Tibia Orthopedic with the Ilizarov External Fixator

Abstract

:1. Introduction

2. Materials and Methods

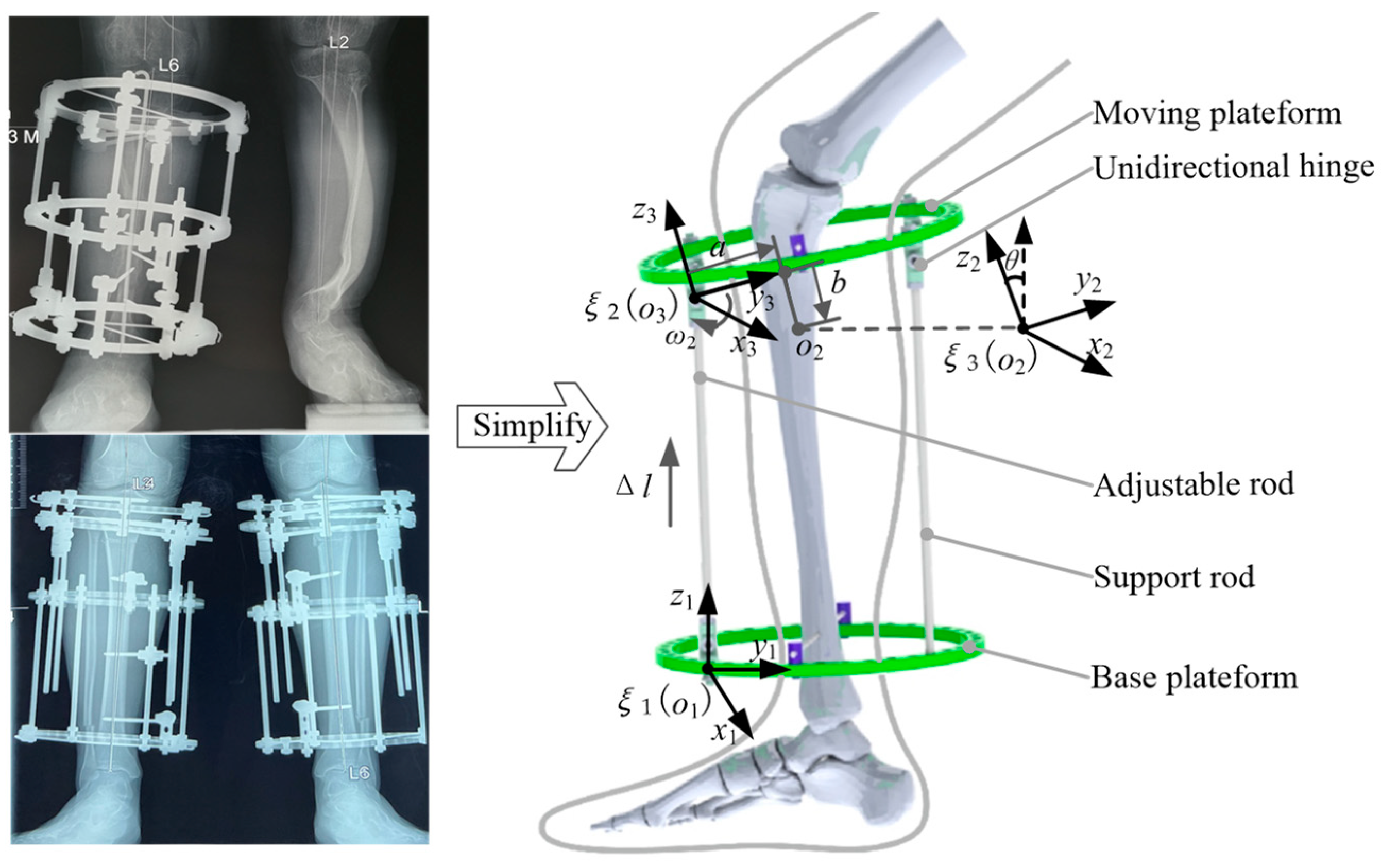

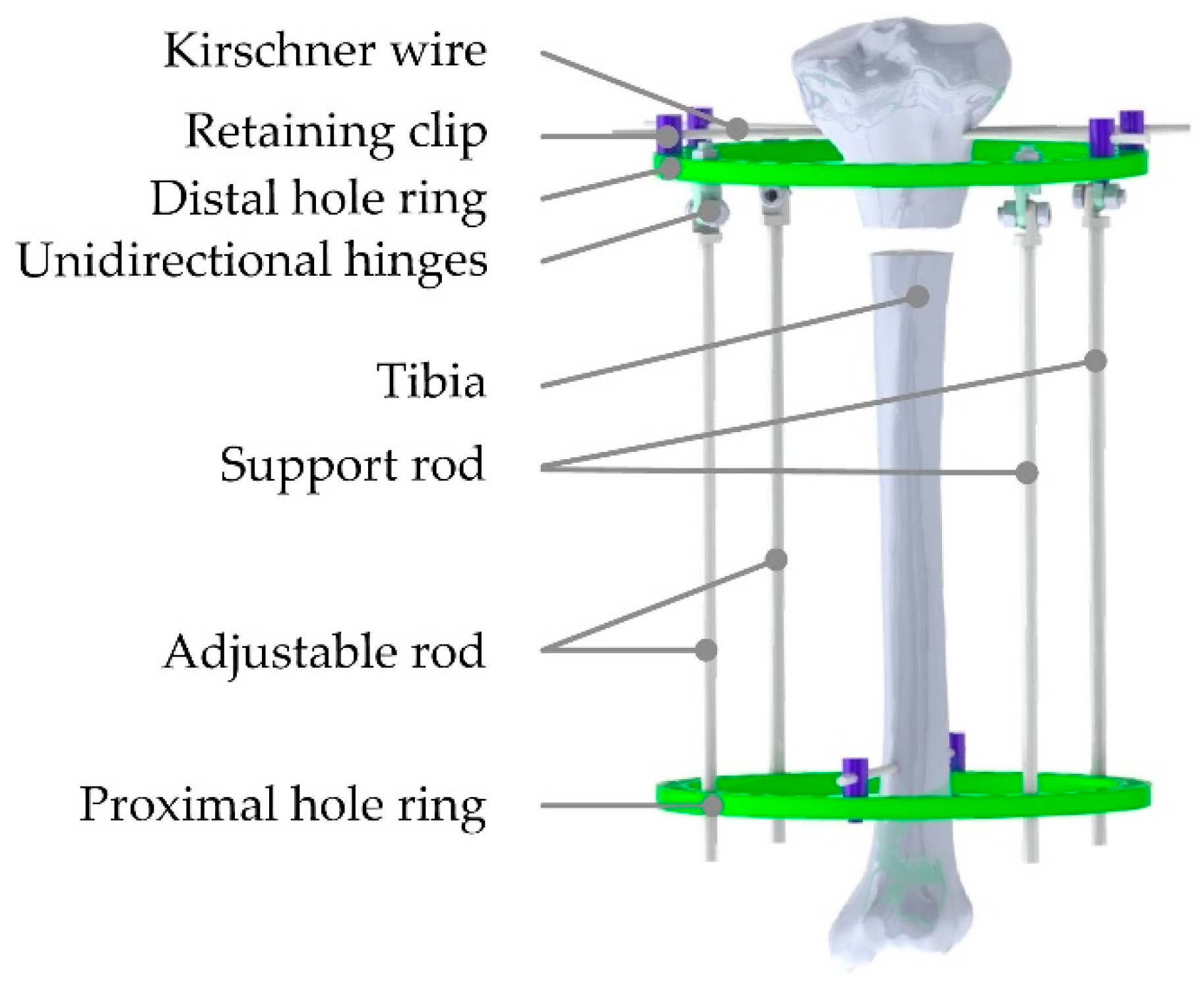

2.1. Screw Model of Ilizarov External Fixator

2.2. Mechanical Model of Ilizarov External Fixator

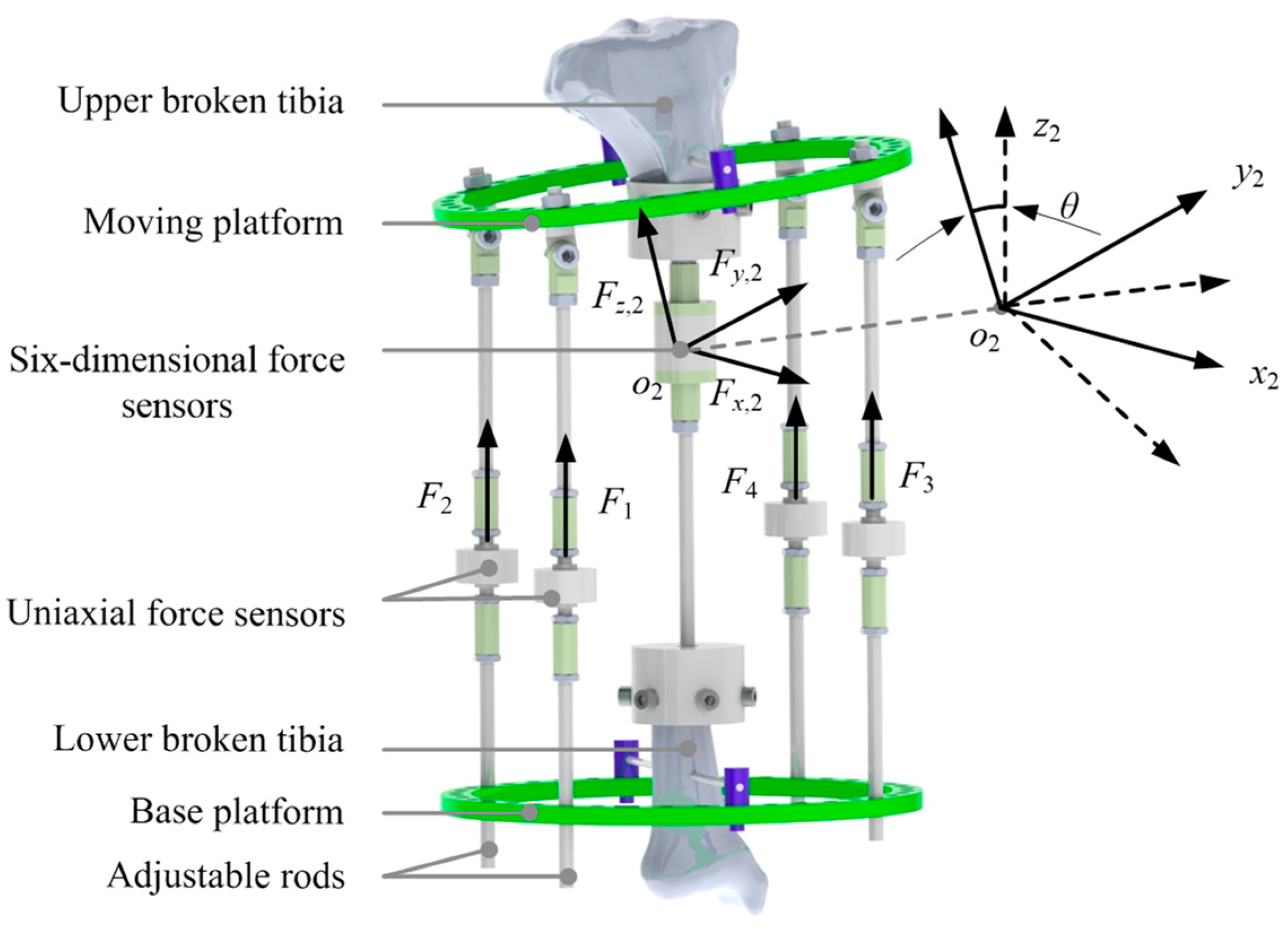

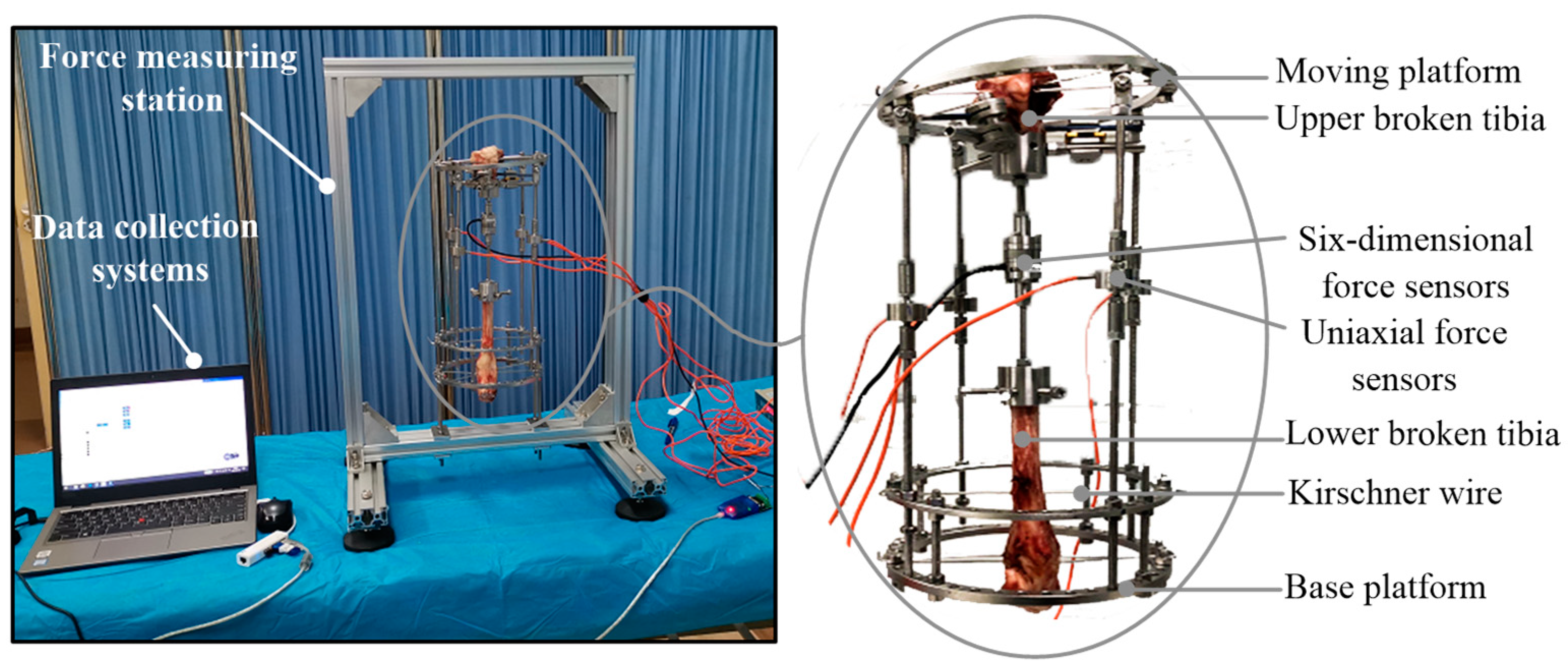

2.3. Measurement of Orthopedic Forces

3. Results

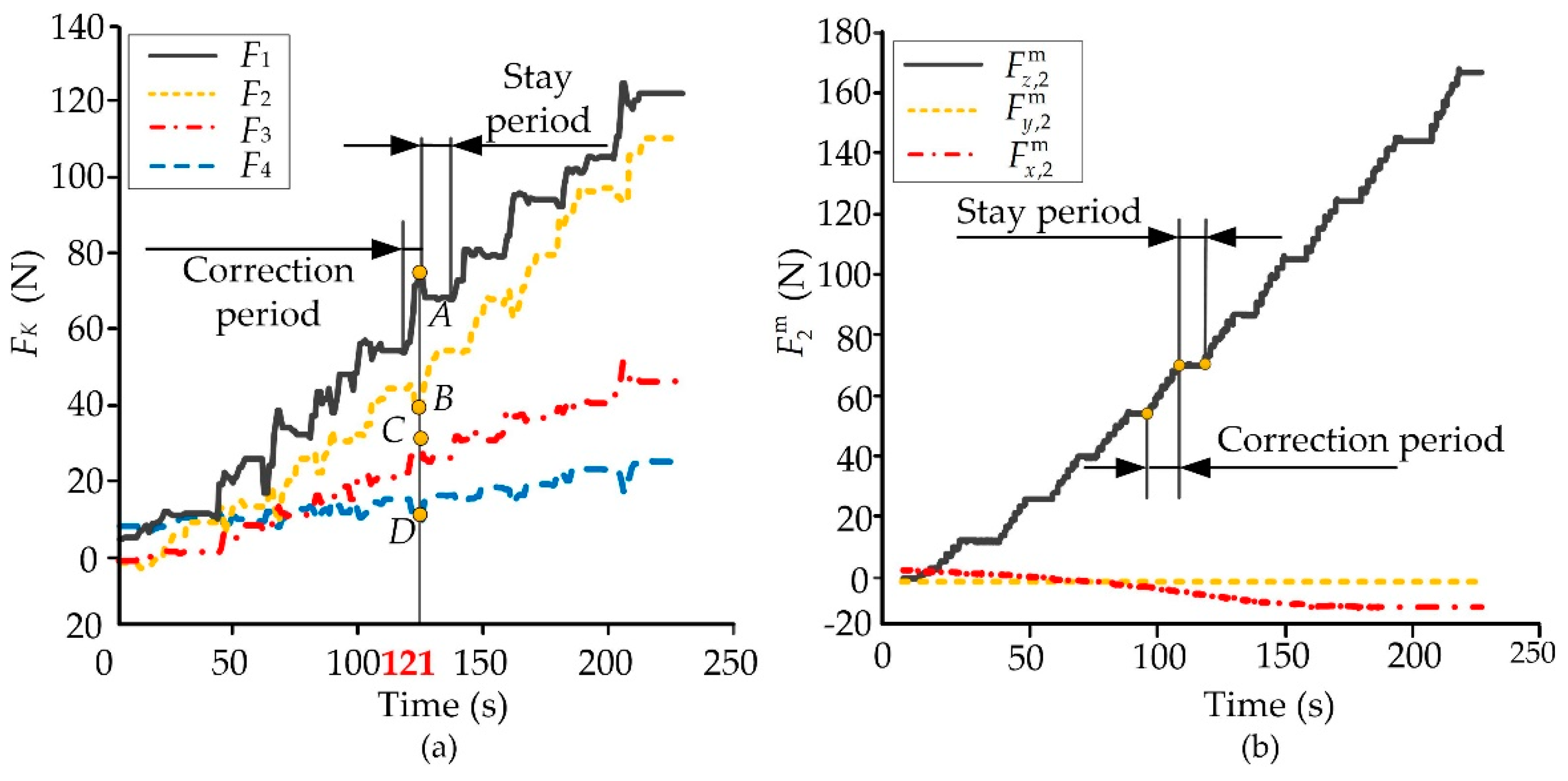

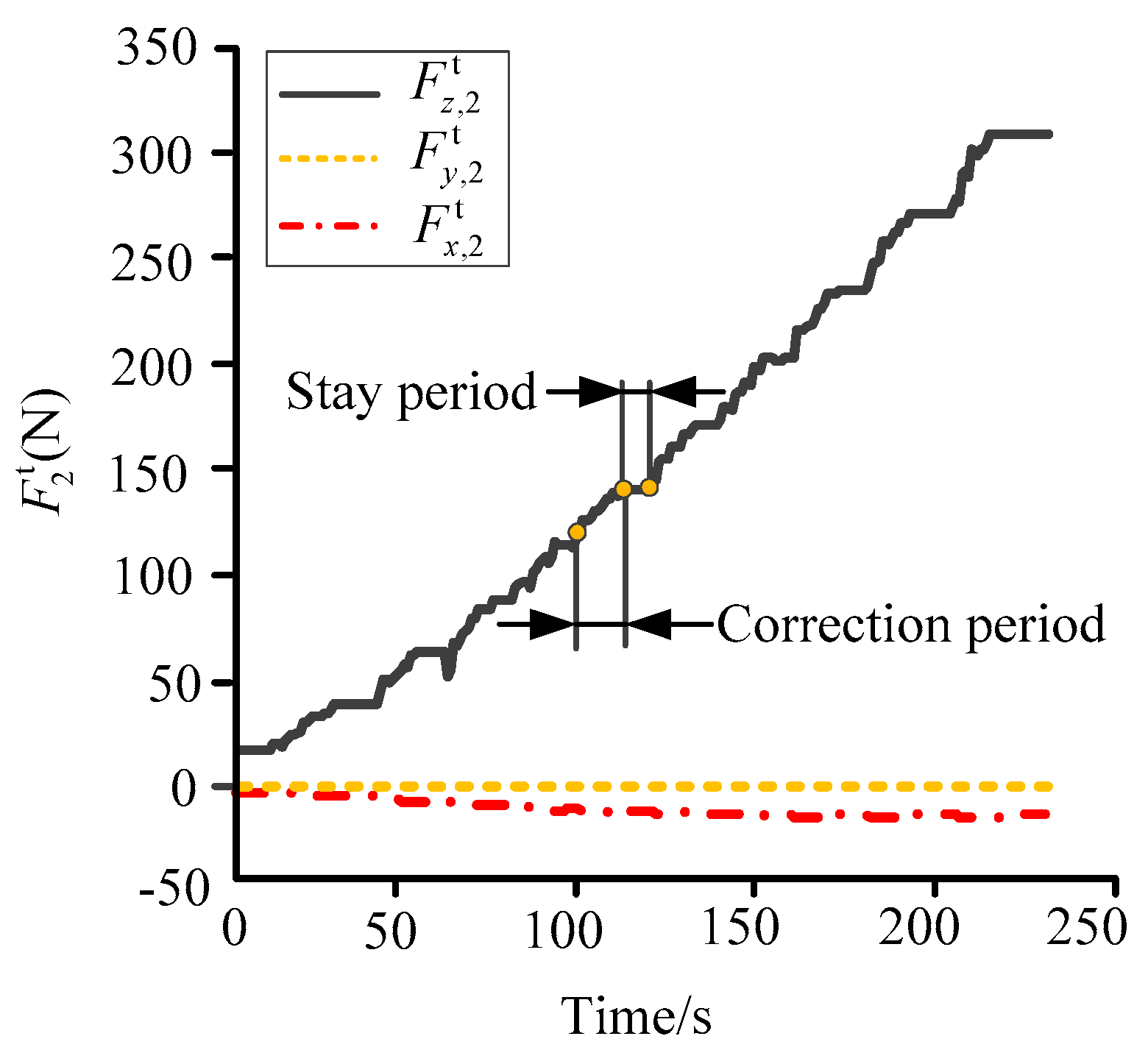

3.1. Orthopedic Force Analysis

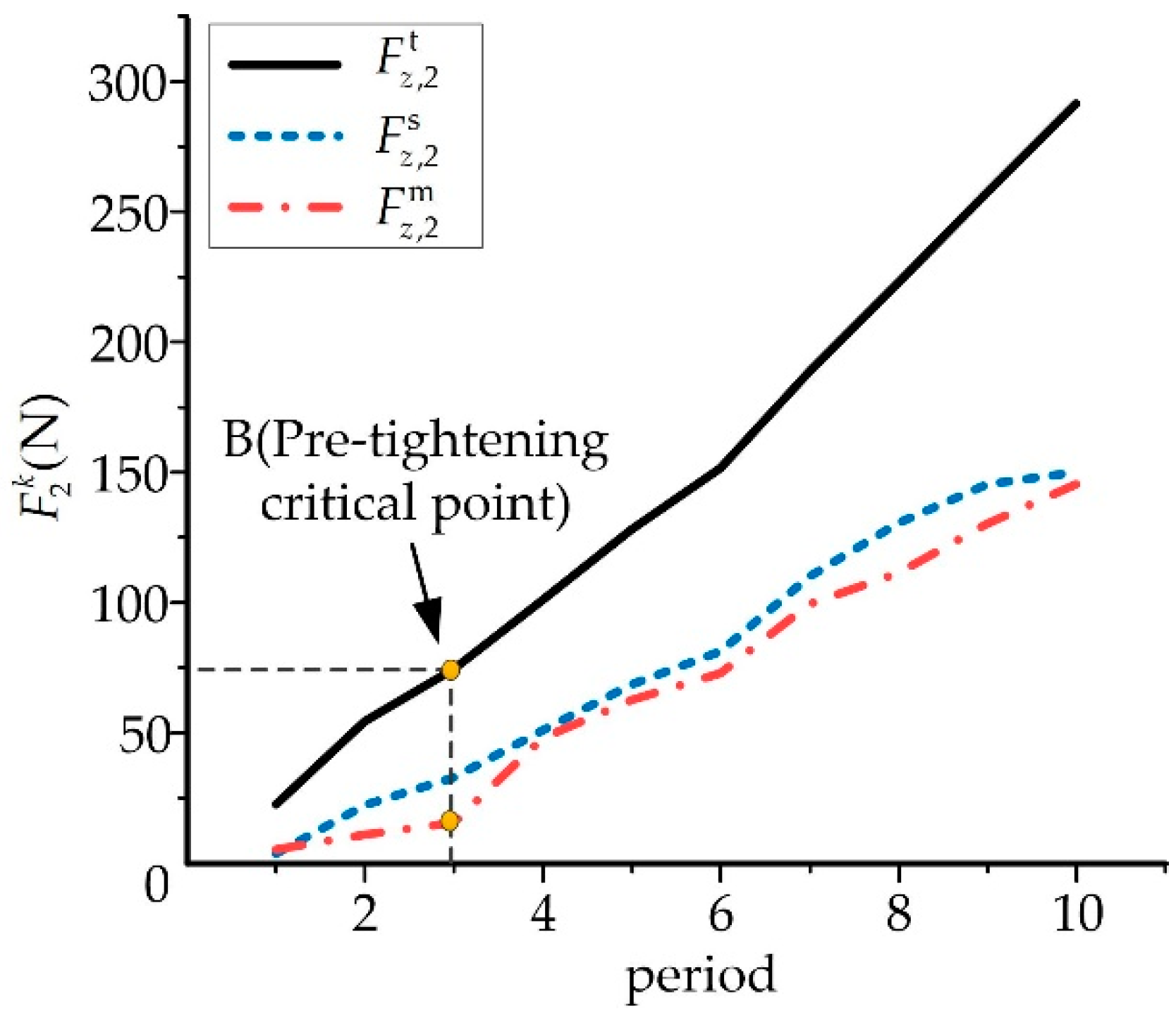

3.2. Orthopedic Force Theoretical Calculate

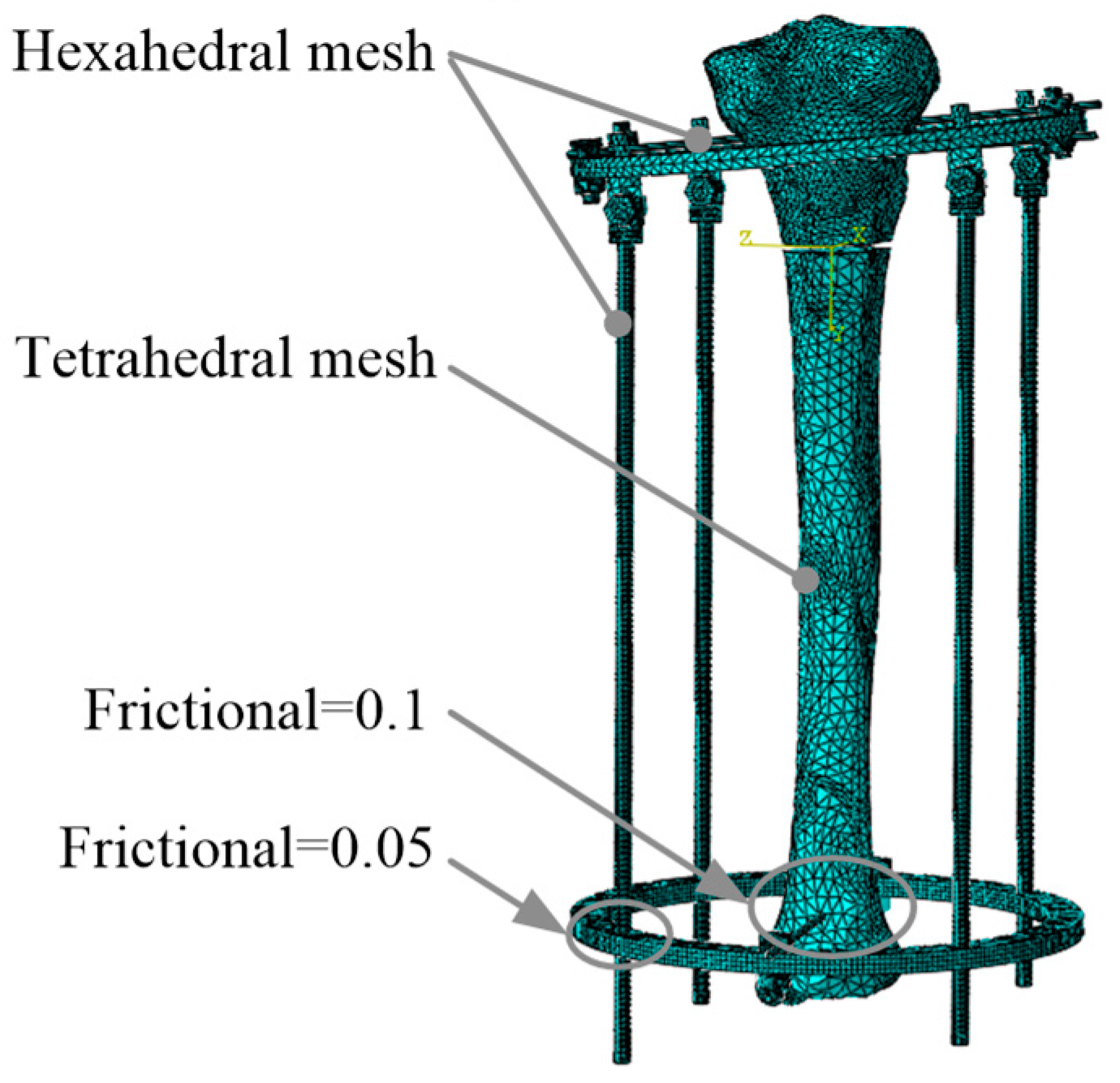

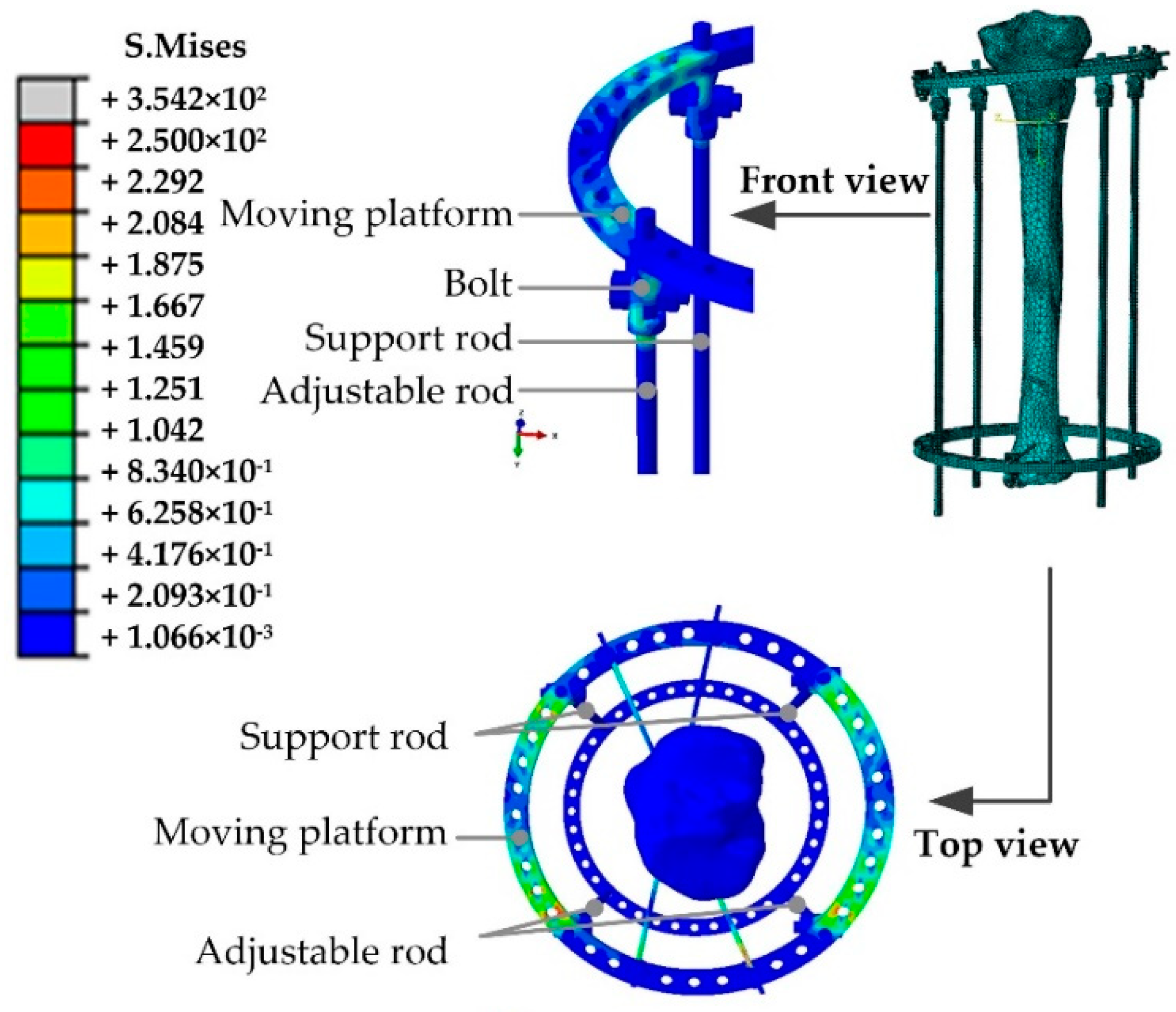

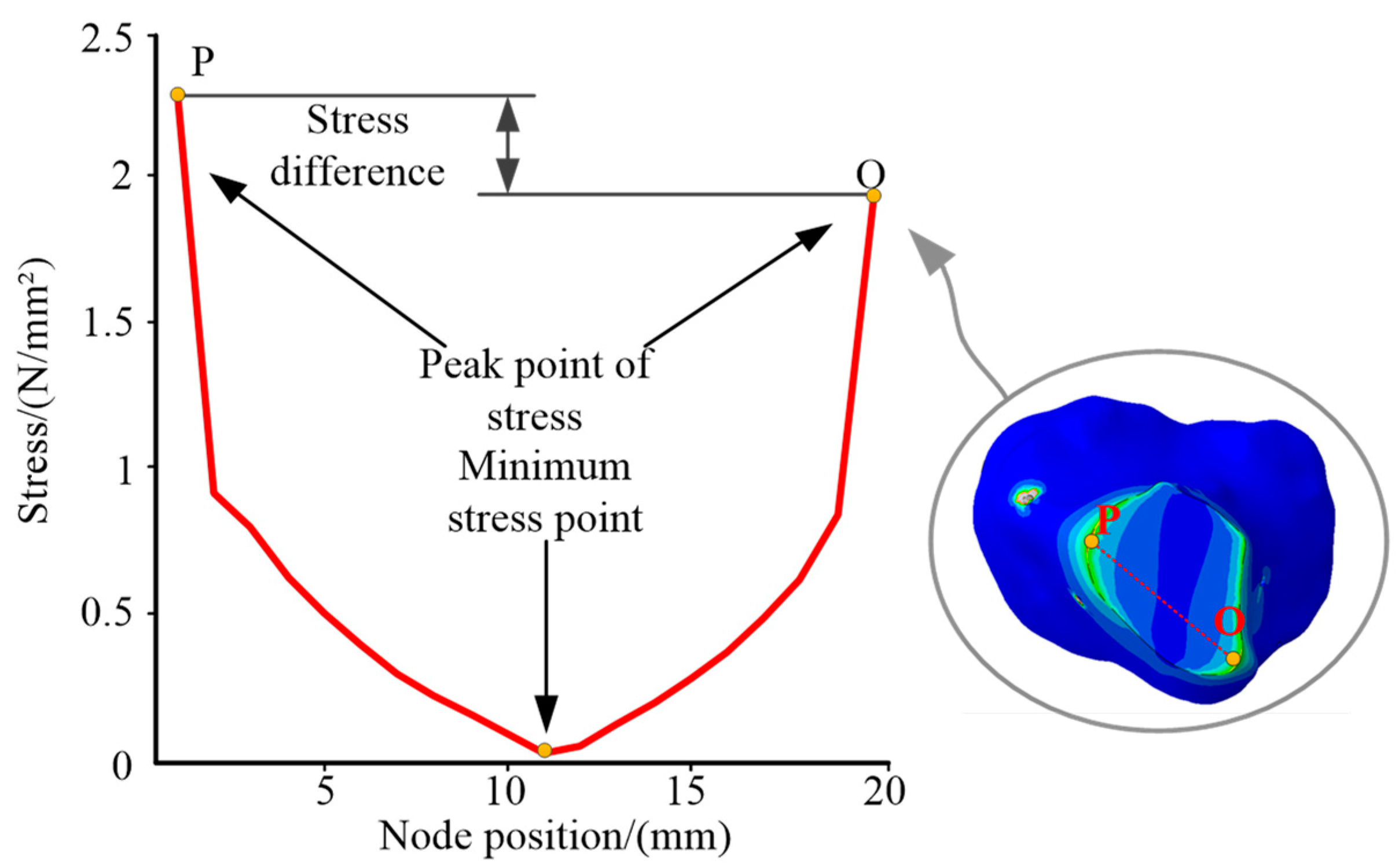

3.3. Stress Distribution of Ilizarov External Fixator and Tibia

3.4. Comparison of Theoretical, Simulation and Experimental Results

4. Discussion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Watson, J.T.; Ripple, S.; Hoshaw, S.J.; Fyhrie, D. Hybrid External Fixation for Tibial Plateau Fractures. Orthop. Clin. N. Am. 2002, 33, 199–209. [Google Scholar] [CrossRef]

- Chen, G.; Xiao, X.; Zhao, X.; Tat, T.; Bick, M.; Chen, J. Electronic Textiles for Wearable Point-of-Care Systems. Chem. Rev. 2021, 122, 3259–3291. [Google Scholar] [CrossRef] [PubMed]

- Niu, J.; Wang, H.; Shi, H.; Pop, N.; Li, D.; Li, S.; Wu, S. Study on structural modeling and kinematics analysis of a novel wheel-legged rescue robot. Int. J. Adv. Robot. Syst. 2018, 15, 172988141775275. [Google Scholar] [CrossRef]

- Ke, W.; Fuzhou, D.; Xianzhi, Z. Algorithm and experiments of six-dimensional force/torque dynamic measurements based on a Stewart platform. Chin. J. Aeronaut. 2016, 29, 1840–1851. [Google Scholar]

- Kang, C.; Liu, Z.; Chen, S.; Jiang, X. Circular trajectory weaving welding control algorithm based on space transformation principle. J. Manuf. Process. 2019, 46, 328–336. [Google Scholar] [CrossRef]

- Qian, Y.J.; Liu, Z.X.; Yang, X.D.; Hwang, I.; Zhang, W. Novel Subharmonic Resonance Periodic Orbits of a Solar Sail in Earth-Moon System. J. Guid. Control. Dyn. 2019, 42, 2532–2540. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, N.; Chai, X.; Li, Q. Kinematic/dynamic analysis and optimization of a 2-URR-RRU parallel manipulator. Nonlinear Dyn. 2016, 88, 503–519. [Google Scholar] [CrossRef]

- Li, B.; Li, Y.M.; Zhao, X.H.; Ge, W.M. Kinematic analysis of a novel 3-CRU translational parallel mechanism. Mech. Sci. 2015, 6, 57–64. [Google Scholar] [CrossRef]

- Mitousoudis, A.S.; Magnissalis, E.A.; Kourkoulis, S.K. A biomechanical analysis of the Ilizarov external fixator. EPJ Web Conf. 2010, 6, 21002. [Google Scholar] [CrossRef]

- Karunratanakul, K.; Schrooten, J.; Oosterwyck, H.V. Finite element modelling of a unilateral fixator for bone reconstruction: Importance of contact settings. Med. Eng. Phys. 2010, 32, 461–467. [Google Scholar] [CrossRef]

- Tan, B.; Shanmugam, R.; Gunalan, R.; Chua, Y.; Hossain, G.; Saw, A. A biomechanical comparison between Taylor’s Spatial Frame and Ilizarov external fixator. Malays. Orthop. J. 2014, 8, 35. [Google Scholar] [CrossRef] [PubMed]

- Kang, C.; Shi, C.; Liu, Z.; Liu, Z.; Jiang, X.; Chen, S.; Ma, C. Research on the optimization of welding parameters in high-frequency induction welding pipeline. J. Manuf. Process. 2020, 59, 772–790. [Google Scholar] [CrossRef]

- Solomin, L.N.; Green, S.A. The Basic Principles of External Skeletal Fixation Using the Ilizarov and other Devices; Springer: Milan, Italy, 2012. [Google Scholar]

- Lu, H.Q. Kinematics and Dynamics Research of Robot Manipulators and Its Application Based on Screw Theory; Nanjing University: Nanjing, China, 2007. [Google Scholar]

- Davidson, J.K.; Hunt, K.H.; Pennock, G.R. Robots and screw theory: Applications of kinematics and statics to robotics. J. Mech. Des. 2004, 126, 763–764. [Google Scholar] [CrossRef]

- Guo, S.; Fang, Y.; Qu, H. Type synthesis of 4-DOF nonoverconstrained parallel mechanisms based on screw theory. Robotica 2012, 30, 31–37. [Google Scholar] [CrossRef]

- Kong, X.; Gosselin, C.M. Type synthesis of 4-DOF SP-equivalent parallel manipulators: A virtual chain approach. Mech. Mach. Theory 2006, 41, 1306–1319. [Google Scholar] [CrossRef]

- Kong, X.; Gosselin, C.M. Type synthesis of 3T1R 4-DOF parallel manipulators based on screw theory. IEEE Trans. Robot. Autom. 2004, 20, 181–190. [Google Scholar] [CrossRef]

- Peng, L.; Bai, J.; Zeng, X.; Zhou, Y. Comparison of isotropic and orthotropic material property assignments on femoral finite element models under two loading conditions. Med. Eng. Phys. 2006, 28, 227–233. [Google Scholar] [CrossRef]

- Baca, V.; Horak, Z.; Mikulenka, P.; Dzupa, V. Comparison of an inhomogeneous orthotropic and isotropic material models used for FE analyses. Med. Eng. Phys. 2008, 30, 924–930. [Google Scholar] [CrossRef]

- Dempsey, I.J.; Southworth, T.M.; Huddleston, H.P.; Yanke, A.; Farr, J., II. Tibial tubercle osteotomy: Anterior, medial, and distal correction. Oper. Tech. Sports Med. 2019, 27, 150686. [Google Scholar] [CrossRef]

- Younger, A.S.; Morrison, J.; MacKenzie, W.G. Biomechanics of external fixation and limb lengthening. Foot Ankle Clin. N. Am. 2004, 9, 433–448. [Google Scholar] [CrossRef]

- Claes, L.; Augat, P.; Schorlemmer, S.; Konrads, C.; Ignatius, A.; Ehrnthaller, C. Temporary distraction and compression of a diaphyseal osteotomy accelerates bone healing. J. Orthop. Res. 2008, 26, 772–777. [Google Scholar] [CrossRef] [PubMed]

- Spiegelberg, B.; Parratt, T.; Dheerendra, S.K.; Khan, W.S.; Jennings, R.; Marsh, D.R. Ilizarov principles of deformity correction. Ann. R. Coll. Surg. Engl. 2010, 92, 101. [Google Scholar] [CrossRef] [PubMed]

- Gundes, H.; Buluc, L.; Sahin, M.; Alici, T. Deformity correction by Ilizarov distraction osteogenesis after distal radius physeal arrest. Acta Orthop. Traumatol. Turc. 2011, 45, 406–411. [Google Scholar] [CrossRef]

- Kawoosa, A.A.; Wani, I.H.; Dar, F.A.; Sultan, A.; Qazi, M.; Halwai, M.A. Deformity correction about knee with Ilizarov technique: Accuracy of correction and effectiveness of gradual distraction after conventional straight cut osteotomy. Ortop. Traumatol. Rehabil. 2015, 17, 587. [Google Scholar] [CrossRef] [PubMed]

- Gubin, A.V.; Borzunov, D.Y.; Malkova, T.A. The Ilizarov paradigm: Thirty years with the Ilizarov method, current concerns and future research. Int. Orthop. 2013, 37, 1533–1539. [Google Scholar] [CrossRef] [PubMed]

- Ilizarov, G. The tension-stress effect on the genesis and growth of tissues: Part, I. The influence of stability of fixation and soft-tissue preservation. Clin. Orthop. 1989, 238, 249–281. [Google Scholar] [CrossRef]

- Gessmann, J.; Citak, M.; Jettkant, B.; Schildhauer, T.A.; Seybold, D. The influence of a weight-bearing platform on the mechanical behavior of two Ilizarov ring fixators: Tensioned wires vs. half-pins. J. Orthop. Surg. Res. 2011, 6, 61. [Google Scholar] [CrossRef]

- Thiart, G.; Herbert, C.; Sivarasu, S.; Gasant, S.; Laubscher, M. Influence of Different Connecting Rod Configurations on the Stability of the Ilizarov/TSF Frame: A Biomechanical Study. Strateg. Trauma Limb Reconstr. 2020, 15, 23. [Google Scholar] [CrossRef]

- Watson, M.; Mathias, K.J.; Maffulli, N.; Hukins DW, L.; Shepherd, D.E.T. Finite element modelling of the Ilizarov external fixation system. Proc. Inst. Mech. Eng. Part H 2007, 221, 863–871. [Google Scholar] [CrossRef]

- Donaldson, F.E.; Pankaj, P.; Simpson, A. Bone properties affect loosening of half-pin external fixators at the pin–bone interface. Inj. Int. J. Care Inj. 2012, 43, 1764–1770. [Google Scholar] [CrossRef]

- Ganadhiepan, G.; Miramini, S.; Patel, M.; Mendis, P.; Zhang, L. Bone fracture healing under Ilizarov fixator: Influence of fixator configuration, fracture geometry, and loading. Int. J. Numer. Methods Biomed. Eng. 2019, 35, e3199. [Google Scholar] [CrossRef] [PubMed]

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| Hole ring | 2 | Diameter of hole ring | 190 mm |

| One-way hinge | 4 pairs | Diameter of Kirschner wire | 2.5 mm |

| Broken bone space | 10 mm | Pulling speed | 1 mm/d |

| Tibia varus angle | 6.85° | Number of adjustments | 10 times |

| The Typical Sites | Number of Elements | Number of Nodes | Type of Mesh |

|---|---|---|---|

| Kirschner wire, steel wire holder | 90,635 | 504,474 | hexahedral mesh |

| tibia | 67,973 | 127,614 | tetrahedral mesh |

| Correction Period | F1/N | F2/N | |

|---|---|---|---|

| 1 | 0.56 | 8.56 | 5.26 |

| 2 | 12.18 | 20.78 | 11.03 |

| 3 | 16.89 | 30.31 | 15.58 |

| 4 | 27.28 | 40.03 | 48.11 |

| 5 | 35.81 | 53.04 | 59.75 |

| 6 | 43.17 | 63.83 | 72.83 |

| 7 | 58.65 | 77.15 | 93.52 |

| 8 | 70.51 | 91.92 | 111.37 |

| 9 | 90.77 | 99.39 | 130.25 |

| 10 | 99.62 | 117.54 | 145.39 |

| Period/Time | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

|---|---|---|---|---|---|---|---|---|---|---|

| Tension/N | 3.667 | 22.32 | 32.71 | 50.89 | 68.53 | 81.28 | 120.00 | 130.60 | 151.31 | 155.0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Su, P.; Wang, S.; Lai, Y.; Zhang, Q.; Zhang, L. Screw Analysis, Modeling and Experiment on the Mechanics of Tibia Orthopedic with the Ilizarov External Fixator. Micromachines 2022, 13, 932. https://doi.org/10.3390/mi13060932

Su P, Wang S, Lai Y, Zhang Q, Zhang L. Screw Analysis, Modeling and Experiment on the Mechanics of Tibia Orthopedic with the Ilizarov External Fixator. Micromachines. 2022; 13(6):932. https://doi.org/10.3390/mi13060932

Chicago/Turabian StyleSu, Peng, Sikai Wang, Yuliang Lai, Qinran Zhang, and Leiyu Zhang. 2022. "Screw Analysis, Modeling and Experiment on the Mechanics of Tibia Orthopedic with the Ilizarov External Fixator" Micromachines 13, no. 6: 932. https://doi.org/10.3390/mi13060932

APA StyleSu, P., Wang, S., Lai, Y., Zhang, Q., & Zhang, L. (2022). Screw Analysis, Modeling and Experiment on the Mechanics of Tibia Orthopedic with the Ilizarov External Fixator. Micromachines, 13(6), 932. https://doi.org/10.3390/mi13060932