A Study on the Detent Torque and Holding Torque of a Micro-Claw Pole Stepper Motor

Abstract

1. Introduction

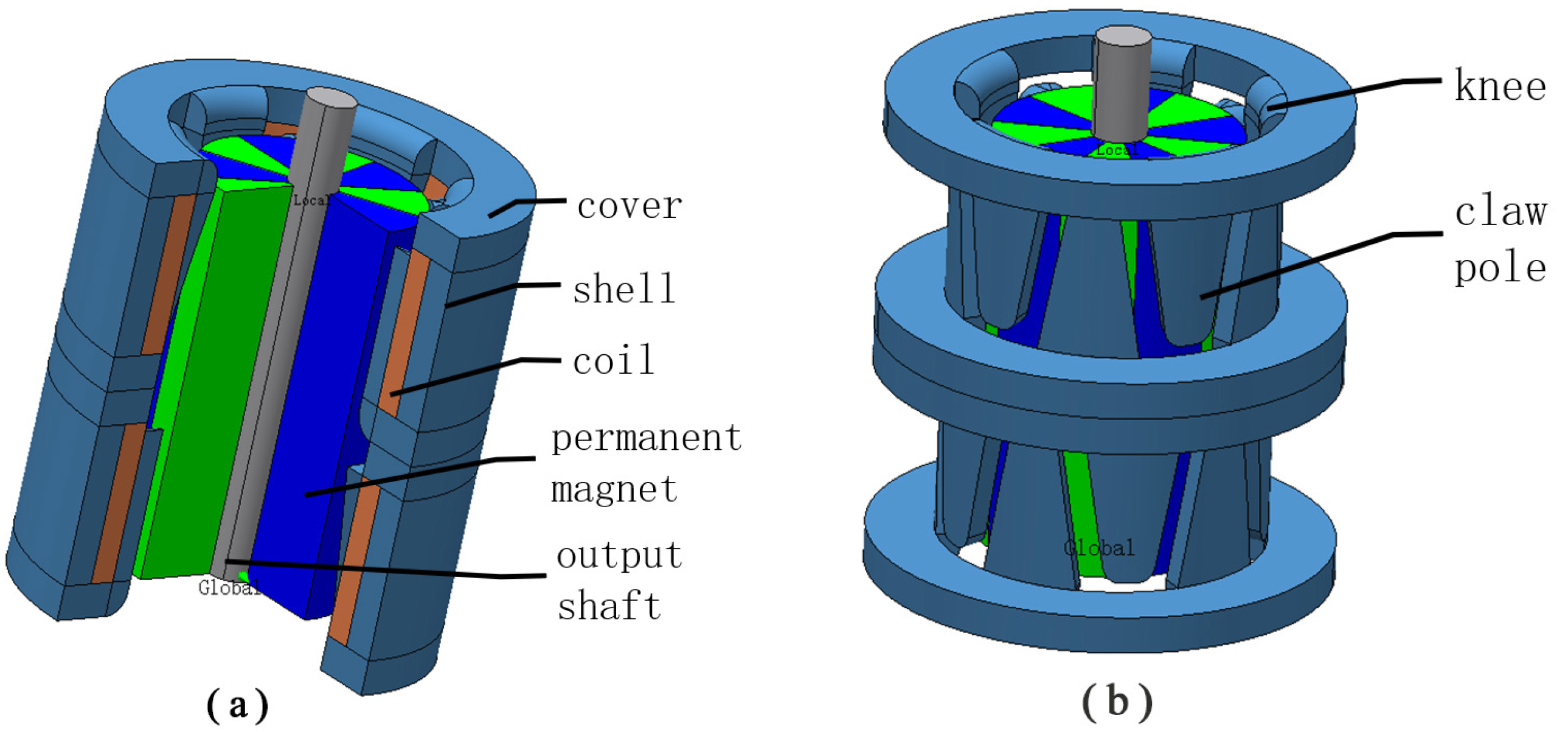

2. Structure of a Micro-Claw Pole Stepper Motor

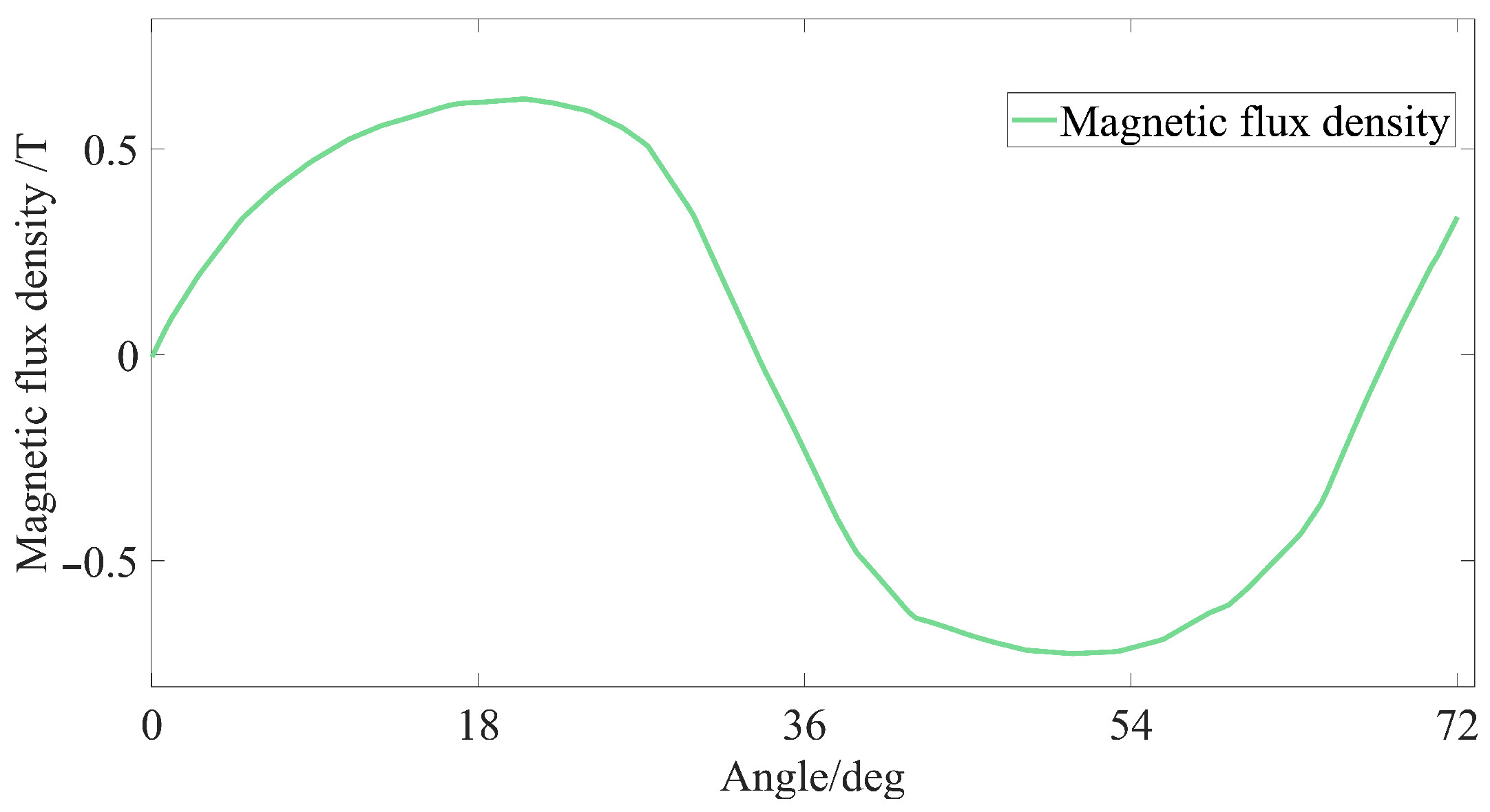

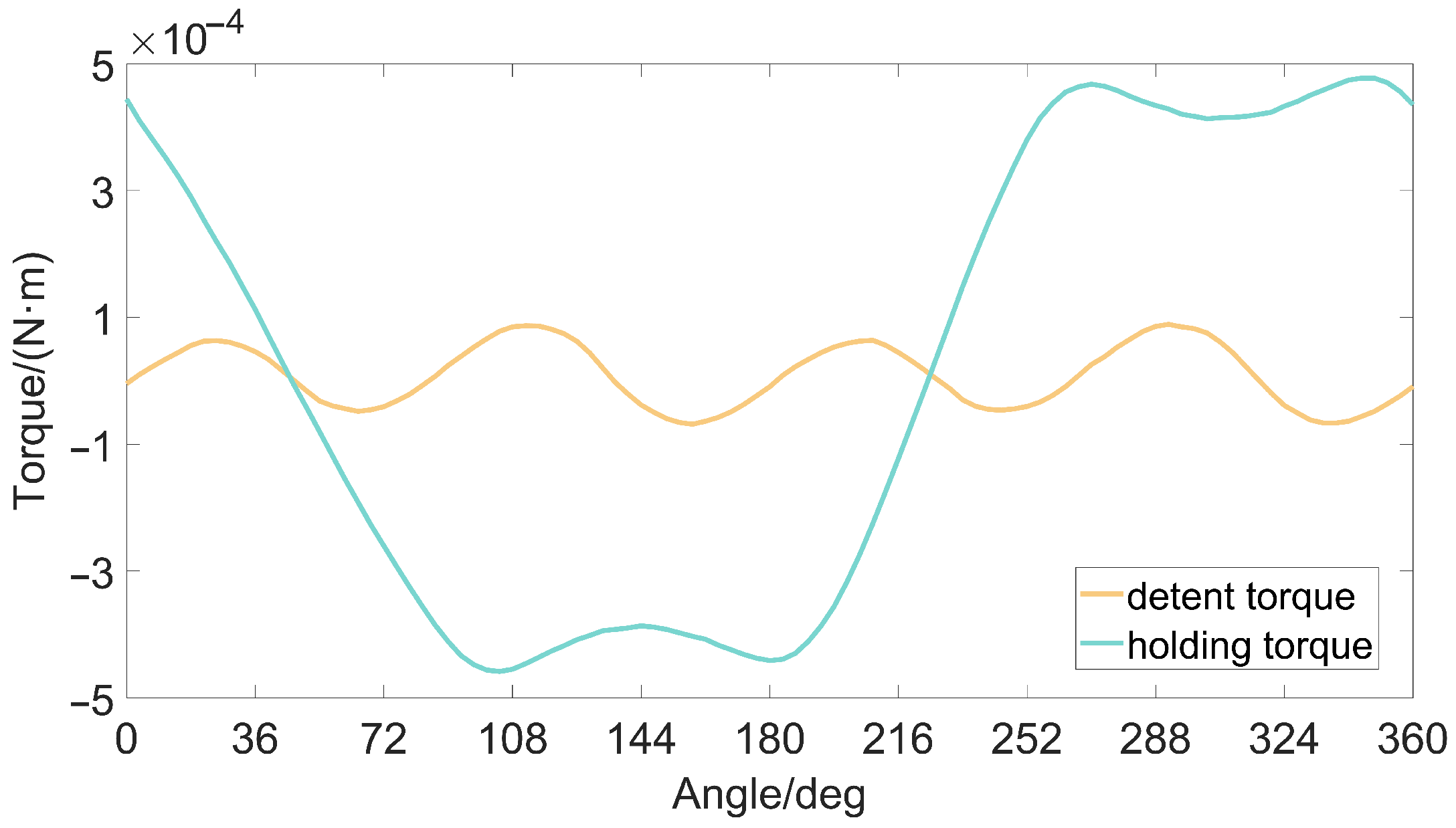

3. Torque Analysis of Micro-Claw Pole Stepper Motor

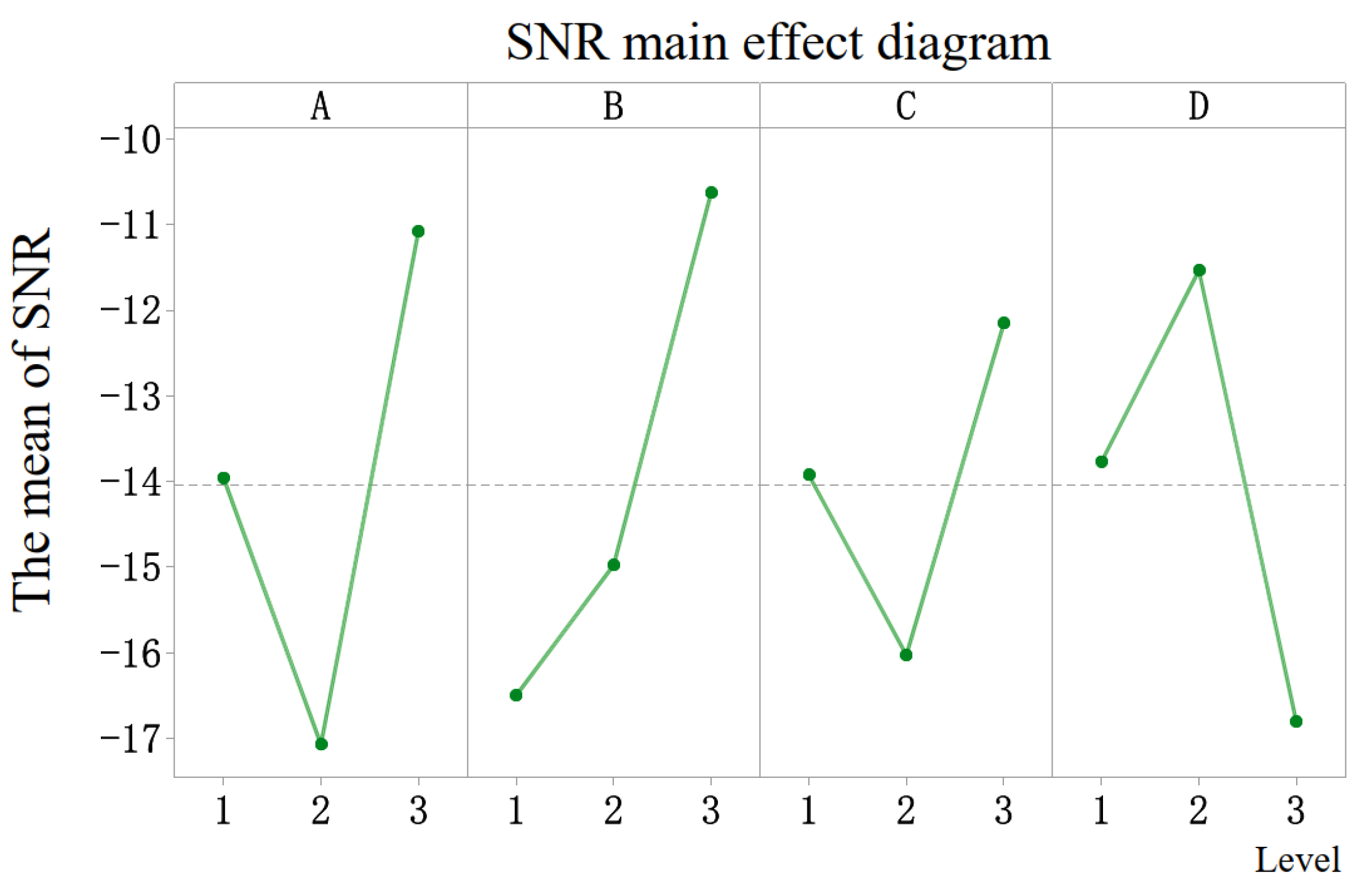

4. Parameter Optimization of Micro-Claw Pole Stepper Motor

5. Verification of Simulation Results

6. Conclusions

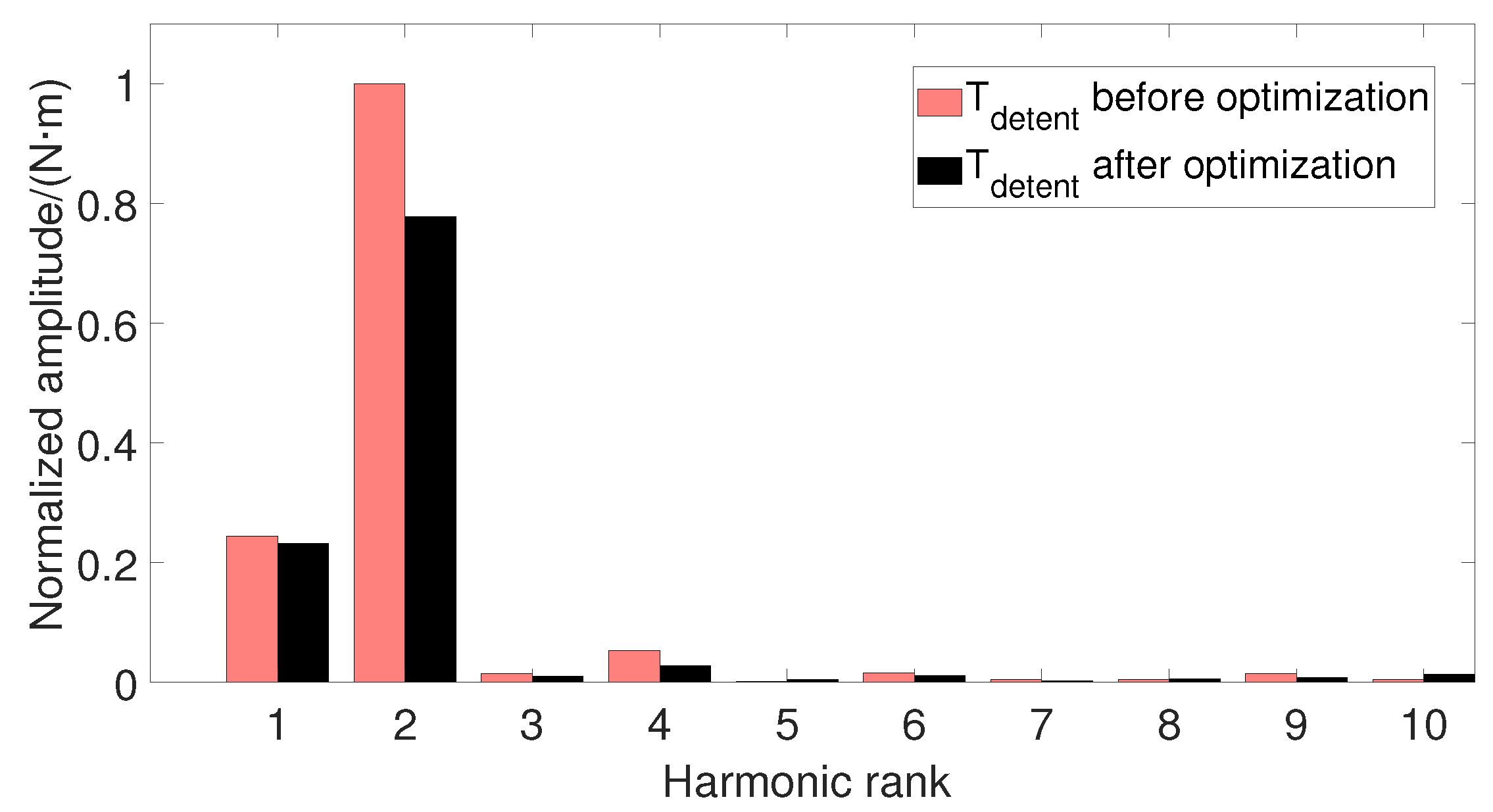

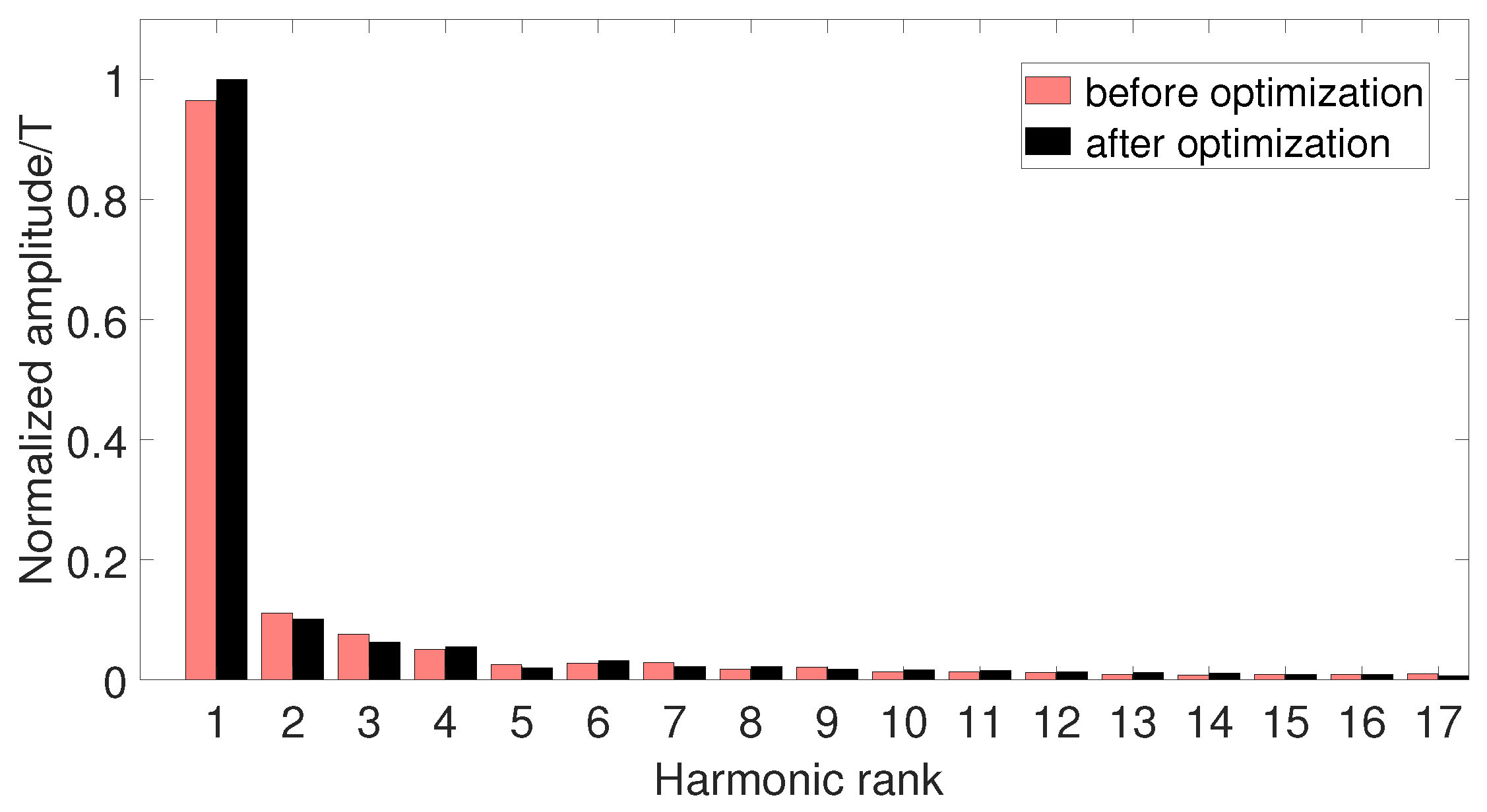

- The air gap of the micro-claw pole permanent magnet stepper motor is the primary parameter affecting the detent torque, but it is a secondary factor affecting the holding torque. Both the detent torque and the holding torque are inversely proportional to the air gap;

- The effect of the magnet thickness on the holding torque is greater than that of the air gap on the holding torque. The influence of the magnet thickness on the detent torque is greater than that of the claw pole thickness on the detent torque;

- The height of the claw pole has little influence on the detent torque, and its influence on the holding torque is greater than that of the thickness of the claw pole on the holding torque. The height of the claw pole determines the axial length of the claw pole stepper motor. When the outer diameter of the motor is determined, we can optimize the height of the claw pole to compensate for the insufficient number of turns of the excitation coil;

- In order to suppress the detent torque and increase the holding torque, if the air gap is not greatly increased, the thickness of the claw pole can be increased or the thickness of the permanent magnet can be reduced, but this also requires other parameters to match optimization.

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| SNR | Signal-to-noise ratio |

| HSM | Hybrid stepper motor |

| FEM | Finite element method |

| DOE | Design of experiment |

| LCM | Least common multiple |

References

- Škofic, J.; Boltežar, M. Numerical modelling of the rotor movement in a permanent-magnet stepper motor. J. Mech. Eng. 2014, 8, 155–163. [Google Scholar] [CrossRef]

- Wang, H.; Miao, H.; Song, Y.; Yu, Y.; Huang, F. Design of Low Cost and High Zoom Ratio Optical Zoom Camera for Mobile Phone. Laser Optoelectron. Prog. 2011, 48, 122202. [Google Scholar] [CrossRef]

- Škofic, J.; Koblar, D.; Boltežar, M. Parametric Study of a Permanent-Magnet Stepper Motor’s Stepping Accuracy Potential. IET Electr. Power Appl. 2014, 60, 255–264. [Google Scholar] [CrossRef]

- Bober, P.; Ferková, Ž. Dynamic analysis of permanent magnet stepper motor with asymetric stator. In Proceedings of the 2015 International Conference on Electrical Drives and Power Electronics (EDPE), Tatranska Lomnica, Slovakia, 21–23 September 2015; pp. 324–327. [Google Scholar]

- Tozune, A.; Takeuchi, T.; Sakamoto, M. Proposal of Claw Pole Type Double 2 Phase PM Stepping Motor. IEEJ Trans. Ind. Appl. 2007, 127, 428–434. [Google Scholar] [CrossRef][Green Version]

- Bednarski, B.; Jackiewicz, K.; Gałecki, A. Influence of Microstepping Signal Shape on Shaft Movement Precision and Torque Variation of the Stepper Motor. Energies 2021, 14, 6107. [Google Scholar] [CrossRef]

- Mahdavian, M.; Shafaghi, P.; Janghorbani, M.; Ganji, E.; Eshaghpour, I.; Javadi, S. Analysis and simulation of behavior dynamic in permanent magnet stepper motor. In Proceedings of the 2017 14th International Conference on Electrical Engineering/Electronics, Computer, Telecommunications and Information Technology (ECTI-CON), Phuket, Thailand, 27–30 June 2017; IEEE: Piscataway, NJ, USA, 2017; pp. 737–740. [Google Scholar]

- Ishikawa, T.; Takakusagi, R.; Matsunami, M. Static torque characteristics of permanent magnet type stepping motor with claw poles. IEEE Trans. Magn. 2000, 36, 1854–1857. [Google Scholar] [CrossRef]

- Yamazaki, K.; Shibamoto, Y.; Tosa, K.; Nuka, M.; Masegi, M. Characteristics Improvement of Claw-Pole Alternators for Automobile Applications by Analyzing 3-D Flux Paths in Rotors. IEEE Trans. Ind. Appl. 2020, 56, 1443–1451. [Google Scholar] [CrossRef]

- Rhyu, S.H. Investigation on the performance of a small sized PM type stepping motor with a newly structured claw-poles. Int. J. Appl. Electromagn. Mech. 2014, 45, 115–122. [Google Scholar] [CrossRef]

- Kim, W.; Lee, Y.; Shin, D.; Chung, C.C. Nonlinear gain position control using only position feedback for permanent magnet stepper motors. IEEE Trans. Power Electron. 2020, 36, 8506–8516. [Google Scholar] [CrossRef]

- Silaban, F.A.; Budiyanto, S.; Raharja, W.K. Stepper motor movement design based on FPGA. Int. J. Electr. Comput. Eng. 2020, 10, 151. [Google Scholar] [CrossRef]

- Groenhuis, V.; Rolff, G.; Bosman, K.; Abelmann, L.; Stramigioli, S. Multi-Axis Electric Stepper Motor. IEEE Robot. Autom. Lett. 2021, 6, 7201–7208. [Google Scholar] [CrossRef]

- Kołota, J.; Stępień, S. Analysis of 3D model of reluctance stepper motor with a novel construction. In Proceedings of the 2017 22nd International Conference on Methods and Models in Automation and Robotics (MMAR), Miedzyzdroje, Poland, 28–31 August 2017; pp. 955–958. [Google Scholar]

- Stranczl, M.; Sarajlic, E.; Krijnen, G.J.; Fujita, H.; Gijs, M.A.; Yamahata, C. Modal analysis and modeling of a frictionless electrostatic rotary stepper micromotor. In Proceedings of the 2011 IEEE 24th International Conference on Micro Electro Mechanical Systems, Cancun, Mexico, 23–27 January 2011; pp. 1257–1260. [Google Scholar]

- Jadhav, V.M.; Jadhav, S.; Mane, D. Effect of Motor Parameter Variations on the Performance of Miniature Claw Pole Permanent Magnet Stepper Motor. J. Res. Vol. 2016, 2, 115–122. [Google Scholar]

- Giraud, D.; Ristagno, B.; Netter, D.; Fontchastagner, J.; Labbe, N.; Lanfranchi, V. Axial claw pole motor: Harmonic torque estimation using finite element method. Compel. Int. J. Comput. Math. Electr. Electron. Eng. 2020, 45, 115–122. [Google Scholar] [CrossRef]

- Ishikawa, T.; Matsuda, M.; Matsunami, M. Finite element analysis of permanent magnet type stepping motors. IEEE Trans. Magn. 1998, 34, 3503–3506. [Google Scholar] [CrossRef]

- Hu, J.; Chen, Y.; Wei, F.; Zhao, M.; Ran, X. Study on Magnetic Field Regulation of a Flux-Variable Partitioned Stator Permanent Magnet Claw Pole Motor. In Proceedings of the 2019 22nd International Conference on Electrical Machines and Systems (ICEMS), Harbin, China, 11–14 August 2019; pp. 1–5. [Google Scholar]

- Hidaka, Y.; Igarashi, H. Three-dimensional shape optimization of claw-pole-motors. J. Adv. Simul. Sci. Eng. 2018, 4, 64–77. [Google Scholar] [CrossRef][Green Version]

- Onsal, M.; Demir, Y.; Aydin, M.; Guven, M.K. Impact of Airgap on the Performance of 3-Phase Permanent Magnet Hybrid Stepper Motor. In Proceedings of the IECON 2021–47th Annual Conference of the IEEE Industrial Electronics Society, Toronto, ON, Canada, 13–16 October 2021; IEEE: Piscataway, NJ, USA, 2021; pp. 1–5. [Google Scholar]

- Pang, D.C.; Shi, Z.J.; Xie, P.X.; Huang, H.C.; Bui, G.T. Investigation of an inset micro permanent magnet synchronous motor using soft magnetic composite material. Energies 2020, 13, 4445. [Google Scholar] [CrossRef]

- Jung, D.S.; Lim, S.B.; Kim, K.C.; Ahn, J.; Go, S.C.; Son, Y.G.; Lee, J. Optimization for improving static torque characteristic in permanent magnet stepping motor with claw poles. IEEE Trans. Magn. 2007, 43, 1577–1580. [Google Scholar] [CrossRef]

- Liu, C.P.; Li, Y.C.; Liu, K.H.; Wu, K.T.; Yao, Y.D. Analysis of the performance of permanent magnetic stepping motor with trapezoid stator tooth. J. Appl. Phys. 2006, 99, 08R316. [Google Scholar] [CrossRef]

- Wu, J.; Fang, L.; Qiu, H. Numerical study on claw-pole electric motors for ele1ctronic expansion valves. Chin. Soc. Electr. Eng. 2012, 32, 73–78. [Google Scholar]

- Lim, S.B.; Jung, D.S.; Kim, K.C.; Koo, D.H.; Lee, J. Characteristic analysis of permanent-magnet-type stepping motor with claw poles by using 3 dimensional finite element method. IEEE Trans. Magn. 2007, 43, 2519–2521. [Google Scholar] [CrossRef]

- Zhang, W.; Xu, Y.; Sun, M. Design of a Novel Claw Pole Transverse Flux Permanent Magnet Motor Based on Hybrid Stator Core. IEEE Trans. Magn. 2021, 57, 1–5. [Google Scholar] [CrossRef]

- Liu, C.P.; Jeng, G.R.; Chen, W.C.; Tsai, M.C.; Wu, K.T.; Yao, Y.D. Performance of claw-poled PM-stepping motor. J. Magn. Magn. Mater. 2007, 310, e910–e912. [Google Scholar] [CrossRef]

- Jung, D.S.; Lee, J.; Lee, S.T. A Study on the Detent Torque Reduction of Claw Pole Permanent Magnet Type Motor. J. Korean Inst. Illum. Electr. Install. Eng. 2013, 27, 125–132. [Google Scholar] [CrossRef]

- Tutelea, L.N.; Staudt, T.; Boldea, I. Magnetic equivalent circuit–based optimal design code of high torque density and efficiency small power claw pole stator PM motor. In Proceedings of the 2021 International Aegean Conference on Electrical Machines and Power Electronics (ACEMP) & 2021 International Conference on Optimization of Electrical and Electronic Equipment (OPTIM), Brasov, Romania, 2–3 September 2021; IEEE: Piscataway, NJ, USA, 2021; pp. 86–92. [Google Scholar]

- Lee, H.W.; Cho, S.Y.; Bae, J.N.; Son, B.O.; Park, K.J.; Lee, J. Yoke Shape Design of Claw-Poles Stepping Motor Using Modified Magnetic Equivalent Circuit Method Including Magnetic Saturation Effect and Leakage Flux. Trans. Korean Inst. Electr. Eng. 2009, 58, 1942–1946. [Google Scholar]

- Wang, Q.; Li, Z.; Ni, Y.; Jiang, W. Magnetic field computation of a PM spherical stepper motor using integral equation method. IEEE Trans. Magn. 2006, 42, 731–734. [Google Scholar] [CrossRef]

- Ionică, I.; Modreanu, M.; Morega, A.; Boboc, C. Numerical analysis of a hybrid stepper motor for the electromagnetic torque calculation. In Proceedings of the 2019 11th International Symposium on Advanced Topics in Electrical Engineering (ATEE), Bucharest, Romania, 28–30 March 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 1–6. [Google Scholar]

- Jung, D.S. The Study on the design of Claw Pole Stepping Motor considering Axial flux. J. Korean Inst. Illum. Electr. Install. Eng. 2014, 28, 28–34. [Google Scholar] [CrossRef]

- Sim, J.H.; Ahn, D.G.; Kim, D.Y.; Hong, J.P. Three-dimensional equivalent magnetic circuit network method for precise and fast analysis of PM-assisted claw-pole synchronous motor. IEEE TRansactions Ind. Appl. 2017, 54, 160–171. [Google Scholar] [CrossRef]

- Du, W.; Zhao, S.; Zhang, H.; Zhang, M.; Gao, J. A Novel Claw Pole Motor with Soft Magnetic Composites. IEEE Trans. Magn. 2020, 57, 1–4. [Google Scholar] [CrossRef]

- Okada, Y.; Kawase, Y.; Hisamatsu, Y. Analysis of claw-poled permanent magnet-stepping motor considering deterioration of material characteristics by remains stress. IEEE Trans. Magn. 2003, 39, 1721–1724. [Google Scholar] [CrossRef]

- Hattori, T.; Suzuki, Y.; Yamada, T. Analysis of permanent magnet type stepping motor with claw poles using electromagnetic field analysis. In Proceedings of the 2008 International Conference on Electrical Machines and Systems, Wuhan, China, 17–20 October 2008; IEEE: Piscataway, NJ, USA, 2008; pp. 3539–3543. [Google Scholar]

- Omri, R.; Ibala, A.; Masmoudi, A. Circuit Coupled Simulation of Claw-Pole Machines: Comparison between Different Topologies. In Proceedings of the 2020 6th IEEE International Energy Conference (ENERGYCon), Gammarth, Tunis, 28 September–1 October 2020; IEEE: Piscataway, NJ, USA, 2020; pp. 110–116. [Google Scholar]

| Parameter | Value |

|---|---|

| Diameter D/mm | 5 |

| Step angle | 18 |

| Pole number | 20 |

| Drive method | 2-2 |

| Remanence /T | 1.45 |

| Coercive force /(KA/m) | 1109 |

| Air gap g/mm | 0.15 |

| Claw pole height /mm | 1.75 |

| Claw pole thickness /mm | 0.27 |

| Magnet thickness /mm | 1.05 |

| Reference | Air Gap mm | Magnet Thickness mm | Claw Pole Height mm | Claw Pole Thickness mm |

|---|---|---|---|---|

| 1 | 0.15 | 1.05 | 1.75 | 0.27 |

| 2 | 0.13 | 0.96 | 1.85 | 0.30 |

| 3 | 0.17 | 0.93 | 1.60 | 0.25 |

| Experiment Number | Air Gap mm | Magnet Thickness /mm | Claw Pole Height mm | Claw Pole Thickness /mm | Detent Torque (N · m) | Holding Torque (N · m) |

|---|---|---|---|---|---|---|

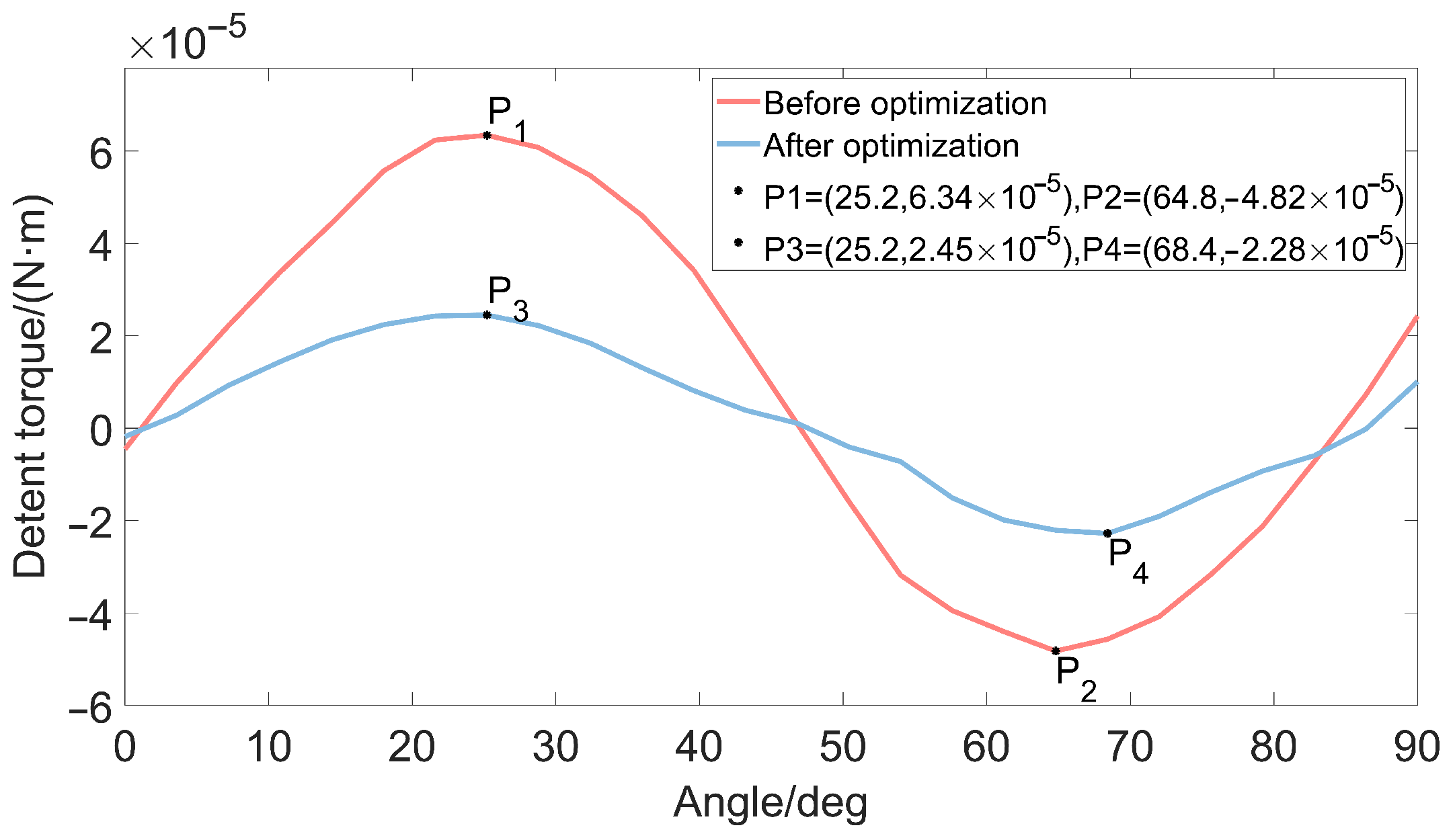

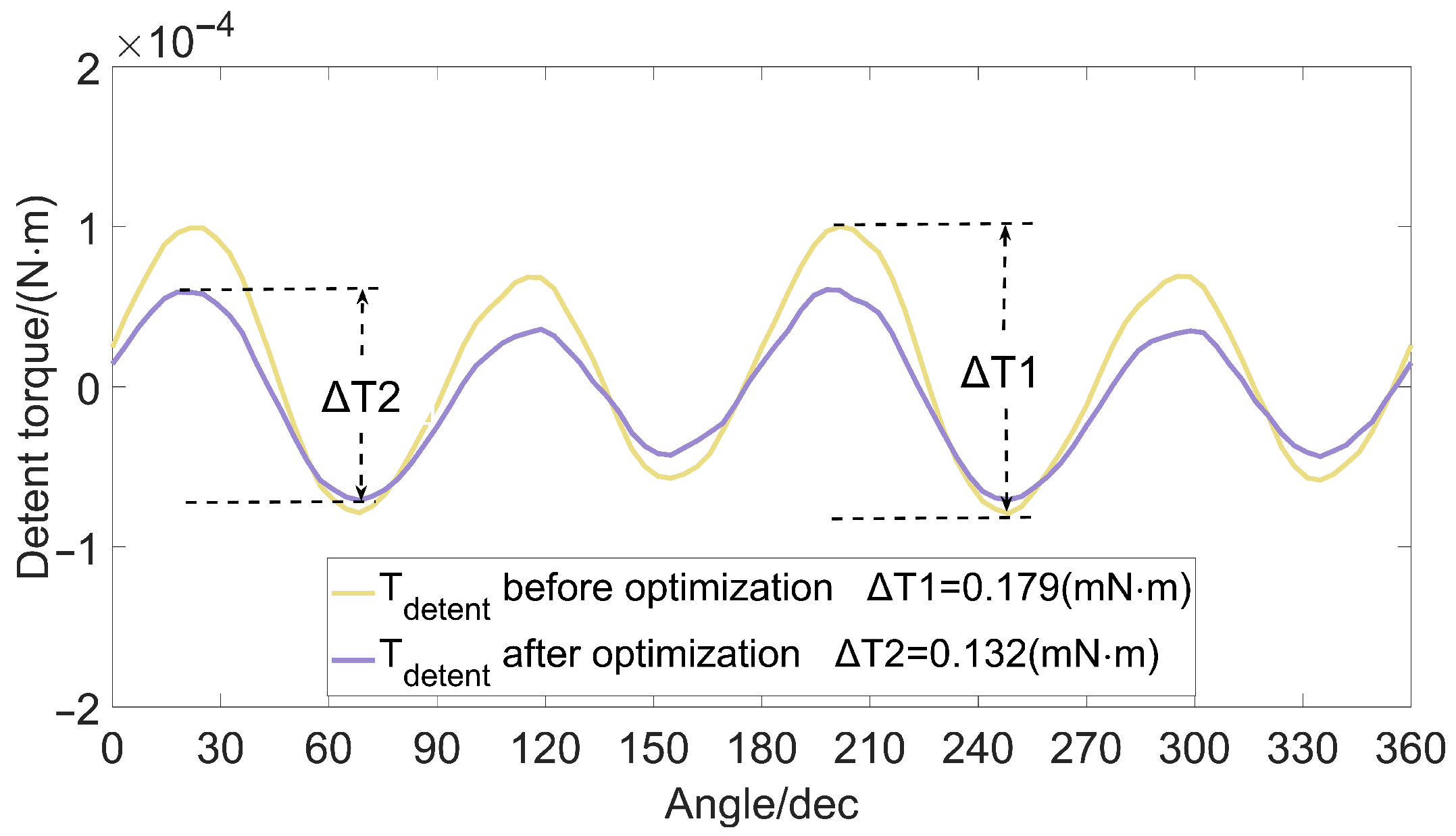

| 1 | 1 | 1 | 1 | 1 | 6.34 | 4.77 |

| 2 | 1 | 2 | 2 | 2 | 5.24 | 4.57 |

| 3 | 1 | 3 | 3 | 3 | 3.73 | 3.95 |

| 4 | 2 | 1 | 2 | 3 | 16.4 | 4.98 |

| 5 | 2 | 2 | 3 | 1 | 6.21 | 4.27 |

| 6 | 2 | 3 | 1 | 2 | 3.57 | 4.19 |

| 7 | 3 | 1 | 3 | 2 | 2.87 | 4.53 |

| 8 | 3 | 2 | 1 | 3 | 5.42 | 3.98 |

| 9 | 3 | 3 | 2 | 1 | 2.95 | 3.84 |

| Level | Air Gap (g) | Magnet Thickness () | Claw Pole Height () | Claw Pole Thickness () |

|---|---|---|---|---|

| 1 | −13.95 | −16.50 | −13.93 | −13.77 |

| 2 | −17.07 | −14.98 | −16.03 | −11.53 |

| 3 | −11.08 | −10.63 | −12.15 | −16.80 |

| Delta | 5.99 | 5.87 | 3.88 | 5.27 |

| Rank | 1 | 2 | 4 | 3 |

| Level | Air Gap (g) | Magnet Thickness () | Claw Pole Height () | Claw Pole Thickness () |

|---|---|---|---|---|

| 1 | 12.90 | 13.55 | 12.67 | 12.62 |

| 2 | 13.00 | 12.60 | 12.94 | 12.92 |

| 3 | 12.27 | 12.02 | 12.55 | 12.62 |

| Delta | 0.73 | 1.52 | 0.39 | 0.30 |

| Rank | 2 | 1 | 3 | 4 |

| Air Gap (g) | Magnet Thickness () | Claw Pole Height () | Claw Pole Thickness () | Holding Torque Fit Value N/m | Detent Torque Fit Value N/m |

|---|---|---|---|---|---|

| 0.141 | 1.070 | 1.776 | 0.301 | 5.048 | 5.663 |

| Test Current A | Arm mm | Test Value N | Holding Torque (N · m) |

|---|---|---|---|

| 0.2 | 2.01 | 0.227 | 4.56 |

| 0.2 | 2.01 | 0.264 | 5.31 |

| 0.2 | 2.01 | 0.228 | 4.58 |

| 0.2 | 2.01 | 0.254 | 5.11 |

| 0.2 | 2.01 | 0.262 | 5.27 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xi, X.; Sun, Y.; Wang, X.; Xin, Y.; Yang, Y. A Study on the Detent Torque and Holding Torque of a Micro-Claw Pole Stepper Motor. Micromachines 2022, 13, 931. https://doi.org/10.3390/mi13060931

Xi X, Sun Y, Wang X, Xin Y, Yang Y. A Study on the Detent Torque and Holding Torque of a Micro-Claw Pole Stepper Motor. Micromachines. 2022; 13(6):931. https://doi.org/10.3390/mi13060931

Chicago/Turabian StyleXi, Xiaofei, Yan Sun, Xudong Wang, Yuanxu Xin, and Yong Yang. 2022. "A Study on the Detent Torque and Holding Torque of a Micro-Claw Pole Stepper Motor" Micromachines 13, no. 6: 931. https://doi.org/10.3390/mi13060931

APA StyleXi, X., Sun, Y., Wang, X., Xin, Y., & Yang, Y. (2022). A Study on the Detent Torque and Holding Torque of a Micro-Claw Pole Stepper Motor. Micromachines, 13(6), 931. https://doi.org/10.3390/mi13060931