Ergonomic Design and Performance Evaluation of H-Suit for Human Walking

Abstract

:1. Introduction

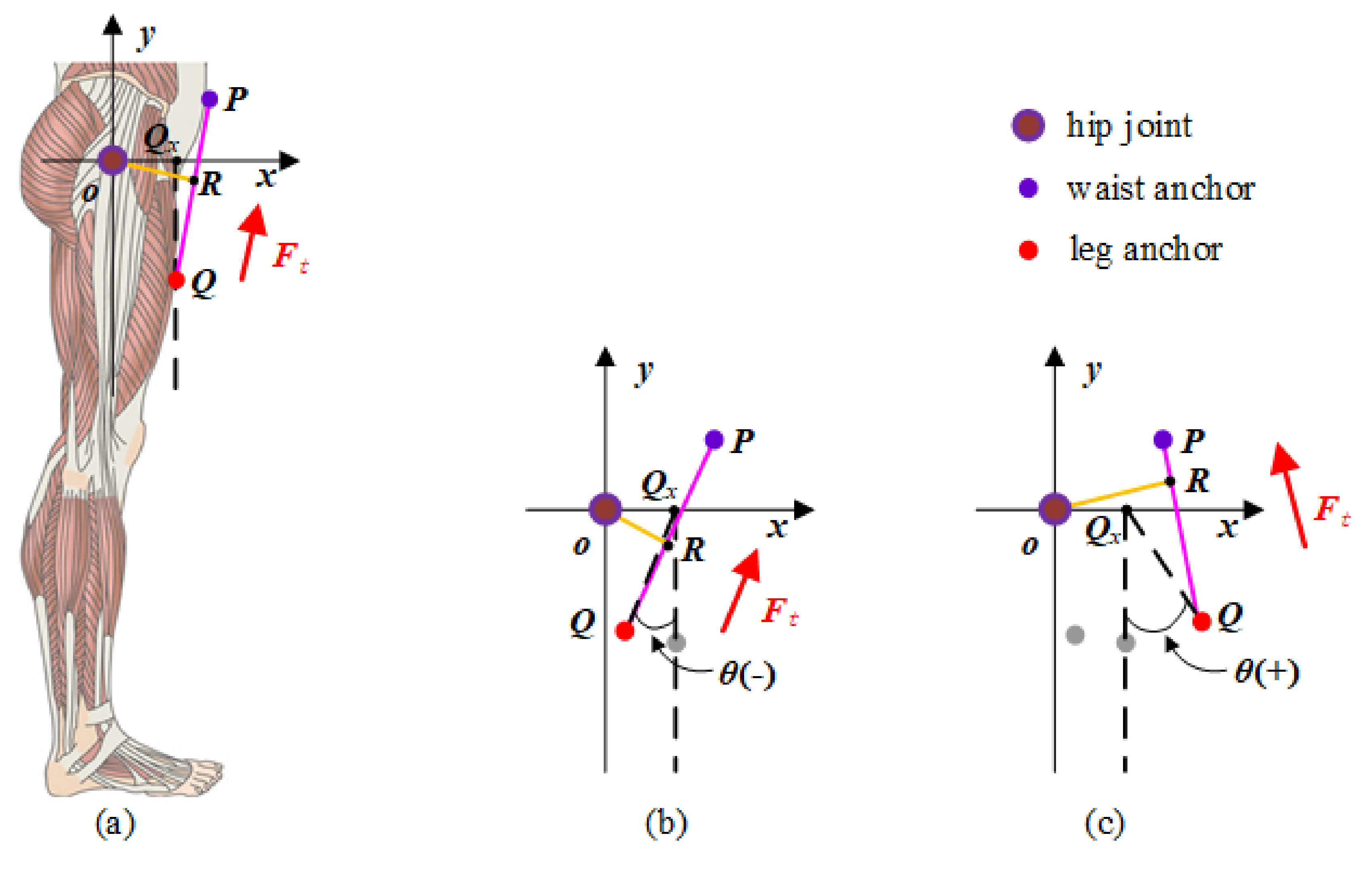

2. Ergonomic Design of the H-Suit

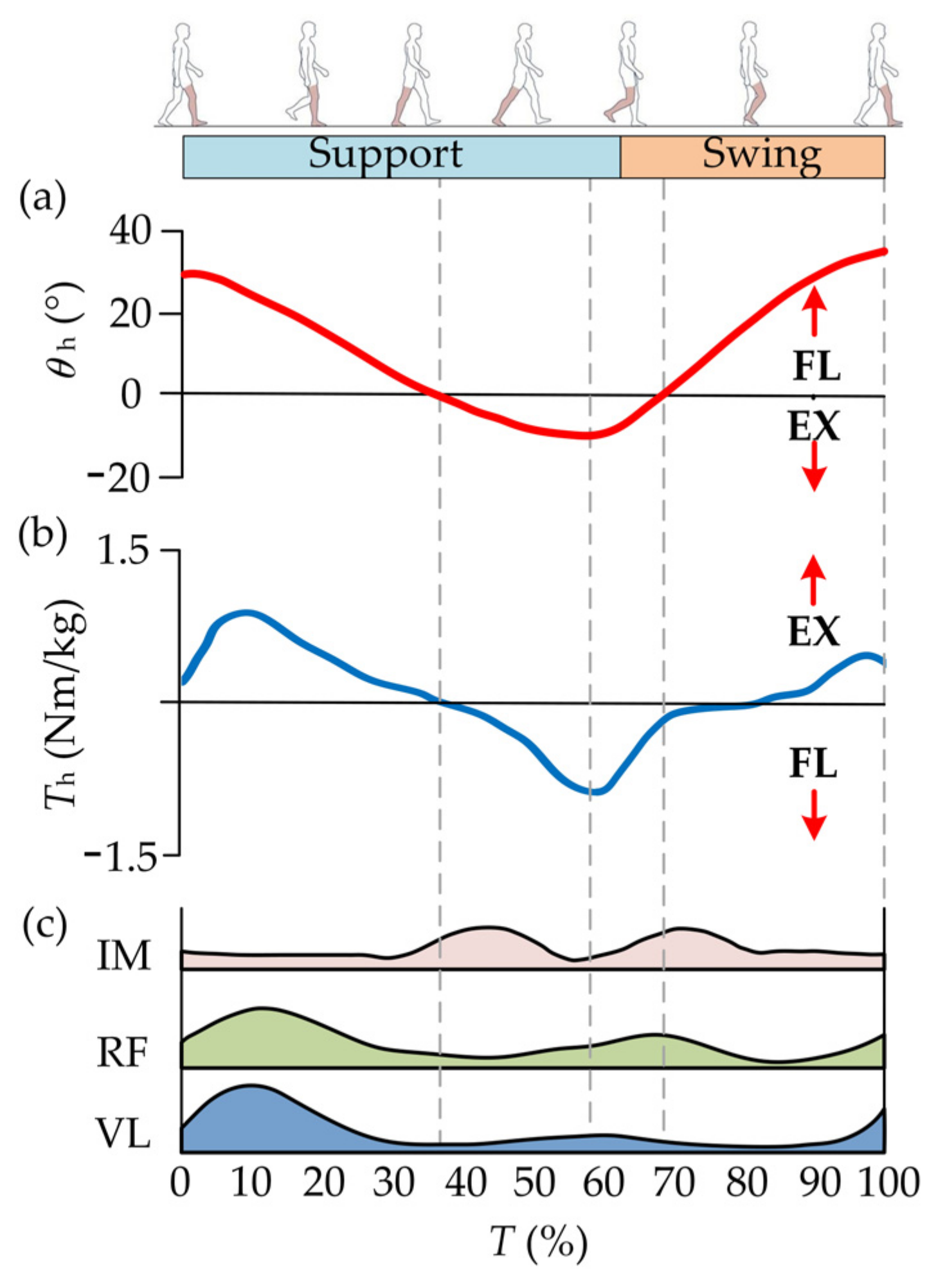

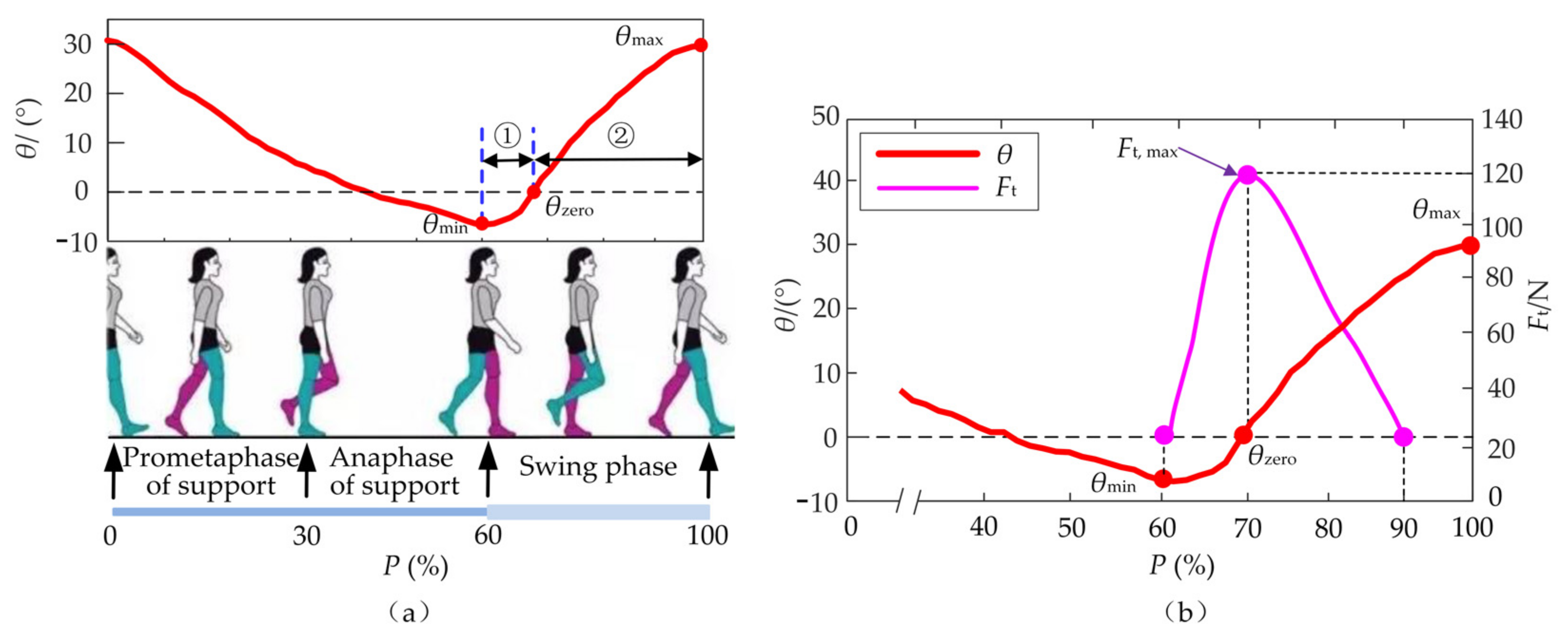

2.1. Kinematics and Biomechanics of Hip Joint

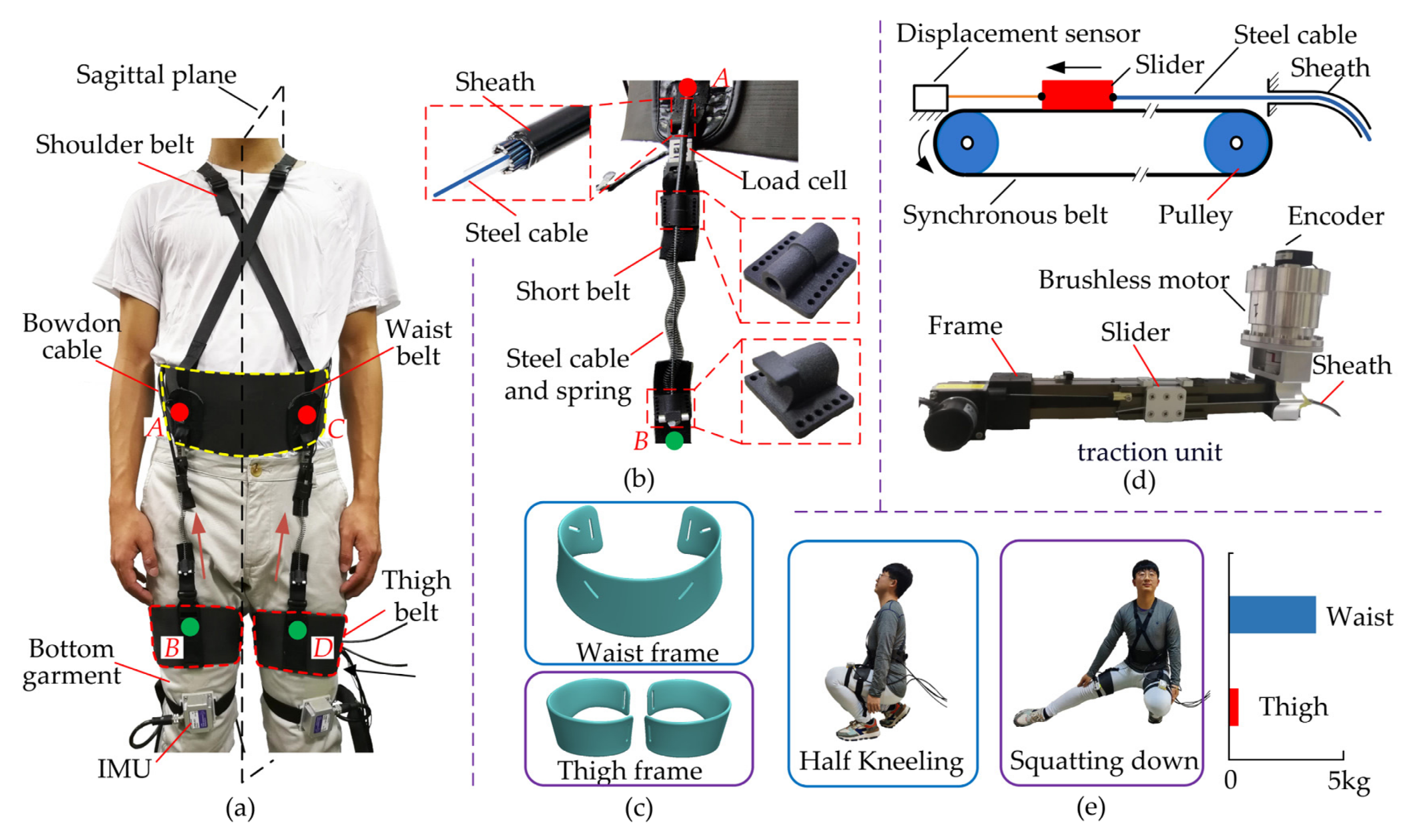

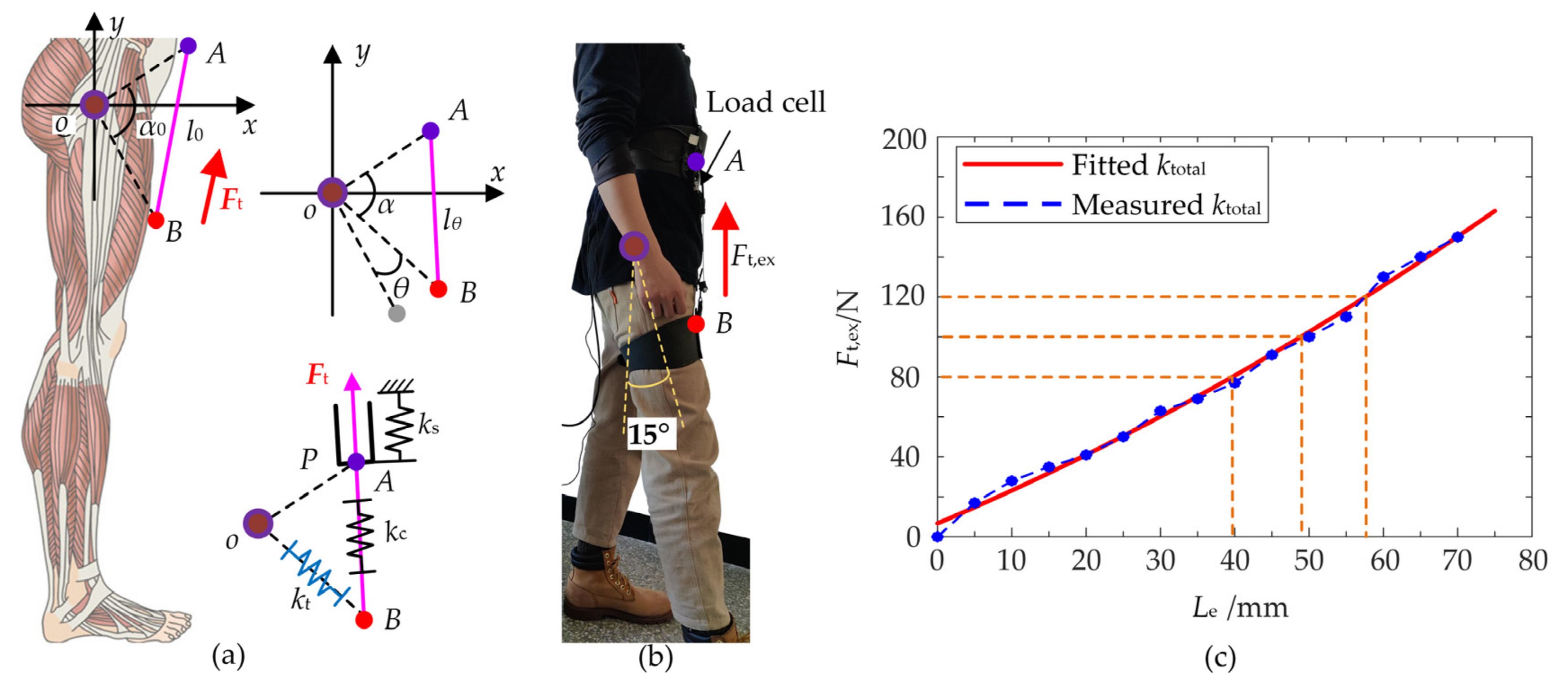

2.2. Ergonomic Design of H-Suit

2.3. Control Unit

3. Assistance Strategy of H-Suit

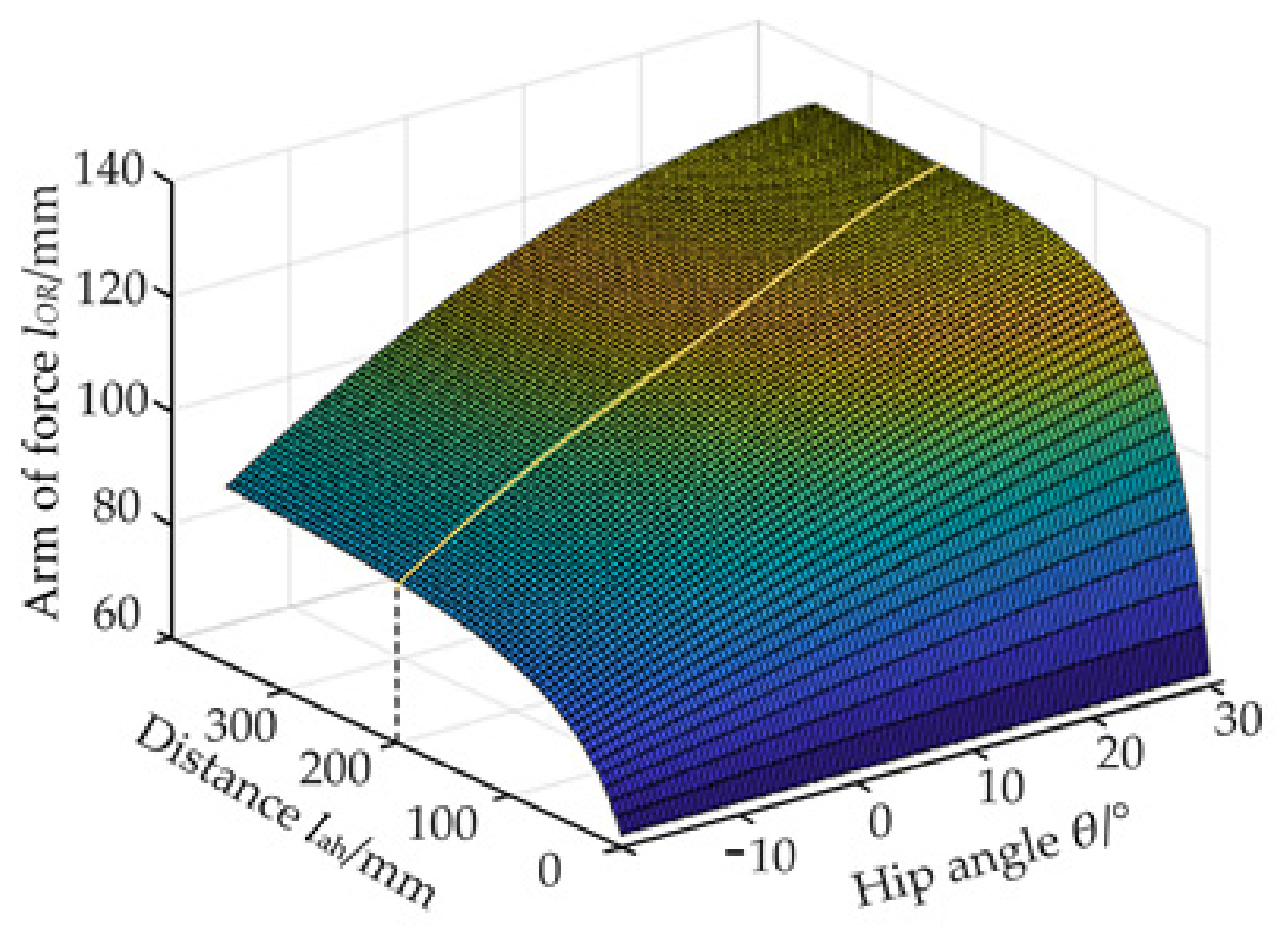

3.1. Auxiliary Force

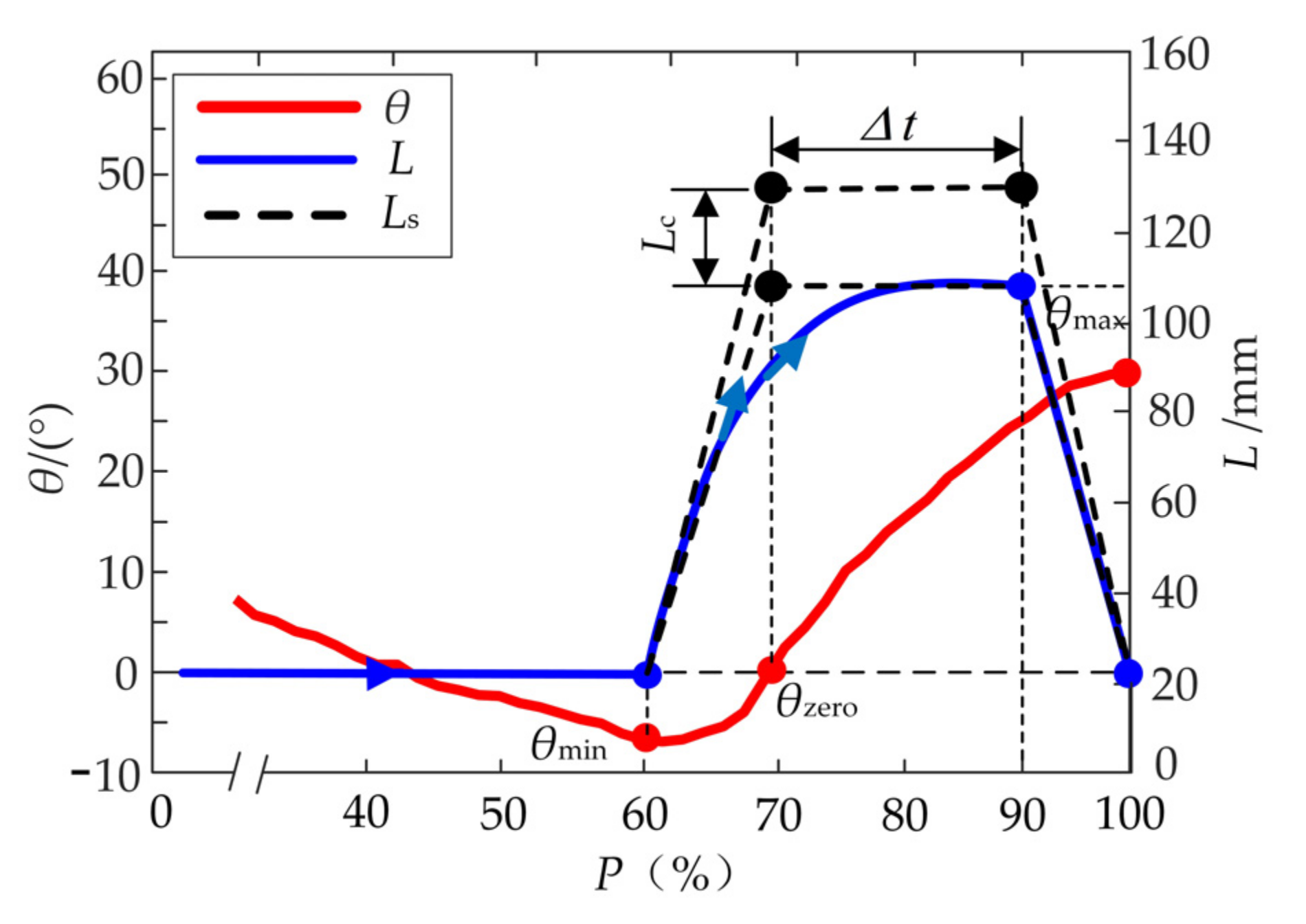

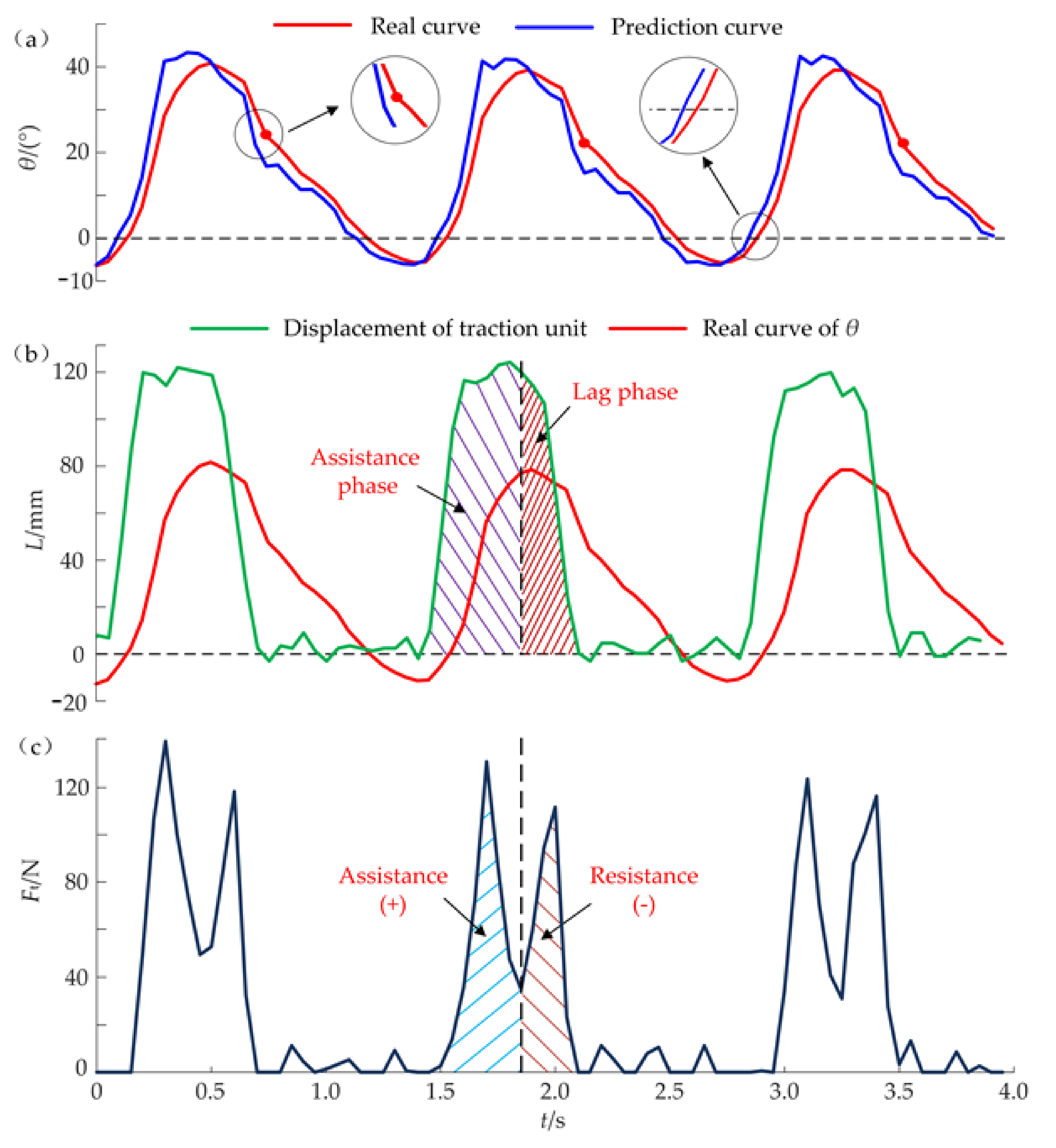

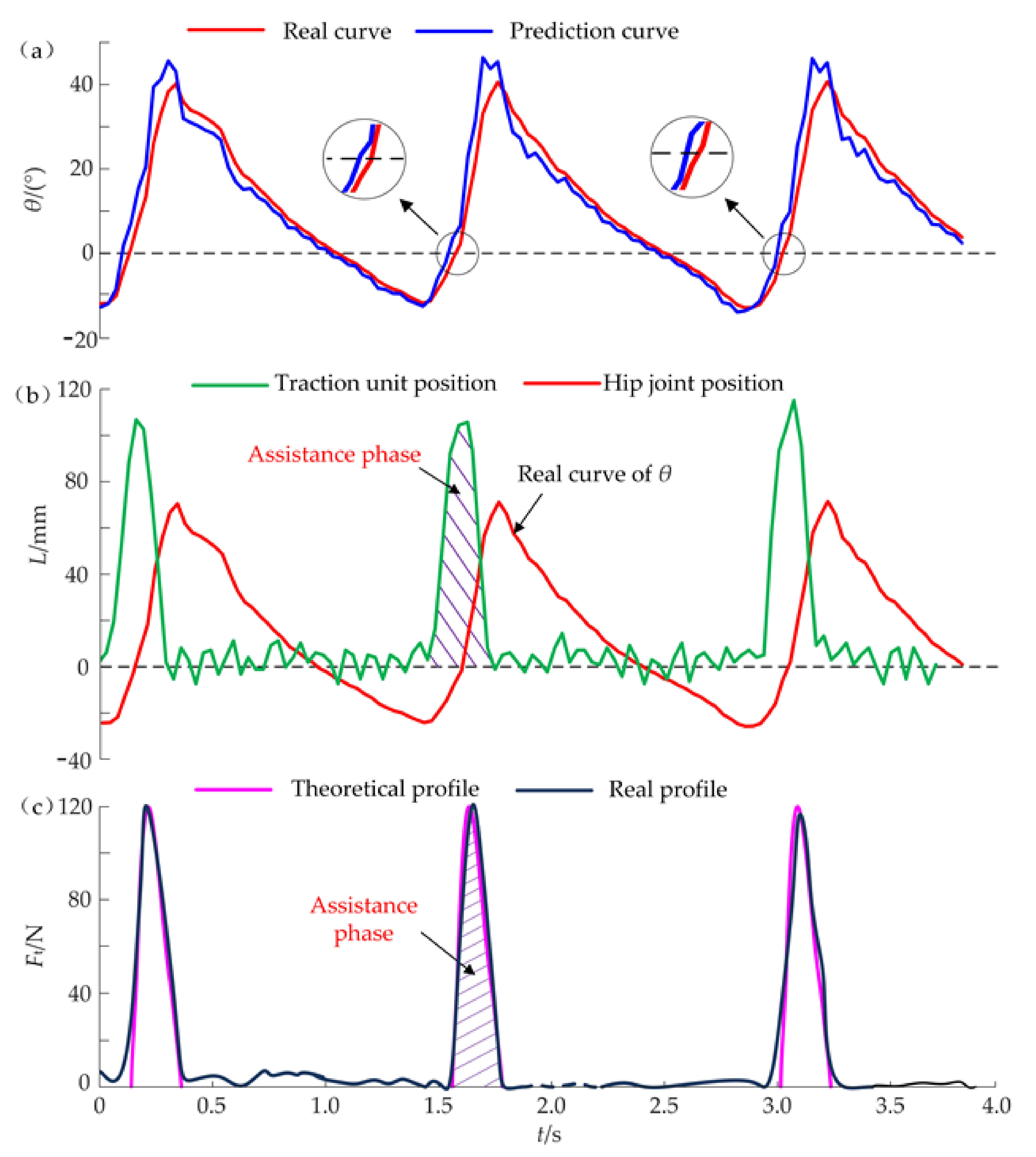

3.2. Desired Displacement of the Traction Unit

3.3. Assistance Strategy

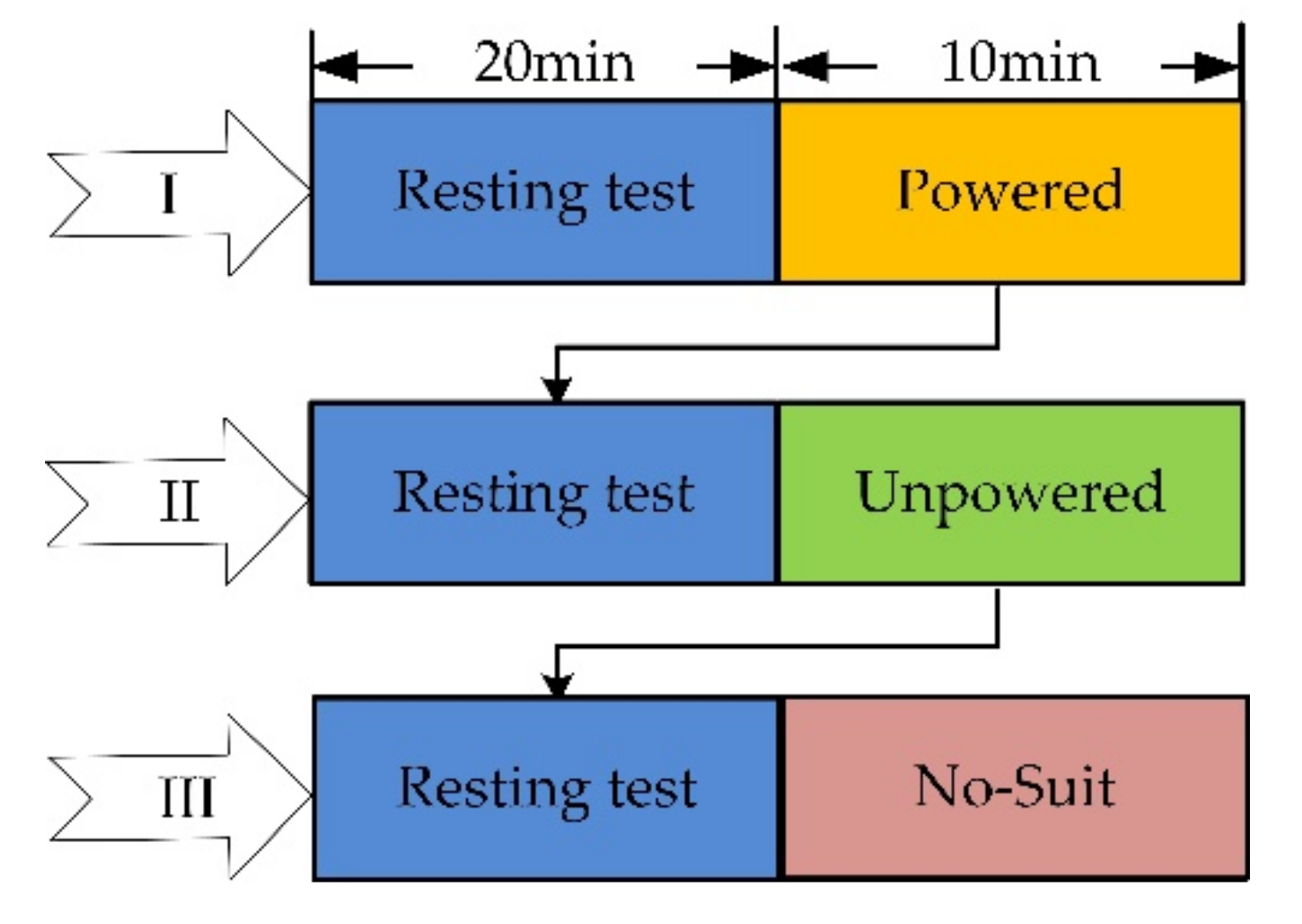

4. Performance Evaluation

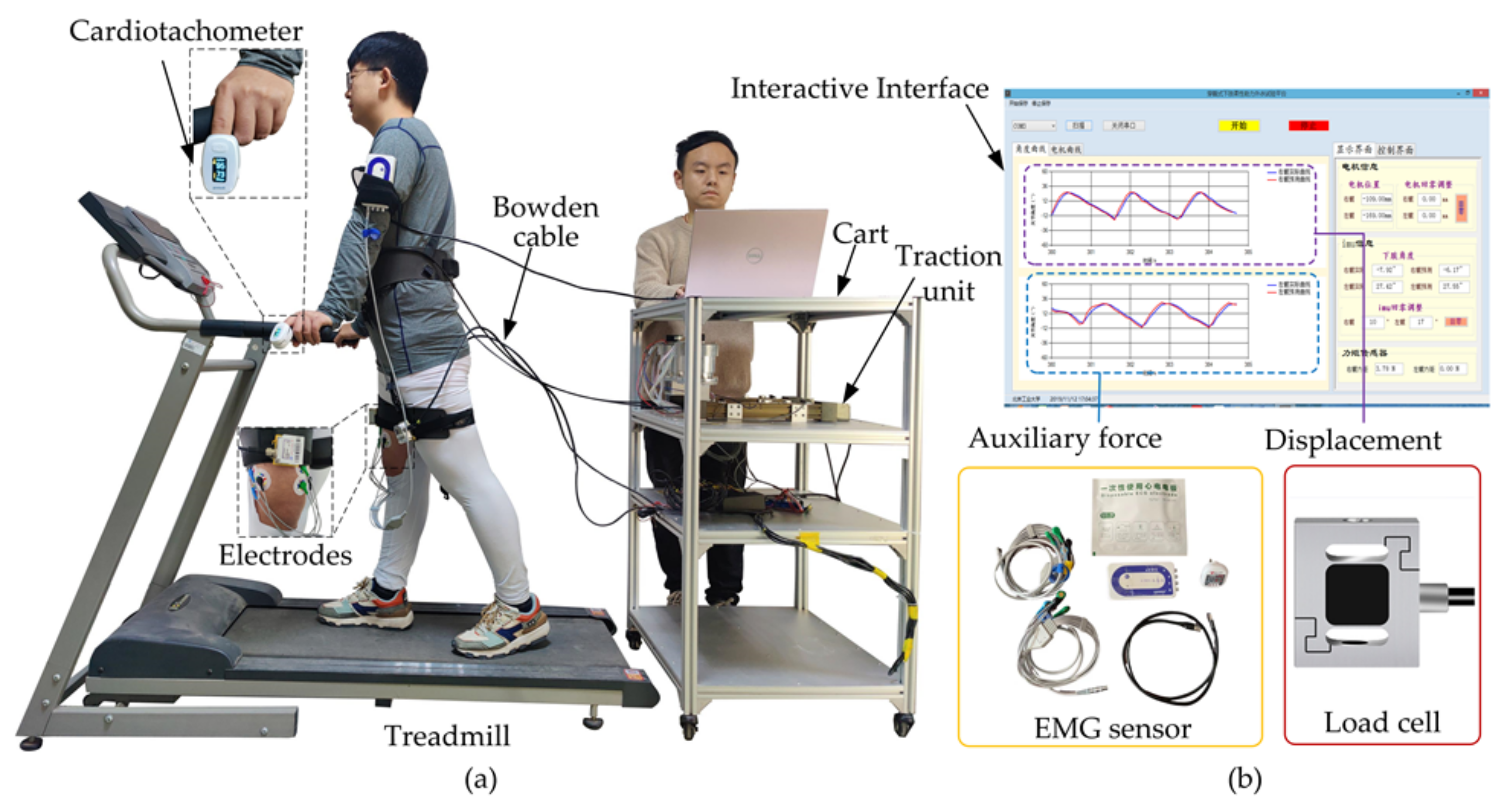

4.1. Experimental Platform

4.2. Evaluation of Auxiliary Force

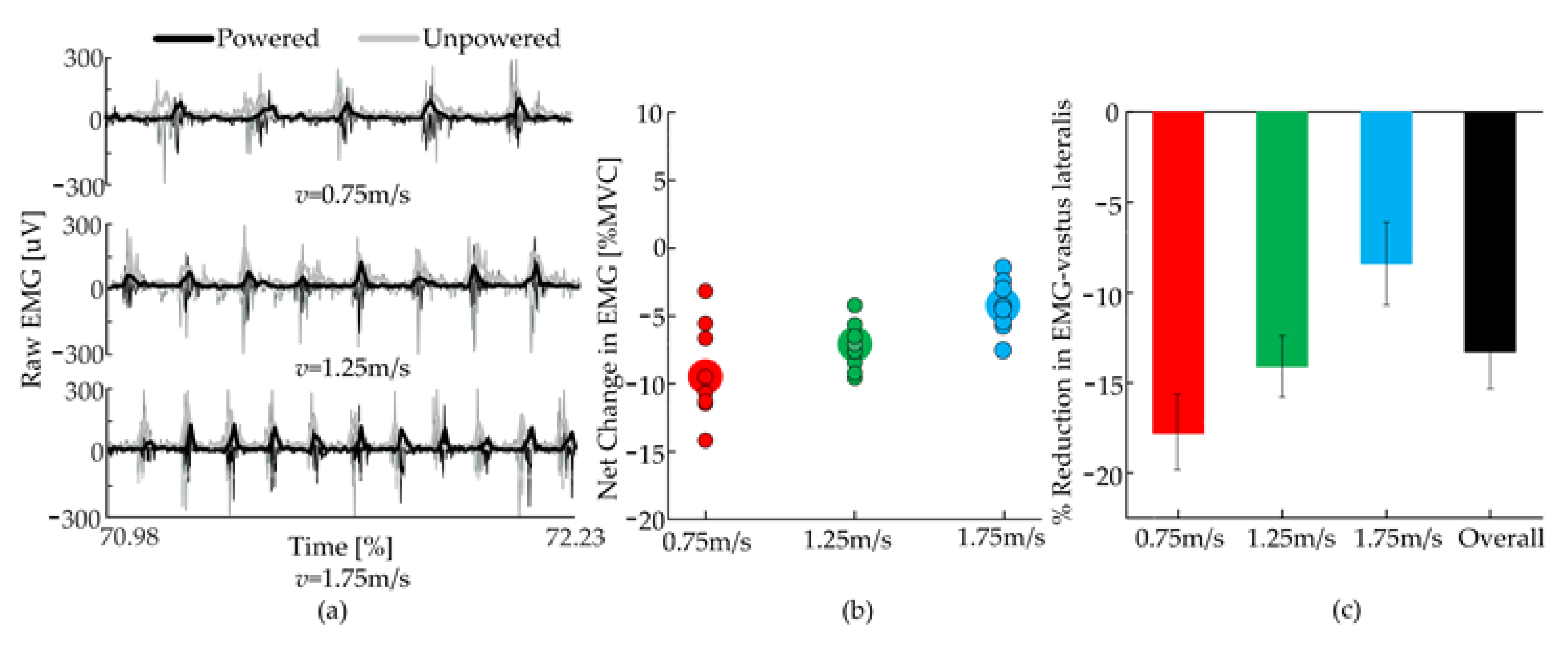

4.3. EMG Signals of Rectus Femoris and Vastus Lateralis

5. Discussion

6. Conclusions

7. Limitations of the Study

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

Appendix A

References

- Xiao, X.; Fang, Y.; Xiao, X.; Xu, J.; Chen, J. Machine-Learning-Aided Self-Powered Assistive Physical Therapy Devices. ACS Nano 2021, 15, 18633–18646. [Google Scholar] [CrossRef] [PubMed]

- Dollar, A.M.; Herr, H. Lower Extremity Exoskeletons and Active Orthoses: Challenges and State-of-the-Art. IEEE Trans. Robot. 2008, 24, 144–158. [Google Scholar] [CrossRef]

- Herr, H.M. Exoskeletons and Orthoses: Classification, Design Challenges and Future Directions. J. Neuro Eng. Rehabil. 2009, 6, 21–29. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Collins, S.H.; Wiggin, M.B.; Sawicki, G.S. Reducing the Energy Cost of Human Walking Using an Unpowered Exoskeleton. Nature 2015, 522, 212–215. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mooney, L.M.; Rouse, E.J.; Herr, H. Autonomous Exoskeleton Reduces Metabolic Cost of Human Walking during Load Carriage. Neuroeng. Rehabil. 2014, 11, 80–91. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kazerooni, H. Exoskeletons for Human Power Augmentation. In Proceedings of the 2005 IEEE/RSJ International Conference on Intelligent Robots and Systems, Edmonton, AB, Canada, 2–6 August 2005; pp. 3459–3464. [Google Scholar]

- Ohta, Y.; Yano, H.; Suzuki, R.; Yoshida, M.; Kawashima, N.; Nakazawa, K. A Two-degree-of-freedom Motor-powered Gait Orthosis for Spinal Cord Injury Patients. Proc. Inst. Mech. Eng. Part H J. Eng. Med. 2007, 221, 629–639. [Google Scholar] [CrossRef]

- Shorter, K.A.; Kogler Géza, F.; Loth, E.; Durfee, W.K.; Hsiao-Wecksler, E.T. A Portable Powered Ankle-foot Orthosis for Rehabilitation. J. Rehabil. Res. Dev. 2011, 48, 459–472. [Google Scholar] [CrossRef]

- Zoss, A.B.; Kazerooni, H.; Chu, A. Biomechanical Design of the Berkeley Lower Extremity Exoskeleton. IEEE ASME Trans. Mechatron. 2006, 11, 128–138. [Google Scholar] [CrossRef]

- Yoko, I.; Michiko, I. Global Rulemaking Strategy for Implementing Emerging Innovation: Case of Medical/Healthcare Robot, HAL by Cyberdyne (Japanese); Policy Discussion Papers; Research Institute of Economy, Trade and Industry (RIETI): Tokyo, Japan, 2019; pp. 1–27.

- Stearns-Yoder, K.A.; Brenner, L.A. Novel Psychological Outcomes with Ekso Bionics Technology. Arch. Phys. Med. Rehabil. 2018, 99, e70–e71. [Google Scholar] [CrossRef]

- Zeilig, G.; Weingarden, H.; Zwecker, M.; Dudkiewicz, I.; Bloch, A.; Esquenazi, A. Safety and Tolerance of the ReWalk Exoskeleton Suit for Ambulation by People with Complete Spinal Cord Injury: A Pilot Study. J. Am. Paraplegia Soc. 2012, 35, 96–101. [Google Scholar] [CrossRef] [Green Version]

- Xiloyannis, M.; Anna-Maria, G.; Haufe, F.L.; Wolf, P.; Masia, L.; Riener, R. Soft Robotic Suits: State of the Art, Core Technologies, and Open Challenges. IEEE Trans. Robot. 2021, 1–20. [Google Scholar] [CrossRef]

- Park, J.; Park, H.; Kim, J. Performance Estimation of the Lower Limb Exoskeleton for Plantarflexion Using Surface Electromyography (sEMG) Signals. J. Biomech. Sci. Eng. 2017, 12, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Walsh, C.J.; Endo, K.; Herr, H.M. A Quasi-passive Leg Exoskeleton for Load-carrying Augmentation. Int. J. Hum. Robot. 2007, 4, 487–506. [Google Scholar] [CrossRef]

- Schiele, A.; Van, D.H.; Frans, C.T. Influence of Attachment Pressure and Kinematic Configuration on Phri with Wearable Robots. Appl. Bionics Biomech. 2009, 6, 157–173. [Google Scholar] [CrossRef] [Green Version]

- Xiao, X.; Xiao, X.; Zhou, Y.; Zhao, X.; Chen, G.; Liu, Z.; Wang, Z.; Lu, C.; Hu, M. An Ultrathin Rechargeable Solid-state Zinc Ion Fiber Battery for Electronic Textiles. Sci. Adv. 2021, 7, eabl3742. [Google Scholar] [CrossRef]

- Kim, J.; Lee, G.; Heimgratner, R.; Arumukhom, R.D.; Karavas, N.; Nathanson, D.; Galiana, I.; Eckert-Erdheim, A.; Murphy, P.; Perry, D.; et al. Reducing the Metabolic Rate of Walking and Running with a Versatile, Portable Exosuit. Science 2019, 365, 668–672. [Google Scholar] [CrossRef]

- Schmidt, K.; Duarte, J.E.; Grimmer, M. The Myosuit: Bi-articular Anti-gravity Exosuit that Reduces Hip Extensor Activity in Sitting Transfers. Front. Neurorobotics 2017, 11, 1–16. [Google Scholar] [CrossRef] [Green Version]

- Li, J.; Li, G.; Zhang, L.; Yang, D.; Wang, H. Advances and Key Techniques of Soft Wearable Lower Limb Power-Assisted Robots. Acta Autom. Sin. 2020, 46, 427–438. [Google Scholar]

- Yang, B.; Huang, J.; Chen, X.; Xiong, C.; Hasegawa, Y. Supernumerary Robotic Limbs: A Review and Future Outlook. IEEE Trans. Med. Robot. Bionics 2021, 3, 623–639. [Google Scholar] [CrossRef]

- Ding, Y.; Galiana, I.; Asbeck, A.T.; De, R.S.M.; Bae, J.; Santos, T.R.; Araujo, V.L.; Lee, S.; Holt, K.G.; Walsh, C. Biomechanical and Physiological Evaluation of Multi-joint Assistance with Soft Exosuits. IEEE Trans. Neural Syst. Rehabil. Eng. 2017, 25, 119–130. [Google Scholar] [CrossRef]

- Ding, Y.; Kim, M.; Kuindersma, S.; Walsh, C.J. Human-in-the-loop Optimization of Hip Assistance with a Soft Exosuit during Walking. Sci. Robot. 2018, 3, eaar5438. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hashimoto, Y.; Nakanishi, Y.; Saga, N.; Nagase, J.; Satoh, T. Development of Gait Assistive Device Using Pneumatic Artificial Muscle. In Proceedings of the 2016 Joint 8th International Conference on Soft Computing and Intelligent Systems (SCIS) and 17th International Symposium on Advanced Intelligent Systems (ISIS), Sapporo, Japan, 25–28 August 2016; pp. 710–713. [Google Scholar]

- Tian, M.; Wang, X.; Wang, J.; Gan, Z. Design of a Lower Limb Exoskeleton Driven by Tendon-sheath Artificial Muscle. In Proceedings of the 2019 IEEE International Conference on Robotics and Biomimetics (ROBIO), Dali, China, 6–8 December 2019; pp. 91–96. [Google Scholar]

- John, S.W.; Murakami, K.; Komatsu, M.; Adachi, S. Cross-wire Assist Suit Concept for Mobile and Lightweight Multiple Degree of Freedom Hip Assistance. In Proceedings of the 2017 International Conference on Rehabilitation Robotics (ICORR), London, UK, 17–20 July 2017; pp. 387–393. [Google Scholar]

- Neumann Donald, A. Kinesiology of the Musculoskeletal System: Foundations for Rehabilitation; Elsevier: Amsterdam, The Netherlands, 2010; pp. 650–652. [Google Scholar]

- Mundt, M.; Thomsen, W.; Witter, T.; Koeppe, A.; David, S.; Bamer, F.; Potthast, W.; Markert, B. Prediction of Lower Limb Joint Angles and Moments during Gait Using Artificial Neural Networks. Med. Biol. Eng. Comput. 2020, 58, 211–225. [Google Scholar] [CrossRef] [PubMed]

- Kyeong, S.; Feng, J.; Ryu, J.K.; Park, J.J.; Lee, K.H.; Kim, J. Surface Electromyography Characteristics for Motion Intention Recognition and Implementation Issues in Lower-limb Exoskeletons. Int. J. Control. Autom. Syst. 2022, 20, 1018–1028. [Google Scholar] [CrossRef]

- Chenyang, G.; Chunhua, R.; Meilin, Z. A Novel Method to Process Surface Electromyography Signal for Pedestrian Lower Limb Motion Pattern Recognition. Trans. Inst. Meas. Control. 2020, 42, 2492–2498. [Google Scholar]

- Zhang, L.; He, Y.; Li, J.; Su, P.; Tao, C.; Ji, Y.; Dong, M. Ergonomic Design of Flexible Lower Limb Assist Exosuit and Gait Prediction. J. Cent. South Univ. (Sci. Technol.) 2021, 52, 1171–1184. [Google Scholar]

- Meng, Q.; Zeng, Q.; Xie, Q.; Fei, C.; Kong, B.; Lu, X.; Wang, H.; Yu, H. Flexible Lower Limb Exoskeleton Systems: A review. NeuroRehabilitation 2022, 1–24. [Google Scholar] [CrossRef]

- Young, A.J.; Hannah, G.; Ferris, D.P. A Biomechanical Comparison of Proportional Electromyography Control to Biological Torque Control Using a Powered Hip Exoskeleton. Front. Bioeng. Biotechnol. 2017, 5, 37. [Google Scholar] [CrossRef] [Green Version]

- Bot, S.D.; Hollander, A.P. The Relationship between Heart Rate and Oxygen Uptake during Non-steady State Exercise. Ergonomics 2000, 43, 1578–1592. [Google Scholar] [CrossRef]

- Hermens, H.J.; Freriks, B.; Disselhorst-Klug, C.; Rau, G. Development of Recommendations for SEMG Sensors and Sensor Placement Procedures. Electromyogr. Kinesiol. 2000, 10, 361–374. [Google Scholar] [CrossRef]

- Merletti, R.; Parker, P. Electromyography: Physiology, Engineering, and Noninvasive Applications; John Wiley & Sons: Hoboken, NJ, USA, 2004; pp. 238–246. [Google Scholar]

- Au, S.K.; Weber, J.; Herr, H. Powered Ankle—Foot Prosthesis Improves Walking Metabolic Economy. IEEE Trans. Robot. 2009, 25, 51–66. [Google Scholar] [CrossRef] [Green Version]

- Quinlivan, B.T.; Lee, S.; Malcolm, P.; Rossi, D.M.; Grimmer, M.; Siviy, C.; Karavas, N.; Wagner, D.; Asbeck, A.; Galiana, I.; et al. Assistance Magnitude Versus Metabolic Cost Reductions for A Tethered Multiarticular Soft Exosuit. Sci. Robot. 2017, 1–17. [Google Scholar] [CrossRef] [PubMed]

- Xiloyannis, M.; Chiaradia, D.; Frisoli, A.; Masia, L. Physiological and Kinematic Effects of A Soft Exosuit on Arm Movements. Neuro Eng. Rehabil. 2019, 16, 29–44. [Google Scholar] [CrossRef] [PubMed]

- Lee, G.; Ding, Y.; Bujanda, I.G.; Karavas, N.; Zhou, Y.M.; Walsh, C.J. Improved assistive profile tracking of soft exosuits for walking and jogging with off-board actuation. In Proceedings of the 2017 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Vancouver, BC, Canada, 24–28 September 2017; pp. 1699–1706. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, L.; Jiao, Z.; He, Y.; Su, P. Ergonomic Design and Performance Evaluation of H-Suit for Human Walking. Micromachines 2022, 13, 825. https://doi.org/10.3390/mi13060825

Zhang L, Jiao Z, He Y, Su P. Ergonomic Design and Performance Evaluation of H-Suit for Human Walking. Micromachines. 2022; 13(6):825. https://doi.org/10.3390/mi13060825

Chicago/Turabian StyleZhang, Leiyu, Zhenxing Jiao, Yandong He, and Peng Su. 2022. "Ergonomic Design and Performance Evaluation of H-Suit for Human Walking" Micromachines 13, no. 6: 825. https://doi.org/10.3390/mi13060825

APA StyleZhang, L., Jiao, Z., He, Y., & Su, P. (2022). Ergonomic Design and Performance Evaluation of H-Suit for Human Walking. Micromachines, 13(6), 825. https://doi.org/10.3390/mi13060825