Improving Breakdown Voltage and Threshold Voltage Stability by Clamping Channel Potential for Short-Channel Power p-GaN HEMTs

Abstract

:1. Introduction

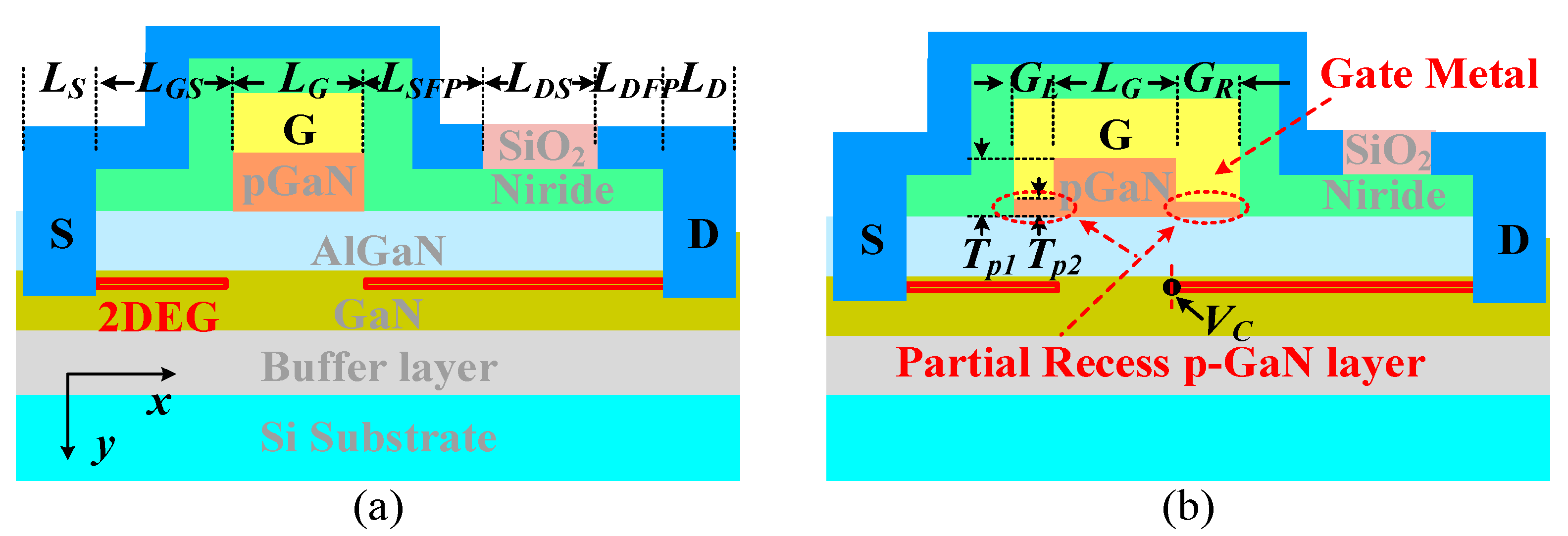

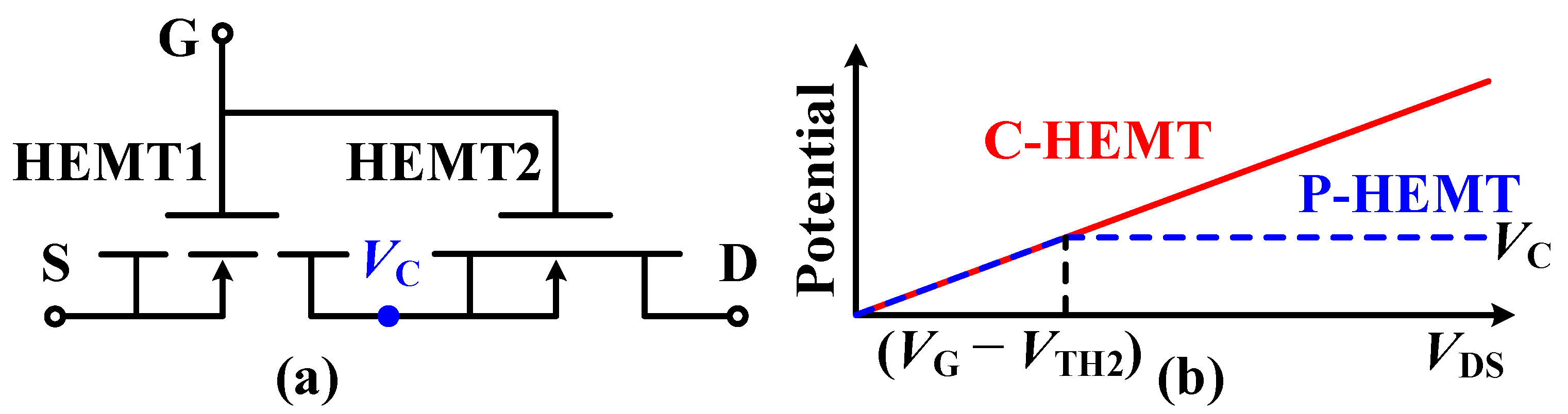

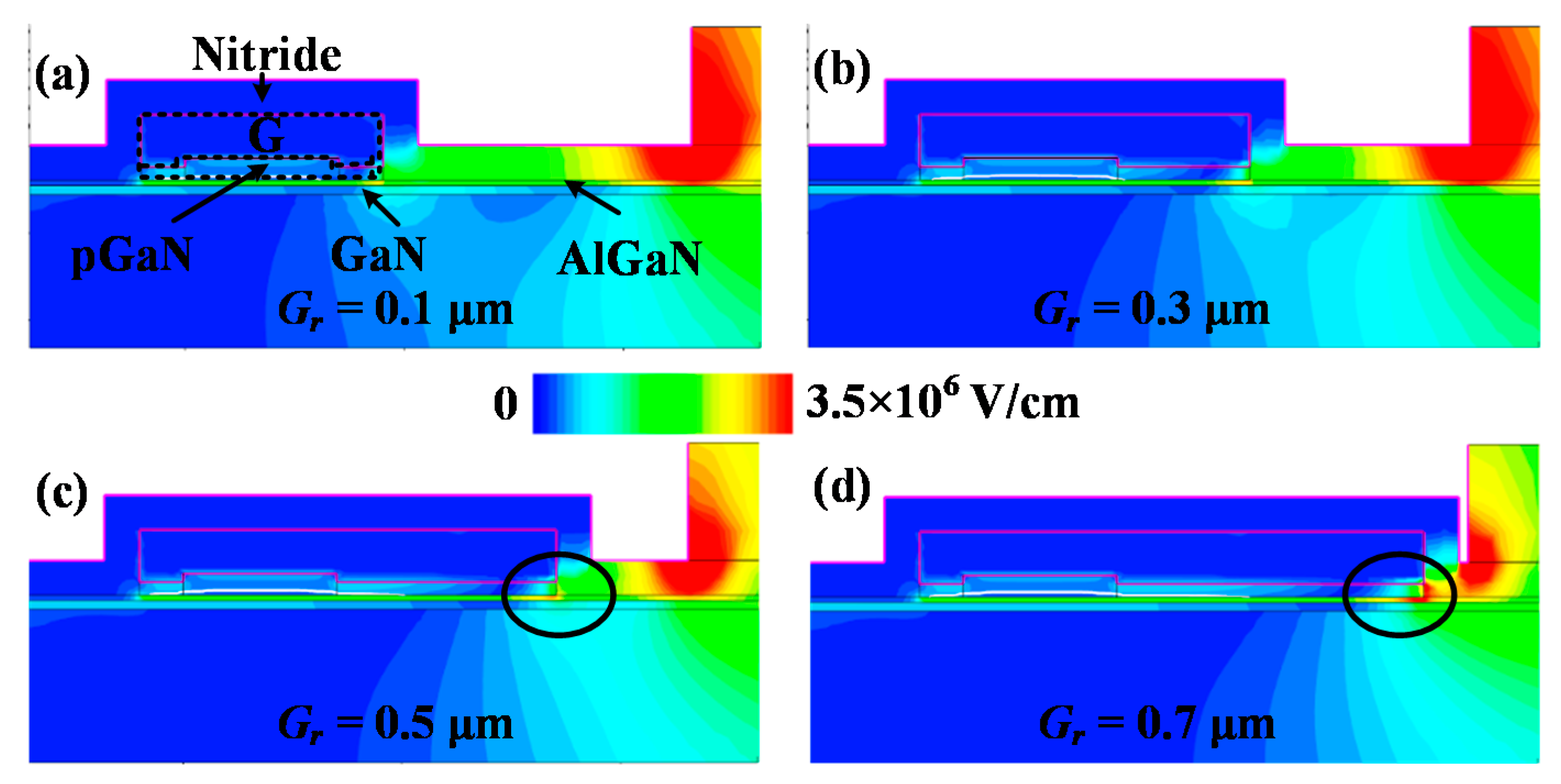

2. Device Structure and Mechanism

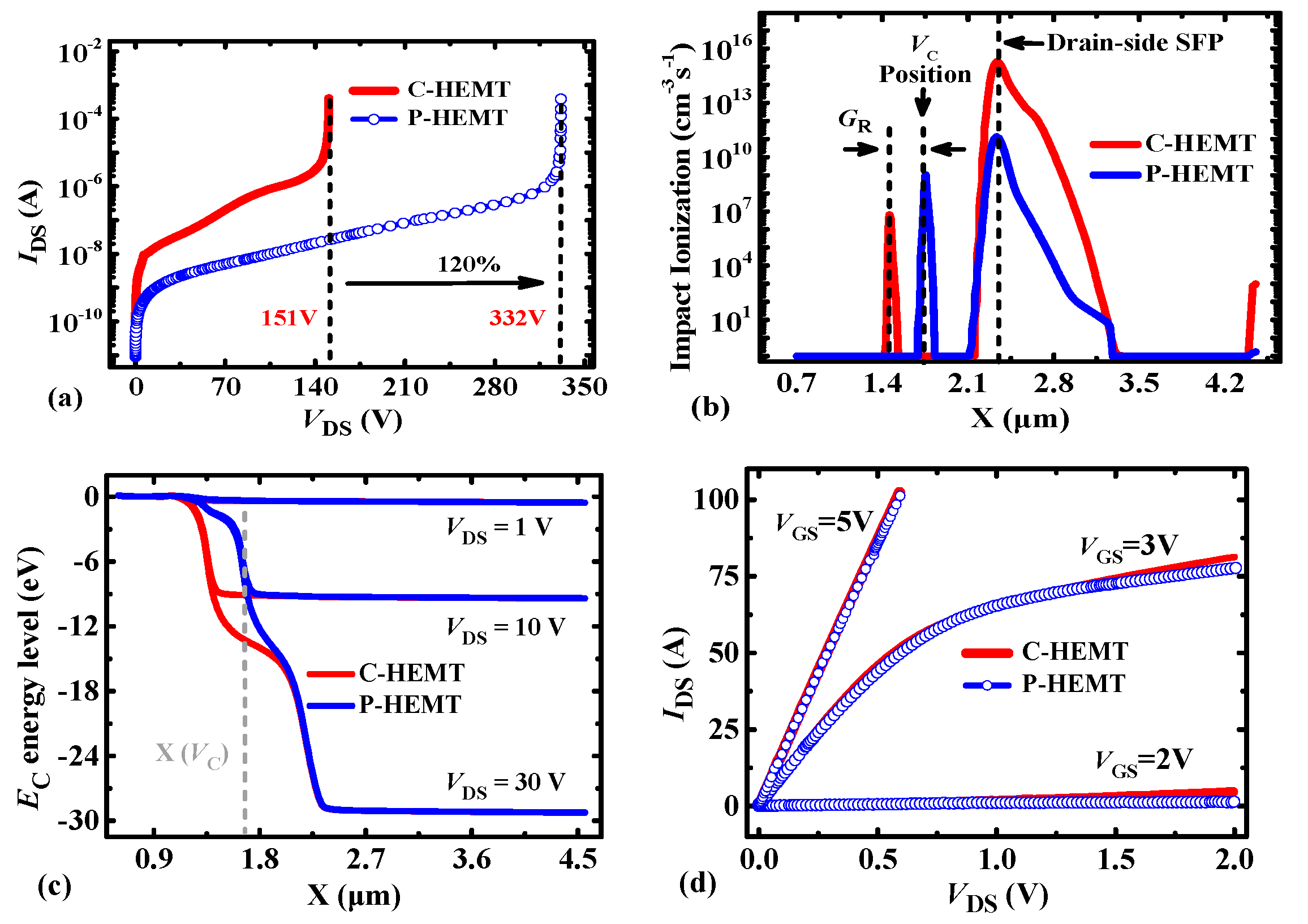

3. Results and Discussions

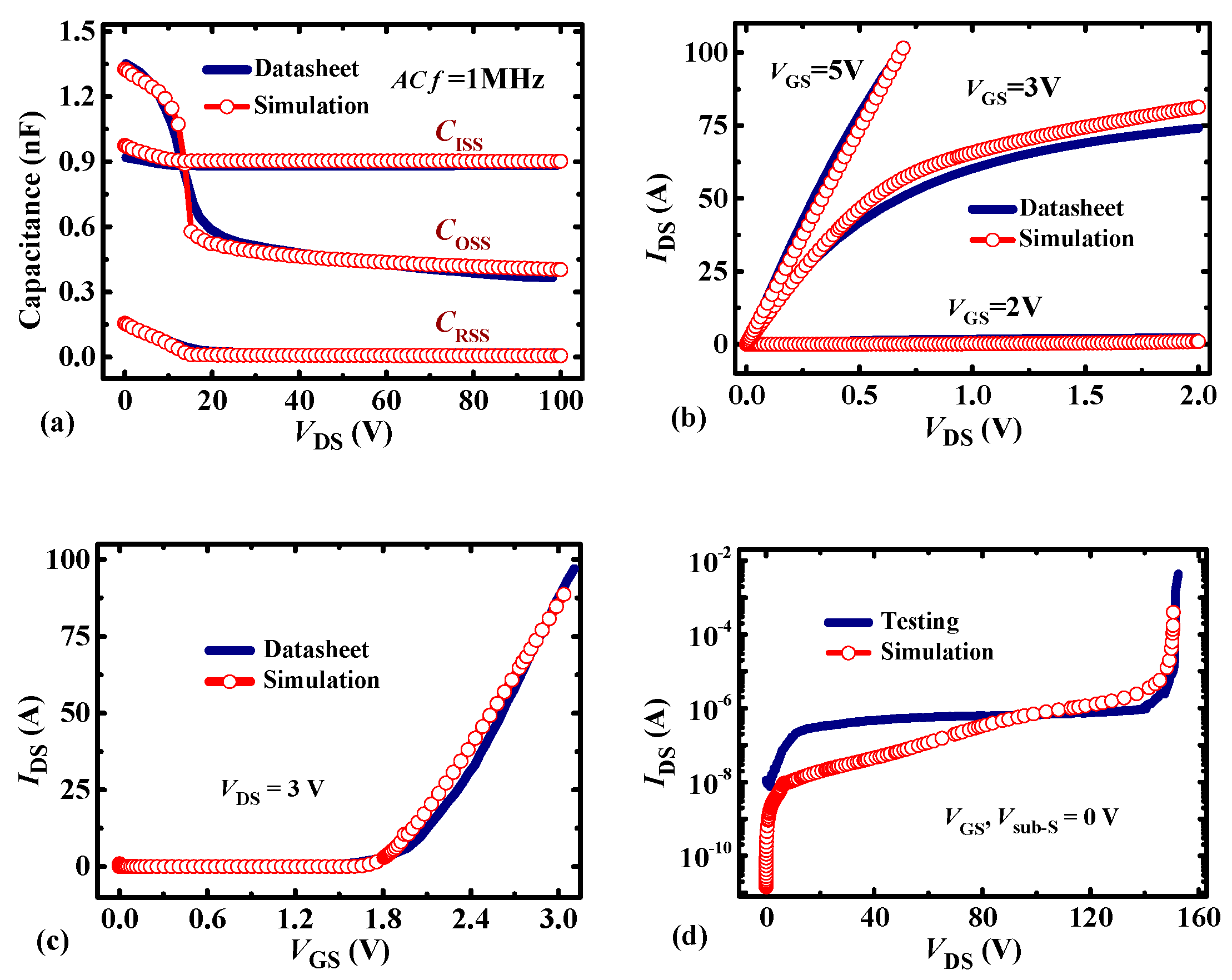

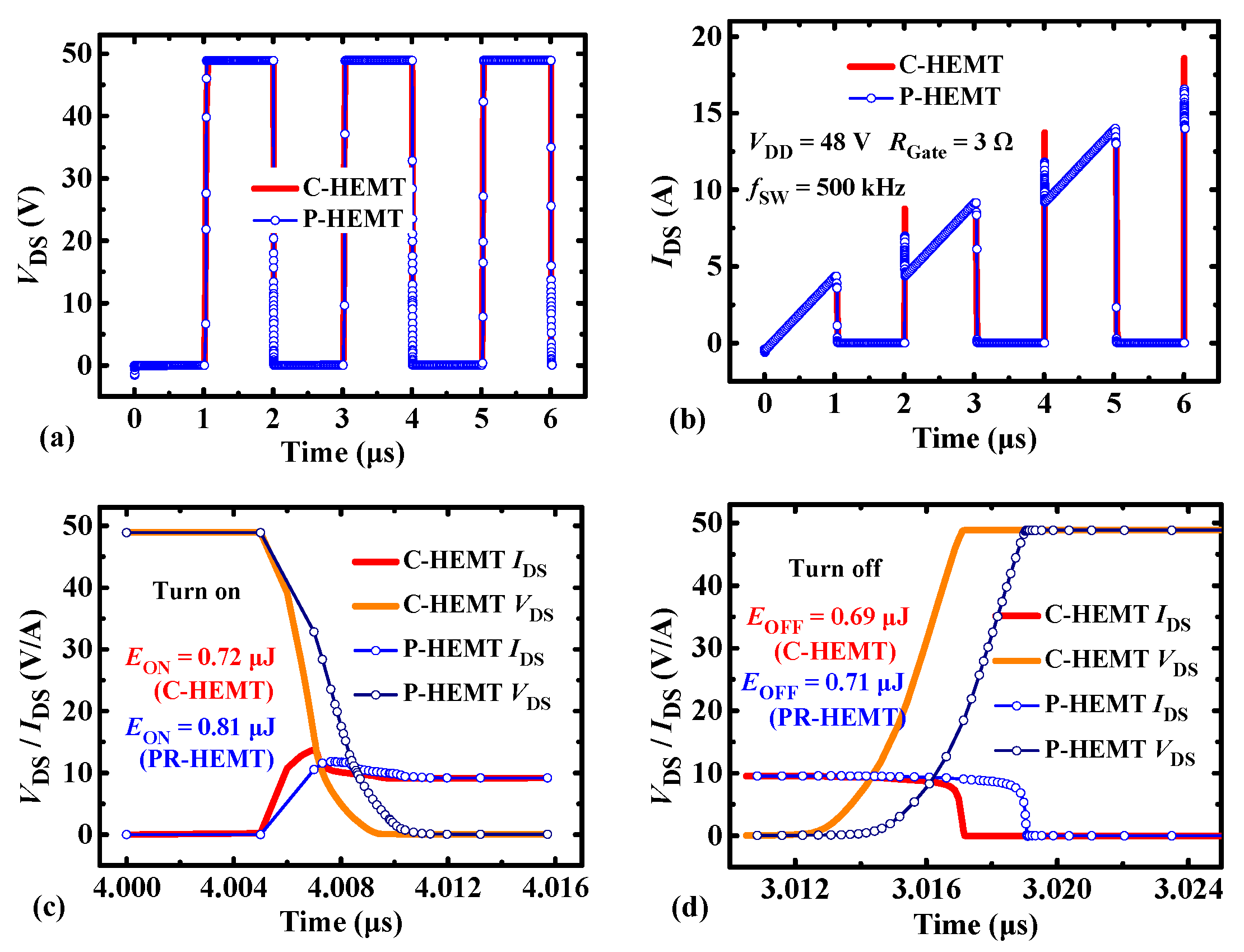

3.1. Static and Transient Characteristics

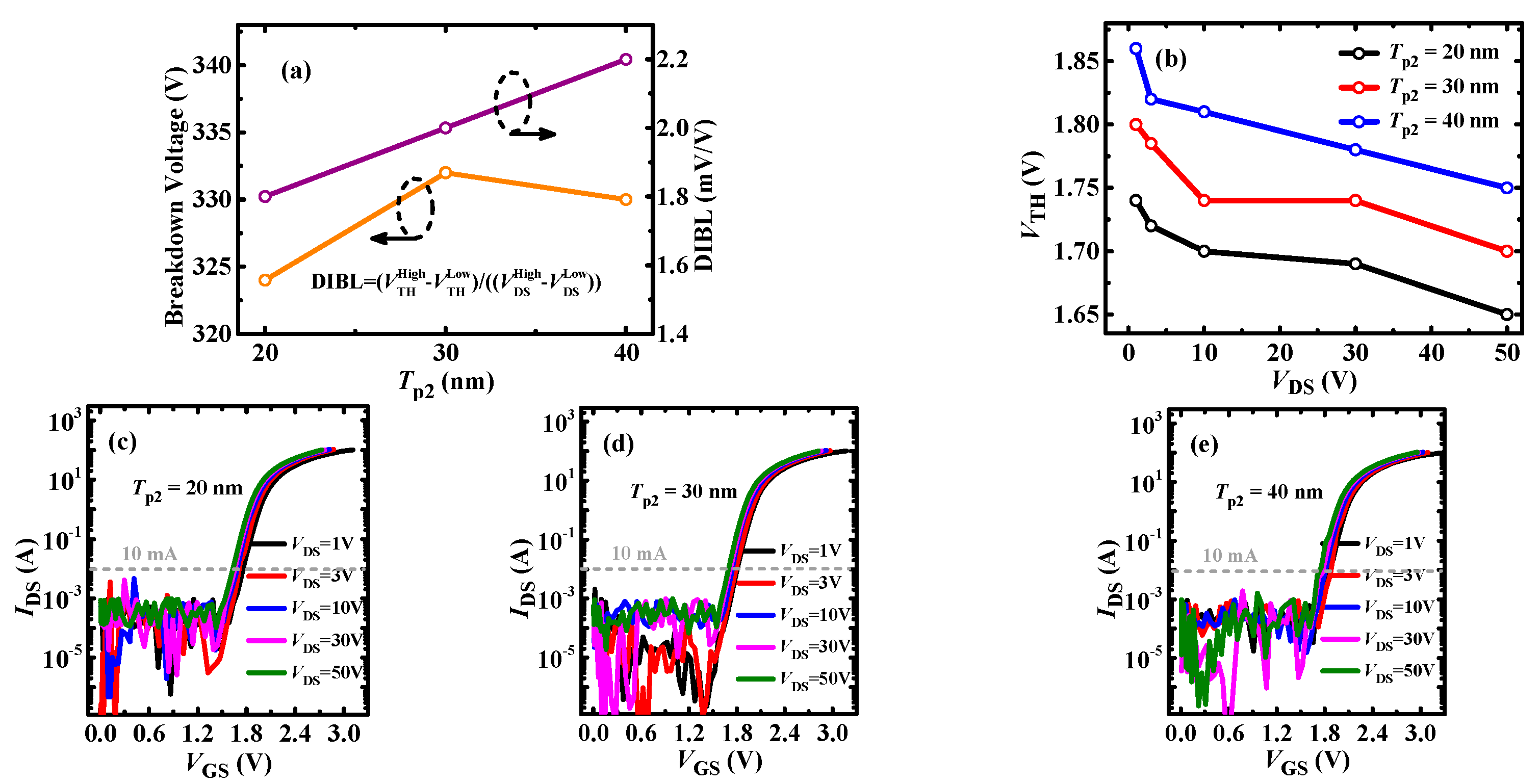

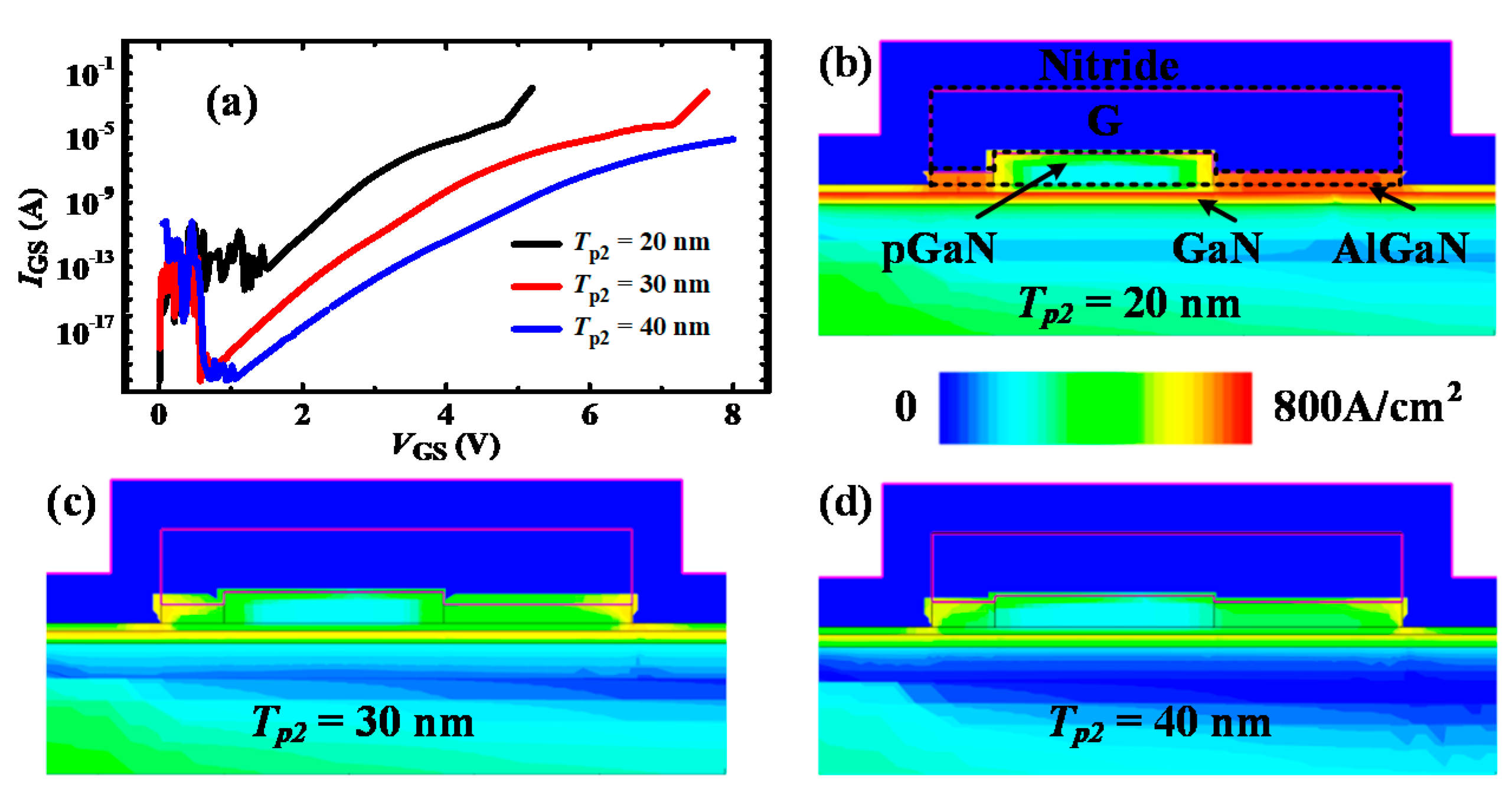

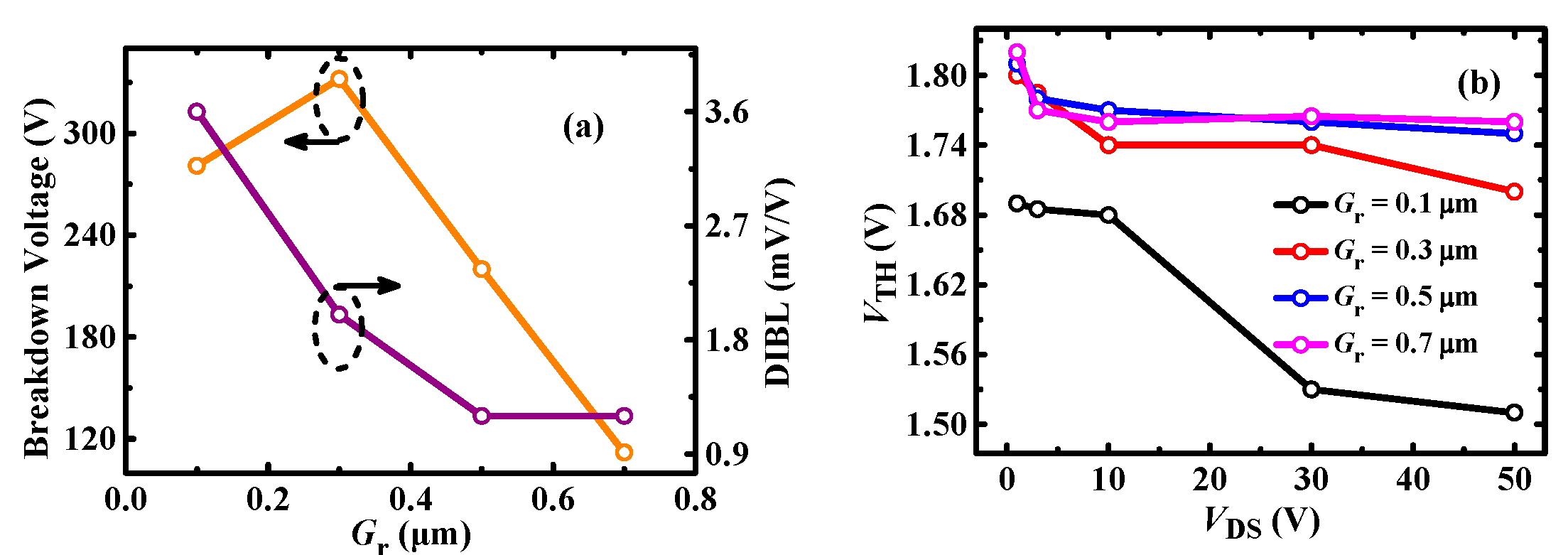

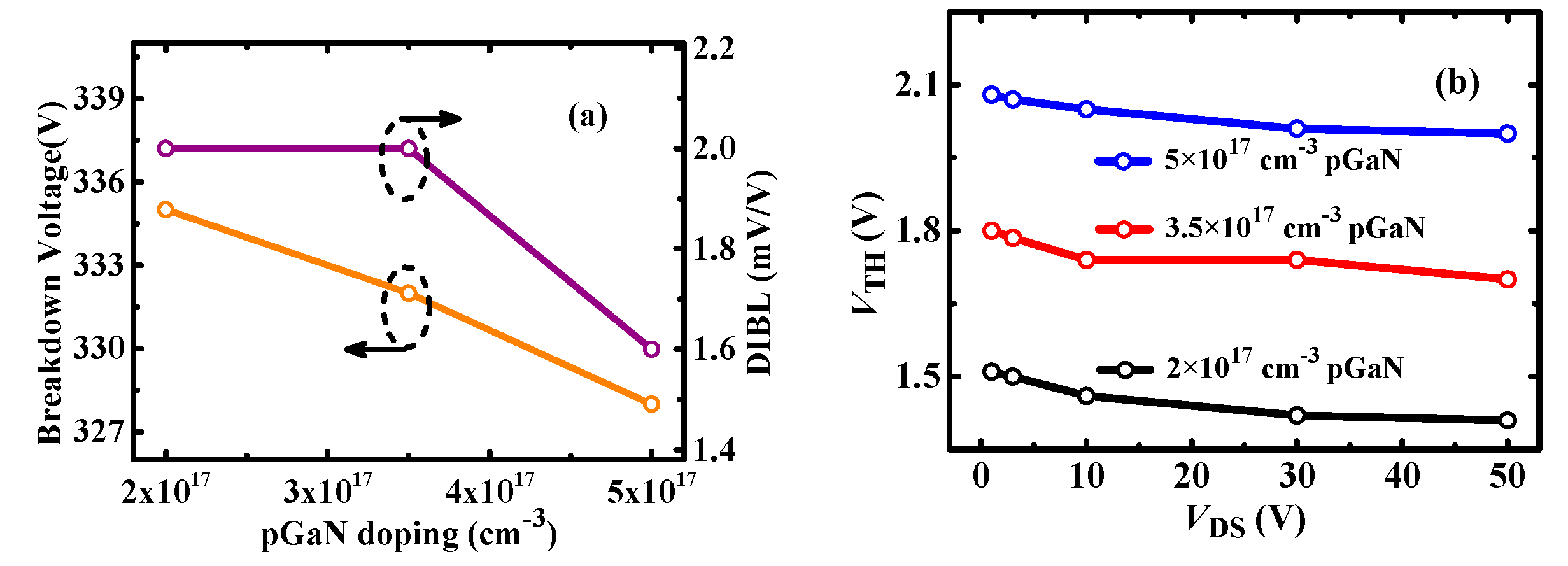

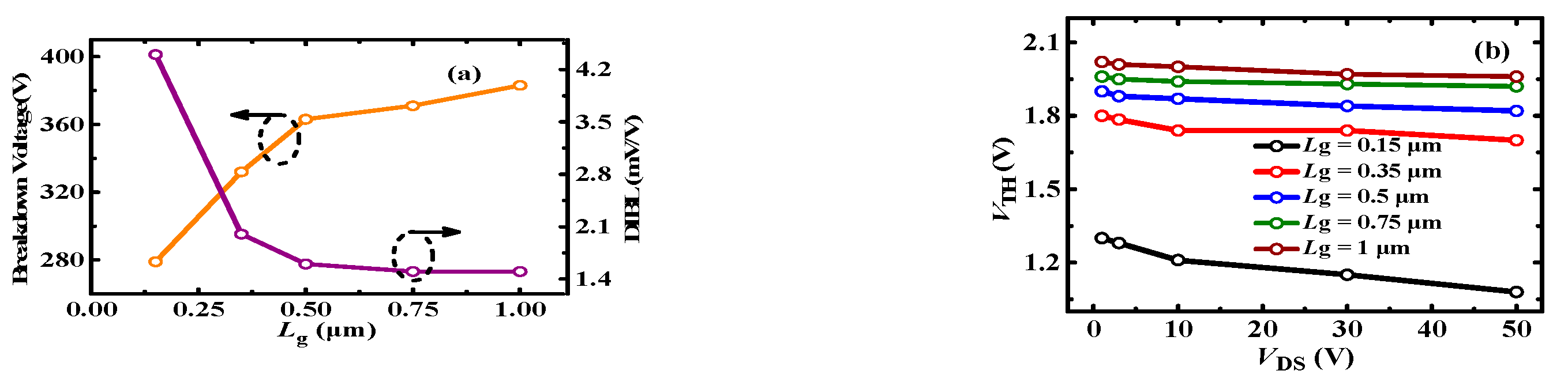

3.2. Design Considerations of P-HEMT

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chen, W.; Wong, K.-Y.; Chen, K.J. Single-Chip Boost Converter Using Monolithically Integrated AlGaN/GaN Lateral Field-Effect Rectifier and Normally Off HEMT. IEEE Electron Device Lett. 2009, 30, 430–432. [Google Scholar] [CrossRef]

- Meneghini, M.; Cibin, G.; Bertin, M.; Hurkx, G.A.M.; Ivo, P.; Šonský, J.; Croon, J.A.; Meneghesso, G.; Zanoni, E. OFF-state degradation of AlGaN/GaN power HEMTs: Experimental demonstration of time-dependent drain-source breakdown. IEEE Trans. Electron Devices 2014, 61, 1987–1992. [Google Scholar] [CrossRef]

- Meneghini, M.; Hilt, O.; Fleury, C.; Silvestri, R.; Capriotti, M.; Strasser, G.; Pogany, D.; Bahat-Treidel, E.; Brunner, F.; Knauer, A. Normally-off GaN-HEMTs with p-type gate: Off-state degradation, forward gate stress and ESD failure. Microelectron. Reliab. 2016, 58, 177–184. [Google Scholar] [CrossRef]

- Wang, H.; Wei, J.; Xie, R.; Liu, C.; Tang, G.; Chen, K.J. Maximizing the performance of 650-V p-GaN gate HEMTs: Dynamic RON characterization and circuit design considerations. IEEE Trans. Power Electron. 2016, 32, 5539–5549. [Google Scholar] [CrossRef]

- Ishida, H.; Kajitani, R.; Kinoshita, Y.; Umeda, H.; Ujita, S.; Ogawa, M.; Tanaka, K.; Morita, T.; Tamura, S.; Ishida, M.; et al. GaN-based Semiconductor Devices for Future Power Switching Systems. In Proceedings of the 2016 IEEE International Electron Devices Meeting (IEDM), San Francisco, CA, USA, 3–7 December 2016. [Google Scholar]

- Chen, K.J.; Häberlen, O.; Lidow, A.; Tsai, C.L.; Ueda, T.; Uemoto, Y.; Wu, Y. GaN-on-Si power technology: Devices and applications. IEEE Trans. Electron Devices 2017, 64, 779–795. [Google Scholar] [CrossRef]

- Kim, J.G.; Cho, C.; Kim, E.; Hwang, J.S.; Park, K.H.; Lee, J.H. High Breakdown Voltage and Low-Current Dispersion in AlGaN/GaN HEMTs with High-Quality AlN Buffer Layer. IEEE Trans. Electron Devices 2021, 68, 1513–1517. [Google Scholar] [CrossRef]

- Duan, B.; Yang, L.; Wang, Y.; Yang, Y. Experimental Results for AlGaN/GaN HEMTs Improving Breakdown Voltage and Output Current by Electric Field Modulation. IEEE Trans. Electron Devices 2021, 68, 2240–2245. [Google Scholar] [CrossRef]

- Xin, Y.; Chen, W.; Sun, R.; Shi, Y.; Liu, C.; Xia, Y.; Wang, F.; Li, M.L.J.; Zhou, Q.; Deng, X.; et al. Analytical Switching Loss Model for GaN-Based Control Switch and Synchronous Rectifier in Low-Voltage Buck Converters. IEEE J. Emerg. Sel. Top. Power Electron. 2019, 7, 1485–1495. [Google Scholar] [CrossRef]

- Zhao, X.; Xu, Y.; Jia, Y.; Wu, Y.; Xu, R.; Li, J.; Hu, Z.; Wu, H.; Dai, W.; Cai, S. Temperature-Dependent Access Resistances in Large-Signal Modeling of Millimeter-Wave AlGaN/GaN HEMTs. IEEE Trans. Microw. Theory Tech. 2017, 65, 2271–2278. [Google Scholar] [CrossRef]

- Das, S.; Kundu, S. Simulation to Study the Effect of Oxide Thickness and High-K Dielectric on Drain-Induced Barrier Lowering in N-type MOSFET. IEEE Trans. Nanotechnol. 2013, 12, 945–947. [Google Scholar] [CrossRef]

- Park, P.S.; Rajan, S. Simulation of Short-Channel Effects in N- and Ga-Polar AlGaN/GaN HEMTs. IEEE Trans. Electron Devices 2011, 58, 704–708. [Google Scholar] [CrossRef]

- Singisetti, U.; Wong, M.H.; Dasgupta, S.; Swenson, B.; Thibeault, B.J.; Speck, J.S.; Mishra, U.K. Enhancement-Mode N-Polar GaN MISFETs with Self-Aligned Source/Drain Regrowth. IEEE Electron Device Lett. 2011, 32, 137–139. [Google Scholar] [CrossRef]

- Pinchbeck, J.; Lee, K.B.; Jiang, S.; Houston, P. Dual metal gate AlGaN/GaN high electron mobility transistors with improved transconductance and reduced short channel effects. J. Phys. D Appl. Phys. 2021, 54, 105104. [Google Scholar] [CrossRef]

- Lu, B.; Saadat, O.I.; Palacios, T. High-Performance Integrated Dual-Gate AlGaN/GaN Enhancement-Mode Transistor. IEEE Electron Device Lett. 2010, 31, 990–992. [Google Scholar] [CrossRef]

- Synopsys. TCAD Sentaurus™ Tutorial. Available online: http://www.sentaurus.dsod.pl/index.html (accessed on 19 January 2022).

- Wang, F.; Chen, W.; Xu, X.; Sun, R.; Wang, Z.; Xia, Y.; Xin, Y.; Liu, C.; Zhou, Q.; Zhang, B. Simulation Study of an Ultralow Switching Loss p-GaN Gate HEMT With Dynamic Charge Storage Mechanism. IEEE Trans. Electron Devices 2021, 68, 175–183. [Google Scholar] [CrossRef]

- Lidow, A.; de Rooij, M.; Strydom, J.; Reusch, D.; Glaser, J. GaN Transistors for Efficient Power Conversion; John Wiley & Sons: Hoboken, NJ, USA, 2019. [Google Scholar]

- Joshi, V.; Tiwari, S.P.; Shrivastava, M. Part I: Physical Insight Into Carbon-Doping-Induced Delayed Avalanche Action in GaN Buffer in AlGaN/GaN HEMTs. IEEE Trans. Electron Devices 2019, 66, 561–569. [Google Scholar] [CrossRef]

- Verzellesi, G.; Morassi, L.; Meneghesso, G.; Meneghini, M.; Zanoni, E.; Pozzovivo, G.; Lavanga, S.; Detzel, T.; Häberlen, O.; Curatola, G. Influence of Buffer Carbon Doping on Pulse and AC Behavior of Insulated-Gate Field-Plated Power AlGaN/GaN HEMTs. IEEE Electron Device Lett. 2014, 35, 443–445. [Google Scholar] [CrossRef]

- Chini, A.; Meneghesso, G.; Meneghini, M.; Fantini, F.; Verzellesi, G.; Patti, A.; Iucolano, F. Experimental and Numerical Analysis of Hole Emission Process From Carbon-Related Traps in GaN Buffer Layers. IEEE Trans. Electron Devices 2016, 63, 3473–3478. [Google Scholar] [CrossRef]

- EPC. eGaN FET Datasheet. Available online: https://epc-co.com/epc/Portals/0/epc/documents/datasheets/epc2001_datasheet.pdf (accessed on 19 January 2022).

- Cheng, Y.; Wang, Y.; Feng, S.; Zheng, Z.; Chen, K.J. Observation and characterization of impact ionization-induced OFF-state breakdown in Schottky-type p-GaN gate HEMTs. Appl. Phys. Lett. 2021, 118, 163502. [Google Scholar] [CrossRef]

- Wang, F.; Chen, W.; Li, X.; Sun, R.; Zhang, B. Charge storage impact on input capacitance in p-GaN gate AlGaN/GaN power high-electron-mobility transistors. J. Phys. D Appl. Phys. 2020, 53, 305106. [Google Scholar] [CrossRef]

| Symbols | Definitions | Typical Value |

|---|---|---|

| LS | Source length | 0.7 μm |

| LG | Gate length | 0.35 μm |

| LD | Source-to-gate length | 0.7 μm |

| LGS | Source-to-gate length | 0.4 μm |

| LDS-C | C-HEMT Gate-to-drain length | 1.95 μm |

| LDS-PR | P-HEMT Gate-to-drain length | 1.95 μm |

| LSFP-C | C-HEMT Source-field-plate length | 0.8 μm |

| LSF-PR | P-HEMT Source-field-plate length | (0.8—Gr) μm |

| LDFP | Drain-field-plate length | 0.25 μm |

| tSiN | Thickness of SiN | 80 nm |

| tSiO2 | Thickness of SiO2 | 270 nm |

| GL | The left PR p-GaN length | 0.1 μm |

| GR | The right PR p-GaN length | 0.3 μm |

| Tp2 | Thickness of PR p-GaN | 30 nm |

| Tp1 | Thickness of p-GaN | 50 nm |

| tba | Thickness of barrier | 12.5 nm |

| tch | Thickness of channel | 20 nm |

| tbu | Thickness of buffer | 2 μm |

| tnu | Thickness of nucleation | 10 nm |

| tsub | Thickness of substrate | 550 μm |

| tgate | Thickness of Schottky gate | 100 nm |

| χba | Al composition of barrier | 25% |

| χbu | Al composition of buffer | 5% |

| WG | Work-function of the gate | 4.8 eV |

| NDT1 | Nitride/AlGaN trap density | 3 × 1013 cm−2 (EC − 0.4 eV) [24] |

| NDTC | Channel UID concentration | 1 × 1015 cm−3 |

| NAT1 | Buffer acceptor trap density | 3 × 1016 cm−3 (EV + 0.9 eV) [17] |

| NDT2 | Buffer donor trap density | 1.3 × 1015 cm−3 (EC − 0.11 eV) |

| NAT2 | Silicon/AlN acceptor trap density | 3 × 1013 cm−2 (EC − 1.7 eV) |

| Np-GaN | Activated Mg Doping | 3.5 × 1017 cm−3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, H.; Shi, Y.; Xin, Y.; Liu, C.; Lu, G.; Huang, Y. Improving Breakdown Voltage and Threshold Voltage Stability by Clamping Channel Potential for Short-Channel Power p-GaN HEMTs. Micromachines 2022, 13, 176. https://doi.org/10.3390/mi13020176

Wang H, Shi Y, Xin Y, Liu C, Lu G, Huang Y. Improving Breakdown Voltage and Threshold Voltage Stability by Clamping Channel Potential for Short-Channel Power p-GaN HEMTs. Micromachines. 2022; 13(2):176. https://doi.org/10.3390/mi13020176

Chicago/Turabian StyleWang, Hongyue, Yijun Shi, Yajie Xin, Chang Liu, Guoguang Lu, and Yun Huang. 2022. "Improving Breakdown Voltage and Threshold Voltage Stability by Clamping Channel Potential for Short-Channel Power p-GaN HEMTs" Micromachines 13, no. 2: 176. https://doi.org/10.3390/mi13020176

APA StyleWang, H., Shi, Y., Xin, Y., Liu, C., Lu, G., & Huang, Y. (2022). Improving Breakdown Voltage and Threshold Voltage Stability by Clamping Channel Potential for Short-Channel Power p-GaN HEMTs. Micromachines, 13(2), 176. https://doi.org/10.3390/mi13020176