Design Approach for Reducing Cross-Axis Sensitivity in a Single-Drive Multi-Axis MEMS Gyroscope

Abstract

:1. Introduction

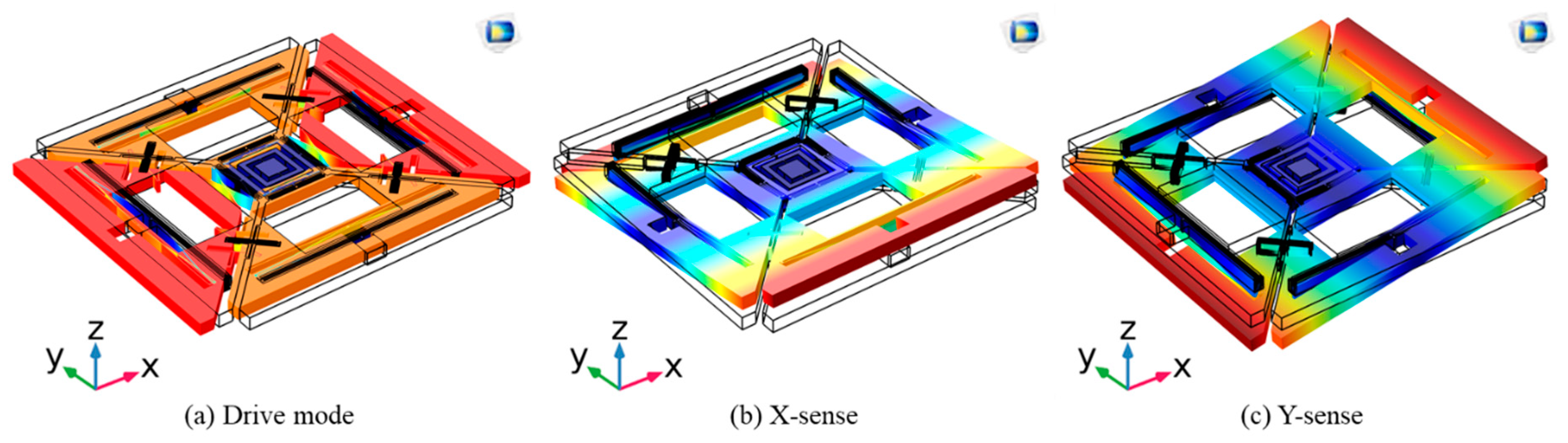

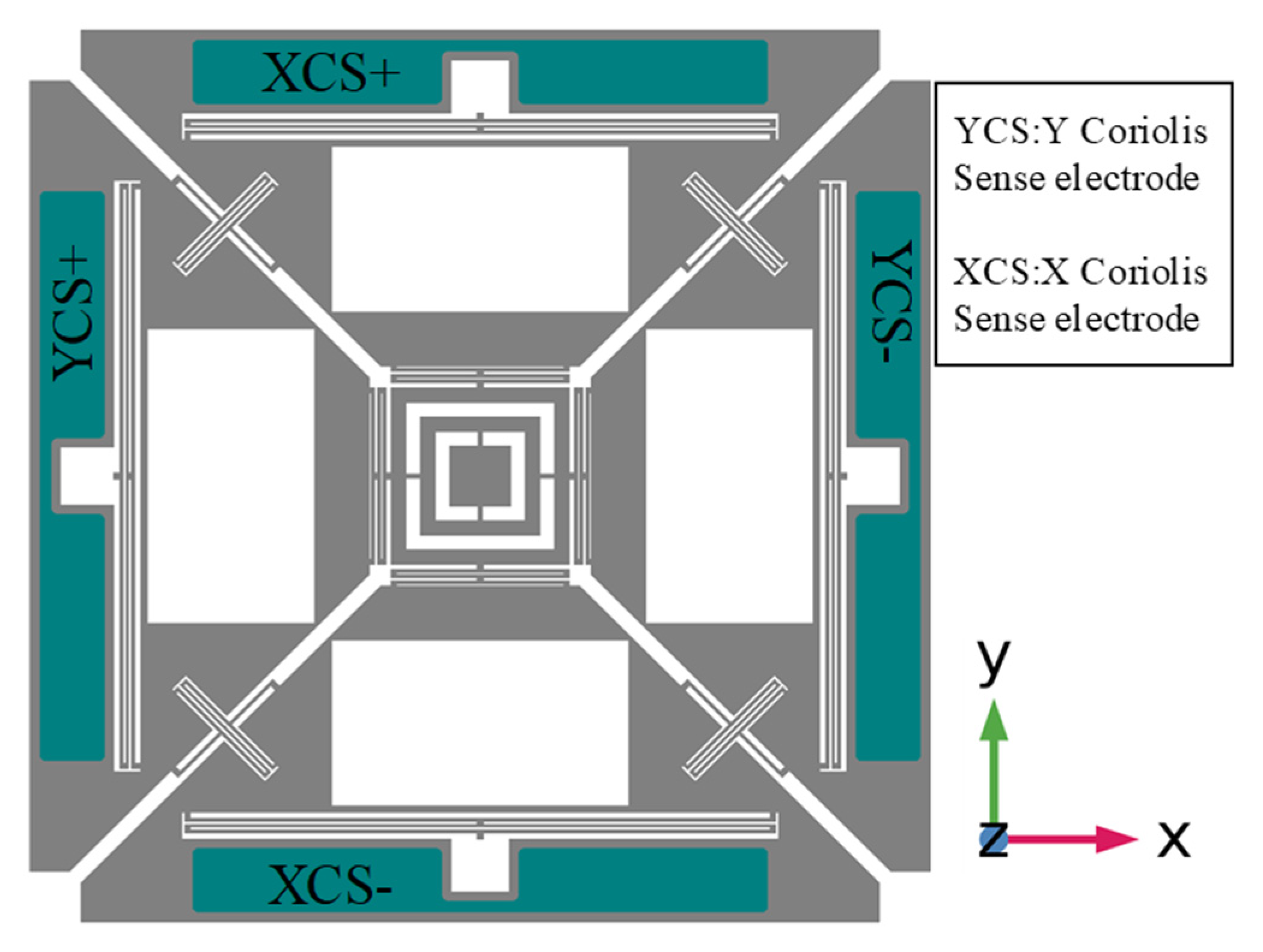

2. Mechanical Structure of the Designed Gyroscope

3. Cross-Axis Sensitivity Modeling

3.1. Gyroscope’s Cross-Axis Sensitivity

3.2. Cross-Axis Sensitivity Modeling in the Designed Gyroscope

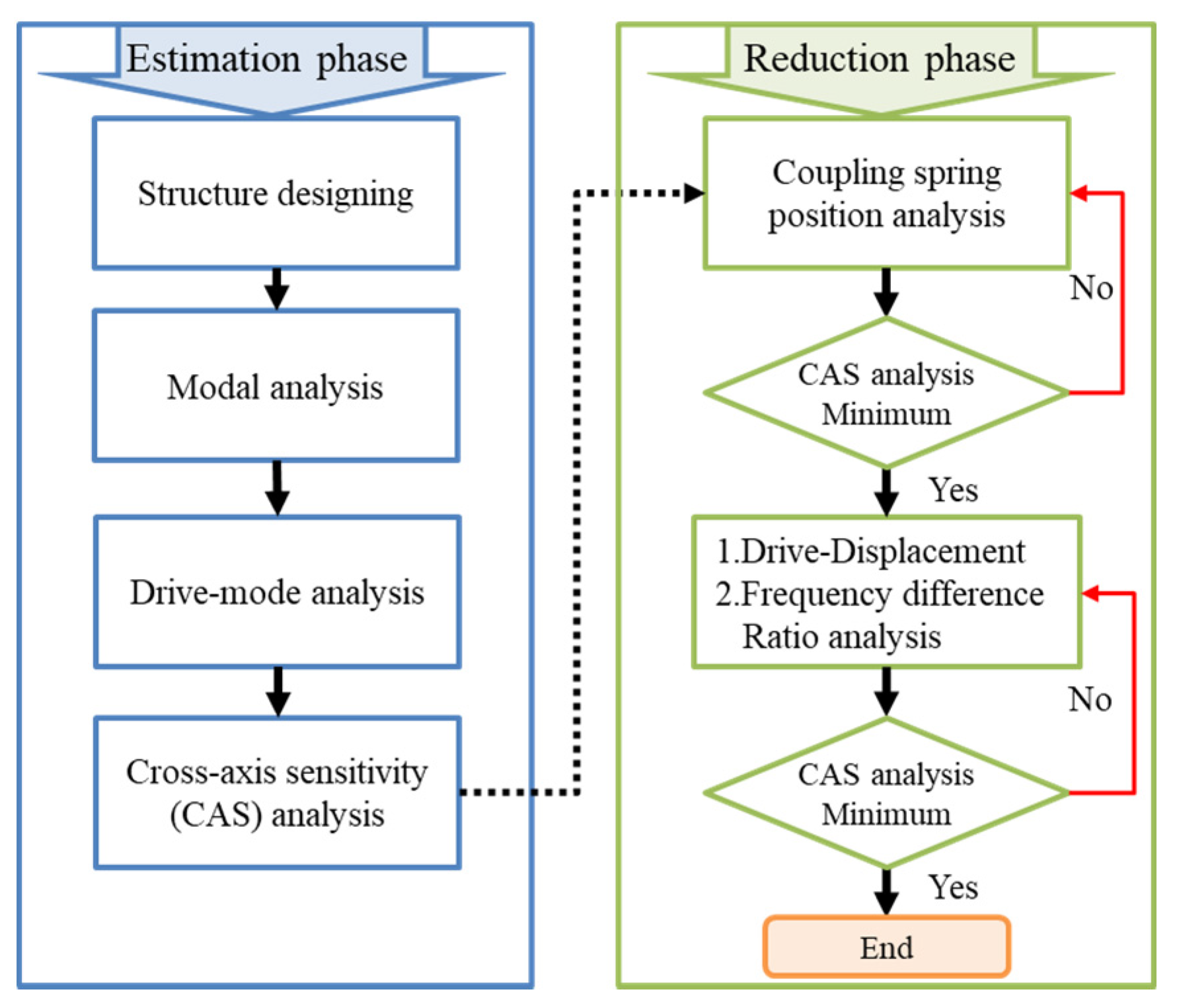

4. Design Approach

4.1. Numerical Analysis of Cross-Axis Sensitivity in the Designed Gyroscope

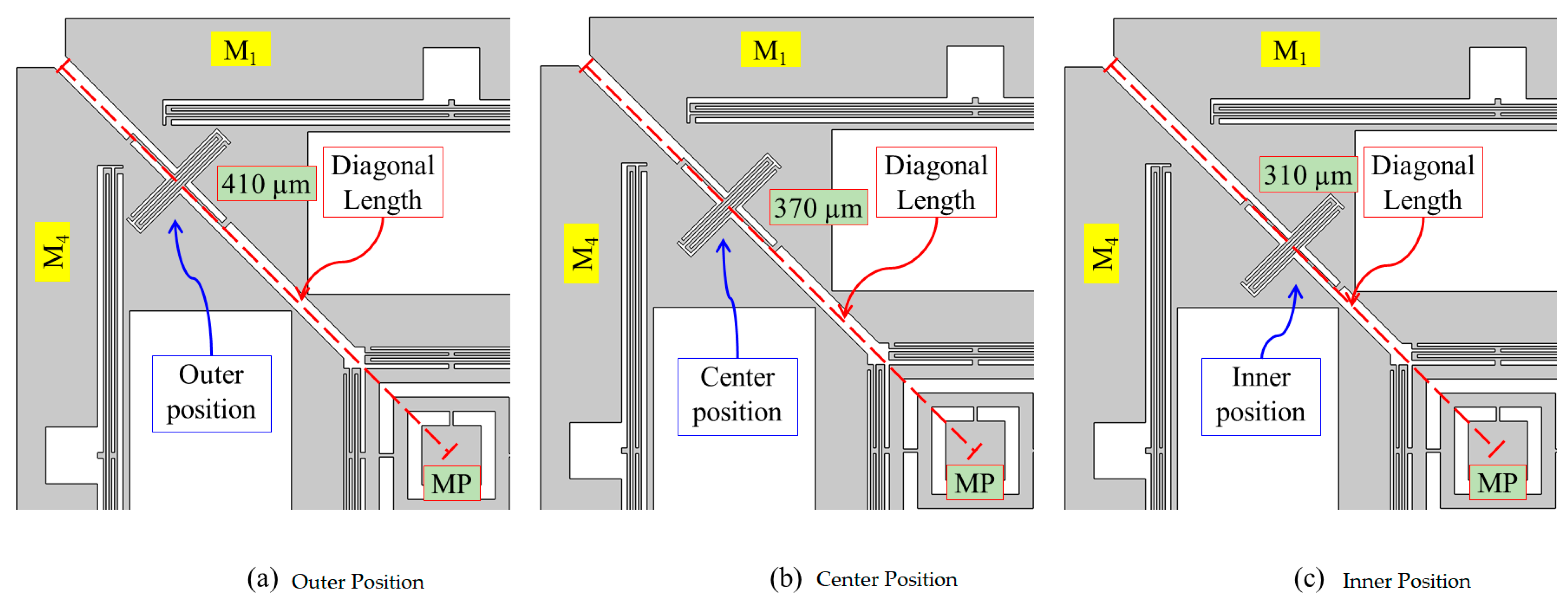

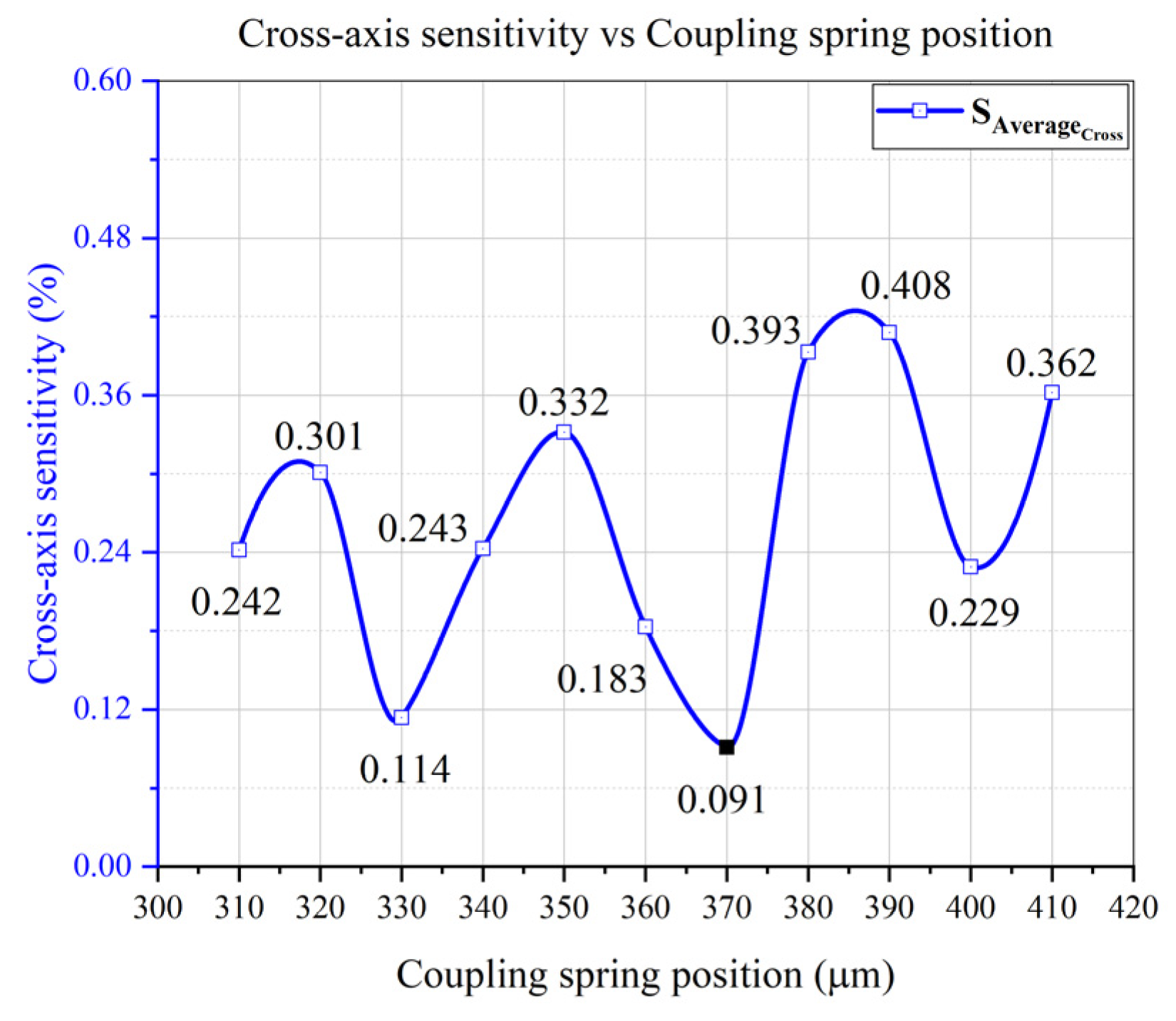

4.2. Effect of Coupling Spring Position on the CAS in the Designed Gyroscope

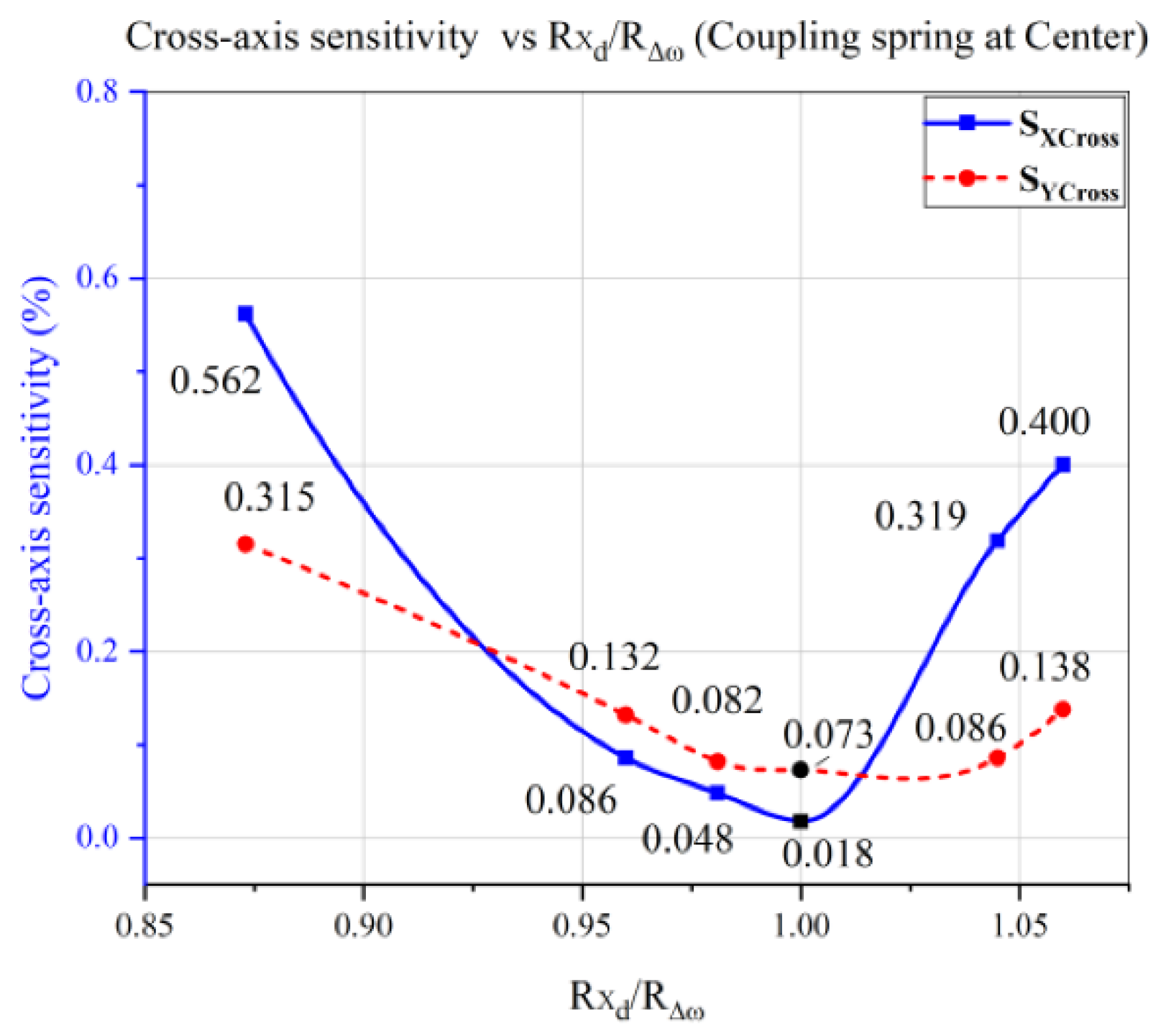

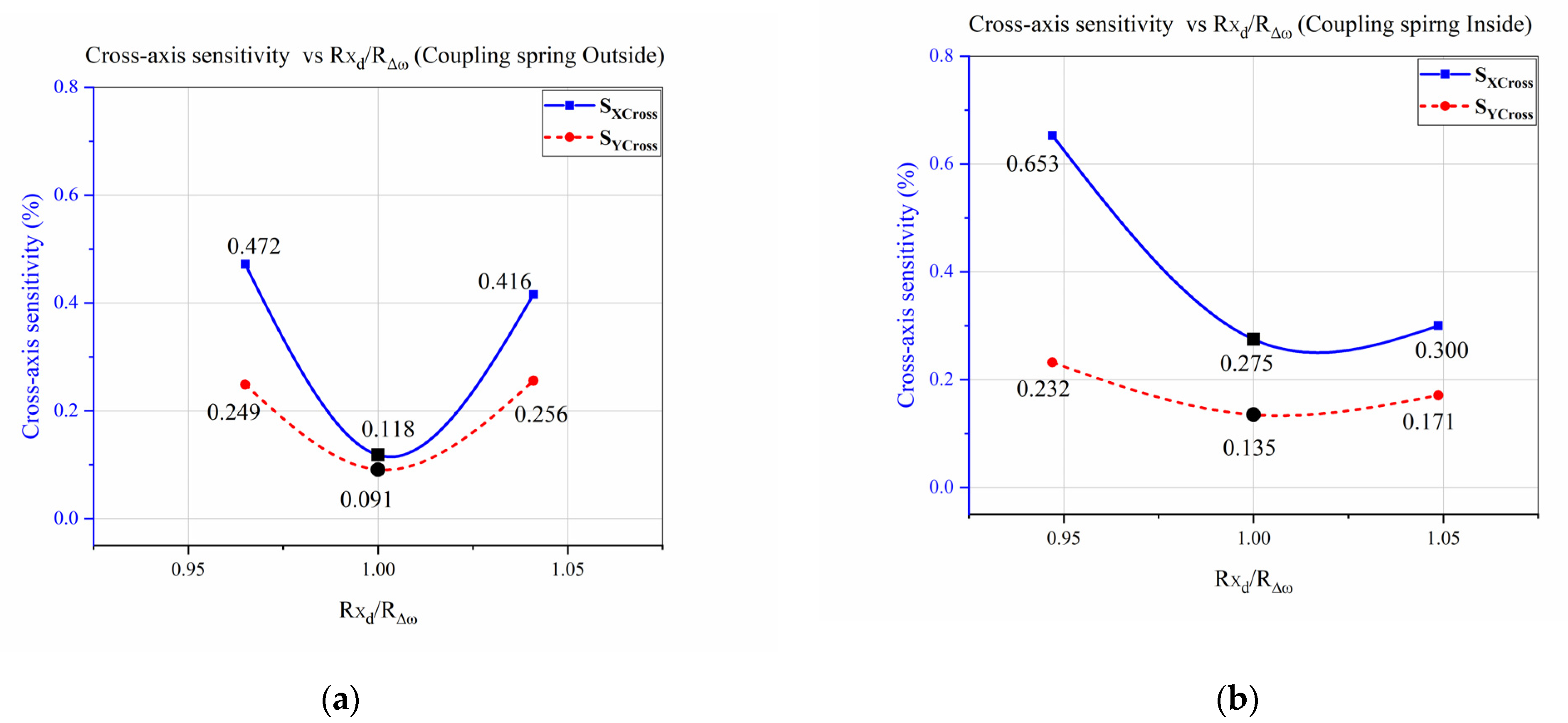

4.3. Drive Displacement Amplitudes vs. Sense Frequency Differences Analysis

5. Results and Discussion

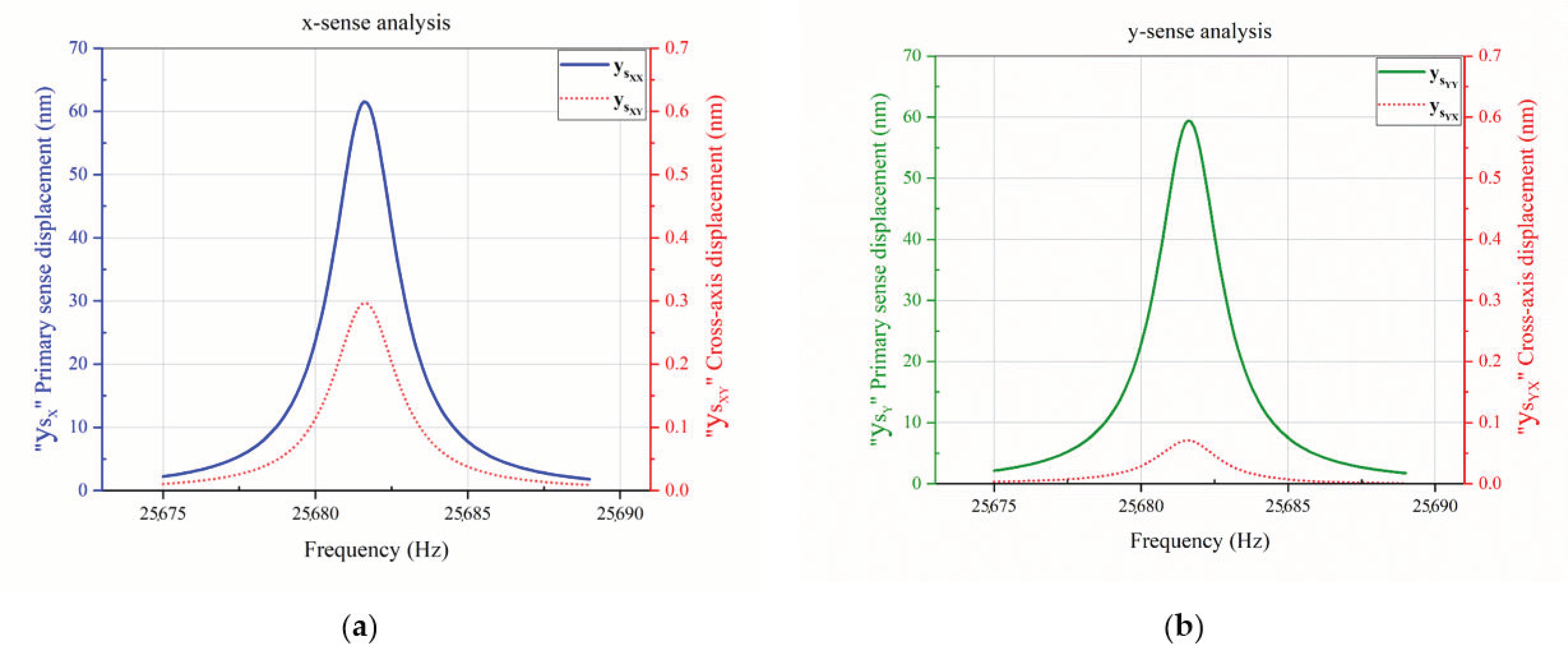

5.1. Simulation Results

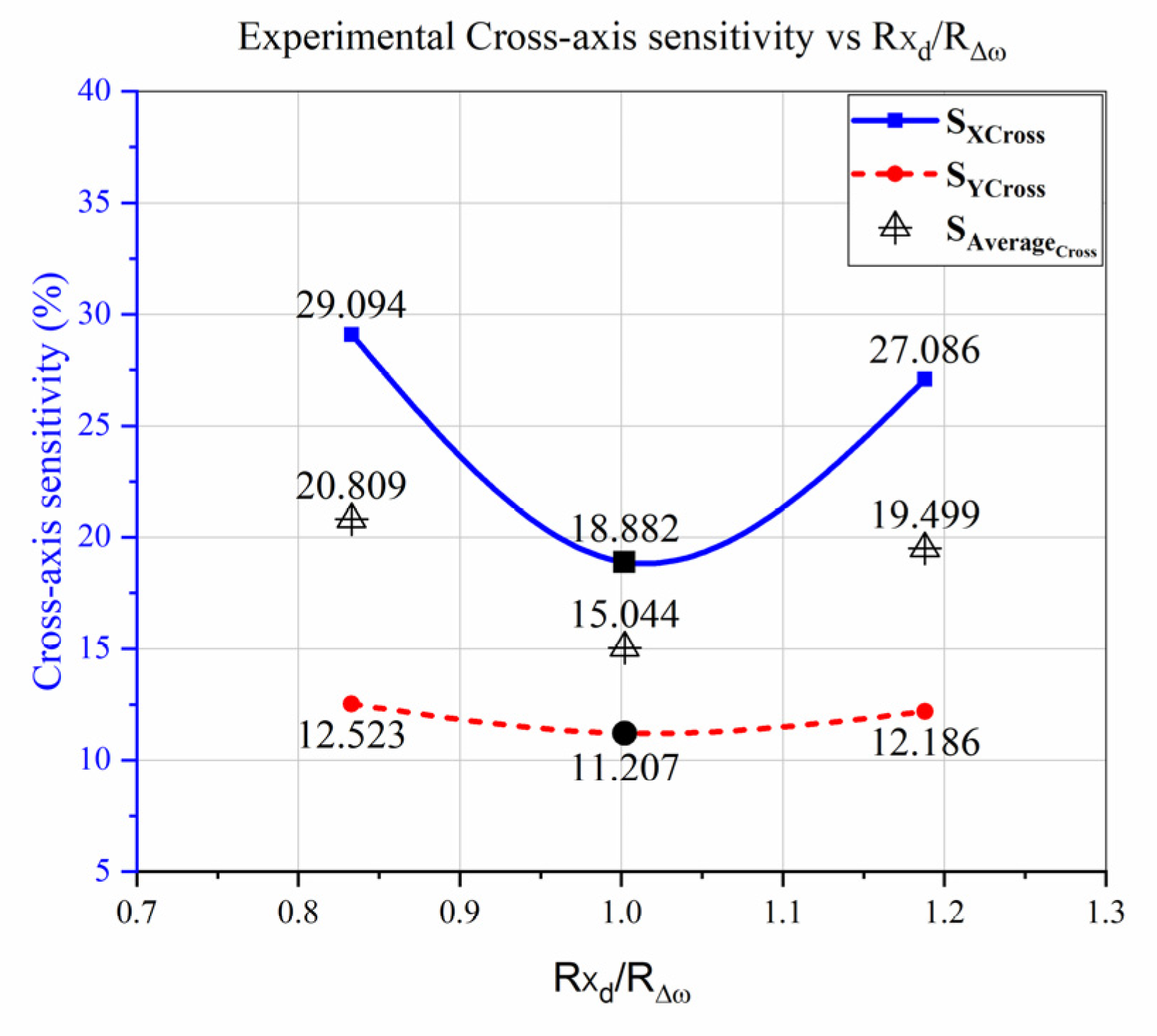

5.2. Experimental Results

6. Conclusions and Future Work

Author Contributions

Funding

Conflicts of Interest

References

- Acar, C.; Schofield, A.R.; Trusov, A.A.; Costlow, L.E.; Shkel, A.M. Environmentally robust MEMS vibratory gyroscopes for automotive applications. IEEE Sens. J. 2009, 9, 1895–1906. [Google Scholar] [CrossRef]

- Xia, D.; Yu, C.; Kong, L. The development of micromachined gyroscope structure and circuitry technology. Sensors 2014, 14, 1394–1473. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Traechtler, M.; Link, T.; Dehnert, J.; Auber, J.; Nommensen, P.; Manoli, Y. Novel 3-Axis Gyroscope on a Single Chip Using SOI-Technology; Sensors, 2007 IEEE: Atlanta, GA, USA, 2007; pp. 124–127. [Google Scholar]

- Trusov, A.A. Overview of MEMS Gyroscopes: History, Principles of Operations, Types of Measurements; University of California: Irvine, CA, USA, 2011. [Google Scholar]

- Wagner, S.; Niklaus, F.; Mokwa, W.; Lemme, M.C. 2D Materials for Piezoresistive Strain Gauges and Membrane Based Nanoelectromechanical Systems. Ph.D. Thesis, RWTH Aachen University, Aachen, Germany, 2018. [Google Scholar]

- Mounier, E. Future of MEMS: A Market & Technologies Perspective. 2014. Available online: http://www1.semi.org/eu/sites/semi.org/files/images/Eric%20Mounier%20-%20Future%20of%20MEMS.%20A%20Market%20and%20Technologies%20Perspective.pdf (accessed on 26 December 2020).

- Ahmad, N.; Ghazilla, R.A.R.; Khairi, N.M.; Kasi, V. Reviews on various inertial measurement unit (IMU) sensor applications. Int. J. Signal Process. Syst. 2013, 1, 256–262. [Google Scholar] [CrossRef] [Green Version]

- Nasiri, S. A Critical Review of MEMS Gyroscopes Technology and Commercialization Status; Inven Sense: San Jose, CA, USA, 2005. [Google Scholar]

- Liu, K.; Zhang, W.; Chen, W.; Li, K.; Dai, F.; Cui, F.; Wu, X.; Ma, G.; Xiao, Q. The development of micro-gyroscope technology. J. Micromech. Microeng. 2009, 19, 113001. [Google Scholar] [CrossRef]

- Ayazi, F.; Najafi, K. A HARPSS polysilicon vibrating ring gyroscope. J. Microelectromech. Syst. 2001, 10, 169–179. [Google Scholar] [CrossRef] [Green Version]

- Sonmezoglu, S.; Taheri-Tehrani, P.; Valzasina, C.; Falorni, L.G.; Zerbini, S.; Nitzan, S.; Horsley, D.A. Single-structure micromachined three-axis gyroscope with reduced drive-force coupling. IEEE Electron. Device Lett. 2015, 36, 953–956. [Google Scholar] [CrossRef]

- Guerinoni, L.; Falorni, L.G.; Gattere, G. Modelling Cross Axis Sensitivity in MEMS Coriolis Vibratory Gyroscopes. Multidiscip. Digit. Publ. Inst. Proc. 2017, 1, 281. [Google Scholar] [CrossRef] [Green Version]

- Li, Z.; Gao, S.; Jin, L.; Liu, H.; Guan, Y.; Peng, S. Design and mechanical sensitivity analysis of a MEMS tuning fork gyroscope with an anchored leverage mechanism. Sensors 2019, 19, 3455. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kim, Y.W.; Yoo, H.H. Design of a vibrating MEMS gyroscope considering design variable uncertainties. J. Mech. Sci. Technol. 2010, 24, 2175–2180. [Google Scholar] [CrossRef]

- Weinberg, M.S.; Kourepenis, A. Error sources in in-plane silicon tuning-fork MEMS gyroscopes. J. Microelectromech. Syst. 2006, 15, 479–491. [Google Scholar] [CrossRef]

- Acar, C. Micromachined Monolithic 3-Axis Gyroscope with Single Drive. U.S. Patent No. 9,246,018, 26 January 2016. [Google Scholar]

- Prandi, L.; Caminada, C.; Coronato, L.; Cazzaniga, G.; Biganzoli, F.; Antonello, R.; Oboe, R. A low-power 3-axis digital-output MEMS gyroscope with single drive and multiplexed angular rate readout. In Proceedings of the 2011 IEEE International Solid-State Circuits Conference, San Francisco, CA, USA, 20–24 February 2011; IEEE: New York, NY, USA, 2001. [Google Scholar]

- Cazzaniga, G.; Coronato, L. Integrated Microelectromechanical Gyroscope with Improved Driving Structure. U.S. Patent No. 8,459,110, 11 June 2013. [Google Scholar]

- Sung, W.; Dalal, M.; Ayazi, F. A mode-matched 0.9 MHz single proof-mass dual-axis gyroscope. In Proceedings of the 2011 16th International Solid-State Sensors, Actuators and Microsystems Conference, Beijing, China, 5–9 June 2011; IEEE: New York, NY, USA, 2011; pp. 2821–2824. [Google Scholar]

- Tsai, N.-C.; Sue, C.-Y. Experimental analysis and characterization of electrostatic-drive tri-axis micro-gyroscope. Sens. Actuators A Phys. 2010, 158, 231–239. [Google Scholar] [CrossRef]

- Juneau, T.; Pisano, A.; Smith, J.H. Dual axis operation of a micromachined rate gyroscope. In Proceedings of the International Solid State Sensors and Actuators Conference, Chicago, IL, USA, 19 June 1997; IEEE: New York, NY, USA, 1997; pp. 883–886. [Google Scholar]

- Yang, B.; Lu, C. Design and analysis of a new three-axis micro-gyroscope. Microsyst. Technol. 2018, 24, 1213–1222. [Google Scholar] [CrossRef]

- Yuzawa, A.; Gando, R.; Masunishi, K.; Ogawa, E.; Hiraga, H.; Tomizawa, Y. A 3-Axis Catch-and-Release Gyroscope with Pantograph Vibration for Low-Power and Fast Start-Up Applications. In Proceedings of the 2019 20th International Conference on Solid-State Sensors, Actuators and Microsystems & Eurosensors XXXIII (TRANSDUCERS & EUROSENSORS XXXIII), Berlin, Germany, 23–27 June 2019; IEEE: New York, NY, USA, 2019; pp. 430–433. [Google Scholar]

- Iqbal, F.; Din, H.; Lee, B. Time Efficient Evaluation of Multi-axis MEMS Gyroscope Using Three-dimensional Test Methodology. J. Semicond. Technol. Sci. 2019, 19, 600–607. [Google Scholar] [CrossRef]

- Painter, C.; Shkel, A. Effect of levitation forces on the performance of surface micromachined MEMS gyroscopes. Sensors 2004, 508–511. [Google Scholar]

- Efimovskaya, A.; Yang, Y.; Ng, E.; Chen, Y.; Flader, I.; Kenny, T.W.; Shkel, A.M. Compact roll-pitch-yaw gyroscope implemented in wafer-level epitaxial silicon encapsulation process. In Proceedings of the 2017 IEEE International Symposium on Inertial Sensors and Systems (INERTIAL), Kauai, HI, USA, 27–30 March 2017; IEEE: New York, NY, USA, 2017; pp. 1–2. [Google Scholar]

- Din, H.; Iqbal, F.; Lee, B. Modelling and optimization of single drive 3-axis MEMS gyroscope. Microsyst. Technol. 2020, 26, 2869–2877. [Google Scholar] [CrossRef]

- Din, H.; Iqbal, F.; Lee, B. Sensitivity Analysis of Single-Drive, 3-axis MEMS Gyroscope Using COMSOL Multiphysics. Micromachines 2020, 11, 1030. [Google Scholar] [CrossRef] [PubMed]

- Iqbal, F.; Din, H.; Lee, B. Single Drive Multi-Axis Gyroscope with High Dynamic Range, High Linearity and Wide Bandwidth. Micromachines 2019, 10, 410. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Shah, M.A.; Iqbal, F.; Shah, I.A.; Lee, B. Modal Analysis of a Single-Structure Multiaxis MEMS Gyroscope. J. Sens. 2016, 2016. [Google Scholar] [CrossRef]

- Kionix. MEMS Sensor Terminology, Accelerometers/Gyroscopes. 2011. Available online: http://kionixfs.kionix.com/en/document/MEMS%20Sensor%20Terminology.pdf (accessed on 12 December 2020).

- Shkel, C.A.A. MEMS Vibratory Gyroscopes: Structural Approaches to Improve Robustness; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2008. [Google Scholar]

- Barrachina, J.M.B.; Peñuelas, C.S.C.; Izquierdo, S.C. Capacitance evaluation on non-parallel thick-plate capacitors by means of finite element analysis. J. Energy Power Eng. 2011, 5, 373–378. [Google Scholar]

- Sankar, A.R.; Das, S. A very-low cross-axis sensitivity piezoresistive accelerometer with an electroplated gold layer atop a thickness reduced proof mass. Sens. Actuators A Phys. 2013, 189, 125–133. [Google Scholar] [CrossRef]

- Iqbal, F.; Shah, M.A.; Lee, B. Analysis of parasitic feed-through capacitance in MEMS gyroscope with push pull configuration. In Proceedings of the 2017 IEEE 12th International Conference on Nano/Micro Engineered and Molecular Systems (NEMS), Los Angeles, CA, USA, 9–12 April 2017; IEEE: New York, NY, USA, 2017; pp. 414–417. [Google Scholar]

| Frequency Mode | Frequency (Hz) | Frequency Difference (Hz) | |

|---|---|---|---|

| Drive mode | 25,682 | ||

| x-sense | |||

| y-sense | |||

| Axis | Parameters | Value | Remarks | |

|---|---|---|---|---|

| x-axis | (nm) | x-sense displacement of M1 | ||

| x-sense displacement of M3 | ||||

| Differential (nm) | 61.573 | x-sense total differential displacement | ||

| (nm) | Two-point method for cross-axis displacement calculation | |||

| Differential (nm) | Total differential cross-axis displacement in x-axis due to the y-axis | |||

| Cross-axis sensitivity in the x-axis | ||||

| y-axis | (nm) | y-sense displacement of M2 | ||

| y-sense displacement of M4 | ||||

| Differential (nm) | y-sense total differential displacement | |||

| (nm) | Two-point method for cross-axis displacement calculation | |||

| Differential (nm) | Total differential cross-axis displacement in y-axis due to the x-axis | |||

| Cross-axis sensitivity in the y-axis | ||||

| Average cross-axis sensitivity | Average CAS in Proposed design | |||

| Methodology | Reference | Cross-Axis Sensitivity (%) | Improvement (%) | ||

|---|---|---|---|---|---|

| x-Axis | y-Axis | x-Axis | y-Axis | ||

| Ratio-Matching method | This Work | ||||

| Integrated automatic gain control for drive mode | [20] | No details | |||

| Quadrature error cancellation | [19] | No details | |||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Din, H.; Iqbal, F.; Lee, B. Design Approach for Reducing Cross-Axis Sensitivity in a Single-Drive Multi-Axis MEMS Gyroscope. Micromachines 2021, 12, 902. https://doi.org/10.3390/mi12080902

Din H, Iqbal F, Lee B. Design Approach for Reducing Cross-Axis Sensitivity in a Single-Drive Multi-Axis MEMS Gyroscope. Micromachines. 2021; 12(8):902. https://doi.org/10.3390/mi12080902

Chicago/Turabian StyleDin, Hussamud, Faisal Iqbal, and Byeungleul Lee. 2021. "Design Approach for Reducing Cross-Axis Sensitivity in a Single-Drive Multi-Axis MEMS Gyroscope" Micromachines 12, no. 8: 902. https://doi.org/10.3390/mi12080902

APA StyleDin, H., Iqbal, F., & Lee, B. (2021). Design Approach for Reducing Cross-Axis Sensitivity in a Single-Drive Multi-Axis MEMS Gyroscope. Micromachines, 12(8), 902. https://doi.org/10.3390/mi12080902