Batch Fabrication of Silicon Nanometer Tip Using Isotropic Inductively Coupled Plasma Etching

Abstract

1. Introduction

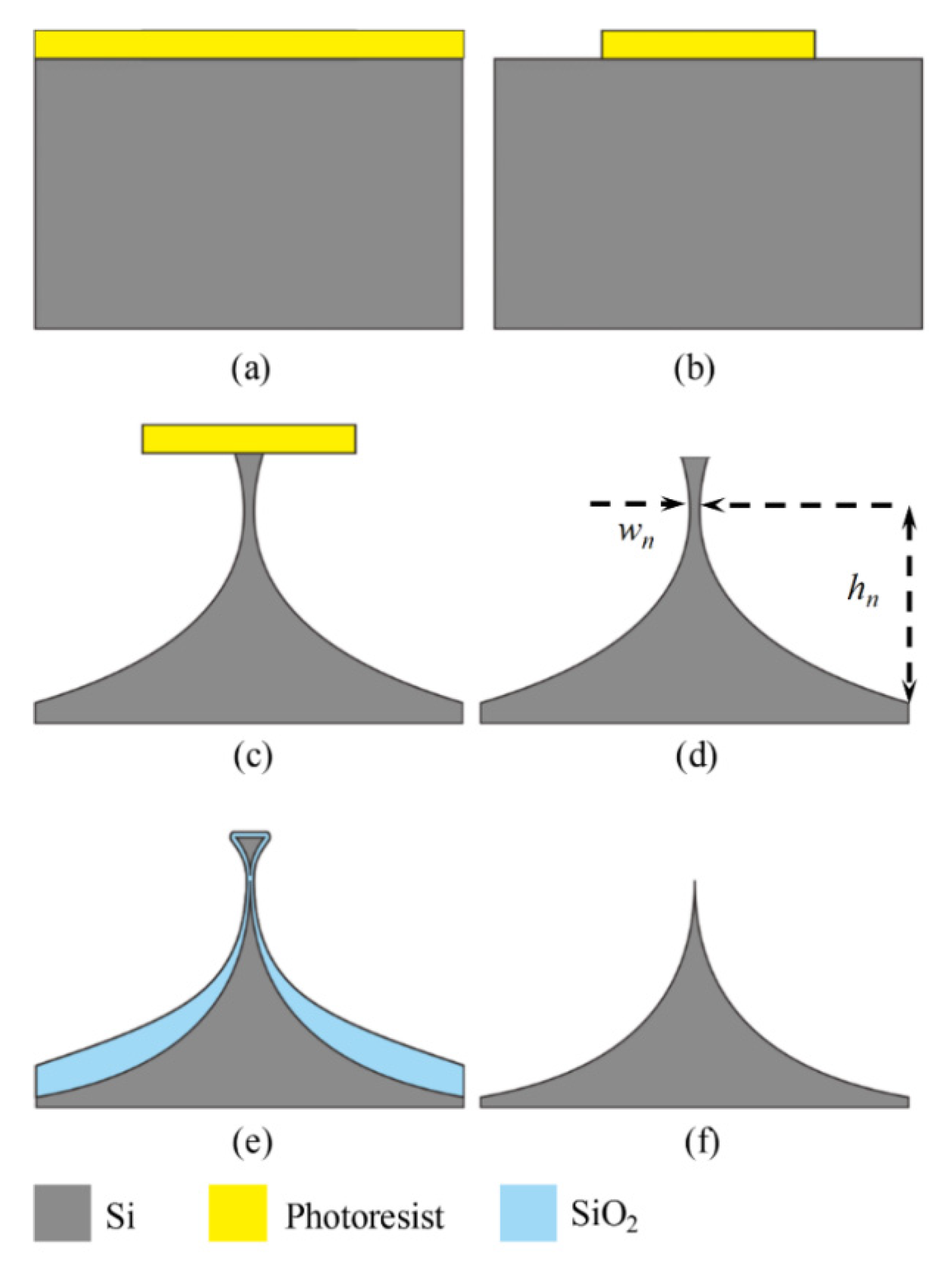

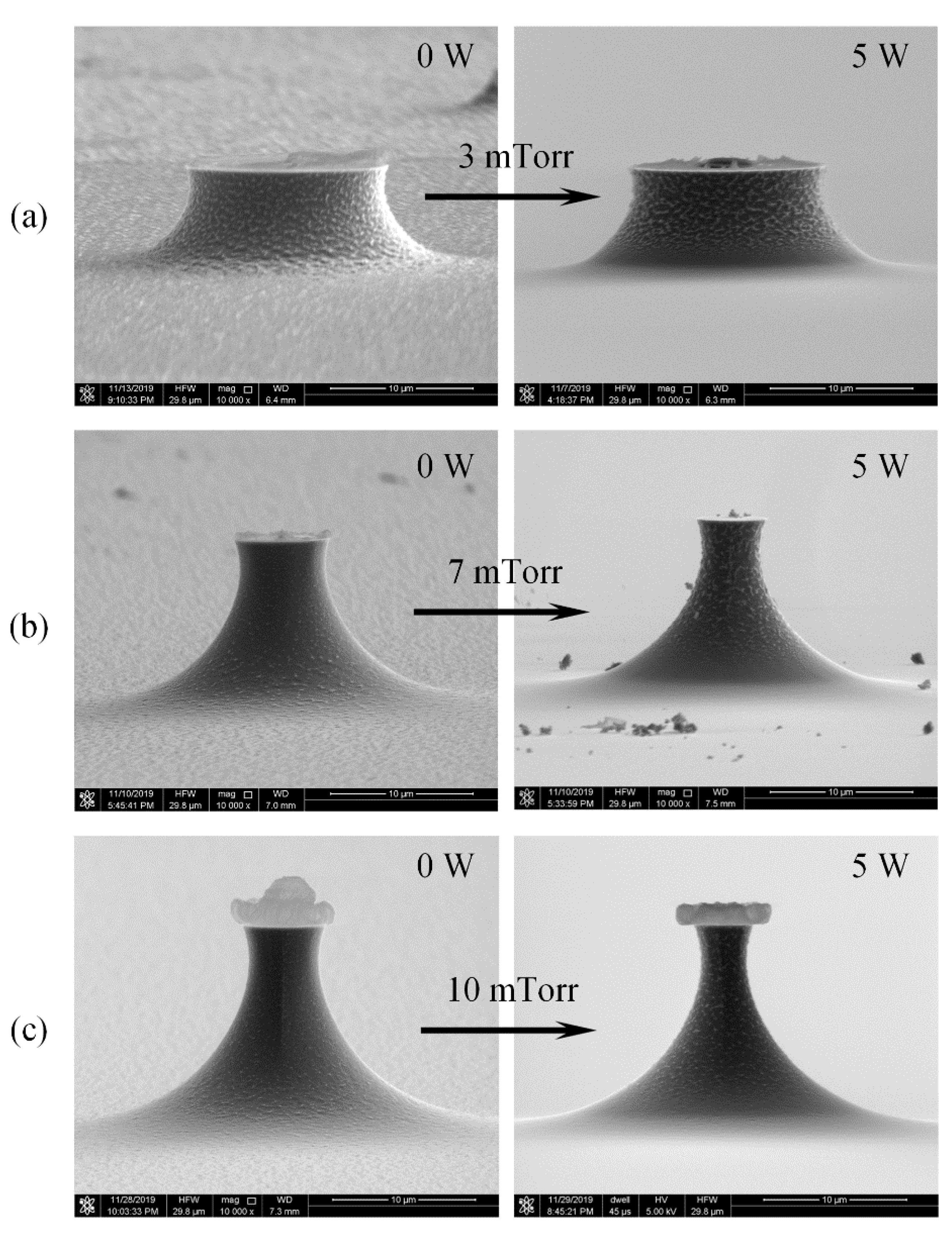

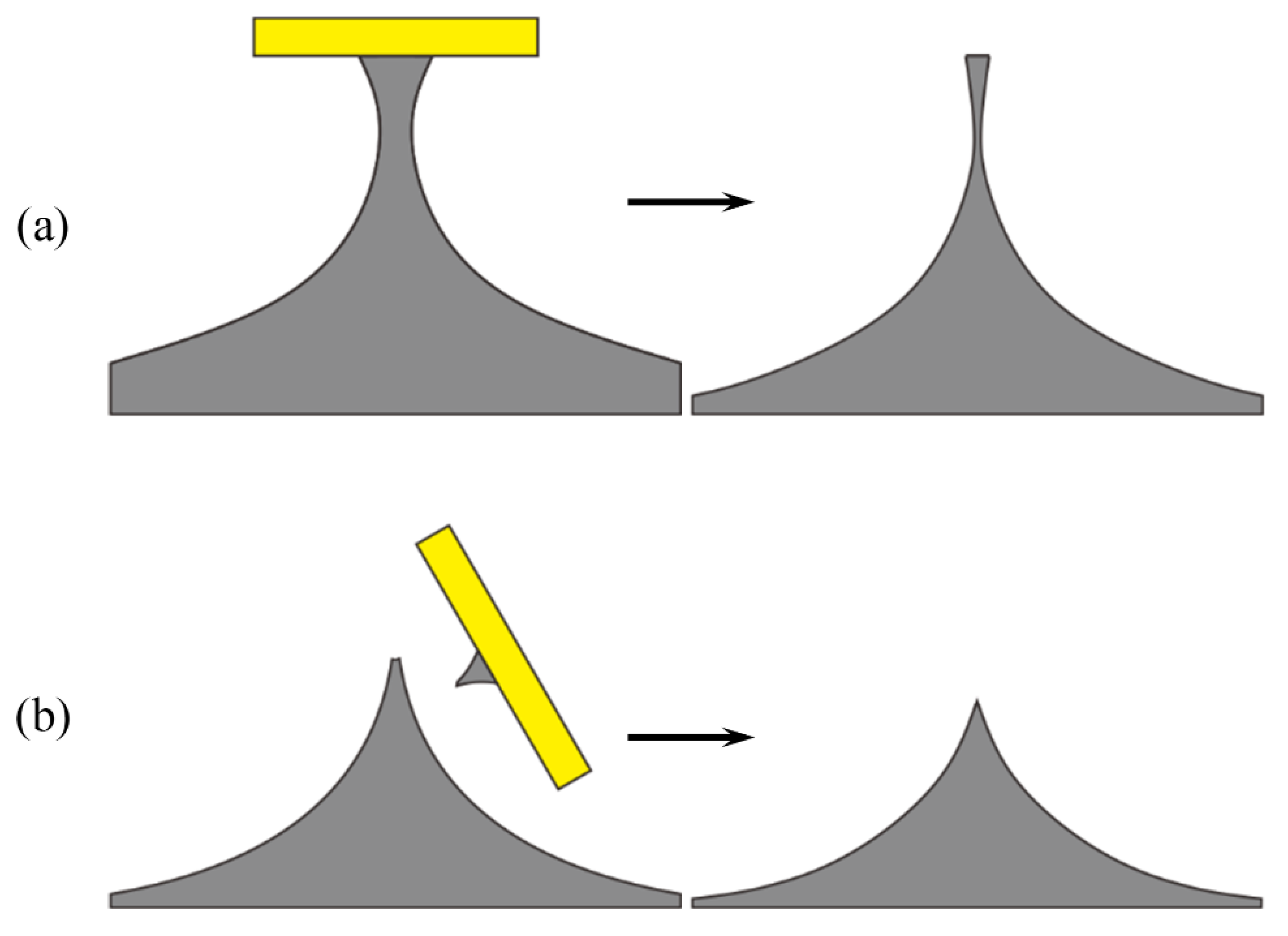

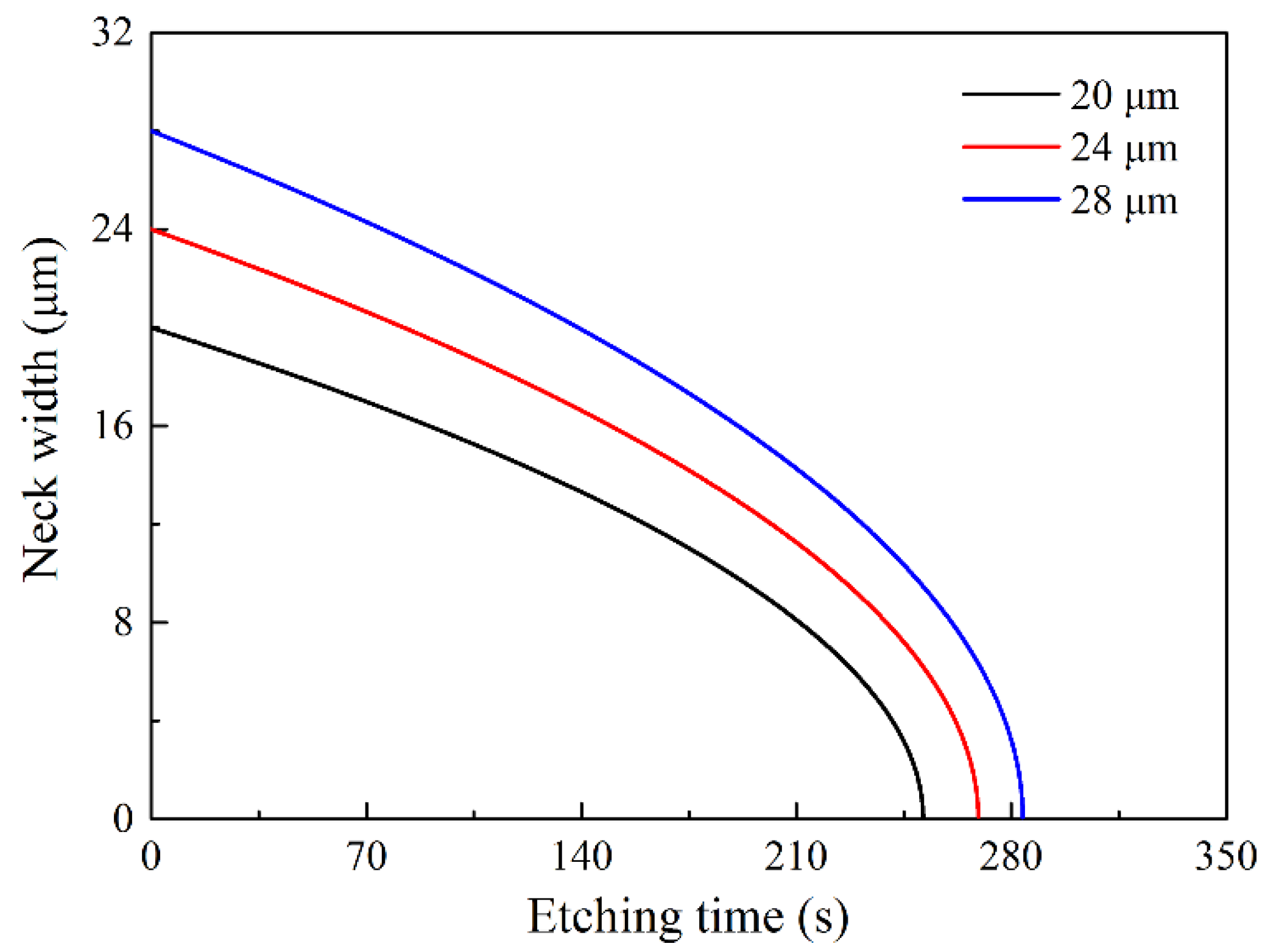

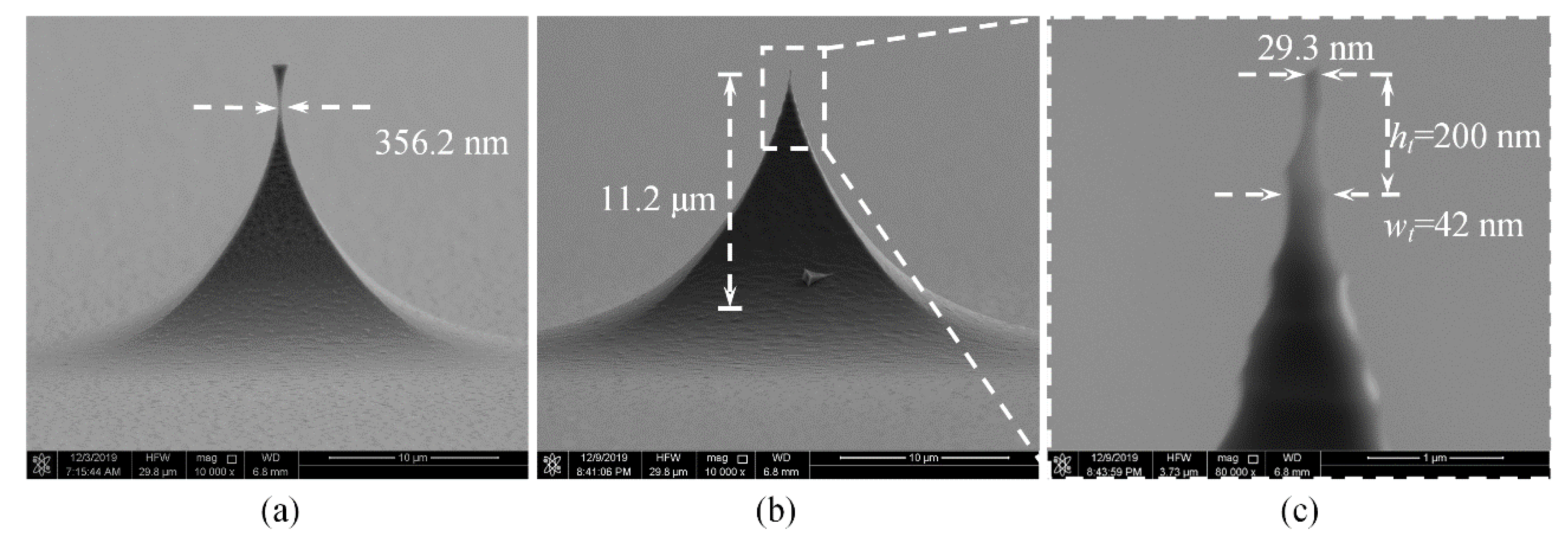

2. Fabrication Process

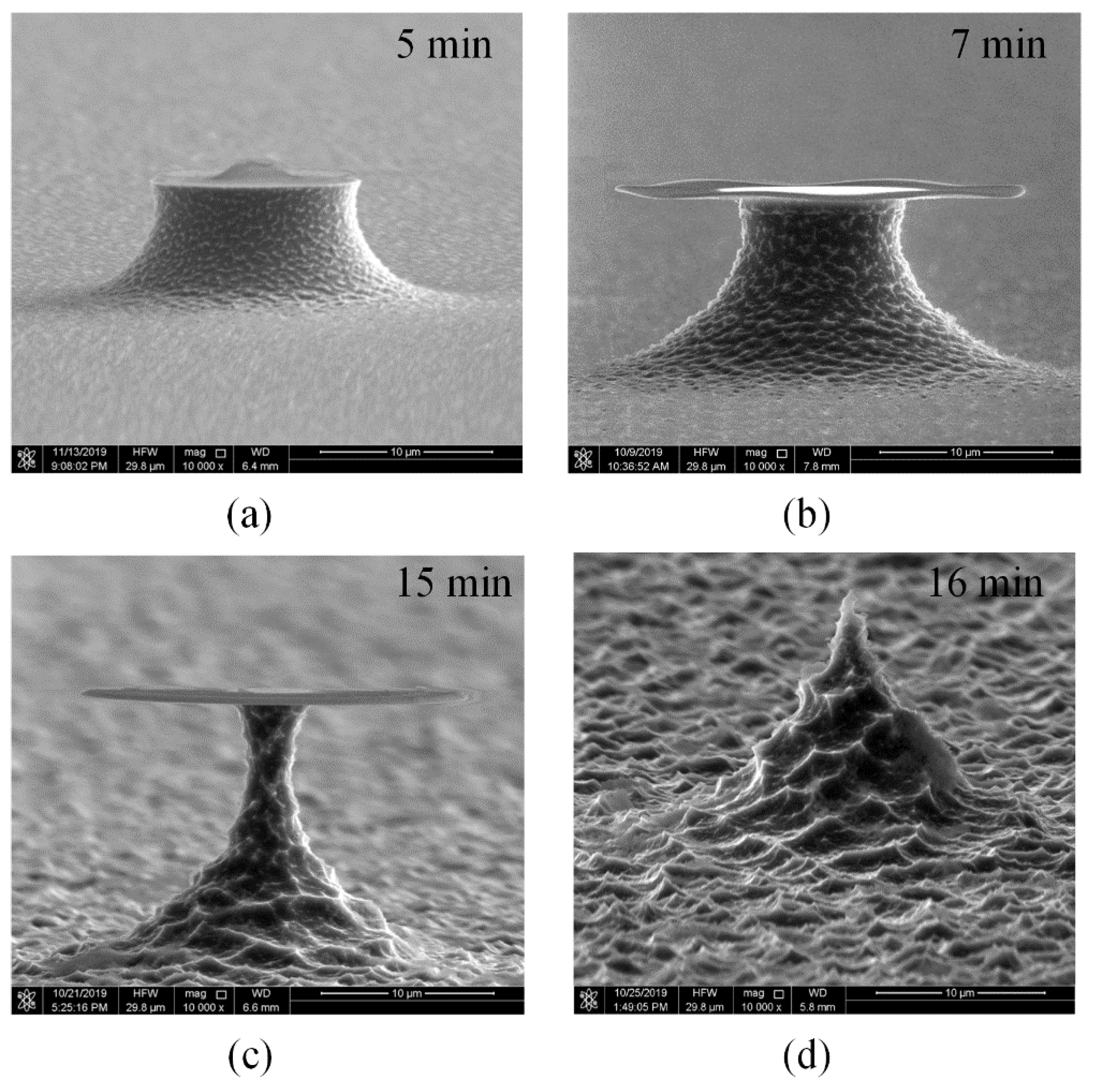

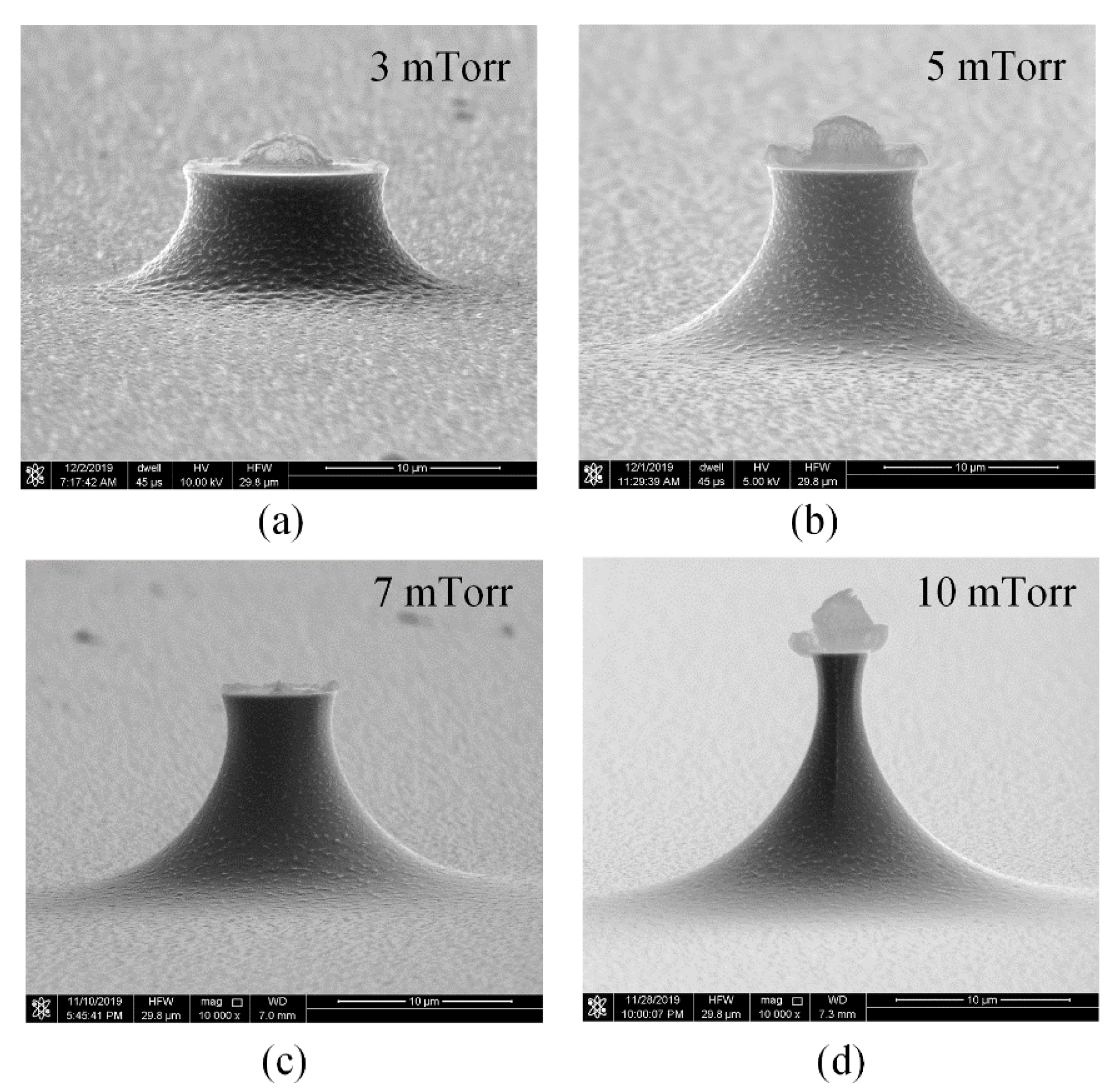

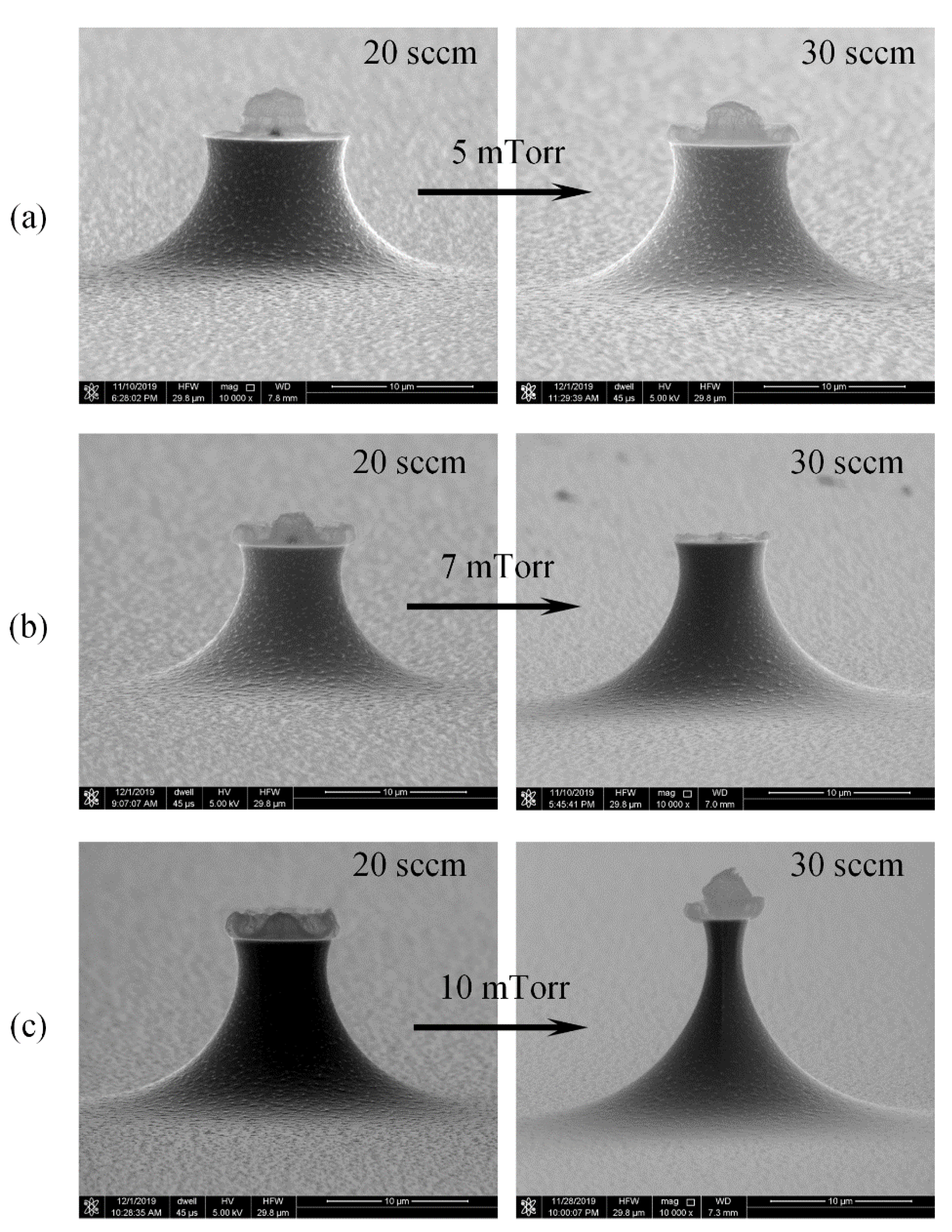

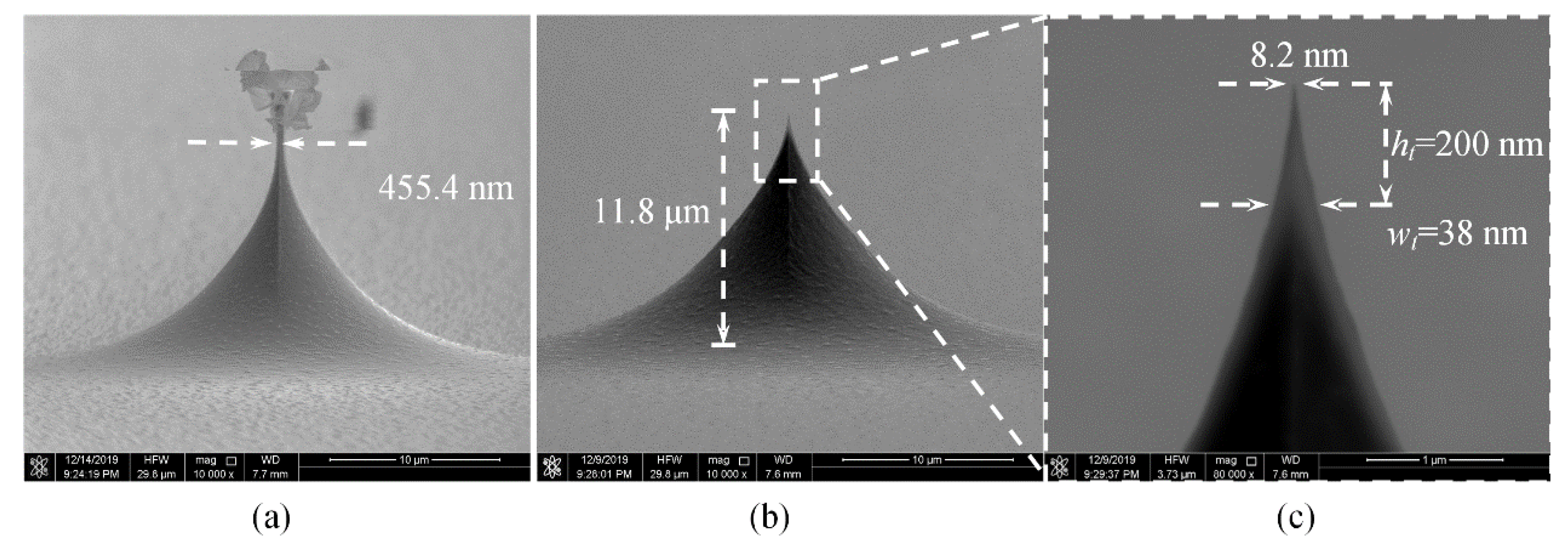

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Lucas, M.; Gall, K.; Riedo, E. Tip size effects on atomic force microscopy nanoindentation of a gold single crystal. J. Appl. Phys. 2008, 104, 269–273. [Google Scholar] [CrossRef]

- Wang, F.; Li, X.; Guo, N.; Wang, Y.; Feng, S. A silicon cantilever probe card with tip-to-pad electric feed-through and automatic isolation of the metal coating. J. Micromech. Microeng. 2006, 16, 1215–1220. [Google Scholar] [CrossRef]

- Wang, F.; Li, X.; Cheng, R.; Jiang, K.; Feng, S. Silicon cantilever arrays with by-pass metal through-silicon-via (TSV) tips for micromachined IC testing probe cards. Microelectron. Eng. 2009, 86, 2211–2216. [Google Scholar] [CrossRef]

- Olfat, M.; Strathearn, D.; Lee, G.; Sarkar, N.; Hung, S.C.; Mansour, R.R. A single-chip scanning probe microscope array. In Proceedings of the IEEE International Conference on Micro Electro Mechanical Systems, Las Vegas, AL, USA, 22–26 January 2017. [Google Scholar]

- Sun, K.; Zhang, W.; Li, B.; Lee, J.Y.; Xie, Y.-H.; Schroeder, T.; Katzer, J.; Wei, X.; Russell, T.P. Field Emission Tip Array Fabrication Utilizing Geometrical Hindrance in the Oxidation of Si. IEEE Trans. Nanotechnol. 2012, 11, 999–1003. [Google Scholar] [CrossRef]

- Resnik, D.; Možek, M.; Pečar, B.; Janež, A.; Urbančič, V.; Iliescu, C.; Vrtačnik, D. In Vivo Experimental Study of Noninvasive Insulin Microinjection through Hollow Si Microneedle Array. Micromachines 2018, 9, 40. [Google Scholar] [CrossRef]

- Folch, A.; Wrighton, M.S.; Schmidt, M.A. Microfabrication of oxidation-sharpened silicon tips on silicon nitride cantilevers for atomic force microscopy. J. Microelectromech. Syst. 1997, 6, 303–306. [Google Scholar] [CrossRef][Green Version]

- Grow, R.; Minne, S.; Manalis, S.; Quate, C. Silicon nitride cantilevers with oxidation-sharpened silicon tips for atomic force microscopy. J. Microelectromech. Syst. 2002, 11, 317–321. [Google Scholar] [CrossRef]

- Kaushik, S.; Hord, A.H.; Denson, D.D.; McAllister, D.V.; Smitra, S.; Allen, M.G.; Prausnitz, M.R. Lack of Pain Associated with Microfabricated Microneedles. Anesth. Analg. 2001, 92, 502–504. [Google Scholar] [CrossRef]

- Kim, Y.C.; Park, J.H.; Prausnitz, M.R. Microneedles for drug and vaccine delivery. Adv. Drug Deliv. Rev. 2012, 64, 1547–1568. [Google Scholar] [CrossRef]

- Mamin, H.J.; Ried, R.; Terris, B.; Rugar, D. High-density data storage based on the atomic force microscope. Proc. IEEE 1999, 87, 1014–1027. [Google Scholar] [CrossRef]

- Persaud, A.; Park, S.J.; Liddle, J.A.; Schenkel, T.; Bokor, J.; Rangelow, I.W. Integration of Scanning Probes and Ion Beams. Nano Lett. 2005, 5, 1087–1091. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Costa, M.; Tarequzzaman, M.; Ferreira, R.; Cardoso, S.; Gaspar, J.; Cardoso, S.F. Towards high-resolution scanning magnetoresistance microscopy. In Proceedings of the 2017 IEEE 12th International Conference on Nano/Micro Engineered and Molecular Systems (NEMS), Los Angeles, CA, USA, 9–12 April 2017; pp. 73–76. [Google Scholar]

- Itoh, H.; Odaka, T.; Niitsuma, J. SPM system for semiconductor device applications. Microscopy 2014, 63 (Suppl. 1), i13. [Google Scholar] [CrossRef]

- Myhra, S. Manipulation of Si oxide and electrically conducting carbon films by scanning probe microscopy (SPM): Nano-lithography and nano-machining. Thin Solid Films 2004, 459, 90–94. [Google Scholar] [CrossRef]

- Lee, S.H.; Lim, G.; Moon, W. A Novel SPM Probe with MOS Transistor and Nano Tip for Surface Electric Properties. J. Phys. Conf. Ser. 2007, 61, 678–682. [Google Scholar] [CrossRef]

- Rodriguez, B.J.; Jesse, S.; Seal, K.; Baddorf, A.P.; Kalinin, S.V.; Rack, P.D. Fabrication, dynamics, and electrical properties of insulated scanning probe microscopy probes for electrical and electromechanical imaging in liquids. Appl. Phys. Lett. 2007, 91, 093130.1–093130.3. [Google Scholar] [CrossRef]

- University of Pittsburgh, Stanford University. Selective Growth of Si Nanowire Arrays Via Galvanic Displacement Processes in Water-in-Oil Microemulsions. J. Am. Chem. Soc. 2005, 127, 4574–4575. [Google Scholar] [CrossRef]

- Qian, W.; Sun, S.; Song, J.; Nguyen, C.; Ducharme, S.; Turner, J.A. Focused electron-beam-induced deposition for fabrication of highly durable and sensitive metallic AFM-IR probes. Nanotechnology 2018, 29, 335702. [Google Scholar] [CrossRef]

- Shandyba, N.A.; Kolomiytsev, A.S.; Panchenko, I.V.; Lisitsyn, S.A. Novel technology for fabrication of probe tips for SPM using focused ion beam-induced deposition method. IOP Conf. Ser. Mater. Sci. Eng. 2019, 699, 012042. [Google Scholar] [CrossRef]

- Givargizov, M.E.; Stepanova, A.N.; Obolenskaya, L.N. Technology “WhiskerProbes”. In AIP Conference Proceedings; AIP Publishing: College Park, MD, USA, 2003; Volume 696, pp. 247–255. [Google Scholar]

- Campanella, H.; Jaafar, M.; Llobet, J.; Esteve, J.; Vazquez, M.; Asenjo, A.; Del Real, R.P.; Plaza, J.A. Nanomagnets with high shape anisotropy and strong crystalline anisotropy: Perspectives on magnetic force microscopy. Nanotechnology 2011, 22, 505301. [Google Scholar] [CrossRef]

- Menozzi, C.; Gazzadi, G.C.; Alessandrini, A.; Facci, P. Focused ion beam-nanomachined probes for improved electric force microscopy. Ultramicroscopy 2005, 104, 220–225. [Google Scholar] [CrossRef]

- Yapici, M.K.; Zou, J. A novel micromachining technique for the batch fabrication of scanning probe arrays with precisely defined tip contact areas. J. Micromech. Microeng. 2008, 18, 085015. [Google Scholar] [CrossRef]

- Chang, W.S.; Jeong, M.S.; Kim, D.C.; Kim, J. Fabrication of Cantilevered Tip-on-Aperture Probe for Enhancing Resolution of Scanning Near-Field Optical Microscopy System. Jpn. J. Appl. Phys. 2007, 46, 5563–5567. [Google Scholar] [CrossRef]

- Tang, B.; Sato, K.; Gosálvez, M.A. Sharp silicon tips with different aspect ratios in wet etching/DRIE and surfactant-modified TMAH etching. Sens. Actuators A 2012, 188, 220–229. [Google Scholar] [CrossRef]

- Bhandari, R.; Negi, S.; Rieth, L.; Solzbacher, F. A wafer-scale etching technique for high aspect ratio implantable MEMS structures. Sens. Actuators, A 2010, 162, 130–136. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Yu, X.; Li, T.; Wang, Y. A novel method to fabricate silicon nanoprobe array with ultra-sharp tip on (111) silicon wafer. Microsyst. Technol. 2018, 24, 2913–2917. [Google Scholar] [CrossRef]

- Imaeda, K.; Bessho, K.; Shikida, M. Design and fabrication of differently shaped pyramids on Si{100} by anisotropic wet etching. Microsyst. Technol. 2016, 22, 2801–2809. [Google Scholar] [CrossRef]

- Izumi, H.; Okamoto, T.; Suzuki, M.; Aoyagi, S. Development of a Silicon Microneedle with Three-Dimensional Sharp Tip by Electrochemical Etching. IEEJ Trans. Sens. Micromach. 2009, 129, 373–379. [Google Scholar] [CrossRef]

- Hamzah, A.A.; Aziz, N.A.; Majlis, B.Y.; Yunas, J.; Dee, C.F.; Bais, B. Optimization of HNA etching parameters to produce high aspect ratio solid silicon microneedles. J. Micromech. Microeng. 2012, 22, 095017. [Google Scholar] [CrossRef]

- Carta, S.; Bagni, R.; Giovine, E.; Foglietti, V.; Evangelisti, F.; Notargiacomo, A. Fabrication of bulk and epitaxial germanium field emitter arrays by dry etching techniques. Microelectron. Eng. 2013, 110, 230–233. [Google Scholar] [CrossRef]

- Chen, K.J.; Fang, T.H.; Ji, L.W.; Chang, S.J.; Young, S.J. Fabrication and characteristics of silicon micro-tip arrays. Int. J. Mod. Phys. B 2014, 24, 1005515. [Google Scholar] [CrossRef]

- Boisen, A.; Hansen, O.; Bouwstra, S. AFM probes with directly fabricated tips. J. Micromech. Microeng. 1996, 6, 58–62. [Google Scholar] [CrossRef]

- Rakhshandehroo, M.R. Simulation and dry etching of field emitter tips in Si. J. Vac. Sci. Technol. A Vac. Surf. Films 1996, 14, 1832. [Google Scholar] [CrossRef]

- Shin, Y.M.; Kim, Y.K.; Lee, S.K.; Park, J.H. Single-mask fabrication of micro-probe electrode array with various tip heights and sharpness using isotropic and anisotropic etching. Micro Nano Lett. 2018, 13, 1245–1247. [Google Scholar] [CrossRef]

- Villanueva, G.; Plaza, J.A.; Sanchez, A.; Zinoviev, K.; Perez-Murano, F.; Bausells, J. DRIE based novel technique for AFM probes fabrication. Microelectron. Eng. 2007, 84, 1132–1135. [Google Scholar] [CrossRef]

- Held, J.; Gaspar, J.; Ruther, P.; Hagner, M.; Cismak, A.; Heilmann, A.; Paul, O. Design of experiment characterization of microneedle fabrication processes based on dry silicon etching. J. Micromech. Microeng. 2010, 20, 025024. [Google Scholar] [CrossRef]

- Kanechika, M.; Mitsushima, Y. Silicon Needles Fabricated by Highly Selective Anisotropic Dry Etching and Their Field Emission Current Characteristics. Jpn. J. Appl. Phys. 2000, 39, 7111. [Google Scholar] [CrossRef]

- Kim, D.W.; Lym, S.H.; Jung, M.Y. Fabrication of field emission Si-tip array using reduced submicron masks generated by isotropic etching of mask patterns. Microelectron. Eng. 1999, 46, 423–426. [Google Scholar] [CrossRef]

- He, H.; Zhang, J.; Yang, J.; Yang, F. Silicon tip sharpening based on thermal oxidation technology. Microsyst. Technol. 2016, 23, 1799–1803. [Google Scholar] [CrossRef]

- Im, H.; Oh, S.H. Oxidation Sharpening, Template Stripping, and Passivation of Ultra-Sharp Metallic Pyramids and Wedges. Small 2014, 10, 680–684. [Google Scholar] [CrossRef]

- Panduranga, P.; Abdou, A.; Ren, Z.; Pedersen, R.H.; Nezhad, M. Isotropic silicon etch characteristics in a purely inductively coupled SF6 plasma. J. Vac. Sci. Technol. B 2019, 37, 061206. [Google Scholar] [CrossRef]

- Larsen, K.P.; Petersen, D.H.; Hansen, O. Study of the Roughness in a Photoresist Masked, Isotropic, SF6-Based ICP Silicon Etch. J. Electrochem. Soc. 2006, 153, G1051–G1058. [Google Scholar] [CrossRef]

- Arnold, J.C. Influence of reactant transport on fluorine reactive ion etching of deep trenches in silicon. J. Vac. Sci. Technol. B Microelectron. Nanometer Struct. 1993, 11, 2071. [Google Scholar] [CrossRef]

- Abe, H.; Yoneda, M.; Fujiwara, N. Developments of Plasma Etching Technology for Fabricating Semiconductor Devices. Jpn. J. Appl. Phys. 2008, 47, 1435–1455. [Google Scholar] [CrossRef]

- Donnelly, V.M.; Kornblit, A. Plasma etching: Yesterday, today, and tomorrow. J. Vac. Sci. Technol. A Vac. Surf. Films 2013, 31, 050825. [Google Scholar] [CrossRef]

| Mask Shape | Normalized Tip Height (Etching for 5 min) | Normalized Neck Width (Etching for 5 min) |

|---|---|---|

| Circle | 0.82 | 0.018 |

| Square | 0.80 | 0.026 |

| Star | 0.71 | 0.027 |

| polygon | 0.67 | 0.039 |

| Pressure (mTorr) | Flow Rate (sccm) | ICP Power and Frequency (W/MHz) | Platen Power and Frequency (W/MHz) | Etching Time (min) |

|---|---|---|---|---|

| 3 3 5 5 7 7 7 9 9 10 10 10 | 20 20 20 30 20 30 30 30 30 20 30 30 | 1000/2 1000/2 1000/2 1000/2 1000/2 1000/2 1000/2 1000/2 1000/2 1000/2 1000/2 1000/2 | 0 5/13.56 0 0 0 0 5/13.56 0 5/13.56 0 0 5/13.56 | 5 5 5 5 5 5 5 5 5 5 5 5 |

| Compensation Mode | Non-Uniformity (%) |

|---|---|

| No Compensation | 9.4 |

| Partial Compensation | 6.6 |

| Full Compensation | 0.3 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, L.; Liu, M.; Zhao, J.; Zhao, J.; Zhu, Y.; Yang, J.; Yang, F. Batch Fabrication of Silicon Nanometer Tip Using Isotropic Inductively Coupled Plasma Etching. Micromachines 2020, 11, 638. https://doi.org/10.3390/mi11070638

Wang L, Liu M, Zhao J, Zhao J, Zhu Y, Yang J, Yang F. Batch Fabrication of Silicon Nanometer Tip Using Isotropic Inductively Coupled Plasma Etching. Micromachines. 2020; 11(7):638. https://doi.org/10.3390/mi11070638

Chicago/Turabian StyleWang, Lihao, Meijie Liu, Junyuan Zhao, Jicong Zhao, Yinfang Zhu, Jinling Yang, and Fuhua Yang. 2020. "Batch Fabrication of Silicon Nanometer Tip Using Isotropic Inductively Coupled Plasma Etching" Micromachines 11, no. 7: 638. https://doi.org/10.3390/mi11070638

APA StyleWang, L., Liu, M., Zhao, J., Zhao, J., Zhu, Y., Yang, J., & Yang, F. (2020). Batch Fabrication of Silicon Nanometer Tip Using Isotropic Inductively Coupled Plasma Etching. Micromachines, 11(7), 638. https://doi.org/10.3390/mi11070638