Additive Manufacturing of Sub-Micron to Sub-mm Metal Structures with Hollow AFM Cantilevers

Abstract

1. Metal Additive Manufacturing at the Micro Scale

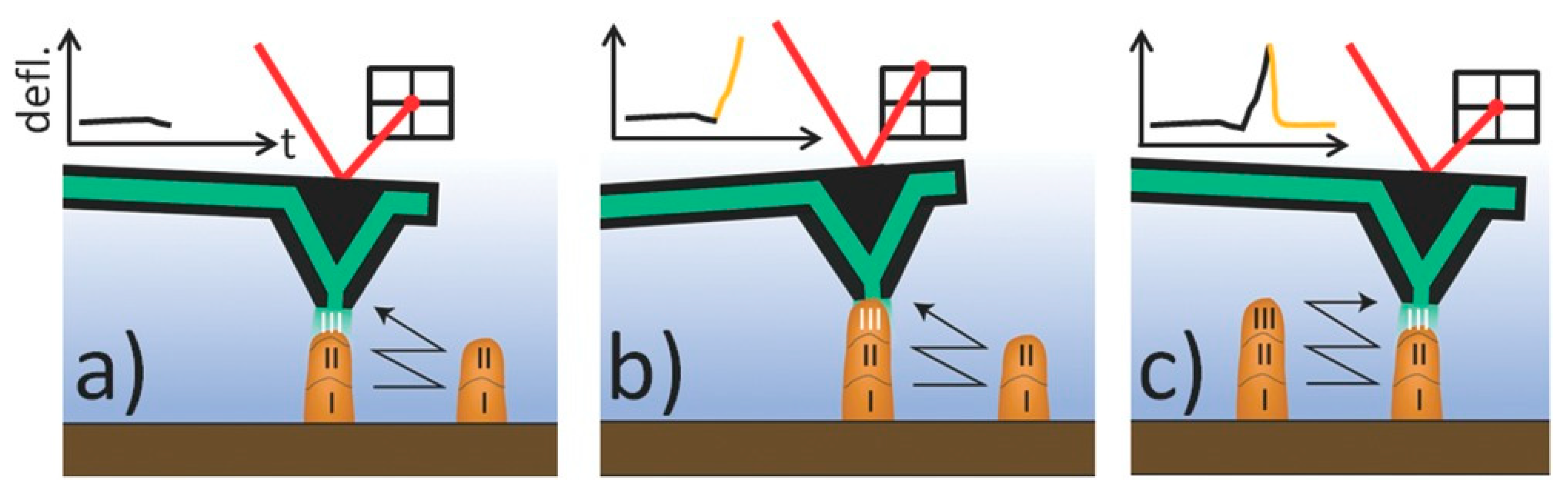

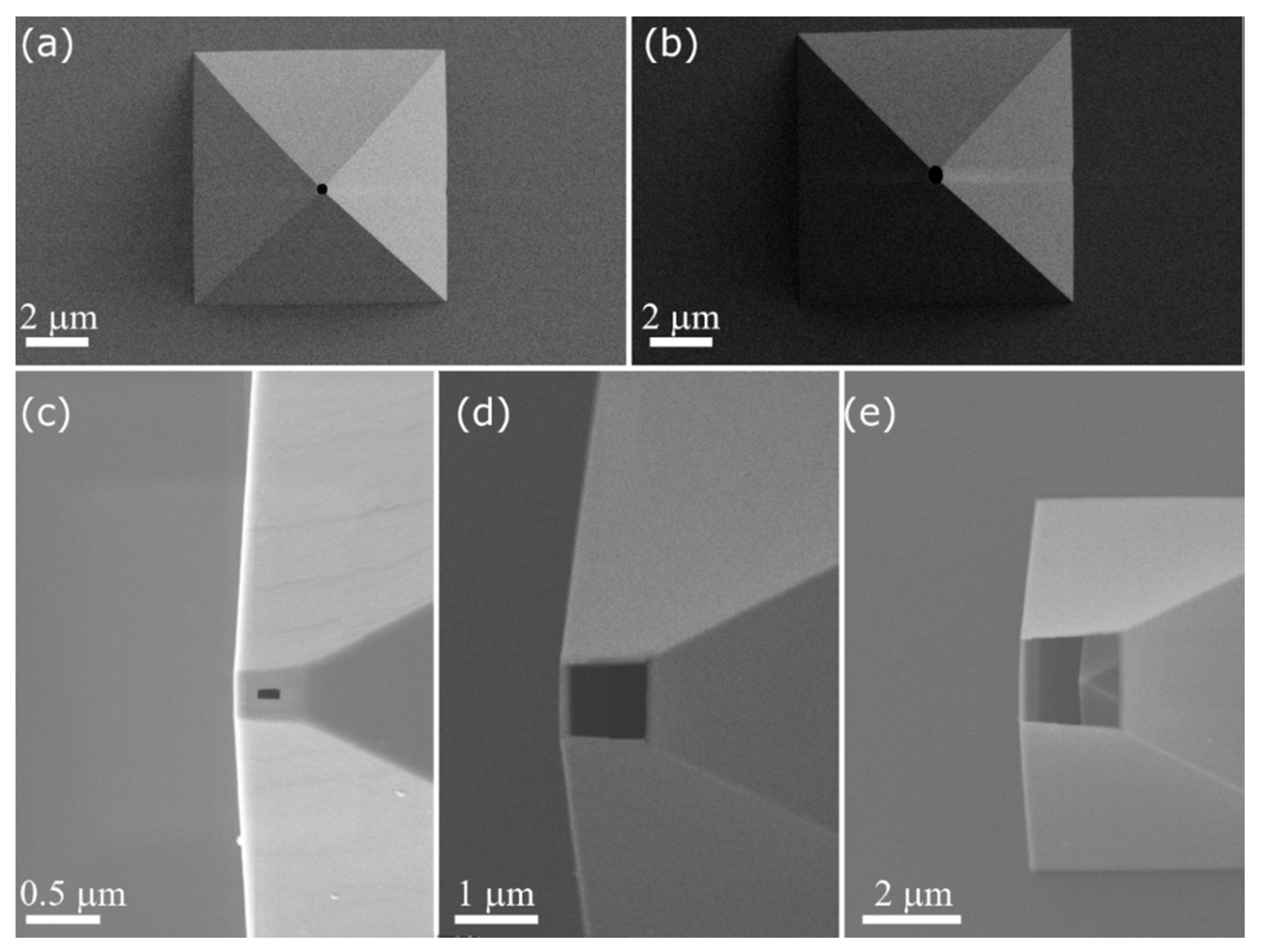

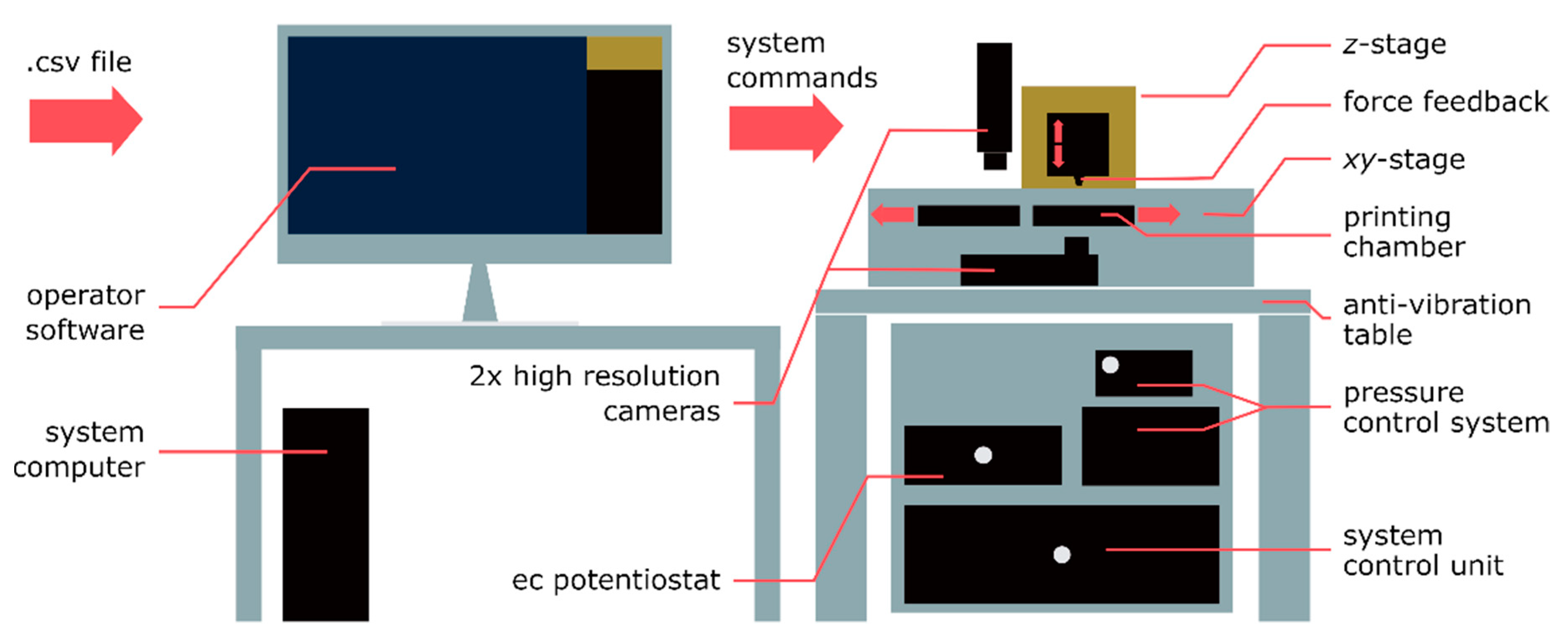

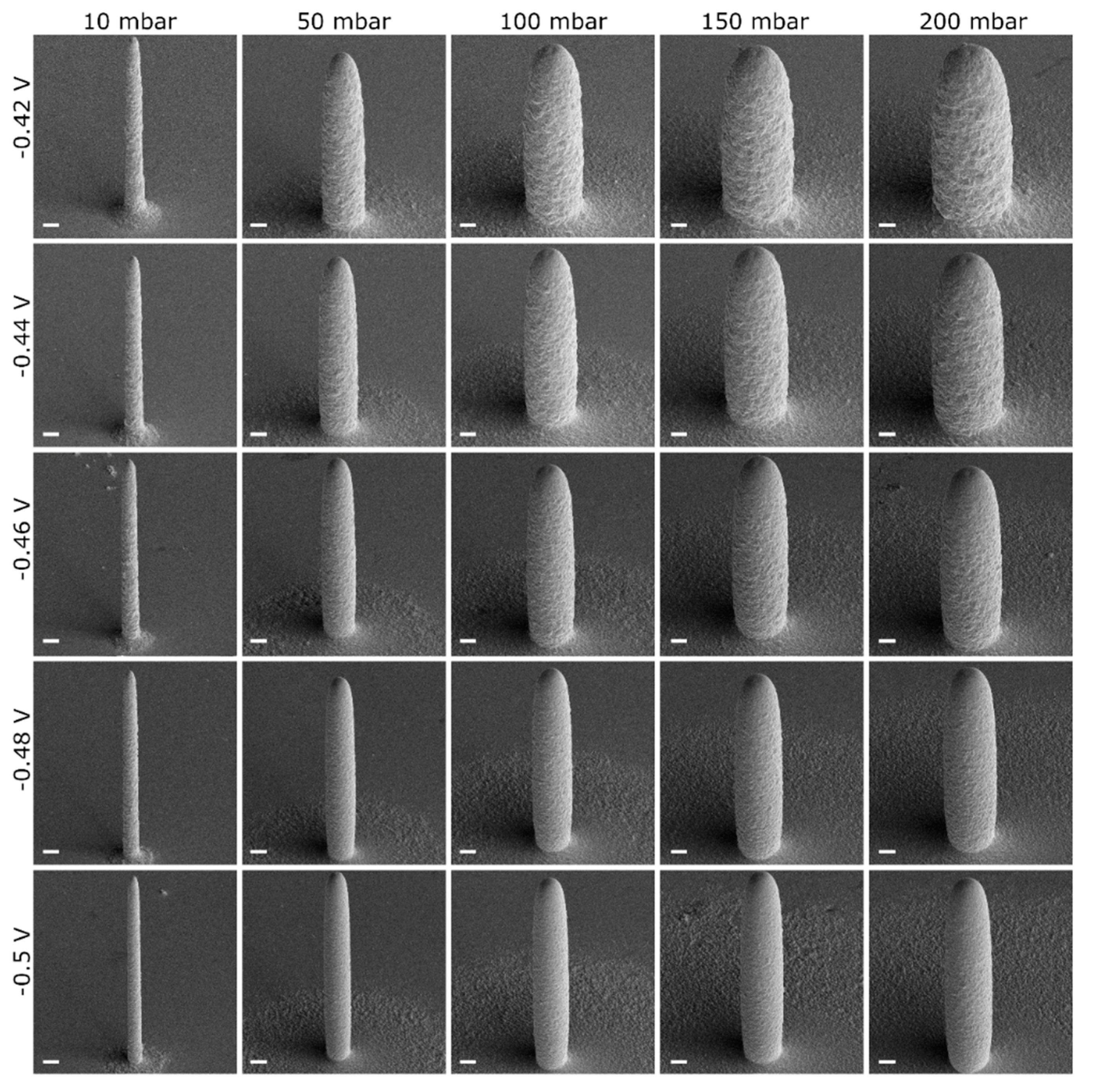

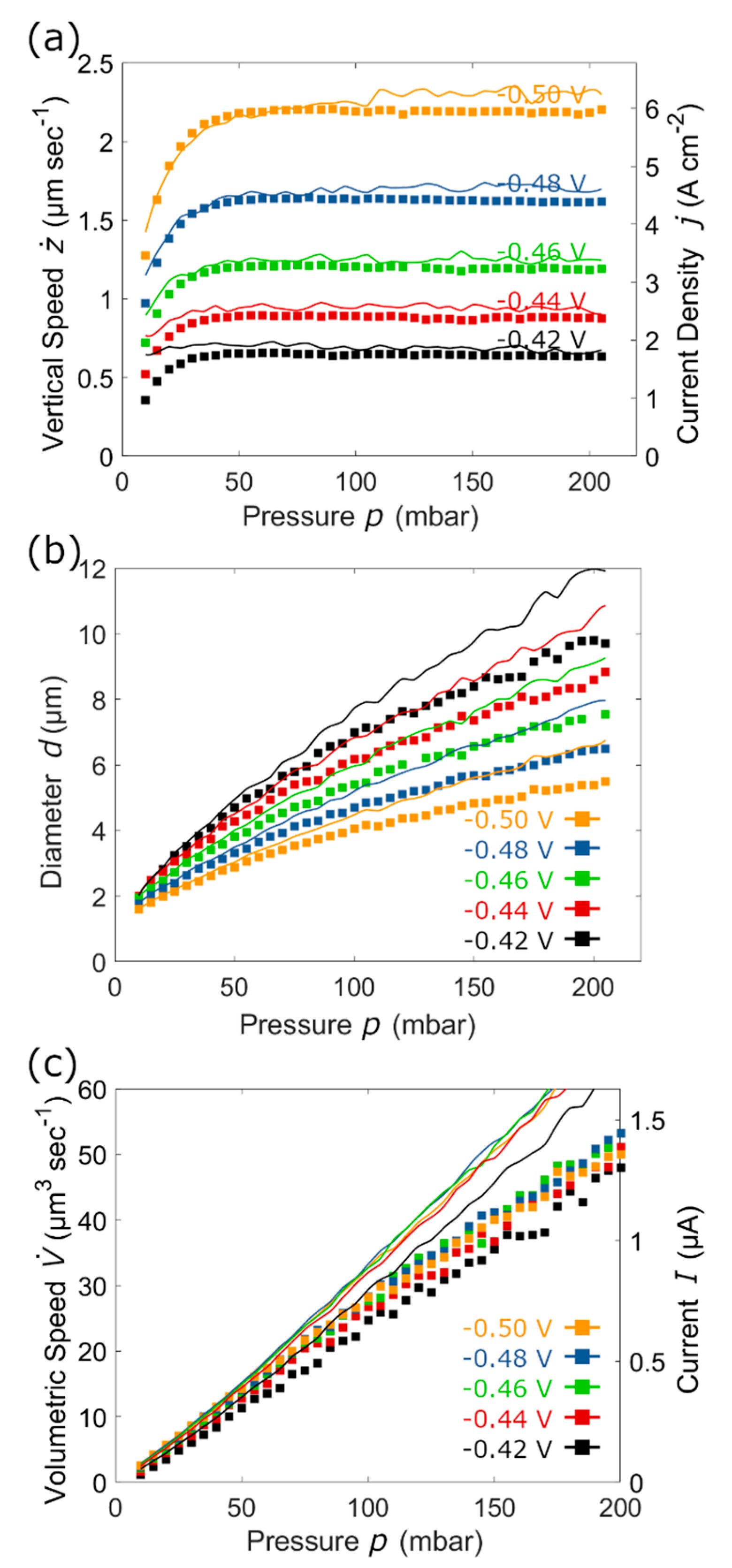

2. The Force-Controlled Microprinting Tool

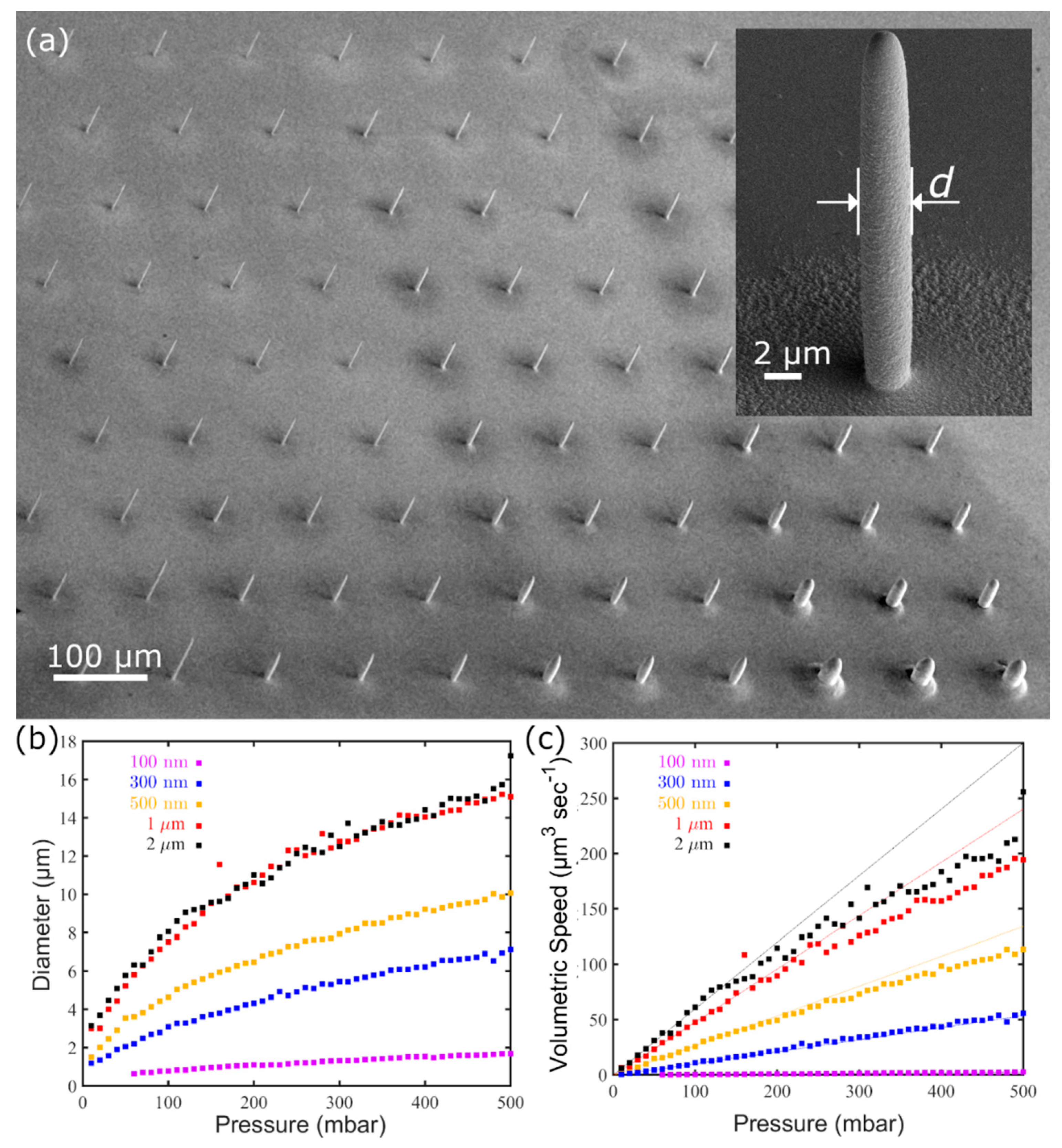

3. Tuning the Voxel Size at Different Scales: from 0.5 to 20 µm

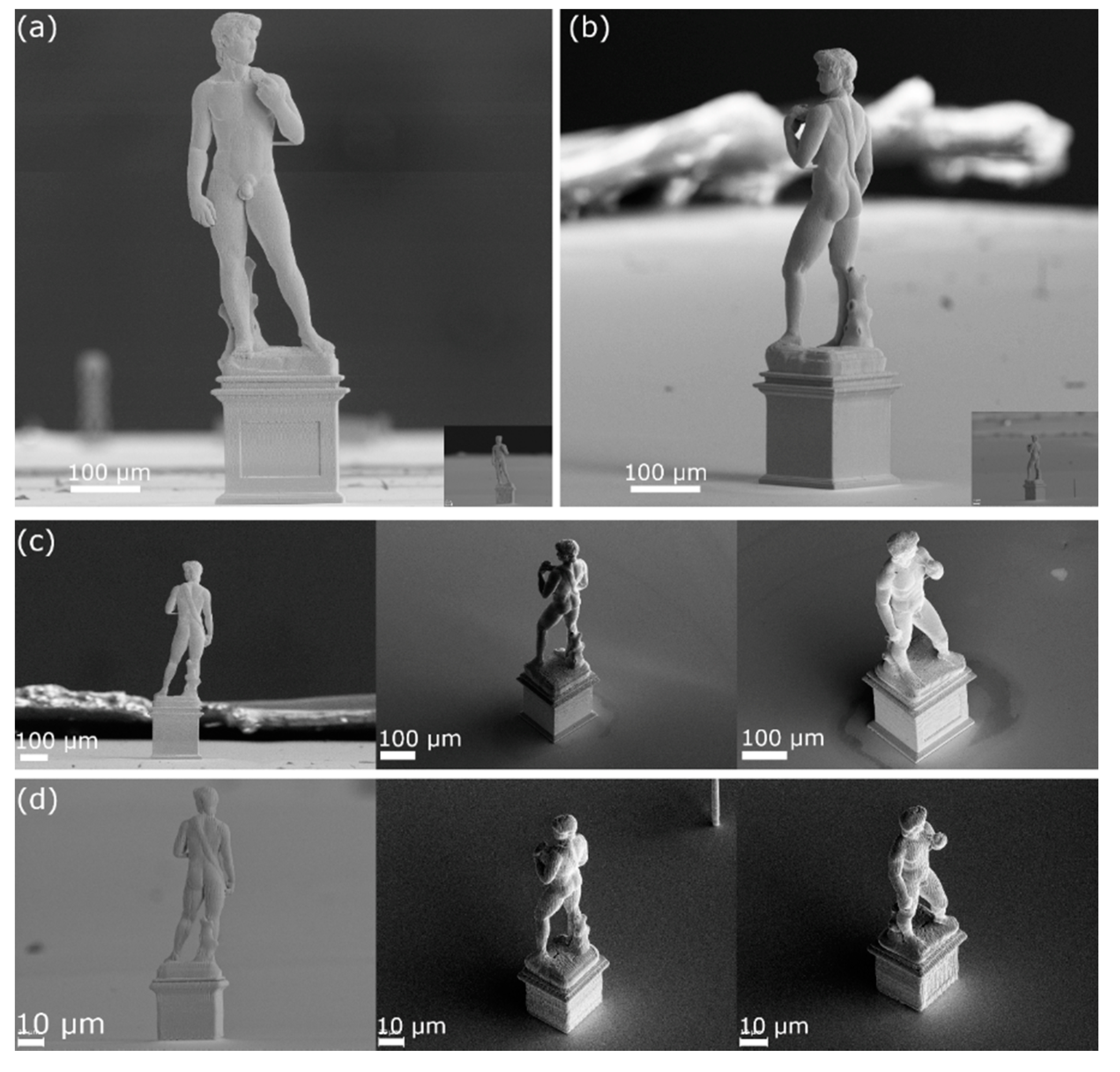

4. Arbitrary-Shaped 3D Structures in a Layer-by-Layer Fashion: Michelangelo’s David

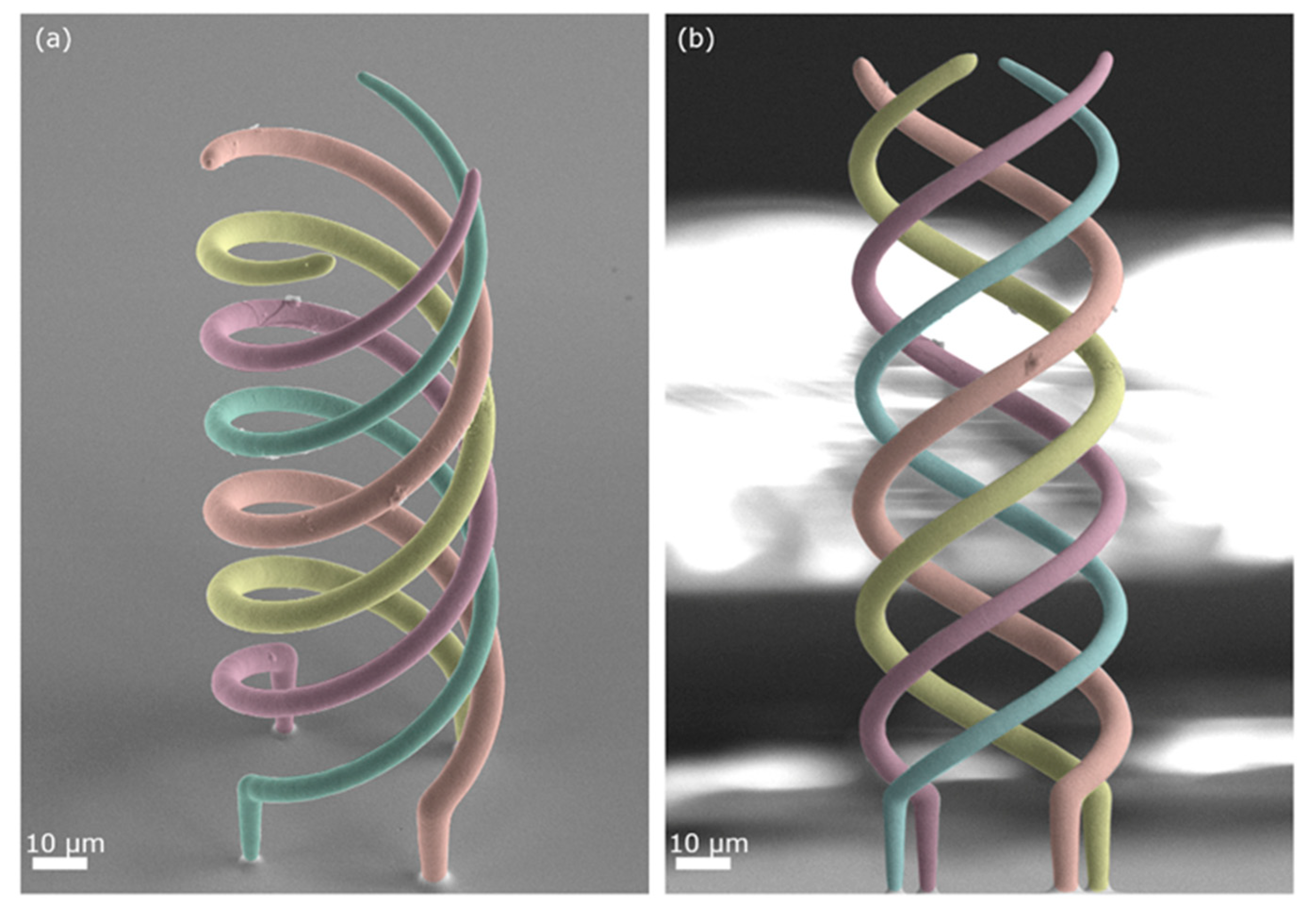

5. Intertwined Coils with Different Section Sizes

6. Conclusions and Outlook

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Murr, L.E.; Gaytan, S.M.; Ramirez, D.A.; Martinez, E.; Hernandez, J.; Amato, K.N.; Shindo, P.W.; Medina, F.R.; Wicker, R.B. Metal Fabrication by Additive Manufacturing Using Laser and Electron Beam Melting Technologies. J. Mater. Sci. Technol. 2012, 28, 1–14. [Google Scholar] [CrossRef]

- Frazier, W.E. Metal Additive Manufacturing: A Review. J. Mater. Eng. Perform. 2014, 23, 1917–1928. [Google Scholar] [CrossRef]

- Herzog, D.; Seyda, V.; Wycisk, E.; Emmelmann, C. Additive manufacturing of metals. Acta Mater. 2016, 117, 371–392. [Google Scholar] [CrossRef]

- Körner, C. Additive manufacturing of metallic components by selective electron beam melting—A review. Int. Mater. Rev. 2016, 61, 361–377. [Google Scholar] [CrossRef]

- Buchanan, C.; Gardner, L. Metal 3D printing in construction: A review of methods, research, applications, opportunities and challenges. Eng. Struct. 2019, 180, 332–348. [Google Scholar] [CrossRef]

- Galati, M.; Iuliano, L. A literature review of powder-based electron beam melting focusing on numerical simulations. Addit. Manuf. 2018, 19, 1–20. [Google Scholar] [CrossRef]

- Jansson, A.; Thornell, G.; Johansson, S. High Resolution 3D Microstructures Made by Localized Electrodeposition of Nickel. J. Electrochem. Soc. 2000, 147, 1810–1817. [Google Scholar] [CrossRef]

- Habib, M.A.; Rahman, M. Performance of electrodes fabricated by localized electrochemical deposition (LECD) in micro-EDM operation on different workpiece materials. J. Manuf. Process. 2016, 24, 78–89. [Google Scholar] [CrossRef]

- Duty, C.; Jean, D.; Lackey, W.J. Laser chemical vapour deposition: Materials, modelling, and process control. Int. Mater. Rev. 2001, 46, 271–287. [Google Scholar] [CrossRef]

- Said, R.A. Localized electro-deposition (LED): The march toward process development. Nanotechnology 2004, 15, S649. [Google Scholar] [CrossRef]

- Braun, T.M.; Schwartz, D.T. The Emerging Role of Electrodeposition in Additive Manufacturing. Electrochem. Soc. Interface 2016, 25, 69–73. [Google Scholar] [CrossRef]

- Brant, A.; Sundaram, M. Molecular dynamics study of direct localized overpotential deposition for nanoscale electrochemical additive manufacturing process. Precis. Eng. 2019, 56, 412–421. [Google Scholar] [CrossRef]

- Drahushuk, L.W.; Govind Rajan, A.; Strano, M.S. Fundamental scaling laws for the direct-write chemical vapor deposition of nanoscale features: Modeling mass transport around a translating nanonozzle. Nanoscale 2019, 11, 2925–2937. [Google Scholar] [CrossRef] [PubMed]

- Hirt, L.; Reiser, A.; Spolenak, R.; Zambelli, T. Additive Manufacturing of Metal Structures at the Micrometer Scale. Adv. Mater. 2017, 29, 1604211. [Google Scholar] [CrossRef] [PubMed]

- Fischer, J.; Wegener, M. Three-dimensional optical laser lithography beyond the diffraction limit: 3D optical lithography off limits. Laser Photonics Rev. 2013, 7, 22–44. [Google Scholar] [CrossRef]

- Hohmann, J.K.; Renner, M.; Waller, E.H.; von Freymann, G. Three-Dimensional μ-Printing: An Enabling Technology. Adv. Opt. Mater. 2015, 3, 1488–1507. [Google Scholar] [CrossRef]

- Sugioka, K.; Cheng, Y. Femtosecond laser three-dimensional micro- and nanofabrication. Appl. Phys. Rev. 2014, 1, 041303. [Google Scholar] [CrossRef]

- Wang, D.; Wen, C.; Chang, Y.; Lin, W.; Chen, S.-C. Ultrafast laser-enabled 3D metal printing: A solution to fabricate arbitrary submicron metal structures. Precis. Eng. 2018, 52, 106–111. [Google Scholar] [CrossRef]

- Ahn, B.Y.; Duoss, E.B.; Motala, M.J.; Guo, X.; Park, S.-I.; Xiong, Y.; Yoon, J.; Nuzzo, R.G.; Rogers, J.A.; Lewis, J.A. Omnidirectional printing of flexible, stretchable, and spanning silver microelectrodes. Science 2009, 323, 1590–1593. [Google Scholar] [CrossRef]

- Zhou, N.; Liu, C.; Lewis, J.A.; Ham, D. Gigahertz Electromagnetic Structures via Direct Ink Writing for Radio-Frequency Oscillator and Transmitter Applications. Adv. Mater. 2017, 29, 1605198. [Google Scholar] [CrossRef]

- Lee, S.; Kim, J.H.; Wajahat, M.; Jeong, H.; Chang, W.S.; Cho, S.H.; Kim, J.T.; Seol, S.K. Three-dimensional Printing of Silver Microarchitectures Using Newtonian Nanoparticle Inks. ACS Appl. Mater. Interfaces 2017, 9, 18918–18924. [Google Scholar] [CrossRef] [PubMed]

- Park, J.-U.; Hardy, M.; Kang, S.J.; Barton, K.; Adair, K.; Mukhopadhyay, D.K.; Lee, C.Y.; Strano, M.S.; Alleyne, A.G.; Georgiadis, J.G.; et al. High-resolution electrohydrodynamic jet printing. Nat. Mater. 2007, 6, 782–789. [Google Scholar] [CrossRef] [PubMed]

- Galliker, P.; Schneider, J.; Eghlidi, H.; Kress, S.; Sandoghdar, V.; Poulikakos, D. Direct printing of nanostructures by electrostatic autofocussing of ink nanodroplets. Nat. Commun. 2012, 3, 890. [Google Scholar] [CrossRef] [PubMed]

- Onses, M.S.; Sutanto, E.; Ferreira, P.M.; Alleyne, A.G.; Rogers, J.A. Mechanisms, Capabilities, and Applications of High-Resolution Electrohydrodynamic Jet Printing. Small 2015, 11, 4237–4266. [Google Scholar] [CrossRef]

- Takai, T.; Nakao, H.; Iwata, F. Three-dimensional microfabrication using local electrophoresis deposition and a laser trapping technique. Opt. Express 2014, 22, 28109–28117. [Google Scholar] [CrossRef]

- Wang, J.; Auyeung, R.C.Y.; Kim, H.; Charipar, N.A.; Piqué, A. Three-dimensional printing of interconnects by laser direct-write of silver nanopastes. Adv. Mater. 2010, 22, 4462–4466. [Google Scholar] [CrossRef]

- Zenou, M.; Sáar, A.; Kotler, Z. Laser Transfer of Metals and Metal Alloys for Digital Microfabrication of 3D Objects. Small 2015, 11, 4082–4089. [Google Scholar] [CrossRef]

- Utke, I.; Hoffmann, P.; Melngailis, J. Gas-assisted focused electron beam and ion beam processing and fabrication. J. Vac. Sci. Technol. B Microelectron. Nanom. Struct. Process. Meas. Phenom. 2008, 26, 1197–1276. [Google Scholar] [CrossRef]

- Huth, M.; Porrati, F.; Dobrovolskiy, O.V. Focused electron beam induced deposition meets materials science. Microelectron. Eng. 2018, 185, 9–28. [Google Scholar] [CrossRef]

- Winkler, R.; Lewis, B.B.; Fowlkes, J.D.; Rack, P.D.; Plank, H. High-Fidelity 3D-Nanoprinting via Focused Electron Beams: Growth Fundamentals. ACS Appl. Nano Mater. 2018, 1, 1014–1027. [Google Scholar] [CrossRef]

- Hada, H.; Yonezawa, Y.; Yoshida, A.; Kurakake, A. Photoreduction of silver ion in aqueous and alcoholic solutions. J. Phys. Chem. 1976, 80, 2728–2731. [Google Scholar] [CrossRef]

- Tanaka, T.; Ishikawa, A.; Kawata, S. Two-photon-induced reduction of metal ions for fabricating three-dimensional electrically conductive metallic microstructure. Appl. Phys. Lett. 2006, 88, 081107. [Google Scholar] [CrossRef]

- Ishikawa, A.; Tanaka, T.; Kawata, S. Improvement in the reduction of silver ions in aqueous solution using two-photon sensitive dye. Appl. Phys. Lett. 2006, 89, 113102. [Google Scholar] [CrossRef]

- Suryavanshi, A.P.; Yu, M.-F. Probe-based electrochemical fabrication of freestanding Cu nanowire array. Appl. Phys. Lett. 2006, 88, 083103. [Google Scholar] [CrossRef]

- Seol, S.K.; Kim, D.; Lee, S.; Kim, J.H.; Chang, W.S.; Kim, J.T. Electrodeposition-based 3D Printing of Metallic Microarchitectures with Controlled Internal Structures. Small 2015, 11, 3896–3902. [Google Scholar] [CrossRef]

- Hirt, L.; Ihle, S.; Pan, Z.; Dorwling-Carter, L.; Reiser, A.; Wheeler, J.M.; Spolenak, R.; Vörös, J.; Zambelli, T. Template-Free 3D Microprinting of Metals Using a Force-Controlled Nanopipette for Layer-by-Layer Electrodeposition. Adv. Mater. 2016, 28, 2311–2315. [Google Scholar] [CrossRef] [PubMed]

- Momotenko, D.; Page, A.; Adobes-Vidal, M.; Unwin, P.R. Write-Read 3D Patterning with a Dual-Channel Nanopipette. ACS Nano 2016, 10, 8871–8878. [Google Scholar] [CrossRef]

- Reiser, A.; Lindén, M.; Rohner, P.; Marchand, A.; Galinski, H.; Sologubenko, A.S.; Wheeler, J.M.; Zenobi, R.; Poulikakos, D.; Spolenak, R. Multi-metal electrohydrodynamic redox 3D printing at the submicron scale. Nat. Commun. 2019, 10, 1853. [Google Scholar] [CrossRef]

- Vyatskikh, A.; Delalande, S.; Kudo, A.; Zhang, X.; Portela, C.M.; Greer, J.R. Additive manufacturing of 3D nano-architected metals. Nat. Commun. 2018, 9, 593. [Google Scholar] [CrossRef]

- Oran, D.; Rodriques, S.G.; Gao, R.; Asano, S.; Skylar-Scott, M.A.; Chen, F.; Tillberg, P.W.; Marblestone, A.H.; Boyden, E.S. 3D nanofabrication by volumetric deposition and controlled shrinkage of patterned scaffolds. Science 2018, 362, 1281–1285. [Google Scholar] [CrossRef]

- Hu, J.; Yu, M.-F. Meniscus-confined three-dimensional electrodeposition for direct writing of wire bonds. Science 2010, 329, 313–316. [Google Scholar] [CrossRef] [PubMed]

- Aaronson, B.D.B.; Güell, A.G.; McKelvey, K.; Momotenko, D.; Unwin, P.R. Scanning Electrochemical Cell Microscopy. Mapping, Measuring, and Modifying Surfaces and Interfaces at the Nanoscale. In Nanoelectrochemistry; CRC Press: Boca Raton, FL, USA, 2015; pp. 655–693. [Google Scholar]

- Lin, Y.-P.; Zhang, Y.; Yu, M.-F. Parallel Process 3D Metal Microprinting. Adv. Mater. Technol. 2019, 4, 1800393. [Google Scholar] [CrossRef]

- Chen, M.; Xu, Z.; Kim, J.H.; Seol, S.K.; Kim, J.T. Meniscus-on-Demand Parallel 3D Nanoprinting. ACS Nano 2018, 12, 4172–4177. [Google Scholar] [CrossRef] [PubMed]

- Yoshioka, M.; Mizutani, Y.; Ushiki, T.; Nakazawa, K.; Iwata, F. Micropillar fabrication based on local electrophoretic deposition using a scanning ion conductance microscope with a theta nanopipette. Jpn. J. Appl. Phys. 2019, 58, 046503. [Google Scholar] [CrossRef]

- Meister, A.; Gabi, M.; Behr, P.; Studer, P.; Vörös, J.; Niedermann, P.; Bitterli, J.; Polesel-Maris, J.; Liley, M.; Heinzelmann, H.; et al. FluidFM: Combining atomic force microscopy and nanofluidics in a universal liquid delivery system for single cell applications and beyond. Nano Lett. 2009, 9, 2501–2507. [Google Scholar] [CrossRef] [PubMed]

- Guillaume-Gentil, O.; Potthoff, E.; Ossola, D.; Franz, C.M.; Zambelli, T.; Vorholt, J.A. Force-controlled manipulation of single cells: From AFM to FluidFM. Trends Biotechnol. 2014, 32, 381–388. [Google Scholar] [CrossRef]

- Binnig, G.; Quate, C.F.; Gerber, C. Atomic force microscope. Phys. Rev. Lett. 1986, 56, 930–933. [Google Scholar] [CrossRef]

- Hirt, L.; Grüter, R.R.; Berthelot, T.; Cornut, R.; Vörös, J.; Zambelli, T. Local surface modification via confined electrochemical deposition with FluidFM. RSC Adv. 2015, 5, 84517–84522. [Google Scholar] [CrossRef]

- Reiser, A.; Koch, L.; Dunn, K.A.; Matsuura, T.; Iwata, F.; Fogel, O.; Kotler, Z.; Charipar, K.; Piqué, A.; Rohner, P.; et al. Metals by micro-scale additive manufaturing: Comparison of microstructure and mechanical properties. arXiv 2019, arXiv:1912.03581. [Google Scholar]

- Ercolano, G.; Zambelli, T.; van Nisselroy, C.; Momotenko, D.; Vörös, J.; Merle, T.; Koelmans, W. Multiscale Additive Manufacturing of Metal Microstructures. Adv. Eng. Mater. 2019. [Google Scholar] [CrossRef]

- Deladi, S.; Tas, N.R.; Berenschot, J.W.; Krijnen, G.J.M.; de Boer, M.J.; de Boer, J.H.; Péter, M.; Elwenspoek, M.C. Micromachined fountain pen for atomic force microscope-based nanopatterning. Appl. Phys. Lett. 2004, 85, 5361–5363. [Google Scholar] [CrossRef]

- Berenschot, E.J.W.; Burouni, N.; Schurink, B.; van Honschoten, J.W.; Sanders, R.G.P.; Truckenmuller, R.; Jansen, H.V.; Elwenspoek, M.C.; van Apeldoorn, A.A.; Tas, N.R. 3D nanofabrication of fluidic components by corner lithography. Small 2012, 8, 3823–3831. [Google Scholar] [CrossRef] [PubMed]

- Dorwling-Carter, L.; Aramesh, M.; Forró, C.; Tiefenauer, R.F.; Shorubalko, I.; Vörös, J.; Zambelli, T. Simultaneous scanning ion conductance and atomic force microscopy with a nanopore: Effect of the aperture edge on the ion current images. J. Appl. Phys. 2018, 124, 174902. [Google Scholar] [CrossRef]

- Yamada, J.; Matsuda, H. Limiting diffusion currents in hydrodynamic voltammetry: III. Wall jet electrodes. J. Electroanal. Chem. Interfacial Electrochem. 1973, 44, 189–198. [Google Scholar] [CrossRef]

- Galleria Dell’Accademia Di Firenze (Italy). Available online: http://www.galleriaaccademiafirenze.beniculturali.it (accessed on 12 November 2019).

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ercolano, G.; van Nisselroy, C.; Merle, T.; Vörös, J.; Momotenko, D.; Koelmans, W.W.; Zambelli, T. Additive Manufacturing of Sub-Micron to Sub-mm Metal Structures with Hollow AFM Cantilevers. Micromachines 2020, 11, 6. https://doi.org/10.3390/mi11010006

Ercolano G, van Nisselroy C, Merle T, Vörös J, Momotenko D, Koelmans WW, Zambelli T. Additive Manufacturing of Sub-Micron to Sub-mm Metal Structures with Hollow AFM Cantilevers. Micromachines. 2020; 11(1):6. https://doi.org/10.3390/mi11010006

Chicago/Turabian StyleErcolano, Giorgio, Cathelijn van Nisselroy, Thibaut Merle, János Vörös, Dmitry Momotenko, Wabe W. Koelmans, and Tomaso Zambelli. 2020. "Additive Manufacturing of Sub-Micron to Sub-mm Metal Structures with Hollow AFM Cantilevers" Micromachines 11, no. 1: 6. https://doi.org/10.3390/mi11010006

APA StyleErcolano, G., van Nisselroy, C., Merle, T., Vörös, J., Momotenko, D., Koelmans, W. W., & Zambelli, T. (2020). Additive Manufacturing of Sub-Micron to Sub-mm Metal Structures with Hollow AFM Cantilevers. Micromachines, 11(1), 6. https://doi.org/10.3390/mi11010006