A Silicon Resonant Accelerometer Embedded in An Isolation Frame with Stress Relief Anchor

Abstract

1. Introduction

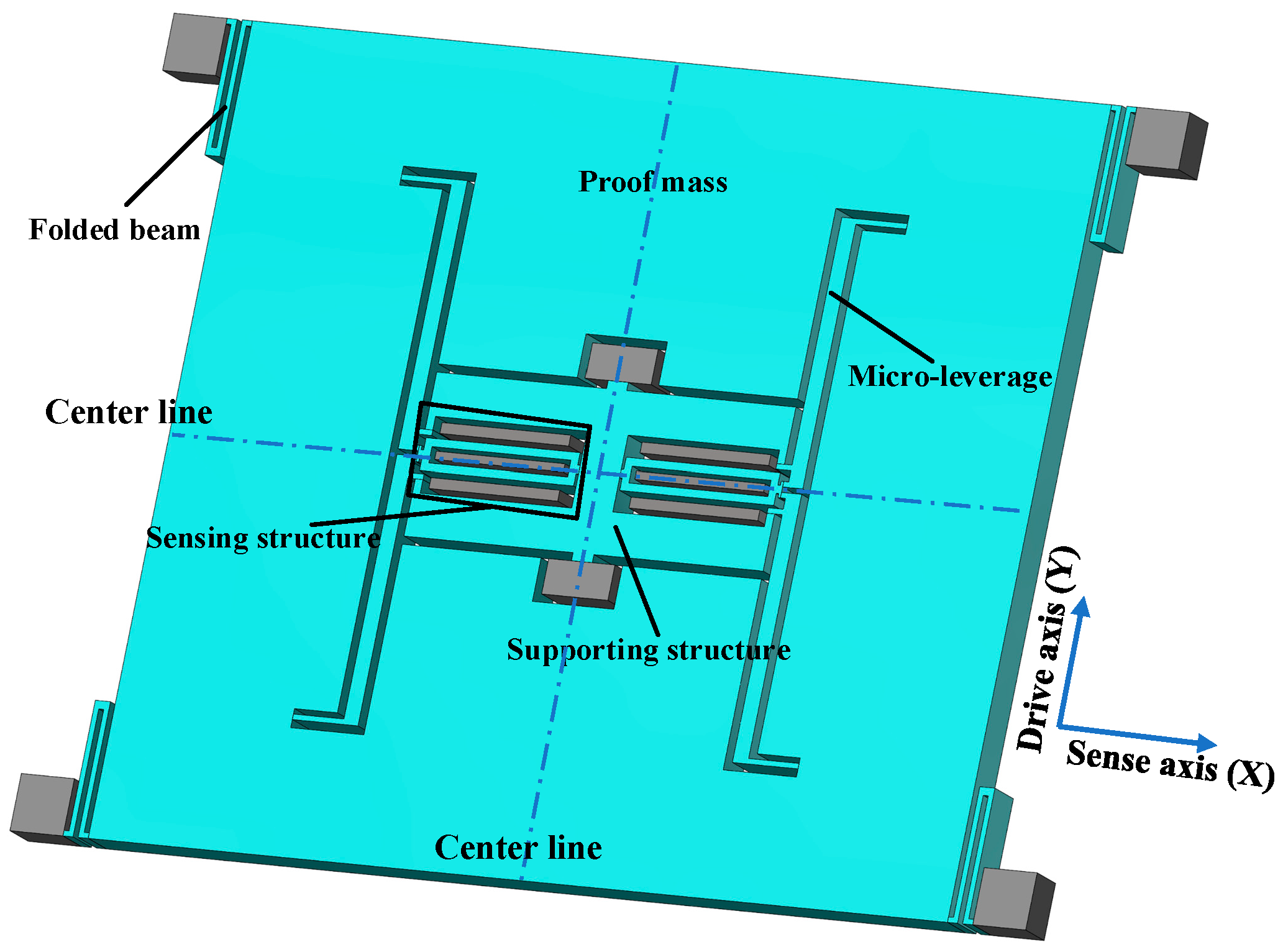

2. Device Design and Fabrication

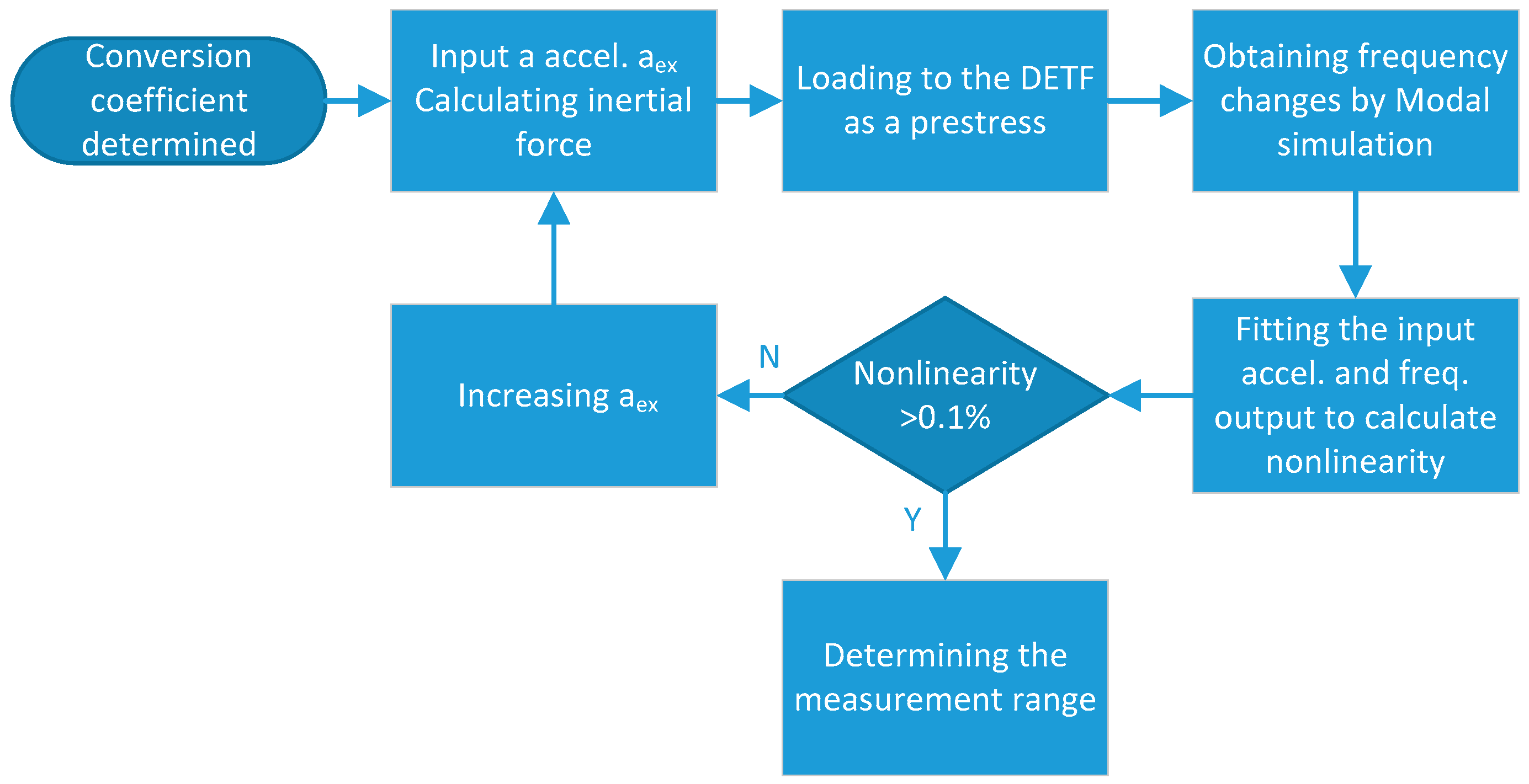

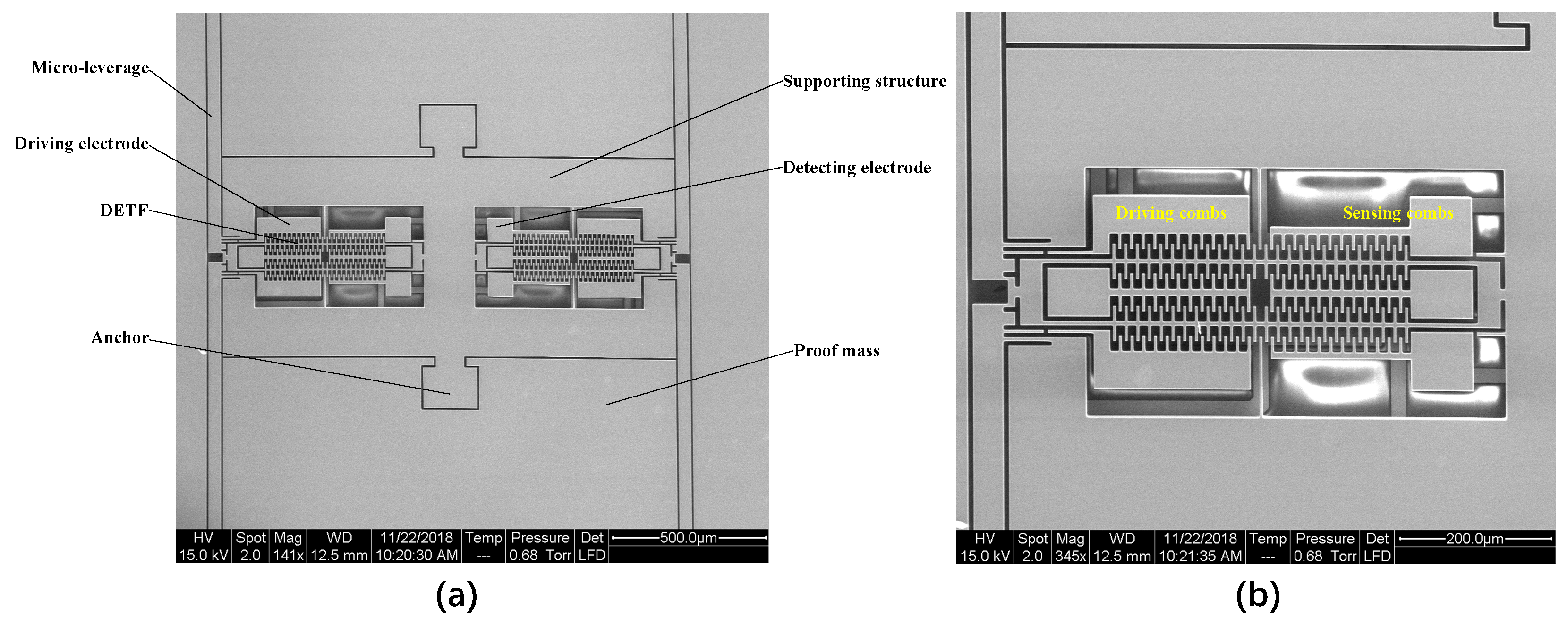

2.1. Mechanical Design

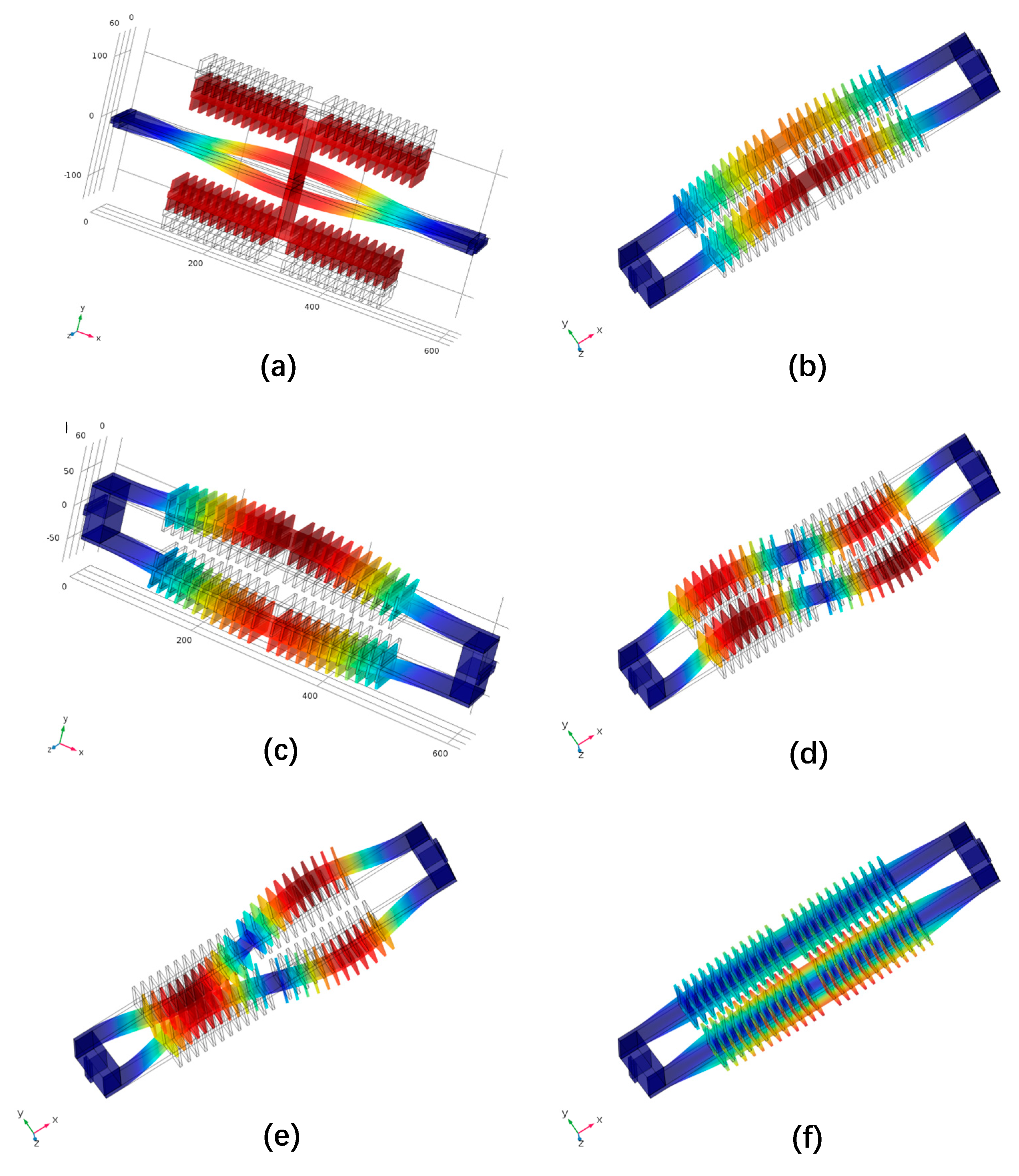

2.2. Modal Analysis

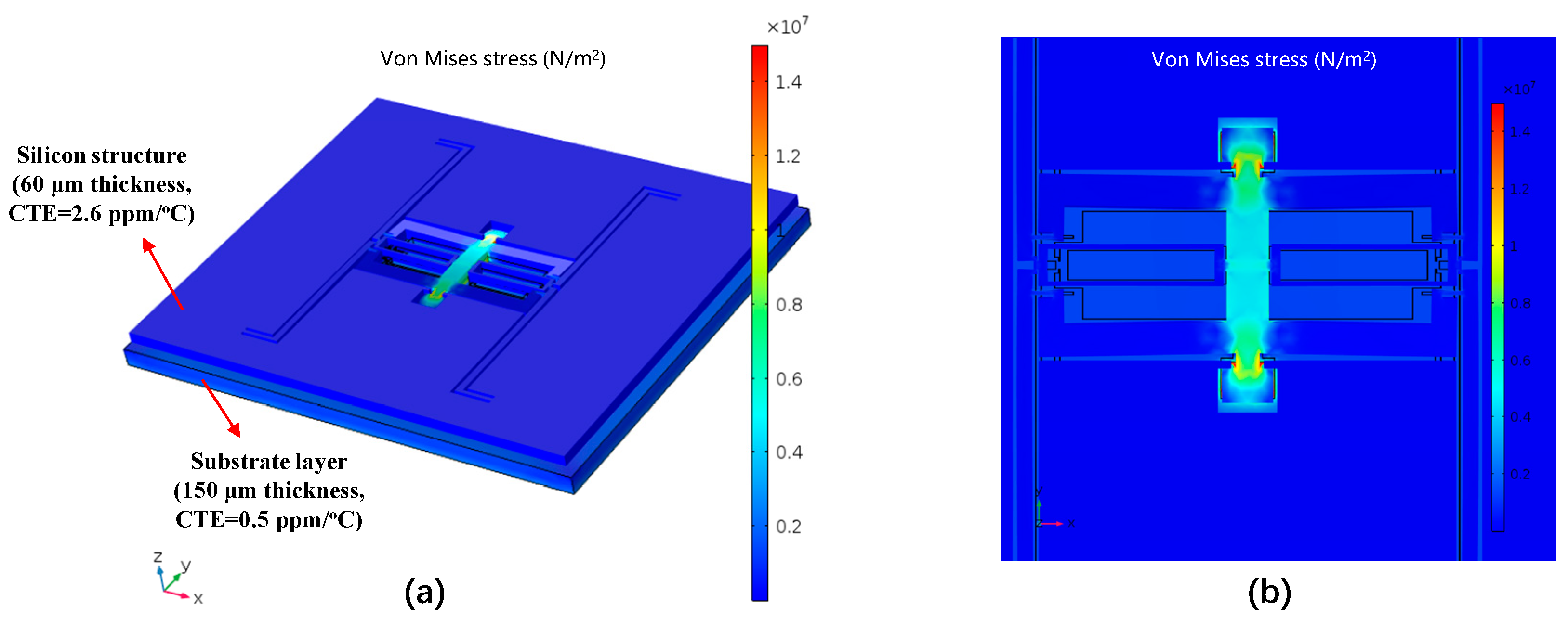

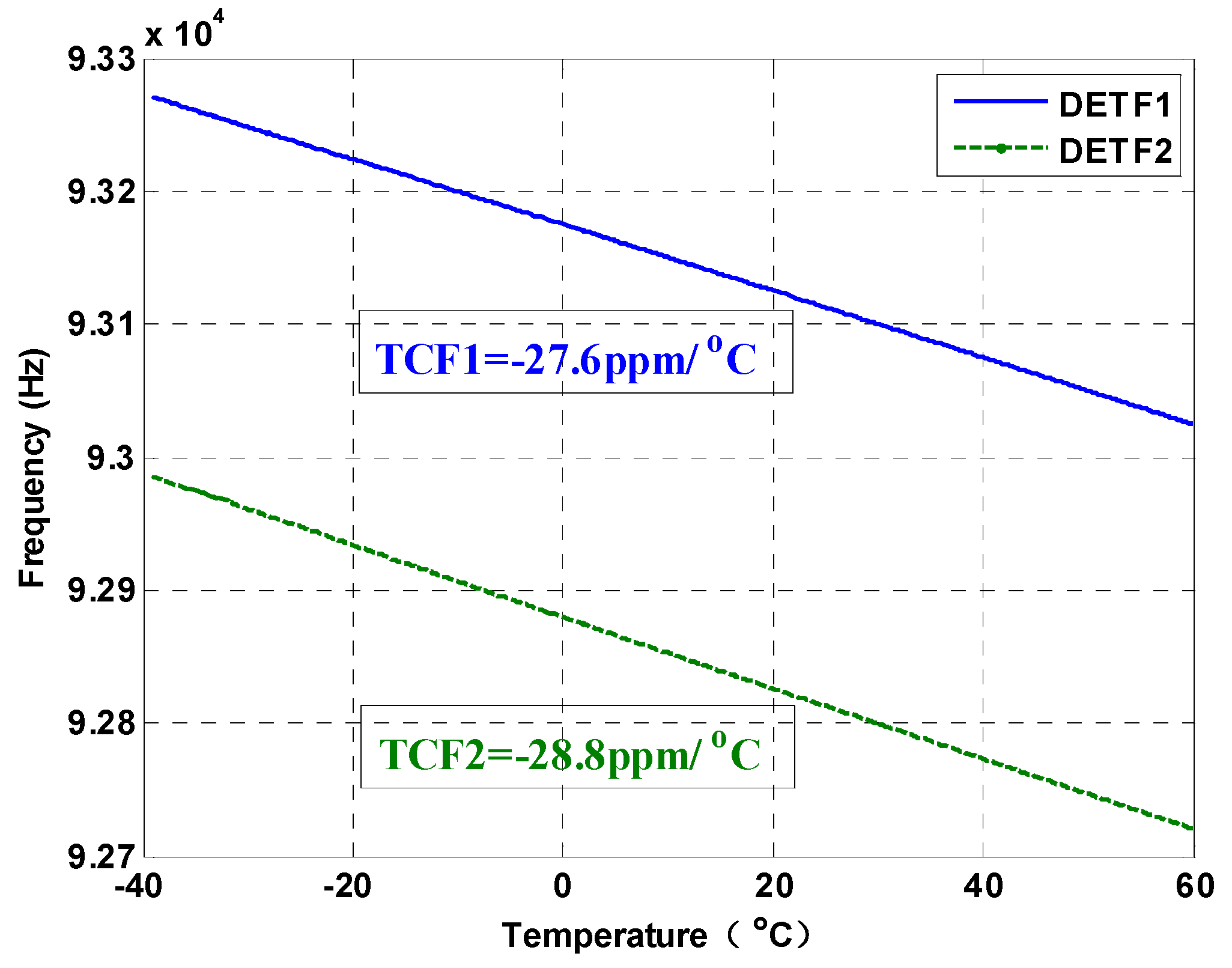

2.3. Thermal Sensitivity of Resonant Frequency

2.4. Stress Insensitive Anchor Design

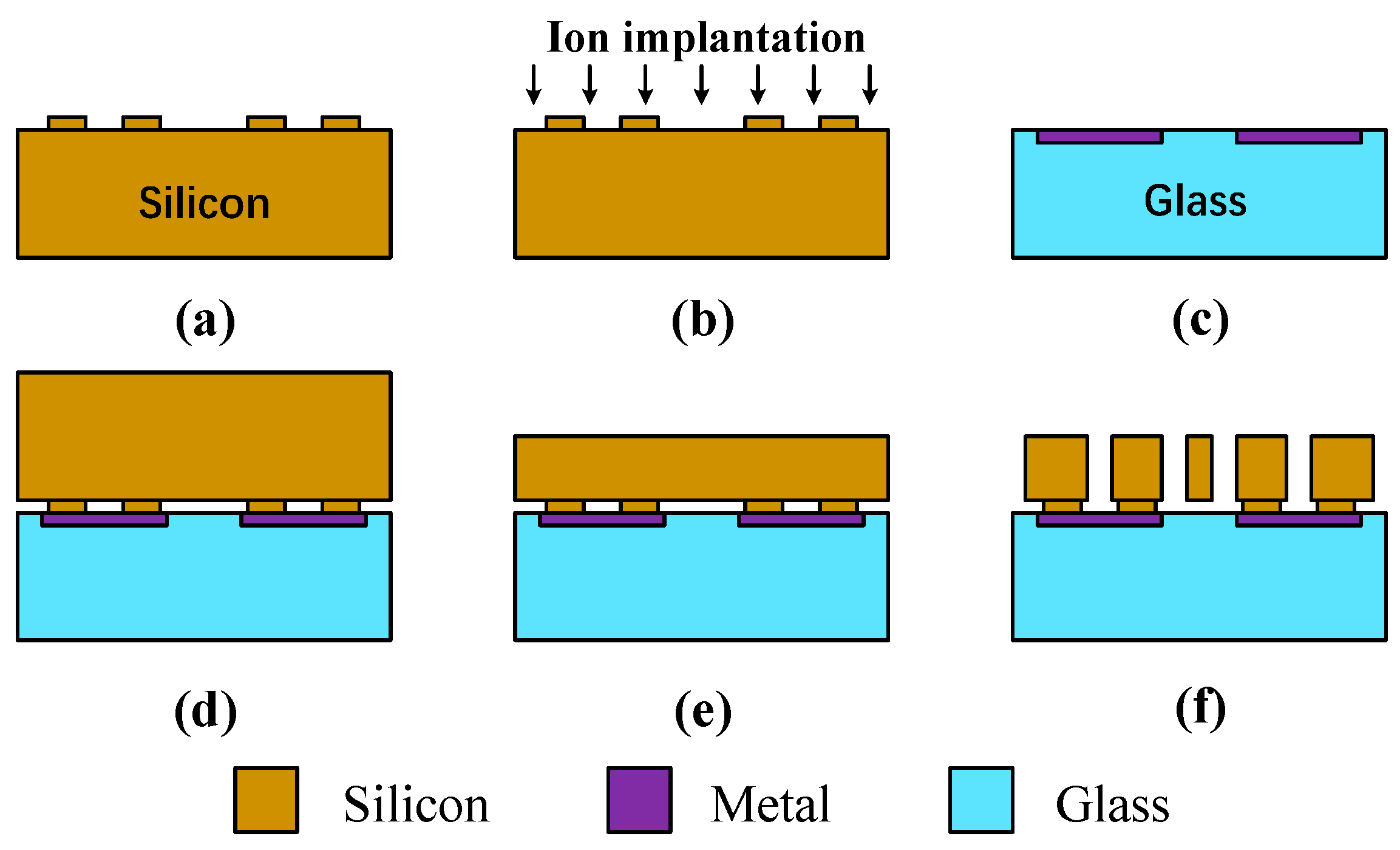

2.5. Fabrication

3. Results and Discussion

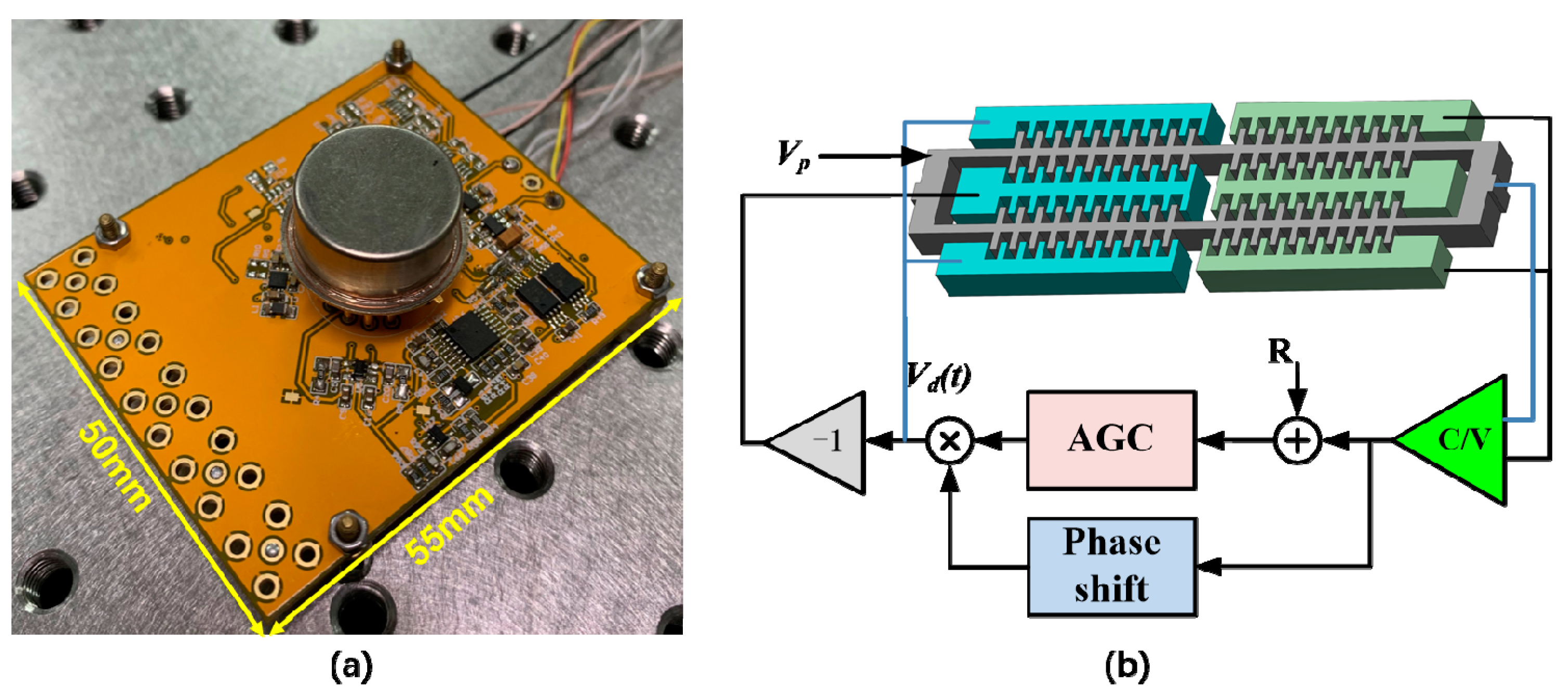

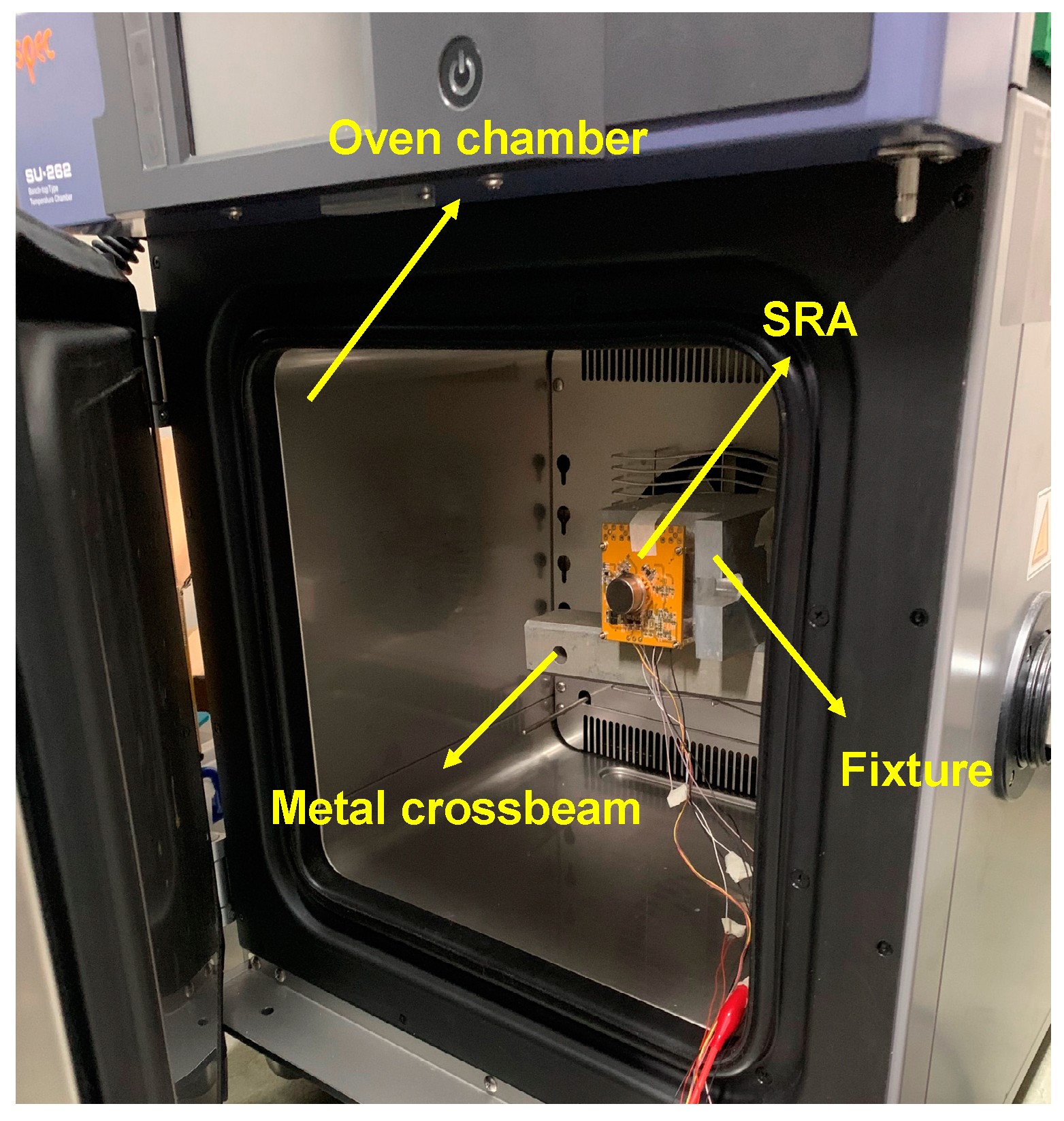

3.1. Packaging and Control Circuit

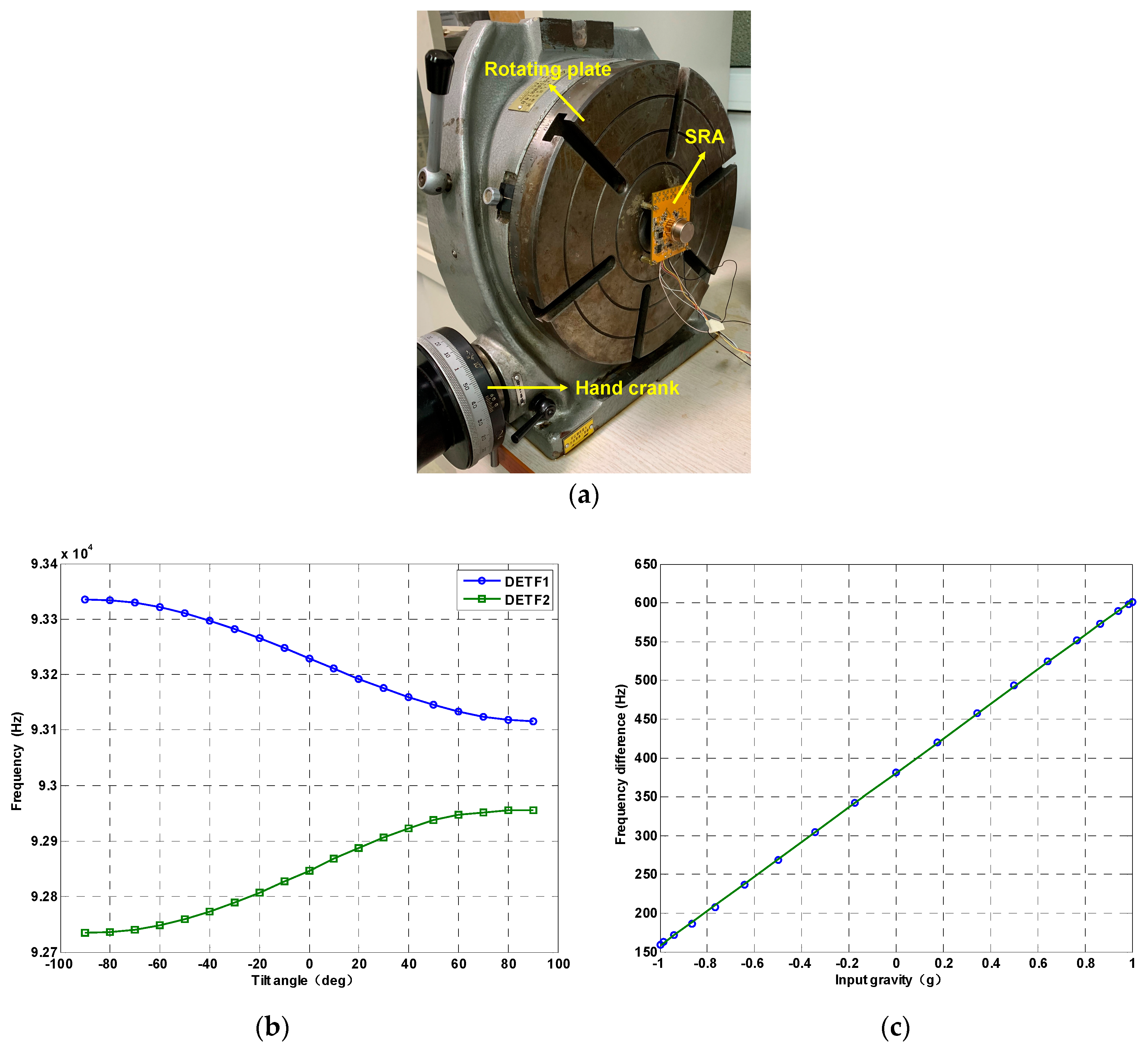

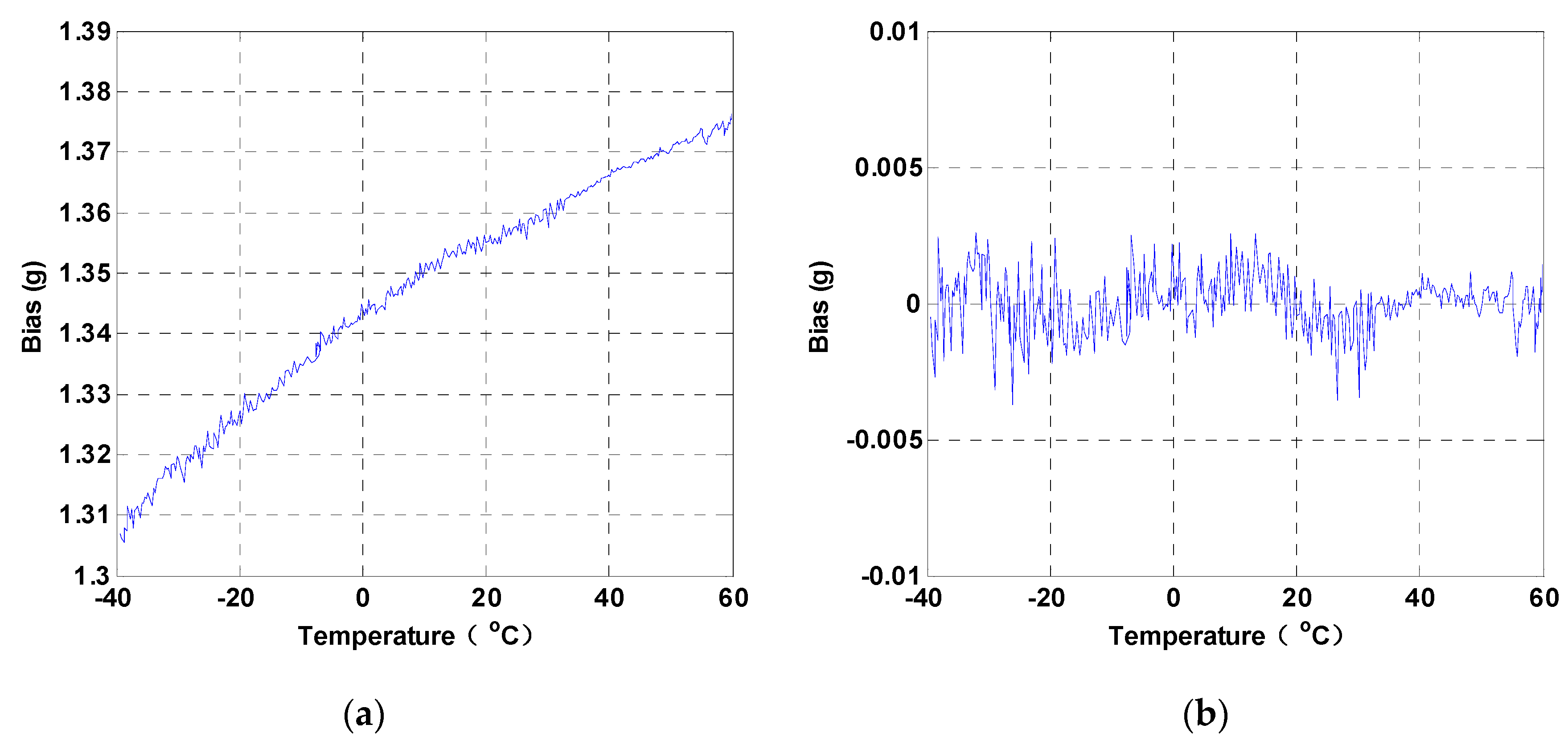

3.2. Test Results

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Hopkins, R.; Miola, J.; Setterlund, R.; Dow, B.; Sawyer, W. The silicon oscillating accelerometer: A high-performance MEMS accelerometer for precision navigation and strategic guidance applications. In Proceedings of the the 61st Annual Meeting of The Institute of Navigation, Cambridge, MA, USA, 27–29 June 2005; pp. 1043–1052. [Google Scholar]

- Beitia, J.; Clifford, A.; Fell, C.; Loisel, P. Quartz pendulous accelerometers for navigation and tactical grade systems. In Proceedings of the 2015 DGON Inertial Sensors and Systems Symposium (ISS), Karlsruhe, Germany, 22–23 September 2015; pp. 1–20. [Google Scholar] [CrossRef]

- Dong, J.; Qiu, A.; Shi, R. Temperature influence mechanism of micromechanical silicon oscillating accelerometer. In Proceedings of the 2011 IEEE Power Engineering and Automation Conference, Wuhan, China, 8–9 September 2011; pp. 385–389. [Google Scholar] [CrossRef]

- Melamud, R.; Hopcroft, M.; Jha, C.; Bongsang, K.; Chandorkar, S.; Candler, R.; Kenny, T.W. Effects of stress on the temperature coefficient of frequency in double clamped resonators. In Proceedings of the The 13th International Conference on Solid-State Sensors, Actuators and Microsystems, 2005. Digest of Technical Papers. TRANSDUCERS ‘05., Seoul, South Korea, 5–9 June 2005; pp. 392–395. [Google Scholar] [CrossRef]

- Kim, B.; Melamud, R.; Hopcroft, M.A.; Chandorkar, S.A.; Bahl, G.; Messana, M.; Candler, R.N.; Yama, G.; Kenny, T. Si-SiO2 Composite MEMS Resonators in CMOS Compatible Wafer-scale Thin-Film Encapsulation. In Proceedings of the 2007 IEEE International Frequency Control Symposium Joint with the 21st European Frequency and Time Forum, Geneva, Switzerland, 29 May–1 June 2007; pp. 1214–1219. [Google Scholar] [CrossRef]

- Tabrizian, R.; Casinovi, G.; Ayazi, F. Temperature-Stable Silicon Oxide (SilOx) Micromechanical Resonators. IEEE Trans. Electron Devices 2013, 60, 2656–2663. [Google Scholar] [CrossRef]

- Sundaresan, K.; Ho, G.K.; Pourkamali, S.; Ayazi, F. Electronically temperature compensated silicon bulk acoustic resonator reference oscillators. IEEE J Solid-St Circ 2007, 42, 1425–1434. [Google Scholar] [CrossRef]

- Traon, O.L.; Janiaud, D.; Lecorre, B.; Pernice, M.; Muller, S.; Tridera, J. Monolithic differential vibrating beam accelerometer within an isolating system between the two resonators. In Proceedings of the SENSORS, 2005 IEEE, Irvine, CA, USA, 30 Oct.–3 November 2005; p. 4. [Google Scholar] [CrossRef]

- Lee, S.; Lee, S.W.; Najafi, K. A Generic Environment-Resistant Packaging Technology for MEMS. In Proceedings of the TRANSDUCERS 2007 - 2007 International Solid-State Sensors, Actuators and Microsystems Conference, Lyon, France, 10–14 June 2007; pp. 335–338. [Google Scholar] [CrossRef]

- Yin, Y.; Fang, Z.; Dong, J.; Liu, Y.; Han, F. A Temperature-Insensitive Micromachined Resonant Accelerometer with Thermal Stress Isolation. In Proceedings of the 2018 IEEE SENSORS, New Delhi, India, 28–31 October 2018; pp. 1–4. [Google Scholar] [CrossRef]

- Jha, C.M.; Hopcroft, M.A.; Chandorkar, S.A.; Salvia, J.C.; Agarwal, M.; Candler, R.N.; Melamud, R.; Kim, B.; Kenny, T.W. Thermal isolation of encapsulated MEMS resonators. J. Microelectromech. Syst. 2008, 17, 175–184. [Google Scholar] [CrossRef]

- Hopcroft, M.A.; Agarwal, M.; Park, K.K.; Kim, B.; Jha, C.M.; Candler, R.N.; Yama, G.; Murmann, B.; Kenny, T.W. Temperature Compensation of a MEMS Resonator Using Quality Factor as a Thermometer. In Proceedings of the 19th IEEE International Conference on Micro Electro Mechanical Systems, Istanbul, Turkey, 22–26 January 2006; pp. 222–225. [Google Scholar] [CrossRef]

- Kose, T.; Azgin, K.; Akin, T. Temperature compensation of a capacitive MEMS accelerometer by using a MEMS oscillator. In Proceedings of the 2016 IEEE International Symposium on Inertial Sensors and Systems, Laguna Beach, CA, USA, 22–25 February 2016; pp. 33–36. [Google Scholar] [CrossRef]

- Xia, G.; Shi, Q.; Qiu, A.; Yu, X.; Pei, Z. An on-chip thermal stress evaluation method for silicon resonant accelerometer. In Proceedings of the 2016 IEEE SENSORS, Orlando, FL, USA, 30 Oct.–3 November 2016; pp. 1–3. [Google Scholar] [CrossRef]

- Okada, Y.; Tokumaru, Y. Precise determination of lattice parameter and thermal expansion coefficient of silicon between 300 and 1500 K. J. Appl. Phys. 1984, 56, 314–320. [Google Scholar] [CrossRef]

- Hopcroft, M.A.; Nix, W.D.; Kenny, T.W. What is the Young’s Modulus of Silicon? J Microelectromech Syst. 2010, 19, 229–238. [Google Scholar] [CrossRef]

- Cui, J.; Chi, X.Z.; Ding, H.T.; Lin, L.T.; Yang, Z.C.; Yan, G.Z. Transient response and stability of the AGC-PI closed-loop controlled MEMS vibratory gyroscopes. J. Micromech. Microeng. 2009, 19, 125015. [Google Scholar] [CrossRef]

- Yan, J.J.; He, C.H.; Ge, F.; Zhao, Q.C.; Cui, J.; Yan, G.Z. Research of Resonant Frequency and Quality Factor Test Methods for High Vacuum Sealed Microgyroscope Based on LabVIEW. Procedia Eng. 2011, 15, 2566–2570. [Google Scholar] [CrossRef][Green Version]

- Shi, R.; Zhao, J.; Qiu, A.P.; Xia, G.M. Temperature Self-Compensation of Micromechanical Silicon Resonant Accelerometer. Appl. Mech. Mater. 2013, 373–375, 373–381. [Google Scholar] [CrossRef]

- Wang, Y.G.; Zhang, J.; Yao, Z.C.; Lin, C.; Zhou, T.; Su, Y.; Zhao, J. A MEMS Resonant Accelerometer With High Performance of Temperature Based on Electrostatic Spring Softening and Continuous Ring-Down Technique. IEEE Sens. J. 2018, 18, 7023–7031. [Google Scholar] [CrossRef]

- Shin, D.D.; Ahn, C.H.; Chen, Y.; Christensen, D.L.; Flader, I.B.; Kenny, T.W. Environmentally robust differential resonant accelerometer in a wafer-scale encapsulation process. In Proceedings of the 2017 IEEE 30th International Conference on Micro Electro Mechanical Systems (MEMS), Las Vegas, NV, USA, 22–26 January 2017; pp. 17–20. [Google Scholar] [CrossRef]

- Comi, C.; Corigliano, A.; Langfelder, G.; Zega, V.; Zerbini, S. Sensitivity and temperature behavior of a novelz-axis differential resonant micro accelerometer. J. Micromech. Microeng. 2016, 26, 035006. [Google Scholar] [CrossRef]

- Huang, L.B.; Yang, H.; Gao, Y.; Zhao, L.Y.; Liang, J.X. Design and Implementation of a Micromechanical Silicon Resonant Accelerometer. Sensors 2013, 13, 15785–15804. [Google Scholar] [CrossRef] [PubMed]

| Parameters | Value |

|---|---|

| Beam length of DETF (L) | 600 μm |

| Beam width of DETF (w) | 5.5 μm |

| Thickness of the structure (h) | 60 μm |

| Finger width | 5 μm |

| Finger length | 20 μm |

| Finger gap | 2.5 μm |

| Number of fingers | 52 |

| Modal Order | Modal Shape | Resonant Frequency (Hz) |

|---|---|---|

| 1st | translation mode | 92905 |

| 2nd | drive mode | 93065 |

| 3rd | in-phase wriggle mode | 255960 |

| 4th | opposite wriggle mode | 258590 |

| 5th | torsional mode | 492900 |

| Reference | [19] | [20] | [21] | [22] | [23] | This Work |

|---|---|---|---|---|---|---|

| Material | Silicon | Silicon | Silicon | Silicon | Silicon | Silicon |

| Frequency (Hz) | 27934 | 3625 | 803950 | 25600 | 31462 | 93228 |

| SF (Hz/g) | 82 | 5.09 | 427 | 10 | 66.2 | 223.7 |

| Freq. TCF (ppm/°C) | — | −28.9 | −23 | −29 | 58 | −28.8 |

| Bias TCF (mg/°C) | 3.1 | 2.64 | 0.14 | 0.11 | 1.1 | 0.7 |

| Temp. range (°C) | 3–30 | −40–40 | −20–80 | 5–95 | −40–60 | −40–60 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cui, J.; Yang, H.; Li, D.; Song, Z.; Zhao, Q. A Silicon Resonant Accelerometer Embedded in An Isolation Frame with Stress Relief Anchor. Micromachines 2019, 10, 571. https://doi.org/10.3390/mi10090571

Cui J, Yang H, Li D, Song Z, Zhao Q. A Silicon Resonant Accelerometer Embedded in An Isolation Frame with Stress Relief Anchor. Micromachines. 2019; 10(9):571. https://doi.org/10.3390/mi10090571

Chicago/Turabian StyleCui, Jian, Haibing Yang, Dong Li, Ziyang Song, and Qiancheng Zhao. 2019. "A Silicon Resonant Accelerometer Embedded in An Isolation Frame with Stress Relief Anchor" Micromachines 10, no. 9: 571. https://doi.org/10.3390/mi10090571

APA StyleCui, J., Yang, H., Li, D., Song, Z., & Zhao, Q. (2019). A Silicon Resonant Accelerometer Embedded in An Isolation Frame with Stress Relief Anchor. Micromachines, 10(9), 571. https://doi.org/10.3390/mi10090571