Resonant Pressure Micro Sensors Based on Dual Double Ended Tuning Fork Resonators

Abstract

1. Introduction

2. Design

2.1. Sensor Description

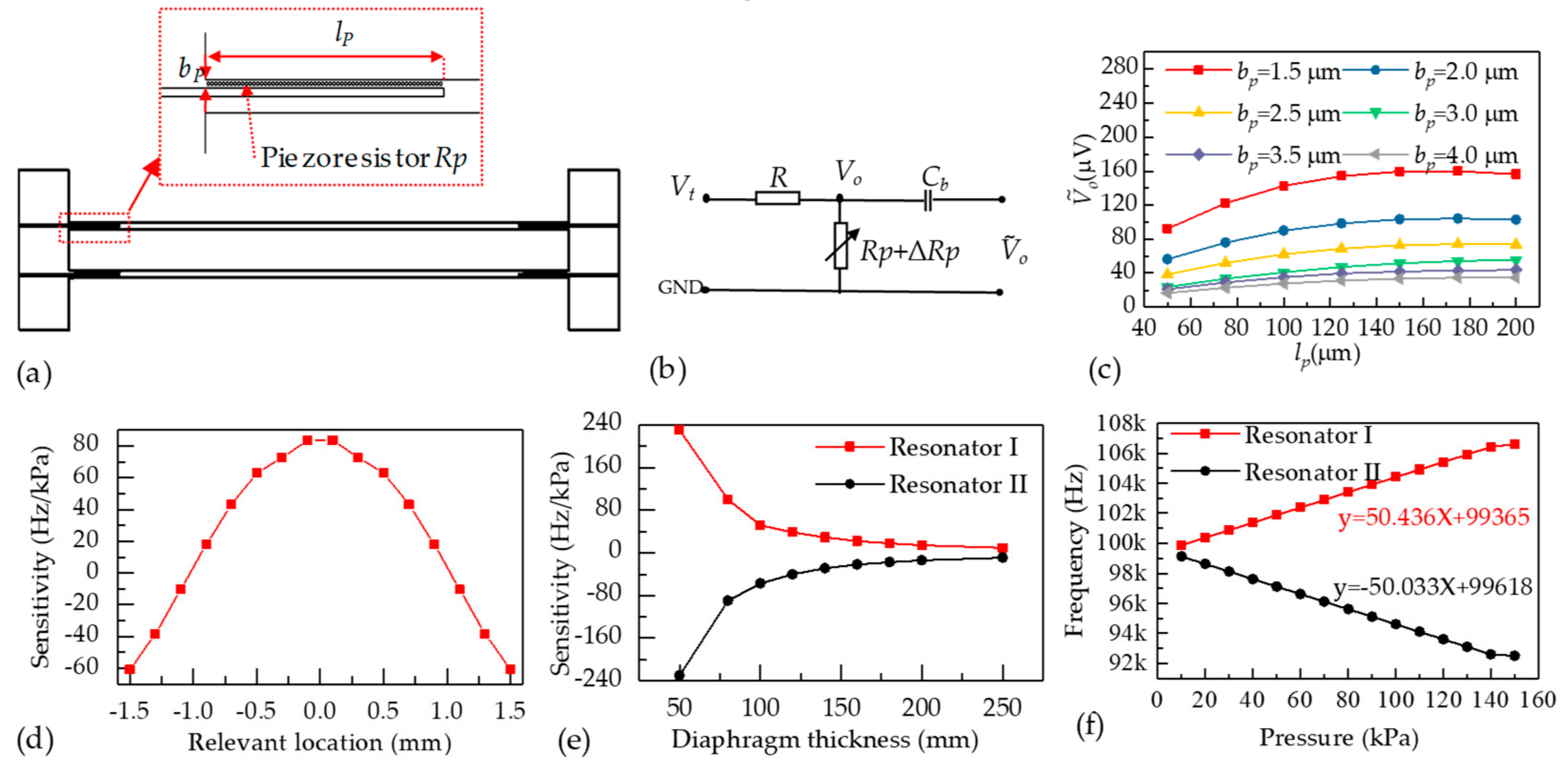

2.2. Sensor Design

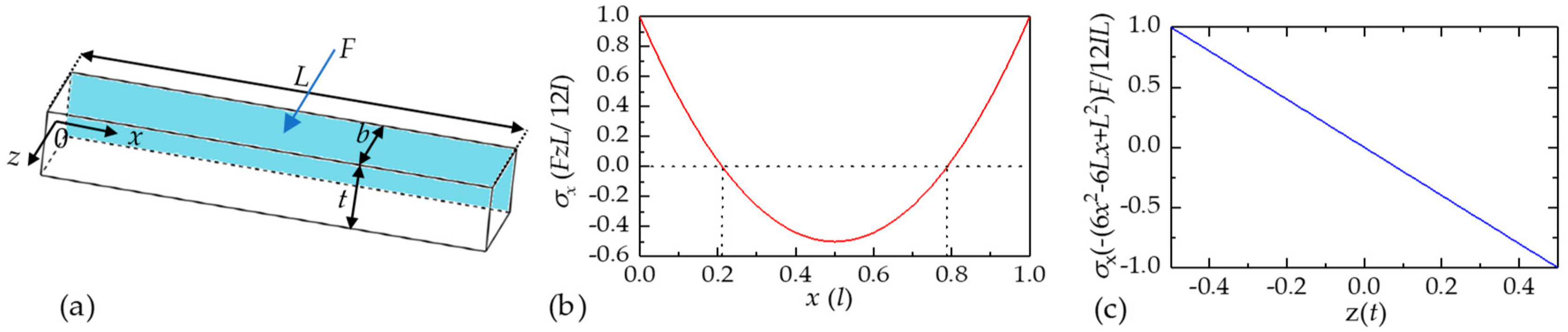

2.2.1. Theoretical Analysis of the DETF Resonator

2.2.2. FEA Simulations

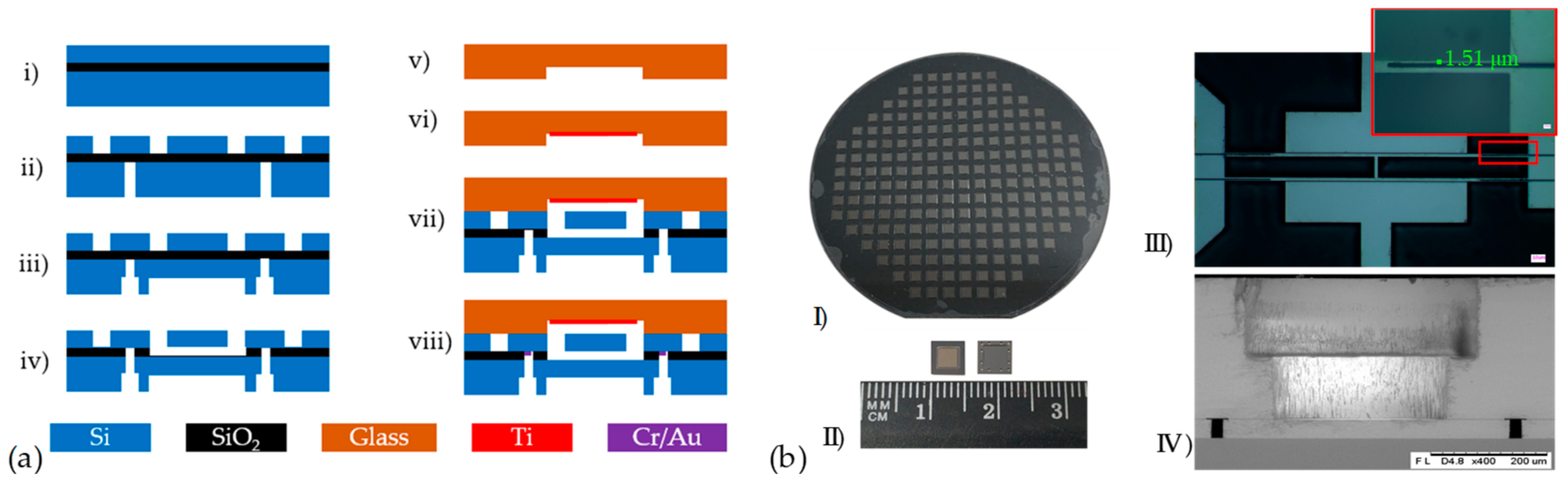

3. Fabrication

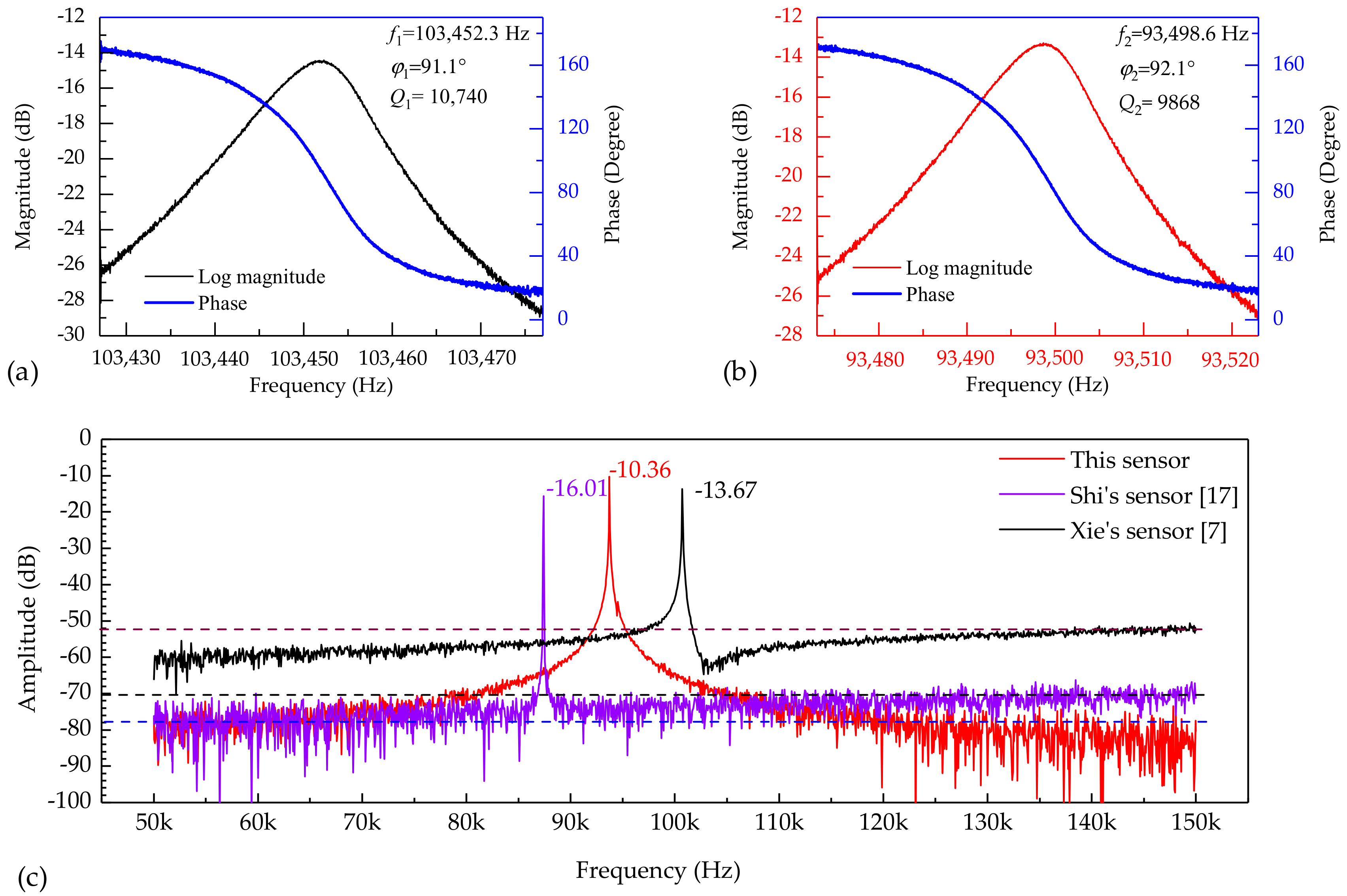

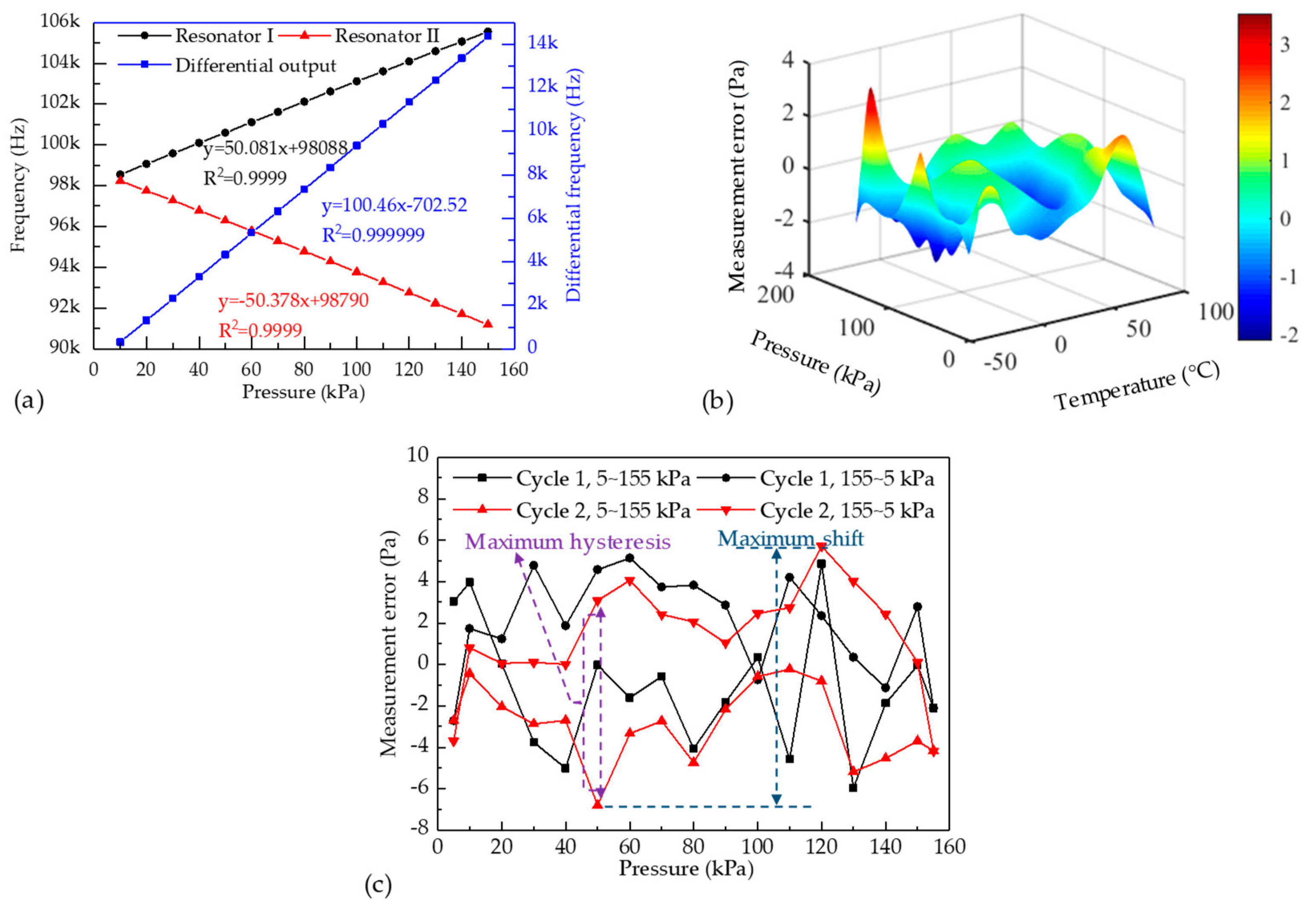

4. Experimental Characterizations

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Eaton, W.P.; Smith, J.H. Micromachined Pressure Sensors: Review and Recent Developments. Smart Mater. Struct. 1997, 6, 530–539. [Google Scholar] [CrossRef]

- Beeby, S.P.; Ensel, G.; Kraft, M.; White, N.M. MEMS Mechanical Sensors; Artech House Inc.: London, UK, 2008; pp. 97–112. [Google Scholar]

- Wang, J.B.; Chen, D.Y.; Xie, B.; Chen, J.; Zhu, L.; Lu, Y.L. A Micromachined Silicon Resonant Pressure Sensor. In Micro Electro Mechanical Systems; Huang, Q.A., Ed.; Springer: Singapore, 2017; pp. 1–34. [Google Scholar]

- Greenwood, J.C. Etched silicon vibrating sensor. J. Phys. E Sci. Instrum. 1984, 17, 650–652. [Google Scholar] [CrossRef]

- Chen, D.Y.; Cui, D.F.; Yu, Z.Y.; Wang, L.; Cui, Z.; Xia, S.H. Thermally-excited SiN Beam Resonant Pressure Sensor. Proceedings of Design, Test, Integration, and Packaging of MEMS/MOEMS 2001, Cannes-Mandelieu, France, 5 April 2001; pp. 548–554. [Google Scholar]

- Tang, Z.Y.; Fan, S.C.; Xing, W.W.; Guo, Z.S.; Zhang, Z.Y. An Electrothermally Excited Dual Beams Silicon Resonant Pressure Sensor with Temperature Compensation. Microsyst. Technol. 2011, 17, 1481–1490. [Google Scholar] [CrossRef]

- Xie, B.; Xing, Y.H.; Wang, Y.S.; Chen, J.; Chen, D.Y.; Wang, J.B. A Lateral Differential Resonant Pressure Microsensor Based on SOI-Glass Wafer-Level Vacuum Packaging. Sensors 2015, 15, 24257–24268. [Google Scholar] [CrossRef] [PubMed]

- Sun, X.D.; Yuan, W.Z.; Qiao, D.Y.; Sun, M.; Ren, S. Design and Analysis of a New Tuning Fork Structure for Resonant Pressure Sensor. Micromachines 2016, 7, 148. [Google Scholar] [CrossRef] [PubMed]

- Luo, Z.Y.; Chen, D.Y.; Wang, J.B.; Li, Y.N.; Chen, J. A High-Q Resonant Pressure Microsensor with Through-Glass Electrical Interconnections Based on Wafer-Level MEMS Vacuum Packaging. Sensors 2014, 14, 24244–24257. [Google Scholar] [CrossRef] [PubMed]

- Harada, K.; Ikeda, K.; Kuwayama, H.; Murayama, H. Various Applications of Resonant Pressure Sensor Chip Based On 3-D Micromachining. Sens. Actuat. A Phys. 1999, 73, 261–266. [Google Scholar] [CrossRef]

- Greenwood, J.C.; Wray, T. High Accuracy Pressure Measurement with A Silicon Resonant Sensor. Sens. Actuat. A Phys. 1993, 37, 82–85. [Google Scholar] [CrossRef]

- Welham, C.J.; Gardner, J.W.; Greenwood, J.C. A Laterally Driven Micromachined Resonant Pressure Sensor. Sens. Actuat. A Phys. 1996, 52, 86–91. [Google Scholar] [CrossRef]

- Shi, X.Q.; Lu, Y.L.; Xie, B.; Li, Y.D.; Wang, J.B.; Chen, D.Y.; Chen, J. A Resonant Pressure Microsensor Based on Double-Ended Tuning Fork and Electrostatic Excitation/Piezoresistive Detection. Sensors 2018, 18, 2494. [Google Scholar] [CrossRef] [PubMed]

- Parsons, P.; Glendinning, A.; Angelidis, D. Resonant Sensor for High Accuracy Pressure Measurement Using Silicon Technology. IEEE Aero. El. Sys. Mag. 1992, 7, 45–48. [Google Scholar] [CrossRef]

- Welham, C.J.; Greenwood, J.; Bertioli, M.M. A High Accuracy Resonant Pressure Sensor by Fusion Bonding and Trench Etching. Sens. Actuat. A Phys. 1999, 76, 298–304. [Google Scholar] [CrossRef]

- Kinnell, P.K.; Craddock, R. Advances in Silicon Resonant Pressure Transducers. Procedia Chem. 2009, 1, 104–107. [Google Scholar] [CrossRef]

- Shi, X.Q.; Zhang, S.; Chen, D.; Wang, J.; Chen, J.; Xie, B.; Lu, Y.; Li, Y. A Resonant Pressure Sensor Based Upon Electrostatically Comb Driven and Piezoresistively Sensed Lateral Resonators. Micromachines 2019, 10, 460. [Google Scholar] [CrossRef] [PubMed]

- Chiou, J.C.; Shieh, L.J.; Lin, Y.J. CMOS-MEMS prestress vertical cantilever resonator with electrostatic driving and piezoresistive sensing. J. Phys. D-Appl. Phys. 2008, 41, 205102. [Google Scholar] [CrossRef]

- Wei, W.S.; You, W.L.; Zhao, W.; Yu, Z.Y.; Pang, J.; Yang, H. A novel approach for MEMS with galvanic protection on SOI wafer. Microsyst. Technol. 2014, 21, 1959–1965. [Google Scholar] [CrossRef]

- Wei, W.S.; You, W.L.; Dou, C.G.; Wang, X.F.; Yang, H. Symmetrical design in piezoresistive sensing for micromechanical resonator. Microsyst. Technol. 2015, 22, 811–816. [Google Scholar] [CrossRef]

- Li, C.S.; Li, M.H.; Chen, C.C.; Chin, C.H.; Li, S.S. A Low-Voltage CMOS-Microelectromechanical Systems Thermal-Piezoresistive Resonator with Q > 10000. IEEE Electron Device Lett. 2015, 36, 192–194. [Google Scholar]

- Bao, M.H. Mechanics of Beam and Diaphragm Structures. In Analysis and Design Principles of MEMS Devices; Elsevier Inc.: San Diego, CA, USA, 2005; pp. 44–63. [Google Scholar]

- Liu, C. Electrostatic Sensing. In Foundations of MEMS, 2nd ed.; Liu, C., Ed.; Pearson Education Inc.: Hoboken, NJ, USA, 2012; pp. 129–132. [Google Scholar]

- Ljung, P.B.; Pisano, A.P. Nonlinear dynamics of micromachined Rate Gyros. J. Microelectromech. Syst. 1996, 59, 393–400. [Google Scholar]

- Liu, M.; Wang, J.B.; Li, Y.X.; Chen, D.Y. Research on Closed-Loop Control for Resonant MEMS Pressure Sensor with Electromagnetic Excitation. Chinese J. Sens. Actuat. 2010, 23, 1066–1069. [Google Scholar]

| Characteristics | Sample 1 | Sample 2 | Sample 3 | Sample 4 | Average | |

|---|---|---|---|---|---|---|

| Q factor | Resonator I Resonator II | 10,740 9868 | 10,438 9765 | 10,148 9641 | 10,713 9683 | 10,510 ± 240 9739 ± 87 |

| Sensitivity (Hz/kPa) | Resonator I Resonator II | +50.1 −50.4 | +51.2 −52.1 | +51.1 −49.3 | +50.8 −50.2 | +50.8 ± 0.4 −50.5 ± 1.0 |

| SNR | 67.64 dB | 58.53 dB | 62.75 dB | 65.88 dB | 63.70 ± 3.46 dB | |

| Accuracy | 0.01% FS | 0.01% FS | 0.01% FS | 0.01% FS | 0.01% FS | |

| Shift | 83 ppm | 86 ppm | 80 ppm | 82 ppm | 83 ± 2 ppm | |

| Hysteresis | 66 ppm | 70 ppm | 62 ppm | 68 ppm | 67 ± 3 ppm | |

| Repeatability error | 39 ppm | 36 ppm | 40 ppm | 42 ppm | 39 ± 2 ppm | |

| Characteristics | Xie [7] | Sun [8] | Shi [13] | Shi [17] | These Sensors |

|---|---|---|---|---|---|

| SNR | 38.33 dB | 30 dB | / | 54.00 dB | 63.70 dB |

| Sensitivity | 166 Hz/kPa | 29 Hz/kPa | 79 Hz/kPa | 48 Hz/kPa | 101 Hz/kPa |

| Sensor dimension | 9 × 9 mm | / | 9 × 9 mm | 7 × 7 mm | 5 × 5 mm |

| Q factor | 11,000 | 10,000 | 10,000 | 17,000 | 10,000 |

| Temperature range | −40~70 °C | −40~80 °C | −35~85 °C | −35~85 °C | −45~85 °C |

| Accuracy | 0.02% FS | 0.05% FS | 0.01% FS | 0.01% FS | 0.01% FS |

| Shift | / | / | / | / | 83 ppm |

| Hysteresis | / | 500 ppm | / | / | 67 ppm |

| Repeatability error | / | 100 ppm | / | / | 39 ppm |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, Y.; Zhang, S.; Yan, P.; Li, Y.; Yu, J.; Chen, D.; Wang, J.; Xie, B.; Chen, J. Resonant Pressure Micro Sensors Based on Dual Double Ended Tuning Fork Resonators. Micromachines 2019, 10, 560. https://doi.org/10.3390/mi10090560

Lu Y, Zhang S, Yan P, Li Y, Yu J, Chen D, Wang J, Xie B, Chen J. Resonant Pressure Micro Sensors Based on Dual Double Ended Tuning Fork Resonators. Micromachines. 2019; 10(9):560. https://doi.org/10.3390/mi10090560

Chicago/Turabian StyleLu, Yulan, Sen Zhang, Pengcheng Yan, Yadong Li, Jie Yu, Deyong Chen, Junbo Wang, Bo Xie, and Jian Chen. 2019. "Resonant Pressure Micro Sensors Based on Dual Double Ended Tuning Fork Resonators" Micromachines 10, no. 9: 560. https://doi.org/10.3390/mi10090560

APA StyleLu, Y., Zhang, S., Yan, P., Li, Y., Yu, J., Chen, D., Wang, J., Xie, B., & Chen, J. (2019). Resonant Pressure Micro Sensors Based on Dual Double Ended Tuning Fork Resonators. Micromachines, 10(9), 560. https://doi.org/10.3390/mi10090560