Analysis and Simulation of Forcing the Limits of Thermal Sensing for Microbolometers in CMOS–MEMS Technology

Abstract

1. Introduction

2. Theory, Design, and Optimization

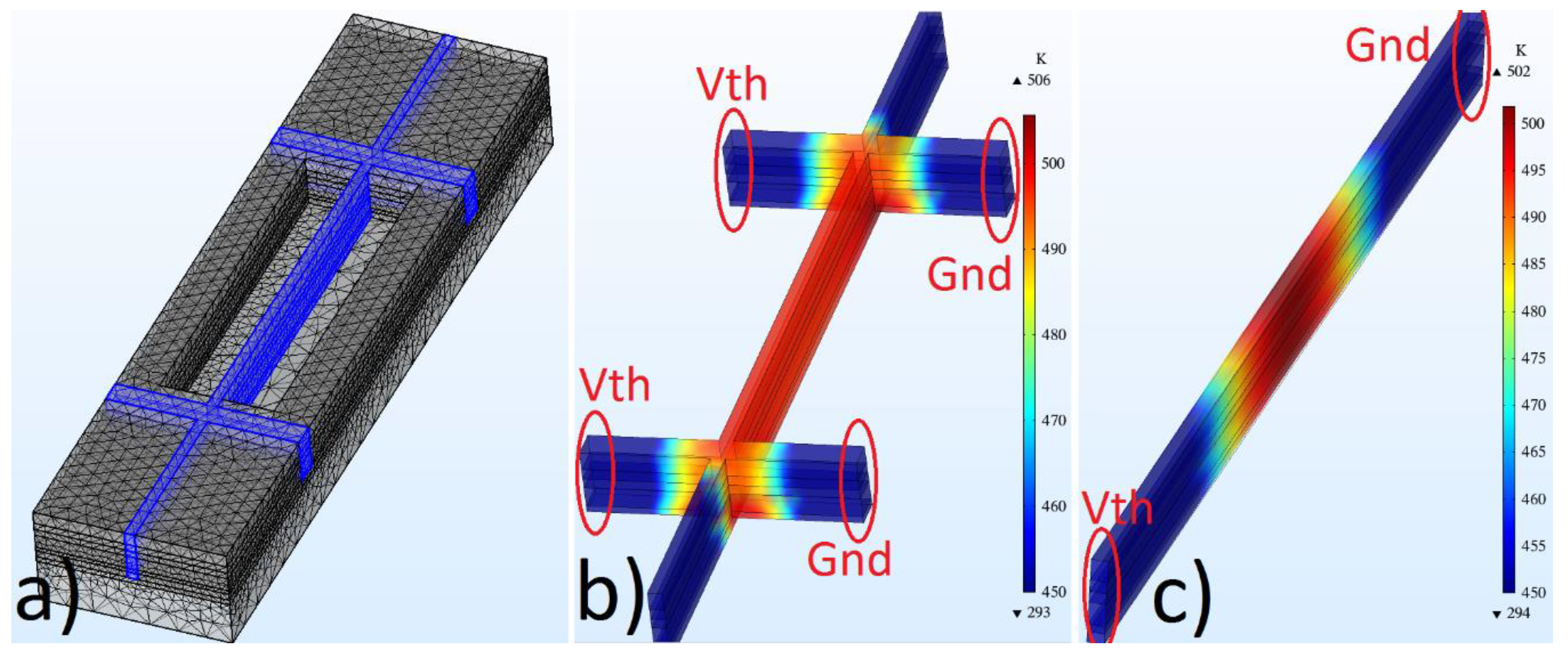

2.1. Design for Uniform Heating

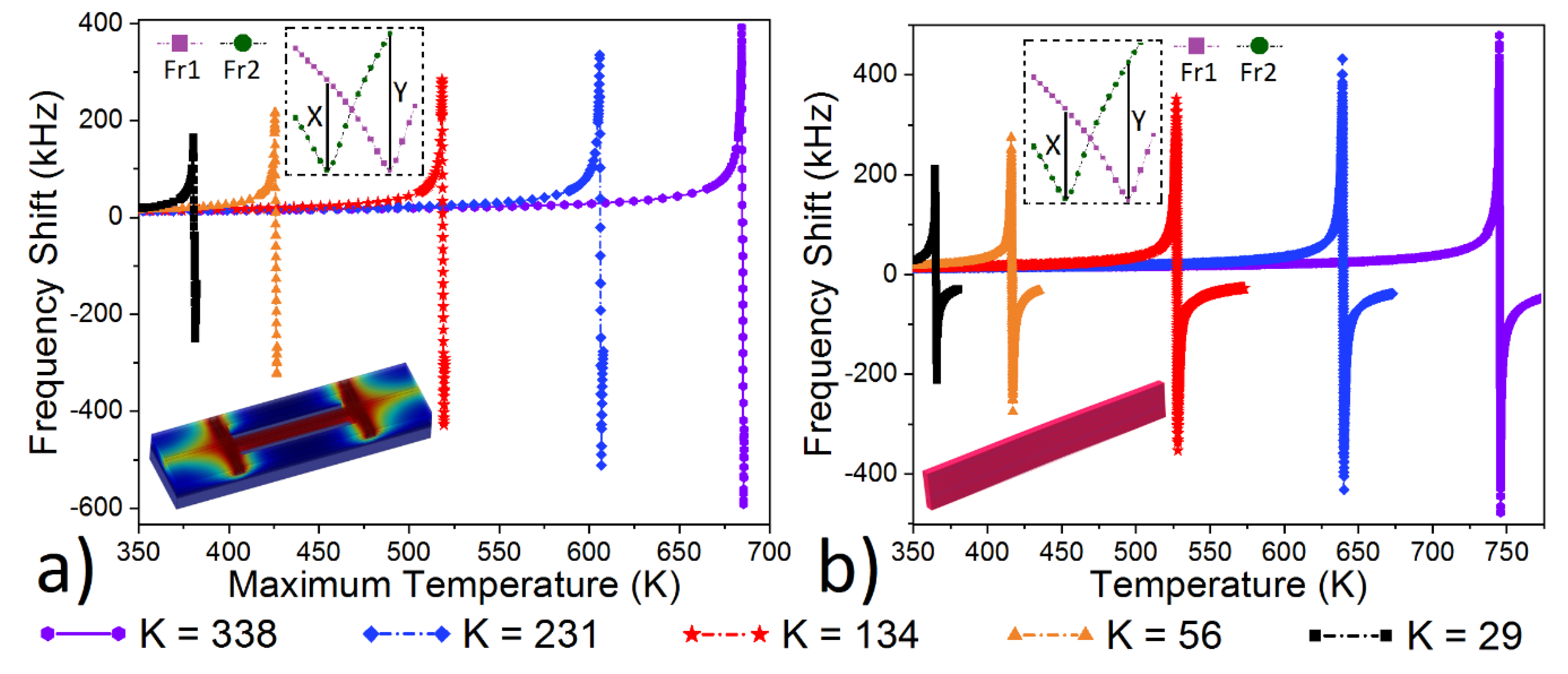

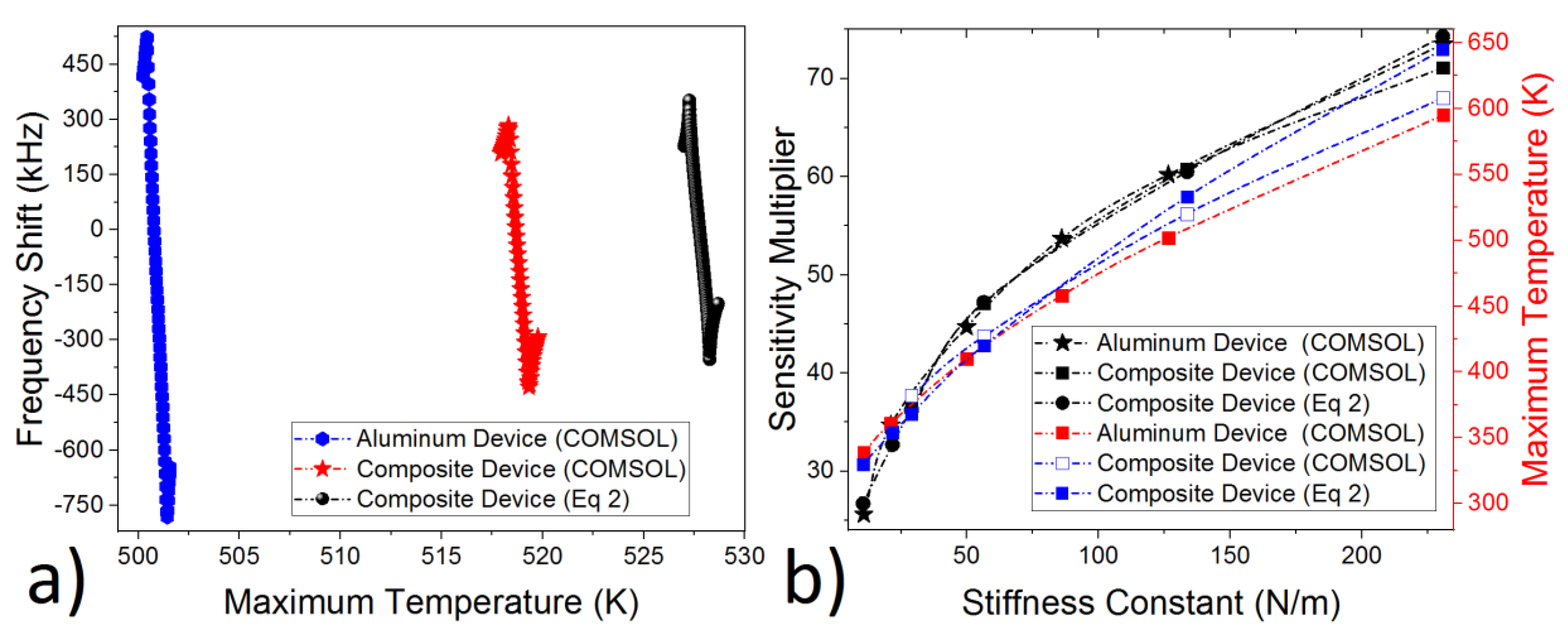

2.2. Design for High Thermal Sensitivity

2.3. Design for Relatively Low Power Consumption

3. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Marsili, F.; Verma, V.B.; Stern, J.A.; Harrington, S.; Lita, A.E.; Gerrits, T.; Vayshenker, I.; Baek, B.; Shaw, M.D.; Mirin, R.P.; et al. Detecting single infrared photons with 93% system efficiency. Nat. Photonics 2013, 7, 210–214. [Google Scholar] [CrossRef]

- Renema, J.J.; Gaudio, R.; Wang, Q.; Zhou, Z.; Gaggero, A.; Mattioli, F.; Leoni, R.; Sahin, D.; de Dood, M.J.A.; Fiore, A.; et al. Experimental Test of Theories of the Detection Mechanism in a Nanowire Superconducting Single Photon Detector. Phys. Rev. Lett. 2014, 112, 117604. [Google Scholar] [CrossRef] [PubMed]

- Forsberg, F.; Lapadatu, A.; Kittilsland, G.; Martinsen, S.; Roxhed, N.; Fischer, A.C.; Stemme, G.; Samel, B.; Ericsson, P.; Høivik, N.; et al. CMOS-Integrated Si/SiGe Quantum-Well Infrared Microbolometer Focal Plane Arrays Manufactured With Very Large-Scale Heterogeneous 3-D Integration. IEEE J. Sel. Top. Quantum Electron. 2015, 21, 30–40. [Google Scholar] [CrossRef]

- Lv, J.; Que, L.; Wei, L.; Zhou, Y.; Liao, B.; Jiang, Y. Uncooled Microbolometer Infrared Focal Plane Array Without Substrate Temperature Stabilization. IEEE Sens. J. 2014, 14, 1533–1544. [Google Scholar] [CrossRef]

- Göktaş, H.; Turner, K.L.; Zaghloul, M.E. Enhancement in CMOS-MEMS Resonator for High Sensitive Temperature Sensing. IEEE Sens. J. 2017, 17, 598–603. [Google Scholar] [CrossRef]

- Hui, Y.; Gomez-Diaz, J.S.; Qian, Z.; Alù, A.; Rinaldi, M. Plasmonic piezoelectric nanomechanical resonator for spectrally selective infrared sensing. Nat. Commun. 2016, 7, 11249. [Google Scholar] [CrossRef]

- Göktaş, H. Towards an Ultra-Sensitive Temperature Sensor for Uncooled Infrared Sensing in CMOS–MEMS Technology. Micromachines 2019, 10, 108. [Google Scholar] [CrossRef] [PubMed]

- Kang, D.H.; Kim, K.W.; Lee, S.Y.; Kim, Y.H.; Keun Gil, S. Influencing factors on the pyroelectric properties of Pb (Zr, Ti) O3 thin film for uncooled infrared detector. Mater. Chem. Phys. 2005, 90, 411–416. [Google Scholar] [CrossRef]

- Tao, Y.; Boss, J.M.; Moores, B.A.; Degen, C.L. Single-crystal diamond nanomechanical resonators with quality factors exceeding one million. Nat. Commun. 2014, 5, 3638. [Google Scholar] [CrossRef]

- Zhang, X.C.; Myers, E.B.; Sader, J.E.; Roukes, M.L. Nanomechanical Torsional Resonators for Frequency-Shift Infrared Thermal Sensing. ACS Nano Lett. 2013, 13, 1528–1534. [Google Scholar] [CrossRef] [PubMed]

- Sawano, S.; Arie, T.; Akita, S. Carbon Nanotube Resonator in Liquid. ACS Nano Lett. 2010, 10, 3395–3398. [Google Scholar] [CrossRef] [PubMed]

- Baek, I.-B.; Byun, S.; Lee, B.K.; Ryu, J.-H.; Kim, Y.; Yoon, Y.S.; Jang, W.I.; Lee, S.; Yu, H.Y. Attogram mass sensing based on silicon microbeam resonators. Nat. Sci. Rep. 2017, 7, 46660. [Google Scholar] [CrossRef] [PubMed]

- Qian, Z.; Hui, Y.; Liu, F.; Kang, S.; Kar, S.; Rinaldi, M. Graphene–aluminum nitride NEMS resonant infrared detector. Nat. Microsyst. Nanoeng. 2016, 2, 16026. [Google Scholar] [CrossRef] [PubMed]

- Foulgoc, B.L.; Bourouina, T.; Traon, O.L.; Bosseboeuf, A.; Marty, F.; Breluzeau, C.; Grandchamp, J.-P.; Masson, S. Highly decoupled single-crystal silicon resonators: An approach for the intrinsic quality factor. IOP J. Micromech. Microeng. 2006, 16, S45–S53. [Google Scholar] [CrossRef]

- Laird, E.A.; Pei, F.; Tang, W.; Steele, G.A.; Kouwenhoven, L.P. A High Quality Factor Carbon Nanotube Mechanical Resonator at 39 GHz. ACS Nano Lett. 2012, 12, 193–197. [Google Scholar] [CrossRef] [PubMed]

- Manca, N.; Pellegrino, L.; Kanki, T.; Yamasaki, S.; Tanaka, H.; Siri, A.S.; Marré, D. Programmable Mechanical Resonances in MEMS by Localized Joule Heating of Phase Change Materials. Adv. Mater. 2013, 25, 6430–6435. [Google Scholar] [CrossRef] [PubMed]

- Göktaş, H.; Zaghloul, M.E. Tuning In-Plane Fixed–Fixed Beam Resonators with Embedded Heater in CMOS Technology. IEEE Electron Device Lett. 2015, 36, 189–191. [Google Scholar] [CrossRef]

- Göktaş, H.; Zaghloul, M.E. The implementation of low-power and wide tuning range MEMS filters for communication applications. Radio Sci. 2016, 51, 1636–1644. [Google Scholar] [CrossRef]

- Duraffourg, L.; Laurent, L.; Moulet, J.-S.; Arcamone, J.; Yon, J.-J. Array of Resonant Electromechanical Nanosystems: A Technological Breakthrough for Uncooled Infrared Imaging. Micromachines 2018, 10, 401. [Google Scholar] [CrossRef] [PubMed]

- Jha, C.M. Thermal and Mechanical Isolation of Ovenized MEMS Resonator. Ph.D. Thesis, Department of Mechanical Engineering, Stanford University, Palo Alto, CA, USA, 2008. [Google Scholar]

- Abawi, A.T. The Bending of Bonded Layers Due to Thermal Stress. Available online: http://hlsresearch.com/personnel/abawi/papers/bend.pdf (accessed on 23 October 2014).

- Verd, J.; Uranga, A.; Abadal, G.; Teva, J.; Torres, F.; Pérez-Murano, F.; Fraxedas, J.; Esteve, J.; Barniol, N. Monolithic mass sensor fabricated using a conventional technology with attogram resolution in air conditions. Appl. Phys. Lett. 2007, 91, 013501. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Göktaş, H.; Gökhan, F.S. Analysis and Simulation of Forcing the Limits of Thermal Sensing for Microbolometers in CMOS–MEMS Technology. Micromachines 2019, 10, 733. https://doi.org/10.3390/mi10110733

Göktaş H, Gökhan FS. Analysis and Simulation of Forcing the Limits of Thermal Sensing for Microbolometers in CMOS–MEMS Technology. Micromachines. 2019; 10(11):733. https://doi.org/10.3390/mi10110733

Chicago/Turabian StyleGöktaş, Hasan, and Fikri Serdar Gökhan. 2019. "Analysis and Simulation of Forcing the Limits of Thermal Sensing for Microbolometers in CMOS–MEMS Technology" Micromachines 10, no. 11: 733. https://doi.org/10.3390/mi10110733

APA StyleGöktaş, H., & Gökhan, F. S. (2019). Analysis and Simulation of Forcing the Limits of Thermal Sensing for Microbolometers in CMOS–MEMS Technology. Micromachines, 10(11), 733. https://doi.org/10.3390/mi10110733