InGaN/GaN Distributed Feedback Laser Diodes with Surface Gratings and Sidewall Gratings

Abstract

:1. Introduction

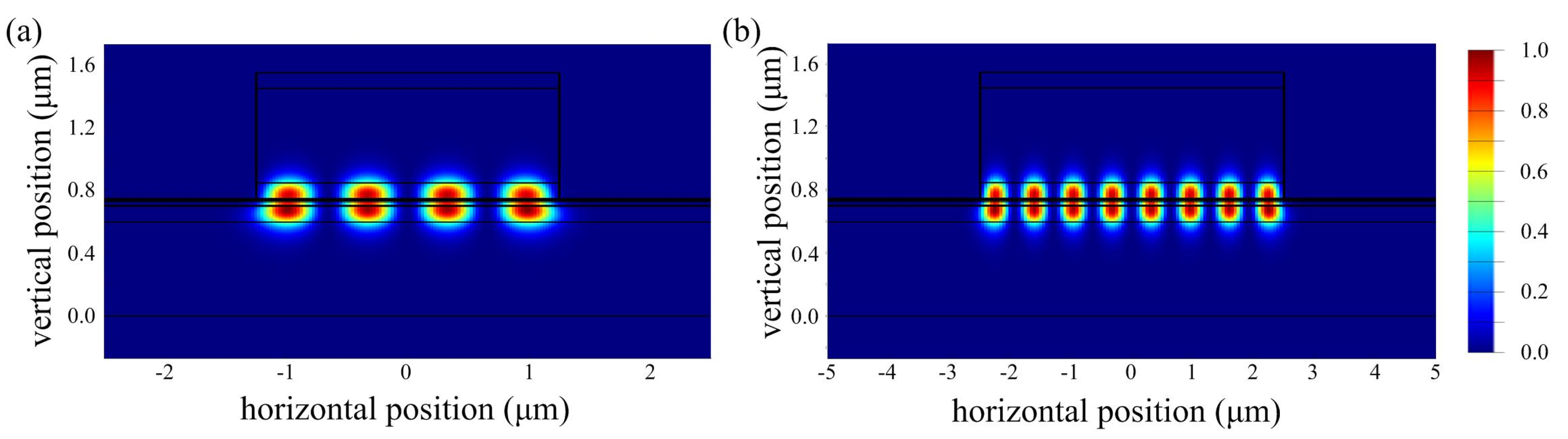

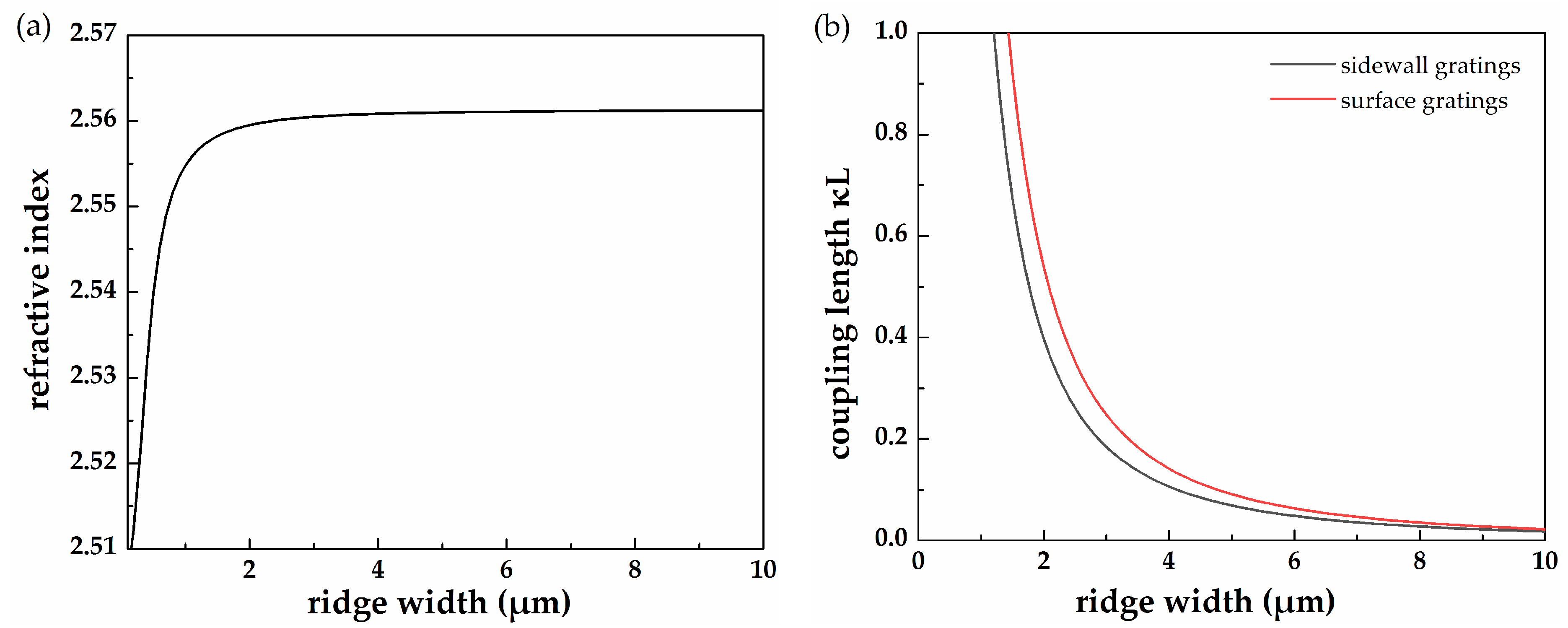

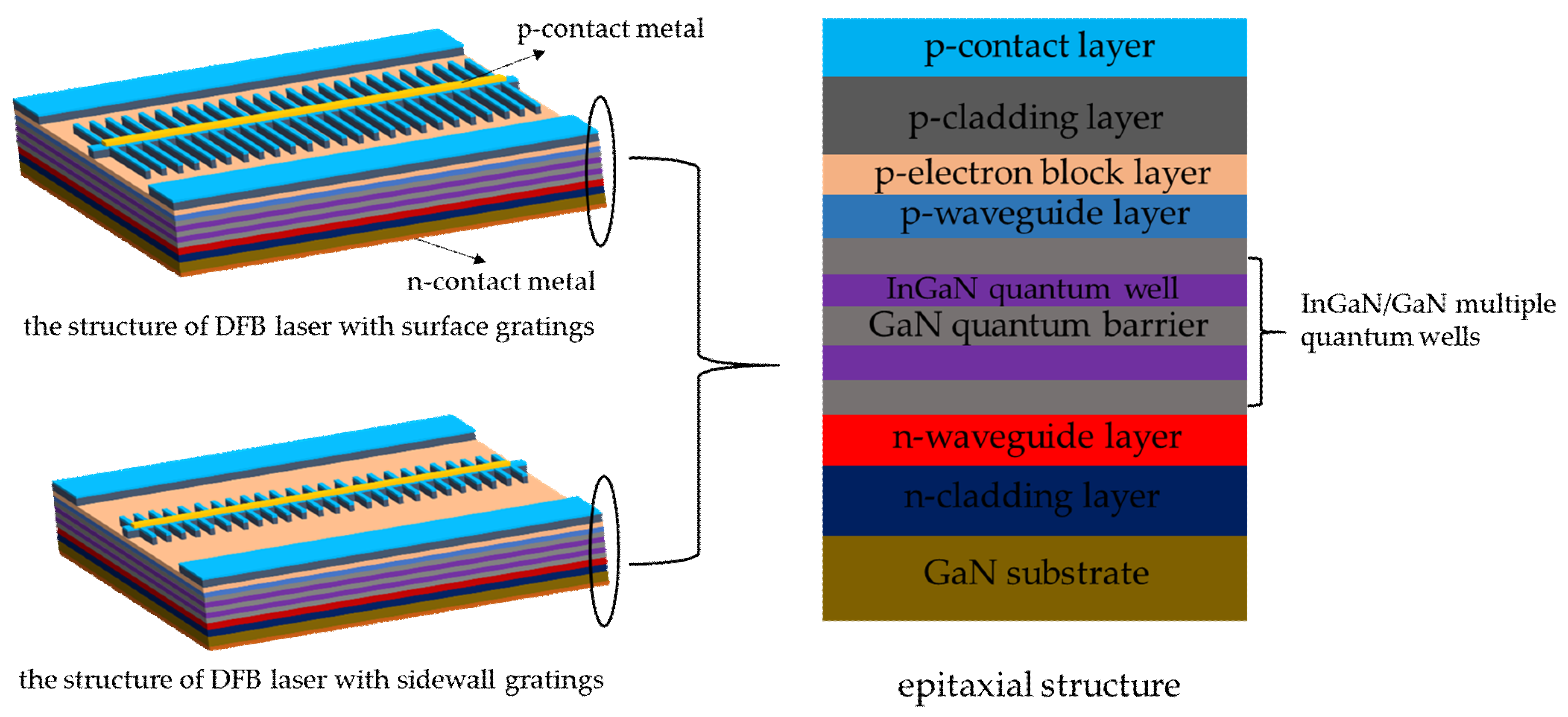

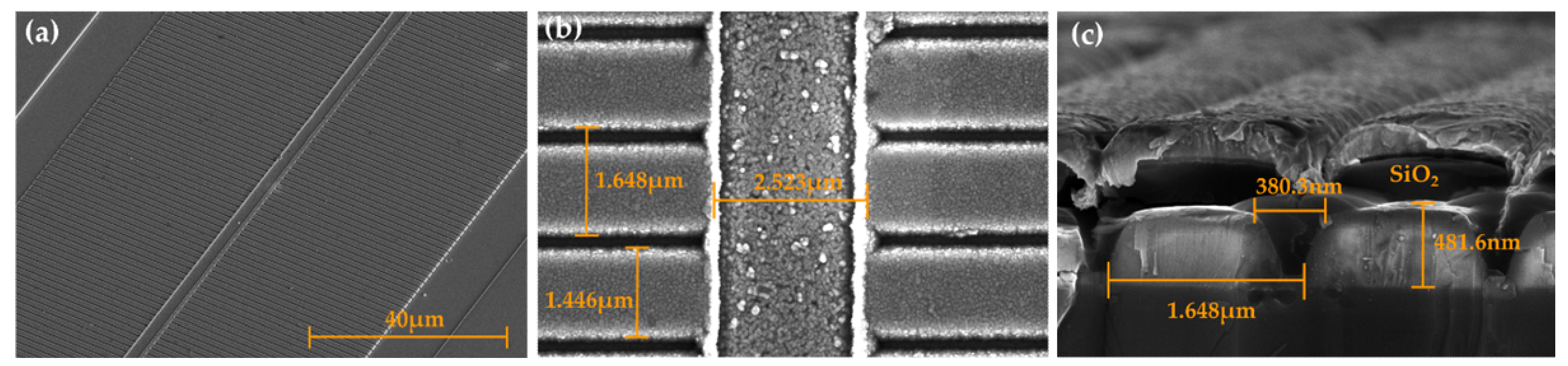

2. Simulation and Fabrication

3. Results and Discussions

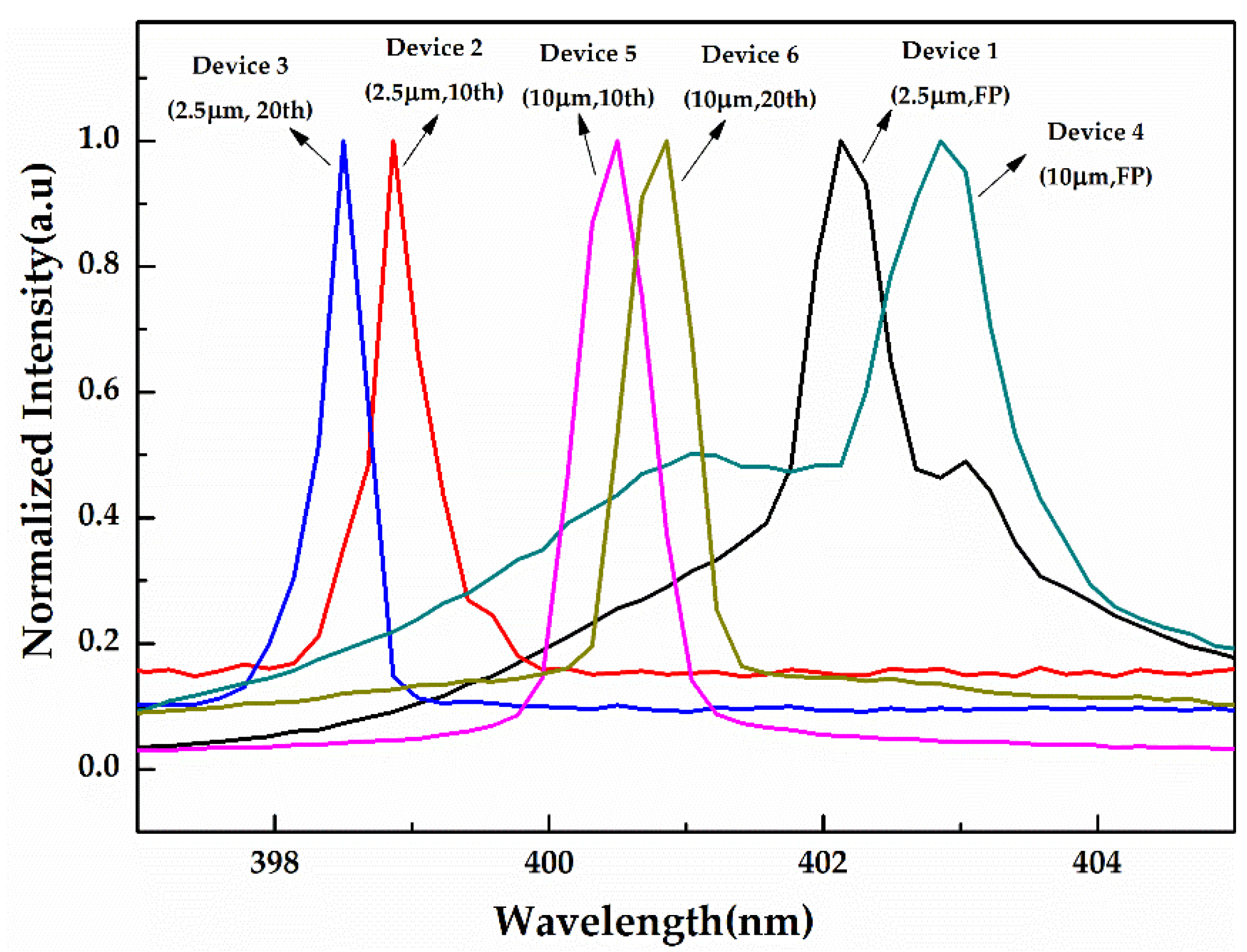

3.1. The DFB LDs with the Surface Gratings

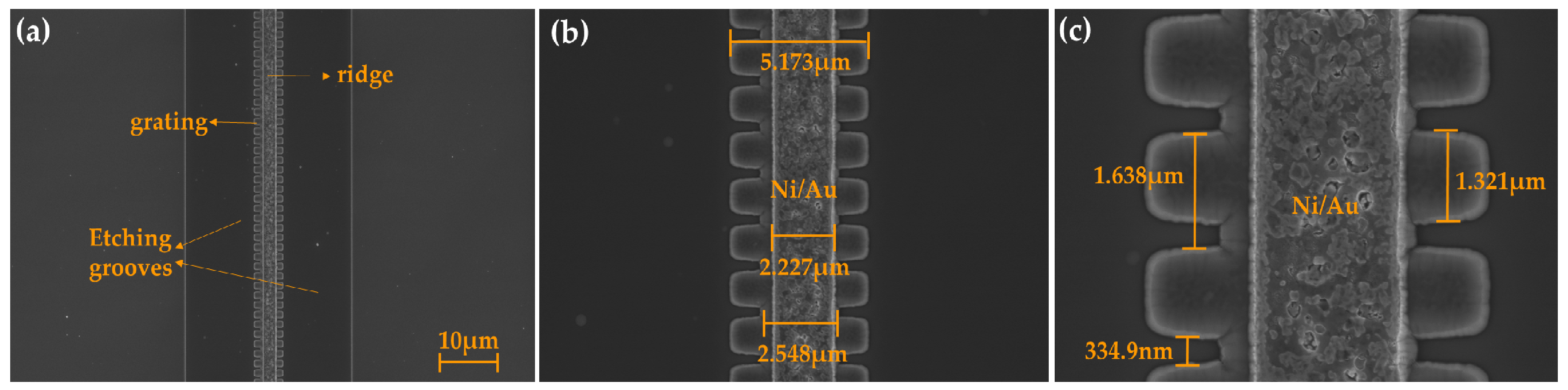

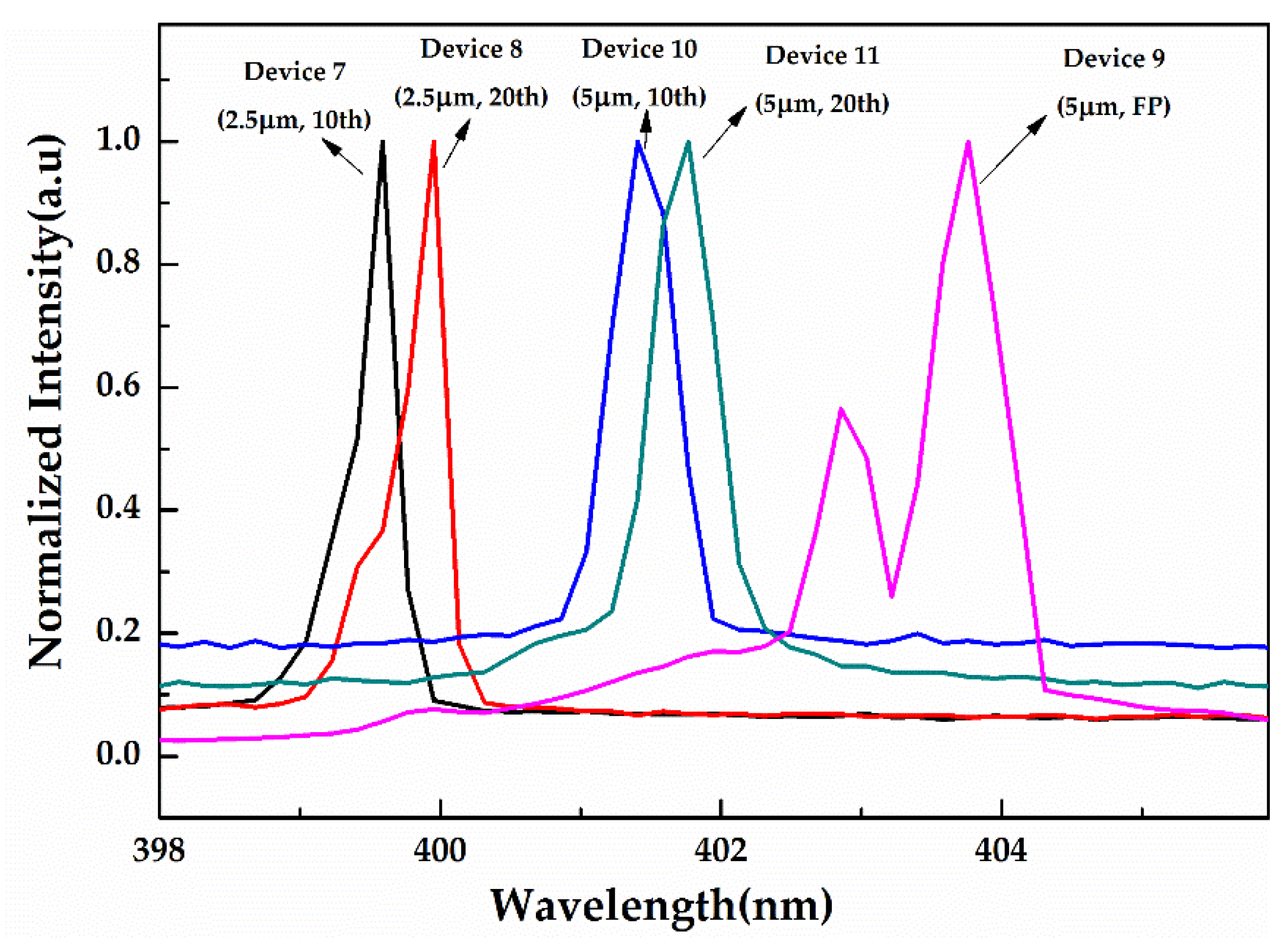

3.2. The DFB LDs with the Sidewall Gratings

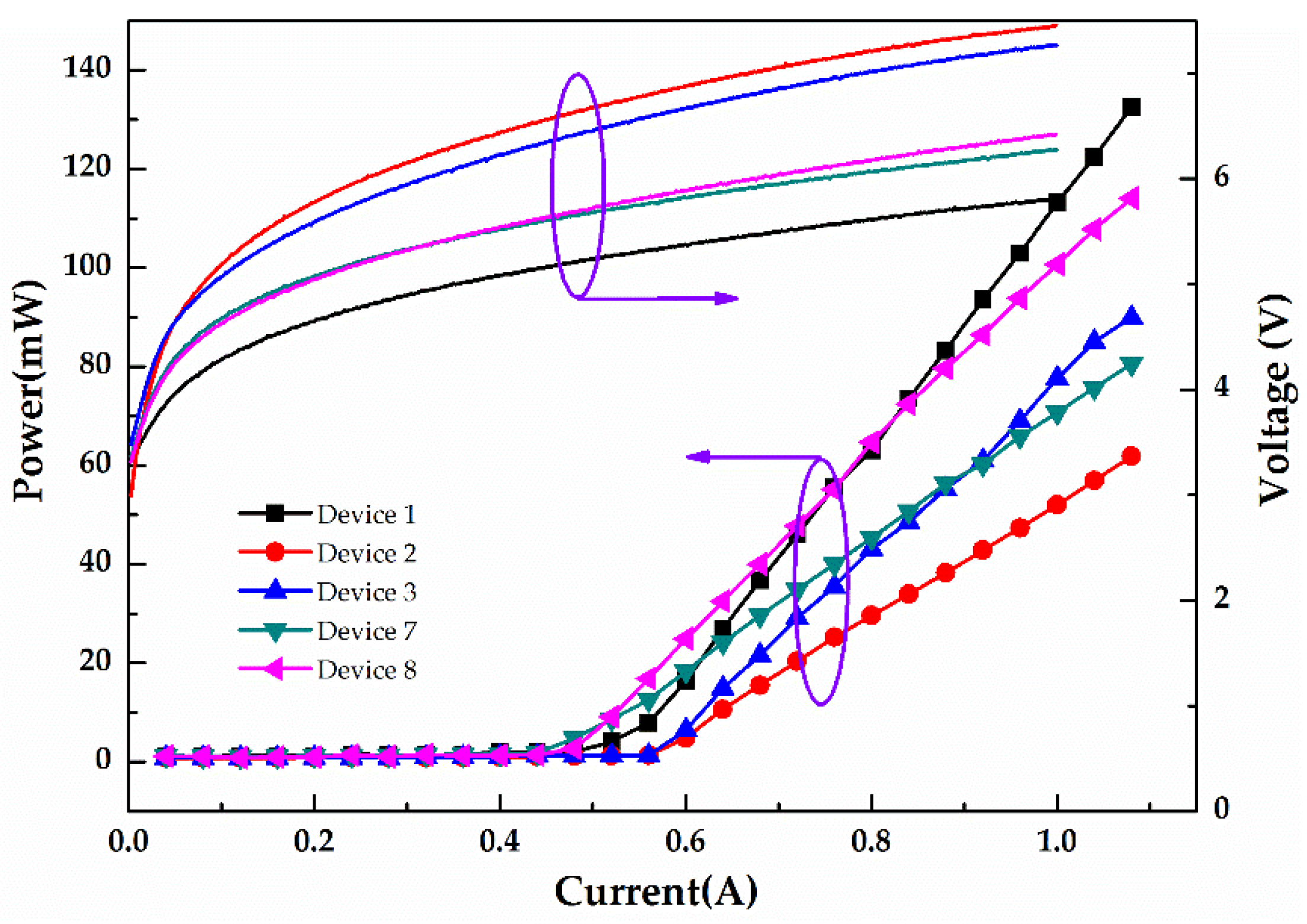

3.3. The Comparison of Properties of the DFB LDs with Surface and Sidewall Gratings

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Chi, Y.C.; Hsieh, D.H.; Tsai, C.T.; Chen, H.Y.; Kuo, H.C.; Lin, G.R. 450-nm GaN laser diode enables high-speed visible light communication with 9-Gbps QAM-OFDM. Opt. Express 2015, 23, 13051–13059. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Watson, S.; Tan, M.; Najda, S.P.; Perlin, P.; Leszczynski, M.; Targowski, G.; Grzanka, S.; Kelly, A.E. Visible light communications using a directly modulated 422 nm GaN laser diode. Opt. Lett. 2013, 38, 3792–3794. [Google Scholar] [CrossRef] [PubMed]

- Zeller, W.; Naehle, L.; Fuchs, P.; Gerschuetz, F.; Hildebrandt, L.; Koeth, J. DFB Lasers Between 760 nm and 16 μm for Sensing Applications. Sensors 2010, 10, 2492–2510. [Google Scholar] [CrossRef] [PubMed]

- Balci, M.H.; Chen, F.; Cunbul, A.B.; Svensen, Ø.; Akram, M.N.; Chen, X. Comparative study of blue laser diode driven cerium-doped single crystal phosphors in application of high-power lighting and display technologies. Opt. Rev. 2018, 25, 166–174. [Google Scholar] [CrossRef]

- Shimada, Y.; Chida, Y.; Ohtsubo, N.; Aoki, T.; Takeuchi, M.; Kuga, T.; Torii, Y. A simplified 461-nm laser system using blue laser diodes and a hollow cathode lamp for laser cooling of Sr. Rev. Sci. Instrum. 2013, 84, 063101. [Google Scholar] [CrossRef] [Green Version]

- Najda, S.P.; Perlin, P.; Leszczyński, M.; Slight, T.J.; Meredith, W.; Schemmann, M.; Moseley, H.; Woods, J.A.; Valentine, R.; Kalra, S.; et al. A multi-wavelength (uv to visible) laser system for early detection of oral cancer. In Imaging, Manipulation, and Analysis of Biomolecules, Cells, and Tissues XIII; International Society for Optics and Photonics: San Francisco, CA, USA, March 2015; p. 932809. [Google Scholar]

- Luo, Y.; Nakano, Y.; Tada, K.; Inoue, T.; Hosomatsu, H.; Iwaoka, H. Fabrication and characteristics of gain-coupled distributed feedback semiconductor lasers with a corrugated active layer. IEEE J. Quantum Electron. 1991, 27, 1724–1731. [Google Scholar] [CrossRef]

- Hofstetter, D.; Romano, L.T.; Paoli, T.L.; Bour, D.P.; Kneissl, M. Realization of a complex-coupled InGaN/GaN-based optically pumped multiple-quantum-well distributed-feedback laser. Appl. Phys. Lett. 2000, 76, 2337–2339. [Google Scholar] [CrossRef] [Green Version]

- Masui, S.; Tsukayama, K.; Yanamoto, T.; Kozaki, T.; Nagahama, S.I.; Mukai, T. First-order AlInGaN 405 nm distributed feedback laser diodes by current injection. Jpn. J. Appl. Phys. 2006, 45, L749. [Google Scholar] [CrossRef]

- Schweizer, H.; Gräbeldinger, H.; Dumitru, V.; Jetter, M.; Bader, S.; Brüderl, G.; Weimar, A.; &Härle, V. Laterally coupled InGaN/GaN DFB laser diodes. Phys. Status Solidi A 2002, 192, 301–307. [Google Scholar] [CrossRef]

- Hofmann, R.; Gauggel, H.P.; Griesinger, U.A.; Gräbeldinger, H.; Adler, F.; Ernst, P.; Bolay, H.; Harle, V.; Schoz, F.; Schweizer, H.; et al. Realization of optically pumped second-order GaInN-distributed-feedback lasers. Appl. Phys. Lett. 1996, 69, 2068–2070. [Google Scholar] [CrossRef]

- Zhang, H.; Cohen, D.A.; Chan, P.; Wong, M.S.; Mehari, S.; Becerra, D.L.; Nakamura, S.; DenBaars, S.P. Continuous-wave operation of a semipolar InGaN distributed-feedback blue laser diode with a first-order indium tin oxide surface grating. Opt. Lett. 2019, 44, 3106–3109. [Google Scholar] [CrossRef] [PubMed]

- Holguín-Lerma, J.A.; Ng, T.K.; Ooi, B.S. Narrow-line InGaN/GaN green laser diode with high-order distributed-feedback surface grating. Appl. Phys. Express 2019, 12, 042007. [Google Scholar] [CrossRef]

- Masui, S.; Tsukayama, K.; Yanamoto, T.; Kozaki, T.; Nagahama, S.I.; Mukai, T. CW operation of the first-order AlInGaN 405 nm distributed feedback laser diodes. Jpn. J. Appl. Phys. 2006, 45, L1223. [Google Scholar] [CrossRef]

- Slight, T.J.; Odedina, O.; Meredith, W.; Docherty, K.E.; Kelly, A.E. InGaN/GaN distributed feedback laser diodes with deeply etched sidewall gratings. IEEE Photonics Technol. Lett. 2016, 28, 2886–2888. [Google Scholar] [CrossRef]

- Slight, T.J.; Yadav, A.; Odedina, O.; Meredith, W.; Docherty, K.E.; Rafailov, E.; Kelly, A.E. InGaN/GaN laser diodes with high order notched gratings. IEEE Photonics Technol. Lett. 2017, 29, 2020–2022. [Google Scholar] [CrossRef]

- Slight, T.J.; Stanczyk, S.; Watson, S.; Yadav, A.; Grzanka, S.; Rafailov, E.; Perlin, P.; Najda, S.P.; Leszczynski, M.; Gwyn, S.; et al. Continuous-wave operation of (Al, In) GaN distributed-feedback laser diodes with high-order notched gratings. Appl. Phys. Express 2018, 11, 112701. [Google Scholar] [CrossRef]

- Kang, J.H.; Martens, M.; Wenzel, H.; Hoffmann, V.; John, W.; Einfeldt, S.; Wernicke, T.; Kneissl, M. Optically pumped DFB lasers based on GaN using 10th-order laterally coupled surface gratings. IEEE Photonics Technol. Lett. 2016, 29, 138–141. [Google Scholar] [CrossRef]

- Kang, J.H.; Wenzel, H.; Hoffmann, V.; Freier, E.; Sulmoni, L.; Unger, R.S.; Einfeldt, S.; Wernicke, T.; Kneissl, M. DFB laser diodes based on GaN using 10th order laterally coupled surface gratings. IEEE Photonics Technol. Lett. 2017, 30, 231–234. [Google Scholar] [CrossRef]

- Li, J.Z.; Huang, F.; Yang, H.J.; Deng, Z.J.; Liao, M.L. The MOCVD overgrowth studies of III-Nitride on Bragg grating for distributed feedback lasers. In 14th National Conference on Laser Technology and Optoelectronics (LTO 2019); International Society for Optics and Photonics: Shanghai, China, May 2019; p. 111701X. [Google Scholar]

- Hofmann, R.; Wagner, V.; Neuner, M.; Off, J.; Scholz, F.; Schweizer, H. Optically pumped GaInN/GaN-DFB lasers: Overgrown lasers and vertical modes. Mater. Sci. Eng. B 1999, 59, 386–389. [Google Scholar] [CrossRef]

- Cao, Y.L.; Hu, X.N.; Luo, X.S.; Song, J.F.; Cheng, Y.; Li, C.M.; Liu, C.Y.; Wang, H.; Liow, T.Y.; Lo, G.Q.; et al. Hybrid III–V/silicon laser with laterally coupled Bragg grating. Opt. Express 2015, 23, 8800–8808. [Google Scholar] [CrossRef]

- Wenzel, H.; Fricke, J.; Decker, J.; Crump, P.; Erbert, G. High-power distributed feedback lasers with surface gratings: Theory and experiment. IEEE J. Quantum. Elect. 2015, 21, 352–358. [Google Scholar] [CrossRef]

- Zolotarev, V.V.; Leshko, A.Y.; Pikhtin, N.A.; Slipchenko, S.O.; Sokolova, Z.N.; Lubyanskiy, Y.V.V.; Voronkova, N.V.; Tarasov, I.Y.S. Integrated high-order surface diffraction gratings for diode lasers. Quantum. Electron. 2015, 45, 1091. [Google Scholar] [CrossRef]

- Bao, S.; Song, Q.; Xie, C. The influence of grating shape formation fluctuation on DFB laser diode threshold condition. Opt. Rev. 2018, 25, 330–335. [Google Scholar] [CrossRef]

- Crump, P.; Schultz, C.M.; Wenzel, H.; Erbert, G.; Tränkle, G. Efficiency-optimized monolithic frequency stabilization of high-power diode lasers. J. Phys. D Appl. Phys. 2012, 46, 013001. [Google Scholar] [CrossRef]

| Sample | Device 1 | Device 2 | Device 3 | Device 4 | Device 5 | Device 6 |

|---|---|---|---|---|---|---|

| Ridge width | 2.5 μm | 2.5 μm | 2.5 μm | 10 μm | 10 μm | 10 μm |

| Width of grating of each side | - | 40 μm | 40 μm | - | 40 μm | 40 μm |

| Period of gratings | z | 824 nm | 1648 nm | - | 824 nm | 1648 nm |

| Duty ratio of grating | - | 80% | 80% | - | 80% | 80% |

| Sample | Device 7 | Device 8 | Device 9 | Device 10 | Device 11 |

|---|---|---|---|---|---|

| Ridge width | 2.5 μm | 2.5 μm | 5 μm | 5 μm | 5 μm |

| Width of gratings of each side | 1.25 μm | 1.25 μm | - | 2.5 μm | 2.5 μm |

| Period of gratings | 824 nm | 1648 nm | - | 824 nm | 1648 nm |

| Duty ratio of gratings | 80% | 80% | - | 80% | 80% |

| Sample | Device 1 | Device 2 | Device 3 | Device 7 | Device 8 |

|---|---|---|---|---|---|

| Type of gratings | - | Surface | Surface | Sidewall | Sidewall |

| Order of gratings | - | 10th | 20th | 10th | 20th |

| Threshold current | (518 ± 12) mA | (539 ± 4) mA | (550 ± 10) mA | (458 ± 7) mA | (485 ± 19) mA |

| The slopes efficiency | (235 ± 15) mW/A | (116 ± 3) mW/A | (172 ± 11) mW/A | (129 ± 7) mW/A | (189 ± 6) mW/A |

| FWHM | 1.96 nm | 0.37 nm | 0.32 nm | 0.25 nm | 0.23 nm |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Deng, Z.; Li, J.; Liao, M.; Xie, W.; Luo, S. InGaN/GaN Distributed Feedback Laser Diodes with Surface Gratings and Sidewall Gratings. Micromachines 2019, 10, 699. https://doi.org/10.3390/mi10100699

Deng Z, Li J, Liao M, Xie W, Luo S. InGaN/GaN Distributed Feedback Laser Diodes with Surface Gratings and Sidewall Gratings. Micromachines. 2019; 10(10):699. https://doi.org/10.3390/mi10100699

Chicago/Turabian StyleDeng, Zejia, Junze Li, Mingle Liao, Wuze Xie, and Siyuan Luo. 2019. "InGaN/GaN Distributed Feedback Laser Diodes with Surface Gratings and Sidewall Gratings" Micromachines 10, no. 10: 699. https://doi.org/10.3390/mi10100699

APA StyleDeng, Z., Li, J., Liao, M., Xie, W., & Luo, S. (2019). InGaN/GaN Distributed Feedback Laser Diodes with Surface Gratings and Sidewall Gratings. Micromachines, 10(10), 699. https://doi.org/10.3390/mi10100699