Mycotoxin Analysis of Grain via Dust Sampling: Review, Recent Advances and the Way Forward: The Contribution of the MycoKey Project

Abstract

:1. Introduction

2. Results

2.1. Review of Available Studies

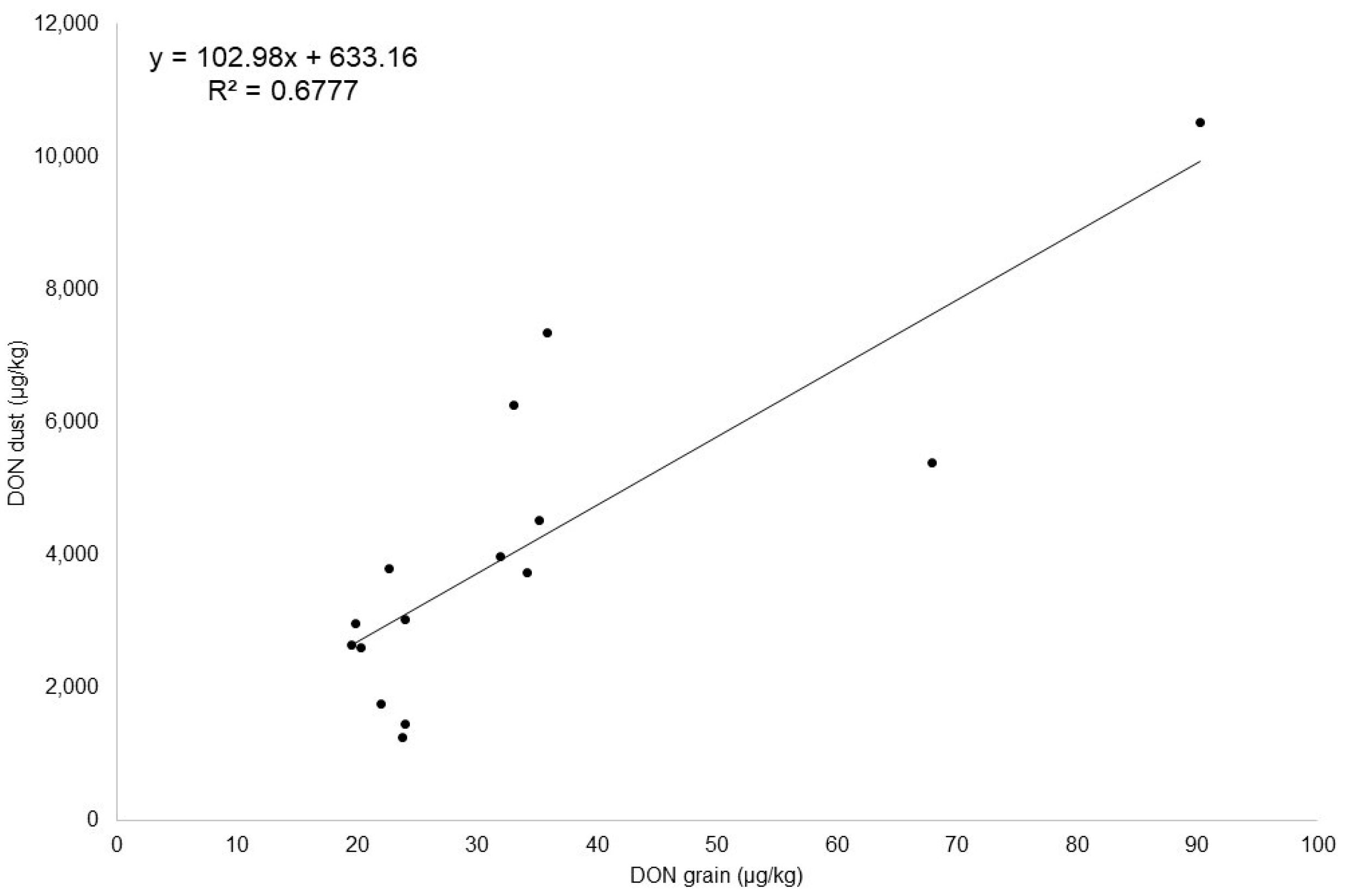

2.2. MycoKey Results

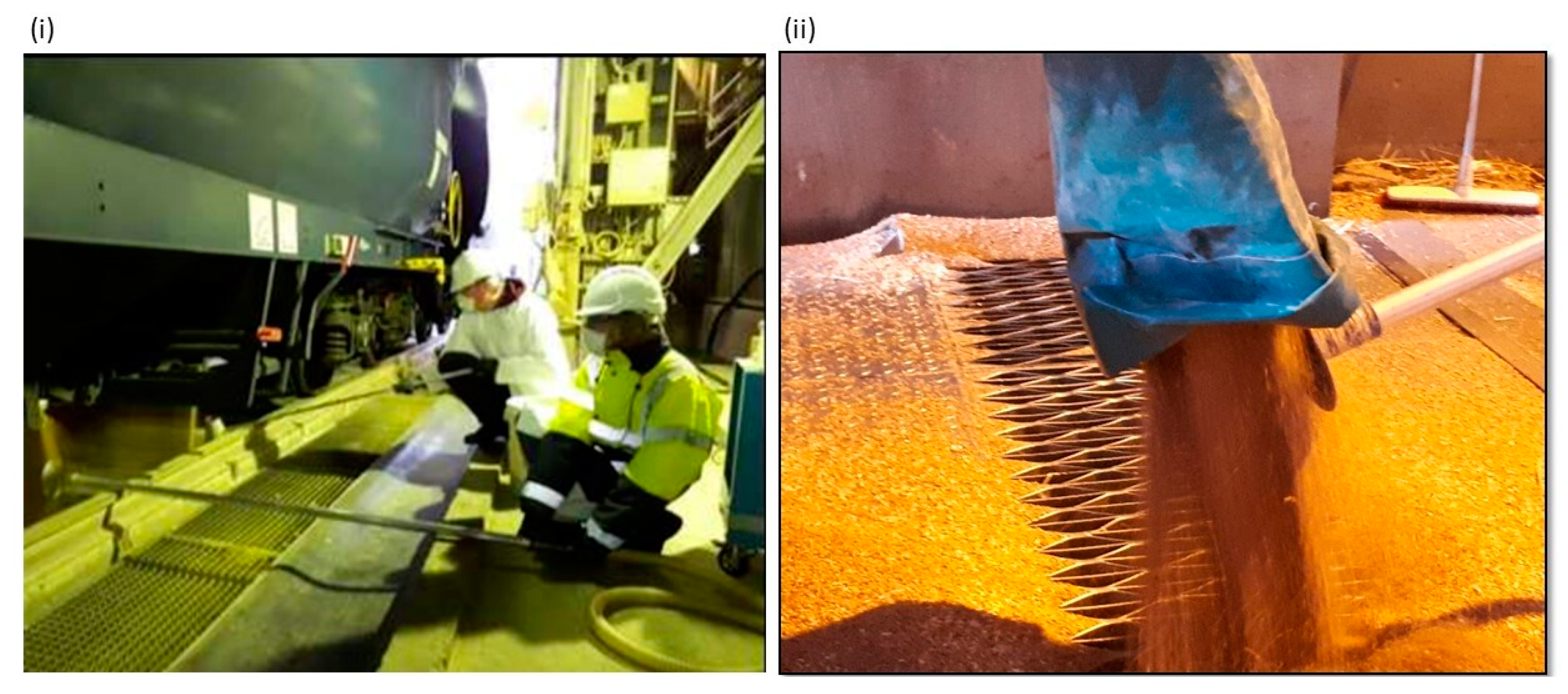

2.2.1. Dust Sampling

2.2.2. Multi-Mycotoxin Analysis in Grain and Dust by LC-MS/MS

3. Discussion

4. Conclusions

5. Materials and Methods

5.1. Reagents

5.2. Dust Sampling Methodology

5.3. Analysis of Multi-Toxins by LC-MS/MS Method

5.3.1. Mycotoxins Solutions

- Mixed stock solution A, to be used for wheat and maize grain spiking: NIV and DON 12.5 µg/mL; T-2 and HT-2 0.625 µg/mL; ZEN1.25 µg/mL; AFB1, 0.12 µg/mL;FB1 and FB2, 12.5 µg/mL and OTA, 0.105 µg/mL. This solution was diluted by 10 times to prepare calibrant solution for external matrix-matched calibration in grain samples;

- Mixed solution B, to be used for spiking experiments and to prepare the calibrant solution for the dust sample: NIV and DON 2.5 µg/mL; T-2 and HT-2 0.625 µg/mL; ZEN1.25 µg/mL; AFB1, 0.03 µg/mL; FB1 and FB2, 2.5 µg/mL and OTA, 0.04 µg/mL.

5.3.2. Sample Preparation

5.3.3. LC-MS/MS Analysis

5.3.4. In House Verification of Method Performances

5.4. Calculation

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Codex Alimentarius Commission; Food and Agriculture Organization of the United Nations (FAO); World Health Organization (WHO). Codex Alimentarius International Food Standards, General Standard for Contaminants and Toxins in Food and Feed. CXS 193-1995; Adopted in 1995. Revised in 1997, 2006, 2008, 2009. Amended in 2010, 2012, 2013, 2014, 2015, 2016, 2017, 2019; WHO: Geneva, Switzerland, 1995. [Google Scholar]

- European Commission (EC). European Commission Regulation No. 401/2006 of 23 February 2006 laying down the methods of sampling and analysis for the official control of the levels of mycotoxins in foodstuffs. Off. J. Eur. Union 2006, L70, 12–34. [Google Scholar]

- European Commission (EC). European Commission Regulation No. 165/2010 of 26 February 2010 amending Regulation (EC) No. 1881/2006 setting maximum levels for certain contaminants in foodstuffs as regards aflatoxins. Off. J. Eur. Union 2010, L50, 8–12. [Google Scholar]

- European Commission (EC). European Commission Regulation No. 519/2014 of 16 May 2014 amending Regulation (EC) No. 401/2006 as regards methods of sampling of large lots, spices, and food supplements, performance criteria for T-2 and HT-2 toxin and citrinin and screening methods of analysis. Off. J. Eur. Union 2014, L147, 29–43. [Google Scholar]

- ISO 24333:2009; Cereals and Cereal Products: Sampling. International Organization for Standardization (ISO): Geneva, Switzerland, 2009.

- Food and Drug Administration (FDA). Investigations Operations Manual. Available online: http://www.fda.gov/ICECI/Inspections/IOM/default.htm (accessed on 29 June 2021).

- Spanjer, M.C. Theory and criteria for practical sampling. In Proceedings of the World Mycotoxin Forum, the IV Conference, Cincinnati, OH, USA, 6–8 November 2006. [Google Scholar]

- Focker, M.; van der Fels-Klerx, H.J.; Oude Lansink, A.G.J.M. Cost-Effective Sampling and Analysis for Mycotoxins in a Cereal Batch. Risk Anal. 2019, 39, 926–939. [Google Scholar] [CrossRef]

- Maestroni, B.; Cannavan, A.A. Sampling Strategies to Control Mycotoxins. In Determining Mycotoxins and Mycotoxigenic Fungi in Food and Feed; De Saeger, S., Ed.; Woodhead Publishing Series in Food Science; Technology and Nutrition: Sawston, UK, 2011; pp. 3–36. ISBN 978-1-84569-674-0. [Google Scholar]

- Whitaker, T.B.; Hagler, W.M., Jr.; Giesbrecht, F.G.; Johansson, A.S. Sampling, sample preparation, and analytical variability associated with testing wheat for deoxynivalenol. J. AOAC Int. 2000, 83, 1285–1292. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Johansson, A.S.; Whitaker, T.B.; Giesbrecht, F.G.; Hagler, W.M., Jr.; Young, J.H. Testing shelled corn for aflatoxin, part II: Modeling the observed distribution of aflatoxin test results. J. AOAC Int. 2000, 83, 1270–1278. [Google Scholar] [PubMed]

- Dickens, J.W.; Whitaker, T.B. Sampling and sample preparation. In Environmental Carcinogens -Selected Methods of Analysis; Egan, H., Stoloff, L., Scott, P., Castegnaro, M., O’Neill, J.K., Borstch, H., Eds.; International Agency for Research on Cancer: Lyon, France, 1982; Volume 5, pp. 17–32. [Google Scholar]

- Whitaker, T.B.; Wiser, E.H. Theoretical investigations into the accuracy of sampling shelled peanuts for aflatoxin. J. Am. Oil Chem. Soc. 1969, 46, 377–379. [Google Scholar] [CrossRef]

- Whitaker, T.B.; Dickens, J.W.; Monroe, R.J.; Wiser, E.H. Comparison of the observed distribution of aflatoxin in shelled peanuts to the negative binomial distribution. J. Am. Oil Chem. Soc. 1972, 49, 590–593. [Google Scholar] [CrossRef]

- Whitaker, T.B.; Dickens, J.W.; Monroe, R.J. Variability of aflatoxin test results. J. Am. Oil Chem. Soc. 1974, 51, 214–218. [Google Scholar] [CrossRef]

- Whitaker, T.B.; Whitten, M.E.; Monroe, R.J. Variability associated with testing cottonseed for aflatoxin. J. Am. Oil Chem. Soc. 1976, 53, 502–505. [Google Scholar] [CrossRef] [PubMed]

- Whitaker, T.B.; Whitten, M.E. Evaluation of cottonseed aflatoxin testing programs. J. Am. Oil Chem. Soc. 1977, 54, 436–441. [Google Scholar] [CrossRef] [PubMed]

- Whitaker, T.B.; Dickens, J.W. Estimation of the Distribution of Lots of Shelled Peanuts According to Aflatoxin Concentrations. Peanut Sci. 1979, 6, 124–126. [Google Scholar] [CrossRef]

- Whitaker, T.B.; Dowell, F.E.; Hagler, W.M., Jr.; Giesbrecht, F.G.; Wu, J. Variability Associated with sampling, sample preparation, and chemical testing of farmers’ stock peanuts. J. AOAC Int. 1994, 77, 107–116. [Google Scholar] [CrossRef]

- Whitaker, T.B.; Giesbrecht, F.G.; Wu, J.; Hagler, W.M., Jr.; Dowell, F.E. Predicting the distribution of aflatoxin test results from farmers’ stock peanuts. J. AOAC Int. 1994, 77, 659–666. [Google Scholar] [CrossRef]

- Whitaker, T.B.; Wu, J.; Dowell, F.E.; Hagler, W.M., Jr.; Giesbrecht, F.G. Effects of sample size and sample acceptance level on the number of aflatoxin-contaminated farmers’ stock lots accepted and rejected at the buying point. J. AOAC Int. 1994, 77, 1672–1680. [Google Scholar] [CrossRef]

- Johansson, A.S.; Whitaker, T.B.; Hagler, W.M., Jr.; Giesbrecht, F.G.; Young, J.H.; Bowman, D.T. Testing shelled corn for aflatoxin, Part I: Estimation of variance components. J. AOAC Int. 2000, 83, 1264–1269. [Google Scholar] [CrossRef] [Green Version]

- Johansson, A.S.; Whitaker, T.B.; Hagler, W.M., Jr.; Giesbrecht, F.G.; Young, J.H.; Bowman, D.T. Testing shelled corn for aflatoxin, Part III: Evaluating the performance of aflatoxin sampling plans. J. AOAC Int. 2000, 83, 1279–1284. [Google Scholar] [CrossRef] [Green Version]

- Whitaker, T.B.; Slate, A.B.; Jacobs, M.; Hurley, J.M.; Adams, J.G.; Giesbrecht, F.G. Sampling Almonds for Aflatoxin, Part I: Estimation of Uncertainty Associated with Sampling, Sample Preparation, and Analysis. J. AOAC Int. 2006, 89, 1027–1034. [Google Scholar] [CrossRef] [Green Version]

- Whitaker, T.B.; Slate, A.B.; Hurley, J.M.; Giesbrecht, F.G. Sampling almonds for aflatoxin, Part II: Estimating risk associated with various sampling plan designs. J. AOAC Int. 2006, 90, 778–785. [Google Scholar]

- Codex Alimentarius Commission; Food and Agriculture Organization of the United Nations (FAO); World Health Organization (WHO). Report of the 4th Session of the Codex Committee on Contaminants in Foods, Izmir, Turkey, 26–30 April 2010, Alinorm 10/33/41; WHO: Geneva, Switzerland, 2010. [Google Scholar]

- Ozay, G.; Seyhan, F.; Yilmaz, A.; Whitaker, T.B.; Slate, A.B. Sampling hazelnuts for aflatoxin, Part I: Estimation of uncertainty associated with sampling, sample preparation, and analysis. J. AOAC Int. 2006, 89, 1004–1011. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ozay, G.; Seyhan, F.; Yilmaz, A.; Whitaker, T.B.; Slate, A.B.; Giesbrecht, F.G. Sampling Hazelnuts for Aflatoxin: Effect of Sample Size and Accept/Reject Limit on Reducing the Risk of Misclassifying Lots. J. AOAC Int. 2007, 90, 1028–1035. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Brera, C.; De Santis, B.; Prantera, E.; Debegnach, F.; Pannunzi, E.; Fasano, F.; Berdini, C.; Slate, A.B.; Miraglia, M.; Whitaker, T.B. The effect of sample size when evaluating “In-Field” sampling plans for aflatoxin AFB1 determination in corn. J. Agric. Food Chem. 2010, 58, 8481–8489. [Google Scholar] [CrossRef] [PubMed]

- Whitaker, T.B.; Dorner, J.W.; Giesbrecht, F.G.; Slate, A.B. Variability among Aflatoxin Test Results on Runner Peanuts Harvested from Small Field Plots. Peanut Sci. 2004, 31, 59–63. [Google Scholar] [CrossRef]

- Trucksess, M.W.; Whitaker, T.B.; Weaver, C.M.; Slate, A.; Giesbrecht, F.G.; Rader, J.I.; Betz, J.M. Sampling and Analytical Variability Associated with the Determination of Total Aflatoxins and Ochratoxin A in Powdered Ginger Sold as a Dietary Supplement in Capsules. J. Agric. Food Chem. 2009, 57, 321–325. [Google Scholar] [CrossRef]

- Whitaker, T.B.; Trucksess, M.W.; Weaver, C.M.; Slate, A. Sampling and analytical variability associated with the determination of aflatoxins and ochratoxin A in bulk lots of powdered ginger marketed in 1-lb bags. Anal. Bioanal. Chem. 2009, 395, 1291–1299. [Google Scholar] [CrossRef]

- Whitaker, T.B.; Richard, J.L.; Giesbrecht, F.G.; Slate, A.B.; Ruiz, N. Estimating Deoxynivalenol in Shelled Corn Barge Lots by Measuring Deoxynivalenol in Corn Screenings. J. AOAC Int. 2003, 86, 1187–1192. [Google Scholar] [CrossRef] [Green Version]

- Freese, L.; Friedrich, R.; Kendall, D.; Tanner, S. Variability of Deoxynivalenol measurements in Barley. J. AOAC Int. 2000, 83, 1259–1263. [Google Scholar] [CrossRef] [Green Version]

- Whitaker, T.B.; Trucksess, M.W.; Johansson, A.S.; Geesbrecht, F.G.; Hagler, W.M., Jr.; Bowman, D.T. Variability Associated with Testing Shelled Corn for Fumonisin. J. AOAC Int. 1998, 81, 1162–1168. [Google Scholar] [CrossRef] [Green Version]

- Whitaker, T.B.; Hagler, W.M., Jr.; Johansson, A.S.; Giesbrecht, F.G.; Trucksess, M.W. Sampling shelled corn for fumonisin. In Mycotoxins and Phycotoxins in Perspective at the Turn of the Millennium; de Koe, W.J., Samson, R.A., van Egmond, H.P., Gilbert, J., Sabino, M., Eds.; IUPAC: Wageningen, The Netherlands, 2001; pp. 97–107. [Google Scholar]

- Whitaker, T.B.; Doko, M.B.; Maestroni, B.M.; Slate, A.B.; Ogunbanwo, B.F. Evaluating the Performance of Sampling Plans to Detect Fumonisin B1 in Maize Lots Marketed in Nigeria. J. AOAC Int. 2007, 90, 1050–1059. [Google Scholar] [CrossRef] [Green Version]

- Food and Agriculture Organization of the United Nations. Mycotoxin Sampling Tool User Guide. 2014. Available online: http://tools.fstools.org/mycotoxins/Documents/UserGuide.pdf (accessed on 8 May 2022).

- Vargas, E.A.; Whitaker, T.B.; Santos, E.A.; Slate, A.B.; Lima, F.B.; França, R.C.A. Testing Green Coffee for Ochratoxin A, Part I: Estimation of Variance Components. J. AOAC Int. 2004, 87, 884–891. [Google Scholar] [CrossRef] [PubMed]

- Vargas, E.A.; Whitaker, T.B.; Santos, E.A.; Slate, A.B.; Lima, F.B.; Franca, R.C.A. Testing green coffee for ochratoxin A, Part II: Observed distribution of ochratoxin A test results. J. AOAC Int. 2005, 88, 780–787. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Vargas, E.A.; Whitaker, T.B.; Santos, E.A.; Slate, A.B.; Lima, F.B.; Franca, R.C.A. Testing green coffee for ochratoxin A, part III: Performance of ochratoxin A sampling plan. J. AOAC Int. 2006, 89, 1021–1026. [Google Scholar] [CrossRef] [PubMed]

- Thimsen, D.J.; Aften, P.W. A Proposed Design for Grain Elevator Dust Collection. J. Air Pollut. Control Assoc. 1968, 18, 738–742. [Google Scholar] [CrossRef]

- Tibola, C.S.; Fernandes, J.M.C.; Guarienti, E.M.; Nicolau, M. Distribution of Fusarium mycotoxins in wheat milling process. Food Control 2015, 53, 91–95. [Google Scholar] [CrossRef] [Green Version]

- Reichel, M.; Staiger, S.; Biselli, S. Analysis of Fusarium toxins in grain via dust: A promising field of application for rapid test systems. World Mycotoxin J. 2014, 7, 465–477. [Google Scholar] [CrossRef]

- Sanders, M.; De Boevre, M.; Dumoulin, F.; Detavernier, C.; Martens, F.; Van Poucke, C.; Eeckhout, M.; De Saeger, S. Sampling of Wheat Dust and Subsequent Analysis of Deoxynivalenol by LC-MS/MS. J. Agric. Food Chem. 2013, 61, 6259–6264. [Google Scholar] [CrossRef]

- Stroka, J.; Spanjer, M.; Buechler, S.; Barel, S.; Kos, G.; Anklam, E. Novel sampling methods for the analysis of mycotoxins and the combination with spectroscopic methods for the rapid evaluation of deoxynivalenol contamination. Toxicol. Lett. 2004, 153, 99–107. [Google Scholar] [CrossRef]

- Biselli, S.; Nkengfack, J.N. Device for Removing a Representative and Non-Destructive Sample of Particles of Bulk Material and Method for Removal Using the Device. Patent WO 2012/048695 A3, 9 September 2010. [Google Scholar]

- Sanders, M.; McPartlin, D.; Moran, K.; Guo, Y.; Eeckhout, M.; O’Kennedy, R.; De Saeger, S.; Maragos, C. Comparison of Enzyme-Linked Immunosorbent Assay, Surface Plasmon Resonance and Biolayer Interferometry for Screening of Deoxynivalenol in Wheat and Wheat Dust. Toxins 2016, 8, 103. [Google Scholar] [CrossRef] [Green Version]

- Sanders, M.; Landschoot, S.; Audenaert, K.; Haesaert, G.; Eeckhout, M.; De Saeger, S. Deoxynivalenol content in wheat dust versus wheat grain: A comparative study. World Mycotoxin J. 2014, 7, 285–290. [Google Scholar] [CrossRef] [Green Version]

- Limay-Rios, V.; Schaafsma, A.W. Relationship between Mycotoxin Content in Winter Wheat Grain and Aspirated Dust Collected during Harvest and after Storage. ACS Omega 2021, 6, 1857–1871. [Google Scholar] [CrossRef] [PubMed]

- Codex Alimentarius Commission (CAC). Guidelines on Estimation of Uncertainty of Results. CAC/GL 59-2006 Adopted in 2006; Codex Alimentarius Commission: Rome, Italy, 2006. [Google Scholar]

- Young, J.C.; Fulcher, R.G.; Hayhoe, J.H.; Scott, P.M.; Dexter, J.E. Effect of milling and baking on deoxynivalenol (vomitoxin) content of eastern Canadian wheats. J. Agric. Food Chem. 1984, 32, 659–664. [Google Scholar] [CrossRef]

- Cheli, F.; Pinotti, L.; Rossi, L.; Dell’Orto, V. Effect of milling procedures on mycotoxin distribution in wheat fractions: A review. LWT 2013, 54, 307–314. [Google Scholar] [CrossRef]

- Edwards, S.; Dickin, E.; Macdonald, S.; Buttler, D.; Hazel, C.; Patel, S.; Scudamore, K. Distribution of Fusarium mycotoxins in UK wheat mill fractions. Food Addit. Contam. Part A 2011, 28, 1694–1704. [Google Scholar] [CrossRef]

- Halstensen, A.S.; Nordby, K.-C.; Klemsdal, S.S.; Elen, O.; Clasen, P.-E.; Eduard, W. Toxigenic Fusarium spp. as Determinants of Trichothecene Mycotoxins in Settled Grain Dust. J. Occup. Environ. Hyg. 2006, 3, 651–659. [Google Scholar] [CrossRef] [PubMed]

- Nowicki, T.; Gaba, D.; Dexter, J.; Matsuo, R.; Clear, R. Retention of the fusarium mycotoxin deoxynivalenol in wheat during processing and cooking of spaghetti and noodles. J. Cereal Sci. 1988, 8, 189–202. [Google Scholar] [CrossRef]

- Vaclavikova, M.; Malachova, A.; Veprikova, Z.; Dzuman, Z.; Zachariasova, M.; Hajslova, J. ‘Emerging’ mycotoxins in cereals processing chains: Changes of enniatins during beer and bread making. Food Chem. 2013, 136, 750–757. [Google Scholar] [CrossRef]

- Hu, L.; Koehler, P.; Rychlik, M. Effect of sourdough processing and baking on the content of enniatins and beauvericin in wheat and rye bread. Eur. Food Res. Technol. 2014, 238, 581–587. [Google Scholar] [CrossRef]

- ISO 4225:2020; Air Quality—General Aspects—Vocabulary. International Standardization Organization: Genève, Switzerland, 2020.

- ISO 4225:1995; Air Quality-Particle Size Fraction Definitions for Health-Related Sampling. International Standardization Organization: Genève, Switzerland, 1995.

- Calvert, J.G. Glossary of atmospheric chemistry terms (Recommendations 1990). Pure Appl. Chem. 1990, 62, 2167–2219. [Google Scholar] [CrossRef] [Green Version]

- Görner, P.; Fabriès, J.F. Industrial aerosol measurement according to the new sampling convention. Occup. Hygiene 1996, 3, 361–376. [Google Scholar]

- European Standard EN 13205; Workplace atmospheres—Assessment of performance instruments for measurement of airborne particle concentration. Comité Européen de Normalization (CEN): Brussels, Belgium, 2002.

- European Standard EN 1540; Workplace exposure—Terminology. Comité Européen de Normalization (CEN): Brussels, Belgium, 2021.

- Mayer, S.; Curtui, V.; Usleber, E.; Gareis, M. Airborne mycotoxins in dust from grain elevators. Mycotoxin Res. 2007, 23, 94–100. [Google Scholar] [CrossRef] [PubMed]

| Aflatoxins | FBs | DON | OTA | ||

|---|---|---|---|---|---|

| Cereals | Barley | ● | |||

| Maize | ●●●● | ●●● | ● | ● | |

| Oats | ● | ||||

| Wheat | ● | ● | |||

| Nuts | Almonds | ●●● | |||

| Pistachios | ● | ||||

| Brazil Nuts | ● | ||||

| Hazelnuts | ● | ||||

| Peanuts | ●●●●●●●● | ||||

| Ginger | ●● | ●● | |||

| Dried Figs | ● | ||||

| Coffee Beans | ●●● | ||||

| Cotton Seed | ●●●● | ||||

| µg/kg | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| NIV | DON | T2+HT2 | ZEN | OTA | ||||||

| Grain | Dust | Grain | Dust | Grain | Dust | Grain | Dust | Grain | Dust | |

| Trial 1 | ||||||||||

| Sample set 1 | ||||||||||

| Wagon 1 | (−) | 308 | (−) | 1097 | (−) | 367 | (−) | (−) | (−) | (−) |

| Wagon 2 | (−) | 176 | (−) | 1057 | (−) | 296 | (−) | (−) | (−) | (−) |

| Wagon 3 | (−) | 159 | (−) | 551 | (−) | 299 | (−) | (−) | (−) | (−) |

| Wagon 4 | (−) | 95 | (−) | 490 | (−) | 196 | (−) | (−) | (−) | (−) |

| Wagon 5 | (−) | 256 | (−) | 860 | (−) | 660 | (−) | (−) | (−) | (−) |

| Wagon 6 | (−) | 161 | (−) | 686 | (−) | 368 | (−) | (−) | (−) | (−) |

| Trial 2 | ||||||||||

| Sample set 2A | ||||||||||

| Truck 1 | (−) | 85 | (−) | 2018 | (−) | 20 | (−) | 51 | (−) | (−) |

| Truck 2 | (−) | 114 | (−) | 795 | (−) | 8.7 | (−) | (−) | (−) | 3.2 |

| Truck 3 | (−) | 77 | 20 | 2648 | (−) | 74 | (−) | (−) | (−) | (−) |

| Truck 4 | (−) | 79 | 34 | 3745 | (−) | 12 | (−) | 308 | (−) | 53 |

| Truck 5 A | (−) | 42 | 24 | 1260 | (−) | 15 | (−) | (−) | (−) | (−) |

| Truck 6 A | (−) | 162 | 35 | 4539 | (−) | 2.3 | (−) | (−) | (−) | 0.4 |

| Truck 7 A | (−) | 344 | (−) | 1129 | (−) | 19 | (−) | (−) | (−) | (−) |

| Truck 8 | (−) | 204 | (−) | 1095 | 52 | 391 | (−) | (−) | (−) | (−) |

| Truck 9 | (−) | 58 | (−) | 1228 | (−) | 14 | (−) | (−) | (−) | (−) |

| Truck 10 | (−) | 14 | (−) | 353 | (−) | 4.5 | (−) | (−) | (−) | 6.3 |

| Truck 11 A | (−) | 255 | (−) | 1194 | 9.5 | 317 | (−) | (−) | (−) | (−) |

| Truck 12 | (−) | (−) | (−) | 4206 | (−) | 5.9 | (−) | (−) | (−) | (−) |

| Truck 13 | (−) | 92 | (−) | 1163 | 54 | 363 | (−) | (−) | (−) | (−) |

| Truck 14 | (−) | 173 | 23 | 3803 | (−) | 4.9 | (−) | (−) | (−) | (−) |

| Truck 15 A | (−) | 94 | (−) | 2174 | (−) | 8.9 | (−) | (−) | (−) | (−) |

| Truck 16 A | (−) | 183 | 36 | 7347 | (−) | 14 | (−) | (−) | (−) | (−) |

| Truck 17 | (−) | 248 | (−) | 5094 | 8.5 | 190 | (−) | 79 | (−) | 6.2 |

| Truck 18 | (−) | 358 | (−) | 4367 | (−) | 446 | (−) | (−) | (−) | (−) |

| Truck 19 A | (−) | 172 | 33 | 6267 | (−) | 88 | (−) | 277 | (−) | 14 |

| Truck 20 | (−) | 696 | (−) | 1628 | 6.8 | 191 | (−) | (−) | (−) | 1.5 |

| Truck 21 | (−) | 335 | 20 | 2972 | 31 | 363 | (−) | (−) | (−) | (−) |

| Truck 22 | (−) | 190 | (−) | 3575 | (−) | 194 | (−) | (−) | (−) | 2.0 |

| Truck 23 | (−) | 168 | 68 | 5404 | (−) | 12 | (−) | (−) | (−) | (−) |

| Truck 24 | (−) | 430 | 20 | 2606 | (−) | 16 | (−) | (−) | (−) | 0.2 |

| Truck 25 | (−) | 398 | 24 | 3028 | 26 | 347 | (−) | (−) | (−) | (−) |

| Truck 26 | (−) | 208 | (−) | 2250 | (−) | 359 | (−) | (−) | (−) | (−) |

| Truck 27 | (−) | 264 | (−) | 1206 | 12 | 854 | (−) | (−) | (−) | (−) |

| Truck 28 A | (−) | 249 | (−) | 1268 | 19 | 605 | (−) | (−) | (−) | 1.1 |

| Truck 29 | (−) | 331 | 24 | 1463 | 27 | 35 | (−) | 232 | (−) | 0.8 |

| Truck 30 | (−) | 187 | 22 | 1760 | 47 | 388 | (−) | (−) | (−) | (−) |

| Truck 31 | (−) | 297 | 90 | 10,531 | 12 | 154 | 0 (−) | (−) | (−) | 3.3 |

| Truck 32 | (−) | 281 | 32 | 3977 | (−) | (−) | (−) | (−) | (−) | (−) |

| Sample set 2B | ||||||||||

| Truck 5 B | (−) | 163 | 24 | 1161 | (−) | 72 | (−) | (−) | (−) | (−) |

| Truck 6 B | (−) | 185 | 35 | 5168 | (−) | 2.4 | (−) | (−) | (−) | (−) |

| Truck 7 B | (−) | 560 | (−) | 2631 | (−) | 199 | (−) | (−) | (−) | (−) |

| Truck 11 B | (−) | 291 | (−) | 932 | 9.5 | 305 | (−) | (−) | (−) | (−) |

| Truck 15 B | (−) | 103 | (−) | 2638 | (−) | 12 | (−) | (−) | (−) | (−) |

| Truck 16 B | (−) | 237 | 36 | 7282 | (−) | 16 | (−) | (−) | (−) | (−) |

| Truck 19 B | (−) | 163 | 33 | 6572 | (−) | 138 | (−) | (−) | (−) | (−) |

| Truck 28 B | (−) | 154 | (−) | 841 | 19 | 447 | (−) | (−) | (−) | (−) |

| Sample Name | DON Contamination in Dust Samples * × 103 (µg/kg) | DON Contamination in Wheat Grains × 102 (µg/kg) | |

|---|---|---|---|

| Calculated by the Correlation Model ** | Direct Determination in Grain Sample * | ||

| Sample set 2B | |||

| Truck 5 B | 1.2 ± 0.4 | 0.1 ± 0.4 | 0.2 ± 0.1 |

| Truck 6 B | 5.2 ± 1.3 | 0.4 ± 0.4 | 0.4 ± 0.2 |

| Truck 7 B | 2.6 ± 0.7 | 0.2 ± 0.4 | (−) |

| Truck 11 B | 0.9 ± 0.3 | 0.0 ± 0.4 | (−) |

| Truck 15 B | 2.6 ± 0.7 | 0.2 ± 0.4 | (−) |

| Truck 16 B | 7.3 ± 1.7 | 0.6 ± 0.4 | 0.4 ± 0.2 |

| Truck 19 B | 6.6 ± 1.5 | 0.6 ± 0.4 | 0.3 ± 0.1 |

| Truck 28 B | 0.8± 0.3 | 0.0 ± 0.4 | (−) |

| Trial (i): Unloading of Train Wagon | Trial (ii): Unloading of Wheat Trucks | |||

|---|---|---|---|---|

| Regulation EC 401/2006 | Dust Sampling | Standard Intake Control Procedures | Dust Sampling | |

| Fraction Weight (Tons) | 60 | 60 | 25–30 | 25–30 |

| Type of Sampling | Dynamic | Dynamic | Static | Dynamic |

| Number of Incremental Sample | 100 | 1 | 3 | 1 |

| Aggregate Sample Weight (kg) | 10 | 0.005 * | 3 | 0.005 * |

| Sampling interval (sec) | 9 | n.a. | n.a. | n.a. |

| Duration of Sampling Procedure (min) | 15–20 | 15–20 | 10 | 10 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ciasca, B.; De Saeger, S.; De Boevre, M.; Reichel, M.; Pascale, M.; Logrieco, A.F.; Lattanzio, V.M.T. Mycotoxin Analysis of Grain via Dust Sampling: Review, Recent Advances and the Way Forward: The Contribution of the MycoKey Project. Toxins 2022, 14, 381. https://doi.org/10.3390/toxins14060381

Ciasca B, De Saeger S, De Boevre M, Reichel M, Pascale M, Logrieco AF, Lattanzio VMT. Mycotoxin Analysis of Grain via Dust Sampling: Review, Recent Advances and the Way Forward: The Contribution of the MycoKey Project. Toxins. 2022; 14(6):381. https://doi.org/10.3390/toxins14060381

Chicago/Turabian StyleCiasca, Biancamaria, Sarah De Saeger, Marthe De Boevre, Mareike Reichel, Michelangelo Pascale, Antonio F. Logrieco, and Veronica M. T. Lattanzio. 2022. "Mycotoxin Analysis of Grain via Dust Sampling: Review, Recent Advances and the Way Forward: The Contribution of the MycoKey Project" Toxins 14, no. 6: 381. https://doi.org/10.3390/toxins14060381

APA StyleCiasca, B., De Saeger, S., De Boevre, M., Reichel, M., Pascale, M., Logrieco, A. F., & Lattanzio, V. M. T. (2022). Mycotoxin Analysis of Grain via Dust Sampling: Review, Recent Advances and the Way Forward: The Contribution of the MycoKey Project. Toxins, 14(6), 381. https://doi.org/10.3390/toxins14060381