1. Introduction

The maintenance plan for a road network must be issued on the basis of updated knowledge of road conditions and relies on field data that must be stored in a dedicated database. The survey method must be efficient, cost-effective and designed to have the lowest impact on road traffic and operators’ safety. It is therefore advisable to develop a reliable and cost-effective monitoring system and a digital model able to precisely describe, at global and regional level, the surface condition of the road pavement. The monitoring system should not depend on the extent of the road networks and should ensure the continuity of traffic flows.

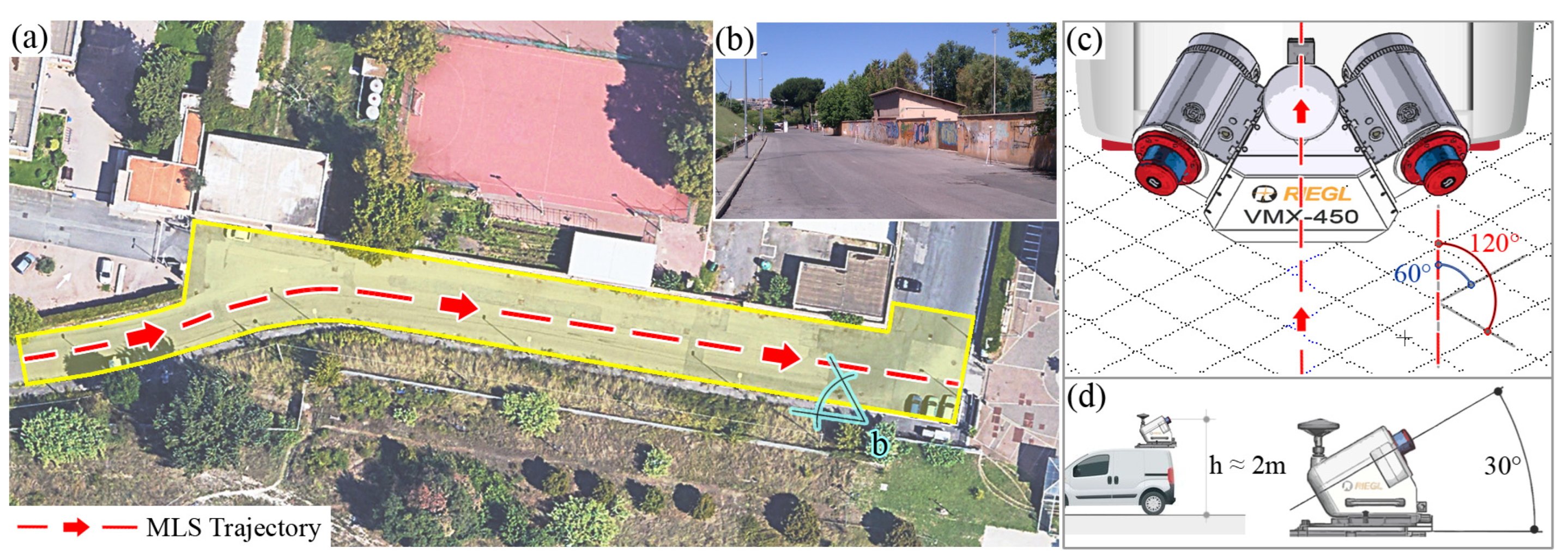

An especially valuable survey technique for road applications is mobile laser scanning (MLS) [

1]. It enables the acquisition of 3D data from one or more laser scanners mounted on a mobile platform [

2]. This technique, first introduced in the recent decades of the twentieth century, when the first mobile systems using LiDAR (light detection and ranging) technology emerged, has developed and spread widely in the last twenty years [

3]. Given the versatility and efficiency of the system, an increasing focus has recently been placed on practical applications in the fields of infrastructure engineering.

Di Stefano et al. critically analyzed the activity of research over the last ten years regarding the applications of MLS systems in various fields, including those of structures and infrastructures [

4]. The authors point out that the interest in the use of the MLS technique is still growing; the technique represents a fast, versatile, customizable solution that can be adapted to different types of mobile platforms. Mendenhall [

5] analyzed the efficiency of the MLS technique in terms of cost and acquisition time. His study was conducted on a 15-mile stretch of an urban road in the city of San Francisco; with respect to standardized techniques, the MLS technique was found to be very cost-effective for generating a database for maintenance purposes, as it results in a significant reduction in cost and acquisition time.

Since linear infrastructures have a much higher longitudinal development than the cross-sectional one, a dynamic measurement at normal traffic speeds, as provided by an MLS, is probably the most suitable solution for this kind of infrastructure [

6]. The MLS technique also brings benefits in terms of safety, efficiency, and cost-effectiveness, as the field survey is carried out by a team of operators aboard an equipped vehicle traveling at operational speed, thus without being subject to any risk conditions [

7].

The MLS survey data supplies a detailed inventory of all the elements that make up the road, including road signage and structural works. The point cloud from MLS is a valuable source of information about the road geometry and the state of damage it is in [

8,

9,

10], allowing for the characterization of the road and the identification and evaluation of its distress [

2,

11,

12,

13]. This also serves as the input data to build an accurate 3D model of the surface of the infrastructure. The accuracy of extracting the parameters of interest and the productivity vary considerably depending on the accuracy of the sensors mounted on board the MLS; thus, the geometric road assessment and the analysis of road distress are more accurate if very precise laser sensors and inertial platforms are used.

The MLS integrates the laser scanners with other sensors that can provide position and attitude data: Global Navigation Satellite System (GNSS), Inertial Measurement Unit (IMU), Distance Measurement Indicator (DMI) and with cameras. Each sensor that is part of the system is affected by an error of its own that influences the overall accuracy of the point position in the cloud. The embedded data are used to compute the 3D position of both the laser center and the impact point of the beam on the target object. In addition, the integration of data sourced from GNSS and IMU makes it possible to identify the target position even when there is little or no satellite visibility [

14], even in areas with infrastructure masked by trees and in urban areas.

A few papers have been published assessing the accuracy of 3D point clouds produced via MLS in road applications, which is proven to be fully adequate for measuring the regularity and geometry of roads, including when high standards for accuracy are required [

15,

16,

17].

Fryskowska et al. [

16] found that the relative accuracy achievable with an MLS survey is on the order of a few millimeters, even in the elevation component up to distances of approximately 5 m from the laser sensor, i.e., in a distance range in line with that used in the survey of the road surface. Same-order accuracy results are achieved by El Issaoui et al. [

15], who analyze the accuracy of MLS-derived rut depths by comparing them with rut depth derived from a static Terrestrial Laser Scanners (TLS) survey. The authors also compare the cross slopes obtained with both techniques. Based on these results, they point out that the MLS technique has the potential to develop a system with a high level of automation and is able to provide accurate results for road surface management.

The NCHRP (National Cooperative Highway Research Program) reported 748 provides guidelines for the use of MLS and other instruments in support of infrastructure planning, design, and maintenance [

18]. In the report, the accuracy and density of the point cloud are acknowledged as key variables, and then discussed in more detail.

Because of the operational velocity, accuracy, cost effectiveness and safety of the technique, MLS can be used for monitoring purposes by periodically scanning the same area, so as to assess changes over time. This causes a significant reduction in costs and acquisition time, as compared to traditional methods [

19].

Managing authorities are, therefore, moving towards the concept of “digital road” through the creation of a BIM (Building Information Modeling) for the design and management of infrastructure. The use of BIM for such applications has grown exponentially. Justo et al. [

20] proposed an automatic procedure for the generation of an IFC (Industry Foundation Classes) model of the infrastructure, starting from a point cloud acquired by MLS; IFC modeling is derived from the automated extraction of horizontal, vertical and guard-rail signs.

An important part of the BIM infrastructure project is an accurate and detailed Digital Elevation Model (DEM) of the infrastructure itself. This is why a special focus is given to the accurate modeling of objects with linear development, such as road infrastructure [

21].

Other digital models of the pavement are also used, essentially related to the management and control of infrastructure networks. Among these, the best known are the Digital Model for a Project (DMP), which represents the ideal road condition after the pavement rehabilitation has been made, and the Digital Differential Model (DDM) used to detect areas with extreme unallowed deviations [

22]. These models are used extensively during the pavement rehabilitation phase as they make it possible to compare the actual deviations with the maximum deviations allowed by the project specifications and to optimize the maintenance process in progress [

23].

Digital road models are also used for the control systems of road building equipment and the vehicle automation for automated transport systems.

The road surface may be affected by either functional or structural distress [

24,

25]. Distress is classified as functional if the pavement is still efficient but has critical issues in terms of regularity and adherence, which can make driving uncomfortable and unsafe and produce significant long-term damage. Otherwise, distress is classified as structural if the pavement is broken due to cyclical loads, i.e., due to aging, or due to poor design or maintenance. This type of distress includes the so-called localized distress, which significantly reduces the safety of users. The analysis of pavement surface conditions can, therefore, be made by focusing on either the regularity analysis or the analysis of localized surface defects. In the planning stage of road maintenance (at “network level”), when it is advisable to analyze the conditions of the whole road network under the corresponding jurisdiction, the analyses of both regularity and ride comfort are usually conducted [

26]. The evaluation of localized defects becomes a key stage in maintenance planning when the specific road segments requiring maintenance have already been identified and a detailed action planning is needed [

27,

28,

29,

30].

The specifications for building the DEM that describes the paved surface, in terms of interpolators and choice of parameters, as well as the resolution closely related to the input data density, are strongly dependent on the specific application for which it will be used.

If the goal of the survey is the analysis of the regularity of the road (through the analysis of longitudinal profiles), the resolution of the DEM will have to be in accordance with the sampling interval suitable for the computation of the regularity index used. For example, if the International Roughness Index (IRI) is used, the sample interval should be no larger than 300 mm for an accurate computation [

31]; a linear interpolation between points, which implies a constant slope, is used. According to the ASTM E950 [

32] standard, for high-precision Class 1 applications, the sample interval should be less than or equal to 25 mm, whereas it can be up to 300 mm for low-precision Class 4 applications. If the goal is rather to identify and quantify localized distress, it is worth setting the resolution of the DEM on the basis of their typical size.

To assess the effect that these distresses have on ride quality, ASTM introduced three severity levels (ASTM D6433 [

33]; low, medium and high), and these differ according to the perception of discomfort that the user has during driving at the normal operating velocity. A low severity level leads to vibrations but no reduction in velocity by the user because there is no perception of a decrease in safety or comfort. A medium level of severity involves vibrations of the vehicle such that a slight reduction in velocity is needed. A high severity level means that vehicle vibrations are so strong that velocity must be reduced greatly in order to ensure an adequate level of safety and comfort. The severity levels are associated with each specific distress as a function of geometric characteristics, characteristics that vary according to the type of distress.

In addition to geometric analysis, the modeled surface can be input into simulation software packages to study the effects of vehicle dynamics on the drivers [

6].

The traditional DEMs are structured according to a regular grid of nodes. The use of the grid DEM is mainly due to the ease-of-mathematical treatment of matrices, even in a GIS environment, without a large computational effort. The grid cell, named pixel, is the main spatial entity in a raster-based GIS [

34]. It is quite evident that a grid structure oriented according to the north–south cartographic grid is not effective for modeling the curvilinear development of the road belt [

35]. The alternative is to use a Triangulated Irregular Network (TIN) model. TINs are preferred when the spatial distribution of the points is not homogeneous. Generally, TIN models are costly when the amount of data is large, whereas regular grid models reduce both computation time and computational complexity, allowing for an efficient implementation of algorithms. This makes them preferable when the amount of data is very large and when data are structured according to a homogeneous spatial distribution [

36].

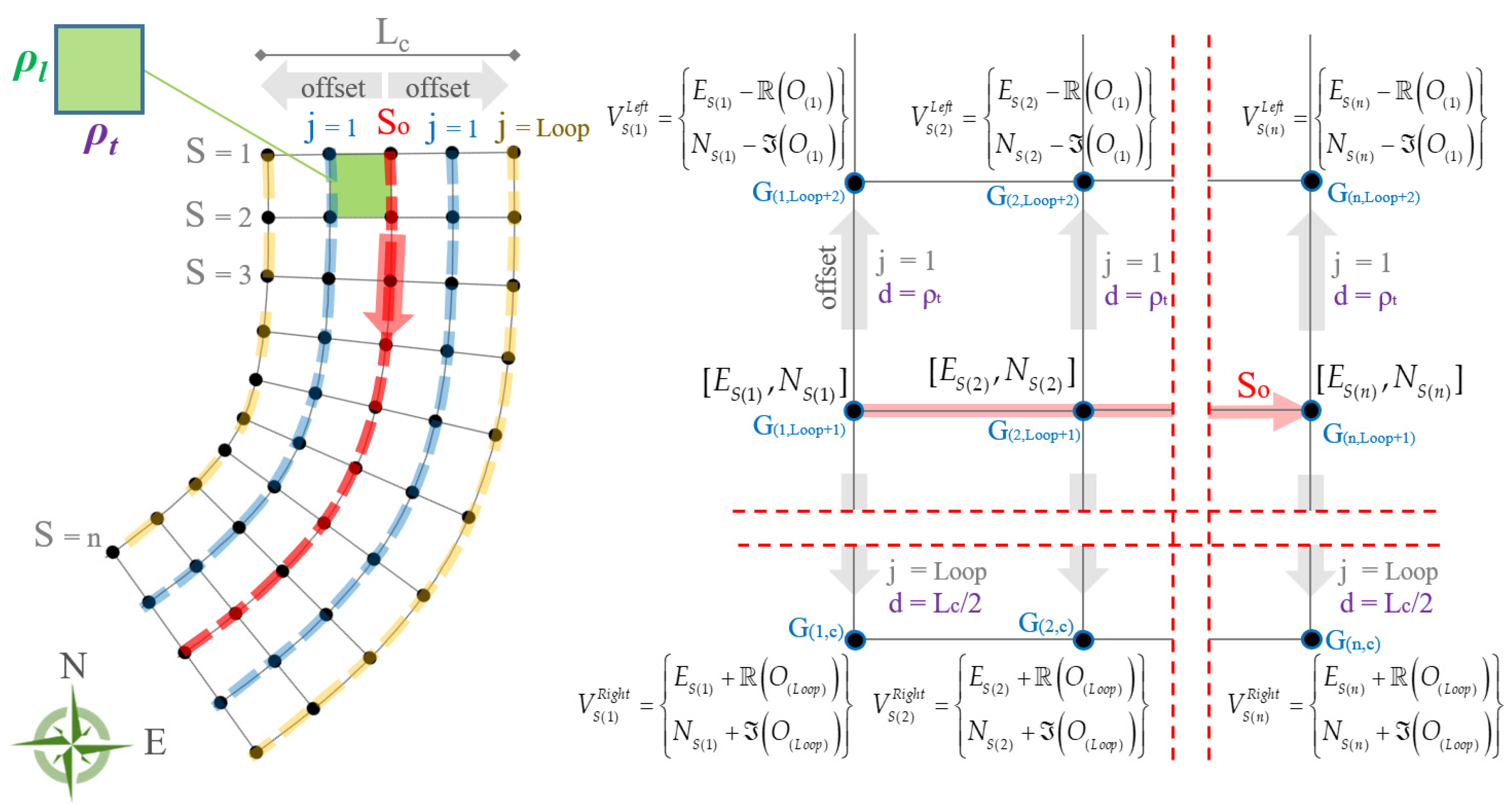

In place of the traditional DEMs, we propose our own methodological approach to build a specific DEM, based on a non-square grid model and with a curved abscissa that follows the course of the road belt. This DEM was specifically designed for road pavements, in order to optimize not only the computational cost but also the organization and extraction of profiles as well as the plano-altimetric analysis. Regarding the proposed DEM, which we believe has a solid rationale, especially in the case of modeling a long and articulated road belt, we outline the mathematical model and the computer implementation; this is one of the original points of our research work.

The grid resolution is one of the main parameters to set in a grid model; as the grid becomes coarser, the overall informative content of the map will progressively decrease and vice versa. The choice of the resolution is influenced by some factors, such as the characteristics of the data and the applications of the model.

The DEM resolution is dependent on the density of the MLS data and the type of distress that can be highlighted depends on it.

The road survey tests with MLS allowed us to correlate data density with the maximum resolution that could be used, and hence the type of distress that could be identified. In particular, the parameters for choosing the grid spacing were specified according to the density of the point cloud and the surface distress that could be quantified. This is, in our opinion, the other original contribution of our research work.

The goal of the work is, therefore, twofold: (i) to introduce a relationship that helps with design, in order to know a priori the average MLS velocity to be maintained so as to be able to “see” the distress that can be quantified and vice versa; (ii) to introduce a methodology able to build a DEM with a curved abscissa, based on a grid model and specifically designed for road pavements.

The paper is organized into five sections. The Introduction section introduces the following sections: Methods, Test Case, Results and Discussion, Conclusions.

The section

Methods is in turn divided into several sub-sections, each dealing with an important aspect of the proposed method:

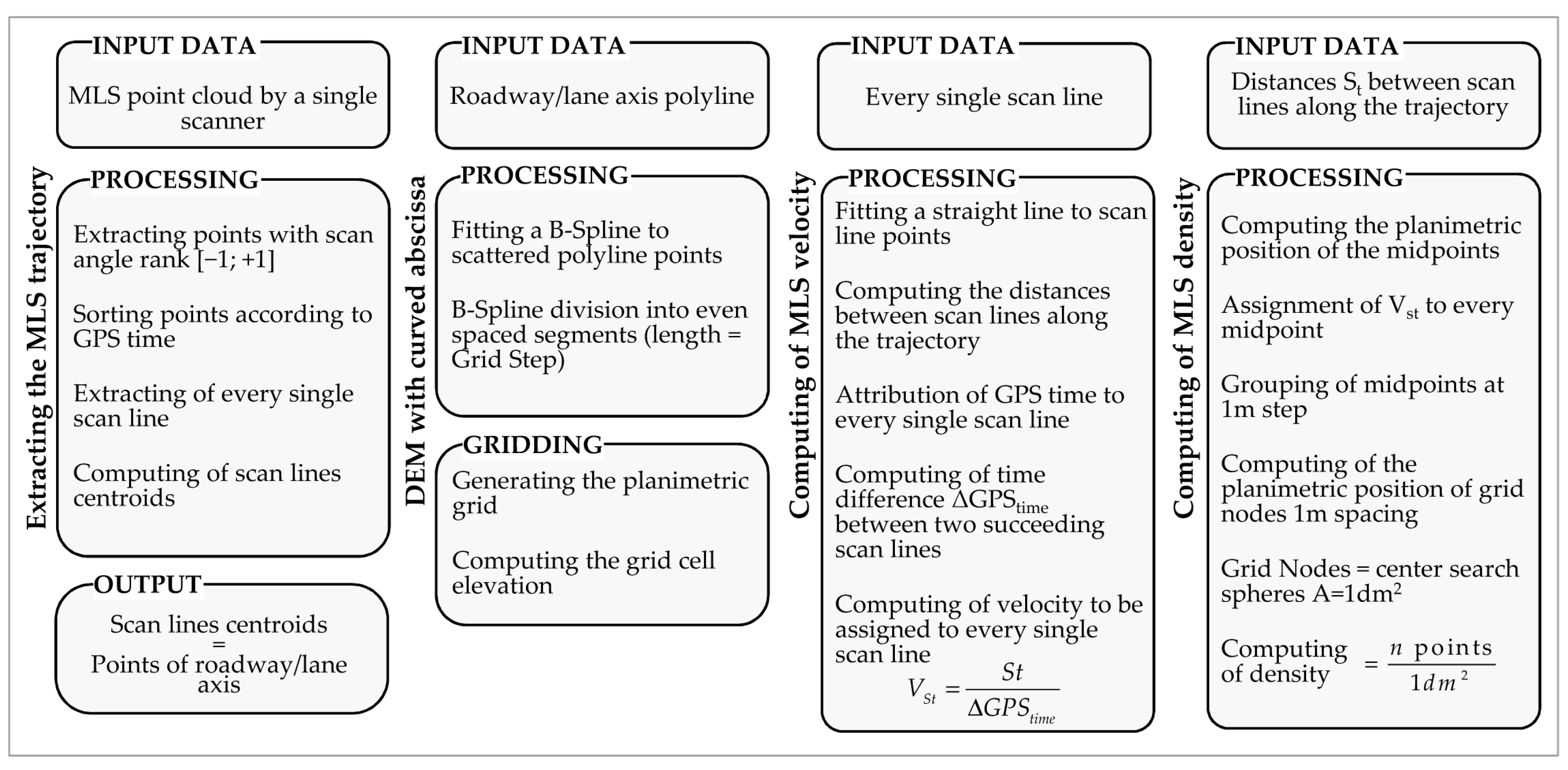

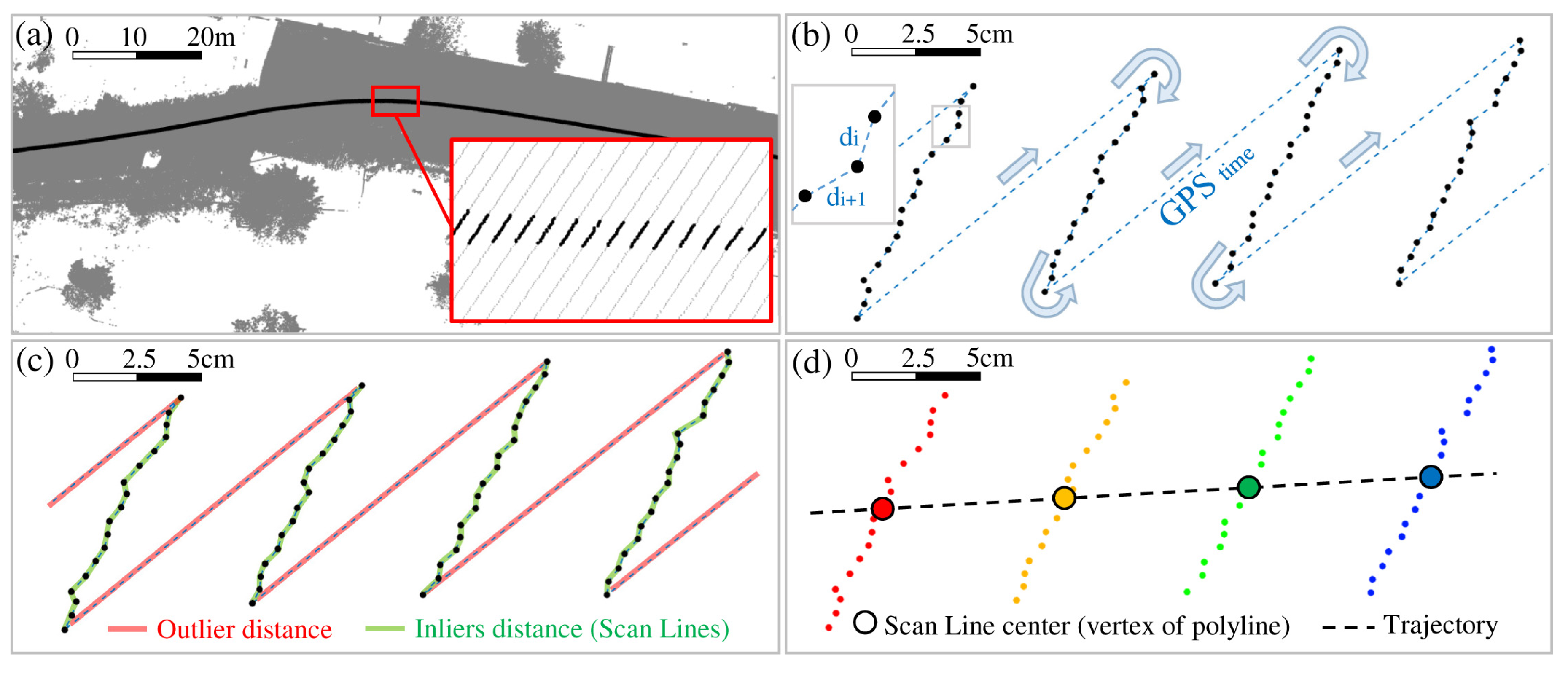

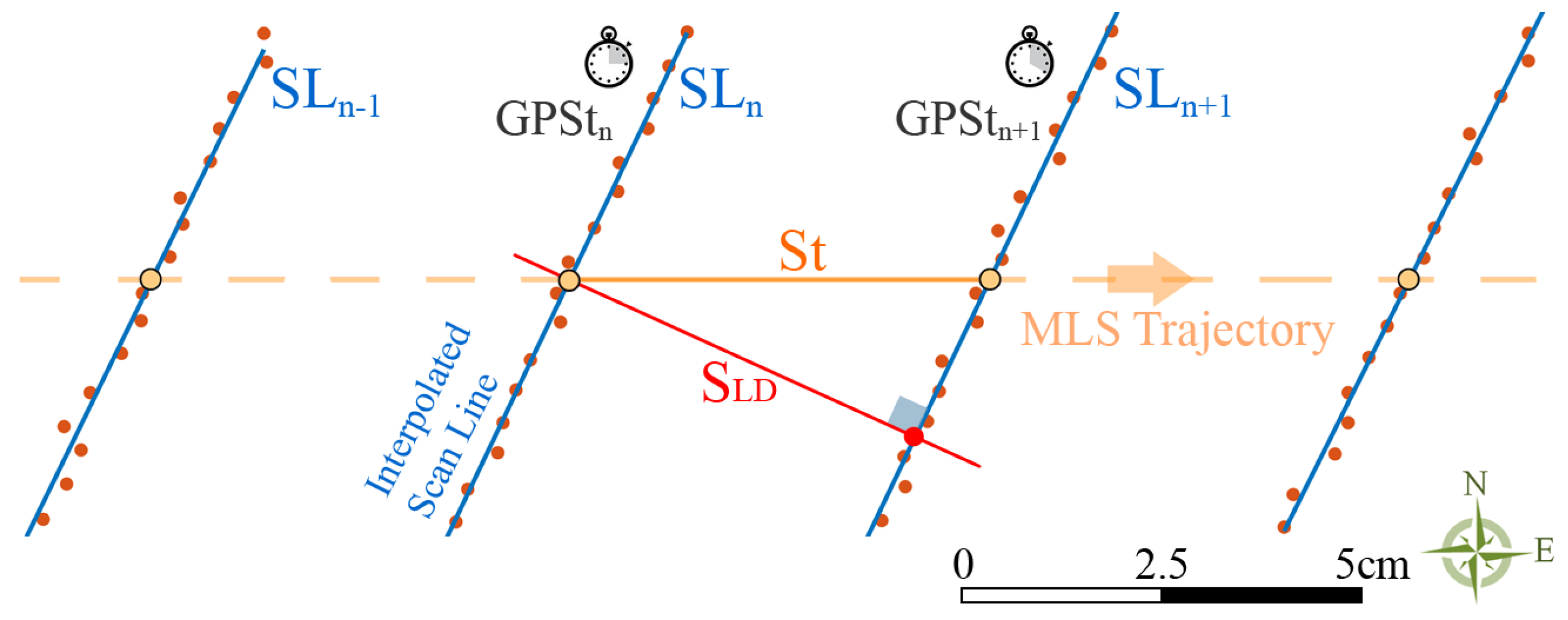

Section 2.1 illustrates the method used to isolate the single scan lines and the computation of the MLS travel velocity along the trajectory;

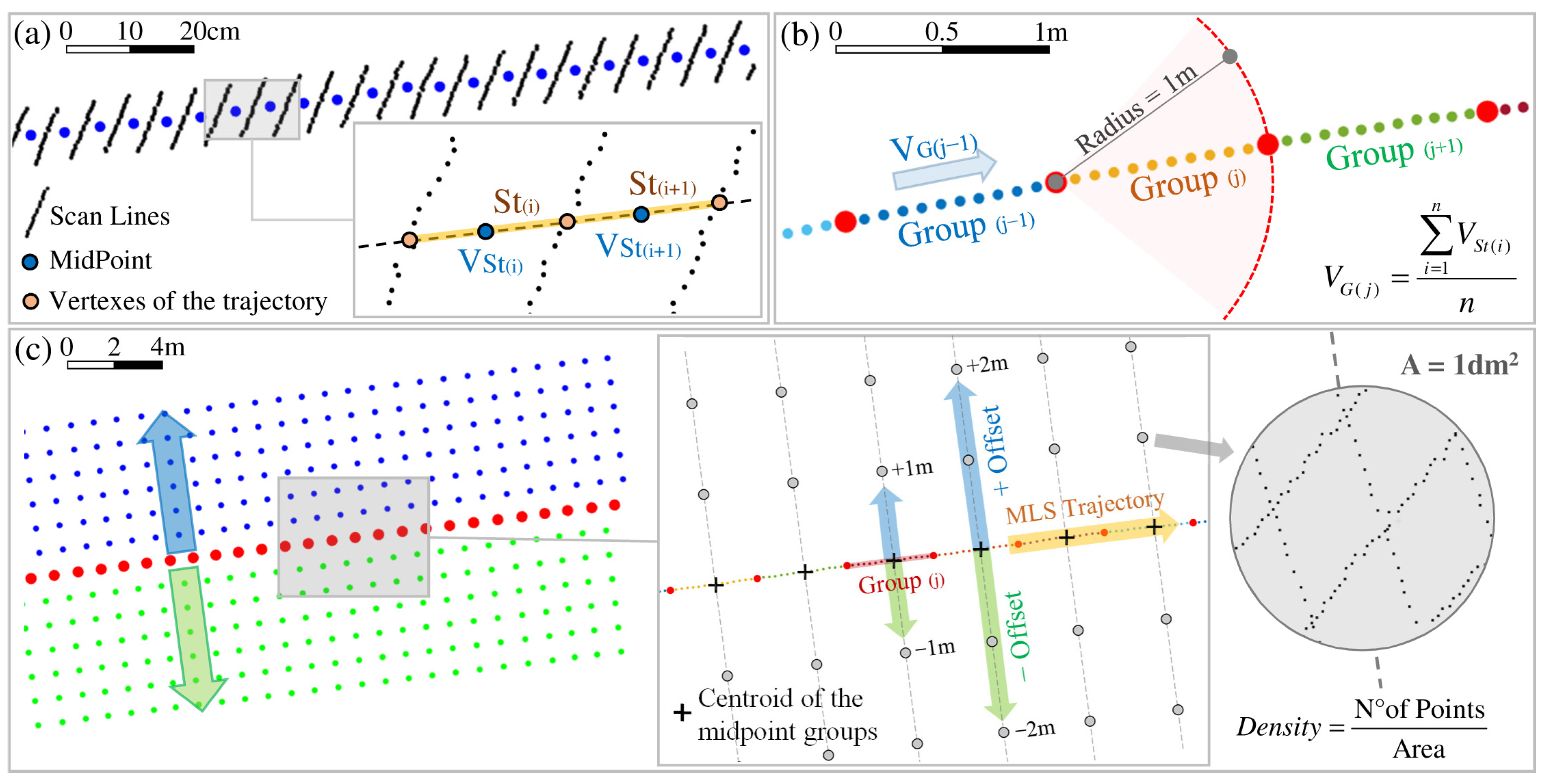

Section 2.2 illustrates the method for the computation of the surface density, which is then related to the velocity;

Section 2.3 address the building of the DEM with a curved abscissa in detail, starting from the method used for the construction of the polyline axis (which consists of the abscissa of the DEM) and then describing the method for the generation of the curvilinear grid in planimetry, the choice of resolution and the attribution of elevation to the nodes through methods of spatial interpolation. The section

Results and Discussion reports the fundamental relationships obtained, correlated by experimental graphs, which are discussed and commented on as they occur. The section ends by showing a test on a particular distress, aiming to highlight the strong sensitivity of the presented method.

4. Results and Discussion

The tests carried out and the data processing methodology developed allow the relationship between the input parameters of the survey (scanning frequency, velocity setting) to be quantified with the density of the points acquired, the resolution of the DEMc, and lastly, with the type of distress that can be identified.

The density of points in the cloud is dependent on the actual travel velocity, yet the rotating laser that is part of the system outputs points at variable spacing in the cross direction (greater for more distant points and more evenly distributed in the travel direction and as a function of actual travel velocity).

Figure 10 shows for each velocity an excerpt of the density map represented through a chromatic scale that shows how the density to the path is almost longitudinally constant, while it ranges greatly with the velocity (from 30,000 points per m

2 to 3000 when the velocity increases from 10 to 60 km/h), while crossways, the variation is very fast even for the few meters of the roadway width (at the roadsides it decreases to 3000 pts/m

2 for a velocity of 10 km/h and to 500 pts/m

2 at 60 km/h).

Given the strong correlation between density and the actual velocity that was estimated, as described in

Section 2.2 (Equation (4)), we aimed to derive a functional relationship between the experimental data that also accounted for the distance from the trajectory in the cross direction; longitudinal stripes were considered for distances (d) from 1 to 6 m.

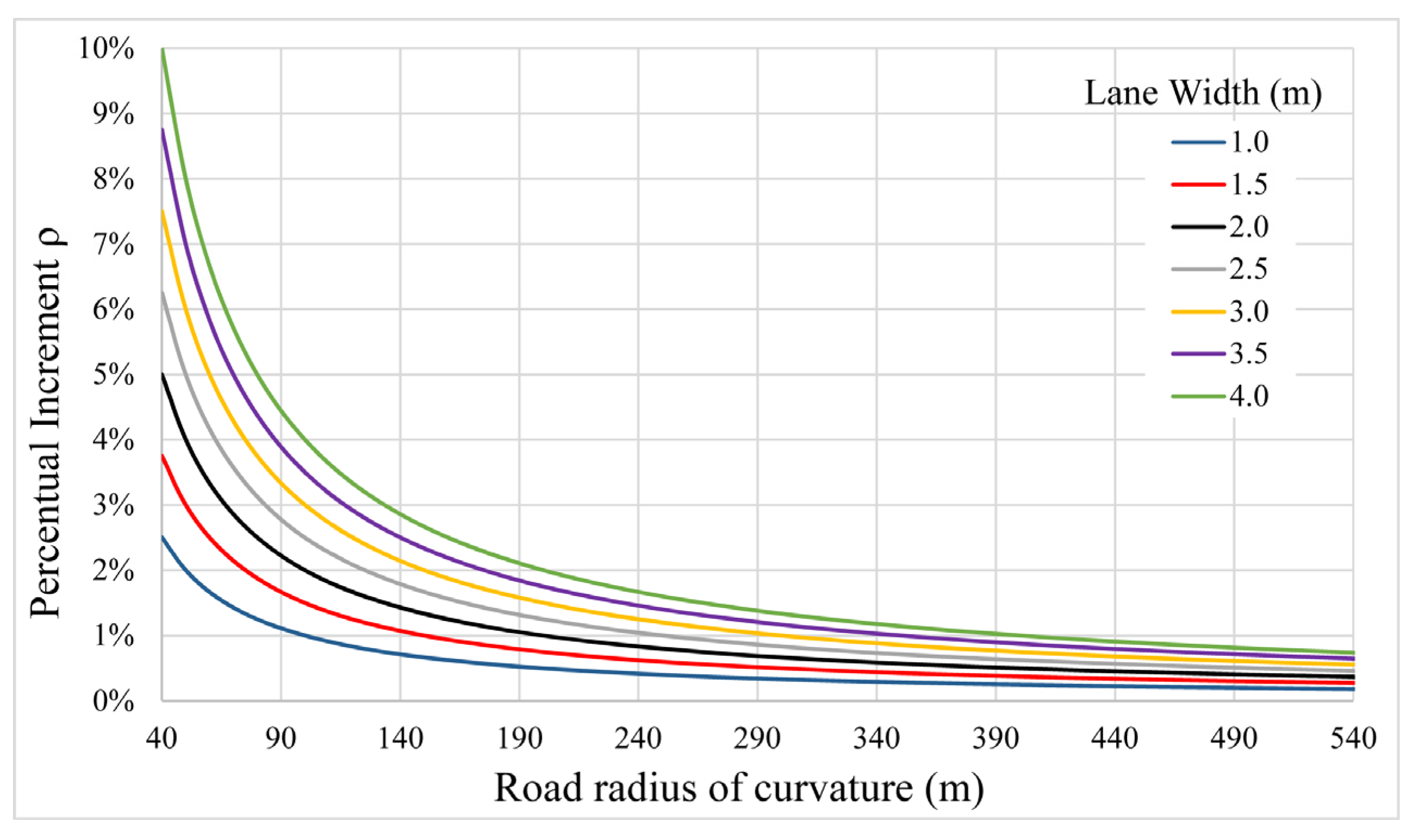

The MLS used allows the input of the average velocity value (velocity set parameter, VSET); the set value also affects the rotation speed of the scanner, i.e., the number of lines per second recorded. To study the effect of this parameter, VSET values equal to 10, 20, 60 km/h were set, while maintaining different effective travel velocities to analyze the data acquired in a variety of scenarios. Multiple passages were driven at different actual average velocities, 10, 20, 40, 60 km/h.

Figure 11 shows the diagrams of the density as a function of the velocity V

G. The diagrams shown in panels a,b,c refer to the V

SET settings of 10, 20 and 60 km/h, respectively.

The coefficients of the equation that defines the best-fit exponential curve for the density data were found using the least squares method. The different color is to specify the distance from the trajectory (from 1 to 6 m). The coefficient values are reported in panel d as well as the value of the coefficient of determination R2, which defines how well the model fits the data.

The data graphed in the figure show that the vehicle is not always capable of traveling at a constant velocity; therefore, the density values, while more centered on the design values, are somewhat scattered, especially when traveling at low velocities.

From the comparison of the curves plotted in the three panels of the figure, it should be noted that the use of different VSET values does not result in a significant change in the best-fit curves, whose trend depends almost only on the actual velocity VG; the R2 values also remain very similar.

The exponential curve fits the experimental data well, especially near the strips at distances less than or equal to 3 m, with R2~0.98, whereas for greater distances, the coefficient of determination decreases rapidly. This is probably due to the increased angle of incidence between the laser beam and the pavement, which results in greater areas of shadow (mainly in areas where the pavement is more distressed), and thus there is a non-uniform density of the data. Additionally, a big difference between the values of VSET and VG results in a decrease in R2 for great values of d.

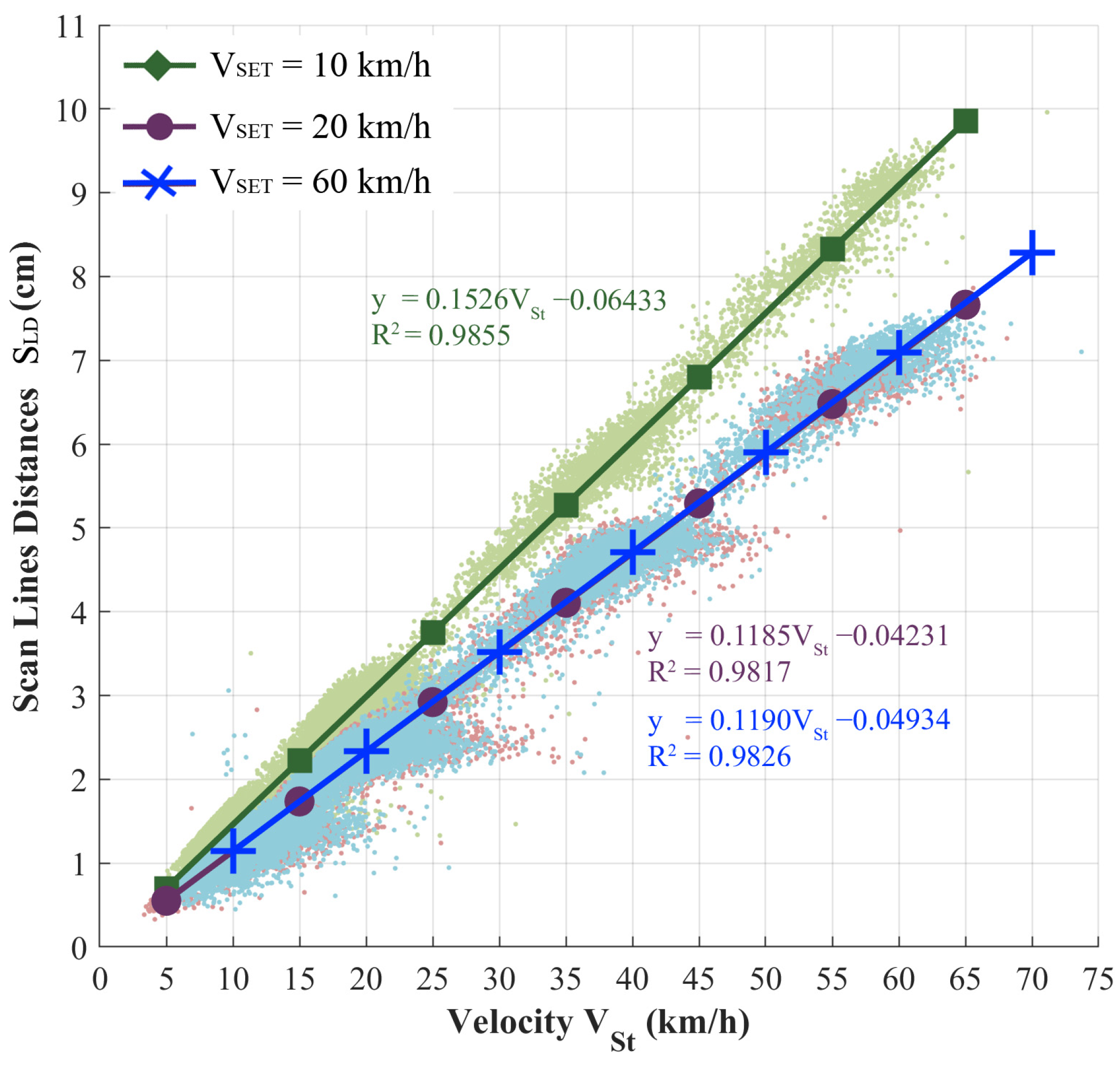

To better analyze the effect of V

SET, the relationship between the velocity V

St computed for each pair of consecutive scan lines (Equation (2)), and the distance S

LD between them, was also computed for the three different V

SET values. The correlation is linear, as

Figure 12 shows. The point clouds are overlaid with the corresponding linear regression line; the coefficients of the equations and the coefficients of determination R

2 are also shown in the figure.

The diagrams show that the velocity VSET being set in the system appears to affect the laser frequency only below a predefined set velocity (10 km/h), since the clouds relative to the other velocities appear as nearly overlapping, and the corresponding regression lines have almost equal coefficients, so that, for VSET set at 20 km/h or 60 km/h, there is the same increment in the SLD inter-distance as VSt increases.

The slope of the best-fit line for VSET = 10 km/h is sharper than for the others; therefore, the distance between scan lines increases more rapidly than when VSET is greater than 10 km/h.

It follows that, for computing the DEM grid spacing, it is advisable to choose the equation in which the grid step is a function of density (Equation (14)).

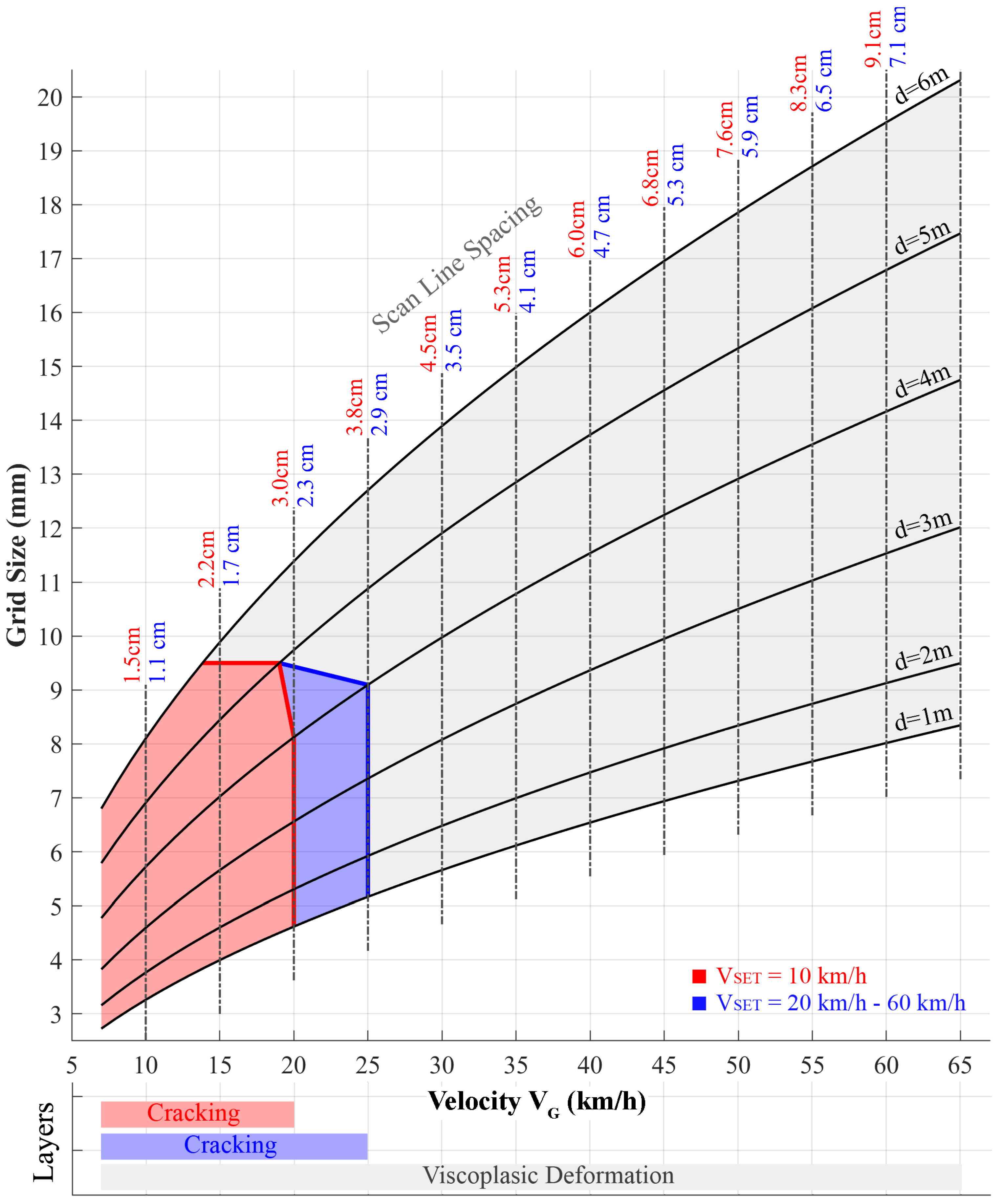

By using Equation (14), the grid spacing was computed as a function of the density values derived from the experimental data. The density in turn is related to the velocity V

G. Figure 13 shows the plot of grid step as a function of velocity V

G at various distances d from the MLS trajectory. Additionally, shown on the diagram is the minimum scan line distance (S

LD) for the different velocities considered.

On the diagram, the domains of the quantifiable distress are highlighted; in particular, three different layers are identified, representative of three main macro-groups [

24,

45]: (i) the cracking according to the resolutions compatible with V

SET = 10 km/h, identified by the red area; (ii) the cracking according to the resolutions compatible with the V

SET > 10 km/h, identified by the blue area; and (iii) the viscoplastic deformation identified by the gray area.

The geometric parameters specific to these macro-groups, used to delineate the domains in

Figure 13, were derived from the relevant literature [

24,

33].

The boundaries of the function domains of the distresses were identified following the criterion indicated in the Nyquist–Shannon sampling theorem, so as to avoid the phenomenon of aliasing. A two-dimensional road profile is theoretically represented by the continuous addition of different sinusoidal curves, each characterized by a different wavelength λ and amplitude h [

46]. The pavement texture can be divided into different classes, each with different wavelengths and amplitude intervals. Each distress is then characterized by a particular combination of wavelength and amplitude, for example: cracking, belonging to the macro-texture class, having both wavelengths and amplitudes (0.5 < λ < 50 mm, 0.2 < h < 10 mm) that are significantly shorter than the viscoplastic deformation group (50 < λ < 500 mm, 1 < h < 50 mm), and belonging to the mega-texture class.

When discretizing the signal, the constant sampling interval should be set at no greater than half the wavelength of the sine wave representing the road profile. This is derived from the Nyquist–Shannon sampling theorem [

47], which defines the minimum frequency required to sample an analog signal without the loss of information (aliasing). The resolution of the DEM consistent with the distresses should, therefore, be equal to their characteristic planimetric dimensions halved, so that there will be no loss of information.

In order to obtain lossless samples, it is advisable to use two points within the wavelength of the distresses being analyzed [

47,

48]; if cracking belongs to the macro-texture class (0.5 < λ < 50 mm), 25 mm should not be exceeded as the sampling interval. In the worst case scenario of using the distance between two scan lines as a reference (thus assuming that only one laser is used) and analyzing a single longitudinal profile, the scan lines should have inter-distances that do not exceed 25 mm, in order to discretize cracking with wavelengths of 50 mm. If two scanners are used, the pattern becomes square-meshed, and thus the distance between two scan lines may slightly exceed the 25 mm limit.

The results of the tests we conducted suggest that choosing 30 mm as a grid size is an appropriate choice. Consequently, driving velocities of 20 km/h (for VSET set at 10 km/h) and 25 km/h (for VSET at 20 or 60 km/h) should ensure a discretization of the generic profile without the loss of data, since the scanning lines are about 30 mm apart.

In order to detect cracking or other types of distress in the DEMc of the road pavement, a resolution of the laser data is required that allows for their correct discretization and modeling. Given the characteristics of the data in terms of resolution, the grid resolution should be chosen to be compatible with the data and allow a proper modeling of cracking or other distresses, that result in a more accurate quantification of the same distresses.

The limit value of grid size is also chosen to be compatible with the characteristic dimensions of the distress to be analyzed. Similarly, according to the Nyquist–Shannon sampling theorem, to obtain the correct modelling of cracking, and therefore a correct measurement of their extent, a grid size must be chosen that is at least equal to half the value of the extent of the dimensions, which is related to the studied severity level. In our tests, the thresholds chosen for the different types of distresses correspond to an average severity level. For cracks, the average severity levels correspond to 19 mm, in terms of crack width; therefore, the frontier was chosen at 9.5 mm.

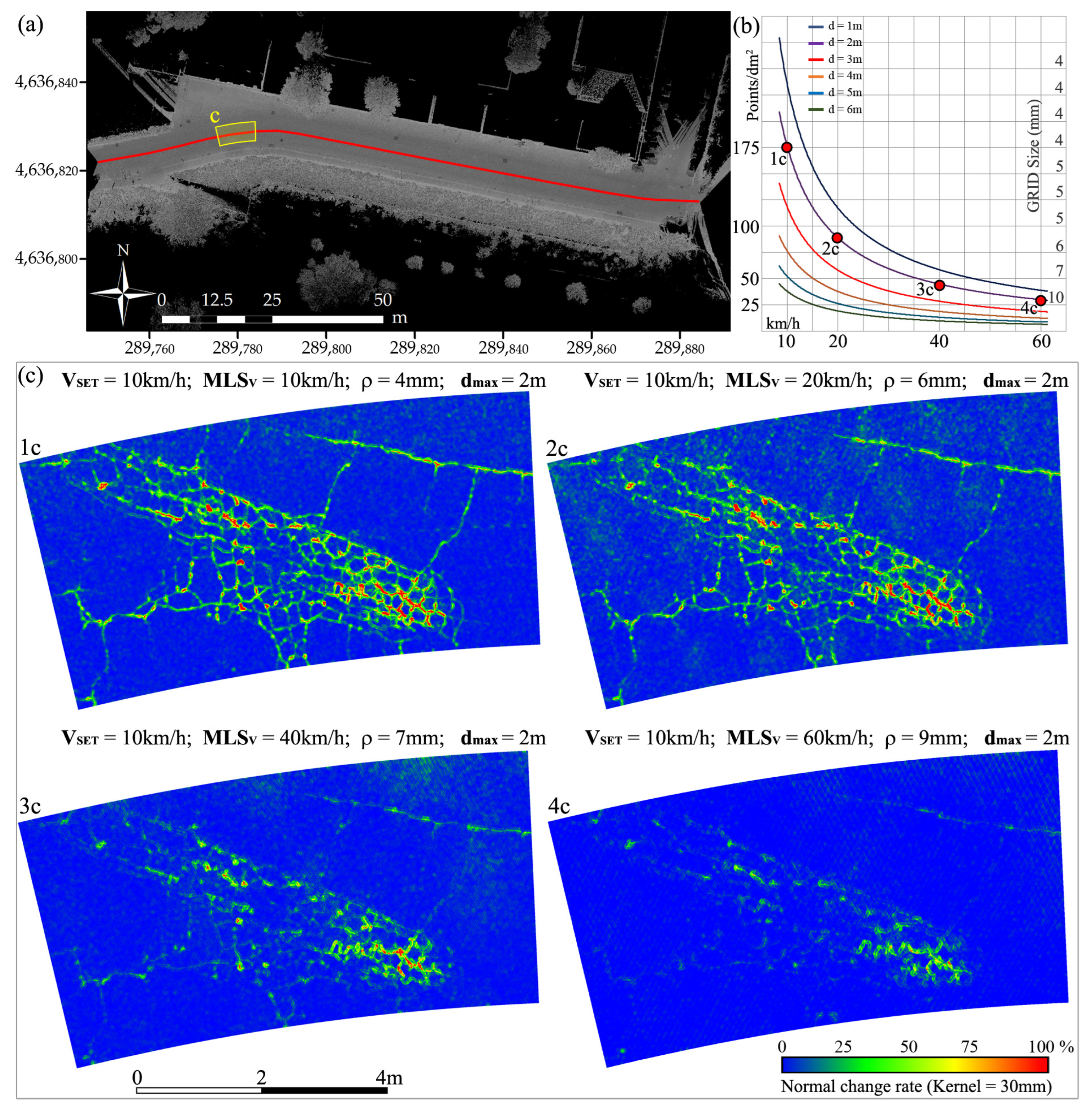

To verify the effectiveness of the proposed method to be used for the design of the MLS survey, which aims to identify some specific type of distress, we analyzed a number of point clouds belonging to our dataset and verified whether the derived DEMc was able to identify and characterize the cracking status of the surface.

We analyzed a portion of road surface (

Figure 14a, highlighted in yellow) 4 m wide, symmetrical to the trajectory followed by the MLS. For this section, we graphed the density as a function of travel speed V

G (

Figure 14b) at various distances d from the trajectory keeping V

SET set to 10 km/h. On the curve corresponding to a 2 m distance from the trajectory (the second one from the top), we identified the velocities corresponding to certain densities (the four red circles 1c, 2c, 3c and 4c), which lead to grid sizes of 4, 6, 7 and 9 mm.

Once the grid size was chosen, the DEMc of the road surface was built by applying the method described in

Section 2.3. In detail, to estimate the node elevation, the local interpolator IDW

2 was used, choosing a variable search radius for each direction depending on the distance between the scan lines.

Starting from the DEMc related to the height values, a DEM of derived features, which better highlight the monitored distresses is built; the parameter used to highlight the cracking status is the normal change rate, a simplified measure of the total curvature. To highlight the distresses, the local curvature variation, expressed as the normal change rate, was computed over a kernel size. The method implemented in CloudCompare software (

https://www.danielgm.net/cc/ (accessed on 10 June 2021) was adopted.

In

Figure 14, panel c shows the excerpts of the four DEMc built at different resolutions, related to the portion of the road highlighted with the yellow box in panel a.

In detail, the DEM in panel 1c provides evidence that the chosen resolution (4 mm) is suitable for the identification of the cracking present on the surface; characterized by medium/low levels of severity, the cracks are well distinguishable and free of noise. Panel 2c shows how the DEMc excerpt, built with data acquired by traveling with a MLS

V equal to 20km/h and thus a resolution of 6 mm, allows to distinguish the cracking status, but the cracks with low levels of severity are not visible and there is some noise, probably due to the resolution chosen in function of the density and therefore of the travel velocity that is that which corresponds to the frontier of the red domain (

Figure 13).

Panel 3c shows the excerpt of the DEMc generated with data acquired by traveling with a MLS

V equal to 40 km/h, congruent with the resolutions in the field of viscoplastic deformations (

Figure 13). It should be noted that the point cloud density and, accordingly, the minimum grid spacing do not allow for the detection of cracks with low/medium severity levels, as well as those acquired by traveling at a MLS

V of 10 km/h. Only those distresses congruent with the proper resolution are evident here, particularly some holes (red areas) and cracks with high severity levels, also present in panels 1c and 2c.

If the grid spacing is too large (thus outside the domain), the crack will, in a few cases, still be detectable but not quantifiable since it will appear as a deep groove proportional in width to the sampling interval (panel 3c). This will artificially increase the roughness of the adjacent area, due to the lack of information caused by the over-reduction in resolution.

Finally, panel 4c shows the DEMc relative to the data acquired by traveling with MLSV = 60 km/h, with a resolution of 9 mm; in this case, the crack state is not detectable. The only clearly visible distresses are those belonging to the macro-group of viscoplastic deformations and some potholes produced by the removal of the surface layer of the pavement.

In summary, depending on the type of degradation to be investigated, the diagram can be used to estimate the travel velocity to be maintained and the maximum distance d from the MLS trajectory.

The diagram aims to help in the design phase, an essential phase prior to the survey, and to optimize the available resources. The resolution is a function of the type of analyzed distress, and the design travel velocity is computed accordingly. If the aim is to measure cracks up to a distance of 6 m from the MLS trajectory, a velocity of less than 15 km/h must be maintained.

In order to obtain an average grid step of 6 mm, a maximum driving velocity of about 35 km/h has to be maintained. More passages must be made to cover the whole road because the distance guarantees a resolution of about 1 m; therefore, in one passage, only 2 m is covered.

The maximum velocity that allows a DEM with a resolution of 10 mm to be built is 45 km/h up to a maximum distance of 3 m. To cover longer distances, with the same resolution value of 10 mm, the velocity must be reduced to 30 km/h to cover a distance of 4 m, to 20 km/h for a distance of 5 m, and to 15 km/h for a distance of 6 m.

Since the distances are computed with respect to the MLS trajectory projected onto the road surface, to analyze a single lane, the considered reference distance is about 2 m to the left and 2 m to the right of the trajectory (for a generic lane, 3.75 m wide), which provides an average resolution of 6 mm at an average velocity of about 25 km/h.

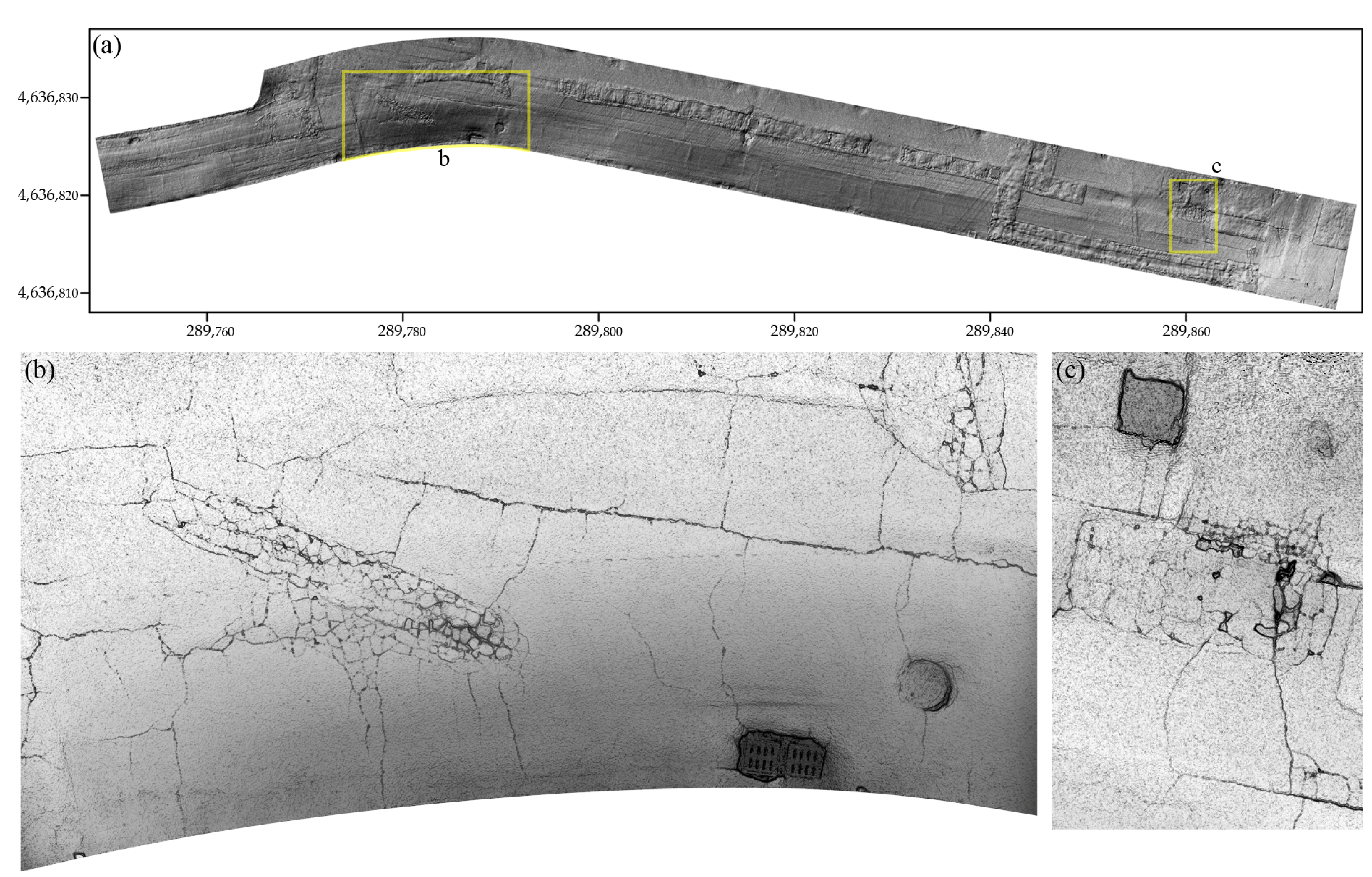

Figure 15 shows the DEMc built on the whole road stretch analyzed. The axis of the DEMc coincides with the axis of the roadway, the grid DEM has a semi-width of 5.50 m, so as to cover the whole 11 m wide roadway. The DEMc was built using the point cloud acquired by keeping the average velocity MLS

V equal to the V

SET one, at 10 km/h. This configuration, at 6 m distance, is compatible with a grid size of 8 mm (

Figure 13). In correspondence to the curve section, in the concave inner part at 6 m from the roadway axis, we computed the decrease in the grid spacing with Equation (15). This was used to produce the graph in

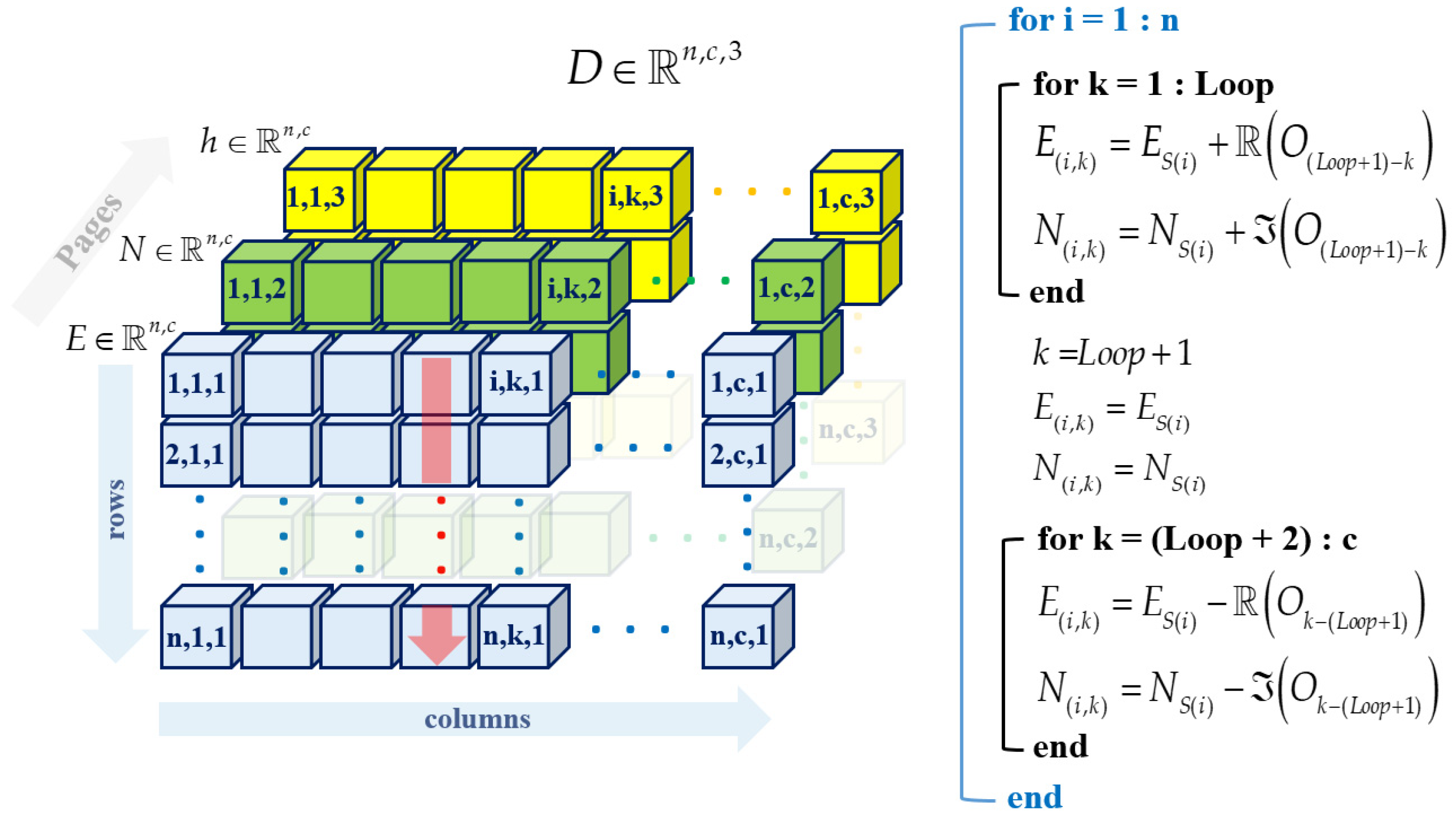

Figure 6, given the curve radius (about 45 m), which was equal to about 0.7 mm; hence, the grid spacing along the concave edge, in the longitudinal direction, assumed a value equal to 8.3 mm. We decided to set a conservative value for the grid spacing on the curved abscissa of the DEM, equal to 9 mm.

The data were interpolated using the IDW

2 interpolator. At the velocity of 10 km/h, the inter-distance between the scanning lines is about 1.5 cm. Given the configuration of the scanning pattern (

Figure 9c), in the most unfavorable conditions where the generic node of the grid is in the center of the rhombus, the planimetric distance from the most distant vertex is equal to the inter-distance of the scanning lines. The search radius was therefore set equal to 1.5 cm.

The panels b and c of

Figure 15 show two zoomed views of the DEMc, made in correspondence of areas characterized by different configurations and types of distresses. It should be that an accurate analysis of the grid size, in the functions of the main variables involved (density and travel velocity), is critical for optimizing the results, a key aspect during the design phase of a survey. Cracks with medium severity levels are clearly visible and can be quantified.

5. Conclusions

The knowledge of the surface pavement condition allows the extent of distress to be detected and estimated, so as to identify all those sections that need high priority interventions. The identification of the critical sections in a road network is mandatory in order to choose the most effective action and planning for the intervention program. A modern pavement management system should help in making decisions to ensure that safety and comfort are achieved at a minimum cost and that available resources are optimized. In most cases, however, planning operations do not aim to achieve an optimal process but tend to identify the best compromise between available budget and impending needs.

Although the MLS technique, in some cases, does not allow to reach accuracy and resolution as required by the managing authorities and by the current rules, nevertheless it allows a fast, at operating velocity, safe and economical survey of the pavement and of the boundary elements, ideal to draw up an emergency program of first intervention in a short time and at a very low cost.

The approach introduced in this paper focuses on three main aspects:

The quantification of the relationship between the parameters given as input for the survey (frequency, velocity), and the density of the acquired points with the DEM resolution;

The optimization of the process of extraction of profiles aiming to address the geometric characterization of the road;

The optimization of the survey design by estimating the travel velocity to be maintained, and the maximum distance from the MLS that provides the expected resolution, related to the kind of distress to be investigated.

The proposed method aims to provide a contribution in the design phase of the survey, that is important for the optimization of available resources. The velocity held by the MLS during the survey is the key parameter for building a model to be used for distress identification.

The procedure described in this paper allows a simple relationship to be established that can be used to design an MLS survey for road condition monitoring. Given the density, it is possible to estimate the optimal resolution of the digital model of the surface compatible with it; the systematic tests carried out and the procedure developed made it possible to associate the velocity of the MLS with the resolution of the DEM, and therefore its capability to highlight distress at different levels of severity.

The resolution, therefore, will be a function of the kind of distress to be analyzed, and the velocity will be a function of the type of road to be monitored, in order not to compromise the normal exercise of the infrastructure.

The resolution is closely dependent on the relative accuracy of the MLS system used; in our case, it was very accurate and had a high performance. The MLS technique is actually in a phase of rapid development; the sensors are becoming better and more accurate and with ever better characteristics (e.g., ever higher frequency rates), and thus the accuracy and resolution are becoming better as well.

Moreover, the proposed methodology allows the operator to choose the most convenient strategy for monitoring the road network, the strategy that, given the same capability to highlight specific distress, maximizes productivity (shorter survey times and maximum velocity).

All of these issues were combined and quantified in the developed abacus (

Figure 13). The grid step was chosen according to the kind of distress that was analyzed; the maximum velocity of the dynamic platform can be estimated using the experimental curves displayed.

The abacuses we produced are also usable with MLS systems other than the system used, given that the main technical characteristics (accuracy and acquisition frequency) are not that different.

The DEMc can be used for a variety of applications. If, for instance, the analysis of the longitudinal regularity of the road pavement is to be carried out over the entire roadway, the DEMc simplifies the extraction of longitudinal profiles because each column of the matrix represents a longitudinal profile. The computational cost depends exclusively on the type of analysis that is carried out. If the analysis is at network level, the grid step will be greater than for a local analysis that requires a greater resolution, and hence a smaller grid step. In addition to the analysis of localized distress and the analysis of the regularity of the longitudinal profiles, the DEMc allows for the analysis of the cross profiles, both for the cross regularity and for the analysis of the cross slopes. To this end, the implemented methodology allows for the setting of a longitudinal step different from the cross step, in order to use a different resolution for the cross and longitudinal profiles.

The effectiveness of the procedure and of the proposed relationships was verified on a test case; the method, applied in a few MLS survey at different velocities for the identification of specific kinds of distress, fully met the objectives.