Analyzing the Drivers of Advanced Sustainable Manufacturing System Using AHP Approach

Abstract

:1. Background

2. Problem Description

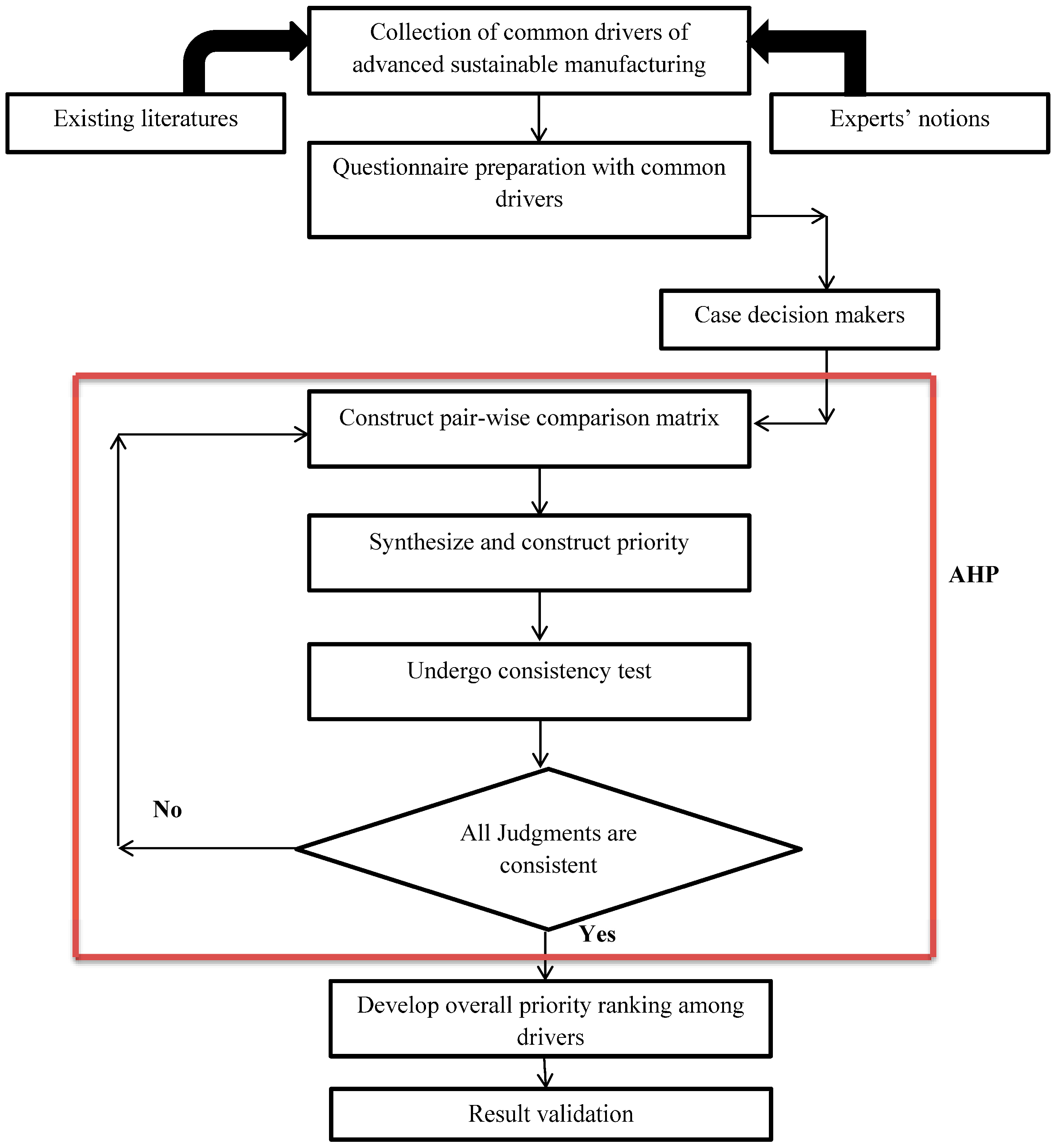

3. Solution Methodology

- Step 1:

- Select the list of attributes (drivers) related to an advanced sustainable manufacturing system combined from the assistance of existing literature review and from field experts’ notions.

- Step 2:

- From the assistance of the decision makers, create a pair-wise comparison on the given criteria. This comparison will be based on the Likert 5-point scale further modified to the Saaty scale for numerical ease. (See Table 1).

- Step 3:

- Evalaute the global weights by formal arthimetic operations of AHP including normalization.

- Step 4:

- Check the reliability of the results through the Consistency Index (C.I.) and the Consistency Ratio (C.R.)

- Step 5:

- If the C.I. < 0.1, then the verdict is satisfactory. Otherwise, pair-wise comparisons can be repeated to elucidate the error. The progression must be a cyclic process until the consistency condition is made satisfactory.

- Step 6:

- Based on the final weights, the drivers of advanced sustaianble manufacturing are prioritized and further circulated to the case industry’s decision makers in order to focus on the most highly-weighted driver.

4. Application of the Proposed Model

4.1. Phase I: Collection of Common Drivers of Advanced Sustainable Manufacturing

4.2. Phase II: Application of AHP

- Step 1: Based on the replies of case industry decision makers and the support of the Saaty scale, a pair-wise comparison among the collected common drivers of advanced sustainable manufacturing was made, which is shown in Table 3.

- Step 2: The pair-wise comparison matrix was normalized with standard arithmetic operations to form a normalized matrix, which has elements ranging from 0 to 1. The normalized matrix is shown in Table 4.

- Step 3: From the normalized matrix, Eigenvalues were obtained and posed for a consistency check in order to ensure that the consistency ratio should be less than 0.1.

- Step 4: Finally, the priority of the factors are ranked based on the Eigenvalues obtained by each driver. The rank, along with the priority of the drivers, is shown in Table 5.

4.3. Phase III: Result Validation

5. Results and Discussions

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Kastalli, I.V.; Van Looy, B. Servitization: Disentangling the impact of service business model innovation on manufacturing firm performance. J. Oper. Manag. 2013, 31, 169–180. [Google Scholar] [CrossRef]

- Rusinko, C.A. Green manufacturing: An evaluation of environmentally sustainable manufacturing practices and their impact on competitive outcomes. IEEE Trans. Eng. Manag. 2007, 54, 445–454. [Google Scholar] [CrossRef]

- Cousins, P.D.; Handfield, R.B.; Lawson, B.; Petersen, K.J. Creating supply chain relational capital: The impact of formal and informal socialization processes. J. Oper. Manag. 2006, 24, 851–863. [Google Scholar] [CrossRef]

- Tao, F.; Cheng, Y.; Zhang, L.; Nee, A.Y.C. Advanced manufacturing systems: Socialization characteristics and trends. J. Intell. Manuf. 2014. [Google Scholar] [CrossRef]

- Infosys. Global Manufacturing Study Shows Early Signs of Adoption of Groundbreaking Machine-to-Data Technologies with China Leading the Way. Available online: https://www.infosys.com/newsroom/press-releases/Pages/strategies-industrial-manufacturing-worldwide.aspx (accessed on 13 May 2016).

- Global Manufacturing Outlook. Available online: https://www.kpmg.com/CN/en/IssuesAndInsights/ArticlesPublications/Documents/Global-Manufacturing-Outlook-O-201506.pdf (accessed on 18 August 2015).

- Zhu, Q.; Lujia, F.; Mayyas, A.; Omar, M.A.; Al-Hammadi, Y.; Al Saleh, S. Production energy optimization using low dynamic programming, a decision support tool for sustainable manufacturing. J. Clean. Prod. 2015, 105, 178–183. [Google Scholar] [CrossRef]

- Lee, D.M.; Drake, P.R. A portfolio model for component purchasing strategy and the case study of two South Korean elevator manufacturers. Int. J. Prod. Res. 2010, 48, 6651–6682. [Google Scholar] [CrossRef]

- Ishizaka, A.; Pearman, C.; Nemery, P. AHPSort: An AHP-based method for sorting problems. Int. J. Prod. Res. 2012, 50, 4767–4784. [Google Scholar] [CrossRef]

- Malik, M.M.; Abdallah, S.; Hussain, M. Assessing supplier environmental performance: Applying Analytical Hierarchical Process in the United Arab Emirates healthcare chain. Renew. Sustain. Energy Rev. 2016, 55, 1313–1321. [Google Scholar] [CrossRef]

- Govindan, K.; Diabat, A.; Shankar, K.M. Analyzing the drivers of green manufacturing with fuzzy approach. J. Clean. Prod. 2015, 96, 182–193. [Google Scholar] [CrossRef]

- Dyer, J.S. Remarks on the analytic hierarchy process. Manag. Sci. 1990, 36, 249–258. [Google Scholar] [CrossRef]

- Harker, P.T.; Vargas, L.G. Reply to ‘Remarks on the analytic hierarchy process’ by J.S. Dyer. Manag. Sci. 1990, 36, 269–273. [Google Scholar] [CrossRef]

- Saaty, T.L. An exposition of the AHP in reply to the paper ‘Remarks on the analytic hierarchy process’. Manag. Sci. 1990, 36, 259–268. [Google Scholar] [CrossRef]

- Kannan, G.; Haq, A.N.; Sasikumar, P.; Arunachalam, S. Analysis and selection of green suppliers using interpretative structural modelling and analytic hierarchy process. Int. J. Manag. Decis. Mak. 2008, 9, 163–182. [Google Scholar] [CrossRef]

- Govindan, K.; Kaliyan, M.; Kannan, D.; Haq, A.N. Barriers analysis for green supply chain management implementation in Indian industries using analytic hierarchy process. Int. J. Prod. Econ. 2014, 147, 555–568. [Google Scholar] [CrossRef]

- Mathiyazhagan, K.; Govindan, K.; Noorul Haq, A. Pressure analysis for green supply chain management implementation in Indian industries using analytic hierarchy process. Int. J. Prod. Res. 2014, 52, 188–202. [Google Scholar] [CrossRef]

- Kannan, G.; Murugesan, P.; Haq, A.N. 3PRLP’s selection using an integrated analytic hierarchy process and linear programming. Int. J. Serv. Technol. Manag. 2009, 12, 61–80. [Google Scholar] [CrossRef]

- Liberatore, M.J.; Nydick, R.L. The analytic hierarchy process in medical and health care decision making: A literature review. Eur. J. Oper. Res. 2008, 189, 194–207. [Google Scholar] [CrossRef]

- Ho, W. Integrated analytic hierarchy process and its applications—A literature review. Eur. J. Oper. Res. 2008, 186, 211–228. [Google Scholar] [CrossRef]

- Akgunduz, A.; Zetu, D.; Banerjee, P.; Liang, D. Evaluation of sub-component alternatives in product design processes. Robot. Comput. Integr. Manuf. 2002, 18, 69–81. [Google Scholar] [CrossRef]

- Braglia, M.; Gabbrielli, R.; Miconi, D. Material handling device selection in cellular manufacturing. J. Multi-Criteria Decis. Anal. 2001, 10, 303–315. [Google Scholar] [CrossRef]

- Hsiao, S.W. Concurrent design method for developing a new product. Int. J. Ind. Ergon. 2002, 29, 41–55. [Google Scholar] [CrossRef]

- Chang, P.T.; Lo, Y.T. Modelling of job-shop scheduling with multiple quantitative and qualitative objectives and a GA/TS mixture approach. Int. J. Comput. Integr. Manuf. 2001, 14, 367–384. [Google Scholar] [CrossRef]

- Kwong, C.K.; Bai, H. A fuzzy AHP approach to the determination of importance weights of customer requirements in quality function deployment. J. Intell. Manuf. 2002, 13, 367–377. [Google Scholar] [CrossRef]

- Madu, C.N.; Kuei, C.; Madu, I.E. A hierarchic metric approach for integration of green issues in manufacturing: A paper recycling application. J. Environ. Manag. 2002, 64, 261–272. [Google Scholar] [CrossRef]

- Shinno, H.; Yoshioka, H.; Marpaung, S.; Hachiga, S. Quantitative SWOT analysis on global competitiveness of machine tool industry. J. Eng. Des. 2006, 17, 251–258. [Google Scholar] [CrossRef]

- Partovi, F.Y. A quality function deployment approach to strategic capital budgeting. Eng. Econ. 1999, 44, 239–260. [Google Scholar] [CrossRef]

- Wang, H.; Xie, M.; Goh, T.N. A comparative study of the prioritization matrix method and the analytic hierarchy process technique in quality function deployment. Total Qual. Manag. 1998, 9, 421–430. [Google Scholar] [CrossRef]

- Yang, T.; Kuo, C. A hierarchical AHP/DEA methodology for the facilities layout design problem. Eur. J. Oper. Res. 2003, 147, 128–136. [Google Scholar] [CrossRef]

- Zakarian, A.; Kusiak, A. Forming teams: An analytic approach. IIE Trans. 1999, 31, 85–97. [Google Scholar] [CrossRef]

- Xu, L.; Kumar, D.T.; Shankar, K.M.; Kannan, D.; Chen, G. Analyzing criteria and sub-criteria for the corporate social responsibility-based supplier selection process using AHP. Int. J. Adv. Manuf. Technol. 2013, 68, 907–916. [Google Scholar] [CrossRef]

- Son, Y.K.; Park, C.S. Economic measure of productivity, quality and flexibility in advanced manufacturing systems. J. Manuf. Syst. 1987, 6, 193–207. [Google Scholar] [CrossRef]

- Joung, C.B.; Carrell, J.; Sarkar, P.; Feng, S.C. Categorization of indicators for sustainable manufacturing. Ecol. Indic. 2013, 24, 148–157. [Google Scholar] [CrossRef]

- Bey, N.; Hauschild, M.Z.; McAloone, T.C. Drivers and barriers for implementation of environmental strategies in manufacturing companies. CIRP Ann. Manuf. Technol. 2013, 62, 43–46. [Google Scholar] [CrossRef]

- Singh Sangwan, K.; Bhamu, J.; Mehta, D. Development of lean manufacturing implementation drivers for Indian ceramic industry. Int. J. Product. Perform. Manag. 2014, 63, 569–587. [Google Scholar] [CrossRef]

| Intensity of Importance | Definition | Explanation |

|---|---|---|

| 1 | Equal importance | Two activities contribute equally to the objective |

| 2 | Weak or slight | |

| 3 | Moderate importance | Experience and judgment slightly favor one activity over another |

| 4 | Moderate plus | |

| 5 | Strong importance | Experience and judgment strongly favor one activity over another |

| 6 | Strong plus | |

| 7 | Very strong or demonstrated importance | An activity is favored very strongly over another; its dominance demonstrated in practice |

| 8 | Very, very strong | |

| 9 | Extreme importance | The evidence favoring one activity over another is of the highest possible order of affirmation |

| Reciprocals of above | If activity i has one of the above non-zero numbers assigned to it when compared with activity j, then j has the reciprocal value when compared with i | A reasonable assumption |

| 1.1–1.9 | If the activities are very close | May be difficult to assign the best value but when compared with other contrasting activities, the size of the small numbers would not be too noticeable, yet they can still indicate the relative importance of the activities |

| S. No. | Drivers | References |

|---|---|---|

| 1 | Quality (D1) | [33,34,35] |

| 2 | Market capabilities (D2) | [11,35,36] |

| 3 | Financial benefit (D3) | [35,36] |

| 4 | Supply chain requirements (D4) | Experts’ opinion |

| 5 | Delivery speed and performance flexibility (D5) | Experts’ opinion |

| 6 | Compliance with regulations (D6) | [35,36] |

| 7 | Green purchasing (D7) | [11,35] |

| 8 | Optimized usage of resources (D8) | [11,35] |

| 9 | Green innovation (D9) | [11,35] |

| 10 | Environmental conservation (D10) | [11,35] |

| 11 | Education and training (D11) | [35] |

| 12 | Employee welfares (D12) | [35] |

| 13 | Stakeholders (D13) | [11,35,36] |

| 14 | Internal motivations (D14) | Experts’ opinion |

| 15 | Customers’ expectations (D15) | [11,35,36] |

| D1 | D2 | D3 | D4 | D5 | D6 | D7 | D8 | D9 | D10 | D11 | D12 | D13 | D14 | D15 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| D1 | 1 | 9 | 2 | 9 | 6 | 7 | 9 | 9 | 9 | 8 | 9 | 9 | 4 | 9 | 5 |

| D2 | 1/9 | 1 | 1/9 | 1/6 | 1/9 | 1/9 | 1/8 | 1/7 | 1/5 | 1/9 | 1/4 | 1/3 | 1/9 | 1/2 | 1/9 |

| D3 | 1/2 | 9 | 1 | 9 | 4 | 5 | 8 | 7 | 9 | 8 | 9 | 9 | 2 | 9 | 3 |

| D4 | 1/9 | 6 | 1/9 | 1 | 1/6 | 1/5 | 1/2 | 1/3 | 2 | 1/4 | 3 | 4 | 1/9 | 5 | 1/9 |

| D5 | 1/6 | 9 | 1/4 | 6 | 1 | 2 | 5 | 4 | 7 | 3 | 8 | 9 | 1/3 | 9 | 1/2 |

| D6 | 1/7 | 9 | 1/5 | 5 | 1/2 | 1 | 4 | 3 | 6 | 2 | 7 | 8 | 1/4 | 9 | 1/3 |

| D7 | 1/9 | 8 | 1/8 | 2 | 1/5 | 1/4 | 1 | 1/2 | 3 | 1/3 | 4 | 5 | 1/7 | 6 | 1/6 |

| D8 | 1/9 | 7 | 1/7 | 3 | 1/4 | 1/3 | 2 | 1 | 4 | 1/2 | 5 | 6 | 1/6 | 7 | 1/5 |

| D9 | 1/9 | 5 | 1/9 | 1/2 | 1/7 | 1/6 | 1/3 | 1/4 | 1 | 1/5 | 2 | 3 | 1/9 | 4 | 1/9 |

| D10 | 1/8 | 9 | 1/8 | 4 | 1/3 | 1/2 | 3 | 2 | 5 | 1 | 6 | 7 | 1/5 | 8 | 1/4 |

| D11 | 1/9 | 4 | 1/9 | 1/3 | 1/8 | 1/7 | 1/4 | 1/5 | 1/2 | 1/6 | 1 | 2 | 1/9 | 3 | 1/9 |

| D12 | 1/9 | 3 | 1/9 | 1/4 | 1/9 | 1/8 | 1/5 | 1/6 | 1/3 | 1/7 | 1/2 | 1 | 1/9 | 2 | 1/9 |

| D13 | 1/4 | 9 | 1/2 | 9 | 3 | 4 | 7 | 6 | 9 | 5 | 9 | 9 | 1 | 9 | 2 |

| D14 | 1/9 | 2 | 1/9 | 1/5 | 1/9 | 9 | 1/6 | 1/7 | 1/4 | 1/8 | 1/2 | 2 | 1/9 | 1 | 1/9 |

| D15 | 1/5 | 9 | 1/3 | 9 | 2 | 3 | 6 | 5 | 9 | 4 | 9 | 9 | 1/2 | 9 | 1 |

| D1 | D2 | D3 | D4 | D5 | D6 | D7 | D8 | D9 | D10 | D11 | D12 | D13 | D14 | D15 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| D1 | 0.305 | 0.091 | 0.374 | 0.154 | 0.332 | 0.213 | 0.193 | 0.232 | 0.138 | 0.244 | 0.123 | 0.108 | 0.432 | 0.099 | 0.381 |

| D2 | 0.034 | 0.010 | 0.021 | 0.003 | 0.006 | 0.003 | 0.003 | 0.004 | 0.003 | 0.003 | 0.003 | 0.004 | 0.012 | 0.006 | 0.008 |

| D3 | 0.153 | 0.091 | 0.187 | 0.154 | 0.222 | 0.152 | 0.172 | 0.181 | 0.138 | 0.244 | 0.123 | 0.108 | 0.216 | 0.099 | 0.229 |

| D4 | 0.034 | 0.061 | 0.021 | 0.017 | 0.009 | 0.006 | 0.011 | 0.009 | 0.031 | 0.008 | 0.041 | 0.048 | 0.012 | 0.055 | 0.008 |

| D5 | 0.051 | 0.091 | 0.047 | 0.103 | 0.055 | 0.061 | 0.107 | 0.103 | 0.107 | 0.091 | 0.109 | 0.108 | 0.036 | 0.099 | 0.038 |

| D6 | 0.044 | 0.091 | 0.037 | 0.086 | 0.028 | 0.030 | 0.086 | 0.077 | 0.092 | 0.061 | 0.096 | 0.096 | 0.027 | 0.099 | 0.025 |

| D7 | 0.034 | 0.081 | 0.023 | 0.034 | 0.011 | 0.008 | 0.021 | 0.013 | 0.046 | 0.010 | 0.055 | 0.060 | 0.015 | 0.066 | 0.013 |

| D8 | 0.034 | 0.071 | 0.027 | 0.051 | 0.014 | 0.010 | 0.043 | 0.026 | 0.061 | 0.015 | 0.068 | 0.072 | 0.018 | 0.077 | 0.015 |

| D9 | 0.034 | 0.051 | 0.021 | 0.009 | 0.008 | 0.005 | 0.007 | 0.006 | 0.015 | 0.006 | 0.027 | 0.036 | 0.012 | 0.044 | 0.008 |

| D10 | 0.038 | 0.091 | 0.023 | 0.068 | 0.018 | 0.015 | 0.064 | 0.052 | 0.077 | 0.030 | 0.082 | 0.084 | 0.022 | 0.088 | 0.019 |

| D11 | 0.034 | 0.040 | 0.021 | 0.006 | 0.007 | 0.004 | 0.005 | 0.005 | 0.008 | 0.005 | 0.014 | 0.024 | 0.012 | 0.033 | 0.008 |

| D12 | 0.034 | 0.030 | 0.021 | 0.004 | 0.006 | 0.004 | 0.004 | 0.004 | 0.005 | 0.004 | 0.007 | 0.012 | 0.012 | 0.022 | 0.008 |

| D13 | 0.076 | 0.091 | 0.094 | 0.154 | 0.166 | 0.122 | 0.150 | 0.155 | 0.138 | 0.152 | 0.123 | 0.108 | 0.108 | 0.099 | 0.152 |

| D14 | 0.034 | 0.020 | 0.021 | 0.003 | 0.006 | 0.274 | 0.004 | 0.004 | 0.004 | 0.004 | 0.007 | 0.024 | 0.012 | 0.011 | 0.008 |

| D15 | 0.061 | 0.091 | 0.062 | 0.154 | 0.111 | 0.091 | 0.129 | 0.129 | 0.138 | 0.122 | 0.123 | 0.108 | 0.054 | 0.099 | 0.076 |

| S. No. | Drivers | Eigenvalue | Rank |

|---|---|---|---|

| 1 | Quality (D1) | 0.2335 | 1 |

| 2 | Market capabilities (D2) | 0.00832 | 15 |

| 3 | Financial benefit (D3) | 0.1684 | 2 |

| 4 | Supply chain requirements (D4) | 0.02488 | 10 |

| 5 | Delivery speed and performance flexibility (D5) | 0.08216 | 5 |

| 6 | Compliance with regulations (D6) | 0.0659 | 6 |

| 7 | Green purchasing (D7) | 0.03298 | 9 |

| 8 | Optimized usage of resources (D8) | 0.04054 | 8 |

| 9 | Green innovation (D9) | 0.01949 | 11 |

| 10 | Environmental conservation (D10) | 0.05201 | 7 |

| 11 | Education and training (D11) | 0.01525 | 12 |

| 12 | Employee welfares (D12) | 0.01203 | 13 |

| 13 | Stakeholders (D13) | 0.1291 | 3 |

| 14 | Internal motivations (D14) | 0.00975 | 14 |

| 15 | Customers’ expectations (D15) | 0.1057 | 4 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shankar, K.M.; Kumar, P.U.; Kannan, D. Analyzing the Drivers of Advanced Sustainable Manufacturing System Using AHP Approach. Sustainability 2016, 8, 824. https://doi.org/10.3390/su8080824

Shankar KM, Kumar PU, Kannan D. Analyzing the Drivers of Advanced Sustainable Manufacturing System Using AHP Approach. Sustainability. 2016; 8(8):824. https://doi.org/10.3390/su8080824

Chicago/Turabian StyleShankar, K. Madan, P. Udhaya Kumar, and Devika Kannan. 2016. "Analyzing the Drivers of Advanced Sustainable Manufacturing System Using AHP Approach" Sustainability 8, no. 8: 824. https://doi.org/10.3390/su8080824

APA StyleShankar, K. M., Kumar, P. U., & Kannan, D. (2016). Analyzing the Drivers of Advanced Sustainable Manufacturing System Using AHP Approach. Sustainability, 8(8), 824. https://doi.org/10.3390/su8080824