Incorporating Life Cycle Assessment into Tunneling Technologies: Environmental Performance of TBM and ADECO–RS Methods

Abstract

1. Introduction

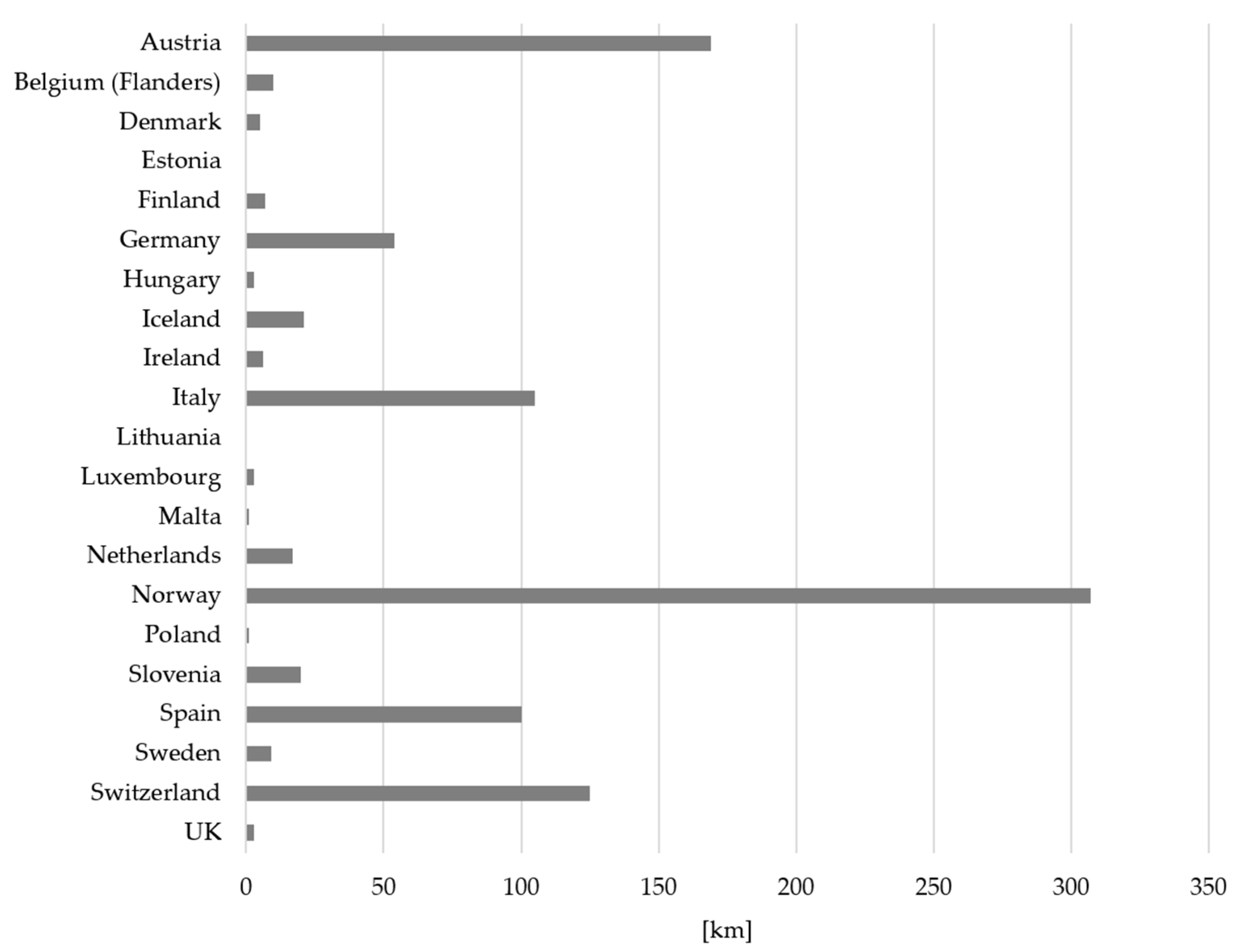

1.1. Research Background and Motivation

1.2. Environmental Context and Life Cycle Assessment in Tunneling

1.3. State of the Art and Research Gap

2. Materials and Methods

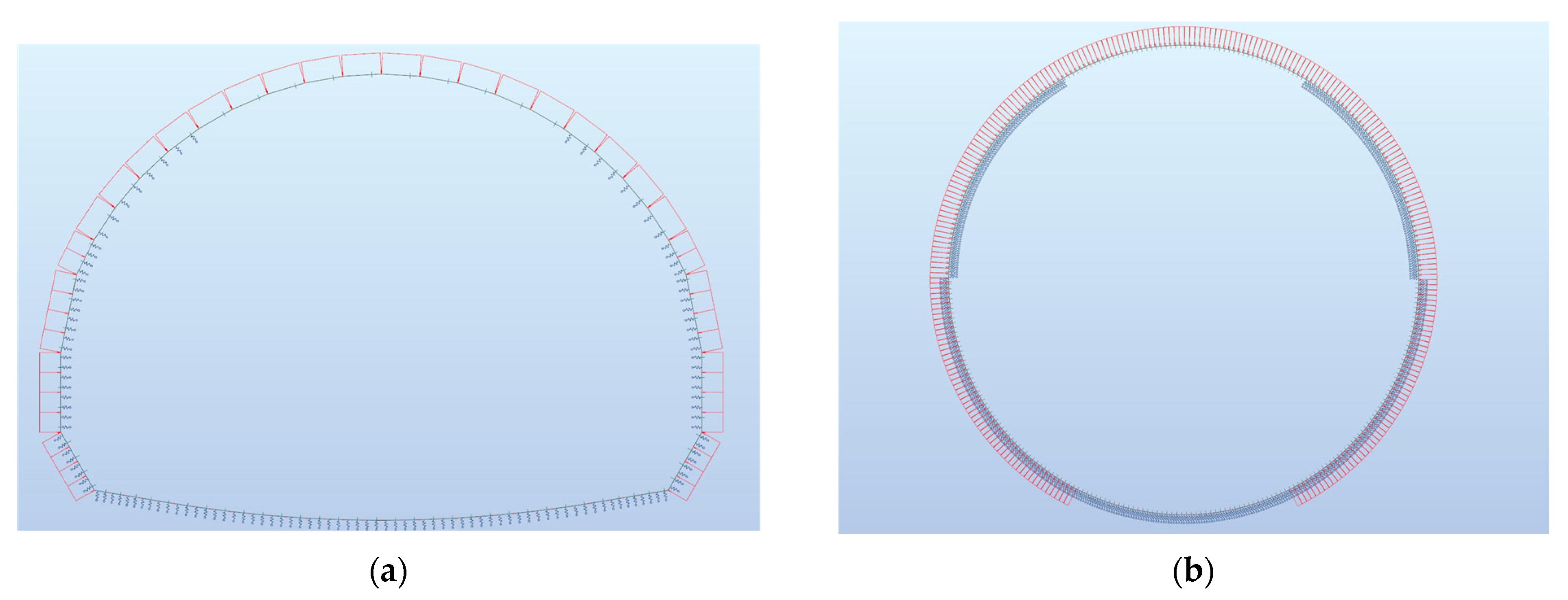

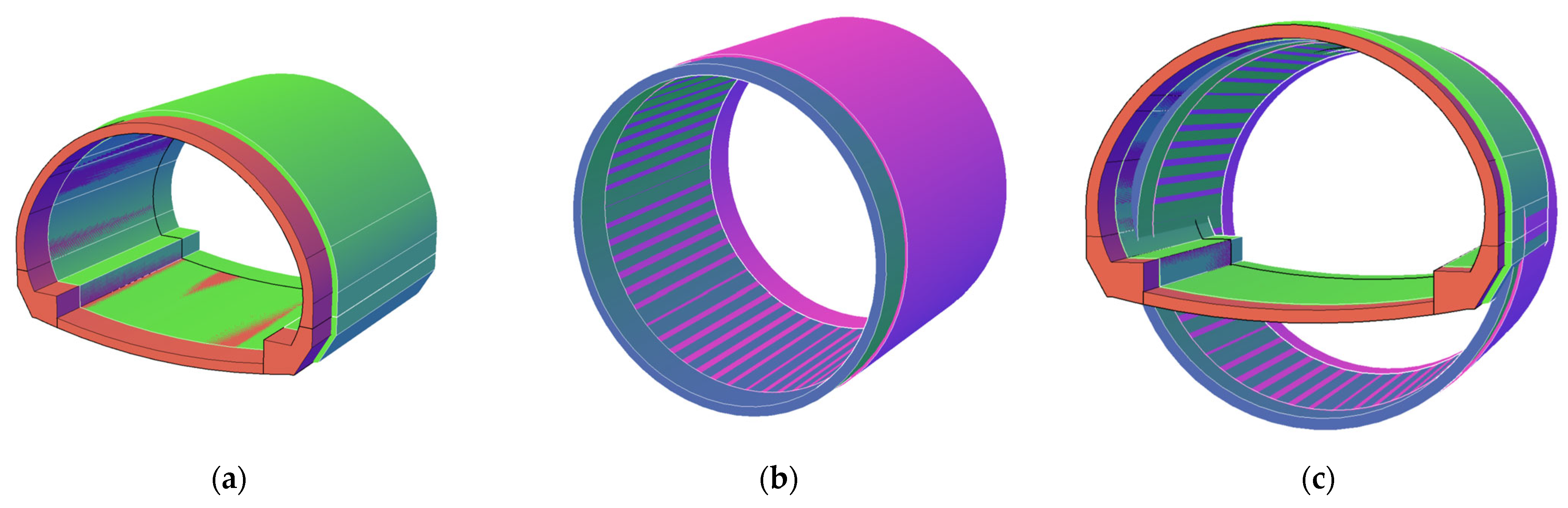

2.1. Computational Models and Scope of Analysis

2.2. Optimization of Concrete Mix Designs

- variant a: mix with Portland cement (CEM I),

- variant b: mix with cement containing secondary (waste-derived) components (CEM II and CEM III).

2.3. LCA Methodology—Scope and Data Sources

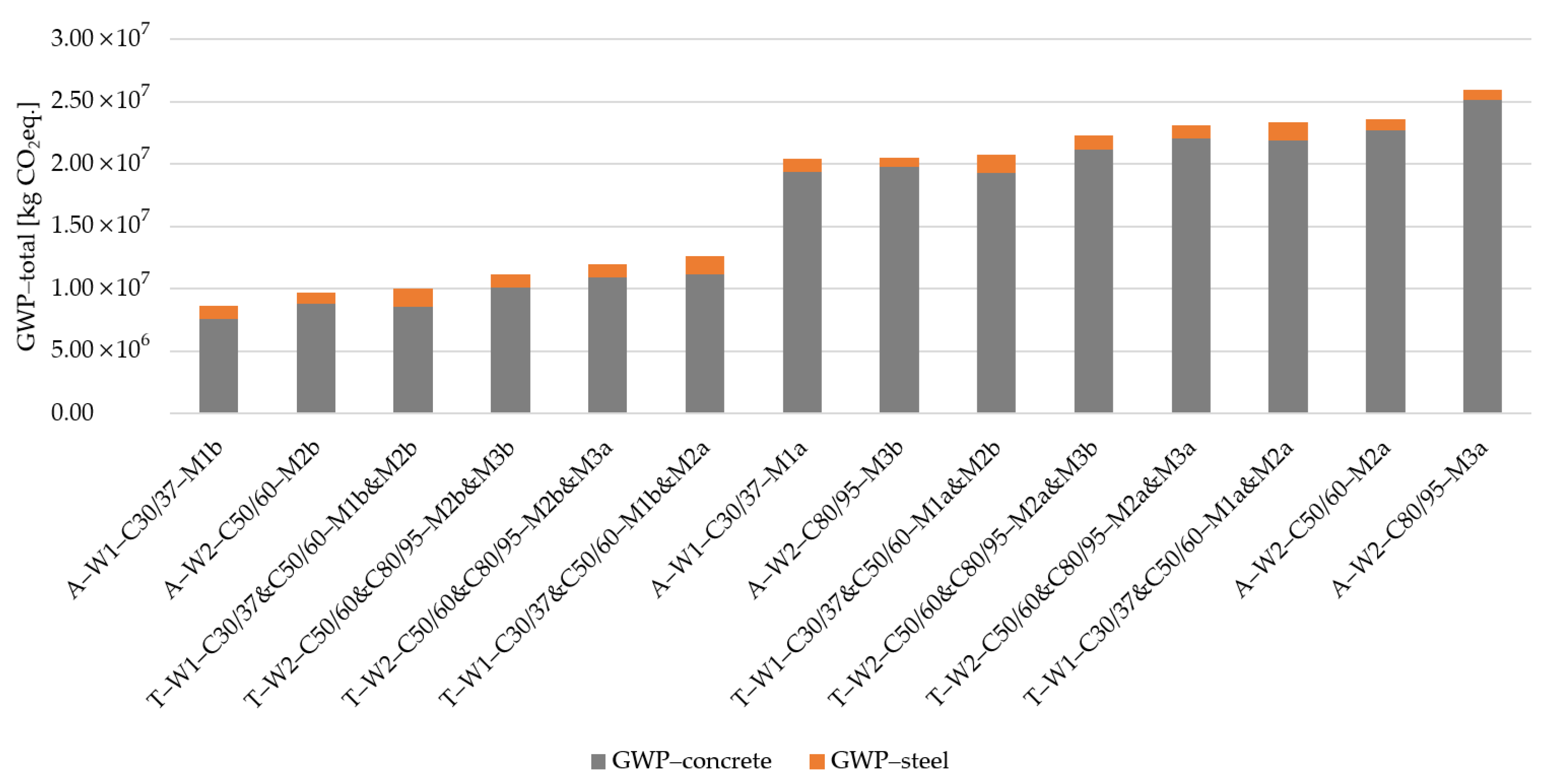

| Impact Category (Indicator) | Normalization Factors Rk | Unit | Weighting Factors wk |

|---|---|---|---|

| Climate change—total (GWP–total) | 7.55 × 103 | kg CO2 eq./person | 2.11 × 10−1 |

| Ozone depletion (ODP) | 5.23 × 10−2 | kg CFC–11 eq./person | 6.31 × 10−2 |

| Acidification (AP) | 5.56 × 101 | mol H+ eq./person | 6.20 × 10−2 |

| Eutrophication aquatic freshwater (EP–freshwater) | 1.61 × 100 | kg P eq./person | 2.80 × 10−2 |

| Eutrophication aquatic marine (EP–marine) | 1.95 × 101 | kg N eq./person | 2.96 × 10−2 |

| Eutrophication terrestrial (EP–terrestrial) | 1.77 × 102 | mol N eq./person | 3.71 × 10−2 |

| Photochemical ozone formation (POCP) | 4.09 × 101 | kg NMVOC eq./person | 4.78 × 10−2 |

| Depletion of abiotic resources—minerals and metals (ADP–minerals & metals) | 6.36 × 10−2 | kg Sb eq./person | 7.55 × 10−2 |

| Depletion of abiotic resources—fossil fuels (ADP–fossil) | 6.50 × 104 | MJ/person | 8.32 × 10−2 |

| Water use (WDP) | 1.15 × 104 | m3 water eq of deprived water/person | 8.51 × 10−2 |

| Particulate matter emissions (PM) | 5.95 × 10−4 | disease incidences/person | 8.96 × 10−2 |

| Ionizing radiation, human health (IRP) | 4.22 × 103 | kBq U–235 eq./person | 5.01 × 10−2 |

| Eco–toxicity (freshwater) (ETP–fw) | 5.67 × 104 | CTUe/person | 1.92 × 10−2 |

| Human toxicity, cancer effects (HTP–c) | 1.73 × 10−5 | CTUh/person | 2.13 × 10−2 |

| Human toxicity, non–cancer effects (HTP–nc) | 1.29 × 10−4 | CTUh/person | 1.84 × 10−2 |

| Land use-related impacts/soil quality (SQP) | 8.19 × 105 | dimensionless/person | 7.94 × 10−2 |

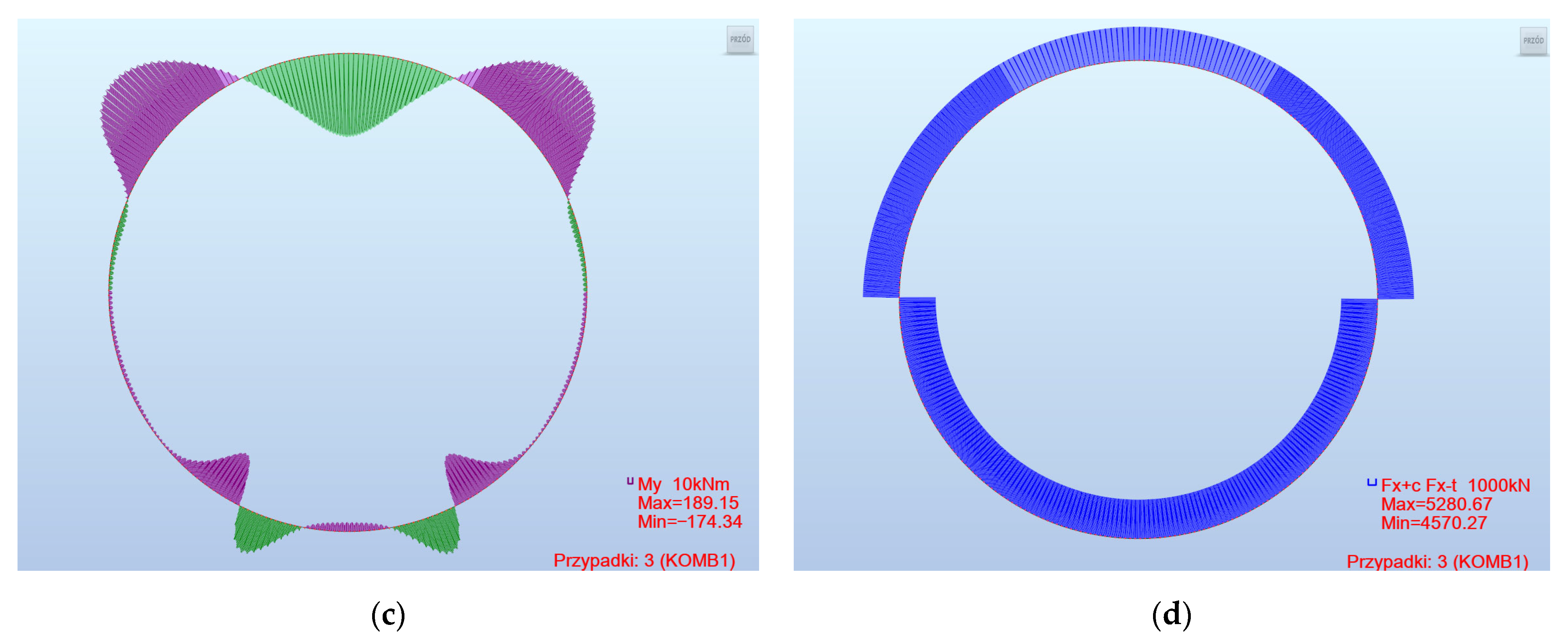

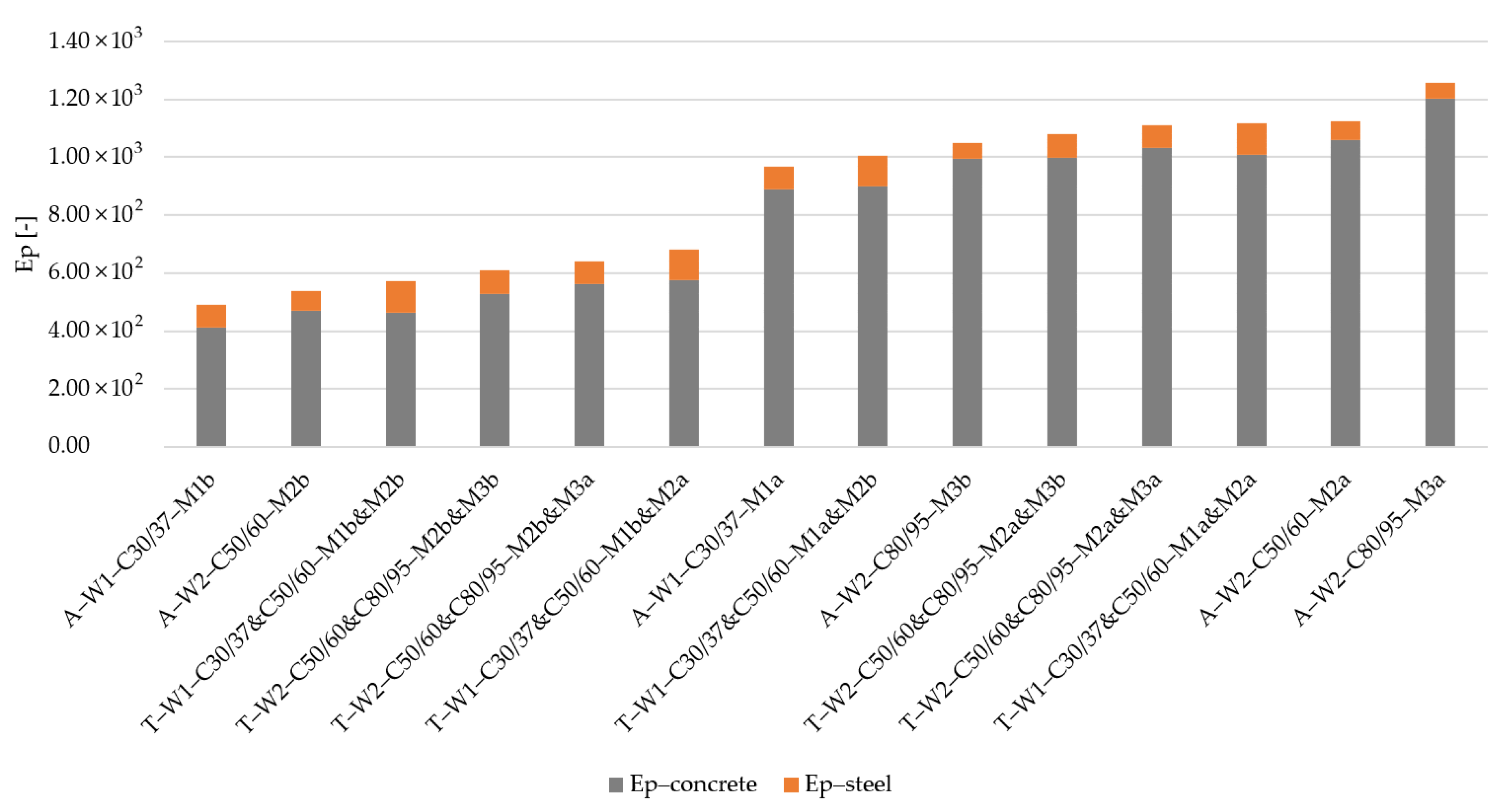

3. Results and Discussion

- Variant TBM–W1: lining with a thickness of 60 cm, made of concrete class C30/37 in sections 1–2 and C50/60 in sections 3, NP, and SP. For this variant, the total concrete volume amounted to 59,126 m3, while the reinforcement mass reached 3,432,120 kg.

- Variant TBM–W2: lining with a thickness of 50 cm, made of concrete class C50/60 (sections 1–2) and C80/95 (sections 3, NP, SP). In this case, the concrete volume was 48,970 m3 and the reinforcement mass was 2,511,404 kg.

- Variant ADECO–RS W1: crown thickness 50–75 cm, invert thickness 50–60 cm, concrete class C30/37. The total concrete volume amounted to 54,381 m3, and the reinforcement mass reached 2,501,226 kg.

- Variant ADECO–RS W2: crown and invert thickness 50 cm, concrete class C50/60. The total concrete volume decreased to 51,417 m3, and the reinforcement mass was 2,085,591 kg.

- Variant ADECO–RS W3: crown and invert thickness 50 cm, concrete class C80/95. A concrete volume of 51,417 m3 was obtained, along with a reinforcement mass of 1,738,915 kg, indicating a reduction in steel demand compared with variant W1.

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| TBM | Tunnel Boring Machine |

| NATM | New Austrian Tunnelling Method |

| ADECO–RS | Analysis of Controlled Deformation in Rocks and Soils |

| LCA | Life Cycle Assessment |

| RMR | Rock Mass Rating |

| GSI | Geological Strength Index |

References

- Athanasopoulou, A.; Bezuijen, A.; Bogusz, W.; Bournas, D.; Brandtner, M.; Breunese, A.; Burbaum, U.; Dimova, S.; Frank, R.; Ganz, H.; et al. Standardisation Needs for the Design of Underground Structures; Athanasopoulou, A., Bogusz, W., Bournas, D., Dimova, S., Eds.; Publications Office of the European Union: Luxembourg, 2019. [Google Scholar]

- Athanasopoulou, A.; Bogusz, W.; Boldini, D.; Brandtner, M.; Brierley, R.; Dimova, S.; Franzen, G.; Ganz, H.; Sousa, M.L.; Van Seters, A.; et al. Prospects for Designing Tunnels and Other Underground Structures in the Context of the Eurocodes—Support to Policies and Standards for Sustainable Construction; Athanasopoulou, A., Dimova, S., Franzen, G., Van Seters, A., Eds.; Publications Office of the European Union: Luxembourg, 2022. [Google Scholar]

- Ustaoglu, A.O.; Unutmaz, B.; Gokceoglu, C. Seismic Fragility and Risk Assessment of Transportation Tunnels in Marmara and Aegean Regions of Türkiye. Sci. Rep. 2025, 15, 33242. [Google Scholar] [CrossRef]

- Pettersson, J.; Group, S.; Limbach, R.; Kerbler, L.; Mannisto, V.; Balazs, H.; Pier, J.; Cartolano, P.; La, S.; Van Der Velde, M.J.; et al. Trans-European Road Network, TEN-T (Roads): 2019 Performance Report; CEDR’s Secretariat-General: Brussels, Belgium, 2020; ISBN 979-10-93321-54-7. Available online: https://www.cedr.eu/news-data/1499/CEDR-publishes-TEN-T-2019-Performance-Report (accessed on 12 December 2025).

- Majcherczyk, T.; Pilecki, Z.; Niedbalski, Z.; Pilecka, E.; Blajer, M.; Pszonka, J. The Influence of Geological Engineering and Geotechnical Conditions on Parameter Selection of the Primary Lining of a Road Tunnel in Laliki. Gospod. Surowcami Miner.—Miner. Resour. Manag. 2012, 28, 103–124. [Google Scholar] [CrossRef]

- Dündar, S.; Bilim, N.; Deresal, D.G.; Kekeç, B. The Most Commonly Used TBM Types and Their Suitability for Hard and Soft Grounds. Min. Rev. 2025, 31, 8–15. [Google Scholar] [CrossRef]

- Mohyla, M.; Vojtasik, K.; Hrubesova, E.; Stolarik, M.; Nedoma, J.; Pinka, M. Approach for Optimisation of Tunnel Lining Design. Appl. Sci. 2020, 10, 6705. [Google Scholar] [CrossRef]

- Vydrová, L.Č. Comparison Of Tunnelling Methods NATM and ADECO-RS. Civ. Eng. J.-Staveb. Obz. 2015, 24, 179–186. [Google Scholar] [CrossRef]

- Wilton, J.L. Cut-and-Cover Tunnel Structures. In Tunnel Engineering Handbook; Bickel, J.O., Kuesel, T.R., King, E.H., Eds.; Springer: Boston, MA, USA, 1996; pp. 320–359. ISBN 978-1-4613-0449-4. [Google Scholar]

- Goel, R.K. Experiences and Lessons from the Use of TBM in the Himalaya—A Review. Tunn. Undergr. Space Technol. 2016, 57, 277–283. [Google Scholar] [CrossRef]

- Omar, E.A. Systematic Review of Innovative Approaches in Tunnel Construction and Design. AJCBM 2024, 8, 20–34. [Google Scholar] [CrossRef]

- Khan, A.; Abdullah, R.A. A Review on Selection of Tunneling Method and Parameters Effecting Ground Settlements. EJEG 2016, 21, 4459–4475. [Google Scholar]

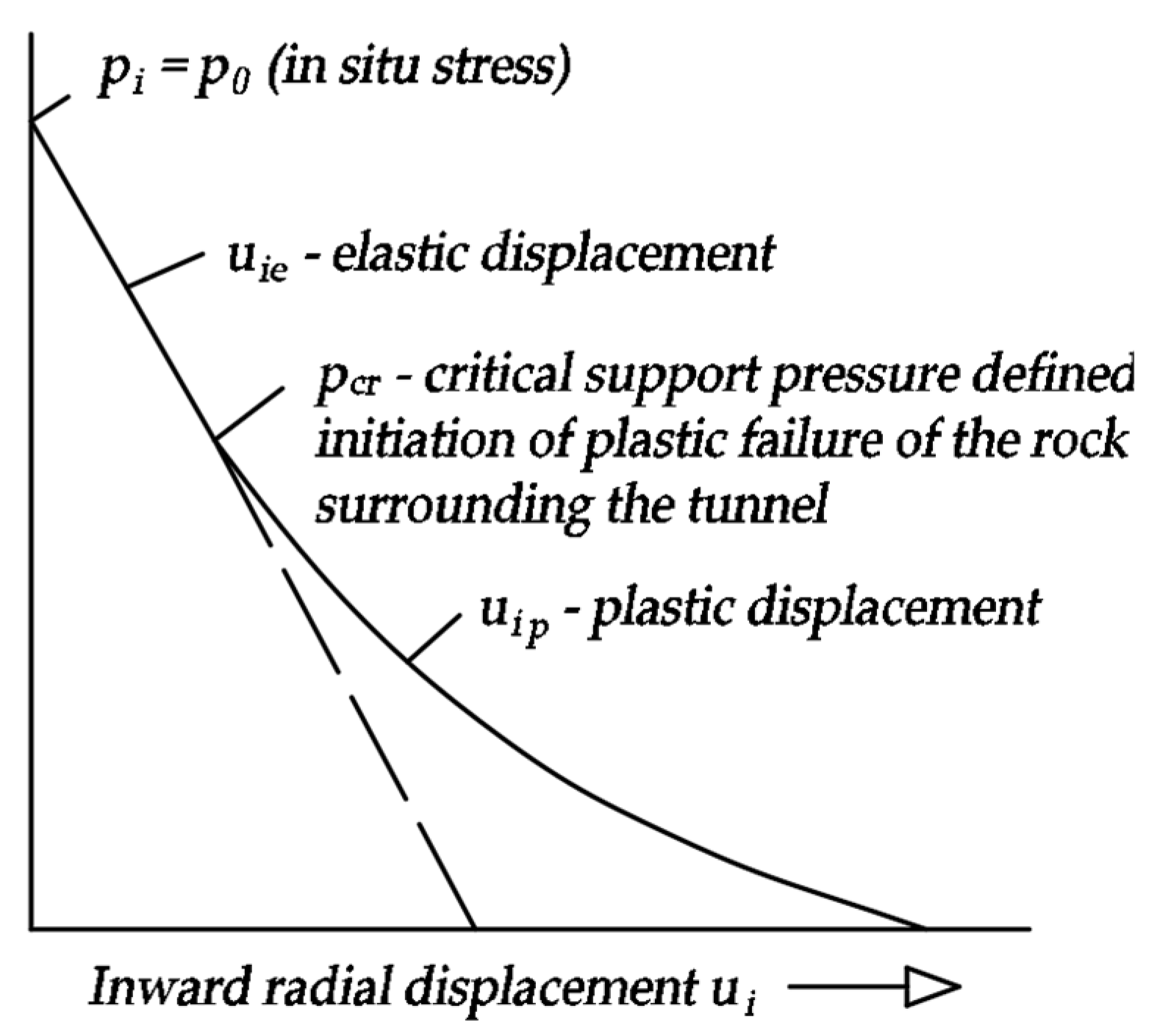

- Blajer, M. Tunnel Lining Design Using Convergence Confinement Method. Mater. Bud. 2023, 609, 13–16. [Google Scholar] [CrossRef]

- Jiang, K.; Huang, L.; Liang, Y.; Du, F. Uneven Longitudinal Deformation Analysis of Prefabricated Subway Station Considering Nonlinear Behavior of Joints. Results Eng. 2025, 28, 107818. [Google Scholar] [CrossRef]

- Bao, X.; Zheng, B.; Shen, J.; Chen, X.; Kong, H.; Li, J.; Wang, X.; Cui, H. Intelligent Technologies for Tunnel Construction and Maintenance: A State-of-the-Art Review of Methods and Supporting Platforms. Tunn. Undergr. Space Technol. 2026, 168, 107207. [Google Scholar] [CrossRef]

- Huymajer, M.; Woegerbauer, M.; Winkler, L.; Mazak-Huemer, A.; Biedermann, H. An Interdisciplinary Systematic Review on Sustainability in Tunneling—Bibliometrics, Challenges, and Solutions. Sustainability 2022, 14, 2275. [Google Scholar] [CrossRef]

- European Commission The European Green Deal. COM/2019/640 Final; Communication from the Commission to the European Parliament, the European Council, the Council, the European Economic and Social Committee and the Committee of the Regions. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:52019DC0640 (accessed on 14 October 2025).

- European Commission A New Circular Economy Action Plan for a Cleaner and More Competitive Europe. COM/2020/98 Final; Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:52020DC0098 (accessed on 14 October 2025).

- European Parliament and Council of the European Union Directive (EU) 2022/2464 of 14 December 2022 Amending Regulation (EU) No 537/2014, Directive 2004/109/EC, Directive 2006/43/EC and Directive 2013/34/EU, as Regards Corporate Sustainability Reporting. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:02022L2464-20250417 (accessed on 14 October 2025).

- Cao, R.; Hao, Y.; Li, Y.; Liao, W. Emerging Trends in Lifecycle Assessment of Building Construction for Greenhouse Gas Control: Implications for Capacity Building. Discov. Appl. Sci. 2025, 7, 398. [Google Scholar] [CrossRef]

- Dossche, C.; Boel, V.; De Corte, W. Use of Life Cycle Assessments in the Construction Sector: Critical Review. Procedia Eng. 2017, 171, 302–311. [Google Scholar] [CrossRef]

- Gudmundsdottir, S.; Sigurjonsson, T.O. A Need for Standardized Approaches to Manage Sustainability Strategically. Sustainability 2024, 16, 2319. [Google Scholar] [CrossRef]

- Korca, B.; Costa, E.; Bouten, L. Disentangling the Concept of Comparability in Sustainability Reporting. Sustain. Account. Manag. Policy J. 2023, 14, 815–851. [Google Scholar] [CrossRef]

- Schwartzentruber, L.D. Life Cycle Assessment Applied to the Construction of Tunnel. In Proceedings of the “SEE Tunnel: Promoting Tunneling in SEE Region” ITA WTC 2015 Congress and 41st General Assembly; Lacroma Valamar Congress Center: Dubrovnik, Croatia, 2015. [Google Scholar]

- Huang, L.; Bohne, R.A.; Bruland, A.; Jakobsen, P.D.; Lohne, J. Life Cycle Assessment of Norwegian Road Tunnel. Int. J. Life Cycle Assess. 2015, 20, 174–184. [Google Scholar] [CrossRef]

- Jarast, P.; Bakhshi, M.; Nasri, V. Carbon Footprint Emissions of Different Tunneling Construction Methods. In Expanding Underground—Knowledge and Passion to Make a Positive Impact on the World- Proceedings of the ITA-AITES World Tunnel Congress, WTC 2023; Benardos, M., Ed.; CRC Press/Balkema: Leiden, The Netherlands, 2023; pp. 65–73. ISBN 9781003348030. [Google Scholar]

- Rodríguez, R.; Pérez, F. Carbon Foot Print Evaluation in Tunneling Construction Using Conventional Methods. Tunn. Undergr. Space Technol. 2021, 108, 103704. [Google Scholar] [CrossRef]

- Zhang, Y.; Wu, S.; Cheng, H.; Zeng, T.; Deng, Z.; Lei, J. Carbon Emission Analysis of Tunnel Construction of Pumped Storage Power Station with Drilling and Blasting Method Based on Discrete Event Simulation. Buildings 2025, 15, 1846. [Google Scholar] [CrossRef]

- Baucal-Poyac, L.; D’alpos Schwartzentruber, L.; Fresnet-Féraille, A.; Subrin, D. Life Cycle Assessment of Tbm Tunnelling: Uncertainty and Sensitivity Analyses. 2025. Available online: https://papers.ssrn.com/sol3/papers.cfm?abstract_id=5291516 (accessed on 12 December 2025). [CrossRef]

- Rodríguez, R.; Bascompta, M.; García, H. Carbon Footprint Evaluation in Tunnels Excavated in Rock Using Tunnel Boring Machine (TBM). Int. J. Civ. Eng. 2024, 22, 995–1009. [Google Scholar] [CrossRef]

- Wang, G.; Lu, D.; Ji, G.; Liang, X.; Lin, Q.; Lv, J.; Du, X. A Lifecycle Carbon Emission Evaluation Model for Urban Underground Highway Tunnel Facilities. Undergr. Space 2025, 24, 352–370. [Google Scholar] [CrossRef]

- Hopf, B.W.; Hoxha, E.; Scherz, M.; Heichinger, H.; Kreiner, H.; Passer, A. Life Cycle Assessment of Tunnel Structures: Assessment of the New Austrian Tunnelling Method Using a Case Study. IOP Conf. Ser. Earth Environ. Sci. 2022, 1078, 012117. [Google Scholar] [CrossRef]

- Shi, X.; Kou, L.; Liang, H.; Wang, Y.; Li, W. Evaluating Carbon Emissions during Slurry Shield Tunneling for Sustainable Management Utilizing a Hybrid Life-Cycle Assessment Approach. Sustainability 2024, 16, 2702. [Google Scholar] [CrossRef]

- Wałach, D.; Mach, A. Effect of Concrete Mix Composition on Greenhouse Gas Emissions over the Full Life Cycle of a Structure. Energies 2023, 16, 3229. [Google Scholar] [CrossRef]

- Mach, A.; Szczygielski, M. Carbon Footprint Analysis throughout the Life Cycle of the Continuous Deep Mixing Method (CDMM) Technology. Energies 2024, 17, 3294. [Google Scholar] [CrossRef]

- Mahmud, A.R. Review on Tunnel Construction Method and Environmental Impact. IJATIR 2022, 4, 97–105. [Google Scholar] [CrossRef]

- Namin, F.S.; Ghafari, H.; Dianati, A. New Model for Environmental Impact Assessment of Tunneling Projects. J. Environ. Prot. 2014, 5, 530–550. [Google Scholar] [CrossRef]

- Moolchandani, K. Industrial Byproducts in Concrete: A State-of-the-Art Review. Next Mater. 2025, 8, 100593. [Google Scholar] [CrossRef]

- Wu, J.; Ye, X.; Cui, H. Recycled Materials in Construction: Trends, Status, and Future of Research. Sustainability 2025, 17, 2636. [Google Scholar] [CrossRef]

- Arvizu-Montes, A.; Guerrero-Bustamante, O.; Polo-Mendoza, R.; Martinez-Echevarria, M.J. Integrating Life-Cycle Assessment (LCA) and Artificial Neural Networks (ANNs) for Optimizing the Inclusion of Supplementary Cementitious Materials (SCMs) in Eco-Friendly Cementitious Composites: A Literature Review. Materials 2025, 18, 4307. [Google Scholar] [CrossRef]

- Sobotka, A.; Sagan, J.; Radziejowska, A. The Estimated Quantities of Building Demolition Waste. Arch. Civ. Eng. 2019, 65, 49–63. [Google Scholar] [CrossRef]

- Kępys, W.; Tora, B.; Václavík, V.; Jaskowska-Lemańska, J. The Effect of Recycled Wind Turbine Blade GFRP on the Mechanical and Durability Properties of Concrete. Sustainability 2025, 17, 8201. [Google Scholar] [CrossRef]

- Kaczmarczyk, G.P.; Wałach, D. New Insights into Cement-Soil Mixtures with the Addition of Fluidized Bed Furnace Bottom Ashes. Appl. Sci. 2024, 14, 11878. [Google Scholar] [CrossRef]

- Sharghi, M.; Jeong, H. The Potential of Recycling and Reusing Waste Materials in Underground Construction: A Review of Sustainable Practices and Challenges. Sustainability 2024, 16, 4889. [Google Scholar] [CrossRef]

- PN-EN 1992-1-1:2008; Eurocode 2: Design of Concrete Structures—Part 1-1: General Rules and Rules for Buildings. Polish Committee for Standardization: Warsaw, Poland, 2008. Available online: https://wiedza.pkn.pl/wyszukiwarka-norm?p_auth=6gYIn8NS&p_p_id=searchstandards_WAR_p4scustomerpknzwnelsearchstandardsportlet&p_p_lifecycle=1&p_p_state=normal&p_p_mode=view&p_p_col_id=column-1&p_p_col_pos=1&p_p_col_count=2&_searchstandards_WAR_p4scustomerpknzwnelsearchstandardsportlet_standardNumber=PN-EN+1992-1-1%3A2008P&_searchstandards_WAR_p4scustomerpknzwnelsearchstandardsportlet_javax.portlet.action=showStandardDetailsAction (accessed on 12 December 2025).

- PN-EN 206+A2:2021-08; Concrete—Specification, Performance, Production and Conformity. Polish Committee for Standardization: Warsaw, Poland, 2021. Available online: https://wiedza.pkn.pl/wyszukiwarka-norm?p_auth=6gYIn8NS&p_p_id=searchstandards_WAR_p4scustomerpknzwnelsearchstandardsportlet&p_p_lifecycle=1&p_p_state=normal&p_p_mode=view&p_p_col_id=column-1&p_p_col_pos=1&p_p_col_count=2&_searchstandards_WAR_p4scustomerpknzwnelsearchstandardsportlet_standardNumber=PN-EN+206%2BA2%3A2021-08P&_searchstandards_WAR_p4scustomerpknzwnelsearchstandardsportlet_javax.portlet.action=showStandardDetailsAction (accessed on 12 December 2025).

- Sadowska-Buraczewska, B.; Grzegorczyk-Frańczak, M. Sustainable Recycling of High-Strength Concrete as an Alternative to Natural Aggregates in Building Structures. Sustainability 2021, 13, 4286. [Google Scholar] [CrossRef]

- Jagadesh, P.; Karthik, K.; Kalaivani, P.; Karalar, M.; Althaqafi, E.; Madenci, E.; Özkılıç, Y.O. Examining the Influence of Recycled Aggregates on the Fresh and Mechanical Characteristics of High-Strength Concrete: A Comprehensive Review. Sustainability 2024, 16, 9052. [Google Scholar] [CrossRef]

- PN-EN 15804+A2:2020-03; Sustainability of Construction Works—Environmental Product Declarations—Core Rules for the Product Category of Construction Products. Polish Committee for Standardization: Warsaw, Poland, 2020. Available online: https://wiedza.pkn.pl/wyszukiwarka-norm?p_auth=6gYIn8NS&p_p_id=searchstandards_WAR_p4scustomerpknzwnelsearchstandardsportlet&p_p_lifecycle=1&p_p_state=normal&p_p_mode=view&p_p_col_id=column-1&p_p_col_pos=1&p_p_col_count=2&_searchstandards_WAR_p4scustomerpknzwnelsearchstandardsportlet_standardNumber=PN-EN+15804%2BA2%3A2020-03P&_searchstandards_WAR_p4scustomerpknzwnelsearchstandardsportlet_javax.portlet.action=showStandardDetailsAction (accessed on 12 December 2025).

- PN-EN 17472:2022-07; Sustainability of Construction Works—Sustainability Assessment of Civil Engineering Works—Calculation Methods. Polish Committee for Standardization: Warsaw, Poland, 2022. Available online: https://wiedza.pkn.pl/wyszukiwarka-norm?p_auth=6gYIn8NS&p_p_id=searchstandards_WAR_p4scustomerpknzwnelsearchstandardsportlet&p_p_lifecycle=1&p_p_state=normal&p_p_mode=view&p_p_col_id=column-1&p_p_col_pos=1&p_p_col_count=2&_searchstandards_WAR_p4scustomerpknzwnelsearchstandardsportlet_standardNumber=PN-EN+17472%3A2022-07P&_searchstandards_WAR_p4scustomerpknzwnelsearchstandardsportlet_javax.portlet.action=showStandardDetailsAction (accessed on 12 December 2025).

- Sala, S.; Crenna, E.; Secchi, M.; Pant, R. Global Normalisation Factors for the Environmental Footprint and Life Cycle Assessment; Publications Office of the European Union: Luxembourg, 2017; ISBN 978-92-79-77214-6. [Google Scholar]

- Sala, S.; Cerutti, A.K.; Pant, R. Development of a Weighting Approach for the Environmental Footprint; Publications Office of the European Union: Luxembourg, 2018; ISBN 9789279680410. [Google Scholar]

- Sphera. Available online: https://lcadatabase.sphera.com/ (accessed on 4 November 2025).

- Hundt, C.; Pothen, F. European Post-Consumer Steel Scrap in 2050: A Review of Estimates and Modeling Assumptions. Recycling 2025, 10, 21. [Google Scholar] [CrossRef]

- Choi, W.; Tae, S. Life Cycle Sustainability Assessment Method for Concrete. Environ. Dev. Sustain. 2024, 27, 27611–27632. [Google Scholar] [CrossRef]

- Walach, D. Economic and Environmental Assessment of New Generation Concretes. IOP Conf. Ser. Mater. Sci. Eng. 2020, 960, 042013. [Google Scholar] [CrossRef]

- Sameer, H.; Weber, V.; Mostert, C.; Bringezu, S.; Fehling, E.; Wetzel, A. Environmental Assessment of Ultra-High-Performance Concrete Using Carbon, Material, and Water Footprint. Materials 2019, 12, 851. [Google Scholar] [CrossRef]

- Onyelowe, K.C.; Ebid, A.M.; Riofrio, A.; Soleymani, A.; Baykara, H.; Kontoni, D.P.N.; Mahdi, H.A.; Jahangir, H. Global Warming Potential-Based Life Cycle Assessment and Optimization of the Compressive Strength of Fly Ash-Silica Fume Concrete; Environmental Impact Consideration. Front. Built Environ. 2022, 8, 992552. [Google Scholar] [CrossRef]

- Jang, H.J.; Ahn, Y.H.; Tae, S.H. Proposal of Major Environmental Impact Categories of Construction Materials Based on Life Cycle Impact Assessments. Materials 2022, 15, 5047. [Google Scholar] [CrossRef]

| Technology | Source | Environmental Indicators/Impact Category * | System Boundaries | Main Results |

|---|---|---|---|---|

| drill and blast tunneling | Schwartzentruber, L. D. (2015) [24] |

| A1–A5 (Construction materials, Construction machines, Transport, Logistic base) | Construction materials: (60–75%); |

| Huang. L. et al. (2015) [25] |

| A1–A5 +B (Construction, Operation, Maintenance) | Construction stage (with material use): GWP (51%), ODP (46%), POFP (77%), TAP (75%); Maintenance stage: PMFP (68%); Operation stage: HTP (57%), IRP (85%), TETP (72%); | |

| Jarast, P.; Bakhshi, M.; Nasri, (2023) [26] |

| A1–A5 | – | |

| Rodríguez, R.; Pérez, F. (2021) [27] |

| A1–A5 (Excavation, Rock waste removal, Support and lining, Auxiliary services) | Construction materials (concrete and steel): (66–88%); | |

| Zhang, Y. et al. (2025) [28] |

| A1–A5 (building material production, transportation, mechanical construction) | Tunnel excavation stage (66%); | |

| TBM | Schwartzentruber, L. D. (2015) [24] |

| A1–A5 (Construction materials, Construction machines, Transport, Logistic base) | Construction materials: (60–75%); |

| Baucal-Poyac, L. et al. (2025) [29] |

| A1–A5 (Segment Production, Backfilling production, TBM maintenance, TBM electricity consumption, TBM supplies (grease, foam, additives) | Construction materials: segment and backfilling production (>67%) for all impact categories (except IRP); TBM electricity consumption—IRP; | |

| Jarast, P.; Bakhshi, M.; Nasri, (2023) [26] | GHG Emissions; | A1–A5 | – | |

| Rodríguez, R.; Bascompta, M.; García, H. (2024) [30] | Carbon Emissions; | A1–A5 (TBM (Electrical energy consumption), Transportation, Auxiliary elements (Ventilation, lighting and other, water), Lining: Composed by pre–cast segments and backfilling) | Construction materials: lining segments (50–75%); | |

| Wang, G. (2025) [31] | Carbon Footprint; | A1–A5 +B (Construction, operation and maintenance stage) | Construction materials | |

| NATM | Hopf, B.W. et al. (2022) [32] | Global Warming Potential; | A1–A5 | Construction materials: steel and concrete (83.7%); |

| Slurry Shield Tunneling | Shi, X. et al. (2024) [33] | GHG emissions; | A1–A5 (Materials production, Materials materialization, Materials Transportation, Tunneling) | Construction materials (94%); |

| Roadheader or hydraulic breaker hammer | Rodríguez, R.; Pérez, F. (2021) [27] | Carbon footprint (CO2 emission); | A1–A5 (Excavation, Rock waste removal, Support and lining, Auxiliary services) | Construction materials: steel and concrete (85%); |

| Cross-Section Type | Total Length [m] | Dominant Rock Type | RMR (Range) | GSI (Range) |

|---|---|---|---|---|

| 1A | 400 | sandstone | 52–61 | 57 |

| 1B | 475 | sandstone/shale | 40–57 | 43 |

| 2 | 733 | sandstone/shale | 42–61 | 43–57 |

| NP | 18 | sandstone | 40–52 | 43 |

| 3 | 294 | shale/sandstone–shale | 35–60 | 30–51 |

| SP | 8.65 | weathered shale | 35–40 | 30 |

| Cross-Section Type | RQD | Density γ [kN/m3] | Rock Mass Elastic Modulus (Incl. Discontinuities) [GPa] | Poisson’s Ratio | Pressure Acting on the Lining—ADECO–RS Method [kPa] | Pressure Acting on the Lining—TBM Method [kPa] |

|---|---|---|---|---|---|---|

| 1A | 86 | 24.2 | 6.6 | 0.3 | 170 | 282 |

| 1B | 73 | 24.2 | 3.0 | 0.3 | 170 | 282 |

| 2 | 62 | 23.1 | 1.89 | 0.3 | 170 | 282 |

| NP | 38 | 22.5 | 0.30 | 0.3 | 490 | 880 |

| 3 | 38 | 22.5 | 0.30 | 0.3 | 490 | 880 |

| SP | 38 | 22.5 | 0.30 | 0.3 | 490 | 880 |

| Variant | Lining Thickness [cm] | Concrete Class—Sections 1–2 | Concrete Class—Sections 3, NP, SP |

|---|---|---|---|

| TBM W1 | 60 | C30/37 | C50/60 |

| TBM W2 | 50 | C50/60 | C80/95 |

| Variant | Crown Thickness [cm] | Invert Thickness [cm] | Concrete Class |

|---|---|---|---|

| ADECO–RS W1 | 50/75 (sections 1–2/sections 3, NP, SP) | 50/60 | C30/37 |

| ADECO–RS W2 | 50 | 50 | C50/60 |

| ADECO–RS W3 | 50 | 50 | C80/95 |

| Concrete Mix | Mix 1a C30/37 | Mix 1b C30/37 | Mix 2a C50/60 | Mix 2b C50/60 | Mix 3a C80/95 | Mix 3b C80/95 |

|---|---|---|---|---|---|---|

| CEM I 32.5R | 370 | |||||

| CEM I 52.5R | 450 | 490 | ||||

| CEM II/B–S 52.5N | 470 | |||||

| CEM III/A 32.5N | 320 | |||||

| CEM III/A 42.5N | 400 | |||||

| Water | 175 | 160 | 160 | 160 | 150 | 150 |

| Sand 0–2 mm | 850 | 850 | 800 | 800 | 700 | 600 |

| Natural gravel 2–8 mm | 450 | 500 | ||||

| Natural gravel 8–16 mm | 450 | |||||

| Crushed aggregate 2–8 mm | 450 | 550 | 1050 | 1150 | ||

| Crushed aggregate 8–16 mm | 500 | |||||

| Recycled aggregate 8–16 mm | 400 | 300 | ||||

| Plasticizer | 3.6 | 5.5 | ||||

| Superplasticizer | 9.1 | 7.4 | 13.2 | 11.75 | ||

| Water–reducing admixture | 4.16 | 4.7 | ||||

| Fly ash | 40 | 40 | 20 | 30 | ||

| Silica fume | 10 | 20 | 10 | 50 | 30 |

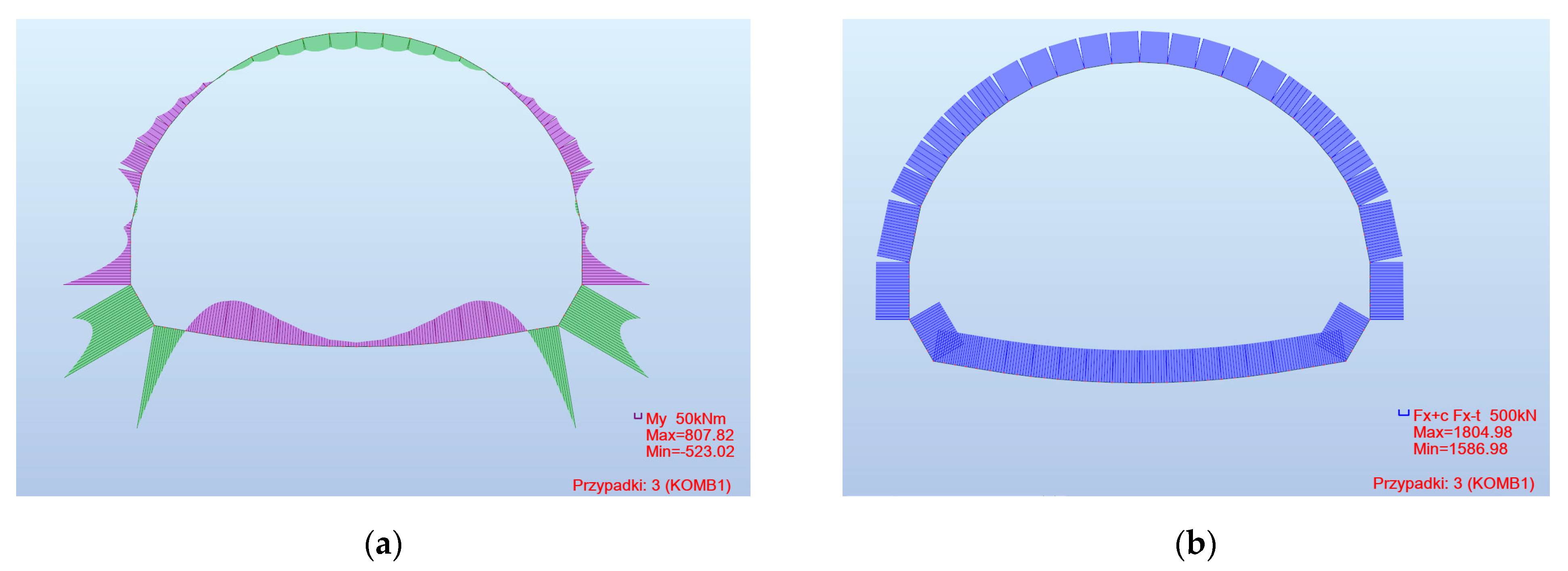

| Variant | Sections 1–2 | Sections 3, NP, SP | ||

|---|---|---|---|---|

| Bending Moments [kNm] | Axial Forces [kN] | Bending Moments [kNm] | Axial Forces [kN] | |

| ADECO–RS W1 | 807.82 | 1804.98 | 1502.04 | 4528.58 |

| ADECO–RS W2 | 831.28 | 1808.12 | 1489.65 | 4490.62 |

| ADECO–RS W3 | 858.15 | 1811.30 | 1541.19 | 4504.81 |

| TBM W1 | 189.15 | 5280.67 | 698.23 | 12,911.97 |

| TBM W2 | 140.69 | 5121.75 | 561.03 | 12,756.71 |

| Variant | Crown Thickness [cm] | Invert Thickness [cm] | Concrete Class | Concrete Volume [m3] | Reinforcement Mass [kg] | Per meter Indicators Concrete [m3]/ Reinforcement [kg] |

|---|---|---|---|---|---|---|

| ADECO–RS W1 | 50/75 (sections 1–2/ sections 3, NP, SP) | 50/60 | C30/37 | 54,381 | 2,501,226 | 28.33/1303.00 |

| ADECO–RS W2 | 50 | 50 | C50/60 | 51,417 | 2,085,591 | 26.79/1086.56 |

| ADECO–RS W3 | 50 | 50 | C80/95 | 51,417 | 1,738,915 | 26.79/905.95 |

| Variant | Lining Thickness [cm] | Concrete Class— Sections 1–2 | Concrete Class— Sections 3, NP, SP | Concrete Volume [m3] | Reinforcement Mass [kg] | Per Meter Indicators Concrete [m3]/ Reinforcement [kg] |

|---|---|---|---|---|---|---|

| TBM W1 | 60 | C30/37 | C50/60 | 59,126 | 3,432,120 | 30.80/1788.08 |

| TBM W2 | 50 | C50/60 | C80/95 | 48,970 | 2,511,404 | 25.51/1308.40 |

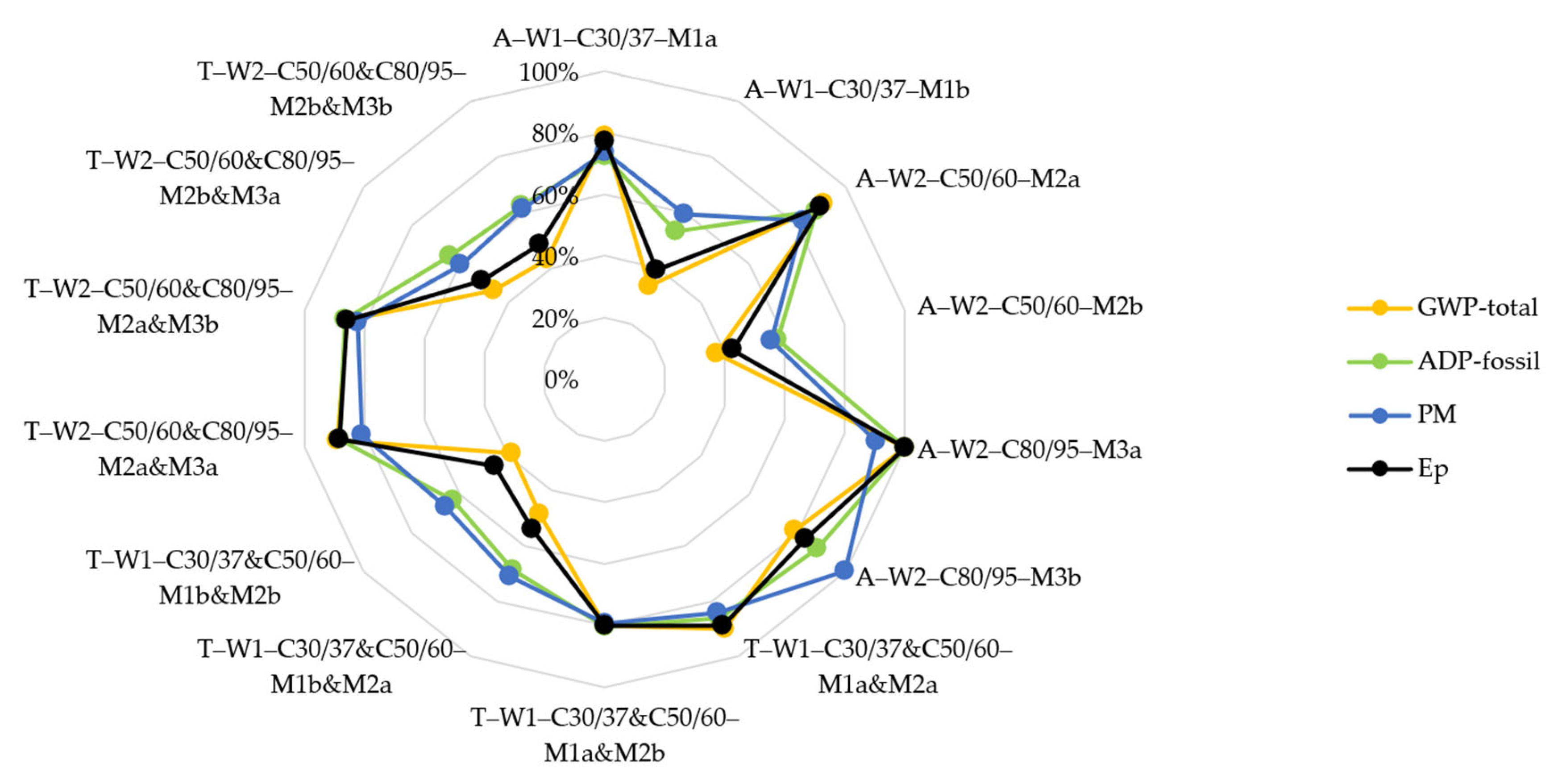

| ADECO–RS | TBM | ||

|---|---|---|---|

| ID | Variant Description | ID | Variant Description |

| A–W1–C30/37–M1a | Technology: ADECO–RS Structural variant: W1 (50/60/75) Concrete class: C30/37 Concrete mix: M1a | T–W1–C30/37&C50/60–M1a&M2a | Technology: TBM Structural variant: W1 (60) Concrete class: C30/37 and C50/60 Concrete mix: M1a and M2a |

| A–W1–C30/37–M1b | Technology: ADECO–RS Structural variant: W1 (50/60/75) Concrete class: C30/37 Concrete mix: M1b | T–W1–C30/37&C50/60–M1a&M2b | Technology: TBM Structural variant: W1 (60) Concrete class: C30/37 and C50/60 Concrete mix: M1a and M2b |

| A–W2–C50/60–M2a | Technology: ADECO–RS Structural variant: W2 (50) Concrete class: C50/60 Concrete mix: M2a | T–W1–C30/37&C50/60–M1b&M2a | Technology: TBM Structural variant: W1 (60) Concrete class: C30/37 and C50/60 Concrete mix: M1b and M2a |

| A–W2–C50/60–M2b | Technology: ADECO–RS Structural variant: W2 (50) Concrete class: C50/60 Concrete mix: M2b | T–W1–C30/37&C50/60–M1b&M2b | Technology: TBM Structural variant: W1 (60) Concrete class: C30/37 and C50/60 Concrete mix: M1b and M2b |

| A–W2–C80/95–M3a | Technology: ADECO–RS Structural variant: W3 (50) Concrete class: C80/95 Concrete mix: M3a | T–W2–C50/60&C80/95–M2a&M3a | Technology: TBM Structural variant: W2 (50) Concrete class: C50/60 and C80/95 Concrete mix: M2a and M3a |

| A–W2–C80/95–M3b | Technology: ADECO–RS Structural variant: W3 (50) Concrete class: C80/95 Concrete mix: M3b | T–W2–C50/60&C80/95–M2a&M3b | Technology: TBM Structural variant: W2 (50) Concrete class: C50/60 and C80/95 Concrete mix: M2a and M3b |

| T–W2–C50/60&C80/95–M2b&M3a | Technology: TBM Structural variant: W2 (50) Concrete class: C50/60 and C80/95 Concrete mix: M2b and M3a | ||

| T–W2–C50/60&C80/95–M2b&M3b | Technology: TBM Structural variant: W2 (50) Concrete class: C50/60 and C80/95 Concrete mix: M2b and M3b | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wałach, D.; Jaskowska-Lemańska, J.; Mach, A. Incorporating Life Cycle Assessment into Tunneling Technologies: Environmental Performance of TBM and ADECO–RS Methods. Sustainability 2025, 17, 11368. https://doi.org/10.3390/su172411368

Wałach D, Jaskowska-Lemańska J, Mach A. Incorporating Life Cycle Assessment into Tunneling Technologies: Environmental Performance of TBM and ADECO–RS Methods. Sustainability. 2025; 17(24):11368. https://doi.org/10.3390/su172411368

Chicago/Turabian StyleWałach, Daniel, Justyna Jaskowska-Lemańska, and Aleksandra Mach. 2025. "Incorporating Life Cycle Assessment into Tunneling Technologies: Environmental Performance of TBM and ADECO–RS Methods" Sustainability 17, no. 24: 11368. https://doi.org/10.3390/su172411368

APA StyleWałach, D., Jaskowska-Lemańska, J., & Mach, A. (2025). Incorporating Life Cycle Assessment into Tunneling Technologies: Environmental Performance of TBM and ADECO–RS Methods. Sustainability, 17(24), 11368. https://doi.org/10.3390/su172411368