Deformation Analysis of 50 m-Deep Cylindrical Retaining Shaft in Composite Strata

Abstract

1. Introduction

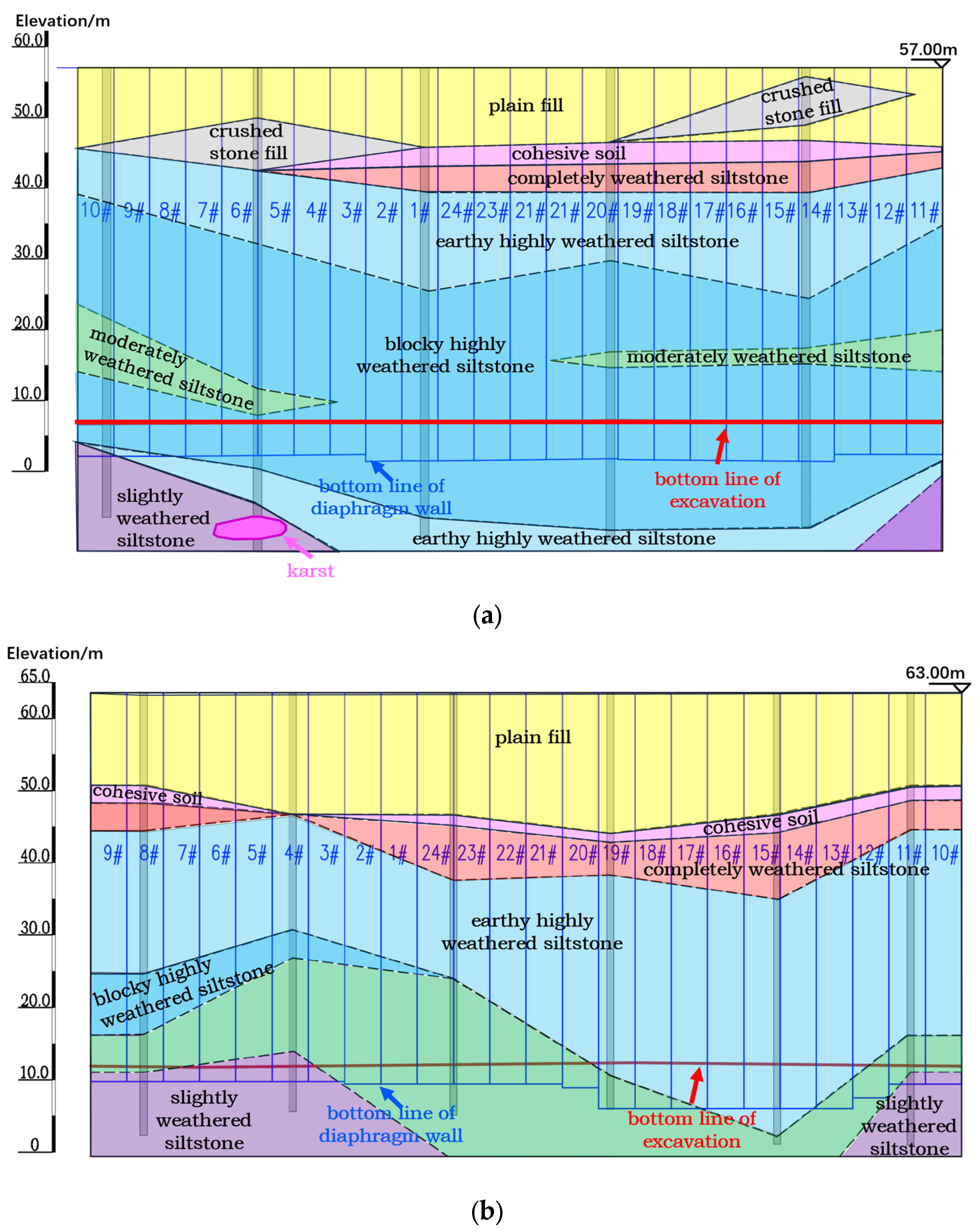

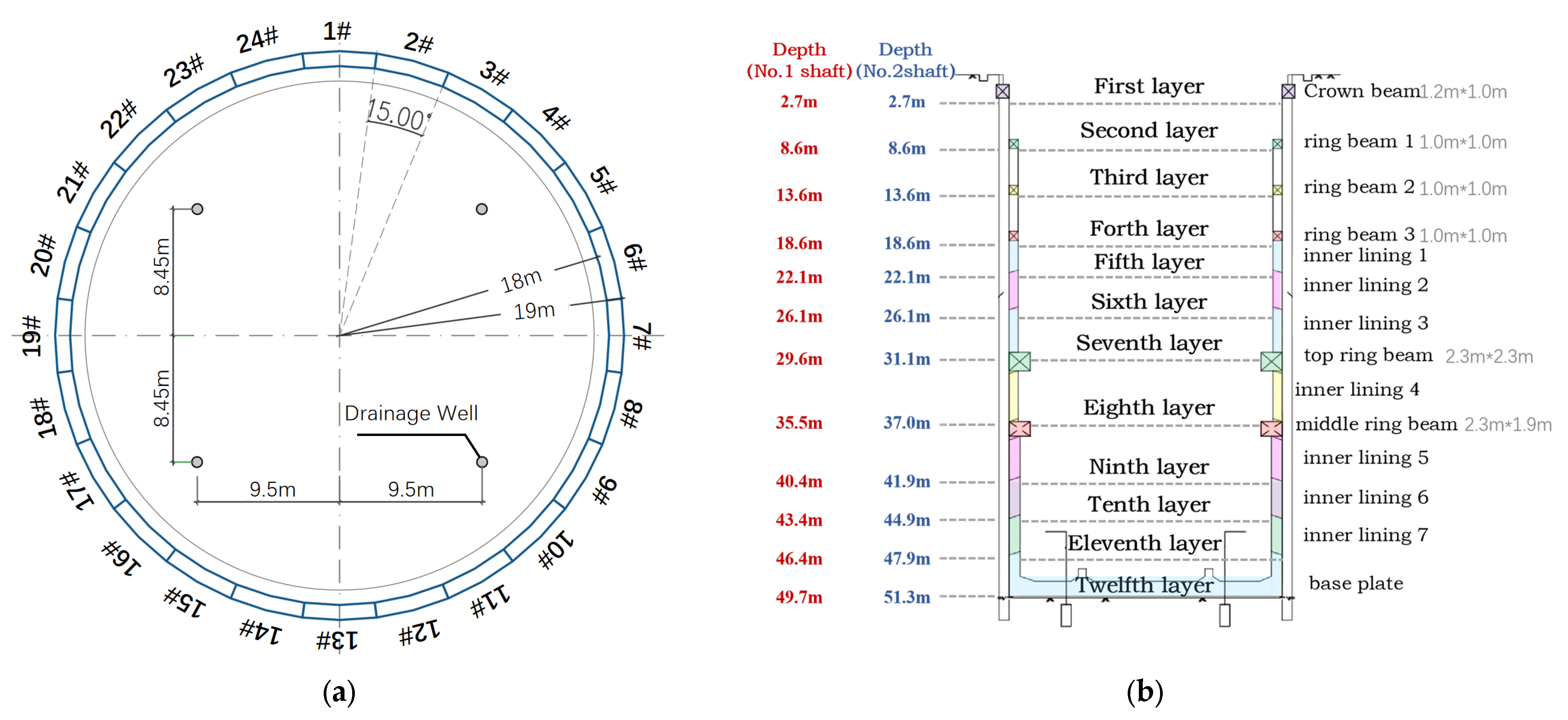

2. Project Overview

2.1. Project Introduction

2.2. Excavation Sequences of the Foundation Pit

- Construct diaphragm walls first, followed by in-pit dewatering to 0.5 m below the upcoming excavation surface.

- Sequentially excavate the first to fourth soil layers, stopping each time 0.5 m below the elevation of the crown beam or ring beam, and then constructing the corresponding retaining structures.

- After the inner ring beam reaches the specified design strength, excavate the fifth to seventh layers in segmented sections, stopping each time 0.5 m below the inner lining wall elevation, and construct the inner lining walls using the top-down method.

- Once the inner lining walls above the main structure roof are completed, excavate the eighth soil layer and install the roof ring beam and inner lining in a top-down method.

- Segmentally excavate the ninth to twelfth soil layers down to the bottom. Subsequently, construct the middle-plate ring beam, side-wall structures, and then install the bottom plate and waterproofing layer.

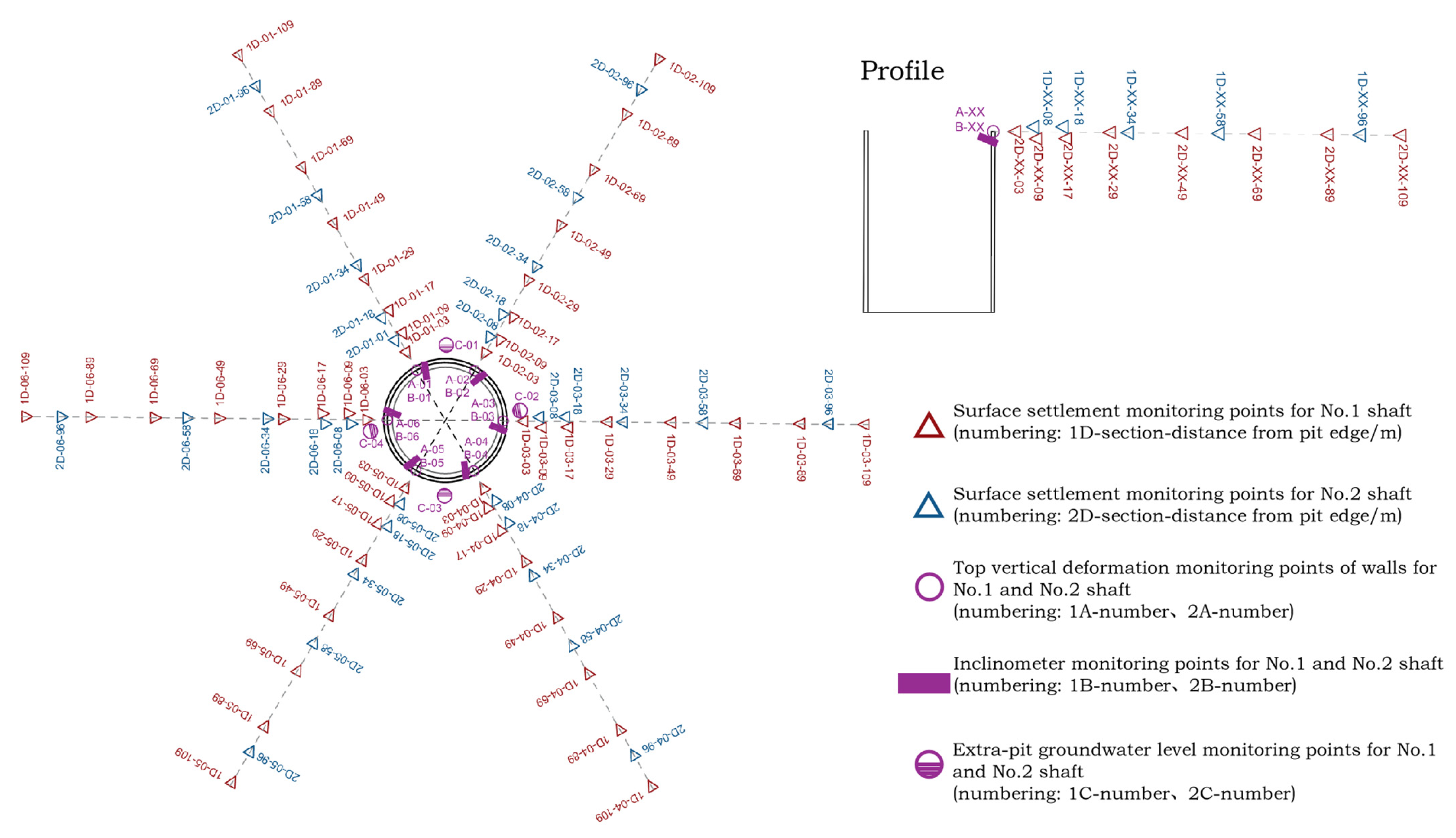

3. Monitoring Point Deployment Scheme

4. Analysis of Monitoring Data

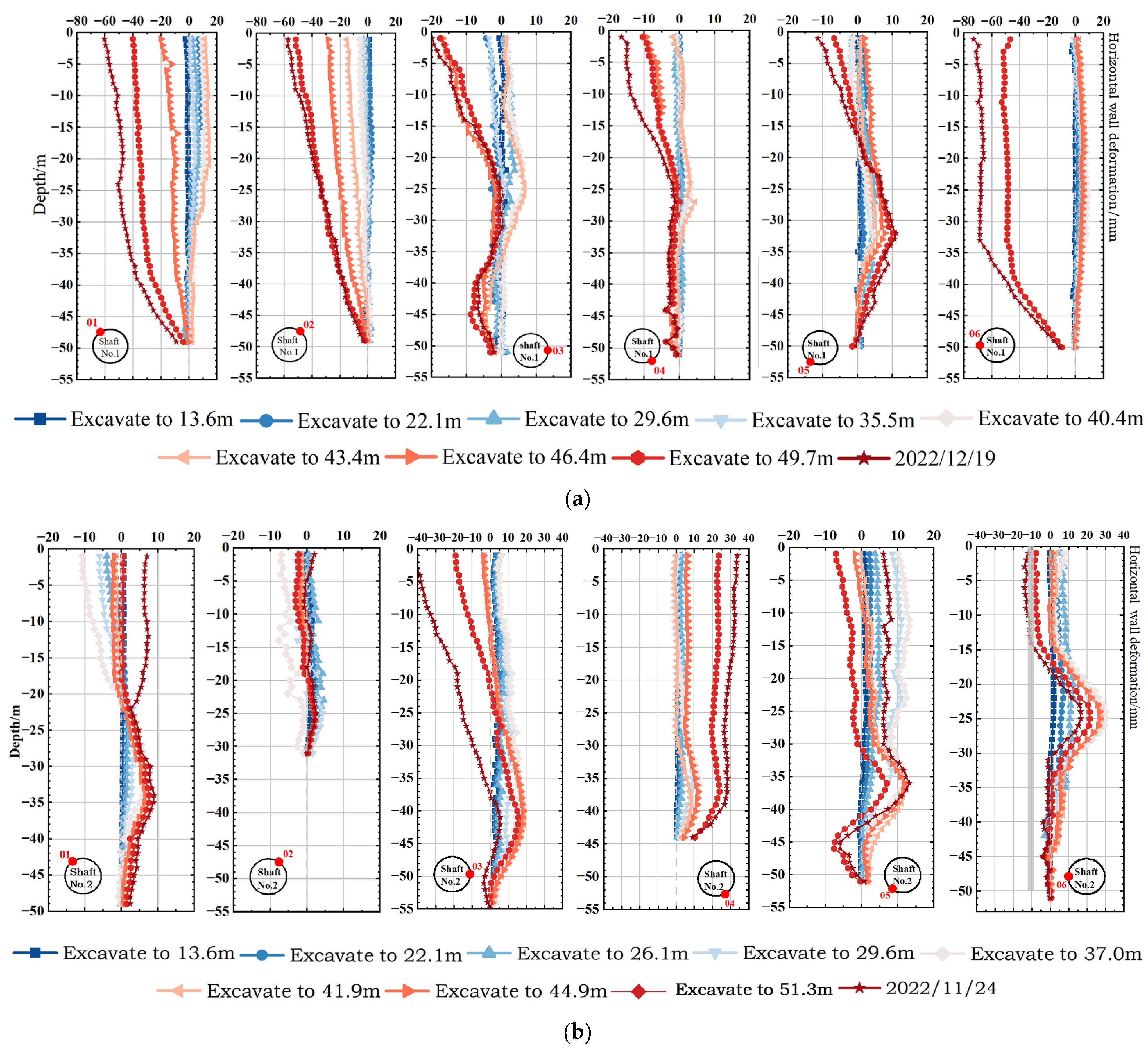

4.1. Horizontal Displacement of the Retaining Wall

- Depth-dependent deformation behavior: The horizontal deformation of retaining walls is strongly correlated with the excavation depth. During the 0–40 m excavation, wall displacements primarily occur inward, increasing progressively as excavation proceeds. Owing to the spatial arching effect of the cylindrical retaining structures, the deformation rate remains relatively moderate, within ±15 mm of horizontal movements. The deformation curves typically exhibit a ‘middle-larger, both-ends-smaller’ or ‘top-larger, bottom-smaller’ profile. This occurs because the foundation pit is subjected to inward-directed soil and water pressures. Additionally, the displacement at the bottom is relatively restrained due to the rock socketing effect of the base slab. Notably, certain measurement points in Shaft 2 displayed outward deformation toward the pit exterior.

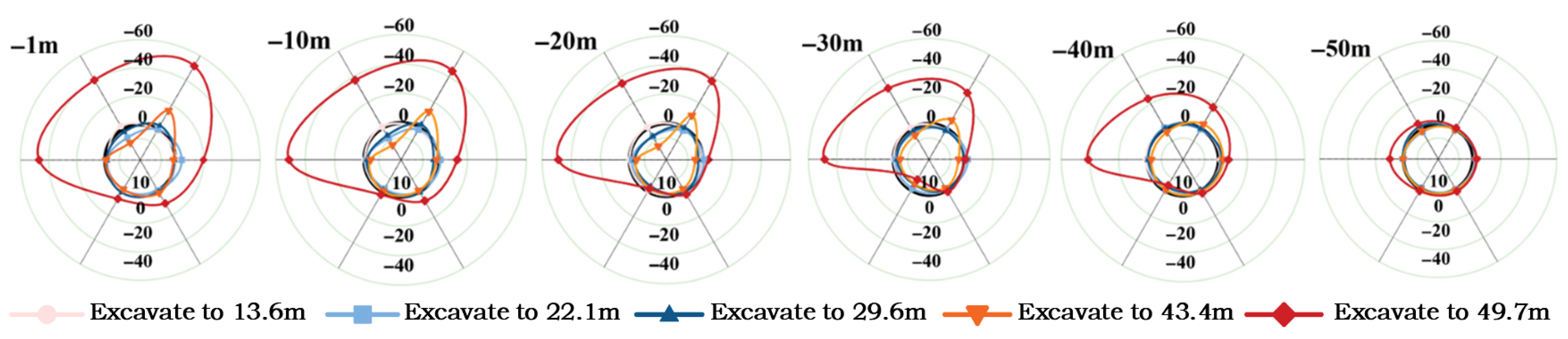

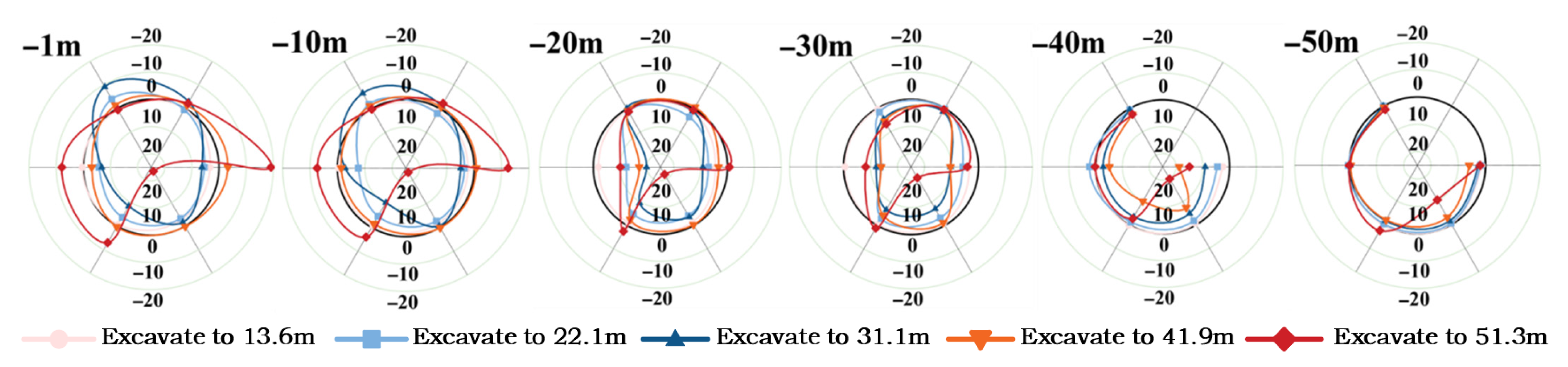

- Uneven soil–water pressures, construction loads on the wall and localized surface surcharge contribute to diverse deformation profiles. For instance, points 2B-01, 2B-03, 2B-05, and 2B-06 exhibit inward heave at the mid or lower-mid wall sections, with minimal displacements at the top and bottom. In addition, point 2B-04 shows rotational tilting deformation of the retaining wall, with the wall pivoting toward the pit around its base. Figure 5 and Figure 6 illustrate notable discrepancies in horizontal displacement of the retaining wall at varying depths. In Shaft 1, the northwestern wall segments exhibit pronounced deformations, contrasting with smaller displacements in the southeastern regions. The deformation profiles are irregular annular patterns, with a maximum circumferential displacement difference of 45.75 mm. For Shaft 2, the 0–10 m cross-section displays a concave deformation curve, while the 20–40 m cross-section shows inward displacements, forming irregular annular shapes with a peak circumferential difference of 45.63 mm.

- Excavation significantly affects the deformation of wall within ±10 m of the excavation surface, where over 5 mm deformations are affected by excavation and recorded at numerous measurement points. Conversely, the portion exceeding 10 m below the excavation surface experiences negligible changes, with displacements consistently under 5 mm.

- After excavation, internal loads from construction of subsequent bottom plate and retaining structure further influence horizontal displacements, primarily by intensifying pre-existing deformation trends. Owing to the weaker mechanical properties of upper soil layers, these loads exert a more pronounced effect on the wall’s upper segment than its mid and lower sections. Consequently, continuous deformation monitoring is essential after soil excavation.

- Elevated horizontal displacements at wall-top points (1B-01–1B-06, 2B-03–2B-04) can be attributed to multiple factors. First, localized surface surcharge—such as that of a construction site located 6 m southeast of Shaft No. 2, where concentrated buildings and equipment induced additional stress at point 2B-04, caused significant inward extrusion, and then led to adjacent outward heave. Second, the soil–rock composite strata plays a key role: shallow soil layers, with lower strength and reduced lateral restraint, are highly sensitive to excavation disturbances, resulting in amplified upper-wall deformations. In contrast, the lower wall, embedded in strongly/moderately weathered rock and benefits from rigid constraints, limiting displacements. Finally, groundwater fluctuations in shallow strata further contribute to these deformation patterns.

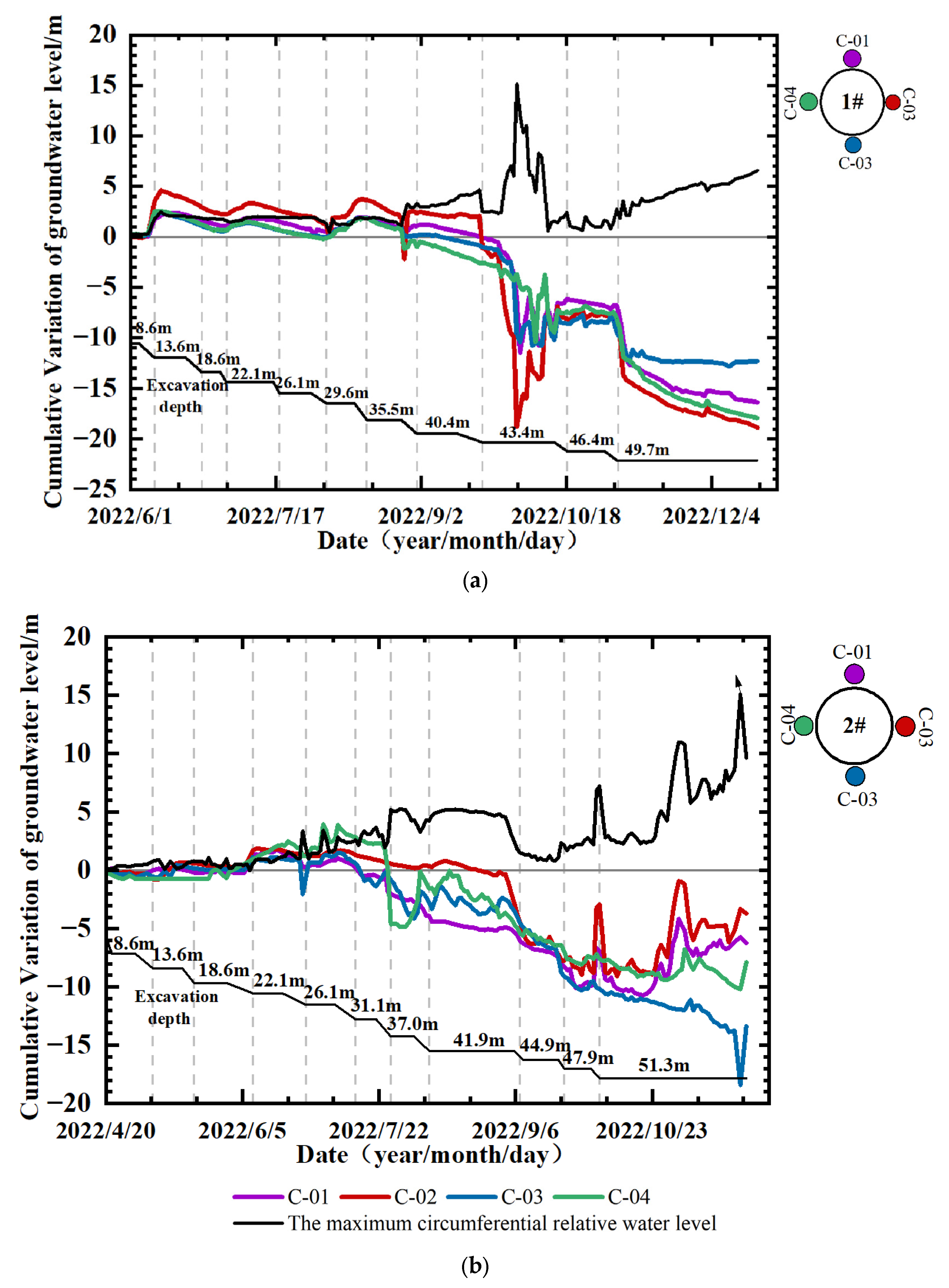

4.2. Groundwater Levels Around the Pit

- Stable phase. During the excavation construction of the soil layer from 0 m to 40 m, the change in each water level measuring point was small, and the fluctuation range was generally within 5 m.

- Fluctuation phase. During the construction of inner lining, with concurrent rotary drilling and impact groove sinking for the 17th diaphragm wall segment, substantial misalignment occurred at the wall’s lower section, triggering groundwater leakage. Monitoring data revealed pronounced fluctuations across all measurement points. Notably, the 1C-02 point, closest to the 17th diaphragm wall segment, experienced the first drastic drop, from −0.52 m to −18.79 m over five days (a 20.84 m decline). This was then followed by rapid drops at 1C-01 and 1C-03, then at 1C-04, indicating that the 1C-02 decline was the primary factor of subsequent water-level reductions. The gradual stabilization of all points afterward implied groundwater redistribution around the shaft, with circumferential flow from higher-level zones (1C-01, 1C-03, 1C-04) to the lower-level 1C-02. The peak maximum circumferential relative water level difference during this phase was 15.11 m, highlighting significant circumferential disparities in water level distribution.

- Steady phase. After the implementation of grouting plugging measures, the water level stabilized gradually, with cumulative changes confined between −6.16 m and −8.82 m.

- Decline phase. During the excavation at 46.4–49.7 m, all measurement points witnessed a drop of approximately 5 m because of the seepage, after which the levels gradually returned to stability.

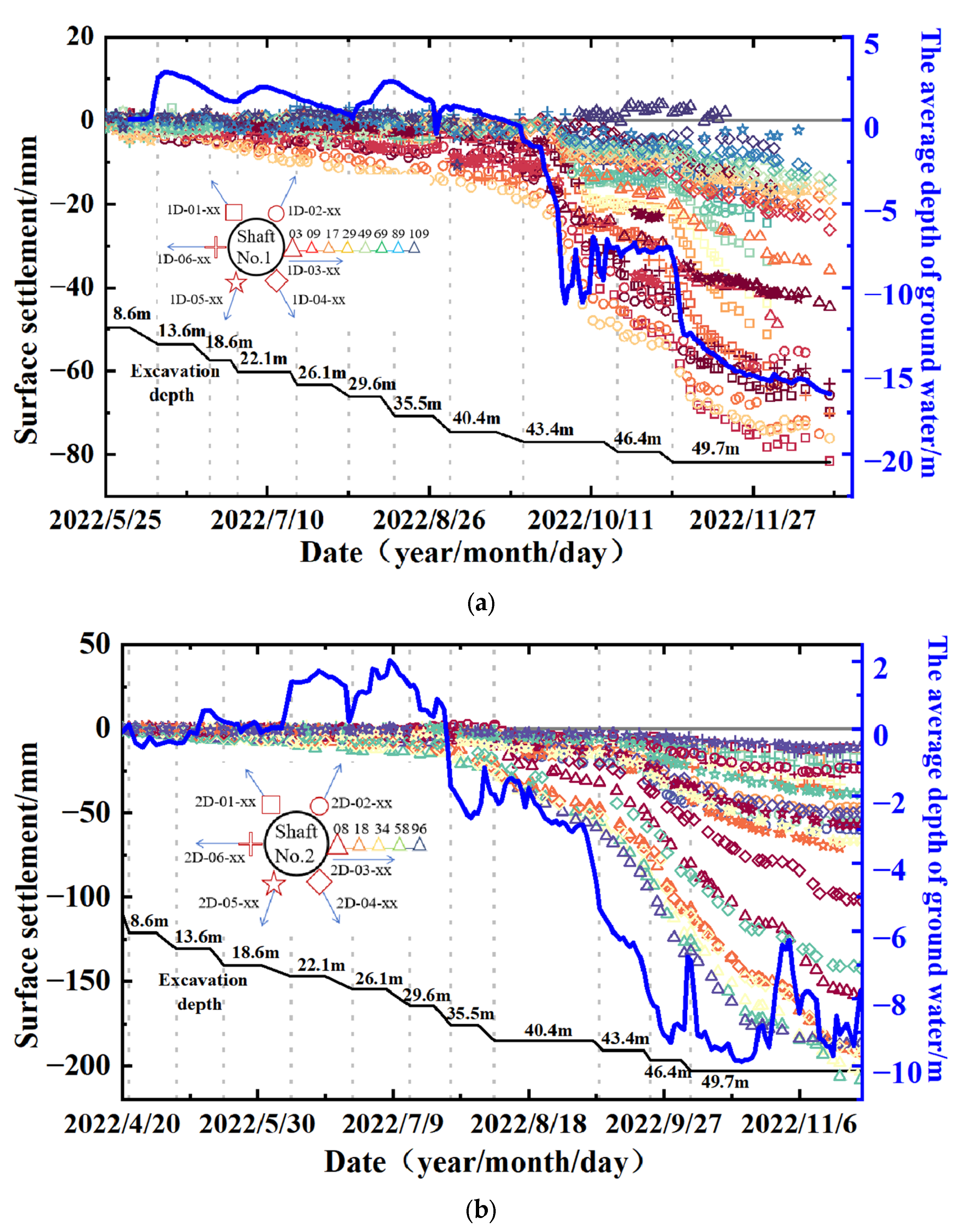

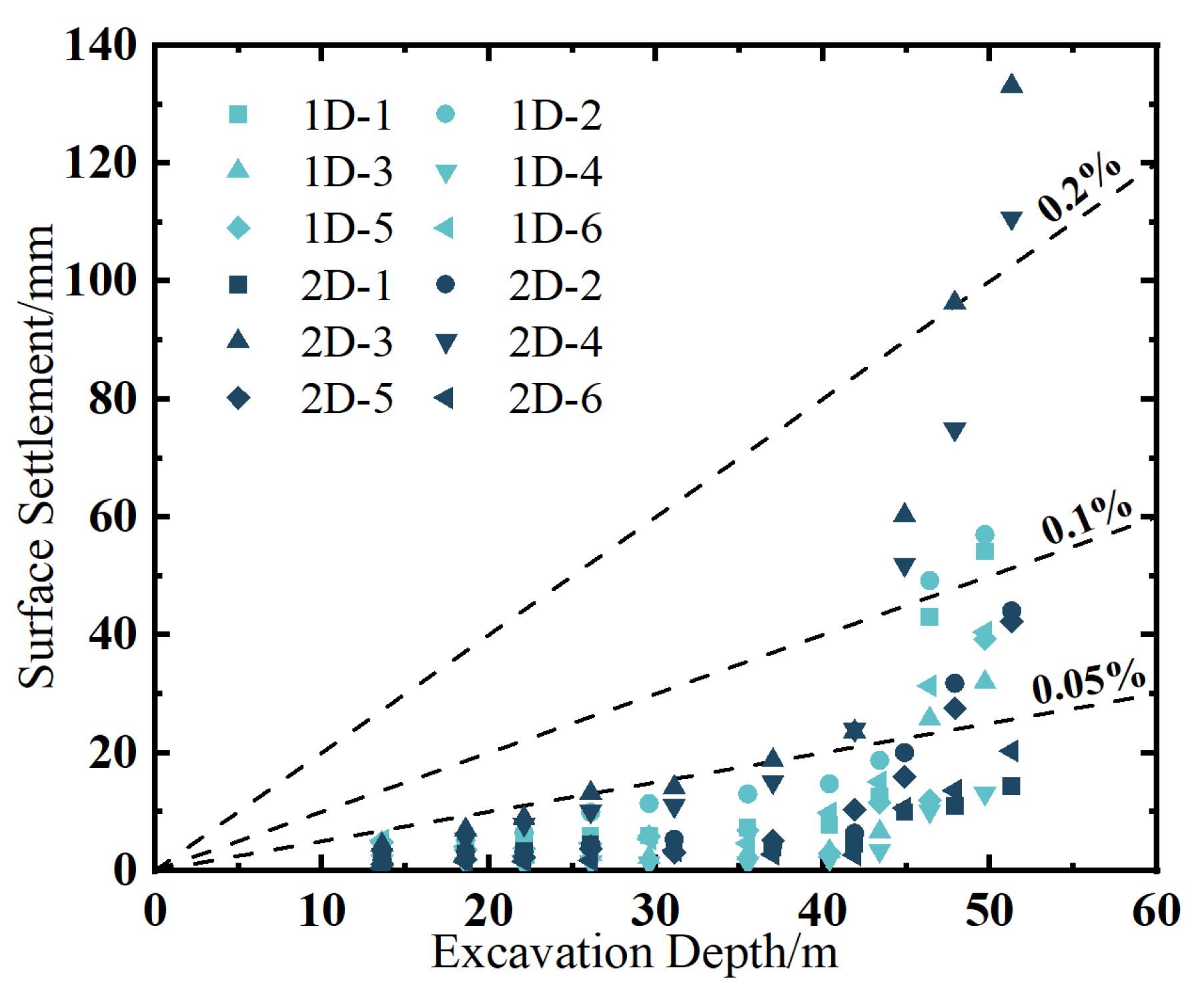

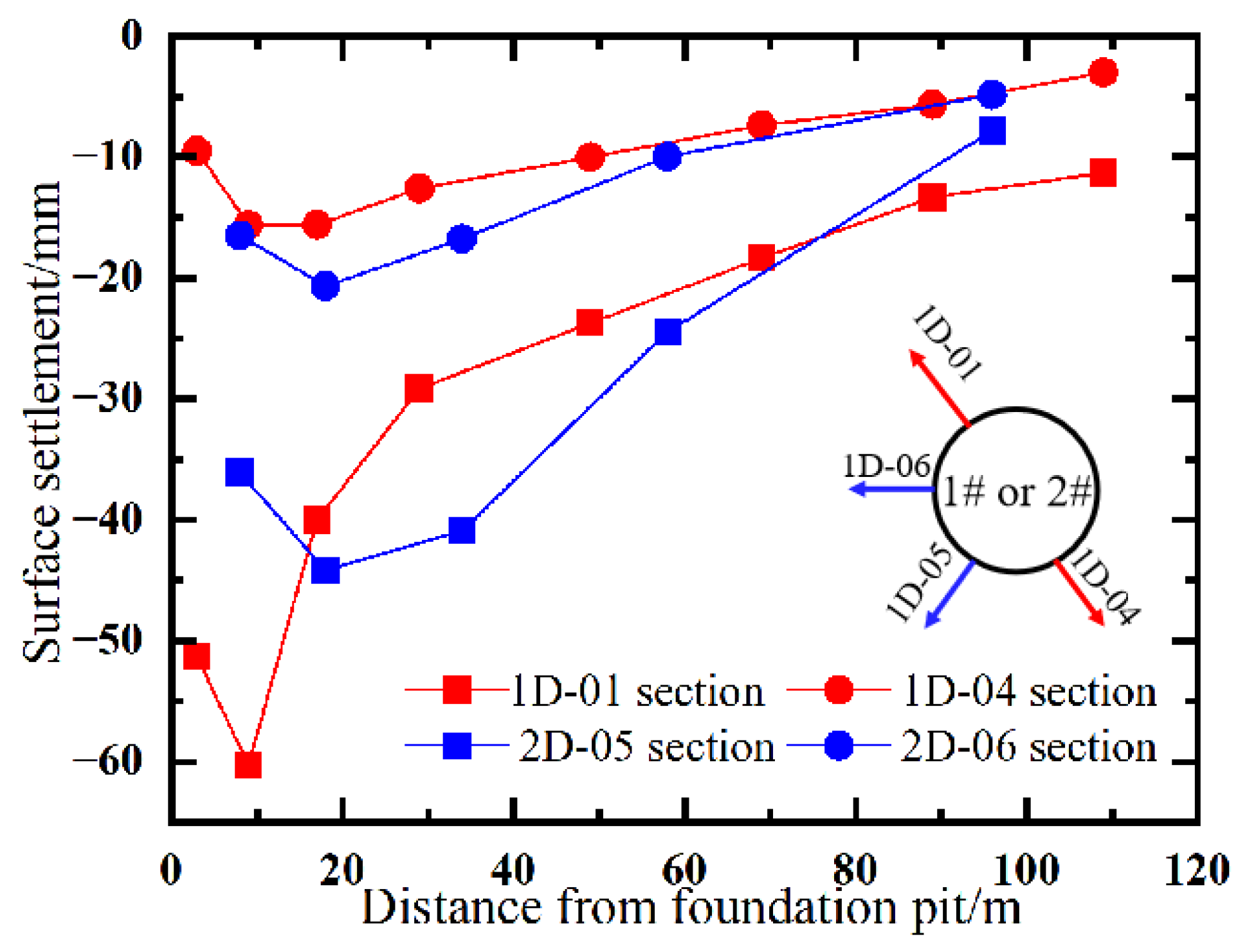

4.3. Surface Settlement

- The decline in groundwater increases the soil effective stress and induces consolidation settlement. During stable-water-level periods (Shaft 1: a1–a10, b11–a12, c; Shaft 2: a1–a10, c), surface settlements develop gradually. Conversely, abrupt water level drops (Shaft 1: b10–a11, b12; Shaft 2: b8–a9, b10–a12) are accompanied by simultaneous acceleration in settlement rates.

- Measurement points 2D-03-34, 2D-03-85, 2D-03-96, and 2D-04-34, 2D-04-85, 2D-04-96, exhibit disproportionately large settlements and rates, with a peak value reaching 200 mm, which substantially exceeds the control limit of 30 mm. This is attributed to poor geological conditions; soil–karst cavities have been found near the monitored section. The collapse of loose soil around cavity is caused by construction disturbances, undermining stratum stability and triggering significant surface settlement.

- After excavation, surface settlements continue to increase slowly due to subsequent activities (e.g., shield component installation, side tunnel construction), with increments exceeding 20% of the maximum monitored settlement. Two primary factors contribute to the above phenomenon. Time-dependent stress release in soils, where gradual dissipation of stress induces sustained deformation. Additionally, the in-pit construction loads also contribute to soil deformation.

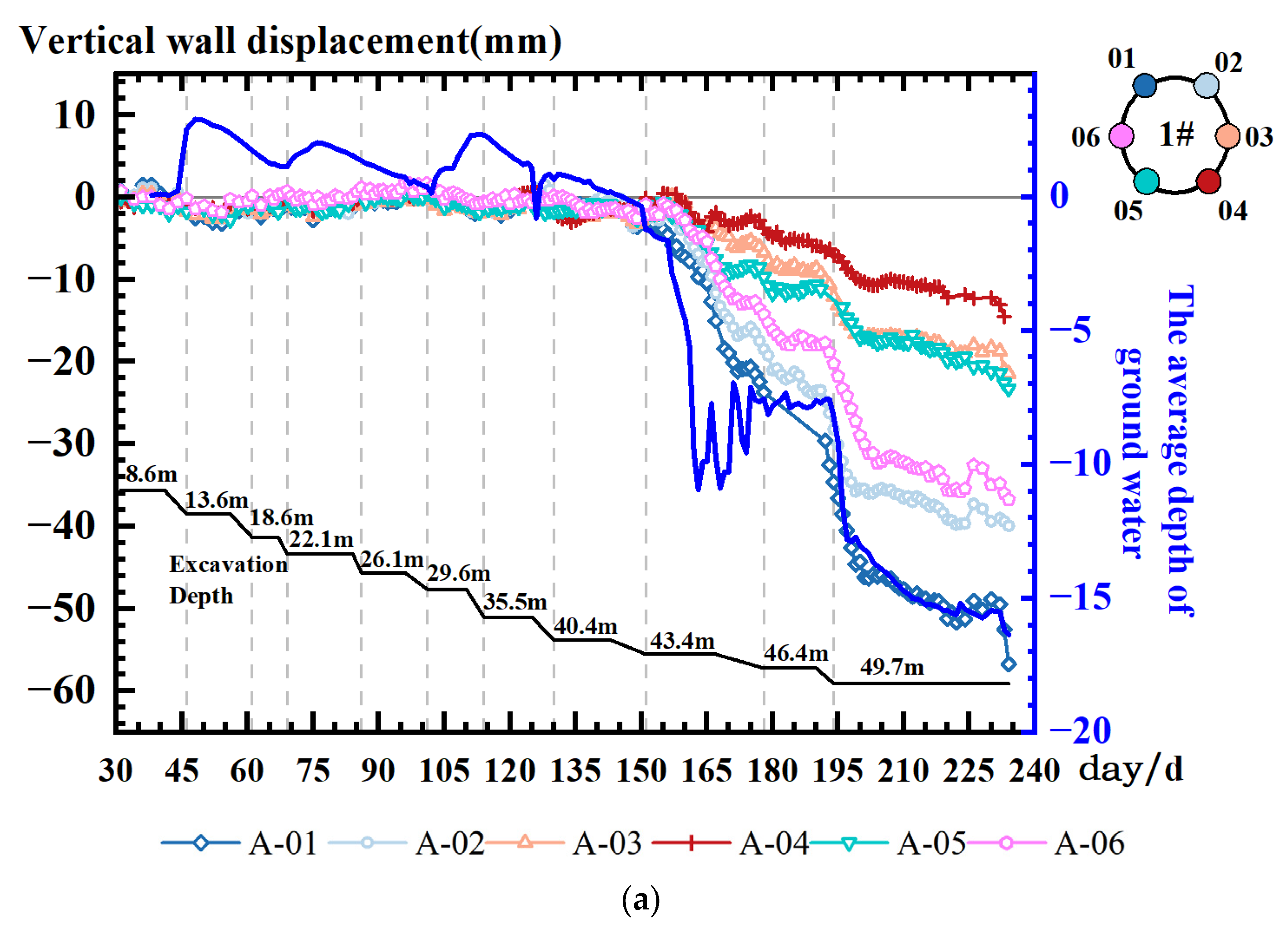

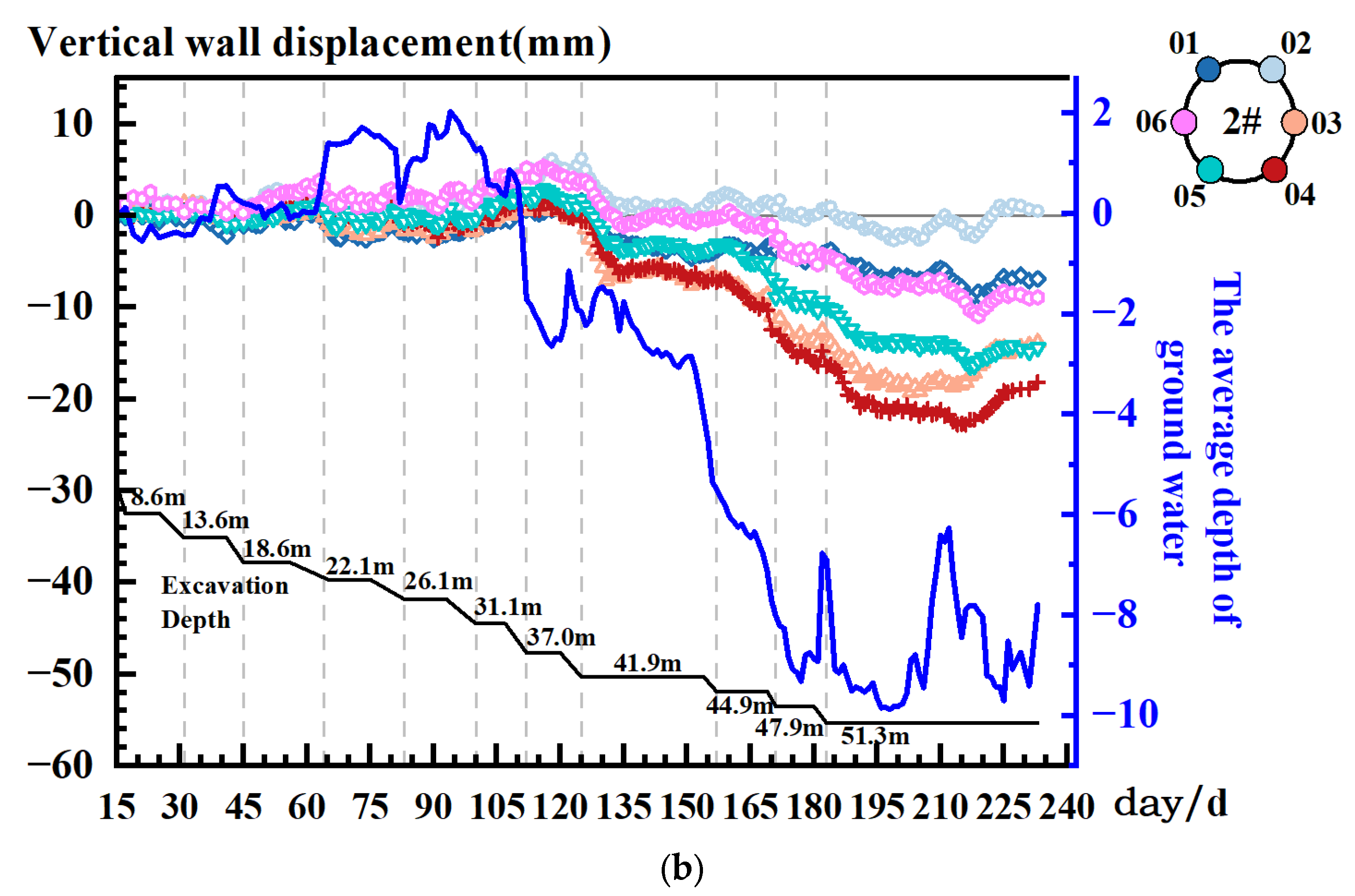

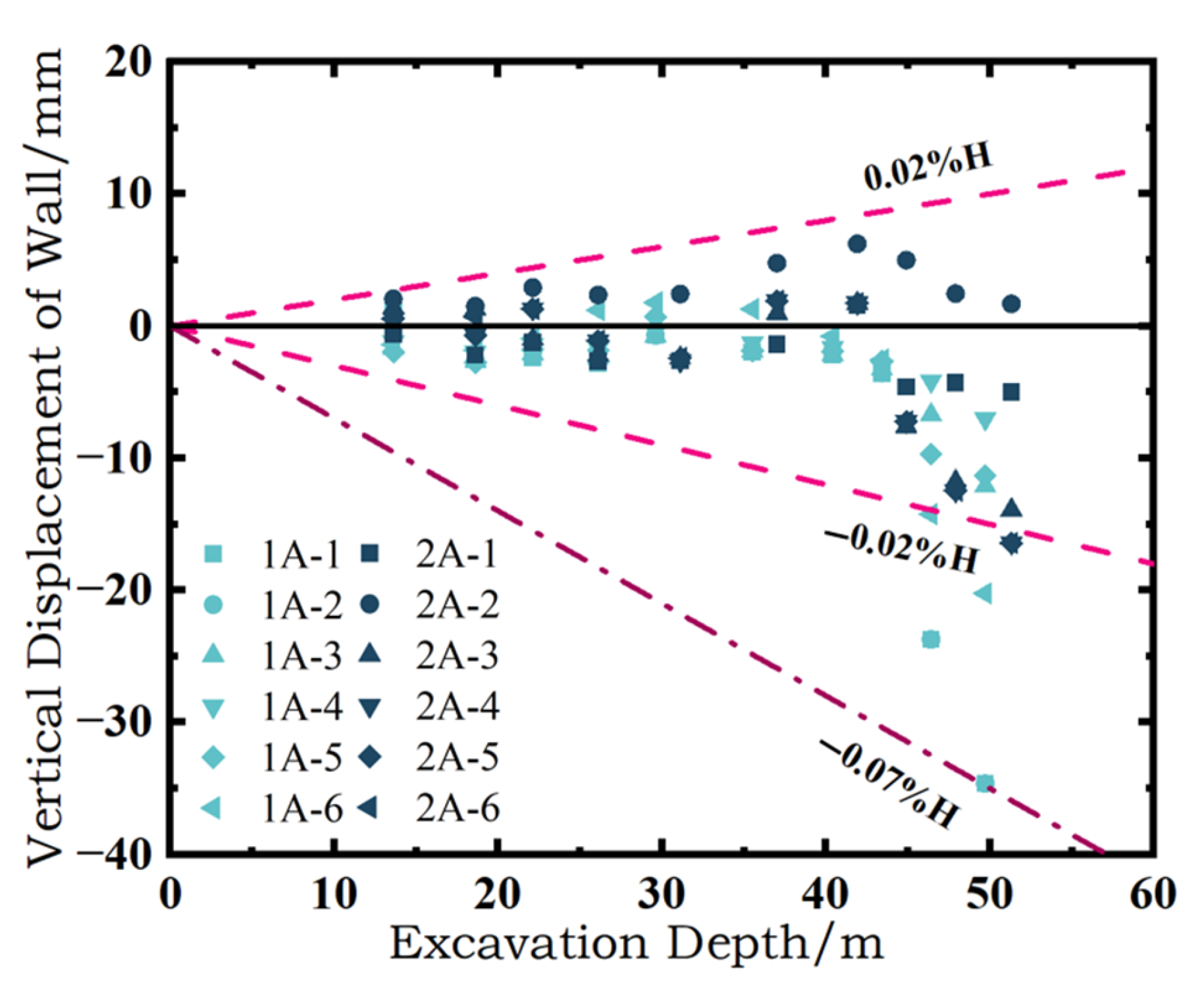

4.4. Vertical Displacement of the Retaining Wall

- Shallow excavation stage (0–40 m). Vertical displacements at the top wall remain minor, some points experiencing heave and others with settlement, all within ±5 mm. This stability attributes to balanced soil–structure interactions in the upper strata.

- Deep excavation stage (40–50 m). The deformation rates is accelerated, leading to notable wall settlement. Significant settlement occurred after abrupt declines in the average groundwater level (Shaft 1: b10–a11, b12; Shaft 2: b8–a9, b10–a12), indicating the pronounced influence of groundwater changes on vertical deformations. The decline in the water level exacerbates the settlement. The large circumferential water level differences (e.g., Shaft 1: b10–a11; Shaft 2: b8–a9, b10–a12) correlate with disparate deformation rates, which indicate that it amplifies non-uniform wall deformations.

- Asymmetric settlement response. Surface settlements were smaller at the side with pronounced groundwater fluctuations compared to the side with stable water levels.

- Deformation mode transition. The deformation mode of walls at measurement points 1B-01, 1B-02, and 1B-06 shifted from flexural to global tilting deformation in late construction stages.

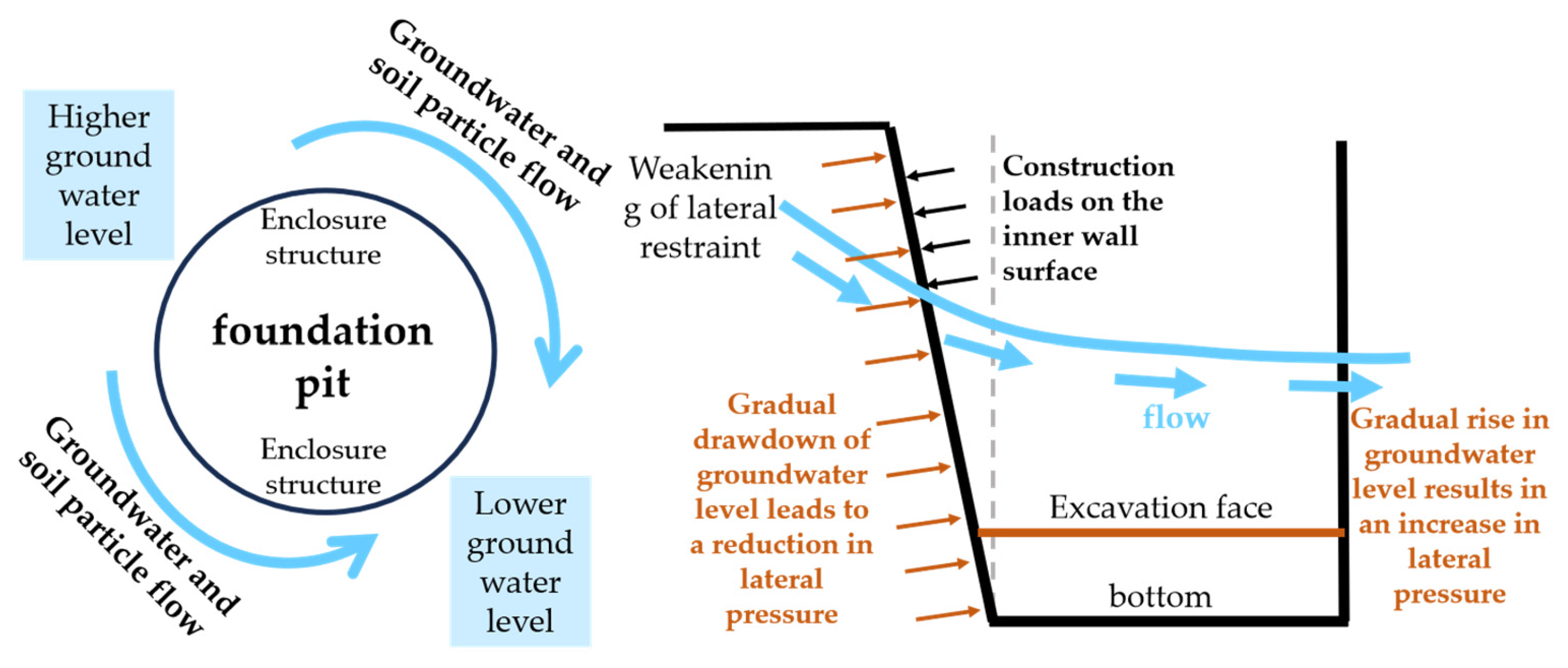

- As analyzed in Section 4.2, groundwater around Shaft No. 1 exhibited both vertical and circumferential flow (Figure 15) during the b10-a11 stage. Seepage forces induced by water level changes mobilized fine soil particles, leading to soil softening and reduced strength at erosion sites.

- In the upper loose strata (plain fill, completely weathered siltstone, etc.), the wall embedment depth was decreased and the foundation constraints were weakened, which created eccentric loading on the cylindrical retaining structure. This imbalanced pressure, combined with inner-wall construction loads, induced outward tilting of the retaining wall.

- The increasing outward deformations widened circumferential wall joints, decreasing structural stiffness and waterproofing. And then it further accelerated deformations. Conversely, the opposite pit side benefited from soil–water supplement, enhancing lateral restraint and mitigating settlements in those areas.

5. Conclusions

- Uneven soil–water pressures, construction loads and localized surface surcharge are the main factors of diverse horizontal deformation patterns in retaining walls, resulting in asymmetric and non-uniform deformations across both the walls and the ground surface.

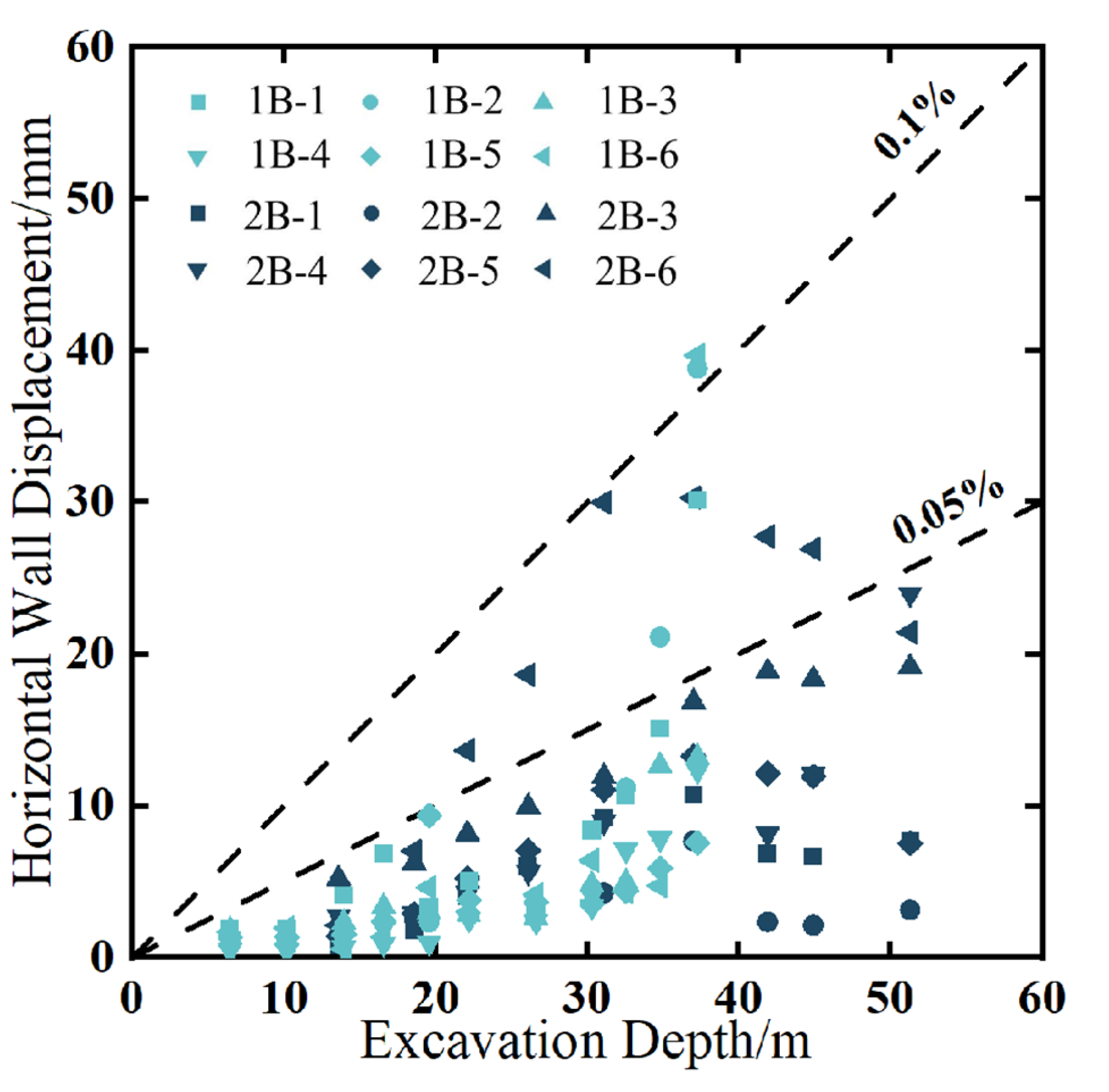

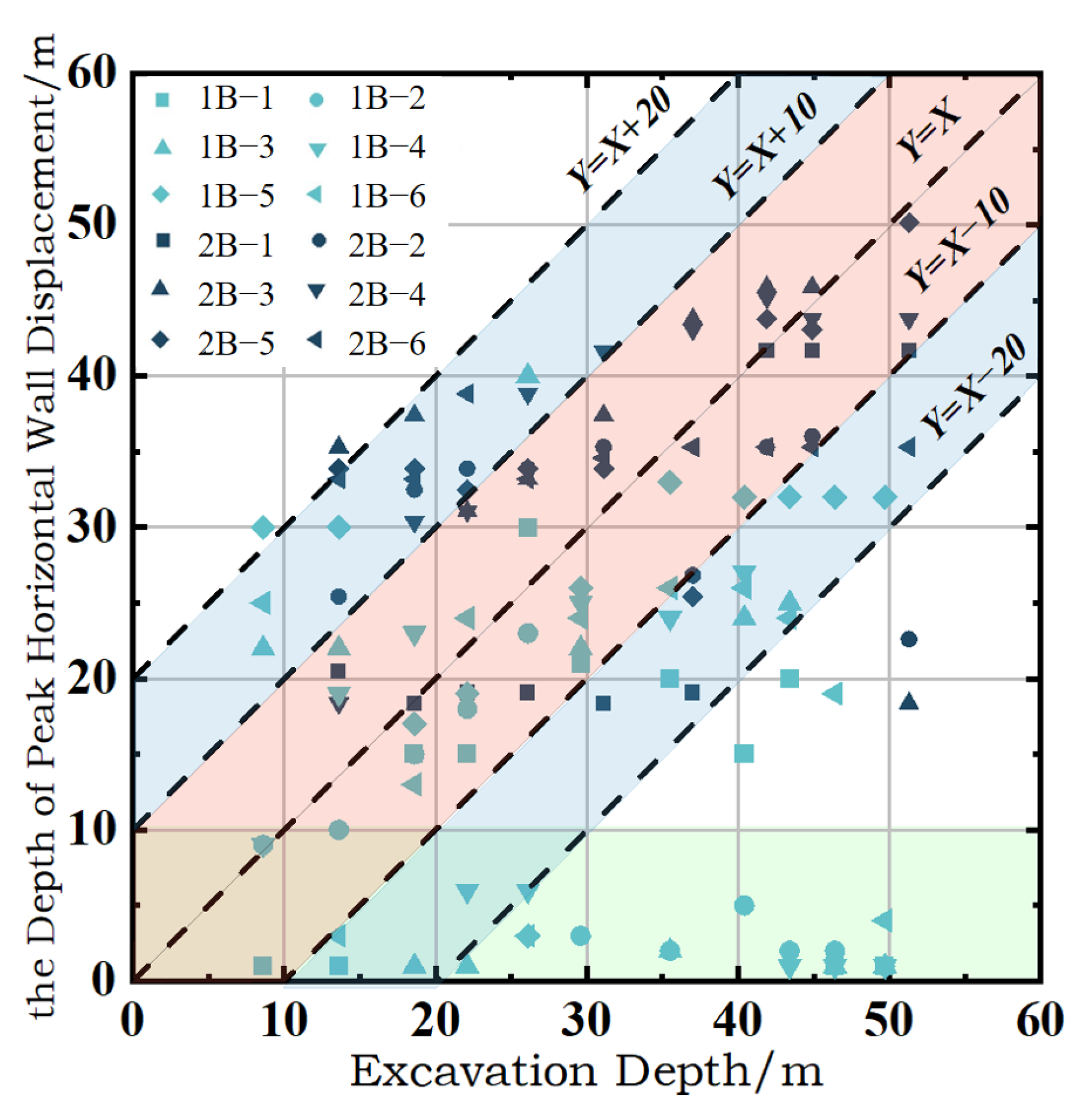

- Analysis of Shaft No. 1 and Shaft No. 2 reveals that maximum horizontal wall deformations generally remain below 0.05% H; peak values occurred in the H − 20 m to H + 20 m depth and the shallow 0–10 m depth. In soil–rock composite strata, the largest horizontal displacements may occur in weaker soil strata (0–10 m). Vertical displacements at the top wall are confined within ±0.2% H. Compared to polygonal counterparts, cylindrical foundation pits demonstrate superior structural stability and reduced environmental disturbance, with smaller horizontal deformations of wall and ground settlements in soil–rock composite strata.

- Groundwater seepage through retaining structure joints triggers substantial declines in groundwater level and the redistribution of circumferential groundwater. Fine-grain migration in adjacent soils occurred with the process of groundwater seepage, leading to outward tilting of the wall at the erosion sites and exacerbating non-uniform deformations of both the structure and the surface. Maintaining groundwater stability and uniformity during construction is critical. The adoption of high-sealing joints and advanced waterproofing techniques is required.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yang, J.; Kong, D. Deformation of deep and large foundation pit in soft soil of Fuzhou Subway. Arab. J. Geosci. 2020, 13, 36. [Google Scholar] [CrossRef]

- Ren, D.; Kang, C.; Liu, H.; Li, Y.; Wang, J. Characteristics of a large-scale deep foundation pit excavated by the central-island technique in chengdu soft clay. KSCE J. Civ. Eng. 2022, 26, 2610–2623. [Google Scholar] [CrossRef]

- Tan, Y.; Lu, Y.; Wang, D. Deep excavation of the Gate of the Orient in Suzhou stiff clay: Composite earth-retaining systems and dewatering plans. J. Geotech. Geoenviron. Eng. 2018, 144, 05017009. [Google Scholar] [CrossRef]

- Cho, J.; Lim, H.; Jeong, S.; Kim, K. Analysis of lateral earth pressure on a vertical cylindrical shaft considering the 3D arching effect. Tunn. Undergr. Space Technol. 2015, 48, 11–19. [Google Scholar] [CrossRef]

- Zhang, J.; Li, M.; Yi, J.; Wu, D.; Chai, X. Analytical Solution for Radial Displacement–Dependent Earth Pressure Acting on Underwater Rock-Socketed cylindrical Diaphragm Walls. Int. J. Geotech. 2024, 24, 04024083. [Google Scholar]

- Borges, J.L.; Guerra, G.T. Cylindrical excavations in clayey soils retained by jet grout walls: Numerical analysis and parametric study considering the influence of consolidation. Comput. Geotech. 2014, 55, 42–56. [Google Scholar] [CrossRef]

- Chehadeh, A.; Turan, A.; Abed, F.; Yamin, M. Lateral earth pressures acting on cylindrical shafts considering soil-structure interaction. Int. J. Geotech. Eng. 2019, 13, 139–151. [Google Scholar] [CrossRef]

- Kim, K.Y.; Lee, D.S.; Cho, J.; Jeong, S.S.; Lee, S. The effect of arching pressure on a vertical circular shaft. Tunn. Undergr. Space Technol. 2013, 37, 10–21. [Google Scholar] [CrossRef]

- Beresantsev, V.G. Earth pressure on the cylindrical retaining wall. Conf. Earth Press. Probl. 1958, 21–27. [Google Scholar]

- Prater, E.G. An examination of some theories of earth pressure on shaft linings. Can. Geotech. J. 1977, 14, 91–106. [Google Scholar] [CrossRef]

- Cheng, Y.M.; Hu, Y.Y.; Wei, W.B. General axisymmetric active earth pressure by method of characteristics—Theory and numerical formulation. Int. J. Geomech. 2007, 7, 1–15. [Google Scholar] [CrossRef]

- Xiong, G.J.; Wang, J.H.; Chen, J.J. Theory and practical calculation method foraxisymmetric active earth pressure based on the characteristics methodconsidering the compatibility condition. Appl. Math. Model. 2019, 68, 563–582. [Google Scholar] [CrossRef]

- Guojun, X.; Jianhua, W. A rigorous characteristic line theory for axisymmetric problems and its application in circular excavations. Acta. Geotech. 2020, 15, 439–453. [Google Scholar] [CrossRef]

- Tangjarusritaratorn, T.; Miyazaki, Y.; Sawamura, Y.; Kishida, K.; Kimura, M. Numerical investigation on arching effect surrounding deep cylindrical shaft during excavation process. Undergr. Space. 2022, 7, 944–965. [Google Scholar] [CrossRef]

- Tran, V.D.H.; Meguid, M.A.; Chouinard, L.E. Discrete element and experimental investigations of the earth pressure distribution on cylindrical shafts. Int. J. Geomech. 2014, 14, 80–91. [Google Scholar] [CrossRef]

- Wang, X.; Xiao, J.; Zhang, T.; Lin, Y. Effect Analysis of supporting structure and surface settlement on deep foundation pit by rainstorm: A case study in Zhengzhou. Water 2022, 14, 3654. [Google Scholar] [CrossRef]

- Chehadeh, A.; Turan, A.; Abed, F. Numerical investigation of spatial aspects of soil structure interaction for secant pile wall circular shafts. Comput. Geotech. 2015, 69, 452–461. [Google Scholar] [CrossRef]

- Muramatsu, M.; Abe, Y. Considerations in Shaft Excavation and Peripheral Ground Deformation. In Geotechnical Aspects of Underground Construction in Soft Ground; ISSMGE: Rotterdam, The Netherlands, 1996. [Google Scholar]

- Aye, T.T.; Tong, M.S.Y.; Yi, K.H.; Arunasoruban, E. Design and Construction of Large Diameter Circular Shafts; Under Ground Singapore: Singapore, 2014. [Google Scholar]

- Tan, Y.; Lu, Y.; Xu, C.; Wang, D. Investigation on performance of a large circular pit-in-pit excavation in clay-gravel-cobble mixed strata. Tunn. Undergr. Space Techno l. 2018, 79, 356–374. [Google Scholar] [CrossRef]

- Tan, Y.; Wang, D. Characteristics of a large-scale deep foundation pit excavated by the central-island technique in shanghai soft clay. I: Bottom-up construction of the central cylindrical shaft. J. Geotech. Geoenviron. Eng. 2013, 139, 1875–1893. [Google Scholar] [CrossRef]

- Njemile, E.F.; Elshafie, M.Z.E.B.; Robert, J.M.; Gerard, Q. Discussion: Case studies of cylindrical shaft construction in London. Proc. Inst. Civ. Eng. Geotech. Eng. 2019, 173, 92. [Google Scholar]

- Qiao, Y.; Xie, F.; Bai, Z.; Lu, J.; Ding, W. Deformation characteristics of ultra-deep cylindrical shaft in soft soil: A case study. Undergr. Space 2024, 16, 239–260. [Google Scholar] [CrossRef]

- Gao, X.; Tian, W.; Zhang, Z. Analysis of deformation characteristics of foundation-pit excavation and cylindrical wall. Sustainability 2020, 12, 3164. [Google Scholar] [CrossRef]

- Ren, B.; Zhu, H.; Shen, Y.; Zhou, X.; Zhao, T. Deformation monitoring of ultra-deep foundation excavation using distributed fiber optic sensors. IOP Conf. Ser. Earth Environ. Sci. 2021, 861, 072057. [Google Scholar] [CrossRef]

- Ren, B.; Shen, Y.; Zhao, T.; Li, X. Deformation monitoring and remote analysis of ultra-deep underground space excavation. Undergr. Space 2023, 8, 30–44. [Google Scholar] [CrossRef]

- Wu, Y.-X.; Shen, S.-L.; Yuan, D.J. Characteristics of dewatering induced drawdown curve under blocking effect of retaining wall in aquifer. J. Hydrol. 2016, 539, 554–566. [Google Scholar] [CrossRef]

- Zhao, G.-Q.; Yang, Y.-Y.; Meng, S.-Y. Failure of circular shaft subjected to hydraulic uplift: Field and numerical investigation. J. Cent. South Univ. 2020, 27, 256–266. [Google Scholar] [CrossRef]

- Liao, S.; Wei, S.; Tan, Y.; Liu, J. Field performance of large-scale deep excavations in Suzhou. Chin. J. Geotech. Eng. 2015, 37, 458–469. (In Chinese) [Google Scholar]

| Code | Excavation Stage | Completion Date (Shaft No.1) | Completion Date (Shaft No.2) | Code | Excavation Stage | Completion Date (Shaft No.1) | Completion Date (Shaft No.2) |

|---|---|---|---|---|---|---|---|

| b1 | Construct crown beam | 10 May 2022 | 13 Apr 2022 | b7 | Construct inner lining 3 | 12 Aug 2022 | 21 Jul 2022 |

| a2 | Second-layer earth excavation | 10 May 2022 | 22 Apr 2022 | a8 | Eighth-layer earth excavation | 16 Aug 2022 | 26 Jul 2022 |

| b2 | Construct ring beam 1 | 04 Jun 2022 | 30 Apr 2022 | b8 | Construct inner lining 4 | 27 Aug 2022 | 03 Aug 2022 |

| a3 | Third-layer earth excavation | 09 Jun 2022 | 06 May 2022 | a9 | Ninth-layer earth excavation | 01 Sep 2022 | 08 Aug 2022 |

| b3 | Construct ring beam 2 | 19 Jun 2022 | 16 May 2022 | b9 | Construct inner lining 5 | 14 Sep 2022 | 06 Sep 2022 |

| a4 | Fourth-layer earth excavation | 24 Jun 2022 | 20 May 2022 | a10 | Tenth-layer earth excavation | 19 Sep 2022 | 08 Sep 2022 |

| b4 | Construct ring beam 3 | 30 Jun 2022 | 31 May 2022 | b10 | Construct inner lining 6 | 23 Sep 2022 | 21 Sep 2022 |

| a5 | Fifth-layer earth excavation | 02 Jul 2022 | 09 Jun 2022 | a11 | Eleventh-layer earth excavation | 19 Oct 2022 | 23 Sep 2022 |

| b5 | Construct inner lining 1 | 17 Jul 2022 | 19 Jun 2022 | b11 | Construct inner lining 7 | 31 Oct 2022 | 02 Oct 2022 |

| a6 | Sixth-layer earth excavation | 19 Jul 2022 | 27 Jun 2022 | a12 | Twelfth-layer earth excavation | 04 Nov 2022 | 05 Oct 2022 |

| b6 | Construct inner lining 2 | 17 Jul 2022 | 07 Jul 2022 | b12 | Construct base plate | 27 Nov 2022 | 21 Oct 2022 |

| a7 | Seventh-layer earth excavation | 03 Aug 2022 | 14 Jul 2022 | c | Construct main structure | 15 Jan 2023 | 27 Nov 2022 |

| Monitoring Items | Quantity | Location of Measurement Points | Monitoring Instruments | Monitoring Frequency | |

|---|---|---|---|---|---|

| Inclinometry | 6 for each | Located in the groove sections 3#, 8#, 11#, 15#, 18#, and 23# of the diaphragm wall (The positions of groove sections 3#, 8#, 11#, 15#, 18#, and 23# are shown in Figure 2a) | Inclinometer (Leica TCA1201+) | Once a day | |

| Extra-Pit Groundwater Level | 4 for each | Respectively located along the outer edges of the north, south, east, and west side walls of the foundation pit | Water Level Meter | ||

| Surface Settlement | Shaft No.1 | 6 × 8 | A total of 6 sections, each containing 8 measurement points. The intervals between measurement points are 3 m, 6 m, 8 m, 12 m, 20 m, 20 m, 20 m, and 20 m successively | Level Meter (Trimble DiNi03) | |

| Shaft No.2 | 6 × 5 | A total of 6 sections, each containing 5 measurement points. The intervals between measurement points are 8 m, 10 m, 16 m, 24 m, and 38 m successively | |||

| Vertical Displacement of the Retaining Wall | 6 for each | Located in the groove sections 3#, 8#, 11#, 15#, 18#, and 23# of the diaphragm wall | Total Station (Trimble DiNi03) | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tang, P.; Fan, X.; Chai, W.; Liang, Y.; Yan, X. Deformation Analysis of 50 m-Deep Cylindrical Retaining Shaft in Composite Strata. Sustainability 2025, 17, 6223. https://doi.org/10.3390/su17136223

Tang P, Fan X, Chai W, Liang Y, Yan X. Deformation Analysis of 50 m-Deep Cylindrical Retaining Shaft in Composite Strata. Sustainability. 2025; 17(13):6223. https://doi.org/10.3390/su17136223

Chicago/Turabian StyleTang, Peng, Xiaofeng Fan, Wenyong Chai, Yu Liang, and Xiaoming Yan. 2025. "Deformation Analysis of 50 m-Deep Cylindrical Retaining Shaft in Composite Strata" Sustainability 17, no. 13: 6223. https://doi.org/10.3390/su17136223

APA StyleTang, P., Fan, X., Chai, W., Liang, Y., & Yan, X. (2025). Deformation Analysis of 50 m-Deep Cylindrical Retaining Shaft in Composite Strata. Sustainability, 17(13), 6223. https://doi.org/10.3390/su17136223