1. Introduction

1.1. Context and Problem Statement

In the context of global sustainability initiatives, the United Nations SDGs—particularly SDG 9 (Industry, Innovation and Infrastructure) and SDG 12 (Responsible Consumption and Production)—highlight the need for resource-efficient industrial systems. Kazakhstan ranks 77th among 141 countries in global sustainability indices, indicating both progress and untapped potential for sustainable industrial transformation [

1].

The mining industry generates significant amounts of waste, and reverse supply chains (RSC) are increasingly studied to transform waste into resources. Strengthening the RSC in the mining sector directly contributes to these goals by advancing resource recovery, innovation, and responsible waste management.

Mining industry waste has been found to hold significant residual value, creating opportunities for resource recovery and economic benefit. As a result, the optimization of RSCs in the sector has emerged as a critical area of research. RSCs, which focus on the management and recycling of products and materials after their initial use, are essential for mitigating the environmental impact of mining activities and improving resource efficiency [

2]. Recent studies have demonstrated that digital technologies play a transformative role in improving supply chain resilience and sustainability. Machine learning and artificial intelligence have been applied to predict disruptions and optimize logistics operations, reinforcing the concept of “digital intelligence” in modern supply chain management [

3,

4]. Within the mining industry, these technologies enable data-driven optimization of reverse flows, enhancing decision-making accuracy and environmental traceability. The integration of Industry 4.0 and emerging Industry 5.0 paradigms promotes transparent, human-centered, and sustainable logistics networks [

5,

6].

However, the complexity of reverse logistics in the mining sector presents unique challenges, including geographical, logistical, and operational constraints, which require tailored optimization strategies.

Recent analyses of reverse logistics implementation in developing economies underline that beyond operational and geographical limitations, institutional and infrastructural barriers also hinder the transition toward circular practices. Factors such as lack of strategic planning, inadequate regulatory support, and limited awareness among stakeholders are recognized as key obstacles preventing the effective adoption of reverse logistics systems. Addressing these barriers is essential to enable sustainable transformation and to align reverse supply chains with circular economy objectives [

7].

Existing research has highlighted the potential of reverse supply chains in various industries, but mining poses unique challenges due to the scale of waste streams and logistical constraints. This makes it necessary to critically assess how global approaches can be adapted to the specific context of Kazakhstan.

This research seeks to address these challenges by developing a mathematical model specifically designed to enhance RSC operations for the strategic exploitation of mining waste in Kazakhstan, leveraging its potential to unlock economic and environmental value.

From a circular economy perspective, mining waste represents an underutilized secondary resource that can be valorized through recovery, recycling, and waste-to-energy processes [

8,

9]. The circular mining framework emphasizes not only material reuse but also environmental rehabilitation and community engagement as part of the social license to operate. Studies on developing economies underline that regulatory gaps, infrastructural limitations, and financial constraints remain key barriers to adopting circular business models [

10]. In Kazakhstan, these challenges are particularly acute due to the absence of established waste valorization infrastructure and limited industrial symbiosis initiatives.

Kazakhstan’s mining sector is a key driver of the national economy, yet it faces substantial challenges related to waste management and resource recovery [

11]. The country’s vast and varied mining operations generate significant quantities of waste, and effective reverse logistics are essential for minimizing environmental impacts and maximizing resource recovery. Despite the importance of these operations, there is a lack of localized models and methodologies that account for Kazakhstan’s unique environmental, economic, and regulatory conditions [

12]. This research seeks to address this gap by developing a mathematical model that incorporates these local factors to optimize RSC processes.

Existing literature highlights various approaches to RSC optimization, including the use of mathematical and simulation models to address general challenges in waste management and resource recovery [

13,

14]. These models often rely on global best practices, which may not fully capture the specific needs and constraints of Kazakhstan’s mining sector. By focusing on localized solutions, this research aims to refine these models and propose new optimization techniques that are better suited to the region’s unique conditions.

While previous studies provide valuable methodological insights, most are grounded in contexts where regulatory frameworks and market demand already exist. Such assumptions limit their transferability to Kazakhstan, where reverse supply chains remain undeveloped and industrial waste recovery is not institutionalized.

Furthermore, technological advancements play a crucial role in optimizing RSCs. Recent innovations in digital technologies, such as IoT and big data analytics, offer new opportunities for enhancing reverse logistics operations [

15]. These technologies do not alter the structure of mathematical models directly, but they expand the variety and accuracy of parameters that can be incorporated, thereby improving the realism and robustness of optimization results.

This study aims to contribute to the growing body of knowledge on RSC management by providing a detailed and localized mathematical model for Kazakhstan’s mining sector. The mining industry in Kazakhstan plays a crucial role in the national economy, but it faces significant challenges related to waste management and resource recovery, highlighting the need for innovative approaches tailored to local conditions [

16]. By bridging the gap between global practices and local realities, the research seeks to offer actionable insights and strategies for optimizing RSCs. This aligns with prior studies that emphasize integrating environmental and economic considerations into mining practices to support sustainability and resource efficiency.

By positioning this study within the gap between global best practices and local realities, we critically evaluate how optimization models must be redefined when no prior infrastructure or demand-side structures exist. This framing allows us to establish the novelty of the proposed model and its contribution to the literature. The implementation of effective RSC strategies in Kazakhstan’s mining sector holds immense potential for both economic and environmental benefits. Economically, the recovery and recycling of materials from industrial waste can create new revenue streams, reduce raw material costs, and foster the development of a circular economy [

17]. Environmentally, proper waste management can significantly reduce pollution, minimize land use for waste disposal, and contribute to the conservation of natural resources. In the context of Kazakhstan, where the mining industry is a crucial economic driver, these benefits can have far-reaching impacts on sustainable development and competitiveness in the global market [

18].

1.2. Research Gap

Despite the availability of global frameworks for reverse supply chain operations, there remains a significant gap in research that addresses the specific challenges and conditions of Kazakhstan’s mining industry. The existing literature tends to focus on generalized models applicable to larger markets [

19,

20,

21], yet it lacks localized frameworks that consider Kazakhstan’s unique environmental, regulatory, and resource-based complexities. Kazakhstan’s mining sector, with its distinct geographic and climatic conditions, presents unique logistical challenges that are not sufficiently addressed by global models designed for different environmental and industrial contexts.

This gap underscores the need for research dedicated to developing and validating localized models and performance metrics that evaluate the economic and environmental impacts of reverse supply chains in Kazakhstan’s mining sector [

22]. Specifically, research must adapt global best practices to Kazakhstan’s regulatory framework, resource distribution, and waste management needs to foster optimized and sustainable operations. The primary objective of this study is to develop an optimization model that is customized to Kazakhstan’s industrial waste management in mining, identifying waste types, assessing value recovery potential, and providing strategic guidelines for policymakers and industry stakeholders.

This critical gap demonstrates that existing models cannot simply be transferred. Instead, they require redefinition of core assumptions, such as demand, waste availability, and budget constraints, to reflect Kazakhstan’s reality. Unlike regions where reverse supply chain practices are already institutionalized, Kazakhstan currently lacks an established framework for industrial waste recovery in mining. Therefore, the proposed model goes beyond simple geographical localization: it adapts general RSC optimization principles to an environment without existing infrastructure, regulations, or market demand for recycled materials. This requires re-defining baseline assumptions in the objective function (e.g., absence of customer demand, full allocation to processing) and tailoring constraints (e.g., budgetary feasibility, minimum processing volumes) to reflect the national context.

The economic component of this study is designed as an early-stage feasibility assessment rather than a full cost-accounting framework. This choice reflects the current development stage of reverse logistics in Kazakhstan, where waste segregation systems, processing capacities, and market-based price signals for secondary materials are not yet established. In such conditions, detailed cost allocation models offer limited explanatory value, whereas a consolidated representation of dominant cost drivers provides more relevant insights for early strategic planning. Accordingly, the model focuses on structural system behavior—long-distance transport, conversion efficiency, and aggregated processing costs—allowing the analysis to capture the fundamental economic dynamics of an emerging reverse supply chain.

Within this scope, the study develops an early-stage optimization framework aimed at identifying key operational constraints and evaluating system-level feasibility, rather than producing a fully elaborated economic model. This framing ensures that the results are interpreted appropriately—as conceptual insights into system behavior under current infrastructural conditions.

2. Background and Case Context

The literature review is organized as follows: first, general studies on reverse supply chains (RSC) are introduced; second, models focusing on waste recycling in the mining sector are discussed; third, we highlight gaps in the Kazakhstan context, which motivate the present study.

2.1. Mining Waste Management in Kazakhstan

Previous research on reverse logistics and supply chains has primarily concentrated on sectors such as electronics, automotive, and textiles. These contexts differ substantially from mining, particularly in terms of waste heterogeneity, transport distances, and lack of established recycling markets. In Kazakhstan, the vast geographical and geological diversity results in a wide range of mining activities, from copper and zinc extraction to uranium and gold mining. These mining processes generate significant amounts of tailings, which are typically stored in tailing dams located near the mining sites.

Tailing dams are critical structures in mining operations, designed to store the waste materials, or tailings, generated during ore extraction and processing [

23]. This work will focus on tailing dams and their optimal operation to address the growing concerns over their structural integrity and the environmental impact they have on surrounding ecosystems [

24,

25], particularly in Kazakhstan’s diverse geographical landscape.

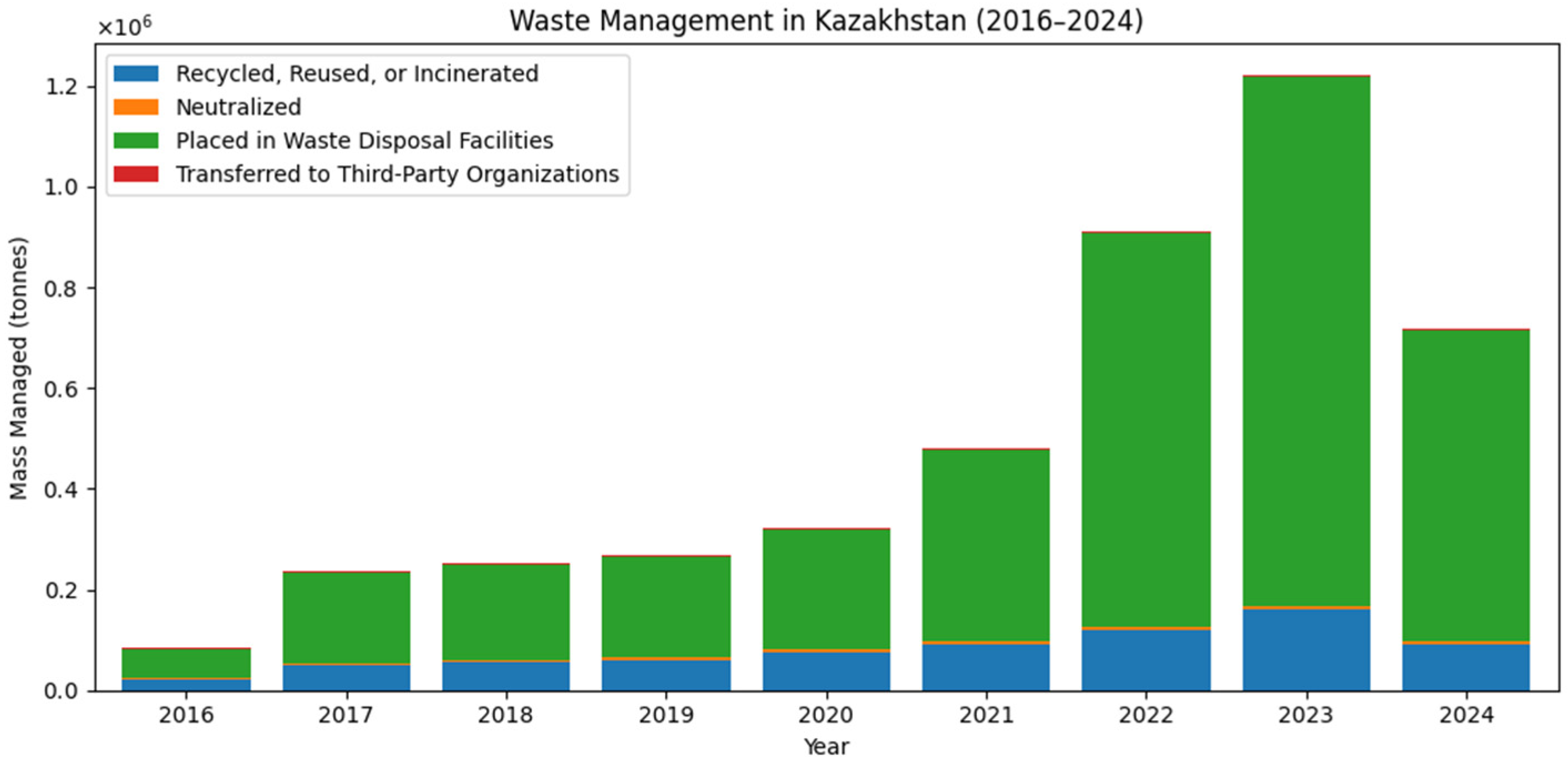

Figure 1 presents an overview of waste management trends in Kazakhstan over the period from 2016 to 2023. It highlights the total amount of waste managed annually, along with detailed categories showing the volumes of waste that were recycled, reused, incinerated, neutralized, or placed in disposal facilities. The category ‘Placed in Waste Disposal Facilities’ refers to waste that is disposed of in specially designated tailing dams or industrial landfills, where no recycling or further processing is carried out. Additionally, it includes the amount of waste transferred to third-party organizations for processing or disposal.

According to the RSE “Information and Analytical Center for Environmental Protection” under the Ministry of Ecology, Geology, and Natural Resources of the Republic of Kazakhstan, as derived from the State Cadastre of Production and Consumption Waste, the reported data exclude technogenic mineral formations as well as surface effusive and intrusive sedimentary rocks of various ages (overburden rocks).

2.2. Data Collection and Case Description

Building on this understanding of Kazakhstan’s waste management framework, the study focuses on optimizing the reverse supply chain for mining waste. Ten key tailing dams located across Kazakhstan have been selected as focal points for this analysis. These tailing dams were chosen based on their strategic importance, the volume of waste generated, and their geographical distribution, which poses significant logistical challenges. The objective is to streamline waste transport and processing through an optimized route design, reducing costs and improving resource recovery.

The following

Table 1 provides an overview of the key tailing dams in Kazakhstan and Kyrgyzstan, their geographical locations, the specific mining activities associated with each site, and the types of waste materials stored in these dams. This table highlights the diverse nature of mining waste management across the region, which requires tailored approaches to ensure environmental sustainability and operational safety.

As shown, the mining industry in the region primarily deals with polymetallic ores, copper, and gold, all of which produce large volumes of tailings that must be carefully managed. Each tailing dam is associated with specific types of mining byproducts, which underscores the need for tailored waste management strategies based on the type of material being stored.

Recycling and waste treatment facilities are primarily concentrated near urban centers and industrial hubs. However, the vast distances between mining sites and these facilities pose significant logistical challenges for reverse supply chain operations.

The spatial distribution of these tailing dams and their connection routes are illustrated in

Figure 2, which visualizes the geographical spread of mining operations and the designated transportation network.

Data used in this testing were collected from historical records of mining operations in Kazakhstan, including cost data for transportation, processing, and waste disposal. The following table provides key data for these selected tailing dams, including their names, index numbers, and the transportation distances to the processing center. This data serves as the input for the mathematical model, which aims to optimize the logistics involved in the reverse supply chain operations.

The data outlined in

Table 2 serves as the foundational input for the optimization of the reverse supply chain model. By integrating historical cost information and transportation distances, the model can accurately simulate the logistics involved in transporting mining waste from tailing dams to processing centers. The study was conducted within an experimental project framework, in which selected tailing dams were defined as the research basis. This setting allows the model to focus on testing the feasibility of in-house waste recycling under controlled conditions.

This contextual overview provides the empirical foundation for the subsequent optimization model.

The following section reviews relevant theoretical and methodological approaches in reverse supply chain optimization and circular economy frameworks that inform the model design.

4. Methodology

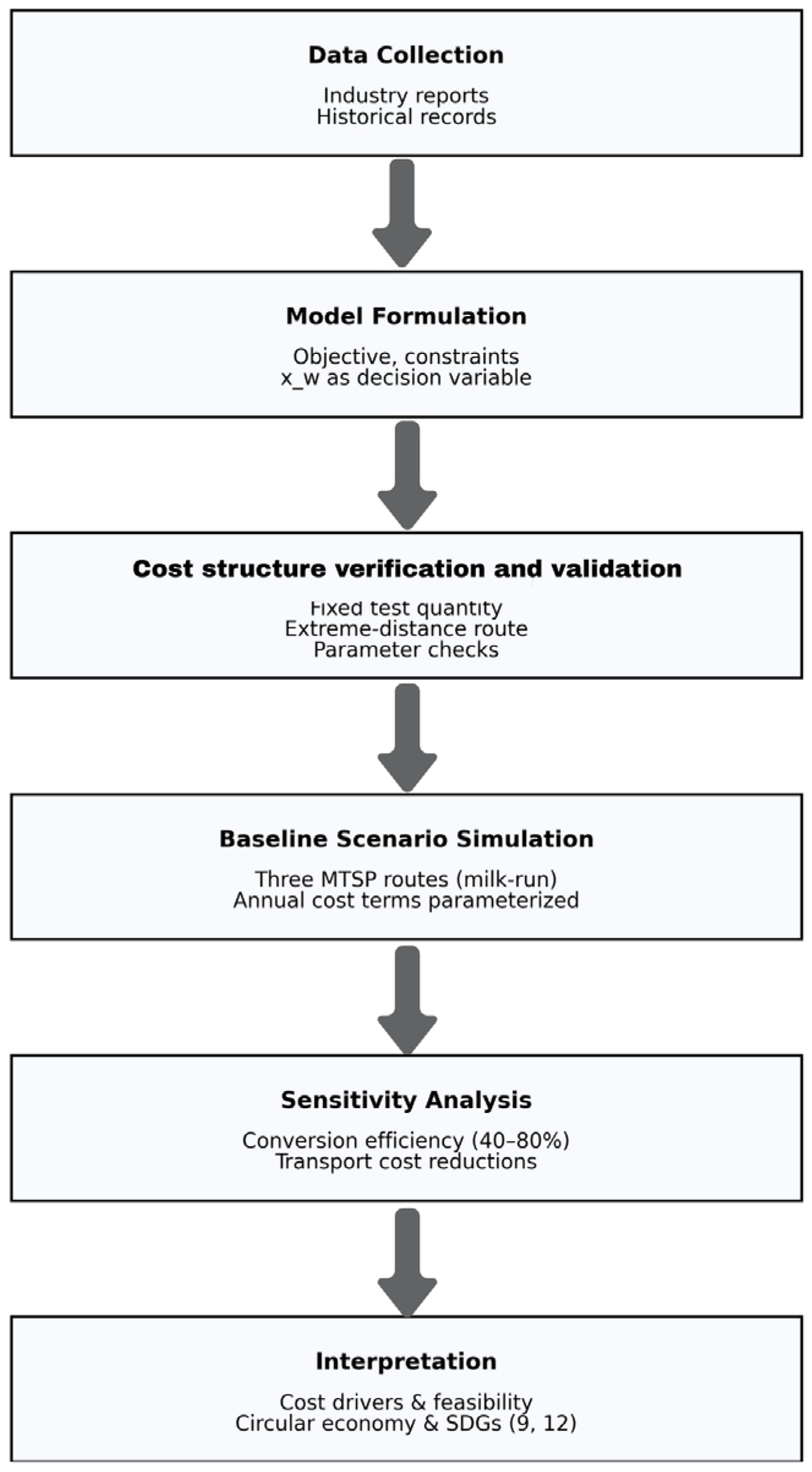

The methodological framework of this study was designed to evaluate the feasibility and cost-effectiveness of reverse supply chain operations for mining waste in Kazakhstan. The research process consisted of two main stages: a cost structure verification test, which served as a proof-of-concept test under simplified conditions, and a baseline scenario, which represented a network-level configuration with multiple routes.

Figure 3 illustrates the sequential stages of the study, beginning with data collection and progressing through model formulation, cost structure verification and validation, baseline simulation, and sensitivity analysis. It clarifies the relationship between the cost structure verification and the baseline scenario, where the cost structure verification served as a proof-of-concept for parameter verification, while the baseline extended the model to multiple routes and aggregated waste volumes. The final interpretation stage connects the findings to cost feasibility, circular economy principles, and the Sustainable Development Goals (SDGs 9 and 12).

The main objective of this study is to develop an exploratory optimization framework to evaluate system-level economic behavior under aggregated cost drivers. To parameterize this framework, illustrative data were compiled from real-world industry sources, including annual reports from major mining companies in Kazakhstan and government statistics on industrial waste generation and management. The annual reports from KAZ Minerals [

32] and Kazakhmys [

31] provide detailed information on copper and polymetallic extraction volumes as well as operational efficiency metrics, which are essential for determining waste generation rates.

Transportation cost minimization was achieved by integrating distance-based parameters between waste sources and recycling facilities. The total transportation cost function (Equation (2)) follows a previously validated methodological framework [

40] that highlights the significance of transportation distance and unit cost in overall efficiency.

Moreover, the inclusion of a CO

2 taxation factor fosters sustainability within the reverse supply chain, aligning environmental incentives with economic performance [

41].

The transportation network is represented through three exogenous heuristic routes (Kokshetau in the North, Ridder in the East, Bozymchak in Kyrgyzstan in the South), each starting and ending at the processing center.

The Almaty recycling center used in this study does not represent an established industrial facility but rather a pilot-scale testing installation selected for experimental modeling purposes. Its inclusion serves to demonstrate the feasibility of reverse logistics under controlled conditions, rather than to reflect existing national infrastructure. While this assumption simplifies the model by defining a single processing point, future extensions will explore optimal facility location through a center-of-gravity approach to minimize transportation costs.

Transportation costs are captured through the consolidated cost function (Equation (10)), which avoids redundancy and ensures consistency across scenarios.

Although the processing stage resembles a forward supply chain, the defining characteristic of this system is that its flows originate from industrial waste rather than from primary raw materials. This distinction justifies its classification as a reverse supply chain, as the primary objective is resource recovery and waste reduction rather than the delivery of new products [

36].

To streamline operations and minimize costs in the reverse supply chain, Linear Programming (LP) techniques were employed. This mathematical optimization approach enabled the systematic allocation of resources and the optimization of logistics processes by solving for the best possible outcomes under a set of defined constraints.

The key parameters used in the optimization model are summarized in

Table 3, including their definitions, units, value ranges, and data sources.

Some parameter values are confidential due to company data restrictions. Approximate ranges or qualitative sources are provided where exact figures cannot be disclosed.

4.1. Formulation of a Mathematical Model

Recycle center p’s utility function is denoted by F. The objective of the recycle center p is to maximize its utility represented by the total revenue minus all total costs of the reverse supply chain network while satisfying various constraints. The model aims to optimize reverse supply chain network design for recycling production waste material.

In this model, xw is defined as the key decision variable representing the total amount of waste processed within the reverse supply chain. The objective function F(xw) maximizes the net profit by determining the optimal processing quantity under transportation, processing, and budgetary constraints. This formulation ensures that directly influences cost and revenue components across all relations.

The initial Cost Structure Verification test was conducted to examine the internal consistency of parameter interactions. Unlike a full optimization, this stage did not aim to determine an optimal value of xw but to verify the proportional relationships among transportation, processing, and fixed costs. In the final model, xw remains an endogenous variable solved through optimization.

The objective function (Equation (1)) includes costs such as Incoming transportation cost (Ctin), operating cost (Cop), fixed operational costs (Cof), outcoming transportation costs (Ctout), carbon tax cost for emissions (CO2fuel) and revenue from selling the recycled product (P). Storage cost (Cstr) and equipment cost (Ceq) are parameters that do not need to be calculated, as they will be given. The result is the total profit or utility that the recycling center can achieve. Unit cost refers to 1 ton of waste.

The notations used in the model are presented in

Appendix A,

Table A1, for clarity and reference.

The Cost Structure Verification serves as an initial structural check that explores how the model behaves under simplified and extreme parameter settings. Building on these preliminary insights, the baseline scenario applies the framework to a sector-wide context by incorporating multiple transportation routes and examining system-level cost patterns. Together, these stages outline the model’s exploratory capabilities without implying full operational validation.

4.2. Assumptions for the Model Parameters

*The proposed Cost Structure Verification model involves one type of waste from one tailing dam.

*During transportation, the lead time is known and constant for the entire supply chain.

*A Cost Structure Verification implementation of the mathematical model was conducted using the route from the most distant tailing dam to the recycling center. This initial test focused on a single, unidirectional route to evaluate the model’s performance.

*For the current phase of the reverse supply chain model, there are no specific customers or demand points for the processed materials. The outbound transportation cost equation has been adjusted to reflect the transport of processed waste from the processing center to a general output location or storage. This model assumes that all collected waste is processed and transported without differentiation between different types of end destinations. Future expansions of the model could introduce parameters for customers or markets for the processed materials.

*The model assumes homogeneous waste composition across all mining sites. This simplification enables focus on logistical and economic optimization rather than compositional variability, which will be addressed in future work once detailed material data become available.

*In the finalized optimization model, however, the processed waste quantity (xw) is treated as a decision variable, allowing the model to determine the economically optimal processing volume under given cost and budget constraints. The Cost Structure Verification, therefore, serves as a verification case rather than a fixed assumption.

The optimization model for reverse supply chain operations in Kazakhstan’s mining sector is presented as follows:

This function represents a simplified economic performance indicator based on aggregated cost and revenue terms.

The model is defined within an annual framework, with all cost and revenue parameters expressed on a yearly basis (USD/year). This time aggregation supports an exploratory assessment of system-wide cost behavior at an annual scale.

The cost parameters in Equations (2)–(9) were defined using standardized unit costs (USD per ton or USD per ton-kilometer) derived from industry benchmarks and available statistical reports. Fixed equipment-related expenditures were represented as an aggregate annual cost term, reflecting typical overhead requirements rather than accounting-based depreciation schedules. This simplified representation is appropriate for an early-stage feasibility model in a context where detailed cost-allocation systems are not yet established.

This approach provides comparability across cost categories and ensures that all values are expressed on an annual basis (USD/year). While these assumptions simplify the real variability of costs, they enable a consistent and transparent economic representation of the reverse supply chain.

This equation represents the total cost of transporting waste materials from the source (tailing dam) to the recycling center.

dwp is the distance between the waste source and the recycling center,

xw is the amount of waste transported, and

Uc are the unit waste collection transport costs. This parameter contributes to the overall cost representation of the system. Because of this aggregation, vehicle capacity constraints and utilization rates are implicitly assumed to be fully satisfied, which may overestimate transport efficiency. Future extensions of the model should relax this assumption by including capacity limitations and temporal distribution of flows.

The operational cost

Cop refers to the variable expenses associated with processing the waste.

ce represents the electricity and energy consumption, and

Convw is the conversion factor for processing waste. This equation is essential for evaluating the operational efficiency of the recycling process.

This fixed cost

Cof includes personnel costs

cper and equipment-related overhead

cam. These are considered static costs that do not vary with the amount of waste processed, but they influence overall profitability.

This equation calculates the cost of transporting the recycled product, sold at a fixed unit price, without differentiating between customers.

Ucout and

Ucoutf are the unit transportation costs, and

dpc is the distance between the recycling center and the customer. This cost depends on the processed quantity of waste and the distances involved, highlighting the logistical complexities in delivering recycled materials to market.

This equation reflects the cost of processing each unit of waste, Cunw. It is directly proportional to the amount of waste (xw) processed at the facility. This parameter is critical for determining the economic feasibility of recycling operations, especially when handling large volumes of waste.

The landfill cost (

Cland) accounts for waste that cannot be recycled and must be disposed of.

Uland and

Utland represent the unit costs of using landfill services,

dland is the distance to the landfill, and Kw is a conversion factor for waste volume. This is a critical factor in determining the environmental and economic costs of non-recyclable waste.

Equation (8) calculates the carbon emissions cost incurred during transportation. fcons is the fuel consumption factor, Ef is the emissions factor, and dp and dpc are distances covered during waste and product transportation, respectively. This cost is a key element in the sustainability assessment of the reverse supply chain.

The model also calculates the carbon emissions from all stages of transportation (Equation (8)).

Finally, the system’s revenues from selling the recycled product depend on the waste material type (Equation (9)). This equation calculates the total revenue from selling recycled products.

pun is the unit price of the recycled material. This revenue contributes directly to the overall profitability of the reverse supply chain.

In this version of the model, wastes from different tailing dams are aggregated and treated as a homogeneous input stream. Consequently, the recycled output is represented as a single generic product, independent of variations in mineral composition. This simplifying assumption enables tractability of the optimization but reduces fidelity with respect to material heterogeneity.

4.3. For the Baseline Scenario

To simplify the transportation cost representation, the three route-specific constraints were consolidated into a single aggregated cost function. This reflects the fact that the routes are treated as exogenous scenarios rather than decision variables. The transportation cost is therefore calculated as follows:

where

dwi denotes the distance (in km) from tailing dam ww to route

I,

xwi is the transported waste flow (t/year) from dam

w assigned to route

i. This formulation preserves cost calculation consistency while reducing redundancy in the mathematical model. The three tours (North, East, South) remain heuristic, exogenous routes with the processing center acting as the common depot.

The set of constraints Equations (11) and (12) are the balance constraints, ensuring that the flow of waste materials remains consistent across all processes. Constraint (11) ensures that the minimum amount of waste processed at any recycling center is at least 1000 kg. This requirement reflects the practical necessity of handling substantial waste volumes to achieve economies of scale in the recycling process. The budgetary constraint (12) ensures that the total costs, including equipment costs (Ceq), operational costs (Cop), and fixed costs (Cof), do not exceed the available budget (Br), thereby maintaining financial feasibility and ensuring that the model’s recommendations align with the operation’s financial limits.

5. Results

This section outlines the key findings derived from the application of the mathematical model, highlighting its impact on waste management processes and the economic benefits of optimized operations. The analysis includes a detailed examination of the core parameters influencing the reverse supply chain, such as transportation costs, processing efficiencies, and waste conversion rates, supported by sensitivity analyses to assess the model’s robustness under varying conditions.

The model additionally estimates transportation-related carbon emissions, which are determined by country-specific emission factors for diesel and electricity. The transportation cost from the waste supplier, the tailing dam itself, to the Recycle Center depends on the amount of waste materials transported, the distance between the tailing dam, and the transportation cost factor. The operational costs consist of the electricity cost and electricity consumption, and depend on the waste material processed. The fixed costs consist of personnel costs and equipment amortization costs per year.

5.1. Cost Structure Verification

Before presenting the main results, an initial Cost Structure Verification was carried out using a simplified single-route configuration to verify the model’s functionality. Specifically, 1 ton of waste from the furthest tailing dam (w4) was transported to the processing center. This exploratory scenario, deliberately chosen to be challenging, aimed to test parameter settings and assess the feasibility of the reverse supply chain model under current logistical conditions. As expected, the outcome was consistent with the aggregated cost structure and showed a net negative profit, reflecting the experimental nature of the run.

This examination served to explore structural model behavior under simplified conditions. This distinction clarifies the experimental nature of the cost structure verification and frames it as a preliminary step toward future validation with empirical data.

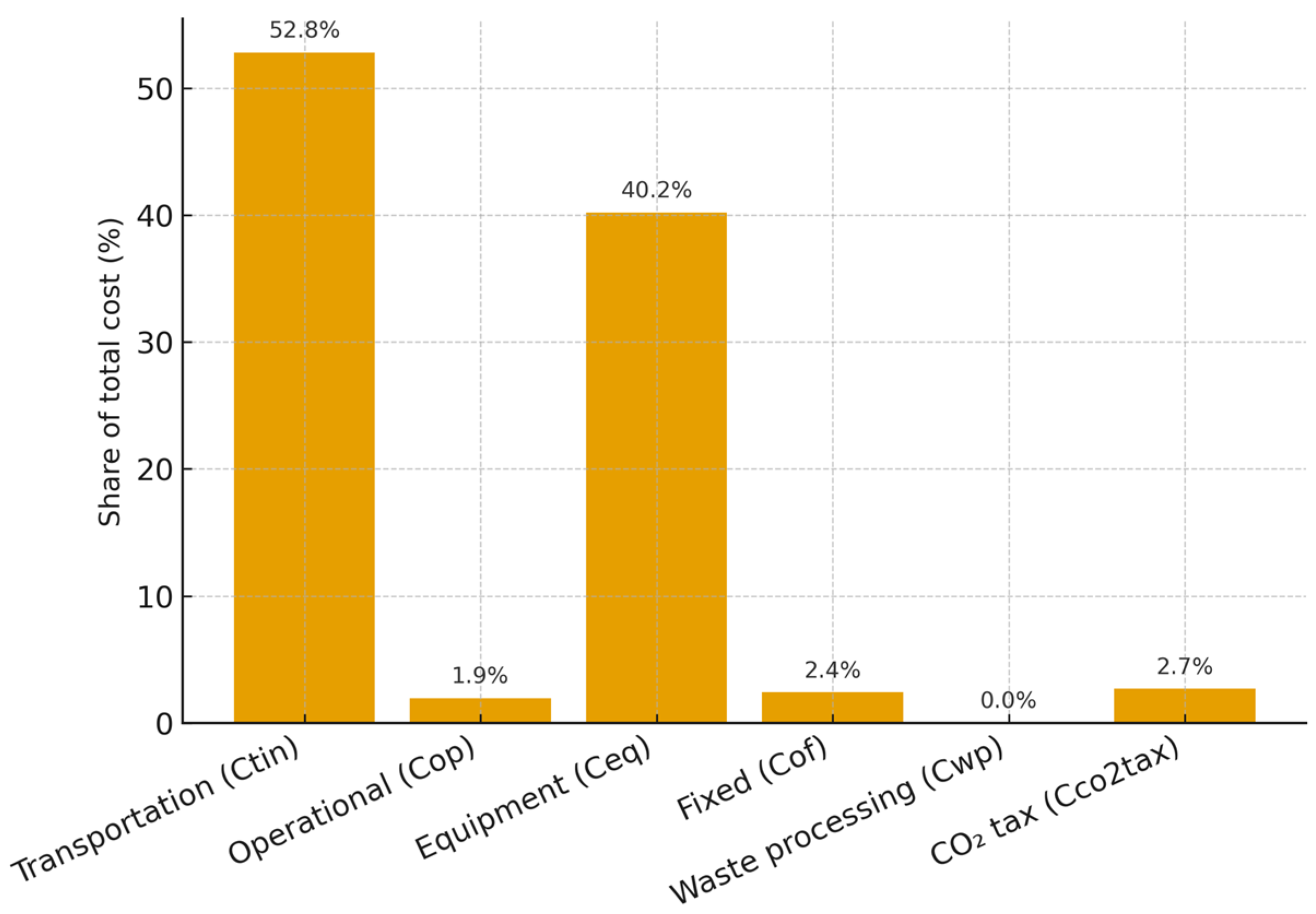

The breakdown of cost components is illustrated in

Figure 4, which summarizes the proportional contribution of transportation, operational, and processing costs within the reverse supply chain. This visualization complements the numerical findings by highlighting the dominance of transportation expenses, confirming that this element is the main cost driver influencing the model’s overall performance

This figure presents the distribution of total annual costs by category under the baseline scenario. Transportation (Ctin) accounts for the largest share, followed by operational (Cop) and equipment maintenance (Ceq) costs. Fixed annualized capital costs (Cof) and CO2 taxation (Cco2tax) represent smaller components. The dominance of transportation costs emphasizes the importance of route optimization and facility location in enhancing overall reverse supply chain performance.

The cost structure verification test has shown that the reverse supply chain model, even at a non-profitable stage, offers important learning opportunities that can guide future model adjustments. This initial analysis helps to define the model’s boundaries and limitations under current conditions, enabling a more informed prediction of how the model might perform in different scenarios or with altered parameters. By refining transportation routes, adjusting conversion rates, or reducing operational costs, the model holds the potential to become profitable under other configurations.

5.2. Assumptions for the Model Parameters for the Cost Structure Verification

To contextualize the findings, it is important to recall several simplifying assumptions that guided the modeling framework. The model presumes a stable and predictable transportation lead time across the reverse supply chain, allowing a controlled evaluation of cost dynamics. For demonstration purposes, the system was initially tested on a single route linking the most distant tailing dam with the recycling center, serving as a proof of concept for the model’s operational feasibility.

Moreover, the current version of the model does not yet differentiate between specific customer or demand nodes for processed materials. Outbound transportation is therefore represented as a generalized flow toward a consolidated destination, consistent with early-stage RSC configurations where market outlets are not yet defined. Future research will extend the framework to include demand-side parameters and differentiated routes for various categories of recycled outputs.

The Cost Structure Verification test involved transporting 1 ton of waste from tailing dam 4 (w4) to the Processing Center, which was deliberately chosen as the furthest tailing dam from the center. Consequently, the transportation costs were disproportionately high, contributing significantly to the overall expenses.

Transportation costs were a critical factor in the negative outcome. To test the model under extreme conditions, the distance between w4 and the Processing Center was maximized. This scenario resulted in high logistical expenses, which were not offset by the revenue generated from the sustainable product.

It should be noted that input parameters, such as transportation rates and conversion efficiency, were adopted from industry-standard estimates. These values were used for experimental validation of the model’s structure rather than for generating final empirical results.

5.3. Baseline Scenario

In the baseline scenario, the model employed the Multiple Traveling Salesman Problem (MTSP) method to define three primary routes for waste transportation. Rather than a single Traveling Salesman Problem (TSP), routing in this study is represented as a multi-stop milk-run setting equivalent to an MTSP with the processing center acting as a common depot. The ten pickup points are partitioned into three tours (North, East, South), each tour starting and ending at the depot. Because our analysis is annual and transport costs are normalized per ton-kilometer, we do not model vehicle capacity, time windows, or detailed schedules; the three tours are treated as exogenous baseline scenarios used to parameterize the transportation cost terms.

In this version, the model explores system-level cost behavior and dominant cost drivers and optimizes flow decisions conditional on a fixed set of routing scenarios, rather than endogenously designing the entire reverse-logistics network. Extending the framework to a capacitated vehicle-routing formulation with endogenous route construction is left for future work.

The routes were strategically selected to cover the most significant geographical areas in Kazakhstan:

The first route starts from Kokshetau in the northernmost part of Kazakhstan, traveling through several intermediate points (Bozshakol, Temirtau, Jairem, Balkhash) on its way to the processing center.

The second route originates in Ridder, located in eastern Kazakhstan, traveling through several intermediate points (Ust’-Kamenogorsk, Maleevka, Aktogai) on its way to the processing center.

The third route originates from Bozymchak, situated in the South within the territory of Kyrgyzstan.

In both the cost structure verification test and the baseline scenario, the conversion factor was varied between 40% and 80%, representing the efficiency of the process in recovering usable materials from the waste. These values were applied to a standard input of 1000 kg of waste, allowing for a consistent evaluation of the model’s performance under different recovery efficiencies. The chosen range of conversion factors reflects realistic scenarios observed in similar reverse supply chain operations, providing a benchmark for the material recovery potential.

It is important to note that in the baseline scenario, three transportation routes were predefined to connect the mining sites with the treatment facility. The model assumes an aggregated waste flow, represented by the decision variable xw, which denotes the total processed volume from all sources. The quantities shipped by individual mines were not separately optimized, as the model focuses on overall system-level cost efficiency under homogeneous waste conditions.

To maintain analytical tractability and focus on system-level performance, the current version of the model assumes homogeneous waste flows aggregated across all mining sites. This simplification allows the identification of dominant cost drivers and operational trade-offs in the early stage of reverse supply chain design.

Future extensions will explicitly incorporate heterogeneous waste compositions and site-level quantities, enabling detailed consolidation and routing analysis once sufficient empirical data become available.

This assumption simplifies the analysis by treating tailings as a uniform material stream and allows the model to concentrate on logistical optimization. The Cost Structure Verification, in contrast, was used to verify computational feasibility under fixed input conditions, whereas the baseline scenario explores network-level optimization under cost and budget constraints. In future work, the model will be extended to incorporate multi-source waste flows and variations in material composition, thereby addressing the current simplification related to the consolidation of heterogeneous inputs.

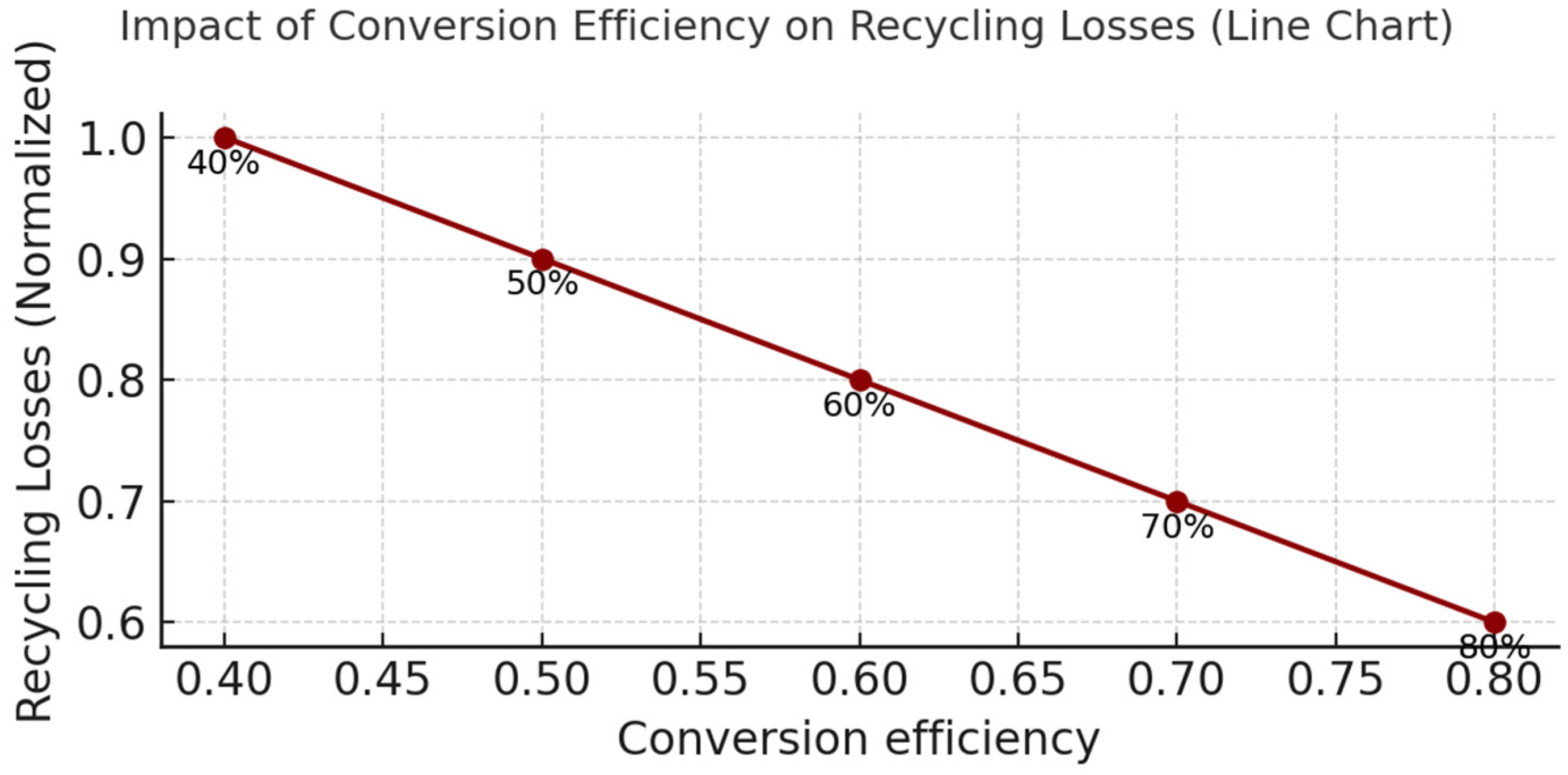

Figure 5 and

Figure 6 illustrate the sensitivity of the model’s profitability to variations in conversion efficiency and transportation costs, respectively. Each figure presents a range of scenarios, enabling a direct comparison of how fluctuations in these factors impact the Recycling losses and overall profit margin.

Figure 5 demonstrates a clear trend: as the conversion factor increases, the losses associated with recycling decrease. Specifically, when conversion efficiency rises from 40% to 80%, the objective function value improves significantly, indicating reduced losses. At 40% conversion efficiency, the model shows the highest losses with substantial negative returns. However, as efficiency increases to 70% and beyond, the losses approach a break-even point.

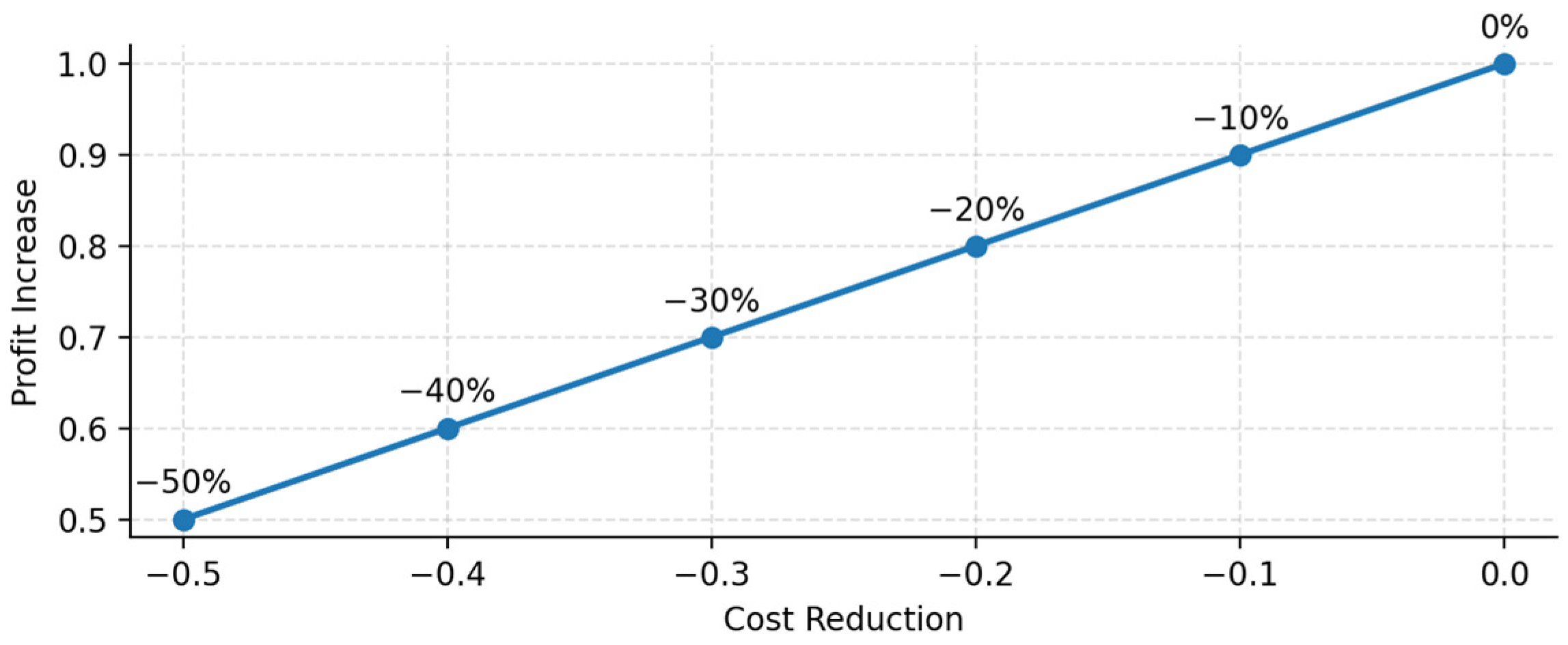

Figure 6 illustrates the impact of transportation cost reductions on profitability, showing that lower transportation costs lead to a decrease in negative profit. This sensitivity analysis was conducted to explicitly address the uncertainty in transportation cost estimation, demonstrating how errors in cost assumptions directly influence profitability outcomes and route selection. As transportation costs decrease progressively by 10% to 50%, the objective function improves, reflecting reduced losses. However, the effect of transportation cost reductions on profitability is less significant compared to the impact of conversion efficiency. While reducing transportation expenses does contribute to improved financial outcomes, even substantial cost reductions result in only marginal improvements, highlighting that conversion efficiency plays a more critical role in achieving profitability.

These results provide strategic insights into the relative influence of transportation costs and conversion efficiency on system profitability, serving as a foundation for more detailed, heterogeneous modeling in future work.

The Almaty recycling center used in this study represents a pilot-scale testing site associated with the research laboratory, rather than an existing industrial facility. Its fixed location was selected to ensure consistency in transportation distance evaluation and to maintain a controlled reference point for parameter calibration. This methodological choice enabled a stable comparison of cost components and operational trade-offs across modeled routes. In future work, the framework will incorporate a dynamic facility-location component based on spatial optimization methods such as the center-of-gravity and clustering approaches, allowing a more realistic evaluation of potential processing center locations.

6. Discussion

This section of the paper reflects on the application of a mathematical model designed to optimize reverse supply chain operations within Kazakhstan’s mining sector. This exercise not only facilitated a deeper understanding of the complexities inherent in such models but also provided practical insights into their implementation in real-world scenarios.

Although both scenarios remain unprofitable under the current assumptions, this comparative analysis illustrates the analytical value of the model. Even with estimated parameters, it helps identify where improvements such as enhanced conversion efficiency or optimized routing can deliver the greatest impact. These findings are not only consistent with prior studies on reverse logistics cost drivers [

32], but also provide strategic insights for policymakers. The results suggest that improving conversion efficiency through investment in processing technologies may yield greater benefits than incremental reductions in transport costs. For companies, the model highlights the strategic value of route optimization, even under limited data availability.

Although the exploratory model yields negative economic outcomes under current assumptions, this outcome highlights a structural barrier rather than a modeling flaw. It reflects the real-life dilemma of reverse supply chain implementation in Kazakhstan, where the absence of dedicated infrastructure, regulatory incentives, and waste classification systems prevents the emergence of economically viable recycling loops. The analysis demonstrates that conversion efficiency is the most influential parameter, suggesting that technological innovation and targeted investment in processing facilities could shift operations toward profitability. For policymakers, these results imply that improving conversion technology and reducing logistical inefficiencies are more effective levers than short-term subsidies. For industry stakeholders, the model provides an evidence-based framework to evaluate when and under what conditions reverse logistics can become self-sustaining. Thus, the findings contribute directly to the identified research gap by showing how economic and institutional constraints interact to shape the feasibility of reverse supply chains in emerging economies.

Beyond economic optimization, the model also contributes to the sustainability dimension of reverse supply chain management. By prioritizing transportation efficiency and integrating CO2 taxation, it directly addresses emission reduction and supports environmentally responsible decision-making. The optimization of routes and processing capacities promotes energy savings and reduces the carbon footprint of logistics operations.

Our findings—that transportation costs and conversion efficiency are the primary drivers of profitability are consistent with earlier reverse supply chain models by Govindan et al. [

2] and Sonar et al. [

7], which similarly identified cost structures and technology efficiency as decisive sustainability factors.

However, most existing RSC frameworks assume pre-existing recycling infrastructure and mature regulatory environments. By contrast, the present study contributes a context-specific model tailored to conditions where such infrastructure is absent, thereby extending RSC optimization to developing-country settings such as Kazakhstan.

This aligns with Ndoka et al. [

10] and Jose et al. [

8], who emphasize that establishing resource-recovery capacity is a prerequisite for achieving SDG 9 and SDG 12 targets in resource-based economies.

From a circular economy perspective, the framework facilitates waste valorization by enabling the reintegration of mining by-products into production cycles instead of disposal. This transformation of tailings into secondary resources reduces the environmental burden of waste accumulation and supports long-term resource efficiency. In contexts such as Kazakhstan—where infrastructure for reverse logistics is still developing—such a model provides a pathway toward more sustainable industrial operations.

The novelty of this work lies in structuring an RSC optimization framework for a context where no reverse supply chain practices currently exist in the mining sector. This contrasts with most existing models, which assume pre-existing infrastructure and operational frameworks.

The process began with the setup of the mathematical model using Excel. While Excel was selected for accessibility and demonstration purposes, additional verification of the optimization equations was carried out in Python 3.12, which provided higher computational reliability. This dual approach ensured that the findings are robust while maintaining transparency and replicability. The model was configured to simulate various operational scenarios within the reverse supply chain, using data collected from industry reports and historical records.

The cost structure verification highlighted the sensitivity of the model to input parameters, such as transportation distances and costs. This approach provided a deeper understanding of the logistics challenges involved and demonstrated the model’s ability to identify cost-intensive factors.

This model could be expanded to incorporate specific time parameters, such as short-term processing lead times, transportation durations, and long-term operational schedules. By integrating time-based metrics into the analysis—such as cycle time, idle time, and overall system throughput—the model would provide a more detailed framework for scheduling optimization and resource allocation. This would enable the identification of bottlenecks, delays, and efficiency gaps across the reverse supply chain. Additionally, analyzing time-dependent operational impacts would enhance the model’s ability to project long-term outcomes, such as cumulative costs and performance improvements over extended periods. Another limitation concerns the use of estimated parameters. For instance, conversion rates were adopted from industry averages and may not fully capture differences in the mineral composition of specific tailings. Nevertheless, the inclusion of sensitivity analyses demonstrates how variations in these parameters affect profitability, thereby enhancing the robustness of the findings. Overall, this study provides a foundational framework that can be refined in future work by incorporating comprehensive datasets, including real-time operational data and seasonal variability, to improve accuracy, scalability, and practical applicability of reverse supply chain optimization.

The cost structure verification test illustrated the feasibility of implementing such a model to support decision-making processes in the mining industry. Although the cost structure verification focused on one type of waste and one transportation route, the findings are promising and suggest that similar strategies could be expanded to include a broader range of waste types and operational settings.

Reflecting on the process, it was evident that while mathematical models provide valuable predictive insights, their accuracy and usefulness are heavily dependent on the underlying assumptions. This realization prompts a more cautious approach to relying solely on theoretical models without considering real-world variabilities.

While core variables such as transportation and processing costs appear common across RSC models, in Kazakhstan’s case, they are redefined to operate under conditions of institutional and infrastructural absence. This makes the framework a first step toward bridging the gap between theoretical models and an industry where reverse supply chain operations are not yet implemented.

In summary, by aligning operational efficiency with environmental and resource-management objectives, the proposed model supports the implementation of SDG 9 and SDG 12 within the mining sector.

6.1. Limitations

This reverse supply chain optimization model, though comprehensive in its current form, has certain limitations that influence its immediate applicability and point to areas for future enhancement. One primary limitation is the reliance on estimated transportation rates, as precise multi-stop route costs are not available from transport companies. In addition, conversion factors and operational costs were derived from industry-standard benchmarks rather than site-specific trials. This approach reflects the exploratory stage of the research. While such estimates reduce precision, they are common in early-stage supply chain modeling [

30]. The sensitivity analyses included in this paper address these uncertainties by illustrating the impact of parameter variations on profitability. This approximation impacts the accuracy of transportation cost projections, particularly across the three distinct routes modeled in the study. While single-route rates provide a foundation for estimating costs, a more accurate multi-stop cost analysis would enhance the model’s reliability, especially in evaluating the economic feasibility of each route.

Additionally, the absence of detailed time parameters restricts the model’s capability to assess time-dependent factors such as processing delays, seasonal fluctuations in transport availability, and long-term scheduling. By not incorporating a time dimension, the model cannot currently address dynamic factors that might influence the reverse supply chain over different operational periods. Expanding the model to include time-based variables would allow for a more granular analysis, enabling planners to better account for processing efficiency over time and optimize resource allocation in response to temporal constraints.

The model’s simplicity in estimating the conversion factor is a notable limitation. Without initial processing trials or empirical data from waste-to-recycle conversion tests, the model relies on industry-standard estimates. This assumption may not fully reflect the specific material composition of waste from the selected tailing dams, potentially impacting revenue projections. A more precise conversion rate, informed by verification testing or waste composition analysis, would provide a stronger basis for revenue estimation and improve the model’s predictive accuracy regarding profitability.

A limitation of this study is the assumption of guaranteed waste availability in the tailing dams. While this reflects the experimental setting of the project, where selected dams were provided as the basis for testing the model’s feasibility, it abstracts from the interdependencies between mineral extraction schedules and waste generation. Future extensions should incorporate variability in waste generation to more closely align the model with operational realities.

By including sensitivity analysis for transportation costs, the model provides insights into the degree of robustness of optimization outcomes under varying cost assumptions. Although precise multi-stop transport rates were unavailable, the analysis illustrates how transportation costs remain a critical driver of profitability.

One primary limitation of this study concerns the reliance on estimated parameters, such as transportation rates and conversion efficiencies. Since no empirical data were available, industry-standard benchmarks were applied. While this approach reduces precision, it is commonly used in early-stage modeling and allows for exploratory analysis. To partially mitigate this limitation, sensitivity analyses were performed to illustrate how variations in these parameters affect profitability outcomes.

Another limitation is that the model operates at an annual level of aggregation, which implicitly assumes full utilization of transport capacities. While this provides a high-level profitability estimate, future research should incorporate capacity constraints and time-dependent scheduling to improve accuracy.

A major limitation of this study is its focus on a single waste type and a single transportation route. Kazakhstan’s mining sector is characterized by diverse minerals, geographically dispersed sites and heterogeneous waste compositions. Future iterations of the model should incorporate multiple waste streams, multimodal transport, and spatial distribution to enhance generalizability and practical applicability.

The model also relies on simplifying assumptions regarding market and product characteristics. Demand is assumed to fully absorb production at a fixed unit price. These abstractions reflect the current situation in Kazakhstan, where reverse supply chains for mining waste have not yet been established and no empirical demand data are available. While such assumptions reduce realism, they enable an exploratory assessment of feasibility and cost drivers. Future work should incorporate multiple waste categories, differentiated products, and demand-side constraints once pilot trials generate empirical data. This will make it possible to evaluate how material heterogeneity and market uptake influence profitability and long-term viability.

6.2. Implications

Despite these limitations, the model provides valuable insights that extend beyond its current configuration. The baseline results and sensitivity analyses offer a foundation for understanding key cost drivers, such as transportation and processing costs, and suggest potential pathways to long-term profitability. For example, the emphasis on conversion efficiency and transportation route optimization highlights specific areas where targeted improvements could reduce operational costs significantly. This makes the model a useful tool for strategic planning, even in its simplified form.

The model’s flexibility allows it to be adapted and expanded to address these limitations over time, making it a foundational framework for reverse supply chain optimization in Kazakhstan’s mining industry. By refining these areas, particularly through the inclusion of empirical data, multi-stop transportation rates, and regulatory factors, the model can evolve into a robust decision-making tool. Its implications for sustainable waste management are particularly relevant, aligning with the growing emphasis on circular economy principles and resource recovery in the mining sector, thus supporting both economic and environmental objectives.

7. Conclusions

It should be emphasized that the present study focuses on a simplified single case of one waste type and one transportation route. This design was intentional to test the feasibility of the optimization framework under controlled assumptions. While this limits the generalizability of conclusions, the framework itself can be readily extended to multiple waste types and geographically distributed routes in future research.

This study developed an exploratory optimization framework specifically suited to the reverse supply chain requirements of Kazakhstan’s mining sector, focusing on managing mining waste. Rather than creating a comprehensive framework, the primary objective was to design a model that could streamline operations and reduce costs in waste collection, transport, and processing.

The sensitivity analyses conducted highlighted the impact of various cost parameters on the model’s outcomes, underscoring the importance of targeted improvements in these areas. Although transportation costs play a significant role in overall expenses, additional adjustments in waste processing and operational efficiency are likely to yield substantial benefits. These findings help guide future model adaptations by pinpointing areas where adjustments could improve cost efficiency.

Despite the simplifications made in this model, such as using estimated data for multi-stop transportation costs and conversion factors, it provides a foundational tool for analyzing reverse logistics in the mining industry. Future iterations of the model can incorporate empirical data from real pilot trials and further refine route optimization to enhance its accuracy and applicability.

Ultimately, this study provides a foundational framework for reverse supply chain optimization in Kazakhstan’s mining sector that aligns directly with the Sustainable Development Goals. By promoting industrial innovation (SDG 9) and responsible production and consumption (SDG 12), the proposed model supports Kazakhstan’s transition toward a circular and sustainable industrial ecosystem. The integration of environmental performance metrics, waste valorization strategies, and digital optimization principles ensures that future applications of the model can contribute meaningfully to national and global sustainability agendas.