Efficiency Enhancement of Photovoltaic Panels via Air, Water, and Porous Media Cooling Methods: Thermal–Electrical Modeling

Abstract

1. Introduction

2. Materials and Methods

2.1. PV System Performance Indices

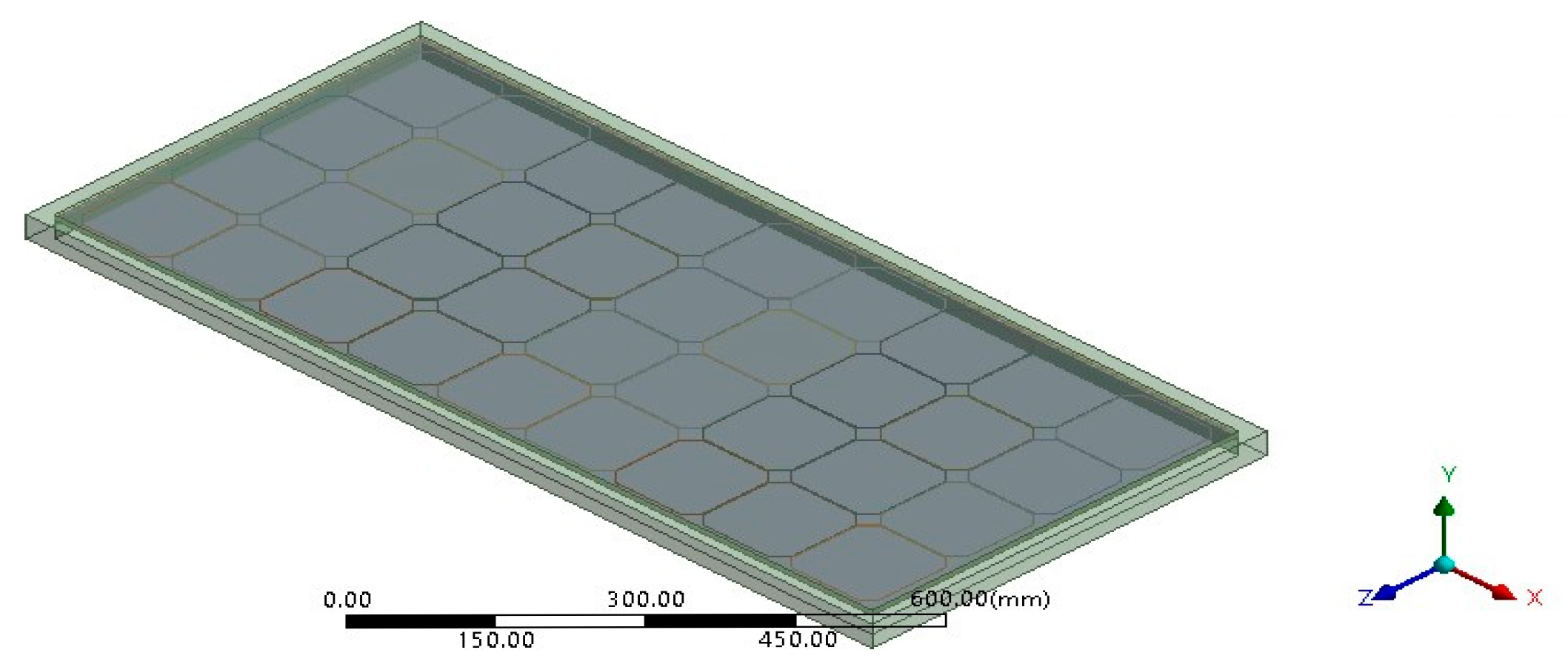

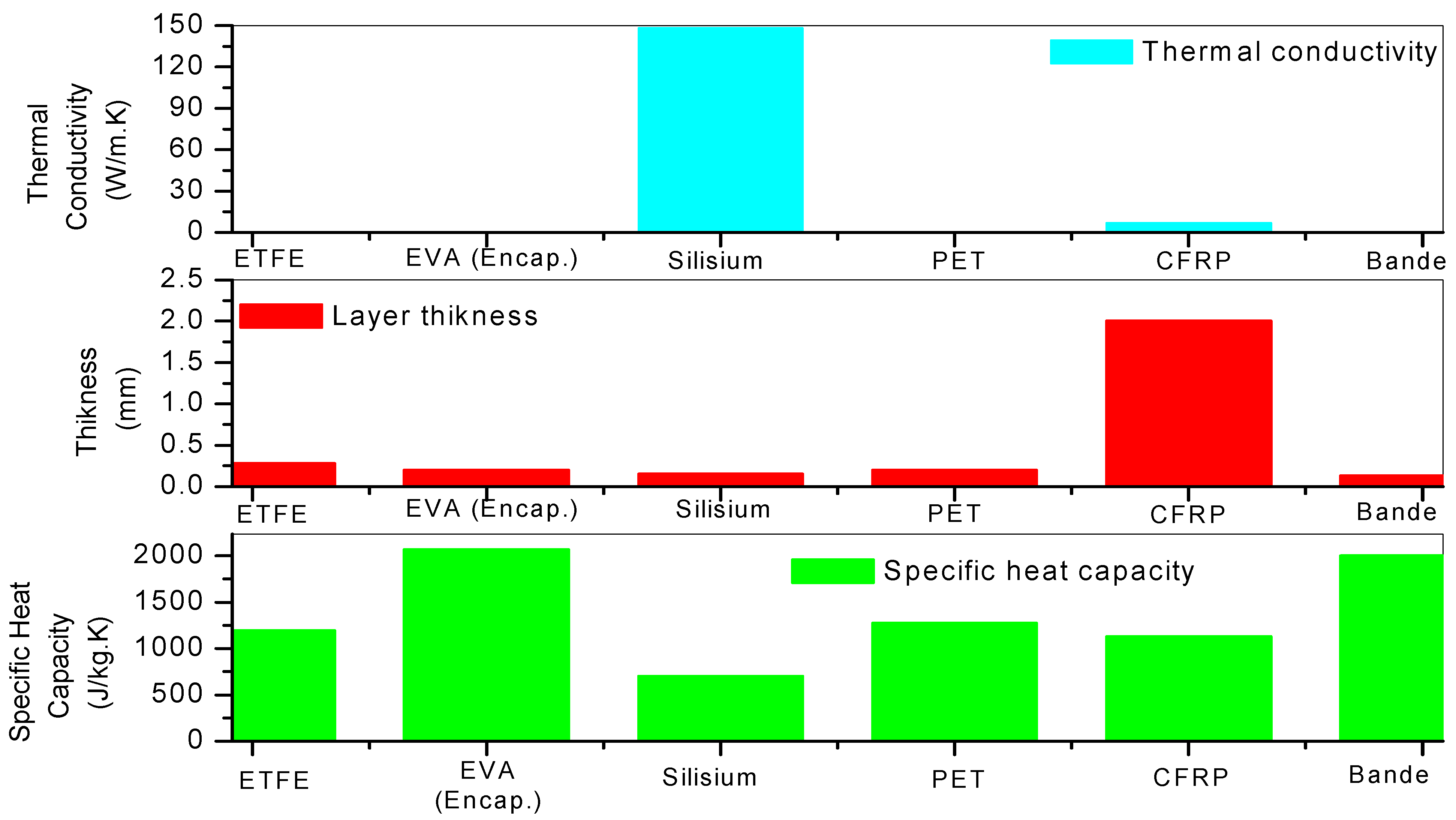

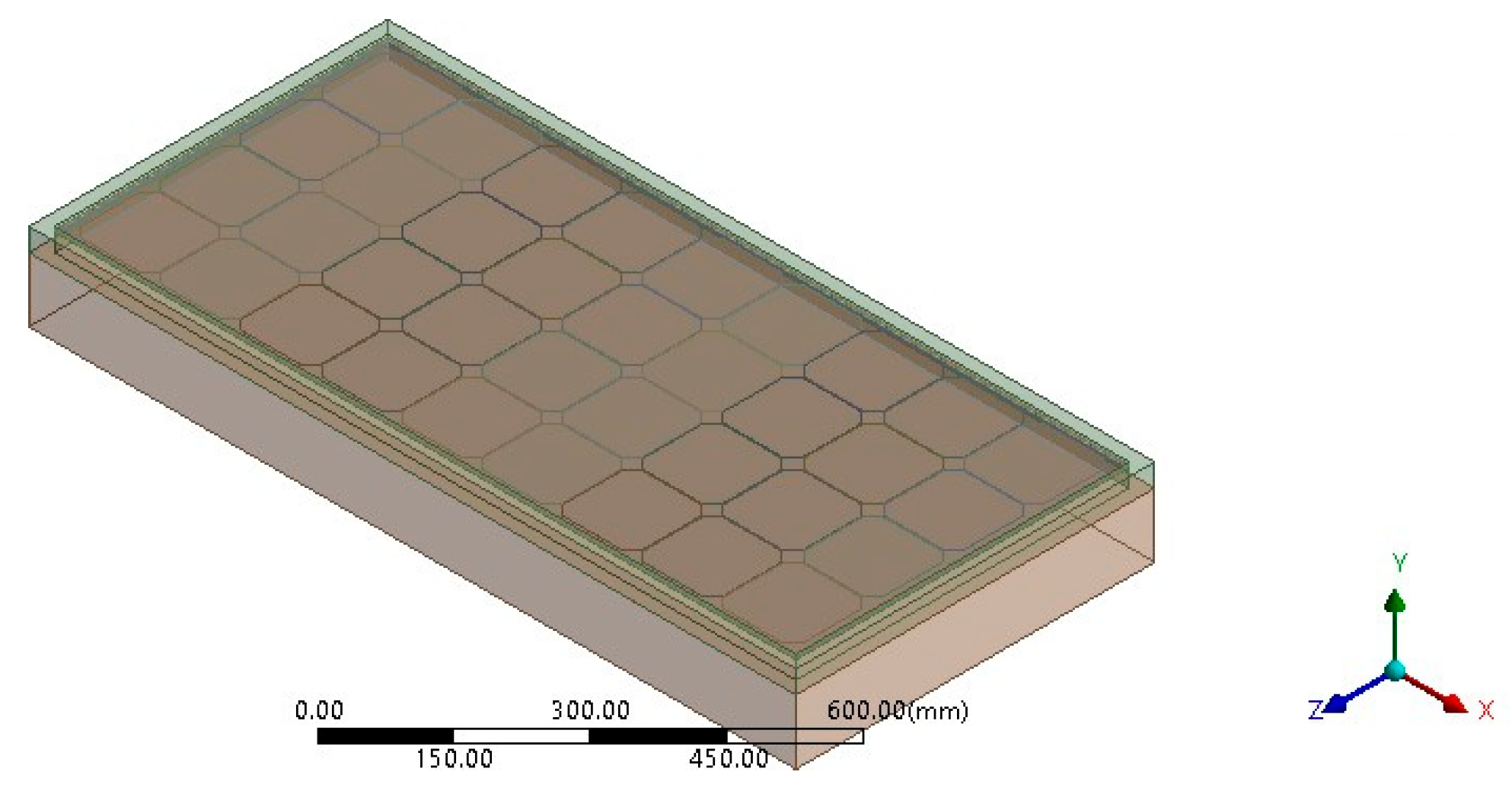

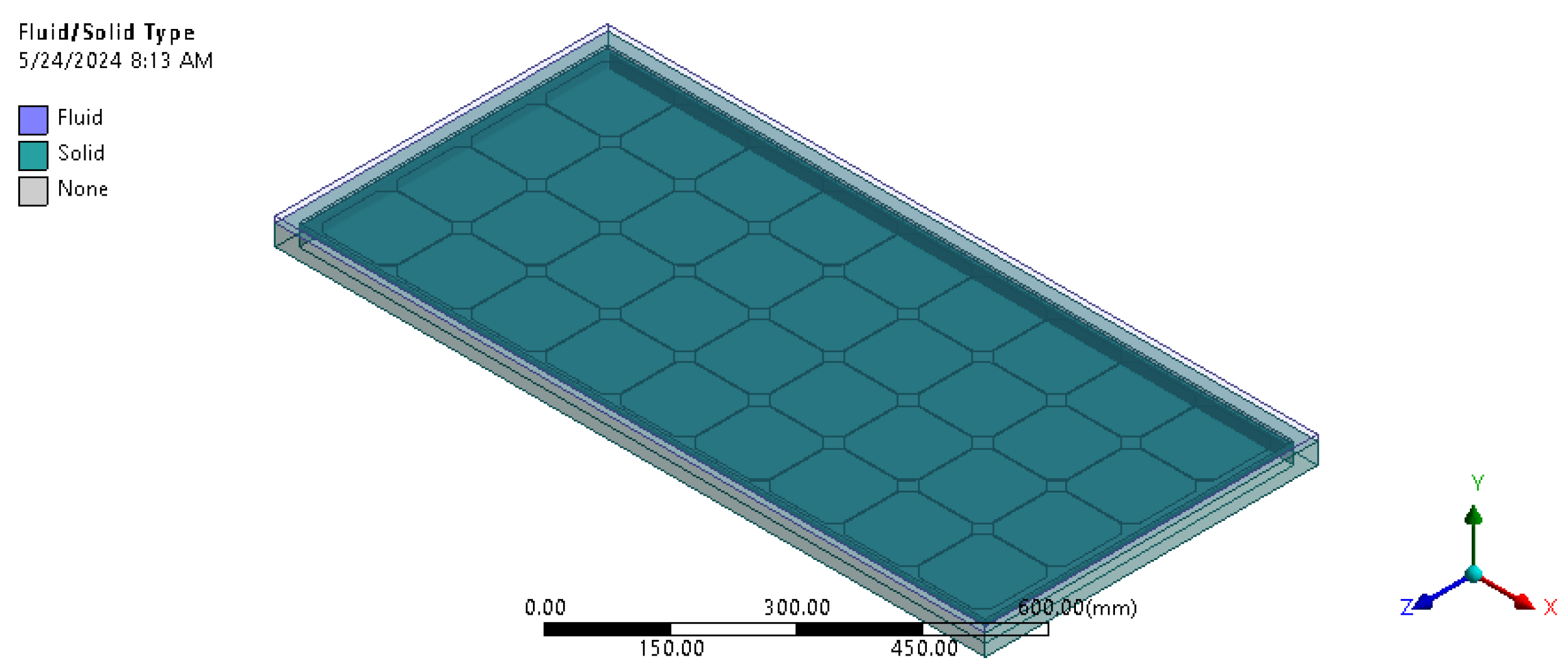

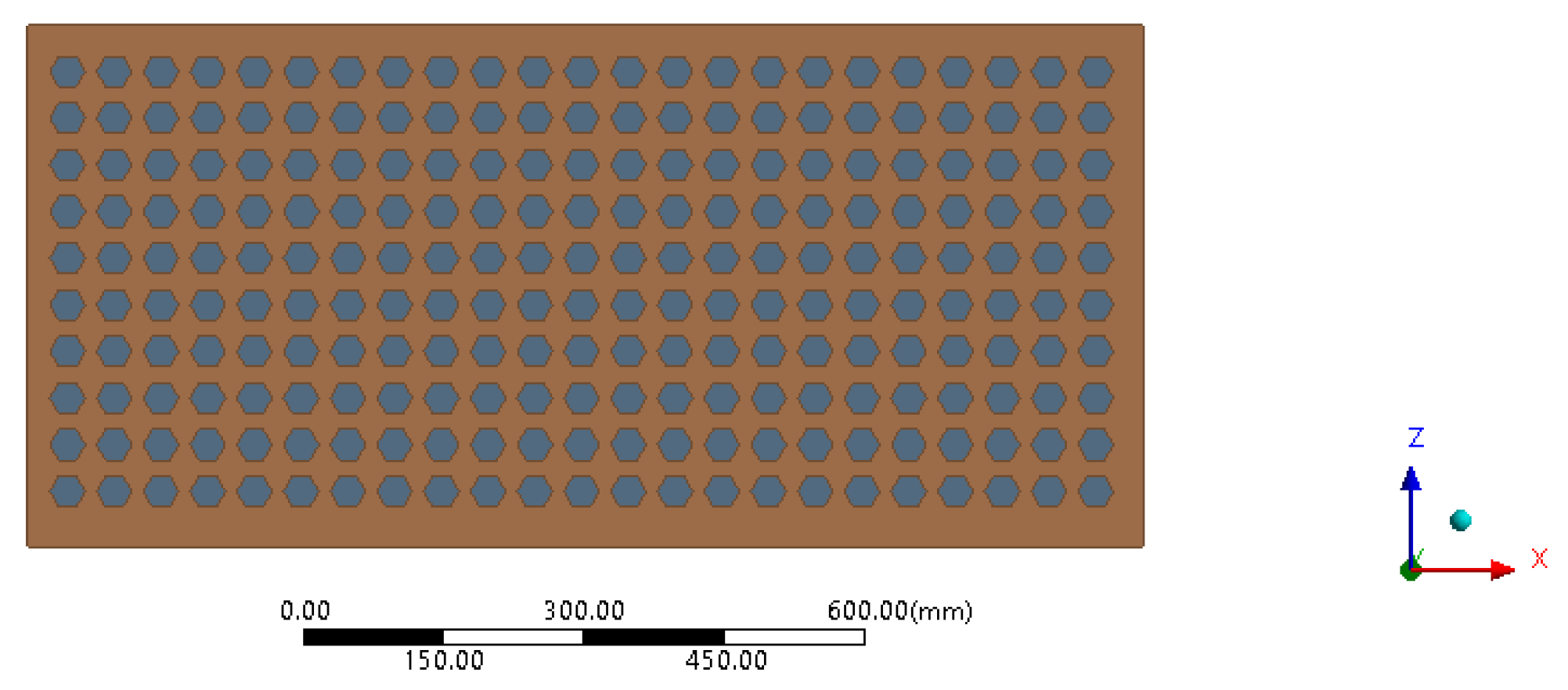

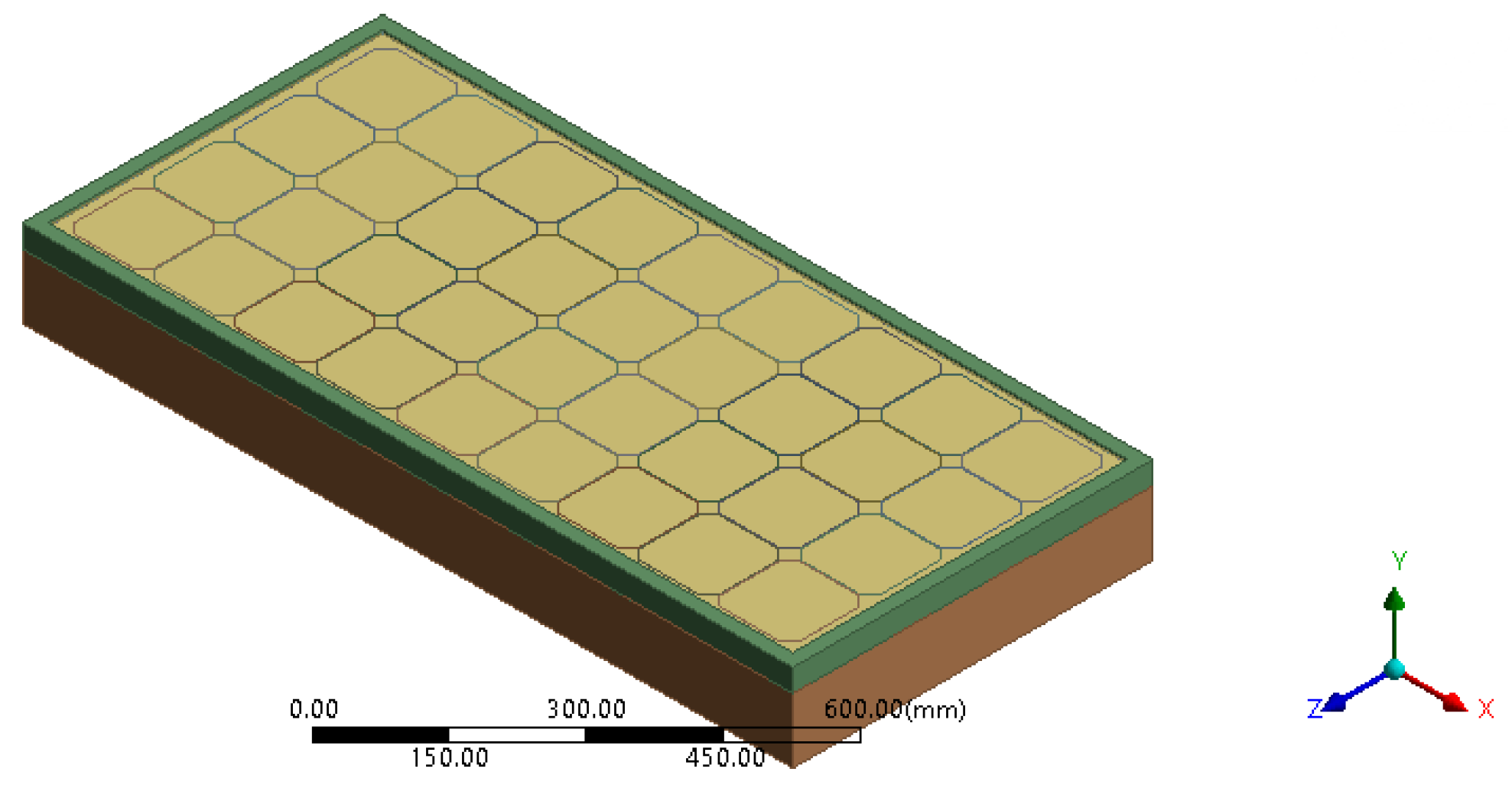

2.2. Numerical Modeling

2.3. Cooling Scenarios

2.3.1. Cooling Solar Panels with Air

2.3.2. Cooling Solar Panels with Water

2.3.3. Cooling Solar Panels with Porous Media

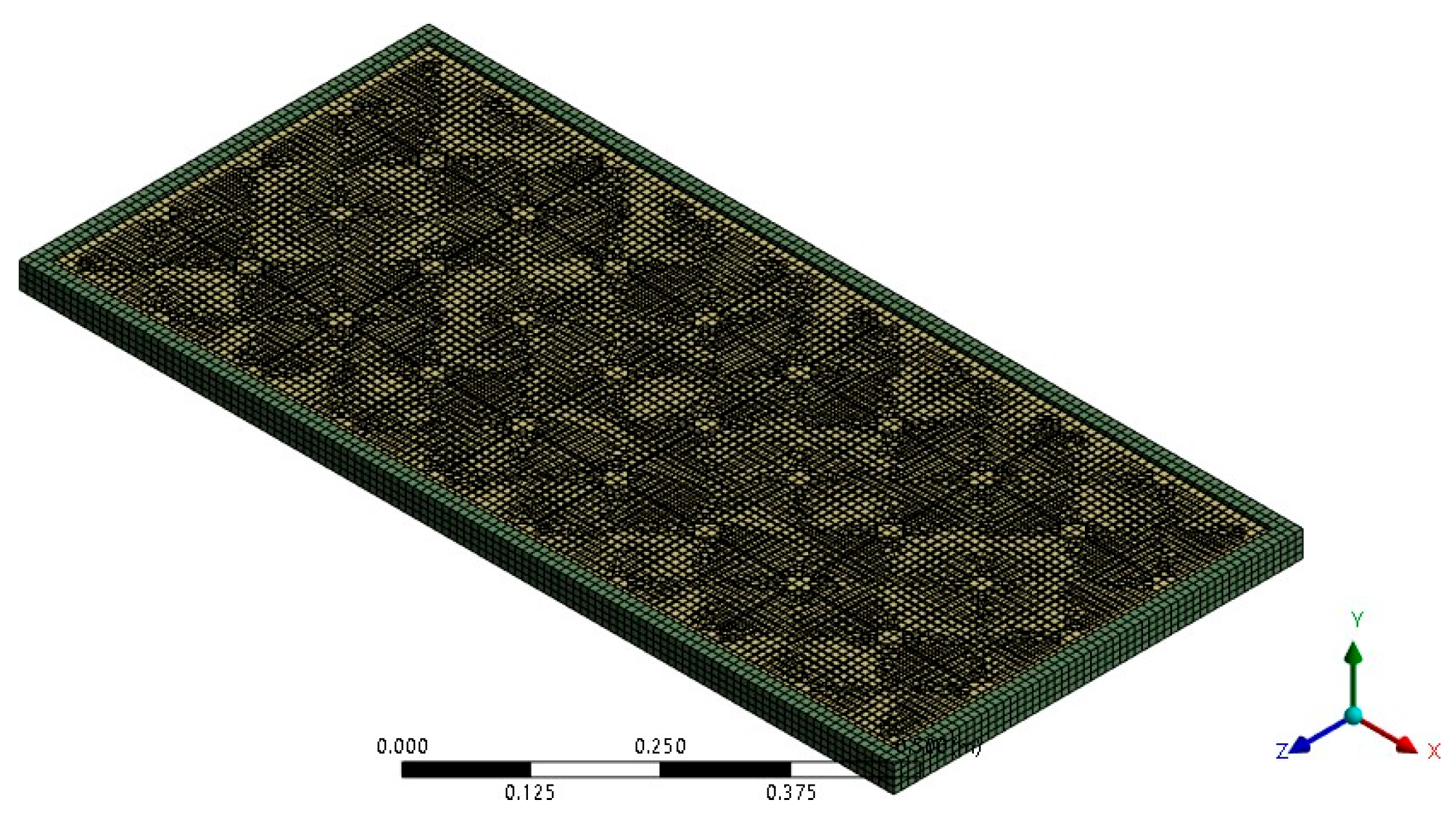

2.4. Mesh Independence Study

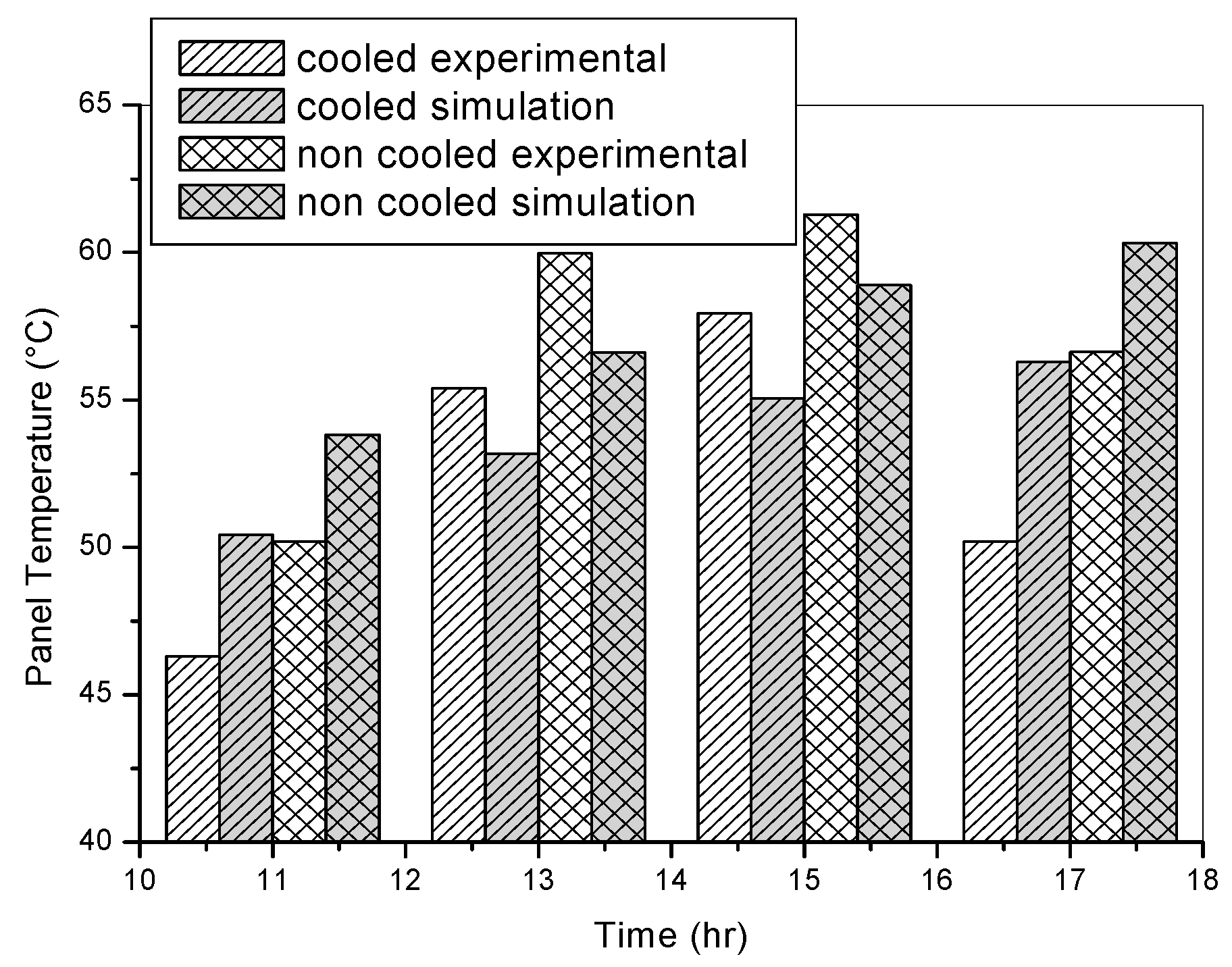

2.5. Model Validation

3. Simulation Results

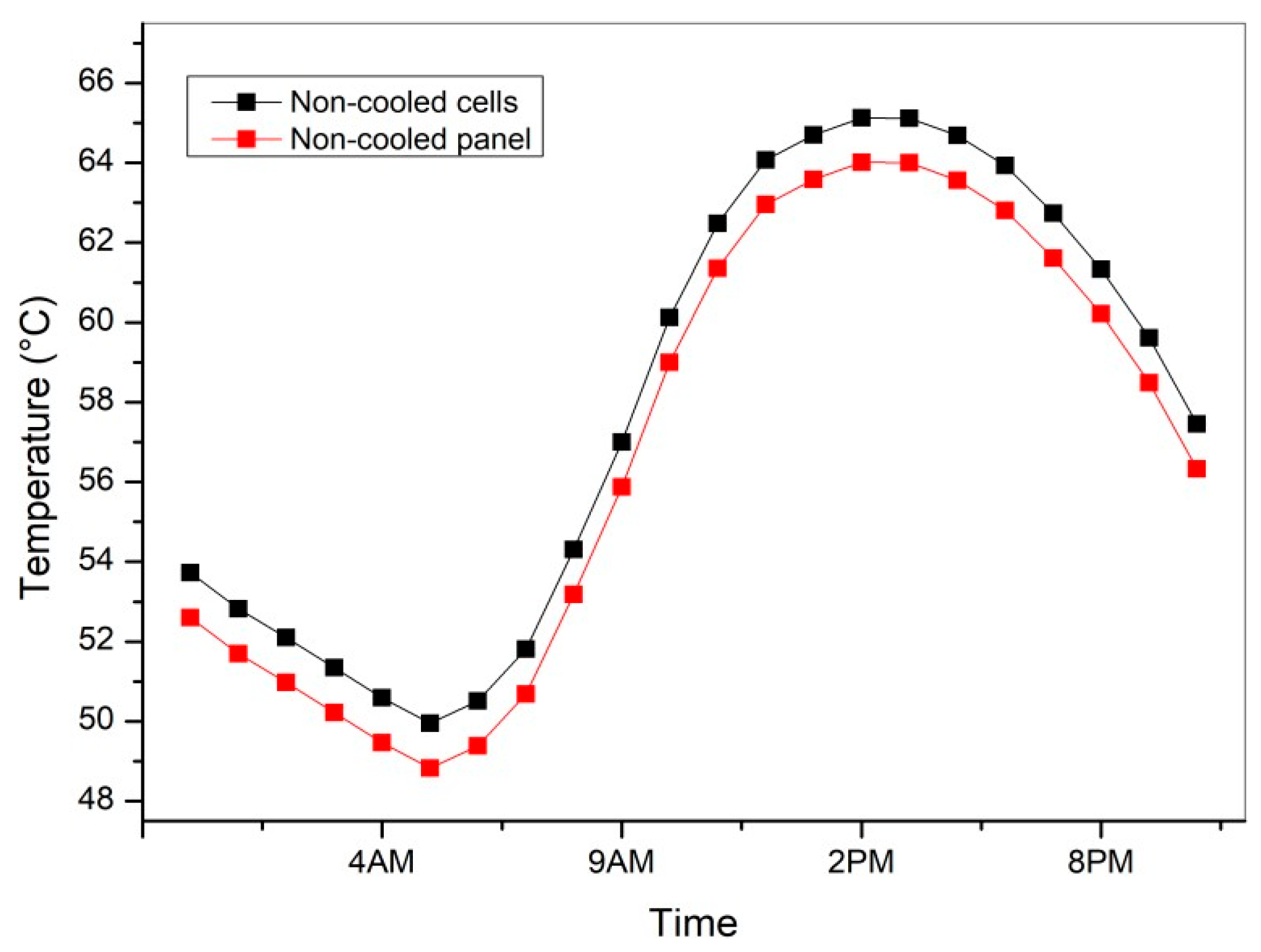

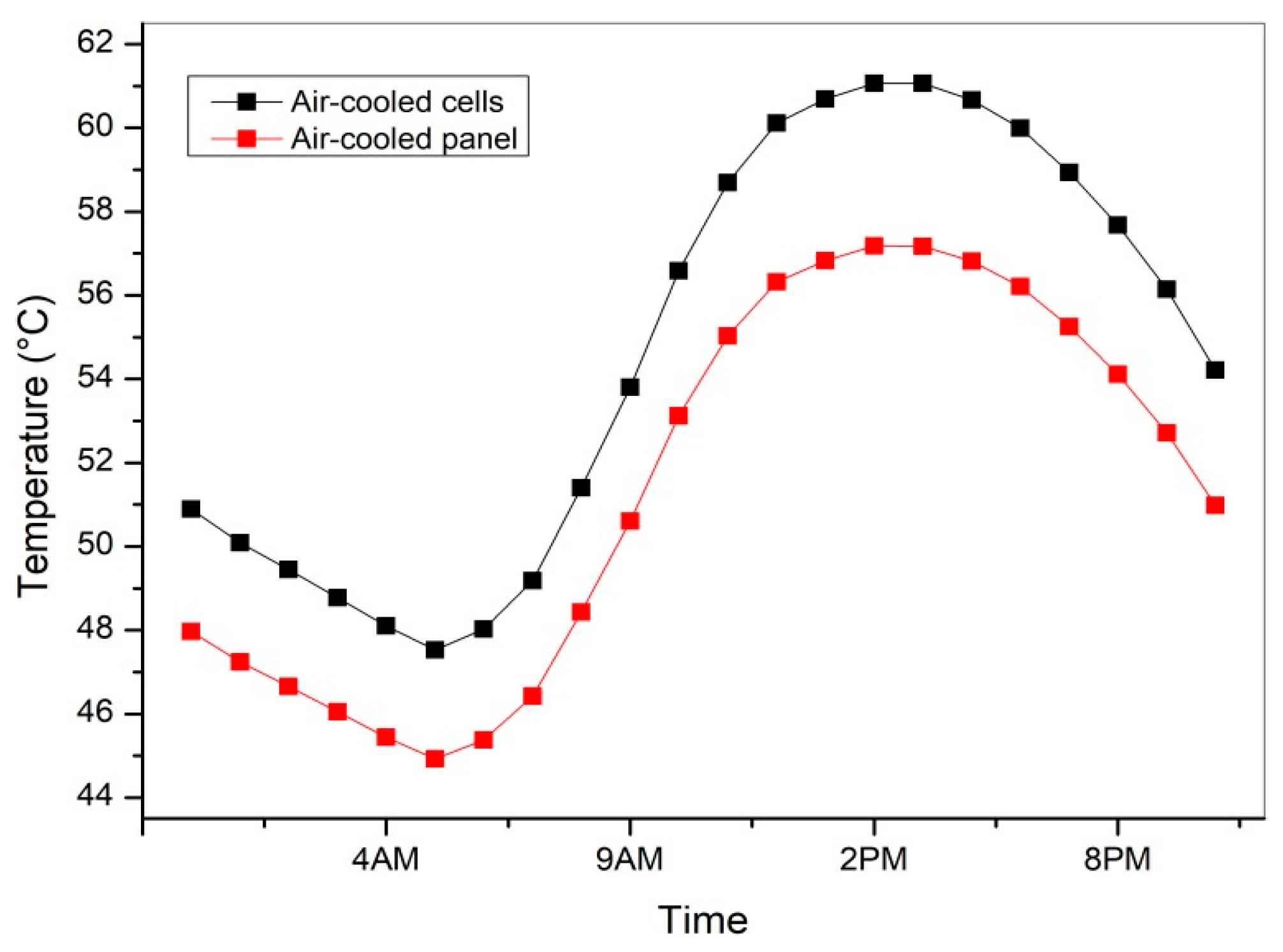

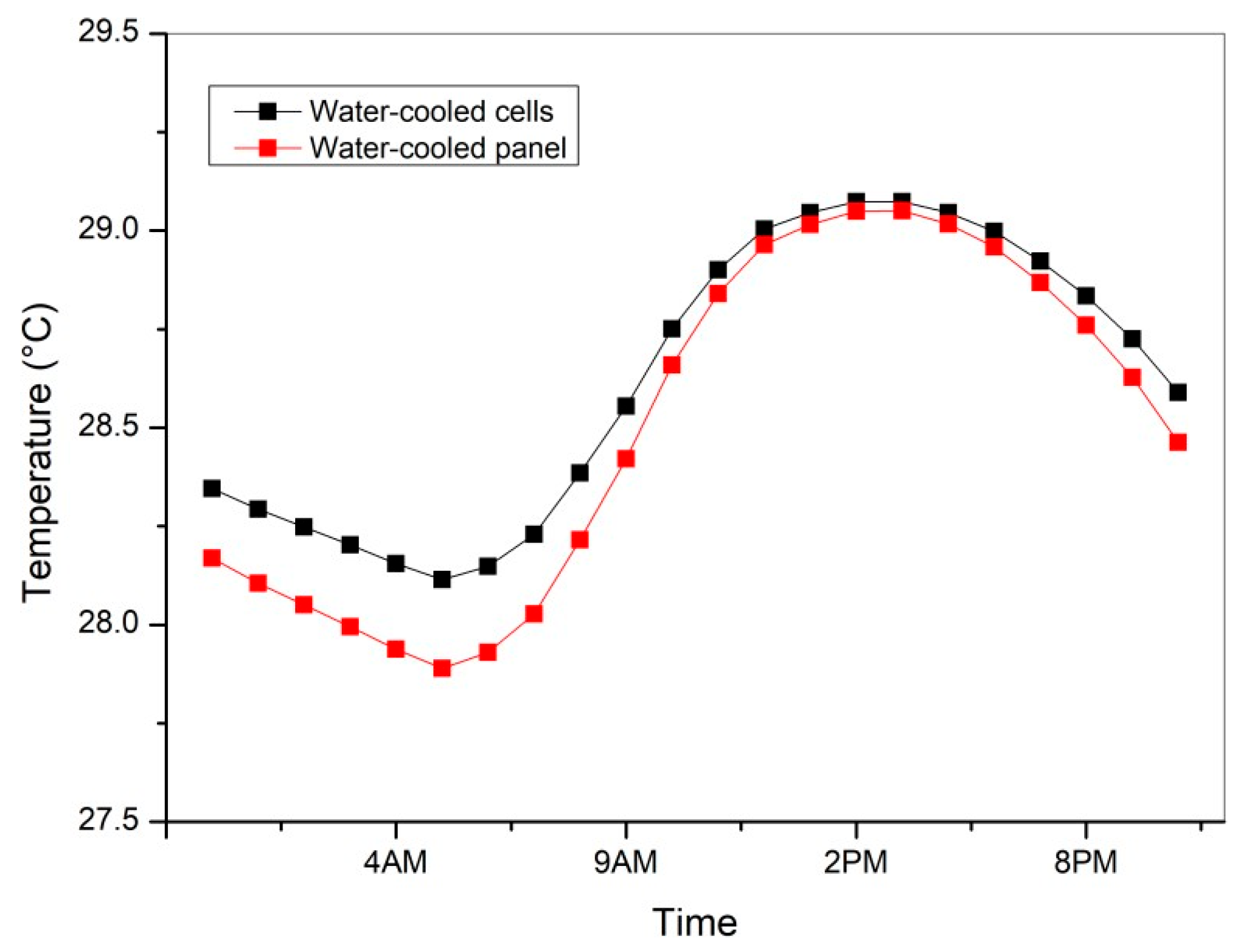

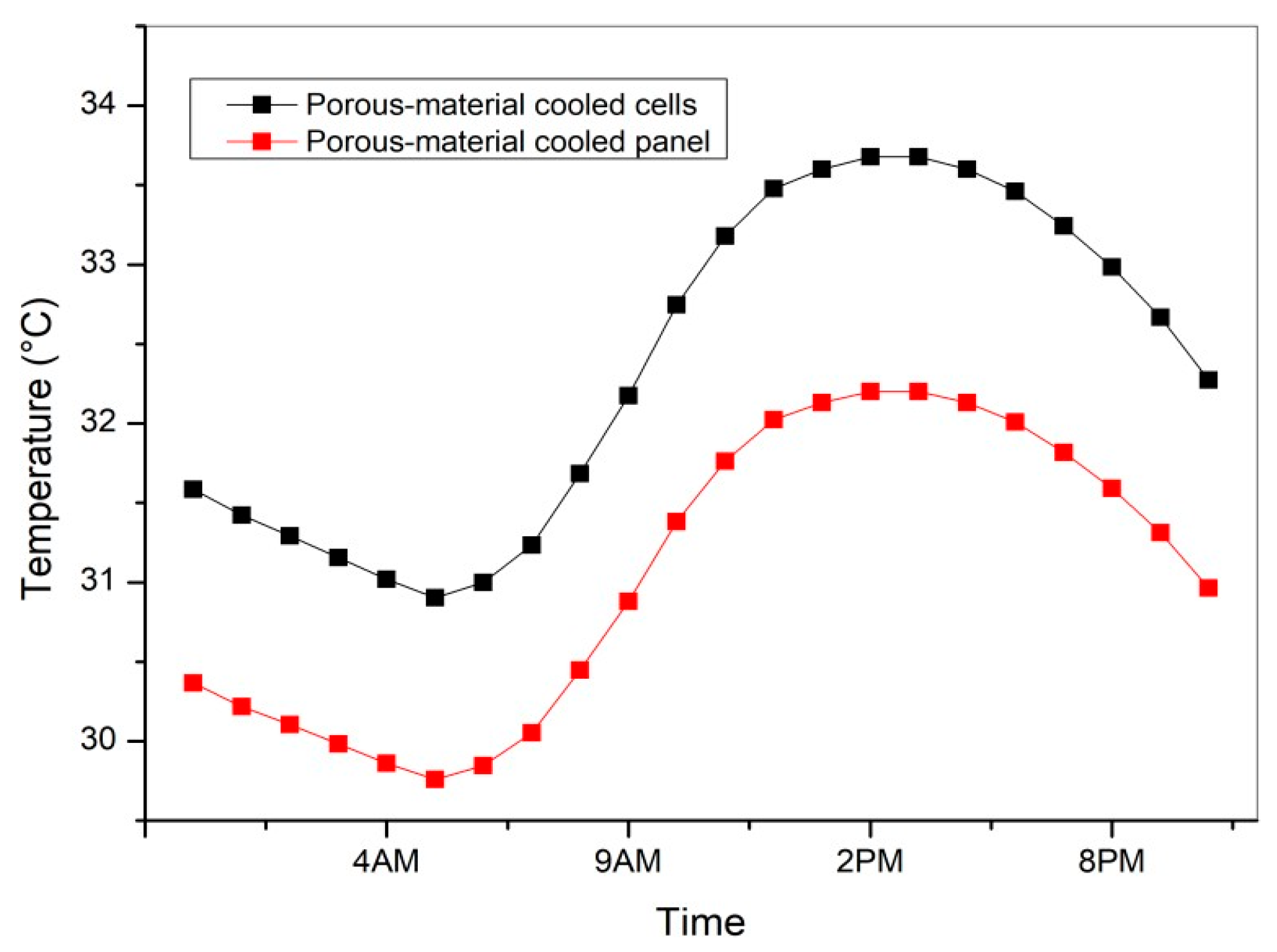

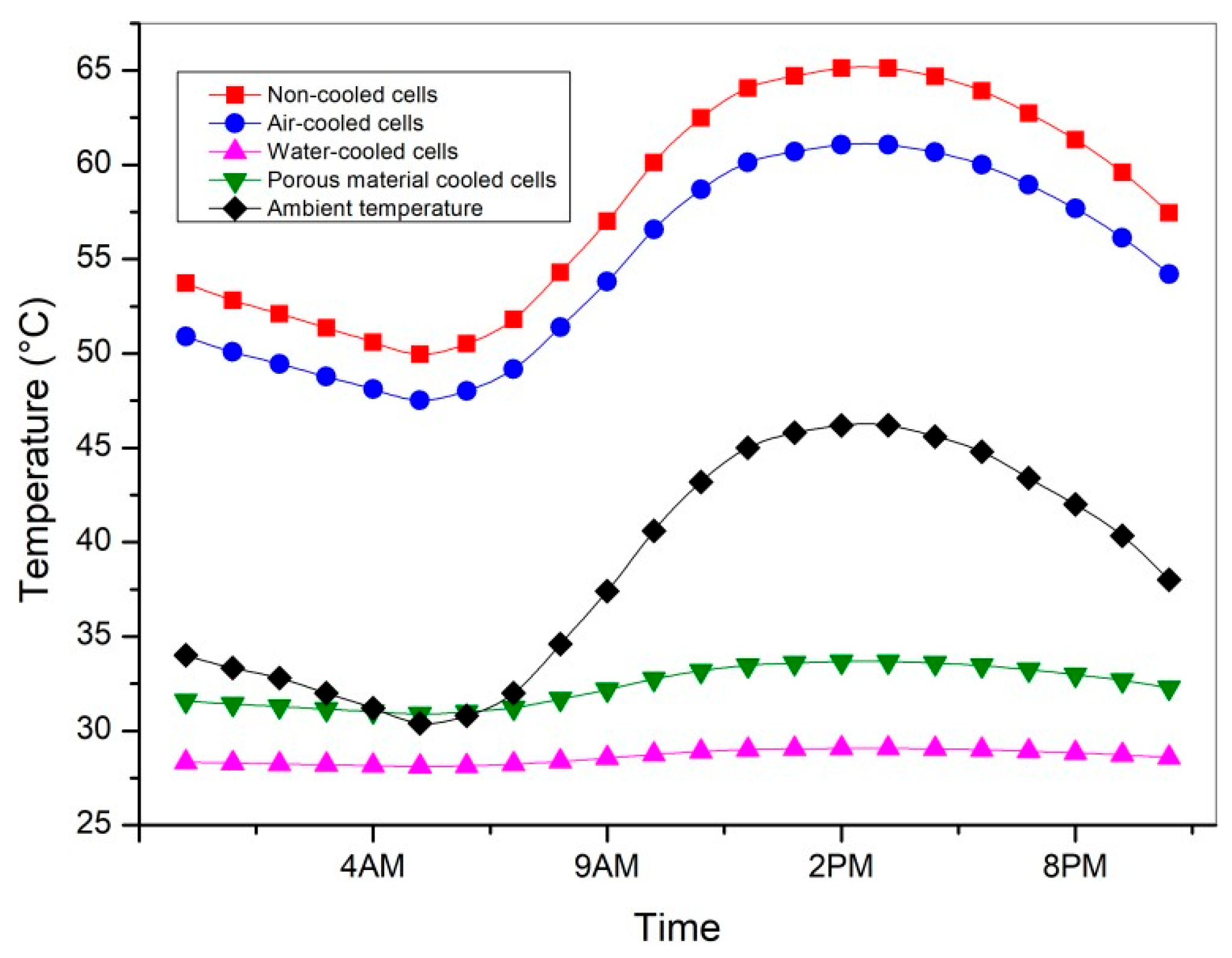

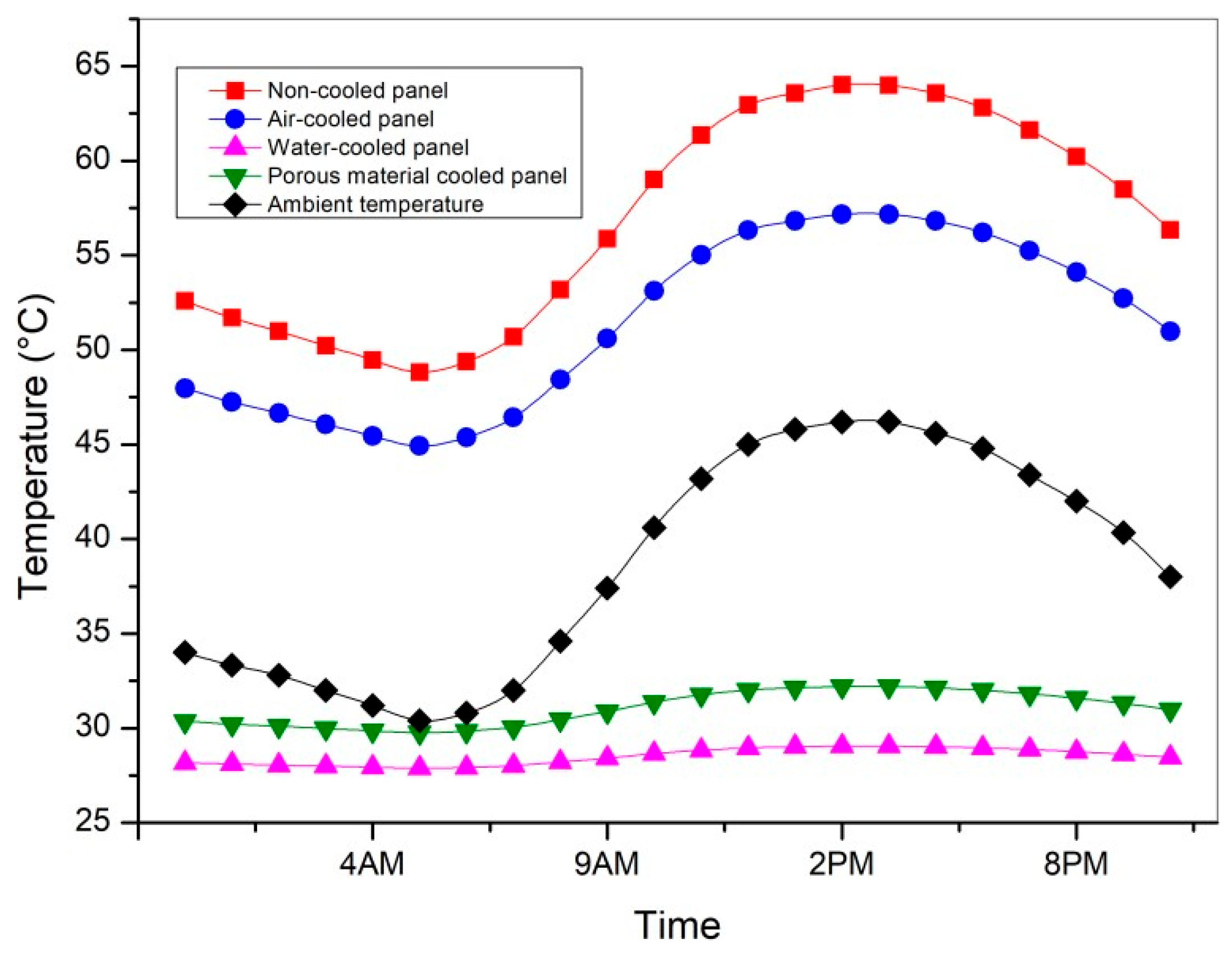

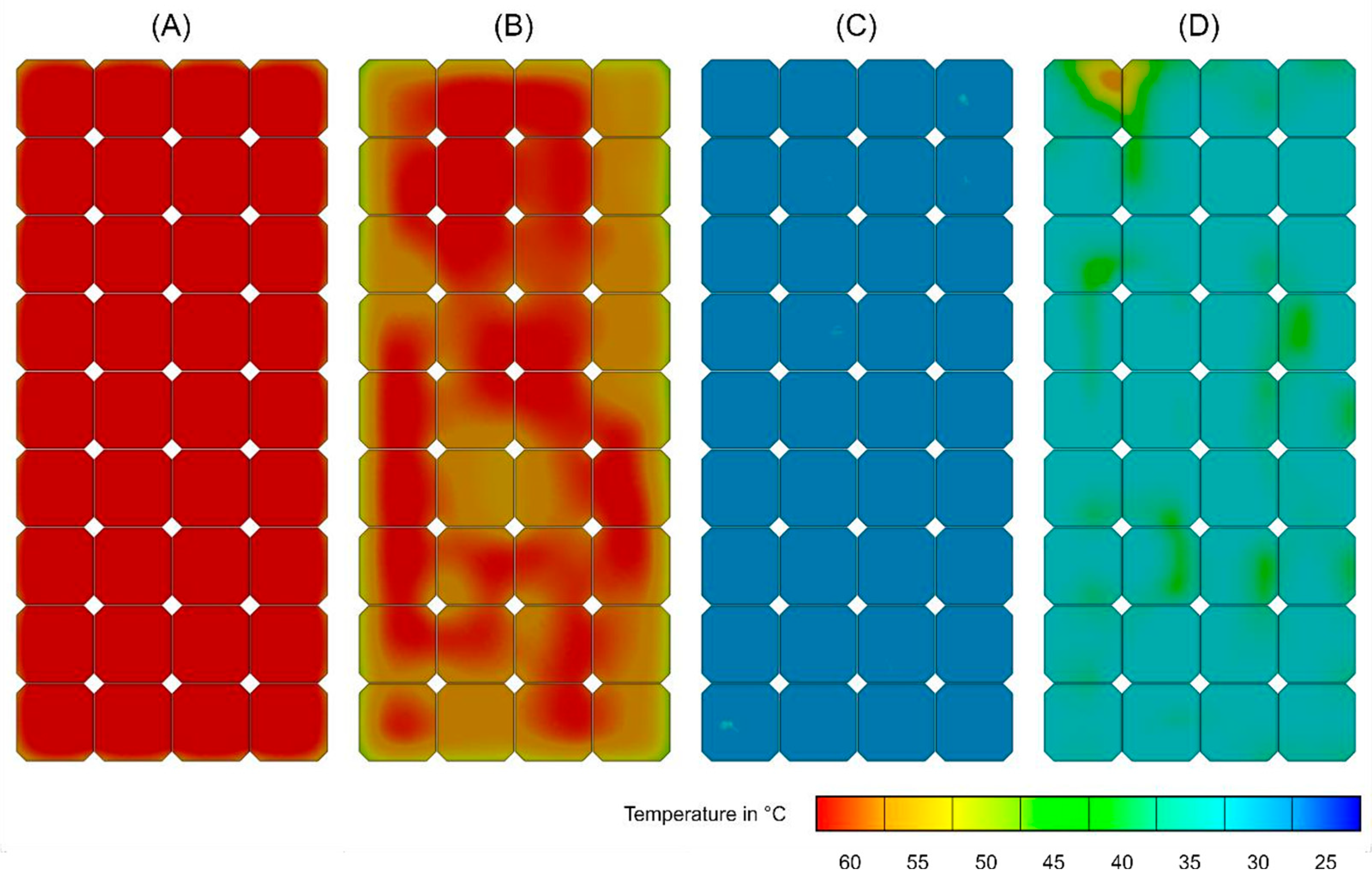

3.1. Temperature Results

3.2. Electrical Output

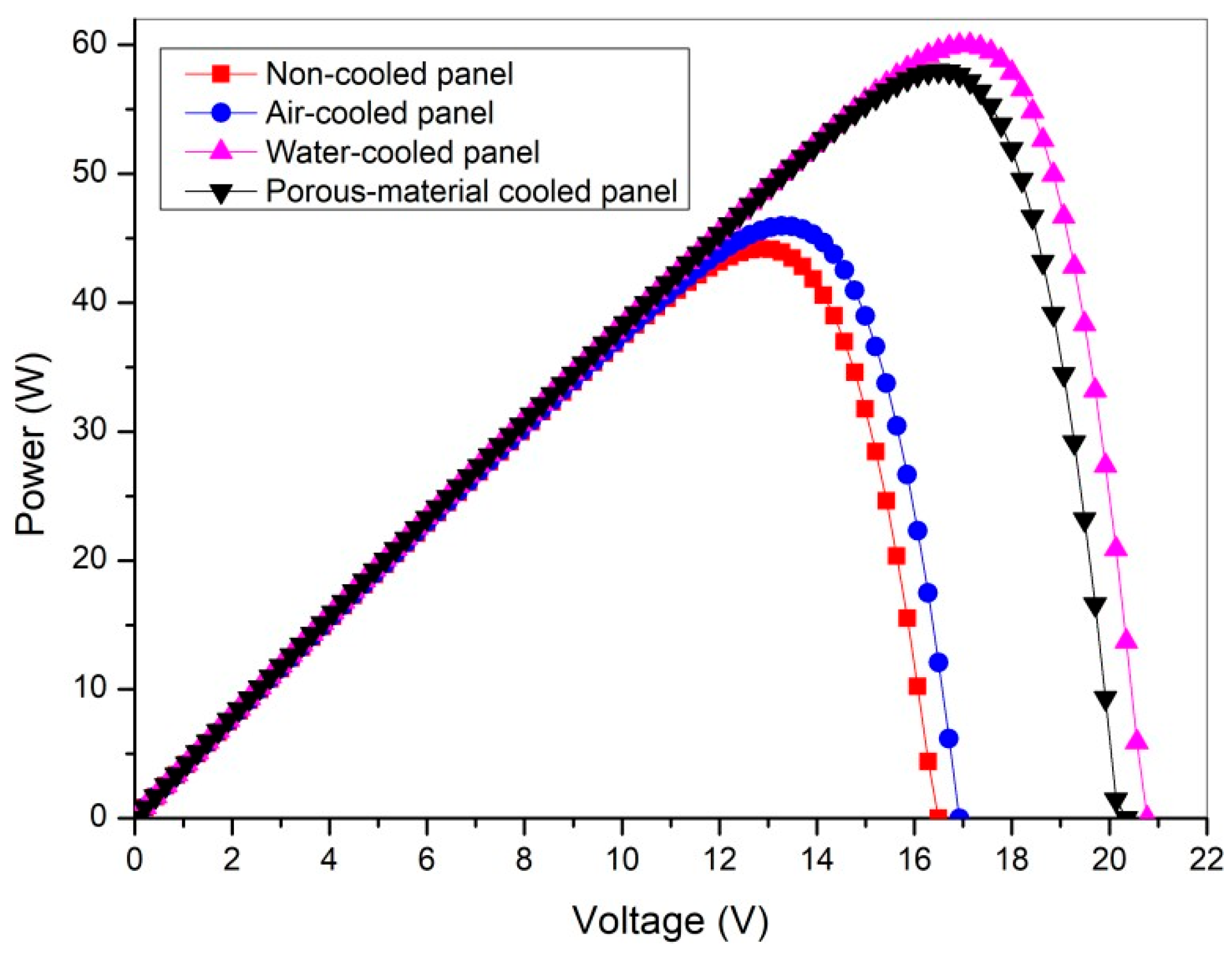

3.2.1. P–V Curve of the Solar Panel

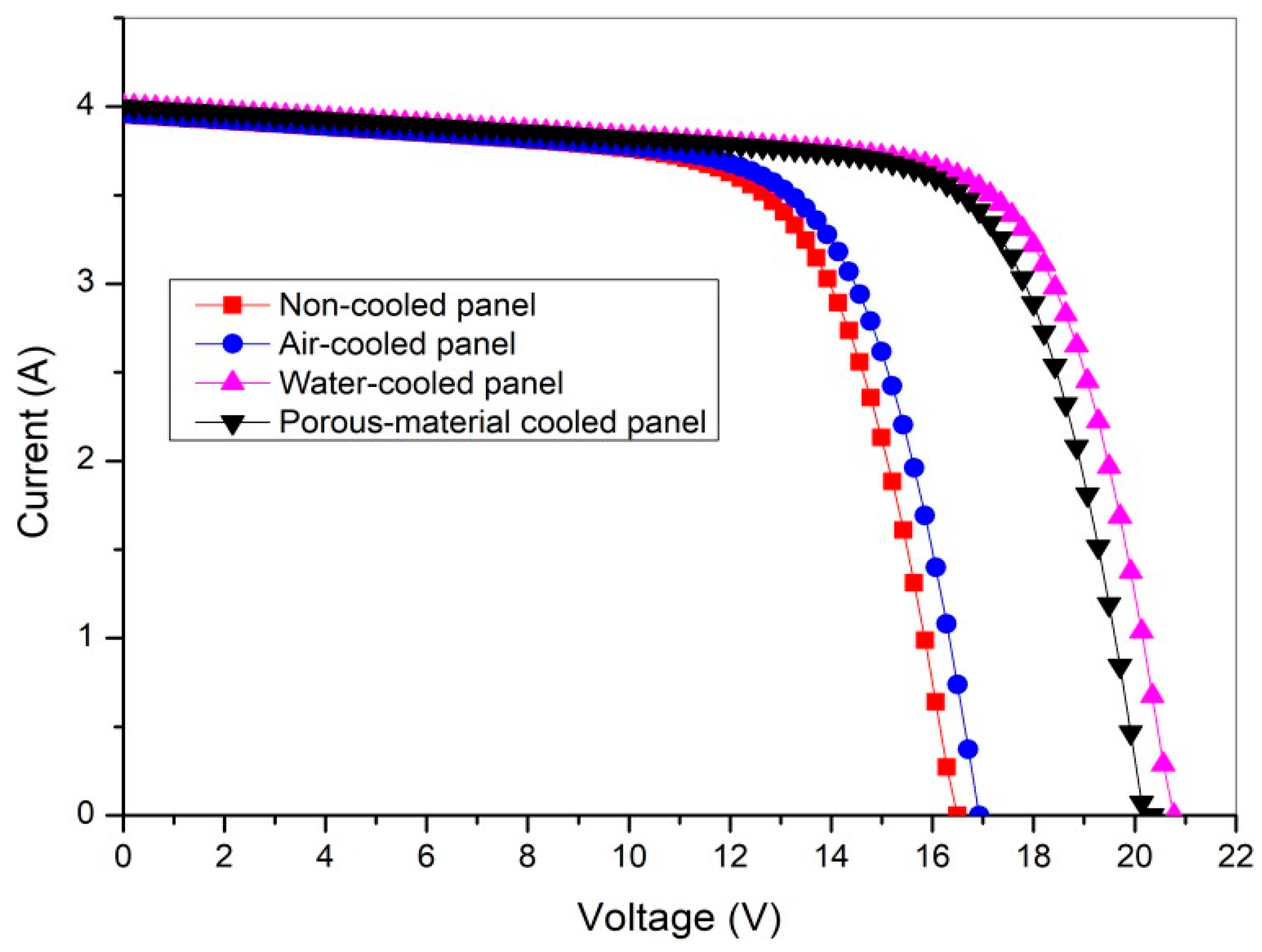

3.2.2. I–V Curve of the Solar Panel

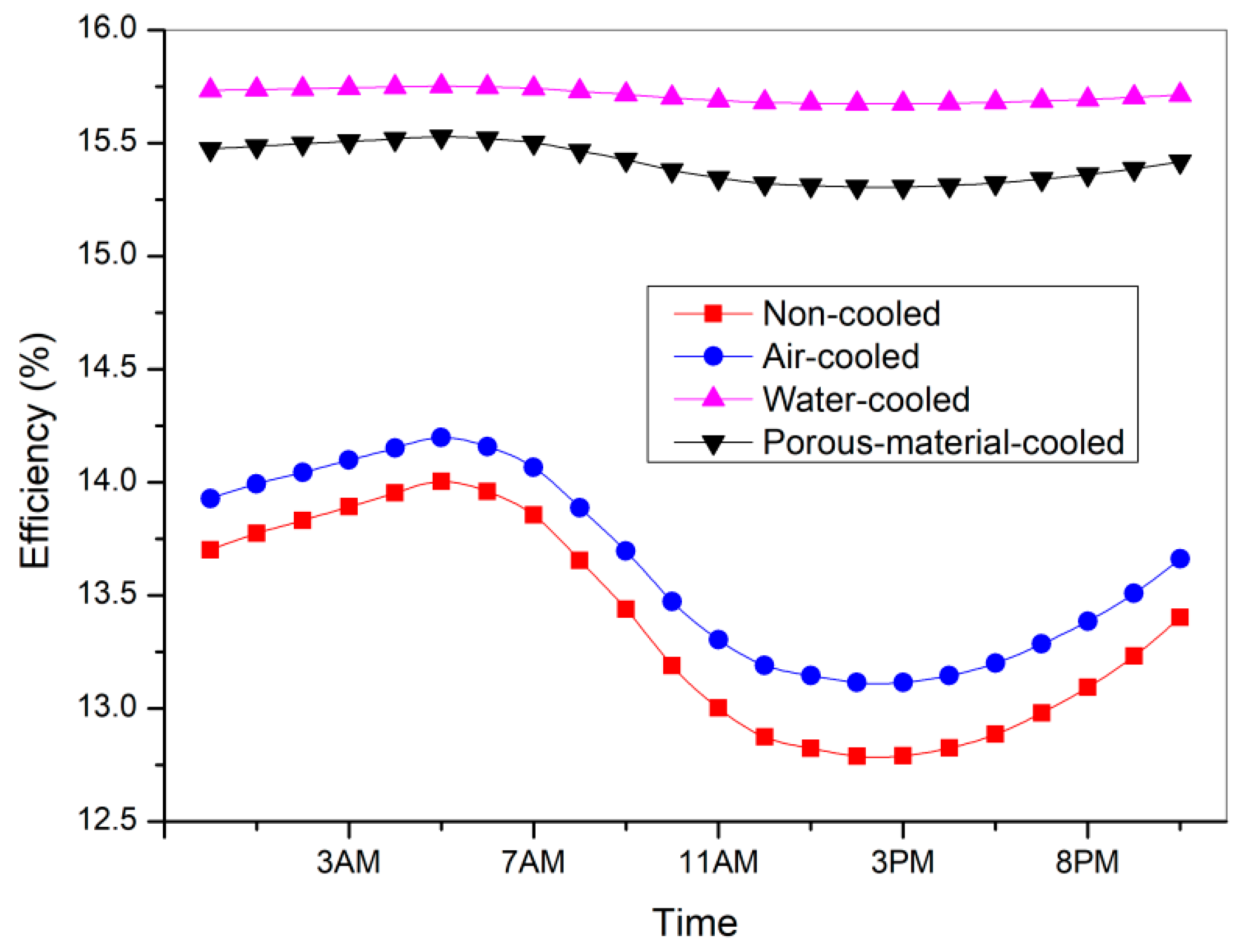

3.3. Efficiency Results

3.4. Power Balance Analysis

3.5. Uncertainty and Sensitivity Analysis

- Convective heat transfer coefficient (h ± 20%)

- Solar flux intensity (±10%)

- Ambient temperature (±5 °C)

| Parameter Varied | Change in Efficiency (%) | Change in Output Power (W) |

|---|---|---|

| h + 20% | +0.42 | +0.95 |

| h − 20% | –0.35 | –0.85 |

| Solar flux + 10% | +0.53 | +1.65 |

| Solar flux − 10% | –0.48 | –1.58 |

| Ambient Temp + 5 °C | –0.27 | –0.74 |

| Ambient Temp − 5 °C | +0.31 | +0.81 |

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Osorio, L.; Moreno, M.; Rivera, M.; Tuninetti, V.; Chavarria, G.R.; Duchêne, L.; Wheeler, P. A Metaheuristic-Based Method for Photovoltaic Temperature Computation under Tropical Conditions. Sol. Energy 2024, 271, 112414. [Google Scholar] [CrossRef]

- Akrouch, M.A.; Chahine, K.; Faraj, J.; Hachem, F.; Castelain, C.; Khaled, M. Advancements in cooling techniques for enhanced efficiency of solar photovoltaic panels: A detailed comprehensive review and innovative classification. Energy Built Environ. 2025, 6, 248–276. [Google Scholar] [CrossRef]

- Wassie, H.M.; Kassie, K.E.; Getie, M.Z. A Comprehensive Review on the Photovoltaic Panel Cooling Technique for Improved Efficiency. In Sustainable Development Research in Materials and Renewable Energy Engineering. Green Energy and Technology; Getie, M.Z., Mequanint, K., Alemu, M.A., Ashebir, G.Y., Tigabu, M.T., Eds.; Springer: Cham, Switzerland, 2025. [Google Scholar] [CrossRef]

- Kumar, V.; Gupta, N.; Yadav, A.; Kumar, N.; Verma, A.; Kumar, A.; Dhasmana, H.; Jain, V.K. Enhancing Solar Photovoltaic System Efficiency: Recent Progress on Its Cooling Techniques. Int. J. Thermophys. 2024, 45, 113. [Google Scholar] [CrossRef]

- Akrouch, M.A.; Faraj, J.; Hachem, F.; Castelain, C.; Khaled, M. A comprehensive review and comparison of cooling techniques for photovoltaic panels: An emphasis on experimental setup and energy efficiency ratios. Int. J. Thermofluids 2024, 23, 100774. [Google Scholar] [CrossRef]

- Sharaf, M.; Yousef, M.S.; Huzayyin, A.S. Review of cooling techniques used to enhance the efficiency of photovoltaic power systems. Environ. Sci. Pollut. Res. 2022, 29, 26131–26159. [Google Scholar] [CrossRef]

- Ibrahim, T.; Abou Akrouch, M.; Hachem, F.; Ramadan, M.; Ramadan, H.S.; Khaled, M. Cooling Techniques for Enhanced Efficiency of Photovoltaic Panels—Comparative Analysis with Environmental and Economic Insights. Energies 2024, 17, 713. [Google Scholar] [CrossRef]

- Muhe, A.J.; Hasan, I.A.; Hussein, A.A. Optimizing solar panel performance with advanced cooling techniques: An investigation of phase change materials and water jackets integration with two different designs. AIP Conf. Proc. 2025, 3169, 040100. [Google Scholar] [CrossRef]

- Abdel-Aziz, M.M.; ElBahloul, A.A. Innovations in improving photovoltaic efficiency: A review of performance enhancement techniques. Energy Convers. Manag. 2025, 327, 119589. [Google Scholar] [CrossRef]

- Sathyamurthy, R.; Kabeel, A.E.; Chamkha, A.; Karthick, A.; Manokar, A.M.; Sumithra, M.G. Experimental investigation on cooling the photovoltaic panel using hybrid nanofluids. Appl. Nanosci. 2021, 11, 363–374. [Google Scholar] [CrossRef]

- Ali, M.G.; Hassan, H.; Ookawara, S.; Nada, S.A. Investigation of the performance enhancement of building-integrated photovoltaic systems using evaporative porous clay applied in different building directions. J. Build. Eng. 2024, 82, 108292. [Google Scholar] [CrossRef]

- Ali, A.A.; Lafta, D.A.; Noori, S.W.; Abdulamir, F.; Rashid, F.L. Innovative materials integrated with PCM for enhancing photovoltaic panel efficiency: An experimental investigation. J. Energy Storage 2024, 102, 114258. [Google Scholar] [CrossRef]

- Zureigat, H.M.; Qawasmeh, B.R. Enhancing the productivity of PV module using cooling method: Experimental and simulation investigation in Jordan. Sol. Energy 2025, 287, 113238. [Google Scholar] [CrossRef]

- Agyekum, E.B.; PraveenKumar, S.; Alwan, N.T.; Velkin, V.I.; Shcheklein, S.E. Effect of dual surface cooling of a solar photovoltaic panel on the efficiency of the module: An experimental investigation. Heliyon 2021, 7, e07920. [Google Scholar] [CrossRef]

- Kumari, S.; Bhende, A.; Pandit, A.; Rayalu, S. Efficiency enhancement of photovoltaic panel by heat harvesting techniques. Energy Sustain. Dev. 2023, 73, 303–314. [Google Scholar] [CrossRef]

- Al Miaari, A.; Mohaisen, K.O.; Al-Ahmed, A.; Ali, H.M. Experimental investigation on thermal management and performance enhancement of photovoltaic panel cooled by a sustainable shape stabilized phase change material. Case Stud. Therm. Eng. 2025, 67, 105763. [Google Scholar] [CrossRef]

- Chanphavong, L.; Chanthaboune, V.; Phommachanh, S.; Vilaida, X.; Bounyanite, P. Enhancement of performance and exergy analysis of a water-cooling solar photovoltaic panel. Total. Environ. Res. Themes 2022, 3–4, 100018. [Google Scholar] [CrossRef]

- Zabihi Sheshpoli, A.; Jahanian, O.; Nikzadfar, K. Performance enhancement of a hybrid photovoltaic/thermal system using wire coils inside the cooling tube: Numerical and experimental case. Environ. Sci. Pollut. Res. 2024, 31, 18260–18280. [Google Scholar] [CrossRef] [PubMed]

- Saada, S.A.; Nebbali, R.; Kecili, I.; Zembri-Nebbali, D.; Rahim, M.; Nguyen, D.M. Operating temperature and electrical efficiency of a photovoltaic panel cooled by laminar water film flowing on its front face: Experimental and numerical approach. Mater. Today Sustain. 2025, 30, 101093. [Google Scholar] [CrossRef]

- Bulat, S.; Büyükbicakci, E.; Erkovan, M. Efficiency Enhancement in Photovoltaic–Thermoelectric Hybrid Systems through Cooling Strategies. Energies 2024, 17, 430. [Google Scholar] [CrossRef]

- Yamini, D.; Rao, G.S.; Tejaswi, M.; Vishal, M.G.; Vennela, M. Enhancement of Solar Panel Efficiency. In Innovations in Energy Management and Renewable Resources; Lecture Notes in Electrical Engineering; Pal, M., Guerrero, J.M., Siano, P., Das, D., Chowdhuri, S., Eds.; Springer: Singapore, 2023; p. 1239. [Google Scholar] [CrossRef]

- Wongwuttanasatian, T.; Sarikarin, T.; Suksri, A. Performance enhancement of a photovoltaic module by passive cooling using phase change material in a finned container heat sink. Sol. Energy 2020, 195, 47–53. [Google Scholar] [CrossRef]

- Dhokane, N.; Ramesh, S. Enhancement of Reliability and Efficiency of Solar Panel Using Cooling Methods. In Techno-Societal; Pawar, P.M., Balasubramaniam, R., Ronge, B.P., Salunkhe, S.B., Vibhute, A.S., Melinamath, B., Eds.; Springer: Cham, Switzerland, 2020. [Google Scholar] [CrossRef]

- Hosseinghorbani, A.; Rivera-Solorio, C.I.; Gijón-Rivera, M. Performance improvement of concentrated photovoltaic thermal (CPVT) system using a novel insert. Energy 2025, 316, 134505. [Google Scholar] [CrossRef]

- Popovici, C.G.; Hudişteanu, S.V.; Mateescu, T.D.; Cherecheş, N.-C. Efficiency Improvement of Photovoltaic Panels by Using Air Cooled Heat Sinks. Energy Procedia 2016, 85, 425–432. [Google Scholar] [CrossRef]

- Sargunanathan, S.; Elango, A.; Tharves Mohideen, S. Performance enhancement of solar photovoltaic cells using effective cooling methods: A review. Renew. Sustain. Energy Rev. 2016, 64, 382–393. [Google Scholar] [CrossRef]

- Metwally, H.; Mahmoud, N.A.; Ezzat, M.; Aboelsoud, W. Numerical investigation of photovoltaic hybrid cooling system performance using the thermoelectric generator and RT25 Phase change material. J. Energy Storage 2021, 42, 103031. [Google Scholar] [CrossRef]

- Javidan, M.; Moghadam, A.J. Experimental investigation on thermal management of a photovoltaic module using water-jet impingement cooling. Energy Convers. Manag. 2021, 228, 113686. [Google Scholar] [CrossRef]

- Saeed, S.; Hussain, A.; Ali, I.; Shahid, H.; Anwar, M.; Ali, H.M. Photovoltaic module efficiency enhancement system by novel cooling techniques: Effect of phase change material and fins. Process. Saf. Environ. Prot. 2025, 194, 1056–1066. [Google Scholar] [CrossRef]

- Prakash, A.; Kukreja, R.; Kumar, P. Cooling of PV panel by using PCM and nanofluid-review. Mater. Today Proc. 2024. [Google Scholar] [CrossRef]

- Kaneesamkandi, Z.; Rehman, A.U. Selection of a Photovoltaic Panel Cooling Technique Using Multi-Criteria Decision Analysis. Appl. Sci. 2023, 13, 1949. [Google Scholar] [CrossRef]

- Faheem, M.; Abu Bakr, M.; Ali, M.; Majeed, M.A.; Haider, Z.M.; Khan, M.O. Evaluation of Efficiency Enhancement in Photovoltaic Panels via Integrated Thermoelectric Cooling and Power Generation. Energies 2024, 17, 2590. [Google Scholar] [CrossRef]

- Hudișteanu, V.-S.; Cherecheș, N.-C.; Țurcanu, F.-E.; Hudișteanu, I.; Romila, C. Impact of Temperature on the Efficiency of Monocrystalline and Polycrystalline Photovoltaic Panels: A Comprehensive Experimental Analysis for Sustainable Energy Solutions. Sustainability 2024, 16, 10566. [Google Scholar] [CrossRef]

- Hajjaj, S.S.H.; Aqeel, A.A.K.A.; Sultan, M.T.H.; Shahar, F.S.; Shah, A.U.M. Review of Recent Efforts in Cooling Photovoltaic Panels (PVs) for Enhanced Performance and Better Impact on the Environment. Nanomaterials 2022, 12, 1664. [Google Scholar] [CrossRef] [PubMed]

- Masalha, I.; Masuri, S.U.; Badran, O.; Alahmer, A. A multi-method approach to investigating porous media cooling for enhanced thermal performance of photovoltaic panels: Exploring the effects of porosity, flow rates, channel design, and coolant types. Int. J. Thermofluids 2025, 27, 101165. [Google Scholar] [CrossRef]

- Venegas, I.; Oñate, A.; Pierart, F.G.; Valenzuela, M.; Narayan, S.; Tuninetti, V. Efficient Mako Shark-Inspired Aerodynamic Design for Concept Car Bodies in Underground Road Tunnel Conditions. Biomimetics 2024, 9, 448. [Google Scholar] [CrossRef] [PubMed]

- Adrar. Algeria Weather Historystar_Ratehome. Available online: https://www.wunderground.com/history/daily/dz/adrar/DAUA/date/2023-7-21 (accessed on 5 June 2025).

- Yesildal, F.; Ozakin, A.N.; Yakut, K. Optimization of operational parameters for a photovoltaic panel cooled by spray cooling. Eng. Sci. Technol. Int. J. 2022, 25, 100983. [Google Scholar] [CrossRef]

- Tuninetti, V.; Ales, B.; Chandía, T.M. Numerical and Experimental Analysis of Thermal Stratification in Locally Heated Residential Spaces. Buildings 2025, 15, 2417. [Google Scholar] [CrossRef]

- Mahdi, E.J.; Algburi, S.; Al-Abadi, N.; Ahmed, O.K.; Ahmed, A.K. Photovoltaic panel cooling using ground source energy: CFD simulation. Results Eng. 2024, 22, 102144. [Google Scholar] [CrossRef]

- Bukar, A.M.; Almerbati, A.; Shuja, S.Z.; Zubair, S.M. Enhancing solar PV panel performance through active and passive cooling techniques: A comprehensive review. Renew. Sustain. Energy Rev. 2025, 216, 115611. [Google Scholar] [CrossRef]

- Sheikh, Y.; Jasim, M.; Qasim, M.; Qaisieh, A.; Hamdan, M.O.; Abed, F. Enhancing PV solar panel efficiency through integration with a passive Multi-layered PCMs cooling system: A numerical study. Int. J. Thermofluids 2024, 23, 100748. [Google Scholar] [CrossRef]

- Jyani, L.; Sankhala, S.; Chaudhary, K.; Purohit, K. Experimental Investigation of Flexible Solar Cells Using Passive Cooling Technique in Hot and Dry Climate of Jodhpur. J. Sol. Energy Res. 2024, 9, 1854–1869. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Rated power | 70 W |

| Rated efficiency | 16% |

| Number of cells | 36 |

| Cell type | Mono-crystalline |

| Cell dimensions | 125 × 125 mm |

| Panel dimensions (W × L × H) | 500 × 1125 × 3 mm |

| Cell configuration | Pseudo-square with rounded corners |

| Diameter of rounded corners | 150 mm |

| Voltage temperature coefficient | 0.5%/°C |

| Current temperature coefficient | 0.02%/°C |

| Standard test conditions | 1000 W/m2, °C |

| Short circuit current (Isc) | 4.48 A |

| Open circuit voltage (Voc) | 21.42 V |

| Rated voltage | 17.64 V |

| Rated current | 3.97 A |

| Time | Temperature (°C) | Wind Speed (m/s) | Wind Gust (m/s) | Conditions |

|---|---|---|---|---|

| 12:00 a.m. | 33.9 | 4.5 | 0 | Fair |

| 02:00 a.m | 32.2 | 6.3 | 0 | Fair |

| 03:00 a.m | 31.1 | 5.4 | 0 | Fair |

| 04:00 a.m. | 31.1 | 6.3 | 0 | Fair |

| 05:00 a.m. | 30.0 | 6.7 | 0 | Fair |

| 06:00 a.m. | 28.9 | 6.3 | 0 | Fair |

| 07:00 a.m. | 28.9 | 5.8 | 0 | Fair |

| 08:00 a.m. | 33.9 | 6.7 | 0 | Fair |

| 09:00 a.m. | 37.8 | 10.7 | 0 | Low Drift |

| 10:00 a.m. | 42.8 | 11.2 | 0 | Low Drift |

| 11:00 a.m. | 42.8 | 10.7 | 0 | Low Drift |

| 12:00 p.m. | 45.0 | 9.4 | 0 | Low Drift |

| 1:00 p.m. | 46.1 | 12.5 | 0 | Low Drift |

| 2:00 p.m. | 46.1 | 9.4 | 0 | Low Drift |

| 3:00 p.m. | 46.1 | 8.9 | 0 | Low Drift |

| 4:00 p.m. | 45.0 | 8.9 | 0 | Low Drift |

| 6:00 p.m. | 45.0 | 8.9 | 0 | Low Drift |

| 7:00 p.m. | 43.9 | 9.8 | 0 | Low Drift |

| 8:00 p.m. | 42.2 | 6.3 | 0 | Fair |

| 9:00 p.m. | 40.0 | 5.8 | 0 | Fair |

| 10:00 p.m. | 37.8 | 5.8 | 0 | Fair |

| 11:00 p.m. | 36.1 | 6.3 | 0 | Fair |

| Surface | Boundary Condition | Boundary Condition Value |

|---|---|---|

| ETFE | Radiation, convection, heat flux | Heat transfer coefficient (h) = 32 W/m2K, Heat flux magnitude = 900 W/m2, Temperatures of 47 °C for air, 23 °C for water, and 31 °C for porous |

| CFRP | Radiation, convection | Temperatures of 44 °C for air, 27 °C for water, and 34 °C for porous |

| EVA1 | Heat flux | Heat flux magnitude = 25 W/m2 |

| Silicon cells | Heat flux | Heat flux magnitude = 673 W/m2 |

| Mesh Density | Max Cell Temp (°C) | Power Output (W) |

|---|---|---|

| Coarse (45k) | 33.78 | 57.1 |

| Medium (90k) | 33.67 | 57.8 |

| Fine (180k) | 33.65 | 57.9 |

| Non-Cooled Panel | Air-Cooled Panel | Water-Cooled Panel | Porous Material-Cooled Panel | |

|---|---|---|---|---|

| PV panel output power generated (W) | 44.2 | 46 | 60 | 58 |

| Power consumption (W) | 0 | 2.71 | 2.16 | 2.16 |

| Net output power (W) | 44.2 | 43.2 | 57.8 | 55.8 |

| Net output power saving (W) | -- | −0.953 | 13.6 | 11.6 |

| Percentage of net output power saving (%) | - | −2.156 | 30.9 | 26.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Menacer, B.; Baghdous, N.E.H.; Narayan, S.; Al-lehaibi, M.; Osorio, L.; Tuninetti, V. Efficiency Enhancement of Photovoltaic Panels via Air, Water, and Porous Media Cooling Methods: Thermal–Electrical Modeling. Sustainability 2025, 17, 6559. https://doi.org/10.3390/su17146559

Menacer B, Baghdous NEH, Narayan S, Al-lehaibi M, Osorio L, Tuninetti V. Efficiency Enhancement of Photovoltaic Panels via Air, Water, and Porous Media Cooling Methods: Thermal–Electrical Modeling. Sustainability. 2025; 17(14):6559. https://doi.org/10.3390/su17146559

Chicago/Turabian StyleMenacer, Brahim, Nour El Houda Baghdous, Sunny Narayan, Moaz Al-lehaibi, Liomnis Osorio, and Víctor Tuninetti. 2025. "Efficiency Enhancement of Photovoltaic Panels via Air, Water, and Porous Media Cooling Methods: Thermal–Electrical Modeling" Sustainability 17, no. 14: 6559. https://doi.org/10.3390/su17146559

APA StyleMenacer, B., Baghdous, N. E. H., Narayan, S., Al-lehaibi, M., Osorio, L., & Tuninetti, V. (2025). Efficiency Enhancement of Photovoltaic Panels via Air, Water, and Porous Media Cooling Methods: Thermal–Electrical Modeling. Sustainability, 17(14), 6559. https://doi.org/10.3390/su17146559