Abstract

Digitization and green low-carbon are the main directions of China’s economic development in the future. This paper aims to explore the relationship between improvements in the digital level of manufacturing industry segments and carbon emissions. It is found that the digitization level of China’s manufacturing industry segments is still at a low level, which needs to be further improved, and the digitization level of technology-intensive industries is higher than that of capital-intensive and labor-intensive industries. There is a serious misallocation of production factors and R&D factors among manufacturing industries, which is mainly caused by capital factors. Improvement in the digital level of manufacturing industry segmentation can significantly improve the double-layer factor allocation efficiency of the manufacturing industry, and can synchronously realize carbon emissions reduction through improvements in the double-layer factor allocation efficiency of the manufacturing industry; in other words, the improvement in the digital level of China’s manufacturing industry has the dual effects of improving factor allocation efficiency and carbon emissions reduction. Further analysis shows that this effect has significant heterogeneity of ownership. Therefore, China should focus on accelerating the digital transformation of the manufacturing industry, improve the allocation efficiency of traditional and R&D factors in the manufacturing industry through this digital transformation, and accelerate the realization of green and low-carbon development.

1. Introduction

In the context of the rapid development of the digital economy, whether the digital transformation of the manufacturing industry can promote the acceleration of carbon reduction and sustainable development while affecting the production efficiency and resource allocation efficiency of the manufacturing industry is a research topic worthy of in-depth exploration. China’s industrial sector carbon emissions have been on a rapid growth track since 2001, and the growth rate of carbon emissions began to ease in 2013, but, in recent years, there has been a trend of upward acceleration; as of 2019, China’s industrial sector carbon emissions are still as high as 9794.75 million tons of carbon dioxide. Therefore, as a major energy consumer and carbon emitter in China, whether the industrial sector can successfully achieve carbon emissions reduction and green development is crucial to the realization of China’s carbon peak and carbon neutrality goals.

This article focuses on China’s manufacturing industry as the research object, analyzing the relationship between its level of digital transformation and carbon emissions. The existing literature has found that the development of the digital economy is beneficial for achieving carbon reduction [1,2], and industrial digitization is an important component of the digital economy. Therefore, the digitalization of the manufacturing industry will inevitably have a significant impact on China’s carbon emissions level. In addition, the digitalization of the manufacturing industry accelerates the deep integration of modern information networks and digital technologies with the real economy, such as manufacturing, and, while releasing the potential of digital technology applications in new organizations, new models, and new business formats, it will also lead to the reorganization, upgrading, and reallocation of factors through the complementarity and substitution of digital technology and capital and labor factors, as well as the expansion of technology [3], which will then act upon the factor allocation efficiency between manufacturing industries, and ultimately lead to the transformation of manufacturing efficiency and total factor productivity. The digital transformation of the manufacturing industry embeds digital technology and data elements into the production process, leading to significant changes in the optimal combination of labor and capital within the manufacturing industry [4]. In addition, the digital transformation of the manufacturing industry will also have an impact on the internal R&D activities of enterprises, thereby affecting the optimal combination of R&D personnel and R&D investment within manufacturing enterprises. In summary, the digital transformation of the manufacturing industry will have a significant impact on the efficiency of the allocation of traditional production factors and research and development factors. This impact stems from the reshuffling and reconfiguration of production factors and research and development factors between and within industries caused by the digital transformation of the manufacturing industry. The reshuffling of factors between industries will inevitably affect the structure of the manufacturing industry. Due to the varying levels of energy consumption and carbon emissions in different industries, changes in the structure of the manufacturing industry will inevitably have an impact on carbon emissions levels. In view of this, it is necessary to explore whether the digital transformation of the manufacturing industry is conducive to achieving carbon emissions reduction while affecting the efficiency of production and research and development factor allocation.

2. Literature Review

In the existing literature, research related to this article mainly includes two aspects: One is the study of the resource allocation effect of digital transformation in manufacturing industry. Most of the existing literature suggests that the development of the digital economy can significantly improve the production efficiency of enterprises. For example, Zhao et al. [5] conducted empirical tests based on Chinese A-share manufacturing listed companies and found that the digital transformation of manufacturing enterprises can improve their production efficiency. Du and Zhang [6] found that there is a significant inverted U-shaped relationship between the level of digital transformation and the productivity of manufacturing enterprises. Bai and Yu [7] found that the development of the digital economy may bring negative impacts, that is, the development of the digital economy will reduce the price markup of enterprises. The main mechanisms by which digital transformation affects enterprise productivity include economies of scale, economies of scope, and technological innovation effects [6], increasing market transparency and information asymmetry [8], strengthening the specialized division of labor among enterprises [9], accelerating knowledge spillovers between enterprises [10], optimizing human capital systems, strengthening inter industry integration and development [5], and enhancing the competitive environment of enterprises [7]. In addition, many scholars have studied the direct impact of digital transformation on the efficiency of factor allocation. At the micro-enterprise level, Wu and Ren [11] found that the use of data elements is beneficial for improving the information asymmetry between supply and demand, enhancing the matching degree between supply and demand, and thus optimizing the efficiency of factor allocation for enterprises. Wei [12] matched enterprise data with city data and conducted empirical research, finding that an increase in the level of digital economic development in a certain urban area is beneficial for improving the efficiency of enterprise factor allocation. At the regional level, research by Cong and Yu [13] has found that the development of regional digital economy can promote the re-flow and allocation of labor, thereby improving the efficiency of labor factor allocation. Wang and Zhang [14] empirically analyzed urban panel data and found that, although the development of the digital economy can significantly improve the efficiency of labor allocation, it deteriorates the efficiency of capital factor allocation. In view of this, the article proposes to improve the above-mentioned contradictions by promoting regional integration of urban agglomerations. Yi and Zhao [15] found that digital transformation mainly improves the efficiency of overseas investment by suppressing management shortsightedness, increasing the level of enterprise risk-taking, and reducing agency costs. Guo and Wang [16] found that digital transformation is beneficial for improving the efficiency of enterprise capital allocation, and this result is more significant in enterprises with better digital economy development environment and higher asset specificity, state-owned enterprises, and capital-intensive and technology-intensive enterprises. Contrasting with the above-mentioned literature on the impact of the digital economy on the allocation efficiency of traditional production factors from the micro enterprise level and the regional level, this paper attempts to further incorporate the high-level factor of R&D factors into the research framework of factor allocation efficiency and study the impact of the digital transformation of manufacturing industry on the allocation efficiency of manufacturing dual-layer factors (traditional production factors and R&D factors).

There are also some studies in the literature on the relationship between digital transformation in manufacturing and carbon emissions. The rapid popularization, penetration, and application of digital technology in the manufacturing industry can not only reduce energy input intensity in the production process, but also promote technological innovation and optimize the industrial structure of the manufacturing industry to achieve carbon emissions reduction goals [17]. In addition, the digital economy can also stimulate the rapid development of green and low-carbon industries [18], which is conducive to reducing the overall carbon emissions level of the manufacturing industry. As can be seen from the above literature, the digital industrialization in the manufacturing industry has received strong support from existing research for achieving carbon reduction [19]. However, the existing literature on the quantitative evaluation of industrial digitization and its impact on carbon emissions is relatively weak.

Based on the above literature, the existing research on the relationship between digital economy and carbon emissions has begun to deepen. As far as digital industrialization and industrial digitalization are concerned, most of the existing studies focus on the impact of digital industrialization on factor allocation efficiency and carbon emissions, but there are few studies on the factor allocation effect and carbon emissions effect of industrial digitalization. In addition, the existing studies do not integrate the digital economy, factor allocation efficiency, and carbon emissions into a unified research framework to systematically study the internal logical relationship among them. This paper examines the impact of the digitalization level of the manufacturing industry on the factor misallocation and carbon emissions. In terms of the analytical framework, on the one hand, this paper tries to incorporate R&D factors into the research framework to investigate the impact of the improvement in the digital transformation of the manufacturing industry on the allocation efficiency of traditional production factors and R&D factors. On the other hand, this paper attempts to incorporate the digitalization of manufacturing sub-sectors, the efficiency of dual-layer factors allocation, and carbon emissions into a unified analytical framework, and comprehensively analyze the internal relationship and mutual influence mechanism of the above three.

The innovation of this paper is the following aspect: This paper incorporates the digitalization of the manufacturing industry, the efficiency of factor allocation, and carbon emissions into the unified theoretical analysis framework, further extends the factor allocation effect of the digital economy development to the field of carbon emissions, and comprehensively examines the comprehensive impact and internal mechanisms of the digital economy development represented by the digitalization of the manufacturing industry on the factor allocation efficiency and carbon emissions in the manufacturing industry.

3. Theoretical Analysis

The digital transformation of the manufacturing industry essentially involves the widespread application and rapid popularization of digital technology and data elements in the segmented industries of the manufacturing industry. A study has found that the rapid popularization and application of digital technology will intensify the level of competition among enterprises, thereby reducing the price markup level of enterprises and ultimately reducing the dispersion of price markup. This is beneficial for improving the resource allocation efficiency and total factor productivity within the manufacturing industry [7]. On the other hand, the improvement in the level of industrial digitalization involves the combination of digital technology and its associated factors with traditional factors of production. The level of industrial digitalization endows traditional factors of production through digital technology and digital factors, as well as the substitution of capital and labor factors through digital technology, which ultimately leads to changes in the complementary and substitution relationship between traditional factors of production, such as capital and labor, in the industry, and triggers changes in the optimal equilibrium allocation and combination of production factors in the industry [3]. However, the digitalization of the manufacturing industry determines the relative substitution of digital technology or digital factors for traditional production factors according to the allocation efficiency [20,21], that is, digital technology or digital elements can strengthen the matching degree between factor demand and their own factor endowment under the optimal combination of factors within manufacturing enterprises by exerting their synergistic effects, ultimately improving the factor allocation efficiency of the manufacturing industry [22]. In addition, the improvement in the digital level of the manufacturing industry further enhances the flexibility of production and operation activities in various sub-industries, that is, on the one hand, the acceleration of the process of “machine substitution” can force workers to improve their digital skills and enable them to adapt to more jobs, improve the flexibility and choice space of workers’ job choice, and expand the incremental space for labor flow and allocation between industries [13]. On the other hand, the increase in the proportion of digital production factor investment in manufacturing enterprises makes working conditions more flexible, and new work scenarios and labor employment models, such as flexible employment and home offices, have triggered the re-flow and allocation of labor between industries and have improved the efficiency of the inter-industry allocation of labor factors.

Improvement in the digitalization level in the manufacturing industry can facilitate enterprises to obtain R&D elements in a wider spatial range, such as through online network spaces, which will undoubtedly help manufacturing enterprises optimize the allocation efficiency of their own R&D elements in a more relaxed manner [23]. In addition, the improvement in digitalization level in the manufacturing industry enables deep integration between new digital technologies and R&D elements, making cross-regional and cross-domain R&D collaboration possible [24]. In summary, the digital transformation of the manufacturing industry can promote manufacturing enterprises to obtain R&D factors on a wider scale, alleviate the constraints of manufacturing enterprises on R&D factors and change the configuration of R&D factors, promoting the reflow and configuration of R&D factors, which is conducive to promoting economic growth by strengthening the spillover effects of R&D factors [25]. According to the research of Bai and Yu [7], improvement in the digital level of the manufacturing industry can significantly promote market competition and improve the level of market competition, which makes manufacturing enterprises more inclined to consolidate their market share and competitiveness through R&D and innovation activities and more motivated to shape a more superior internal innovation environment, adopt a more active strategy to gather R&D factor resources, and ensure that their R&D elements maintain a high input–output efficiency as much as possible so as to improve the allocation efficiency of R&D elements.

Based on the above theoretical analysis, this paper proposes a first hypothesis to be verified, which is to be empirically tested later.

Hypothesis 1.

The improvement of the digital level of the manufacturing industry can significantly improve the allocation efficiency of the double factors (traditional production factors and R&D factors) in the manufacturing industry.

The manufacturing industry, as the main economic sector with carbon emissions, directly affects the input intensity and output efficiency of energy intermediate products in various industries due to changes in its factor allocation efficiency. And this will have a significant impact on the scale and proportion of high-polluting and high-emissions industries in the manufacturing industry. According to the research of Bai [4], the factor flow caused by wage differences between industries will lead to a decrease in the proportion of high-polluting and high-emissions industries in the manufacturing industry. The mismatch of factors between industries with different factor intensities results in a lower proportion of technology-intensive industries within the manufacturing sector. In terms of R&D factors, Jin [26] found that the mismatch of R&D factors between China’s high-tech industries and non-high-tech industries decreases innovation output efficiency. Currently, China’s high-tech industry still has a serious shortage of R&D factor investment. From this, the following conclusion can be drawn: the mismatch of R&D elements in China’s manufacturing sector will inevitably have a negative impact on the technological innovation of China’s manufacturing industry, and the speed of technological upgrading will decrease, which will be detrimental to carbon reduction in the manufacturing sector. Based on the above analysis, this article proposes a second hypothesis that needs to be verified.

Hypothesis 2.

The misallocation of double factors in the manufacturing industry is not conducive to carbon emission reduction in the manufacturing industry.

Based on the above two theoretical hypotheses, it can be found that, if the above two hypotheses are true at the same time, this would indicate that improvement in the digital level of the manufacturing industry can achieve overall carbon emissions reduction in the manufacturing industry by optimizing the efficiency of the allocation of double-factors between manufacturing industries. Therefore, this paper proposes a third hypothesis to be verified based on the above two hypotheses.

Hypothesis 3.

The improvement of the digital transformation level of the manufacturing industry can reduce the overall carbon emission level of the manufacturing industry by improving the allocation efficiency of double factors in the manufacturing industry.

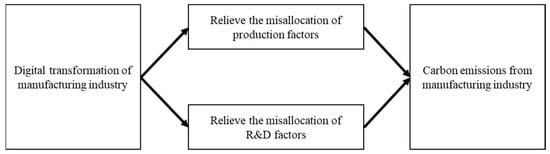

The third hypothesis can perfectly explain the three-level transmission framework diagram of “digitalization of manufacturing → efficiency of dual-factor allocation → carbon emissions”, which can be shown in Figure 1.

Figure 1.

The three-level transmission framework diagram of this article. Source: Own compilation.

4. Data Description and Construction of Main Variable Indicators

4.1. Data Selection and Source Description

The data used in this paper are mainly divided into three categories: (1) The data used to calculate the digital level of the manufacturing industry are mainly from the input-output data of the WIOD database from 2006 to 2014, and the latest sample interval is 2014 because the latest year of the input–output table data in the WIOD database is 2014. (2) The data used to calculate the allocation efficiency of two-tier factors between China’s manufacturing industries are mainly from the China Industrial Statistical Yearbook (2007–2021) and the Industrial Enterprise Science and Technology Activity Statistical Yearbook (2007–2021), corresponding to the relevant data from 2006 to 2020, and the sample of the year interval is selected: one is to match the sample time of the digital level variable of the manufacturing sub-industry, and, on the other hand, 2006–2015 is the three five-year planning periods of China’s “Eleventh Five-Year Plan”, “Twelfth Five-Year Plan”, and “Thirteenth Five-Year Plan”. In different planning periods, the state’s support for manufacturing sub-sectors has changed, which will affect the efficiency of two-tier factor allocation among manufacturing industries. The selection of this time-period sample is conducive to incorporating the influencing factors of national key industrial policy into the empirical model in the empirical process and to avoid the endogeneity problem caused by the omission of variables. (3) The carbon emissions data of various sub-sectors of China’s manufacturing industry over the years were mainly obtained from the WIND database.

4.2. Construction of Main Variable Indicators

The level of digitalization of manufacturing sub-industries: This paper examines the digitalization level of each sub-industry of the manufacturing industry from the input side, drawing on the method of Bai [27]. According to the international standard industry classification (ISIC Rev4.0), the three industries of computer, electronic, and optical products manufacturing, the postal and communication industry, and the telecommunications industry in the WIOD database are regarded as the basic sectors of the digital economy. And this paper uses the industrial input–output data of the WIOD database to calculate the direct consumption coefficient and the complete consumption coefficient of the digital elements of each industry by calculating the input consumption level of each sub-industry in the manufacturing industry in the above-mentioned basic sectors of the digital economy. The direct consumption coefficient is calculated as follows:

Among them, is the direct consumption of production and is the unit output of industry i to industry j. The specific formula for calculating the complete consumption coefficient of the manufacturing industry i to the basic industry sector j of the digital economy is as follows:

The items on the right side represent the direct consumption of industry i to the basic industry sector j of the digital economy, the first round of indirect consumption, the second round of indirect consumption, etc. The specific calculation is simplified with the use of the Leontief inverse matrix.

The efficiency of the allocation of two-tier factors between manufacturing industries: In terms of the output of traditional production factors and R&D factors, this paper draws on the method to select the added value of each sub-sector of the manufacturing industry and the number of patent applications of each sub-sector of the manufacturing industry as output variables. Capital elements include traditional productive capital and R&D capital. Among them, the production capital is expressed by the net fixed asset value of the corresponding industry in the China Industrial Statistical Yearbook over the years. R&D capital is calculated by using the perpetual inventory formula Kit = (1 − η) Kit−1 + Iit: among them, the depreciation rate (η) is 15%, Iit is the amount of internal R&D expenditure of the industry i in year t, and then, according to the internal R&D expenditure of each industry in 2006, the formula Ki2006 = Ii2006/(gi + η) is used to determine the capital stock of the base period, where gi represents the average annual growth rate of Ii in the sample range of 2006–2015. Based on the method of Brandt et al. [28], this paper constructs a mathematical model framework that can uniformly measure the allocation efficiency of double-factors in the manufacturing industry. It is assumed that the overall production function of the manufacturing industry at the national level and the production function of the manufacturing sub-industry i are, respectively, and . The production function not only describes the traditional production activities, but also the production function of the R&D and innovation activities of the manufacturing industry, and the subsequent model derivation and related frameworks are also applied to the traditional production activities and R&D activities so that the efficiency of the allocation of double-factors can be measured under the unified model framework. At the same time, it is assumed that the overall output of the manufacturing industry at the national level is the CES production function of the output of each sub-sector: . From this, the overall productivity or innovation efficiency of the manufacturing industry can be calculated as follows:

And ki = Ki/K, li = Li/L. It can be seen that the focus of the model calculation is to obtain the proportion of factor inputs. By assuming two states, the distorted state and the effective state, assuming that the factor prices of capital and labor (productive physical capital and labor, R&D capital, and R&D personnel) in the distorted state are and , respectively, and, assuming that the distortion coefficient or is 1, the proportion of industrial factor input in the undistorted state can be obtained. The input ratios of the two states are ki, li and , and the calculation formulas are as follows:

And . Substituting Equations (4) and (5) into Equation (3) can obtain the total factor productivity A and A* of the manufacturing industry in the distorted state and the effective state, and then the degree of factor misallocation (production factors and R&D factors) between manufacturing industries is d = A*/A − 1. If only the price distortion coefficient of capital factor is assumed to be 1, the production or innovation efficiency Ak* can be obtained when only the capital misallocation is eliminated, and then the efficiency loss caused by capital misallocation is dk = Ak*/A − 1. If only the price distortion coefficient of the labor factor is assumed to be 1, the production or innovation efficiency Al* can be obtained when only the labor misallocation is eliminated, then the efficiency loss caused by labor misallocation is dl = Al*/A − 1. The empirical model of this paper focuses on the factor misallocation of the manufacturing industry segments, so this paper calculates the overall factor misallocation of the manufacturing industry; the misallocation of capital and labor, the expressions of total factor misallocation, capital misallocation, and labor misallocation of manufacturing industry i are, respectively, , , and . Among them, , , and are the output levels of the industry i according to the proportion of effective factor input, only capital according to the proportion of effective input, and only labor according to the proportion of effective input. Y represents the actual output level of the manufacturing industry, and the above expression is the deviation level between the industry output in the effective state and the actual output, which is used as a proxy index for the misallocation of factors in the manufacturing sub-industry. Similarly, the above expressions are simultaneously applicable to the traditional production factors and R&D factors of the manufacturing sub-industry.

Main control variables: (1) Industry capital intensity (rcap), which is measured by the proportion of the industry’s net fixed assets in the total output value. (2) Industry R&D density (rd), measured by the proportion of the output value of new products in the industry to the total output value. (3) Industry monopoly power (mono), which is measured by the ratio of the industry’s main business income to the main business cost. (4) Whether it is a key support industry (g) during the “Eleventh Five-Year Plan” or “Twelfth Five-Year Plan” period, it is a key industry supported by the state, so the variable is equal to 1, and otherwise it is 0. (5) Ownership structure (own), expressed by the proportion of the total output value of state-owned enterprises in the industry to the total output value of the industry, as shown in Table 1.

Table 1.

Calculation steps, procedures, and functions of main variable indicators.

4.3. Characteristic Facts

4.3.1. The Level of Digitalization of Manufacturing Sub-Industries

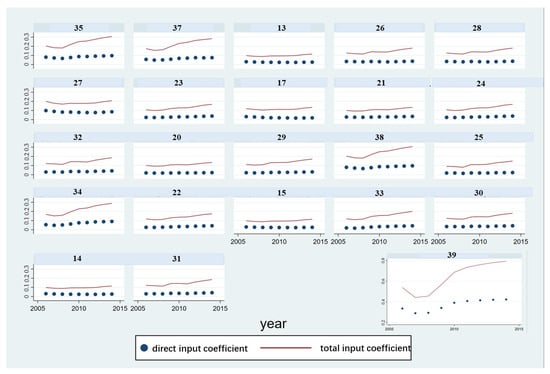

As can be seen in Figure 2, the level of digitalization in China’s manufacturing sub-sectors is on the rise year by year. However, as of the latest year of the sample, the digitalization of most of China’s manufacturing industry segments is still at a low level. In terms of the complete consumption coefficient, which can more comprehensively reflect the digital level of various sub-sectors of the manufacturing industry, the complete consumption coefficient of labor-intensive industries is low, basically between 10% and 20%. The digital complete consumption coefficient of technology-intensive industries is more than 20%, and the computer, communication, and other electronic equipment manufacturing industry is the highest, and its digital level is close to 80%. The digitalization level of capital-intensive industries and high-emissions and heavy-polluting industries is between labor-intensive industries and technology-intensive industries, and the value of the complete consumption coefficient of digital factors fluctuates between 15 and 20%. To summarize, in the choice of industrial structure of the digital economy, due to the natural complementarity of digital technology and the intangibility and low energy consumption of the service industry, the digital economy will be more biased towards the service industry in terms of industrial structure bias, and the pace of the deep integration of digital technology into the manufacturing industry is significantly slower than that of the service industry, resulting in the general low level of digitalization in China’s manufacturing sub-industries, and there is still a lot of room for improvement.

Figure 2.

Schematic diagram of the digitalization level of China’s manufacturing sub-industries. Source: Own compilation. Data source: The author calculated and plotted the data according to the input-output table of the WIOD database.

Figure 2 fully demonstrates the accelerating trend of the digital transformation of China’s manufacturing industry. Therefore, using this data for empirical testing, the results still have important implications for China’s present and future.

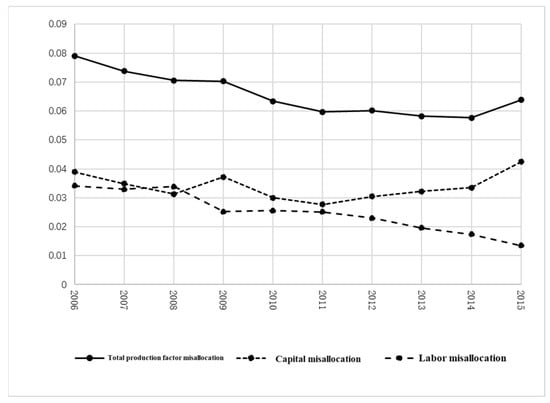

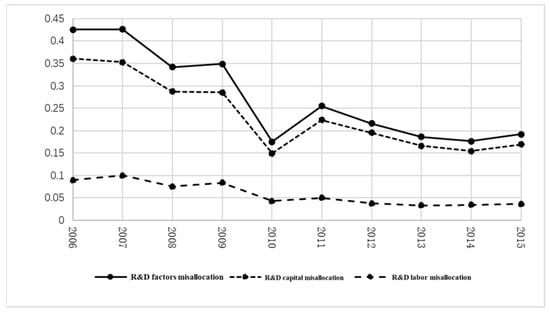

4.3.2. Double-Factor Allocation Efficiency in the Manufacturing Industry

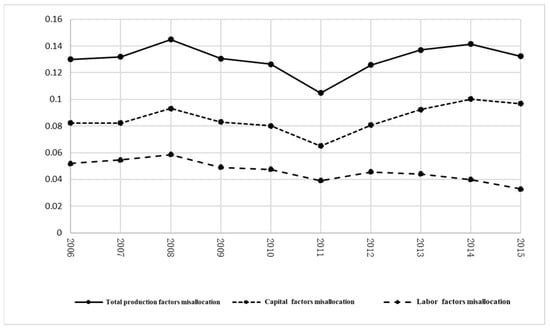

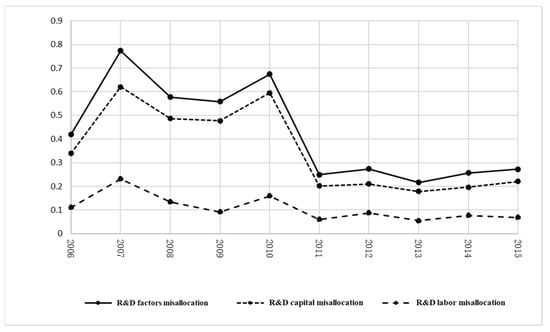

Based on the quantitative evaluation model of the double-factor allocation efficiency between manufacturing industries discussed above and the production and the R&D-related data of China’s manufacturing industry from 2006 to 2015, the model parameters were calibrated with reference to Brandt et al. [28] to make σ = 1/3. Referring to the estimation results of Yang [29] on the production function of China’s manufacturing enterprises and He et al. [24] on the output elasticity of the production factors in China’s innovation function, this paper takes the α of the production process and the innovation process as 2/3. As can be seen in Figure 3 and Figure 4, there is a serious misallocation between production factors and R&D factors in China’s manufacturing industry. As far as production factors are concerned, although the degree of misallocation is declining year by year, as of 2015, the overall misallocation level is still as high as 6.38%, and, from the perspective of factor misallocation, the severity of capital factor misallocation is significantly higher than that of labor factor misallocation. In terms of R&D factors, the level of R&D factors’ misallocation between manufacturing industries also showed a significant decline from 2006 to 2015, but, as of 2015, the total misallocation of R&D factors between manufacturing industries was still as high as 19.19%, and the misallocation of R&D capital was significantly higher than that of R&D personnel. In summary, the level of R&D factor misallocation between manufacturing industries is significantly higher than that of production factors, which further highlights the necessity of including R&D factors in the research scope of this paper.

Figure 3.

The degree of production factor misallocation between manufacturing industries. Source: Own compilation.

Figure 4.

The degree of R&D factor misallocation between manufacturing industries. Source: Own compilation.

According to the above model, the factor input intensity of each industry is = li/li*, = . If and are greater than 1, it means that the factor investment in the industry is excessive, while less than 1 means that the factor investment is insufficient. In order to distinguish between production factors and R&D factors, and are used to represent the investment intensity in production factors in industries, and and are used to represent the investment intensity in industry R&D factors. As can be seen in Table 2, the investment intensity in double-layer factors in various manufacturing industries in the most recent year (2015) is very heterogeneous. Among them, the industries in which the input of capital and labor factors into production factors are in a state of insufficiency, and they are all labor-intensive industries, and the rest also include four technology-intensive industries. However, the investment in labor and capital factors in heavily polluting industries, such as paper and paper products and chemical fiber manufacturing, is seriously excessive. The two major energy industries, as well as the two major metal smelting industries, are all high-carbon emissions industries, and, since these two industries are capital-intensive natural-monopoly industries, their capital factor input is in a state of serious excess, while labor factor input is seriously insufficient. It can be seen that the current efficiency of production factor input in China’s manufacturing industry is still low, and the excessive factor input of high-pollution and high-emissions industries coexists with the insufficient factor investment of technology-intensive industries, which is an important reason for the high level of carbon emissions in the manufacturing industry, and it is urgent to solve this by improving the efficiency of factor allocation. In terms of the industrial investment in R&D factors, the structural problems are mainly manifested in the excessive and redundant investment in R&D factors in labor-intensive industries and heavy pollution and high-emissions industries, while the investment in R&D factors in technology-intensive industries with a high level of digitalization is seriously insufficient, which will inevitably drag down the pace of innovation in technology-intensive industries, and it is not conducive to technology-intensive industries to play a synergistic effect to promote the production process and technological innovation of heavy-pollution and high-carbon-emissions industries and drag down the overall emissions reduction and efficiency of the manufacturing industry. The above-mentioned characteristics also provide preliminary evidence for the inferences and hypotheses put forward in the theoretical analysis part of this paper.

Table 2.

Input efficiency of double factors in each sub-sector of the manufacturing industry in 2015.

5. Empirical Strategies and Empirical Results Analysis

5.1. Model Settings

Based on the above theoretical analysis, the benchmark model for empirical regression analysis is constructed as follows:

Models (6) and (7) are used to empirically test the impact of the digitalization level of manufacturing sub-sectors on the allocation efficiency of production factors and R&D factors, respectively. Among them, i and t represent the industry and time, respectively; , , and represent the total misallocation, capital misallocation, and labor misallocation of production factors in year t of the industry i; , , and represent the total misallocation, capital misallocation, and labor misallocation of R&D factors in year t of industry i; and and represent the direct consumption coefficient and complete consumption coefficient of the digital elements of industry i, that is, the digital level of industry i. represents a series of control variables, which have been described above and will not be repeated here. is the time effect and is the error term.

In order to test hypothesis 2 proposed in this paper, the empirical model is constructed as follows:

The explained variables of models (8) and (9) are the logarithms of the carbon dioxide emissions of industry i in year t, and the core explanatory variables are the misallocation variables of production factors and R&D factors, respectively. Other settings of the models are the same as those of model (6) and model (7). The descriptive statistical results of the main variables used for empirical regression are shown in Table 3.

Table 3.

Descriptive statistical results for the main variables.

5.2. Endogenous Problem Handling

The main endogenous problems faced by the above models in this paper are the interaction between the misallocation of double-factors and the digitalization of the manufacturing industry, as well as the omission of important explanatory variables. In order to solve the above endogeneity problem, this paper uses the lag term of the direct consumption coefficient and the complete consumption coefficient of digital elements as the instrumental variables, and selects the two-stage least squares method (IV-2SLS) for regression, and then continues to use the generalized moment estimation (GMM) method to perform the correlation robustness test.

5.3. Analysis of Empirical Results

In order to explore the relationship among the digitalization of the manufacturing industry, the allocation efficiency of double-factors, and carbon emissions, this paper firstly uses the two-digit industry-level panel data from 2006 to 2014 to perform IV-2SLS regression according to model (6) and model (7), and empirically explores the impact of the digitalization level of the manufacturing industry on the efficiency of double-factor allocation. The empirical results of model (6) are shown in Table 4; regardless of whether the explanatory variable is the total misallocation of production factors or capital misallocation, the regression coefficients of digi1 and digi2 are significantly negative at the 1% significance level, indicating that the improvement in the digitalization level of the manufacturing industry can significantly reduce the total misallocation of production factors and capital misallocation. When the explained variable is the labor misallocation of production factors, the coefficient of digi1 is significantly negative at the 1% significance level, and the coefficient of digi2 is significantly negative at the 5% significance level, which also indicates that the improvement in the digitalization of the manufacturing industry can significantly improve the allocation efficiency of labor factors.

Table 4.

The impact of digitalization in the manufacturing industry on the allocation efficiency of production factors in the manufacturing industry.

In order to explore the impact of the improvement in the digital transformation of the manufacturing industry on the allocation efficiency of R&D factors in the manufacturing industry, the empirical regression results of model (7) are shown in Table 5. From the empirical results in Table 5, it can be seen that when the explained variables are replaced by the misallocation of R&D factors (total misallocation, R&D capital misallocation, and R&D personnel misallocation) in the manufacturing industry, the regression coefficients of digi1 and digi2 are significantly negative in at least a 5% significance level, indicating that the improvement in the digital level of the manufacturing industry can significantly reduce the misallocation of R&D factors in the manufacturing industry and improve the allocation efficiency of R&D factors in the manufacturing industry. The empirical results of model (6) and model (7) show that the improvement in the digital transformation of the manufacturing industry can significantly improve the allocation efficiency of the double-factors (traditional production factors and R&D factors) in the manufacturing industry, and the content of Hypothesis 1 proposed above is verified.

Table 5.

The impact of digitalization of the manufacturing industry on the R&D factor allocation efficiency in the manufacturing industry.

Next, the empirical regression analysis of models (8) and (9) was carried out to explore the impact of the allocation efficiency of double-factors in the manufacturing industry on the carbon emissions level of the industry. As shown in Table 6, the regression coefficients of the production factors misallocation (total misallocation, capital misallocation, and labor misallocation) and the R&D factors (total misallocation, R&D capital misallocation, and R&D personnel misallocation) are all significantly positive at the 1% significance level, indicating that the increase in the degree of double-layer factors misallocation between manufacturing industries will increase the carbon emission level of the industry. This empirical result indicates that the improvement in the efficiency of production and R&D factors allocation among manufacturing industries will contribute to the upgrading of the manufacturing industry structure. In other words, the proportion of high-energy-consuming and high-emissions industries in the manufacturing sector will decrease, while the proportion of technology-intensive industries is expected to increase. This will inevitably help the manufacturing industry reduce carbon dioxide emissions. In addition, technology-intensive industries will gain more abundant R&D and production factors in the process of improving the efficiency of dual-factors allocation between manufacturing industries, which will inevitably benefit the enhancement of independent innovation capabilities and the upgrading of production and manufacturing technologies in technology-intensive industries, and this will have a positive impact on carbon emissions reduction. Thus, Hypothesis 2 is empirically verified.

Table 6.

The impact of the double-factor allocation efficiency on the carbon emissions in the manufacturing industry.

Based on the above empirical regression results, it can be found that there is a significant positive correlation between the digitalization level of the manufacturing industry and the allocation efficiency of the double-factor allocation of the manufacturing industry, while there is a significant negative correlation between the allocation efficiency of the double-factor allocation of the manufacturing industry and the carbon emissions level of the industry, and the relationship among the three shows the following characteristics: The improvement in the digitalization level of the manufacturing industry will improve the allocation efficiency of dual-layer factors in the manufacturing industry, thereby reducing the carbon emission level of the manufacturing sub-industry. It can be preliminarily inferred that Hypothesis 3 is valid, that is, the improvement in the digital level of the manufacturing industry can reduce the overall carbon emissions level of the manufacturing industry by improving the efficiency of the allocation of double-factors in the manufacturing industry.

5.4. Robustness Test

Firstly, the GMM method is used to estimate the robustness of model (6)–model (9) instead of the former estimation method, and the results of the robustness test are shown in Table 7. In the GMM results, when the explained variables are the misallocation of production factors (total misallocation, capital misallocation, and labor misallocation) and R&D factors misallocation (total misallocation, R&D capital misallocation, R&D personnel misallocation), the regression coefficients of manufacturing digital variables are all significantly negative at least 5% significance level, and when the explained variable is industry carbon dioxide emissions, the regression coefficients of each factor’s misallocation variable are significantly negative at the 1% significance level. The above empirical regression results are completely consistent with the estimation results of the IV-2SLS method in the previous paper, indicating that the empirical results in this paper have strong robustness.

Table 7.

Robustness test based on IV-GMM method (Robustness test 1).

In order to further verify the effectiveness of the double-factor allocation efficiency of manufacturing industry mentioned in Hypothesis 3 as the mediating effect between the improvement of manufacturing digitalization level and carbon emissions, this paper continues to construct an intermediary effect model to verify the three hypotheses proposed in this paper. The mediating effect model is constructed as follows:

Table 8 reports the regression estimation results of the above mediating effect model, and the first column examines the impact of the improvement in digitalization level in the manufacturing industry on carbon emissions without considering the double-factor misallocation variables. The regression results show that the variable coefficient of the digitalization level of the manufacturing industry is negative and significant at the 5% level, indicating that the improvement in the digitalization level of the manufacturing industry can reduce the carbon emissions level of the industry.

Table 8.

Robustness test based on mediation effect (Robustness test 2).

The regression results show that the coefficient of the variable coefficient of the digitalization level of the manufacturing industry is negative and significant at the 1% level, indicating that the improvement in the digitalization level of the manufacturing industry can significantly reduce the misallocation of the double factors in the manufacturing industry and improve the allocation efficiency of the double-factors. Columns three and five of Table 7 introduce both digital variables and double-layer factor misallocation variables in the manufacturing industry to investigate their impacts on the carbon emissions level of the industry. The regression results show that the coefficient of the misallocation variable of the double-factor is significantly positive at the level of 1%, and the variable coefficient of the digital level of the manufacturing industry changes from the original significantly negative to non-significant, indicating that the double-factor allocation efficiency, as an intermediary mechanism of the digital level of the manufacturing industry affecting the carbon emissions level of the industry, is supported by the empirical test results, and the content of Hypothesis 3 is further confirmed, which also shows the robustness of the empirical results in this paper.

5.5. Further Analysis of Ownership Heterogeneity Analysis

Considering that there are significant differences in the flow allocation mode and efficiency of production factors and R&D factors in different ownership departments, it is likely that the impact of the improvement in industry digitalization level on the allocation efficiency of two-tier factors in the state-owned sector and the non-state-owned sector in the industry may be significantly heterogeneous. Therefore, it is necessary to conduct an ownership heterogeneity analysis on the factor allocation effect of industry digitalization so as to explore whether the double-factor allocation efficiency is effective as an intermediary mechanism for the level of industry digitalization to affect industry carbon emissions in different ownership sectors. Based on this, this paper deducts the data of state-controlled industrial enterprises from the variable data of industrial enterprises above a designated size, distinguishes the industry data of the non-state-owned sector from the state-owned sector, and then uses the factor allocation efficiency model of this paper to measure the double-factor allocation efficiency of different ownership departments, and then introduces it into the empirical model for empirical testing.

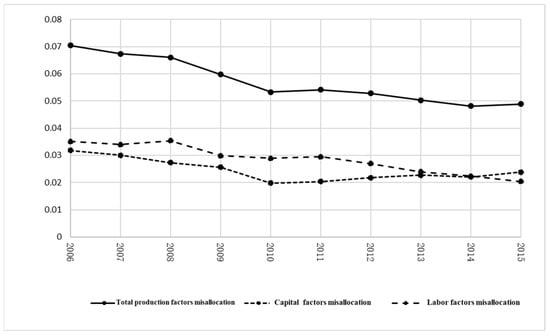

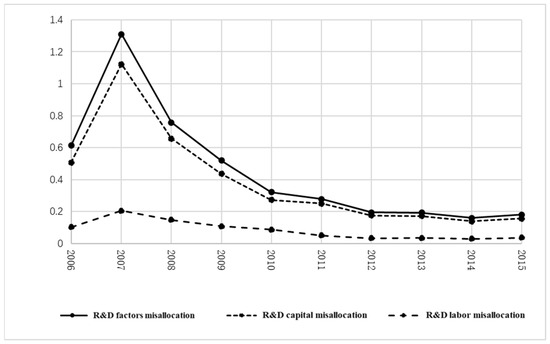

Figure 5 and Figure 6 are schematic diagrams of the degree of two-tier factor misallocation within the state-owned sector. Figure 7 and Figure 8 illustrate the degree of two-tier factor misallocation within the non-state-owned sector. Through comparison, it can be seen that the degree of production factors misallocation within the state-owned sector is significantly higher than that of the non-state-owned sector, and the degree of production factors misallocation in the state-owned sector has not shown an alleviating trend, and its total misallocation level is still as high as 13.22% as of 2015. The degree of production factors misallocation in the non-state-owned sector has been decreasing year by year, and, as of 2015, it is less than 5%. In terms of different factors misallocation, the capital misallocation within the state-owned sector is always higher than the labor misallocation, while the labor misallocation within the non-state-owned sector was higher than the capital misallocation before 2014, but the capital misallocation exceeded the labor misallocation level for the first time in 2015. This shows that alleviating capital misallocation has become the focus of different ownership sectors to improve the allocation efficiency of production factors. In terms of the R&D factors misallocation, the R&D factors misallocation in the state-owned sector has always been at a high level during the “Eleventh Five-Year Plan” period, and there is no sign of alleviation, and the misallocation level has been significantly alleviated during the “Twelfth Five-Year Plan” period, but it has not further declined, and its total misallocation is still as high as 27.29% as of 2015. During the “Eleventh Five-Year Plan” period, the misallocation of R&D factors in the non-state-owned sector showed a trend of first high and then low misallocation, and the misallocation mitigation trend continued to the “Twelfth Five-Year Plan” period, which has decreased by 18.19% as of 2015. In summary, the allocation efficiency of two-tier factors in different ownership departments shows a very different changing trend, so it is necessary to conduct an ownership heterogeneity analysis.

Figure 5.

The degree of production factors misallocation between industries within the state-owned sector.

Figure 6.

The degree of R&D factors misallocation between industries within the state-owned sector. Source: Own compilation.

Figure 7.

The degree of production factors misallocation between industries within the non-state-owned sector. Source: Own compilation.

Figure 8.

The degree of R&D factors misallocation between industries within the non-state-owned sector. Source: Own compilation.

Firstly, the impact of the improvement in industry digitalization level on the efficiency of two-tier factor allocation within the state-owned sector is empirically analyzed. As can be seen from Table 9, unlike the regression results of the overall sample, the impact of the improvement of industry digitalization level on the total misallocation of production factors and capital misallocation in the state-owned sector is positive, but its regression coefficient is not significant. When the explained variable is the misallocation of labor factors, the regression coefficients of the industry digitalization level variables are all significantly positive at the 1% significance level. The reason for this is that when the level of industry digitalization is improved and the degree of industry competition intensifies [7], the mechanism of factor reorganization, upgrading, reallocation, and efficiency change caused by digitalization are ineffective because the “institutional staffing” system with special property rights within the state-owned sector hinders the implementation of the fundamental principle of the free flow and allocation of labor and survival of the fittest. From the perspective of the impact of industry digitalization on the efficiency of R&D factor allocation in the state-owned sector, the regression coefficients of industry digitalization variables are all significantly positive at the 1% significance level, indicating that the improvement in industry digitalization level has significantly worsened the efficiency of R&D factor allocation within the state-owned sector.

Table 9.

The impact of industry digitalization on the efficiency of two-tier factor allocation in the state-owned sector.

Table 10 shows that improvement in the industry digitalization level can significantly reduce the double-factors’ misallocation within the non-state-owned sector and improve the allocation efficiency of the double-factors.

Table 10.

The impact of industry digitalization on the two-tier factor allocation efficiency in the non-state-owned sector.

6. Conclusions and Implications

This paper calculates the digitization level of China’s manufacturing sub-sectors by using the data of the world input–output table from the WIOD database, matches it with the two-digit industry data of China’s manufacturing industry, and discusses the mechanism of the digitalization of the manufacturing industry and the allocation efficiency of double-factors in the manufacturing industry on carbon emissions. Using theoretical and empirical analysis, this paper found the following: (1) The digital level of China’s manufacturing sub-industries is mostly at a low level, and the digital level of technology-intensive industries is relatively high compared to capital-intensive and labor-intensive industries. Overall, the digitalization level of China’s manufacturing sub-sectors needs to be further improved. (2) There is a serious misallocation between production factors and R&D factors in China’s manufacturing industry, and the misallocation of R&D factors is more serious. From the perspective of subdivided factors, the misallocation between productive capital and R&D capital is higher than that between labor and R&D personnel. (3) Improvement in the digital level of the manufacturing sub-industry can significantly improve the efficiency of the double-factor allocation of the manufacturing industry, and the carbon emissions reduction in the manufacturing industry can be realized through improvement in the double-factor allocation efficiency of the manufacturing industry, that is, the improvement in the digital level of China’s manufacturing industry has the dual effects of factor allocation efficiency improvement and carbon emissions reduction.

The policy recommendations derived from the previous text are as follows: (1) Further deepen the supply-side structural reform and effectively reduce the structural misallocation of two-tier factors in the manufacturing industry. That is, through comprehensive measures, such as changing the way of industrial support, eliminating industry monopolies, and accelerating the pace of reform of the household registration system, the barriers to the cross-industry flow of production factors and R&D factors will be effectively broken. According to the conclusion of this paper, the improvement on the allocation efficiency of the double-factor in the manufacturing industry can not only improve the overall total factor productivity of the manufacturing industry, but also significantly reduce the carbon emissions level of the manufacturing industry. Therefore, the elimination of the misallocation of two-tier factors is not only related to the “efficiency increase” of the industry, but also to the sustainable development and green emissions reduction in the industry. (2) Especially for state-owned enterprises, due to the incomplete marketization of the flow and allocation of production factors in China’s state-owned enterprise sector, the digital transformation of state-owned manufacturing enterprises cannot affect their factor allocation efficiency, and thus cannot have a positive effect on their carbon emissions reduction. Therefore, it is suggested that state-owned enterprise departments must strengthen market-oriented reforms and promote the free and dynamic replacement and flow of internal factors. (3) The research conclusion of this article also has clear implications for manufacturing enterprises, that is, in the process of promoting digital transformation, manufacturing enterprises will inevitably the face dynamic replacement and reconfiguration of R&D personnel and ordinary employees. Only by smoothing the path for digital transformation and adjusting the allocation of production and R&D factors can the efficiency of factor allocation be improved and the green development goals of enterprises be achieved through digital transformation.

Due to factors such as the timeliness and availability of data, the limitations of this study mainly lie in the following aspects: (1) Due to the selection of double-digit industry panel data from China’s manufacturing industry for empirical testing, there are relatively few endogeneity processing methods available. And the data year is relatively outdated, mainly due to the fact that the WIOD database data only goes up to 2014. In future research, authors should strive to collect data on manufacturing industry segmentation in various provinces of China. If the frequency of publishing input–output table data between industries in China is increased to once a year, authors should use the updated yearly and richer “provincial industry” data for empirical research. (2) In the quantitative evaluation model of factor allocation efficiency used in this article, sensitivity and robustness tests were not conducted on the selection of parameters such as the output elasticity coefficients of capital and labor, as well as the output substitution elasticity between industries. This is mainly due to the fact that the model is already a very mature mathematical model, and a large number of existing studies have been applied, which confirms that the model has strong reliability, scientific validity, and robustness. However, in the future, the parameter selection and model setting of the model can still be modified and improved based on the research question and the selection of empirical objectives.

Author Contributions

Conceptualization, B.Z. and W.D.; methodology, B.Z. and J.Y.; software, W.D. and J.Y.; validation, B.Z., W.D. and J.Y.; formal analysis, B.Z. and W.D.; investigation, B.Z., W.D. and J.Y.; resources, W.D. and J.Y.; data curation, J.Y.; writing—original draft preparation, B.Z. and W.D.; writing—review and editing, W.D. and J.Y.; visualization, B.Z. and W.D.; supervision, B.Z. and W.D.; project administration, B.Z. and W.D.; funding acquisition, B.Z. and W.D. All authors have read and agreed to the published version of the manuscript.

Funding

The work was supported by the National Social Science Foundation of China [24BJL087].

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Xu, W.X.; Zhou, J.P.; Liu, C.J. The Impact of Digital Economy on Urban Carbon Emissions: Based on the Analysis of Spatial Effects. Geogr. Res. 2022, 1, 111–129. [Google Scholar]

- Deng, R.R.; Zhang, A.X. Research on the Impact of Urban Digital Economy Development on Environmental Pollution and Its Mechanism. South China J. Econ. 2022, 2, 18–37. [Google Scholar]

- Bai, P.W.; Zhang, Y. Digital Economy, Declining Demographic Dividends and the Rights and Interests of Low-and Medium-skilled Labor. Econ. Res. J. 2021, 5, 91–108. [Google Scholar]

- Bai, P.W. Effects of Labor Allocation Distortion and Distortion-Free Scenarios on Industrial Output in China—An Empirical Study Based on Data of Production Industry Sectors. China Econ. 2014, 9, 99–113. [Google Scholar]

- Zhao, C.Y.; Wang, W.C.; Li, X.S. How Does Digital Transformation Affect the Total Factor Productivity of Enterprises? Financ. Trade Econ. 2021, 7, 114–129. [Google Scholar]

- Du, C.Z.; Zhang, Y. The Research on the Impact Mechanism of the Development of Digital Economy on the Growth of Enterprise Productivity. Secur. Mark. Her. 2021, 2, 41–51. [Google Scholar]

- Bai, P.W.; Yu, L. Digital Economy Development and Firms’ Markup: Theoretical Mechanisms and Empirical Facts. China Ind. Econ. 2021, 11, 59–77. [Google Scholar]

- Goldfarb, A.; Tucker, C. Digital Economics. J. Econ. Lit. 2019, 1, 3–43. [Google Scholar] [CrossRef]

- Yuan, C.; Xiao, T.S.; Geng, C.X.; Sheng, Y. Digital Transformation and Division of Labor Between Enterprises: Vertical Specialization or Vertical Integration. China Ind. Econ. 2021, 9, 137–155. [Google Scholar]

- Tu, X.Y.; Yan, X.L. Digital Transformation, Knowledge Spillover, and Enterprise Total Factor Productivity: Empirical Evidence from Listed Manufacturing Companies. Ind. Econ. Res. 2022, 2, 43–56. [Google Scholar]

- Wu, X.X.; Ren, B.P. The Path and Policy Adjustment of the Reconstruction of Resource Allocation Mechanism under the Background of Digital Economy. Reform Econ. Syst. 2022, 2, 5–10. [Google Scholar]

- Wei, Z.Y. Research on the Impact of the Development of Digital Economy on the Efficiency of Resource Allocation in Manufacturing Enterprises. J. Quant. Technol. Econ. 2022, 3, 66–85. [Google Scholar]

- Cong, Y.; Yu, B.Y. The Influence of Digital Economy on the Efficiency of Chinese Labor Force Resource Allocation. Theory Pract. Financ. Econ. 2020, 2, 108–114. [Google Scholar]

- Wang, Y.; Zhang, Z.B. Digital Economy, Factor Allocation and Regional Integration. Southeast Acad. Res. 2021, 5, 129–138. [Google Scholar]

- Yi, C.; Zhao, X. Does Digital Transformation Improve the Efficiency of Chinese Multinational Enterprises’ Overseas Investment. China Ind. Econ. 2024, 1, 150–169. [Google Scholar]

- Guo, J.; Wang, Z. The Impact of Digital Transformation on Corporate Capital Allocation Efficiency: Empirical Evidence from Listed Manufacturing Enterprises. J. Nanjing Univ. Financ. Econ. 2023, 3, 67–76. [Google Scholar]

- Liu, J.L.; Chen, Y.Y. Digital Technology Development, Temporal and Spatial Effects, Regional Carbon Emissions. Stud. Sci. Sci. 2023, 5, 841–853. [Google Scholar]

- Wu, C.X.; Gao, Y. The Research on the Mechanism and Effect of Digital Economy Driving the Development of Low-carbon Industries. Guizhou Soc. Sci. 2020, 11, 155–161. [Google Scholar]

- Xie, Y.F. The Effect and Mechanism of Digital Economy on Regional Carbon Emission Intensity. Contemp. Econ. Manag. 2022, 2, 68–78. [Google Scholar]

- Wang, L.H.; Yuan, L. Directed Technical Change, Industrial Structural Transformation and Factor Shares in China. Econ. Res. J. 2018, 11, 115–131. [Google Scholar]

- Agrawal, A.; Gans, J.S.; Goldfarb, A. Artificial Intelligence: The Ambiguous Labor Market Impact of Automating Prediction. J. Econ. Perspect. 2019, 2, 31–49. [Google Scholar] [CrossRef]

- Zhang, B.; Dong, W.; Yao, J.; Cheng, X. Digital Economy, Factor Allocation Efficiency of Dual-Economy and Urban-Rural Income Gap. Sustainability 2023, 15, 13514. [Google Scholar] [CrossRef]

- Zhang, X.W. Research on Evolution of Innovation Model under the Condition of Digital Economy. Economist 2019, 7, 32–39. [Google Scholar]

- He, D.A.; Ren, X. Evolution and Prospect of Resource Allocation Mechanism in the Internet Era. Economist 2018, 10, 63–71. [Google Scholar]

- He, X.; Chu, D. The digital transformation of government governance and the increase in urban entrepreneurial activity. Shanghai J. Econ. 2023, 9, 41–53. [Google Scholar]

- Jin, L.Q. Analysis of the Paradox between High R&D Investment and Low Productivity in China: From the Perspective of Distorted R&D Factor Allocation. Mod. Econ. Res. 2022, 6, 22–32. [Google Scholar]

- Bai, P.W. Estimating the Degree of Distortion of Labor Resources Allocation in China. China Ind. Econ. 2012, 10, 19–31. [Google Scholar]

- Brandt, L.; Tombe, T.; Zhu, X. Factor Market Distortions Across Time, Space and Sectors in China. Rev. Econ. Dyn. 2013, 1, 39–58. [Google Scholar] [CrossRef]

- Yang, R.D. Study on the Total Factor Productivity of Chinese Manufacturing Enterprises. Econ. Res. J. 2015, 2, 61–74. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).