Assessing the Energy and Economic Performance of Green and Cool Roofs: A Life Cycle Approach

Abstract

1. Introduction

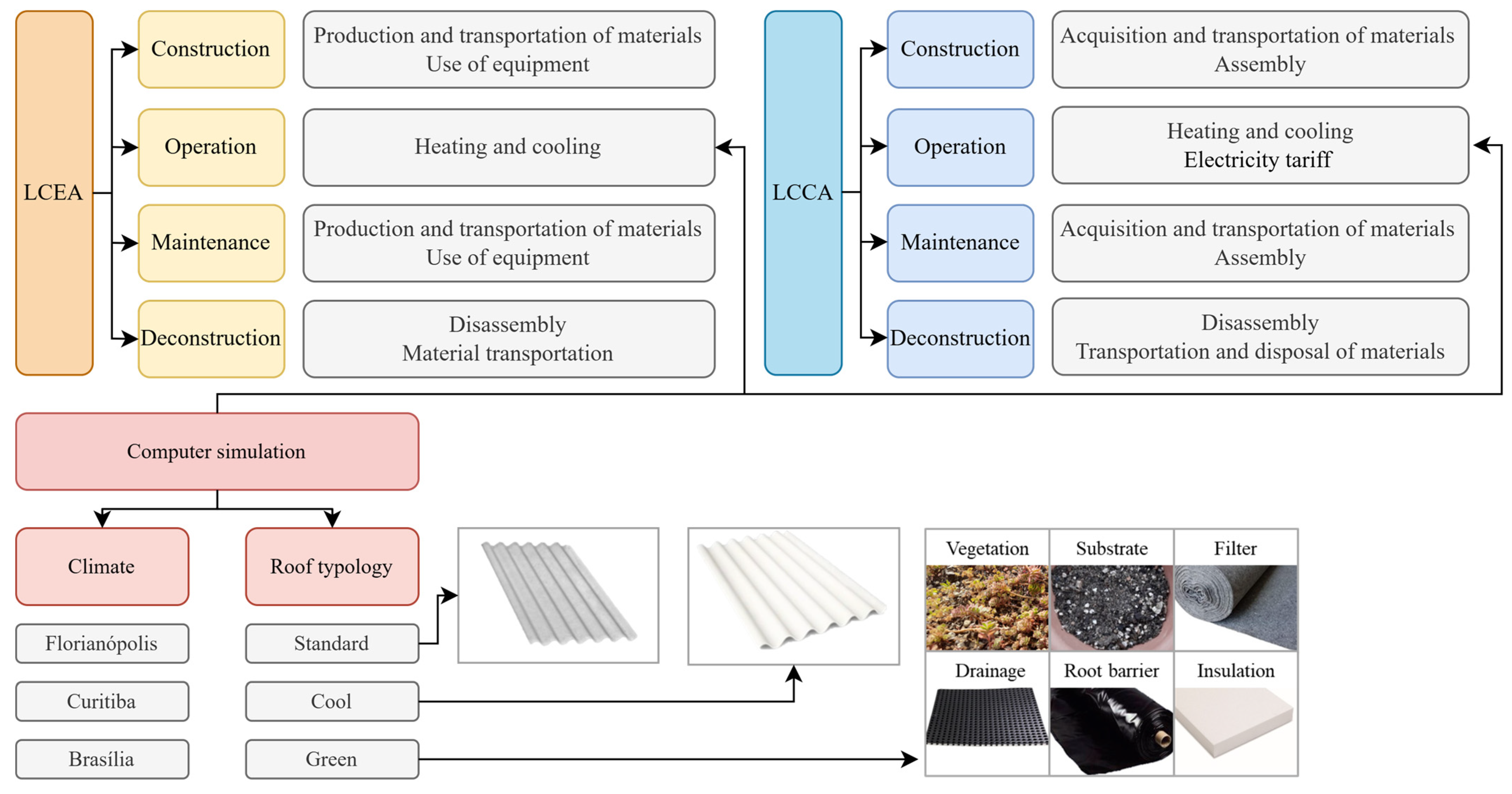

2. Materials and Methods

2.1. Computer Simulation

2.2. Life Cycle Assessment

2.2.1. Goal and Scope

2.2.2. Inventory

2.2.3. Life Cycle Energy Assessment

2.2.4. Life Cycle Cost Assessment

2.2.5. Interpretation

3. Results and Discussion

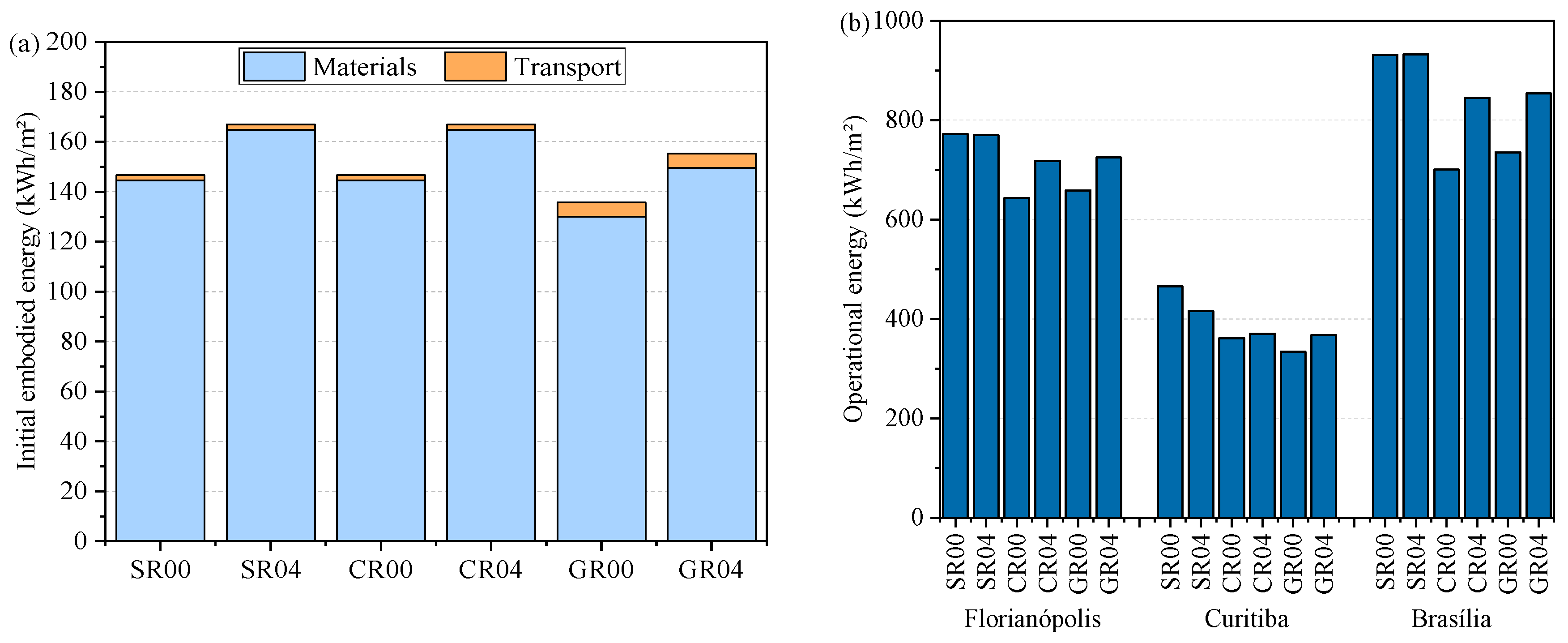

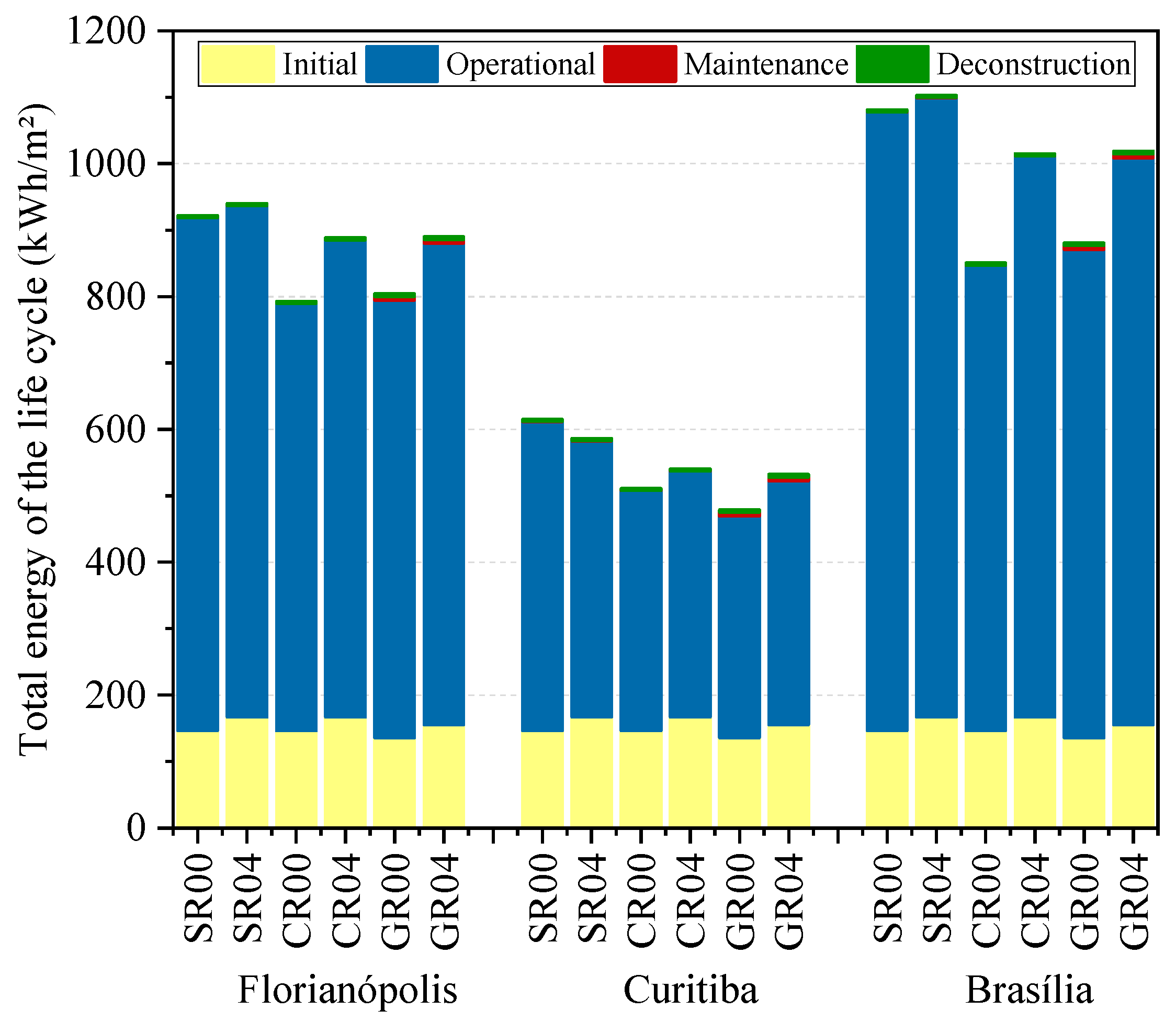

3.1. Energy in the Life Cycle Phases

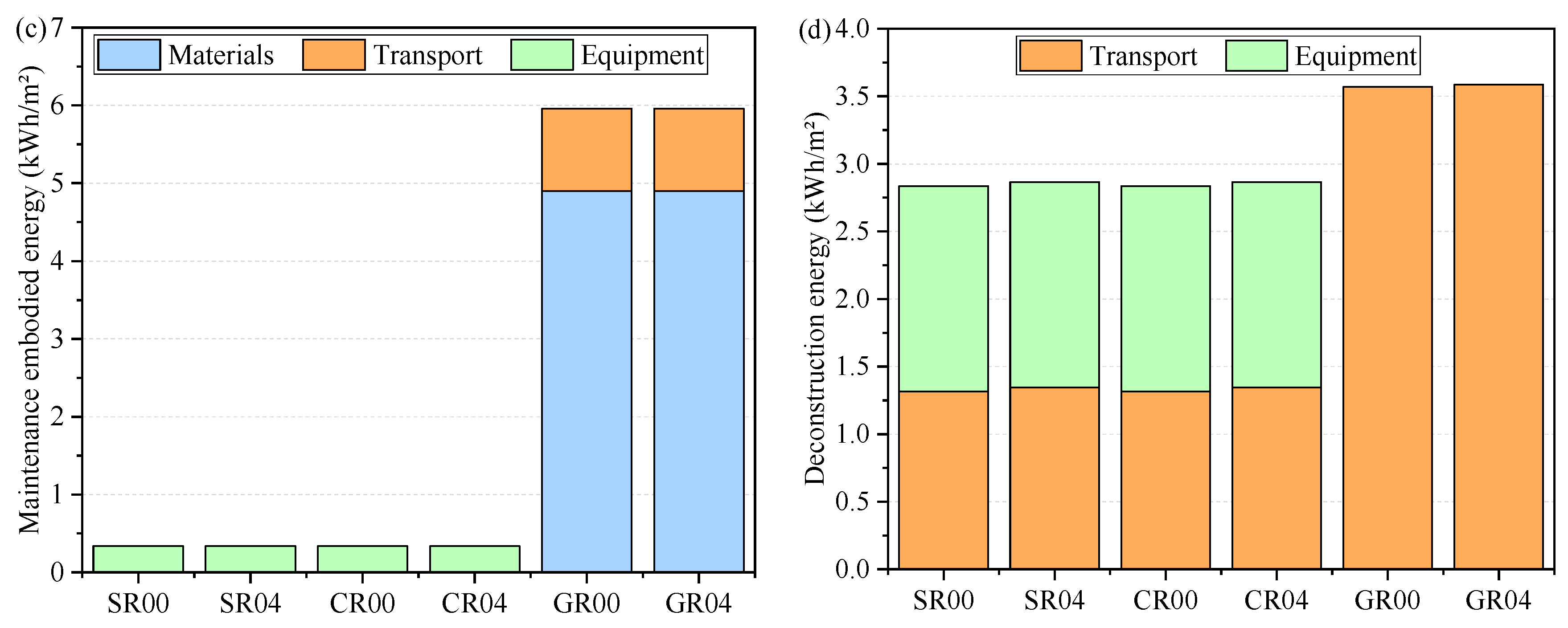

3.2. Total Life Cycle Energy

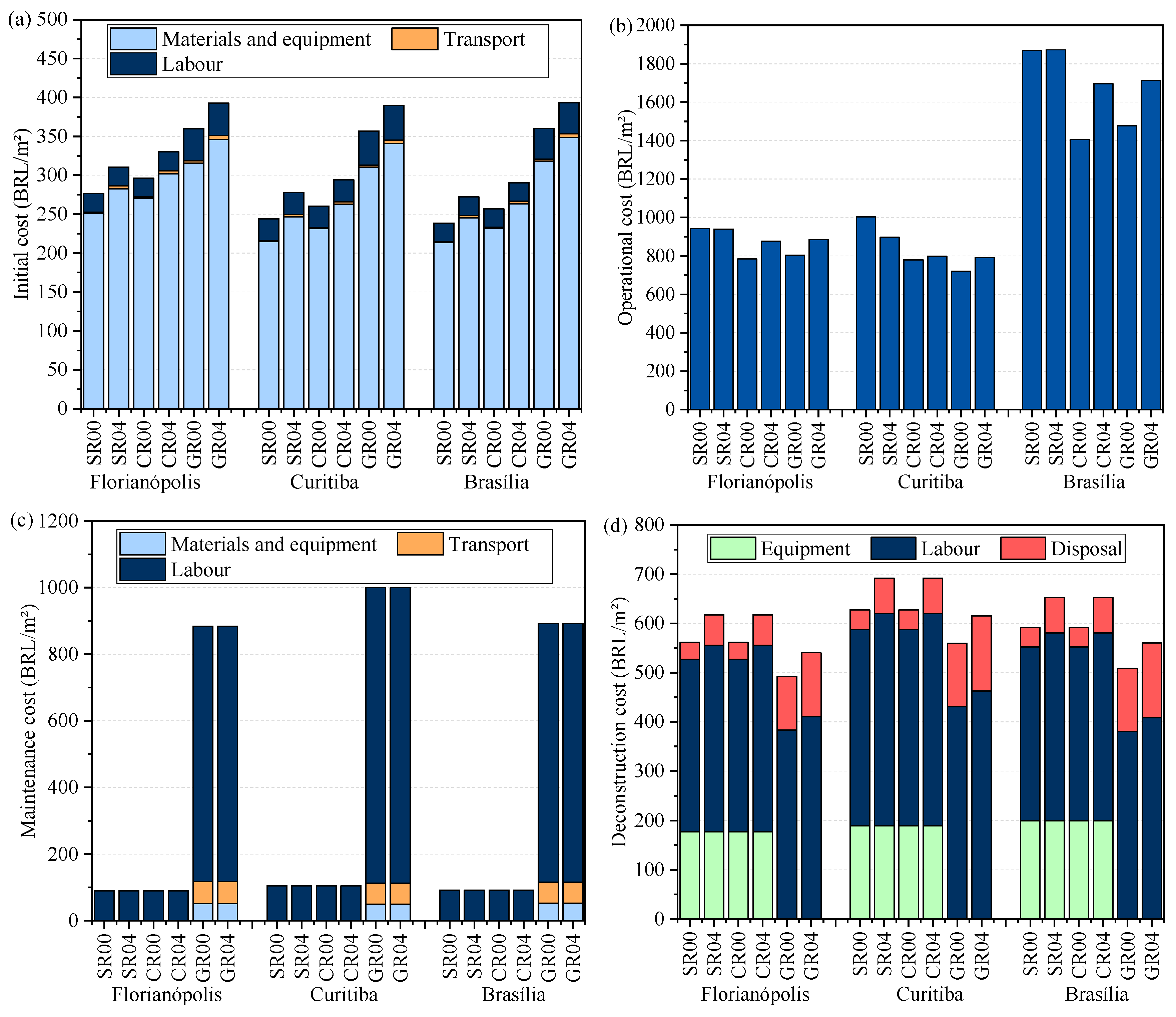

3.3. Cost in the Life Cycle Phases

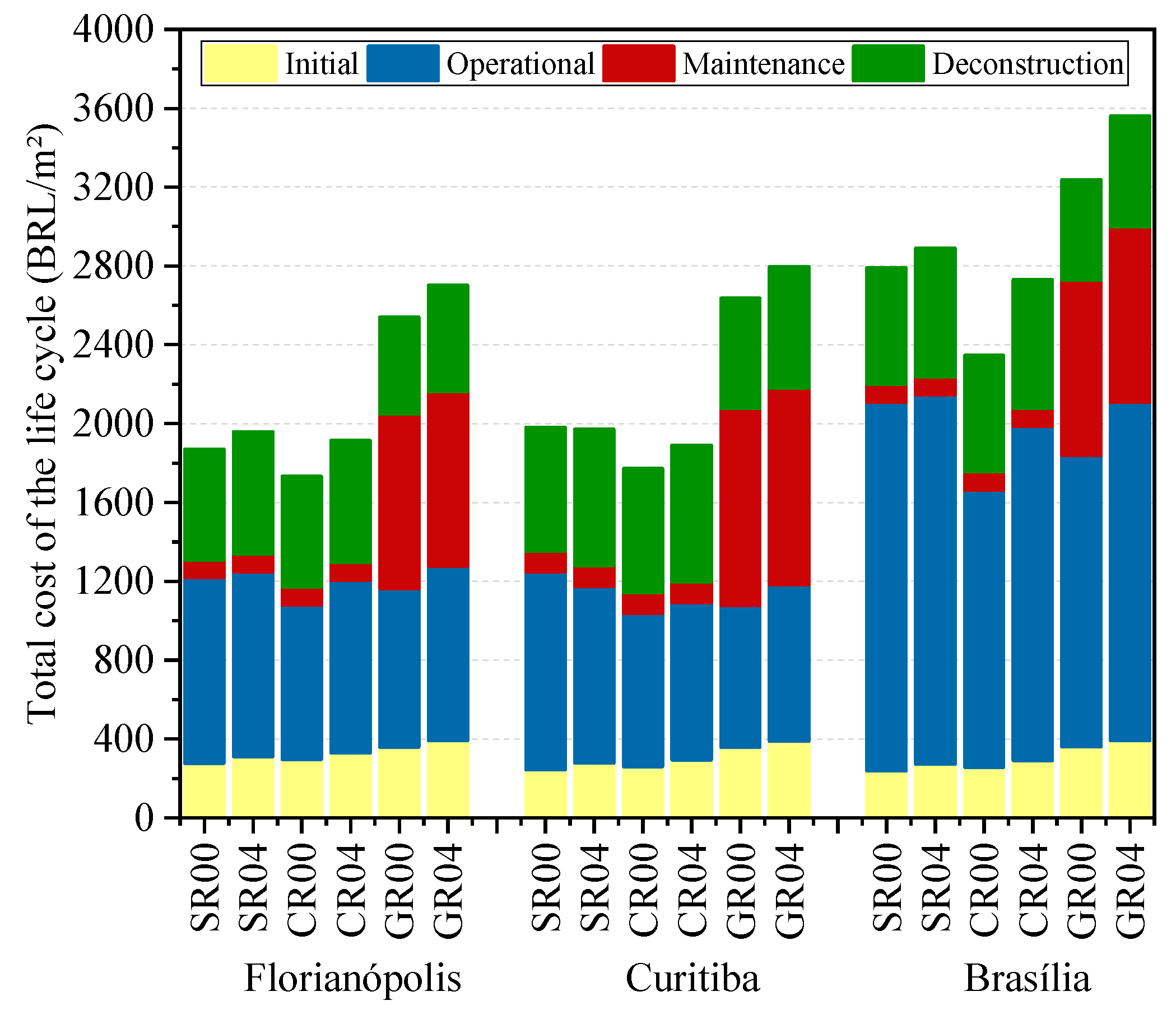

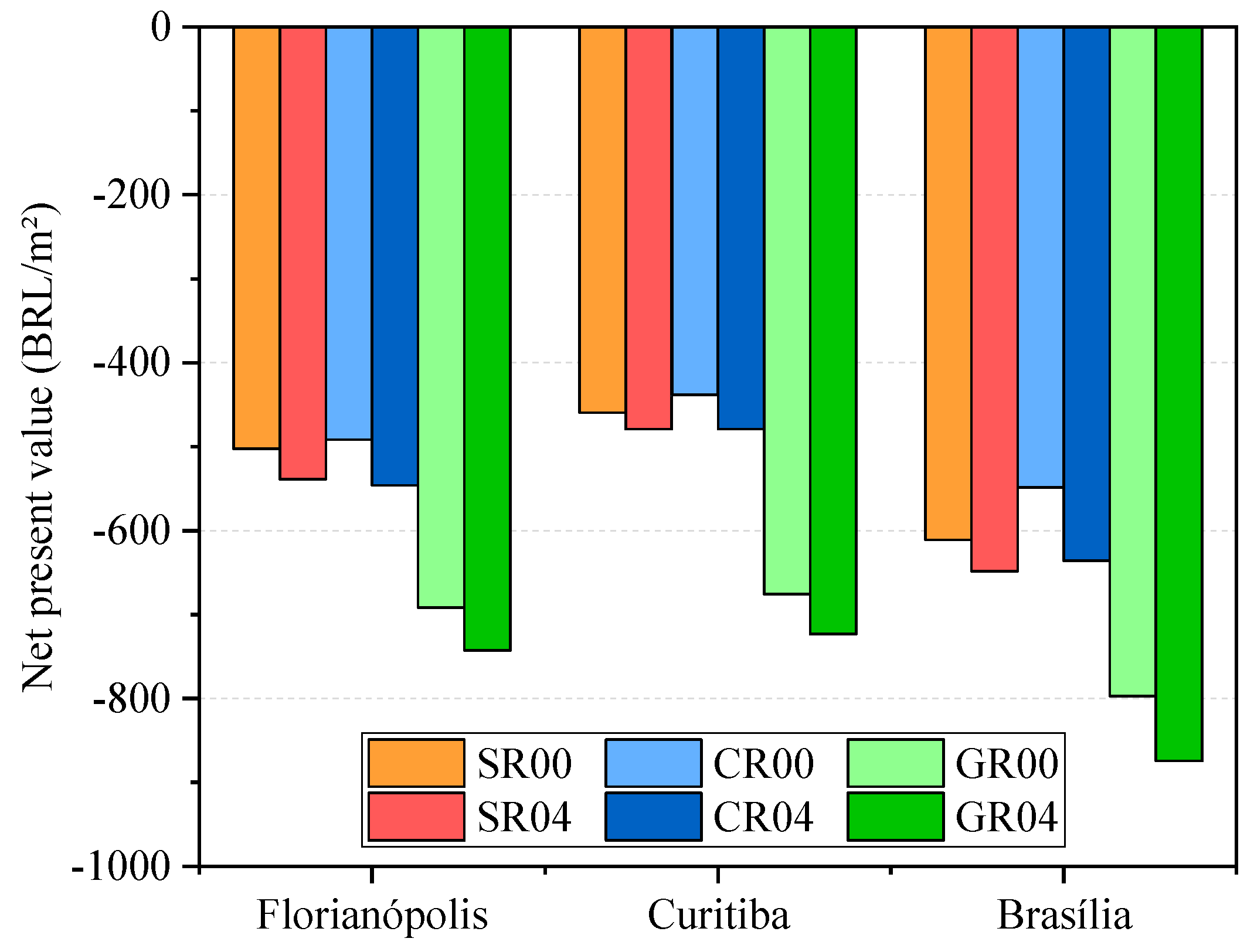

3.4. Total Life Cycle Cost

4. Implications and Suggestions for Future Research

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Santamouris, M.; Synnefa, A.; Karlessi, T. Using Advanced Cool Materials in the Urban Built Environment to Mitigate Heat Islands and Improve Thermal Comfort Conditions. Sol. Energy 2011, 85, 3085–3102. [Google Scholar] [CrossRef]

- Shafique, M.; Kim, R.; Rafiq, M. Green Roof Benefits, Opportunities and Challenges—A Review. Renew. Sustain. Energy Rev. 2018, 90, 757–773. [Google Scholar] [CrossRef]

- Scolaro, T.P.; Ghisi, E. Life Cycle Assessment of Green Roofs: A Literature Review of Layers Materials and Purposes. Sci. Total Environ. 2022, 829, 154650. [Google Scholar] [CrossRef] [PubMed]

- Tighnavard Balasbaneh, A.; Sher, W.; Madun, A.; Ashour, A. Life Cycle Sustainability Assessment of Alternative Green Roofs—A Systematic Literature Review. Build. Environ. 2024, 248, 111064. [Google Scholar] [CrossRef]

- Shittu, E.; Stojceska, V.; Gratton, P.; Kolokotroni, M. Environmental Impact of Cool Roof Paint: Case-Study of House Retrofit in Two Hot Islands. Energy Build. 2020, 217, 110007. [Google Scholar] [CrossRef]

- Mahmoud, A.S.; Asif, M.; Hassanain, M.A.; Babsail, M.O.; Sanni-Anibire, M.O. Energy and Economic Evaluation of Green Roofs for Residential Buildings in Hot-Humid Climates. Buildings 2017, 7, 30. [Google Scholar] [CrossRef]

- Shi, D.; Gao, Y.; Guo, R.; Levinson, R.; Sun, Z.; Li, B. Life Cycle Assessment of White Roof and Sedum-Tray Garden Roof for Office Buildings in China. Sustain. Cities Soc. 2019, 46, 101390. [Google Scholar] [CrossRef]

- Silva, A.L.G.; Etulain, C.R. Avaliação Do Impacto Econômico Da Proibição Do Uso Do Amianto Na Construção Civil No Brasil; Universidade Estadual de Campinas: Campinas, Brazil, 2010; p. 36. (In Portuguese) [Google Scholar]

- Nwodo, M.N.; Anumba, C.J. A Review of Life Cycle Assessment of Buildings Using a Systematic Approach. Build. Environ. 2019, 162, 106290. [Google Scholar] [CrossRef]

- ISO 14040; Environmental Management—Life Cycle Assessment—Principles and Framework. ISO: Geneva, Switzerland, 2006.

- Chau, C.K.; Leung, T.M.; Ng, W.Y. A Review on Life Cycle Assessment, Life Cycle Energy Assessment and Life Cycle Carbon Emissions Assessment on Buildings. Appl. Energy 2015, 143, 395–413. [Google Scholar] [CrossRef]

- Cabeza, L.F.; Rincón, L.; Vilariño, V.; Pérez, G.; Castell, A. Life Cycle Assessment (LCA) and Life Cycle Energy Analysis (LCEA) of Buildings and the Building Sector: A Review. Renew. Sustain. Energy Rev. 2014, 29, 394–416. [Google Scholar] [CrossRef]

- NBR 16401-2; Instalações de Ar-Condicionado—Sistemas Centrais e Unitários. Parte 2: Parâmetros de Conforto Térmico. ABNT: Rio de Janeiro, Brazil, 2008. (In Portuguese)

- Castleton, H.F.; Stovin, V.; Beck, S.B.M.; Davison, J.B. Green Roofs; Building Energy Savings and the Potential for Retrofit. Energy Build. 2010, 42, 1582–1591. [Google Scholar] [CrossRef]

- NBR 15575-1; Edificações Habitacionais—Desempenho. Parte 1: Requisitos Gerais. ABNT: Rio de Janeiro, Brazil, 2021. (In Portuguese)

- Anexo II Da Portaria INMETRO No 309/2022; Instrução Normativa Inmetro Para a Eficiência Energética Das Edificações Residenciais. INMETRO: Rio de Janeiro, Brazil, 2022. (In Portuguese)

- Gagliano, A.; Detommaso, M.; Nocera, F.; Berardi, U. The Adoption of Green Roofs for the Retrofitting of Existing Buildings in the Mediterranean Climate. Int. J. Sustain. Build. Technol. Urban Dev. 2016, 7, 116–129. [Google Scholar] [CrossRef]

- Koroxenidis, E.; Theodosiou, T. Comparative Environmental and Economic Evaluation of Green Roofs under Mediterranean Climate Conditions—Extensive Green Roofs a Potentially Preferable Solution. J. Clean. Prod. 2021, 311, 127563. [Google Scholar] [CrossRef]

- Chenani, S.B.; Lehvävirta, S.; Häkkinen, T. Life Cycle Assessment of Layers of Green Roofs. J. Clean. Prod. 2015, 90, 153–162. [Google Scholar] [CrossRef]

- Cascone, S.; Catania, F.; Gagliano, A.; Sciuto, G. A Comprehensive Study on Green Roof Performance for Retrofitting Existing Buildings. Build. Environ. 2018, 136, 227–239. [Google Scholar] [CrossRef]

- Ziogou, I.; Michopoulos, A.; Voulgari, V.; Zachariadis, T. Energy, Environmental and Economic Assessment of Electricity Savings from the Operation of Green Roofs in Urban Office Buildings of a Warm Mediterranean Region. J. Clean. Prod. 2017, 168, 346–356. [Google Scholar] [CrossRef]

- Crawley, D.; Lawrie, L. Repository of Free Climate Data for Building Performance Simulation. Available online: https://climate.onebuilding.org/ (accessed on 22 January 2024).

- Alvares, C.A.; Stape, J.L.; Sentelhas, P.C.; de Moraes Gonçalves, J.L.; Sparovek, G. Köppen’s Climate Classification Map for Brazil. Meteorol. Z. 2013, 22, 711–728. [Google Scholar] [CrossRef]

- ISO 14044; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. ISO: Geneva, Switzerland, 2006.

- Marques, V.M.; Gomes, L.P.; Kern, A.P. Avaliação Ambiental Do Ciclo de Vida de Telhas de Fibrocimento Com Fibras de Amianto Ou Com Fibras de Polipropileno. Ambiente Construído 2016, 16, 187–201. [Google Scholar] [CrossRef]

- SINAPI. Sistema Nacional de Pesquisa de Custos e Índices Da Construção Civil. Available online: https://www.caixa.gov.br/poder-publico/modernizacao-gestao/sinapi/Paginas/default.aspx (accessed on 5 July 2023). (In Portuguese)

- TCPO. Tabelas de Composições de Preços Para Orçamentos, 13th ed.; Pini: São Paulo, Brazil, 2010. (In Portuguese) [Google Scholar]

- Tavares, S.F. Metodologia de Análise Do Ciclo de Vida Energético de Edificações Residenciais Brasileiras. Doctoral Thesis, Universidade Federal de Santa Catarina, Florianópolis, Brazil, 2006. (In Portuguese). [Google Scholar]

- Kamimura, A.M.; Rupp, R.F.; Fossati, M.; Lamberts, R. Relatório: Fatores de Conversão de Energia Elétrica e Térmica Em Energia Primária e Em Emissões de Dióxido de Carbono a Serem Usados Na Etiquetagem de Nível de Eficiência Energética de Edif; CB3E: Centro Brasileiro de Eficiência Energética Em Edificações: Florianópolis, Brazil, 2020. [Google Scholar]

- Francesquett, J.Z.; da Costa, A.B.; Ferrao, M.F.; Marder, L.; Viera, M.d.S. Quantificação Do Poder Calorífico Da Gasolina Utilizando Infravermelho Próximo e Análise Multivariada. In Proceedings of the XXXI Encontro Nacional de Engenharia de Produção, Belo Horizonte, Brazil, 4–7 October 2011. [Google Scholar]

- Vacek, P.; Struhala, K.; Matějka, L. Life-Cycle Study on Semi Intensive Green Roofs. J. Clean. Prod. 2017, 154, 203–213. [Google Scholar] [CrossRef]

- Bretz, S.E.; Akbari, H. Long-Term Performance of High-Albedo Roof Coatings. Energy Build. 1997, 25, 159–167. [Google Scholar] [CrossRef]

- ANEEL. Tarifa. Available online: https://www.aneel.gov.br (accessed on 29 August 2023). (In Portuguese)

- BCB. Taxas de Juros Básicas—Histórico. Available online: https://www.bcb.gov.br/controleinflacao/historicotaxasjuros (accessed on 23 May 2024). (In Portuguese)

- Myrans, K. Comparative Energy and Carbon Assessment of Three Green Technologies for a Toronto Roof. Master’s Thesis, University of Toronto, Toronto, ON, Canada, 2009. [Google Scholar]

- Hammond, G.; Jones, C. A BSRIA Guide. Embodied Carbon: The Inventory of Carbon and Energy. Ice; BSRIA: Bracknell, UK, 2011. [Google Scholar]

- Silva, C.M.; Gomes, M.G.; Silva, M. Green Roofs Energy Performance in Mediterranean Climate. Energy Build. 2016, 116, 318–325. [Google Scholar] [CrossRef]

- Yazdani, H.; Baneshi, M. Building Energy Comparison for Dynamic Cool Roofs and Green Roofs under Various Climates. Sol. Energy 2021, 230, 764–778. [Google Scholar] [CrossRef]

- He, Y.; Yu, H.; Dong, N.; Ye, H. Thermal and Energy Performance Assessment of Extensive Green Roof in Summer: A Case Study of a Lightweight Building in Shanghai. Energy Build. 2016, 127, 762–773. [Google Scholar] [CrossRef]

- Jia, S.; Weng, Q.; Yoo, C.; Xiao, H.; Zhong, Q. Building Energy Savings by Green Roofs and Cool Roofs in Current and Future Climates. Urban Sustain. 2024, 4, 23. [Google Scholar] [CrossRef]

- Sartori, I.; Hestnes, A.G. Energy Use in the Life Cycle of Conventional and Low-Energy Buildings: A Review Article. Energy Build. 2007, 39, 249–257. [Google Scholar] [CrossRef]

- Sproul, J.; Wan, M.P.; Mandel, B.H.; Rosenfeld, A.H. Economic Comparison of White, Green, and Black Flat Roofs in the United States. Energy Build. 2014, 71, 20–27. [Google Scholar] [CrossRef]

- Ulubeyli, S.; Arslan, V. Economic Viability of Extensive Green Roofs through Scenario and Sensitivity Analyses: Clients’ Perspective. Energy Build. 2017, 139, 314–325. [Google Scholar] [CrossRef]

- Kim, E.; Jung, J.; Hapsari, G.; Kang, S.; Kim, K.; Yoon, S.; Lee, M.; Han, M.; Choi, Y.; Choe, J.K. Economic and Environmental Sustainability and Public Perceptions of Rooftop Farm versus Extensive Garden. Build. Environ. 2018, 146, 206–215. [Google Scholar] [CrossRef]

- IBGE. IPCA—Índice Nacional de Preços Ao Consumidor Amplo. Séries Históricas. Variação Acumulada No Ano Durante o Plano Real (%), Dezembro 1995—Dezembro 2022. Available online: https://www.ibge.gov.br/estatisticas/economicas/precos-e-custos/9256-indice-nacional-de-precos-ao-consumidor-amplo.html?t=series-historicas (accessed on 27 August 2023). (In Portuguese)

- IPEA. Salário Mínimo. Available online: http://www.ipeadata.gov.br/ExibeSerie.aspx?serid=1739471028 (accessed on 27 August 2023). (In Portuguese)

- Kang, C.Q.; Ng, P.K.; Liew, K.W. A TRIZ-Integrated Conceptual Design Process of a Smart Lawnmower for Uneven Grassland. Agronomy 2022, 12, 2728. [Google Scholar] [CrossRef]

- Manso, M.; Teotónio, I.; Silva, C.M.; Cruz, C.O. Green Roof and Green Wall Benefits and Costs: A Review of the Quantitative Evidence. Renew. Sustain. Energy Rev. 2021, 135, 110111. [Google Scholar] [CrossRef]

- Scolaro, T.P.; Ghisi, E.; Silva, C.M. Assessing the Impact of Evapotranspiration from Green Roofs on Reducing Surface Temperatures. J. Build. Eng. 2024, 95, 110095. [Google Scholar] [CrossRef]

- NBR ISO 10456; Materiais e Produtos de Construção—Propriedades Higrotérmicas—Valores e Procedimentos de Projeto Tabulados Para Determinar Valores Térmicos Declarados e de Projeto. ABNT: Rio de Janeiro, Brazil, 2022. (In Portuguese)

- NBR 15220-2; Norma de Desempenho Térmico de Edificações. Parte 2: Métodos de Cálculo Da Transmitância Térmica, Da Capacidade Térmica, Do Atraso Térmico e Do Fator Solar de Elementos e Componentes de Edificações. ABNT: Rio de Janeiro, Brazil, 2005. (In Portuguese)

- Triana, M.A.; Lamberts, R.; Sassi, P. Characterisation of Representative Building Typologies for Social Housing Projects in Brazil and Its Energy Performance. Energy Policy 2015, 87, 524–541. [Google Scholar] [CrossRef]

- Tavares, S.F.; Bragança, L. Índices de CO2 Para Materiais de Construção Em Edificações Brasileiras. In Proceedings of the SBE16 Brazil & Portugal, Vitória, Brazil, 7–9 September 2016. (In Portuguese). [Google Scholar]

| Layer | Parameter | Value |

|---|---|---|

| Vegetation | Vegetation height (m) | 0.10 |

| Leaf area index (LAI) | 3.00 | |

| Leaf reflectivity | 0.19 | |

| Leaf emissivity | 0.97 | |

| Minimum stomatal resistance (s/m) | 120.00 | |

| Substrate | Thickness (m) | 0.10 |

| Dry soil conductivity (W/m·K) | 0.20 | |

| Dry soil density (kg/m3) | 1020.00 | |

| Dry soil specific heat (J/kg·K) | 1093.00 | |

| Saturated volumetric moisture content | 0.26 | |

| Residual volumetric moisture content | 0.01 | |

| Initial volumetric moisture content | 0.15 |

| Phase | Energy Components Considered | Assumptions and Parameters |

|---|---|---|

| Initial |

| |

| Operational |

|

|

| Maintenance |

|

|

| Deconstruction |

|

|

| Phase | Cost Components Considered | Assumptions and Parameters |

|---|---|---|

| Initial |

|

|

| Operational |

| |

| Maintenance |

|

|

| Deconstruction |

|

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Scolaro, T.P.; Ghisi, E. Assessing the Energy and Economic Performance of Green and Cool Roofs: A Life Cycle Approach. Sustainability 2025, 17, 5782. https://doi.org/10.3390/su17135782

Scolaro TP, Ghisi E. Assessing the Energy and Economic Performance of Green and Cool Roofs: A Life Cycle Approach. Sustainability. 2025; 17(13):5782. https://doi.org/10.3390/su17135782

Chicago/Turabian StyleScolaro, Taylana Piccinini, and Enedir Ghisi. 2025. "Assessing the Energy and Economic Performance of Green and Cool Roofs: A Life Cycle Approach" Sustainability 17, no. 13: 5782. https://doi.org/10.3390/su17135782

APA StyleScolaro, T. P., & Ghisi, E. (2025). Assessing the Energy and Economic Performance of Green and Cool Roofs: A Life Cycle Approach. Sustainability, 17(13), 5782. https://doi.org/10.3390/su17135782