1. Introduction

Agriculture, forestry, and various land use practices account for approximately one-fifth of annual carbon dioxide emissions, establishing them as the second most significant source of global emissions [

1]. Peru does not make a difference; the agricultural sector is a major contributor to national greenhouse gas (GHG) emissions, responsible for 26,044 Gg CO

2eq in 2012, primarily due to inefficient practices such as poor soil management and livestock emissions [

2].

Peru’s agriculture plays a critical role in economic development and environmental management, with around 28% of households engaged in agricultural activities between 2015 and 2021 [

3]. This figure rises to over 90% in rural areas, indicating the significant impact of the sector on rural livelihoods. Over the years, Peru’s agricultural productivity has remained low; for many years, the production has been valued at USD 0.03 per hectare, which is lower than the upper middle income and the OECD, which the OECD averages as USD 0.09 and USD 0.26, respectively [

4]. Despite these challenges, Peru’s agriculture is an essential sector, reaching 7.83% of GDP and employing 30% of the workforce in 2024 [

3].

Furthermore, Peru’s diverse climate and geography exacerbate the complexity of balancing agricultural productivity with sustainability. Peruvian climate projections indicate significant changes in rainfall patterns and temperature increases, increasing the risks to their agricultural production [

5]. Recognizing these challenges, Peru has committed to ambitious sustainability targets under the Paris Agreement, 2015, aiming to reduce GHG emissions by 30% by 2030 using a 2010 Business-as-Usual scenario as a baseline. The agricultural sector is a focal point of these efforts, as reducing inefficiencies and adopting sustainable technologies are essential for meeting these goals [

6]. However, Peru’s low ranking in the 2023 Global Innovation Index (76th out of 132 economies) and its significant gap between innovation input (60th) and output (84th) underscore the difficulties in translating research and development investments into scalable solutions for rural farming systems [

7].

Targeted financial schemes and technological interventions are urgently needed to overcome these barriers. Programs such as COFIDE’s Bio-business Program, in collaboration with international organizations like the Inter-American Development Bank (IDB), demonstrate the potential for supporting green and sustainable initiatives in agriculture [

8]. Expanding such efforts to include autonomous agricultural technologies offers a significant opportunity to address the sector’s productivity and environmental challenges. Field management systems and autonomous vehicles tailored to smallholder farming can provide data-driven insights, enhance resource efficiency, and support environmentally responsible practices.

In this context, the AgriRover project is presented as a comprehensive contribution that addresses the systemic challenges of smallholder viticulture in Ica, Peru, through a context-sensitive, needs-driven design. A key contribution of this work lies in its thorough understanding of the realities faced by smallholder farmers-characterized by environmental pressures, market volatility, limited technological infrastructure, and scarce resources. Rather than integrating existing sensors, this study conducts an in-depth review of the literature and available technologies to identify which sensing and actuation tools are most appropriate for proximity-based monitoring at different BBCH phenological stages of grapevines and how the AgriRover Material Composition and End-of-Life Processing will impact the environment. This mapping effort, grounded in environmental and agronomic challenges, enables the conceptual design of a modular and affordable robotic solution with high potential for local acceptance and long-term sustainability.

2. Characterizing Sustainable Viticulture and Ica’s Vineyards

Christi and Townsend [

9] characterize viticulture as a complex form of horticulture that requires a precise combination of environmental variables, such as geomorphology, climate, and soil characteristics. They emphasize the need for further research to understand these interactions under changing environmental conditions, which is essential for guiding sustainable farming practices. Building upon this perspective, the design and development of the AgriRover for small grape growers in the Ica region was initiated with a comprehensive assessment of the region’s environmental conditions, market contributions, and structural challenges. Understanding these factors was crucial for identifying key functionalities that AgriRover should integrate to serve as an effective co-pilot for winegrowers. This section outlines the foundational aspects that informed the rover’s development, ensuring its affordability, adaptability, and long-term scalability. The proposed solution follows a progressive implementation approach, with incremental enhancements in capacity and functionality to be reported in future research, aligning with the project’s development timeline.

2.1. Characterizing Sustainable Viticulture

Sustainable viticulture integrates environmental, economic, and social dimensions, with producers commonly favouring eco-efficiency to improve quality and cost- effectiveness, despite often lacking clarity between sustainable, organic, and biodynamic systems [

10,

11]. Since 2004, the International Organization of Vine and Wine (OIV) has established official definitions and principles to guide sustainable practices, complemented by national and regional frameworks developed in response to local needs, consumer expectations, and territorial identity [

10,

12,

13,

14]. However, viticulture continues to face growing pressure to enhance sustainability without compromising productivity. Traditional practices—reliant on intensive labour, chemical inputs, and inefficient resource use—pose environmental and economic challenges, particularly for small and medium-sized farms [

15]. In this context, the adoption of precision agriculture technologies and autonomous solutions is emerging as a viable path forward, enabling automation, data-driven decision making, and more efficient energy use tailored to the realities of smallholders.

However, understanding the phenological development of grapevines is fundamental for effective vineyard management, particularly under sustainable viticulture frameworks. The seminal work [

16] provides the most widely accepted classification system for phenological stages in Vitis vinifera, commonly called the BBCH scale. This scale delineates the grapevine growth cycle into principal growth stages numbered from 0 to 9, with each stage further subdivided into secondary stages to capture the crop’s developmental nuances. Notably, the BBCH scale for grapevines omits stages 2 (formation of side shoots), 3 (elongation of the main shoot), and 4 (development of vegetative propagating organs) as they are deemed non-essential for field-based phenological assessments for determining the timing of critical interventions such as fertilization or pest management. The stages’ details are in [

14] (pp. 101–102, Figure 1 and Table 1). The BBCH scale for grapevines is a valuable reference for aligning vineyard operations—such as irrigation, pruning, canopy management, and disease control—with the crop’s physiological state. This alignment becomes even more critical for smallholder farmers in developing countries, who often face multiple challenges, such as in the Ica region in Peru (see

Table 1).

2.2. Characterizing the Peruvian Grape Market and the Ica Region’s Contribution

Peru has experienced significant growth in its grape export sector over the past two decades, particularly in the fresh grape market. By 2000, the country exported 3000 tons of fresh grapes to the North American market. By 2018, this figure had increased to an impressive 343,000 tons, reflecting a remarkable average annual growth rate of 21% over time, continuing to rise; in 2022 and 2023, it reached 929,000 tons. Thus, Peru has consolidated its position as a global leader in fresh grape exports. By the end of the 2022/2023 campaign, the country surpassed Chile as the leading exporter in the region, with an expected export volume of 595,000 tons compared to Chile’s 555,000 tons [

17]. The economic impact of this achievement is evident in the export value, which reached USD 667 million in the first half of 2023 alone, despite adverse climatic conditions earlier in the year [

18].

The Ica region stands out as a key area for grape production in Peru, contributing significantly to the country’s total yield. In 2010, Ica accounted for 41.32% of the total grape surface harvested in the country, ranking first out of the 14 producing regions. Within the region, the provinces of Ica, Chincha, and Pisco contribute 73.4%, 18.5%, and 7.6% of production, respectively [

19]. Over the years, the region has demonstrated remarkable growth over the years, with grape production increasing by 24.73% between 2000 and 2010 [

20]. In 2022, Ica produced approximately 430,000 tons of grapes, accounting for 47% of national grape production. This substantial contribution underscores the region’s importance in Peru’s overall grape industry. Ica’s grape production is critical in Peru’s agro-export sector and is also essential for domestic consumption.

In 2023, Ica’s agricultural exports reached revenues of USD 990 million, representing an increase of 60% over 2022. The main grape export destinations for 2023 included the United States (51%), Hong Kong (8.2%), Mexico (7.7%), the Netherlands (7.4%), and China (6.8%). The leading agroindustrial and agro-export companies include Corporación Agrolatina, Agrícola Don Ricardo, El Pedregal, and Sociedad Agrícola Drokasa. Almost all of the production of these companies is destined for the foreign market [

21].

2.3. Characterizing the Ica Region for Viticulture

The Ica region, located in southern Peru, is renowned for its favourable conditions for grape cultivation, driven by its warm and dry climate. This environment provides optimal temperatures, abundant sunlight, and well-drained soils, all of which are essential for grapevine growth and quality. The extended growing season in the region facilitates higher yields. It improves grape quality, with recent data indicating a 5% increase in production volume, demonstrating effective use of Ica’s natural resources [

18]. Despite these strengths, Ica’s soils present unique challenges. Predominantly sandy with a coarse texture and excellent drainage capabilities, these soils require precise irrigation and nutrient management due to their low organic matter content [

2].

The viticultural zones of the Ica region in Peru are characterized by distinct climatic and soil conditions that significantly influence grape cultivation and wine production. These areas exhibit a neutral soil pH (6.7–7.2) conducive to grapevine growth and varying levels of organic matter, which affect soil fertility and water retention. The altitude across the region ranges from 60 to 398 m above sea level, with temperature variations that create microclimates essential for developing unique grape profiles. Maximum temperatures in these zones reach 32.8 °C, while minimum temperatures drop to 9.6 °C, with average annual temperatures hovering around 21 °C. Notably, the region experiences extremely low annual precipitation, typically less than 0.5 mm, highlighting the importance of efficient irrigation practices in viticulture. These environmental factors underscore the need for precision agricultural technologies, such as the AgriRover, to optimize resource management and support sustainable viticulture in the Ica region.

Table 1 summarizes the key climate, soil, and altitude conditions across the primary viticultural zones in Ica, providing essential context for understanding the environmental challenges and opportunities faced by local grape producers [

18].

Ica geographic coordinates (approx. 14.067° S, 75.728° W) permit the classification of the region as BWh (hot desert climate) according to updated Köppen–Geiger maps [

22]. This globally recognized framework climate classification system integrates long-term temperature and precipitation patterns, which are particularly useful for defining agro-ecological zones for agricultural planning. Ica’s classifications align with the climatological data presented in

Table 1, which highlights extremely low annual rainfall (less than 0.5 mm/year), high average temperatures (ranging from 20.9 °C to 21.9 °C), and significant thermal amplitude between day and night. These conditions—particularly the high solar radiation and aridity—play a vital role in grape ripening, promoting the accumulation of sugars and phenolic compounds that enhance grape quality. However, they also underscore the region’s vulnerability to water scarcity, salinity buildup, and soil degradation, necessitating precision resource management strategies in viticulture.

Advanced agricultural practices, such as drip irrigation and integrated pest management, are widely adopted in the region by agro-industrial and agro-export companies that we named previously, thus mitigating risks posed by adverse climatic conditions like the El Niño phenomenon, which can cause excessive rainfall and temperature fluctuations. These practices support productivity and contribute to the sustainable use of resources in viticulture, ensuring their efficient and sustainable production of grapes, mainly for export markets and branded wine and Pisco production. Their implementation of modern agricultural techniques significantly contributes to the region’s socioeconomic development and provides formal employment opportunities. Despite these advancements, Ica is not widely recognized for high-quality wine production. Instead, the area is celebrated for producing Pisco, a traditional Peruvian beverage made from distilled grapes.

2.4. Characterizing Small Traditional Vineyards in Ica, Peru

National agricultural censuses reveal a consistent rise in small farm units (of less than 5 hectares), which now constitute 79% of Peru’s total agricultural holdings. This land fragmentation has contributed to the prevalence of subsistence agriculture, which accounts for 71% of the country’s 2.2 million agricultural producers. In contrast, only 22% of producers are classified under transitional agriculture, and a mere 8% operate within consolidated, commercial agricultural systems [

21]. In Ica, smallholder farmers (SHFs) typically manage plots averaging between 0.9 and 1.4 hectares, facing significant economic constraints. These farmers earn approximately 20% of the income of their non-small-scale counterparts, reflecting broader systemic inequalities within the sector [

3].

Despite agriculture employing 24% of Peru’s labour force, the sector’s contribution to GDP was only 5.4% in 2019, highlighting the limited economic returns relative to its workforce size. Daily wages in the agricultural sector range from USD 9 to USD 12, with slight increases during peak harvest periods, particularly in agro-exporting regions like Ica. These figures underscore the precarious position of SHFs, who, despite their substantial role in Peru’s agricultural economy, remain highly vulnerable to market fluctuations, resource scarcity, and the broader pressures of globalization. Consequently, smallholder farmers serve a dual role; they are both vital contributors to regional and national economic development and among the most susceptible actors in Peru’s competitive and evolving agricultural system.

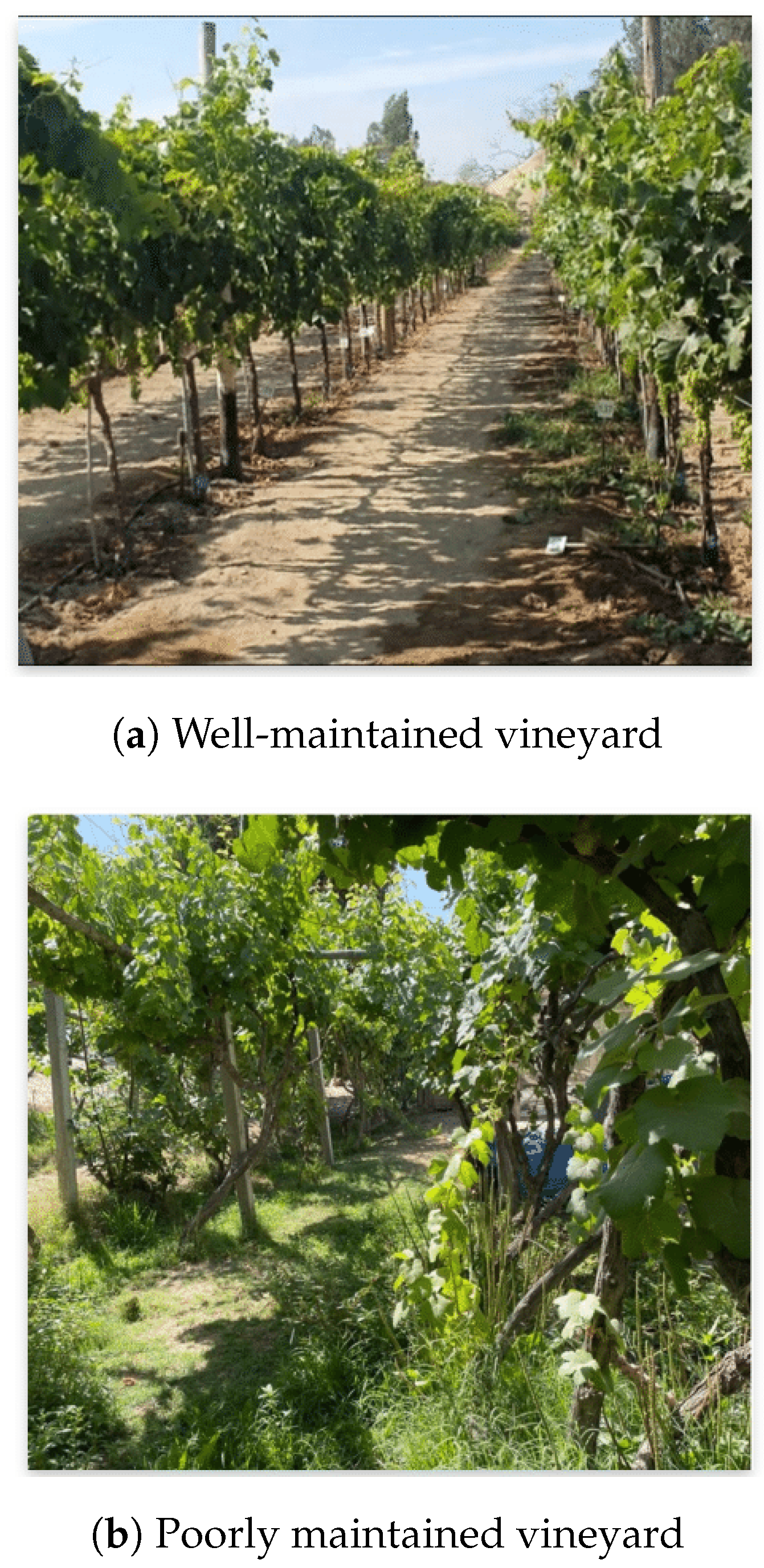

During our field visits to various vineyards in the Ica region, we documented notable differences in vineyard maintenance and configuration, as illustrated in the comparative photos (

Figure 1a,b).

These visits also allowed us to collect key structural information about vineyard plots, including their surface area, number of lines, and plant distribution. These data, compiled from a representative sample of small vineyards in the region (see

Figure 2), provide a clearer understanding of the typical field configurations within which AgriRover must operate.

The vineyard plots surveyed in Ica display notable diversity in size and configuration. They average 9.8 rows, 836 grapevines, and 0.40 hectares per plot but range from as small as 0.018 ha with a single row to over 1.03 ha with 20 rows and 1700+ vines. This variability reflects the fragmented nature of smallholder viticulture in the region and underscores the importance of adaptable, modular solutions like AgriRover.

Pisco, Peru’s iconic grape-based spirit, holds deep cultural, historical, and economic significance–particularly in the Ica region, which serves as the heart of national production. Since the late 16th century, Pisco has been crafted from both aromatic and non-aromatic Vitis vinifera L. varieties in valleys such as Chincha, Ica, and Pisco, where wineries like La Caravedo, Viña Tacama (see

Figure 3), and Vista Alegre preserve both artisanal and industrial methods. This tradition fostered the construction of wineries ranging from modest, vernacular structures to grand estates managed by religious orders and elite landowners. These estates historically drove regional agricultural diversity, cultivating grapes alongside crops like cotton and sugarcane. However, the contrast with today’s fragmented and under-resourced smallholder viticulture is stark. While large estates thrive through access to infrastructure and innovation, most small and medium producers in Ica face systemic challenges—limited land, labour shortages, and technological gaps—that undermine their productivity and competitiveness in a rapidly evolving agricultural landscape.

Addressing these challenges requires fostering greater collaboration among small producers. Forming cooperatives or strategic alliances could enable smallholders to pool resources, increase production capacity, and strengthen their market bargaining power [

18]. Such integration could facilitate access to technology, infrastructure, and financing, thereby allowing small farmers to benefit from the growing international demand for high-quality grapes. With Peru’s emphasis on varietal improvements and technological investments, organized smallholders have the potential to play a more prominent role in both domestic and export markets.

3. The Ica Region: Relevant Issues

This section presents an overview of the critical challenges affecting viticulture in the Ica region, focusing on environmental, logistical, and technological constraints. Soil salinity accumulation threatens grapevine health and productivity, while climate variability introduces uncertainty in water availability and temperature regulation. Additionally, labour shortages and logistical limitations hinder the ability of small and medium-sized vineyards to maintain consistent yields and meet market demands. Low technological readiness further restricts the adoption of precision agriculture tools, limiting smallholders’ opportunities to improve sustainability and operational efficiency.

To systematically address these region-specific barriers,

Table 2 summarizes how each challenge is matched with corresponding AgriRover design requirements. The table highlights the rationale behind specific technical and strategic design decisions made during the development of AgriRover, illustrating how the platform aligns with the unique environmental, economic, and operational constraints faced by smallholder vineyards in Ica. By connecting critical needs—such as managing soil salinity, ensuring water efficiency, compensating for labour shortages, and coping with low technological readiness—to tangible rover functionalities, this table provides a concise framework for contextualizing the design of affordable, scalable mechanization technologies.

The following subsections further elaborate the justification and detailed analysis of each challenge listed in

Table 2. These sections delve into the agronomic, environmental, and socio-technical factors contributing to each issue, grounding the design requirements of AgriRover in the specific realities of the Ica region. This structured approach allows for a deeper understanding of the local context and supports the development of tailored, effective, and sustainable technological solutions for smallholder viticulture.

3.1. Salinity Accumulation in Soil

A significant concern in the region is salinity accumulation, which weakens soil structure, reduces moisture retention, and impairs nutrient absorption. High salt concentrations can lead to osmotic stress, causing reduced plant growth and diminished yields [

23]. Addressing salinity issues involves targeted strategies, such as leaching for saline soils and gypsum application for sodic soils, ensuring the long-term sustainability of viticulture [

24].

Soil health is critical to plant growth, water retention, and overall agricultural sustainability [

25]. Studies show that soil characteristics, including texture, pH, and nutrient content, influence grape quality and yield, making soil management a pivotal aspect of viticulture [

26]. Effective soil management enhances fertility and ensures long-term sustainability in agricultural practices [

27]. However, the unique sandy soils and mineralized zones of Ica present specific challenges for vineyard cultivation, including salinity accumulation, which exacerbates soil degradation and reduces agricultural productivity [

28].

Ica’s soils are characterized by high salinity due to improper irrigation practices, inadequate leaching, and poor drainage. These issues contribute to abiotic stress in plants, resulting in growth retardation, hormonal imbalances, and oxidative stress [

29]. Globally, soil salinity affects approximately 950 million hectares, leading to an annual economic loss of USD 27.3 billion and contributing to ecosystem degradation, groundwater contamination, and increased flood risks [

30]. In Ica, human-induced salinization from irrigation and chemical fertilizers further compounds these issues, highlighting the need for innovative management strategies to support sustainable agriculture [

31].

To mitigate the effects of salinity, several adaptive strategies are recommended. Selecting salt-tolerant rootstocks is one practical approach, as these varieties maintain ion balance and improve water uptake efficiency under saline conditions [

32]. Additionally, deficit irrigation practices help regulate soil moisture while minimizing salt accumulation in the root zone [

33]. These measures safeguard vine health and improve grape yield and quality, contributing to more sustainable viticulture practices.

3.2. Climate Variability and Resource Management

Climate variability poses significant risks to viticulture [

34]. In Ica, the irregular rainfall patterns, increased and altered temperatures, and extreme weather events linked to phenomena such as El Niño [

5] worsen the situation. These changes exacerbate existing challenges in resource management, particularly water use, which is critical in the region’s arid environment. Inefficient water use and over-reliance on groundwater have led to resource depletion [

35], threatening long-term agricultural sustainability [

36]. A recent study highlighted that 87% of Ica’s water footprint comes from groundwater, with severe depletion risks, especially in areas dominated by large-scale farming [

37]. Such behaviour underscores the importance of effective water management practices to mitigate such impacts [

38]. For these reasons, understanding and addressing the environmental and climatic variations in Ica are essential for developing resilient viticultural practices.

Elevated temperatures in Ica have been observed to accelerate grapevine phenological stages, resulting in earlier budburst and ripening periods. While these changes can enhance certain grape qualities, they also pose risks of over-ripening and reduced acidity, negatively affecting wine balance. In response to these challenges, local institutions, such as the National Meteorology and Hydrology Service of Peru (SENAMHI) and the Center for Technological Innovation in Agroindustry (CITEagroindustrial Ica) have initiated projects to assess and mitigate the effects of climate change on viticulture in the region. These initiatives provide viticulturists with data-driven insights and adaptive strategies to cope with climatic variations, ensuring the sustainability of grape production in Ica [

39]. By adopting adaptive measures and leveraging local research initiatives, viticulturists can continue to produce high-quality grapes, contributing to the region’s economic vitality and cultural heritage [

40].

3.3. Logistical and Labor Challenges

For all vineyards in one region, more or less at the same time, the plants must be free of weeds, require adequate irrigation and appropriate nutrients, not be infected by pests, and require rigorous disease control. Continuous visual control is crucial, and vinegrowers are responsible. Still, the decision to harvest is made mainly by winemakers and vineyard managers based on systematic evaluations of grape maturity [

41]. Conventional techniques for assessing grape composition, such as laboratory-based chemical analysis, are reliable but limited in scope and time-consuming.

Such a habit, together with the lack of personnel and frequent and unexpected climatic changes, worsens the situation, making it increasingly difficult to predict the needs of inputs and personnel for each activity along the process. Labour shortages in Ica, driven by its prominence as the leading exporter of agricultural products, exacerbate the difficulties of managing the field and hinder the ability of smallholders to perform timely vineyard maintenance; for comparison, see

Figure 1a,b. Keeping the vineyard well maintained is critical for following the vegetative and productive cycles of the vines [

42]. Unlike agro-export companies, small producers struggle to attract and retain labour, which limits their ability to follow the vines’ vegetative and productive cycles and delays essential vineyard maintenance. These constraints often result in lower yields and diminished grape quality, reducing smallholders’ market viability. Therefore, those processes must be instrumentalized to achieve the expected yields with fruits that guarantee fresh products and quality by-products.

Labour shortages hinder routine vineyard maintenance and limit smallholders’ ability to implement precision monitoring throughout the grapevine’s phenological cycle. This challenge is exacerbated by limited awareness and technical capacity to identify and respond to BBCH phenological stages, which are critical for optimizing input use and scheduling agronomic interventions [

16,

41].

Additionally, the Ica region faces logistical constraints that disproportionately affect smallholder farmers. High transportation and exportation costs and limited infrastructure access create barriers for small producers to compete effectively in the grape supply chain. During the 2024–2025 season, for example, a persistent shortage of refrigerated containers and severe congestion at the Port of Callao disrupted Peru’s table grape exports, underscoring the urgent need for improved logistics and decentralized infrastructure such as the expansion of the ports of Pisco and Chancay [

43,

44].

3.4. Low Technological Readiness for Innovative Product Adoption

Innovative technological solutions hold great promise for transforming small-scale viticulture. Nowadays, real-time data collection is used to manage vineyards, the expert systems that rely on permits to optimize operations, improve resource efficiency, and help to be environmentally and food safety-compliant. Emerging technologies, such as precision agriculture tools and autonomous vehicles like drones and field rovers, offer actionable insights for small farmers to improve productivity and grape quality. Suppose technology is affordable and easy to use; in that case, small farmers can adopt them and enhance their participation in the market, reduce environmental impact, and align with global sustainability goals, ultimately improving their quality of life and economic resilience.

However, Peru’s low technological readiness significantly hinders the adoption of innovative agricultural solutions, particularly in rural areas where infrastructure and resources are limited. The 2023 Global Innovation Index (GII) ranks Peru 76th out of 132 economies, with a sharp contrast between innovation input (60th) and innovation output (84th). This disparity highlights structural barriers that prevent research and development investments from translating into scalable, practical technologies for sectors like agriculture [

7]. In 2020, Peru’s Technological Readiness Index was 3.30, ranking 92nd globally, below the average for middle-income countries [

4]. Such a result underscores a systemic gap in the capacity to integrate advanced solutions into small-scale farming systems.

The agricultural sector, specifically viticulture in regions like Ica, exemplifies these challenges. Small-scale farmers, who dominate grape production in the region, often lack access to essential mechanization, let alone advanced tools like autonomous vehicles. This limited access arises from financial constraints and the absence of tailored technologies that address their specific needs, such as managing salinity, optimizing water use, and improving labour efficiency. Without a robust technological readiness framework, these farmers cannot adopt innovations that could transform their productivity and environmental sustainability [

4].

Despite these barriers, the growing enrollment in engineering and technical programs at Peruvian universities and superior technological institutes offers a potential solution. This emerging workforce is primarily trained in mechatronics, electronics, systems, and environmental engineering, aligning with the skill sets needed to develop accessible and affordable technologies for small-scale farmers. By leveraging this talent, Peru has the opportunity to bridge its technological readiness gap and create innovations tailored to its agricultural landscape. However, addressing Peru’s low technological readiness requires a multifaceted approach that includes improving infrastructure, fostering public–private collaboration, and supporting the development of affordable, locally relevant technologies. By focusing on these areas, the AgriRover project can contribute to narrowing the technological readiness gap and promoting sustainable innovation in Peru’s viticulture sector and beyond.

4. Actual Technological Solutions for Viticulture

Precision agriculture (PA) has emerged as an innovative approach to meet the growing demand for food production while minimizing environmental impacts. Integrating advanced technologies enables farmers to optimize resource use, improve crop yields, and increase overall agricultural efficiency [

45]. A key aspect of PA is the management of spatial and temporal variables that influence agricultural production to improve crops’ economic, environmental, and social sustainability. A key principle of PA is the recognition of intra-field heterogeneity, in contrast to the uniform approach typical of conventional agriculture. Such a solution allows agricultural inputs to be optimized, reducing costs and increasing productivity [

46].

As highlighted in previous sections, viticulture in Peru faces increasing challenges related to natural resource management, labour shortages, and climate variability. These difficulties are particularly pronounced on small and medium-sized farms, where traditional practices struggle to maintain productivity and sustainability. Addressing these challenges, therefore, requires the integration of advanced technologies that optimize vineyard operations, improve resource efficiency, and ensure long-term environmental sustainability. The goal is to increase the resilience and competitiveness of small and medium-sized enterprises in the sector, ensuring sustainable practices that protect the environment, conserve biodiversity and protect human health while promoting a balance between productivity and ecological impacts.

This section provides an overview of the leading technological solutions for viticulture. These include fixed environmental mini-stations for real-time monitoring, autonomous vehicles for efficient vineyard management, and precision agriculture technologies (PATs) that improve decision making and sustainability. These technologies are key in modernizing viticulture by reducing dependence on manual labour, increasing productivity, and enabling a more data-driven approach to agriculture [

47].

4.1. Fixed Enviromental Mini-Stations in Vineyards

Fixed environmental mini-stations (

Figure 4) are sensor-based monitoring systems installed in vineyards to collect real-time data on climatic and ecological conditions. These systems help winemakers optimize farming practices and ensure crop quality by providing accurate information on vineyard microclimates [

48]. Mini-stations typically collect temperature, humidity, soil moisture levels, precipitation, wind speed, and solar radiation data. These data support crucial activities such as disease risk assessment, irrigation planning, and climate adaptation strategies [

49]. In addition, predictive analytics further improve these systems, enabling farmers to implement preventive measures against extreme weather variations and fungal disease outbreaks, which can significantly affect grape quality and yield [

25].

Thus, sensors can help to preserve soil quality, promote biodiversity, protect native yeasts by improving wine’s aromatic quality, reduce grape growers’ exposure to chemicals, and accurately analyze climate data for more efficient agronomic management [

48]. The adoption of automated weather monitoring systems is becoming increasingly relevant in viticulture, especially for managing water resources and optimizing microclimates in vineyards. Vineyard managers can receive real-time alerts and recommendations by integrating cloud platforms for data analysis [

50], reducing response time to adverse weather events.

Implementing these environmental monitoring stations improves productivity and contributes to sustainable viticulture. Smart weather stations, powered by solar panels and connected to the Internet of Things (IoT), reduce operational costs and provide continuous and autonomous monitoring. In addition, applying machine learning models to historical weather data enables more accurate forecasts, helping winemakers make informed irrigation and pest control decisions [

51].

4.2. Autonomous Viticulture Vehicles

Autonomous vehicles for viticulture are a promising solution to reduce dependence on labour and automate repetitive tasks in vineyards. These vehicles, ranging from robotic rovers to automated tractors, are designed to perform various vineyard tasks with minimal human intervention. Early crop monitoring solutions relied on drones to measure vegetation indices (VIs) to assess plant health and machine vision techniques to determine the fraction of plant cover (Fc) as a measure of plant vigour [

52]. However, proximity to rows is crucial in viticulture to detect plant vigour and disease-free growth. Such an issue has led to the development of rovers designed to monitor climatic parameters, overall vineyard health, and disease detection as well as to track insect presence and water resources in harsh environments [

53]. These rovers are becoming increasingly available for monitoring soil, climate, canopy, harvest, and irrigation, depending on the specific needs and operations of the vineyard [

54]. Universities in wine regions, such as Europe, Australia, and the United States, have mainly developed rovers designed for tasks in vineyards (

Figure 5), such as environmental and pest monitoring, grass pruning and harvesting [

55]. These prototypes explore vehicle mechanics, autonomy, operational capability, and human–robot interaction. Despite these advances, significant challenges remain regarding navigation safety, terrain-related mechanical issues, and the vehicle’s ability to manoeuvre and effectively perform various operations in rough and uneven environments [

56].

Advances in agricultural robotics have led to the development of artificial intelligence-based autonomous systems capable of performing crucial tasks such as precision pruning, targeted spraying, soil management, and automated harvesting. These vehicles integrate machine vision, multispectral imaging, LiDAR navigation, and GPS guidance to adapt to different vineyard structures and terrains. These capabilities improve efficiency and reduce chemical use, optimizing sustainability and operational costs [

57].

Recent studies have highlighted the role of autonomous vehicles in managing labour shortages in viticultural regions. In many countries, the decline in the skilled agricultural labour force has necessitated the adoption of automated vineyard management solutions. Autonomous vehicles with artificial intelligence-based decision-making capabilities can analyze vineyard conditions, identify disease outbreaks, and apply targeted treatments autonomously, reducing chemical waste and ensuring optimal grape quality [

58]. Despite the advantages, cost is still a significant barrier to large-scale deployment, especially for small and medium-sized wineries in developing countries. Commercial vineyard robots (

Figure 6), such as those developed by Naïo Technologies (TED robot), Saga Robotics (Thorvald robot), VineScout, and VitiBot’s Bakus, demonstrate high efficiency but remain financially unaffordable for most small producers. High upfront costs, ranging between EUR 80,000 and 130,000 [

55], limit the adoption of these technologies, highlighting the need for cheaper and more modular robotic solutions that can be integrated into different agricultural settings [

59]. As a result, many farms remain without tools that could significantly improve productivity and resource use efficiency [

60].

4.3. Precision Agriculture Technologies (PATs)

A study of patents related to precision viticulture indicates that since 2010, there has been significant interest in applying technology to improve vineyard processes. The number of patent applications tripled by 2014 and doubled again by 2017, reflecting the growing adoption of technologies to improve productivity, reduce input usage, and enhance sustainability in viticulture [

56]. Among these patents, most applications have been filled for fungicide compositions (39 patents), followed by biological control (14 patents), insecticides (3 patents), pesticides (3 patents), productivity enhancement (2 patents), and seed treatment (1 patent). In the machinery and equipment category, almost 133 patents have been reported from China submitted 85 applications, followed by France with 12, the United States with 9, and 8 by the World Intellectual Property Organization (WIPO) [

56].

The adoption of precision agriculture technologies (PATs) has revolutionized modern viticulture by providing vineyard managers with data-driven tools to improve decision making and resource allocation. These technologies use remote sensing, IoT-based monitoring, artificial intelligence-based decision support systems (DSSs), and variable rate technology (VRT) to increase vineyard productivity while reducing environmental impact [

47].

One of the most significant uses of PATs in viticulture is remote sensing, which uses multispectral and hyperspectral imaging. Drones equipped with thermal and multispectral cameras provide viticulturists with real-time crop health assessments, identifying signs of water stress, disease outbreaks, and nutritional deficiencies. These imaging techniques enable targeted interventions, ensuring precision irrigation and fertilization strategies that optimize grape yields while reducing input costs [

25].

Integrating IoT sensors and Variable Rate Technology (VRT) in vineyards has further optimized precision irrigation management and pest control through real-time data, reducing waste and environmental impact. Soil moisture sensors, sap flow meters, and foliar wetting detectors provide continuous data on vine transpiration rates and hydration levels, allowing grape growers to irrigate only when needed [

45]. Studies show that vineyards using smart irrigation systems save up to 30% of water while maintaining or even improving grape quality [

49].

In parallel, adopting agro-ecological practices such as grassing and sustainable vegetation management contributes to reducing CO

2 emissions by up to 10% compared to conventional methods [

61]. A significant example is the application of Eddy Covariance (EC) technology to monitor carbon fluxes. A study conducted on panicum (

Panicum virgatum L.) cultivation in the Po Valley showed a net uptake of 8.4 Mg of CO

2 per hectare per year, with a positive climatic impact of up to −12.4 Mg of CO

2 per hectare per year over the entire life cycle of the plant [

62].

Adopting advanced monitoring technologies, GPS-guided machinery, and predictive data analysis systems is a key strategy through which to improve productivity and reduce dependence on labour [

25]. Artificial intelligence and decision support systems (DSSs) are revolutionizing vineyard management by combining historical climate data, soil conditions, and predictive models to optimize production and prevent disease [

51].

To make these innovations accessible to a wider range of winemakers, it is critical to develop low-cost sensors, intuitive analytics platforms, and user-friendly tools. Integrating IoT, remote sensing, and VRT represents the future of viticulture, providing sustainable, efficient, and cost-effective solutions for modern vineyard management. In this direction, this study proposes a further step forward by adopting "smart farming" based on advanced sensors installed on the AgriRover. These devices not only optimize farming operations but also enable significant reductions in emissions from both machine operation and the farmer’s daily activities. Using these sensors makes it possible to rationalize the consumption of resources, such as irrigation water, thus reducing environmental impact without compromising productivity. In addition to improving operational efficiency, these technologies help preserve soil health and promote more sustainable agricultural management, directly benefiting the ecosystem and the entire wine supply chain.

4.4. Integrating Mechanization Technologies for Vineyard Sustainability

In resource-constrained regions such as Ica, Peru, integrating diverse agricultural mechanization technologies can significantly enhance the efficiency and sustainability of viticulture. While tools like fixed environmental monitoring stations, Precision Agriculture Technologies (PATs), and autonomous field vehicles have traditionally been applied independently, their convergence offers new possibilities for site-specific management. Fixed stations monitor macro-level climate conditions, while PATs, such as IoT-based sensors and multispectral imaging, enable precise, localized decision making. AgriRover is a mobile, affordable, and modular platform that bridges these systems, delivering proximity-based sensing and adaptability throughout the grapevine’s phenological stages (see

Table 3). Its architecture is guided by the BBCH framework, allowing targeted integration of sensors and interventions aligned with crop development cycles and tailored to smallholder needs.

5. Our Solution: The AgriRover for Sustainable Viticulture

This section introduces AgriRover, a scalable and affordable robotic platform for smallholder viticulture in Ica, Peru. The solution is organized into four key components: a step-by-step development approach aligned with standard machinery design principles; an affordable, modular, and locally adaptable architecture aligned with constraint resources; an autonomous navigation and control system suited to small vineyard environments; and a proximity-based monitoring strategy mapped to the grapevine phenological stages. Together, these elements demonstrate how AgriRover integrates sustainability and innovation, starting from the design requirements for real-world impact.

5.1. A Step-by-Step Approach to Agricultural Robotics

The development of the AgriRover system fits within the classical machine design paradigm, articulated according to the phases of need identification, problem definition, synthesis, analysis and optimization, and final evaluation. The goal is to realize a modular, affordable robotic platform suitable for promoting sustainable viticulture practices in small-scale contexts, with particular reference to developing countries.

Figure 7 graphically illustrates the temporal articulation of the project phases and their progress within the AgriRover project, which, due to its interdisciplinary nature, was strategically divided into several steps.

The first step involved application contextualization and case study definition, focusing on the region of Ica, Peru. In this step, an analysis of the specific needs of local viticulture was conducted, addressing the main systemic critical issues: soil salinity, labour shortage, high climatic variability, and limited technological penetration (see

Section 3). Rather than viewing these issues as isolated technical needs, they were framed as interdependent elements of a complex system, requiring a flexible, context-sensitive, and locally adapted solution. Such knowledge laid the foundation for defining the design philosophy of AgriRover, which is based on modularity, cost-effectiveness, and proximity monitoring capabilities.

During this phase, an analysis of technologies currently used in agronomy (e.g., fixed environmental stations, PAT systems, and mobile platforms) was also conducted, evaluating their potential for the phenological stages of grapevines according to the BBCH classification [

16]. The results of this comparison, summarized in

Table 3, revealed gaps in monitoring and agronomic response, which AgriRover aims to fill through a scalable and adaptable solution. The activity, conducted in collaboration between research groups in Italy and Peru, led to the formulation of a preliminary concept for the system. Although not yet validated, this concept allowed for a structured reflection on the project’s critical points and improvable aspects. Through a qualitative analysis of sustainability, estimated costs, and technical feasibility, areas on which to focus subsequent design insights were identified to balance performance, adaptability, and accessibility.

Future developments assume modelling of the platform in the Simscape Multibody multi-domain environment, with simulations capable of reproducing typical vineyard operating conditions, such as narrow rows, uneven terrain, and the presence of obstacles [

63]. This activity will be accompanied by kinematic, dynamic, and structural analyses to identify the most influential parameters for system optimization and subsequent validation. Finally, the integration of smart sensors and the use of AI algorithms will be able to enable advanced forms of mobile precision viticulture adapted to the local context, aiming to find an optimal balance between sustainability, affordability, and scalability to enable small-scale producers to adopt efficient and contextually relevant monitoring practices.

5.2. Affordable, Modular, and Scalable Rover

Existing autonomous viticulture vehicles (AVVs) such as TED, TREKTOR, and VineScout, though highly effective, remain financially inaccessible for smallholder farmers [

64]. These commercial AVVs are also optimized for structured, large-scale vineyards, limiting their adaptability to the unstructured layouts of traditional SMVs. AgriRover is a potentially affordable alternative to existing systems integrating cost-effective automation capabilities. The initial concept envisions a modular and scalable structure that can be adapted to the specific needs of the vineyard. The idea is to offer a progressive solution where farmers can start with essential monitoring functions and, over time, integrate more advanced components based on affordability and agronomic requirements.

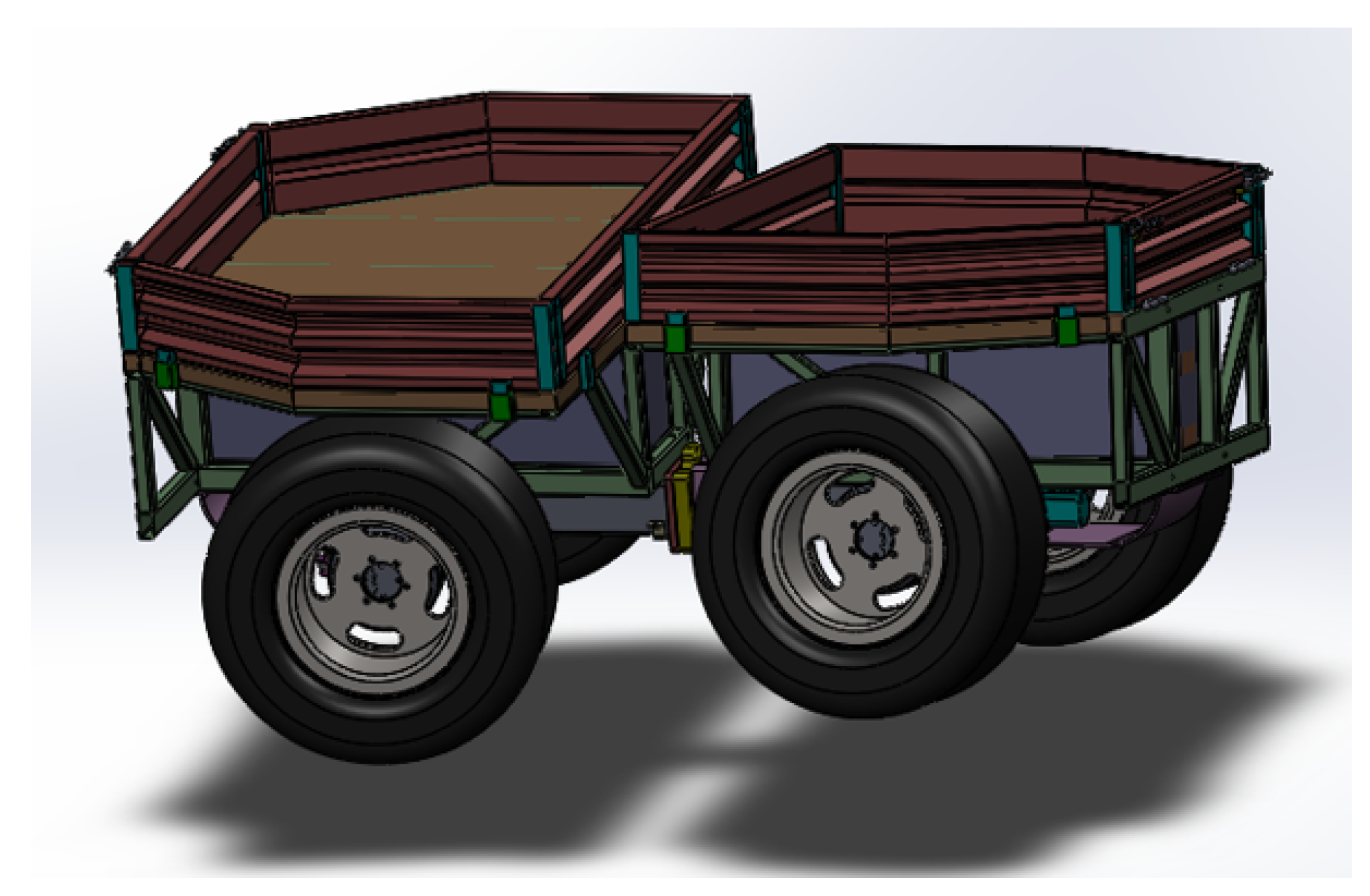

AgriRover emphasizes affordability, modularity, and ease of maintenance, ensuring accessibility for smallholder farmers. The articulated chassis allows efficient navigation in rugged vineyard landscapes, minimizing soil compaction and preserving soil health [

65]. With compact dimensions of 1.90 × 1.27 × 0.87 m (see

Figure 8), it efficiently manoeuvres through narrow vine rows while supporting various vineyard operations.

The initial concept for the rover envisions a four-wheel all-wheel drive vehicle, with each driven by brushless electric motors powered by an energy-efficient battery system. A total power output of about 10 kW is assumed for the energy system, a value considered sufficient to ensure adequate drive torque to cope with high-gradient terrain and low-grip surfaces, such as sand or rocky substrates [

66]. The chassis structure, with a total weight of 565 kg, can support a maximum payload of 300 kg, enabling the transport of agricultural implements and precision sensors. The independent steering axles and suspension system allow adaptive mobility, ensuring stability on uneven slopes.

Virtual simulations with Matlab/SimScape R2024b and multibody software will be key to fine-tuning AgriRover’s kinematics and dynamics, validating tractive force distribution, torque balance, and energy efficiency before deployment [

67]. Unlike standard AVVs, AgriRover incorporates an articulated chassis and independent steering system, enhancing mobility in rugged vineyard terrains [

63]. This adaptability ensures minimal soil compaction, making it suitable for sustainable viticulture practices while providing robust mechanical stability across varied landscapes.

5.3. Autonomous Control and Navigation System

AgriRover’s autonomous navigation system will be developed and tested in simulated vineyard environments to ensure optimal performance in structured and semi-structured agricultural settings [

68]. We hypothesize that adopting a motion control system will combine inverse kinematics and direct dynamics, allowing the rover to adapt speed, steering angles, and power distribution to varying terrain conditions. In particular, inverse dynamics will be used for torque management, allowing optimal engine settings to be determined and ensuring consistent motion and propulsion even under varying payloads. A multibody modelling approach will be adopted to optimize and refine these capabilities, which can provide detailed information on vehicle response as a function of different terrain types and load conditions. Simulation of the rover’s motion in virtual environments will allow precise calibration of the articulation system, suspension parameters, and wheel–ground interaction dynamics. To analyze the rover’s response to external conditions, different scenarios, including uneven and rough terrain, with loose surfaces, varying slopes, and different soil compositions (sand, clay, stones), will be tested (

Figure 9). The goal is to achieve a robust mechanical structure, all-wheel drive, and adaptive suspension to ensure the rover maintains stability, traction, and adequate row cover under all operating conditions.

Future developments will integrate advanced sensors and actuators for autonomous navigation and monitoring of weather and soil conditions in vineyards at each phenological stage of BBCH, using relevant sensing techniques such as LiDAR, stereo vision, and infrared depth sensors. This improvement will enable greater real-time environmental awareness and dynamic field adjustments [

65,

69]. In addition, the integration of the path planning algorithm will enable precise movements through rows of vines with irregular spacing, integrating real-time obstacle detection, row tracking adjustments, and adaptive trajectory correction [

70].

5.4. Autonomous Monitoring

To ensure effective phenological and environmental monitoring aligned with the BBCH stages of grapevine development,

Table 4 presents a curated selection of affordable sensors suitable for integration into the AgriRover platform. These sensors were selected based on their relevance to the specific challenges of smallholder viticulture in Ica. Each entry details the intended BBCH monitoring stage, estimated costs, energy requirements, impact potential, and operational lifespan. Additionally, high-impact but higher-cost technologies like hyperspectral imaging and robotic manipulators are proposed as optional enhancements for future scalability or in cases in which funding allows. The table supports strategic sensor integration decision making based on agronomic needs and smallholder affordability.

The construction of this sensor matrix is based on a set of critical assumptions and contextual factors relevant to AgriRover’s deployment in smallholder vineyards. Unit and total costs reflect current market estimates and serve as preliminary financial indicators, recognizing that actual prices may vary depending on sourcing and regional availability. Sensor quantities are determined based on the preliminary AgriRover concept, which is assumed to support proximity monitoring along the vineyard rows. Power consumption values are included to assess compatibility with AgriRover’s energy systems and to anticipate battery demands. The projected agronomic impacts—i.e., yield improvements and input savings—are derived from meta-analyses and peer-reviewed studies in precision viticulture, with full references provided. These data guide informed decisions on cost-effectiveness and energy efficiency.

Advanced technologies like hyperspectral cameras and robotic manipulators are presented as optional enhancements. Although these tools significantly increase the total investment (estimated at approximately USD 10,500), they offer high-resolution data for early disease detection, maturity indexing, and stress identification, ultimately enhancing decision timing and productivity. However, their elevated energy demands may necessitate battery redesign or solar-assisted systems. As such, these technologies are best suited for smallholder farmers (SHFs) undergoing digital transition or operating in cooperatives with pooled resources. Overall, this matrix provides a practical foundation for tailoring AgriRover’s sensor suite to meet the agronomic needs and economic constraints of SHFs in developing regions.

5.5. Energy Management and Battery Supply

AgriRover’s energy management system is under conceptual development to optimize sustainability while reducing dependence on fossil fuels [

85]. Two battery technologies are being evaluated: lithium iron phosphate (LFP) and nickel cobalt manganese (NCM).

LFP batteries, known for their thermal stability (>250 °C) and long life (3000–5000 charge cycles), are safer and more environmentally friendly. This characteristic makes them ideal for hot climates with frequent vibration [

86]. In 2024, the average cost of LFP cells was around USD 60/kWh, with projections indicating further reductions to USD 36–56/kWh by 2025 [

87]. However, their lower energy density requires more storage capacity (15–20 kWh) to ensure sufficient operational range. They are also less susceptible to thermal degradation and support more charging cycles, thus reducing the risk of rapid capacity loss. Although they have a lower energy density and thus a shorter operating range, their use reduces the overall environmental impact. Their longer operating life and lower replacement frequency, supported by careful charging planning, route optimization, and efficient driving, contribute to a more sustainable life cycle. In addition, LFP batteries are more sustainable than NCMs because they do not contain cobalt and have more excellent chemical stability, reducing the overall environmental impact, with the average cost of NCM cells being about USD 68.6/kWh in 2024; however, there is price volatility due to raw materials such as nickel and cobalt [

87].

NCM batteries offer higher energy density and more extended range, making them more efficient for longer missions. However, the extraction of nickel and cobalt raises sustainability issues, as their extraction processes generate significant environmental impacts [

88]. LFP batteries, on the other hand, are more sustainable due to the absence of cobalt, excellent chemical stability, and lower environmental impacts. Recycling, particularly hydrometallurgical recycling, maximizes environmental benefits and reduces resource and energy consumption. LFP batteries have a smaller carbon footprint than NCMs, with less depletion of mineral resources and lower greenhouse gas emissions, contributing substantially to the overall environmental impact reduction. The chemical stability of LFPs also reduces the risk of thermal degradation, extending battery life and lowering the number of replacements needed. In addition, hydrometallurgical recycling of LFP batteries is particularly efficient in material recovery, significantly reducing energy consumption and related environmental impacts. This process allows a significant portion of the materials to be recovered, helping to limit the need for new mining [

89].

Finally, LFP batteries are ideally suited for cascading use due to their longer life and robustness. This property means that once they run out of capacity to operate electric vehicles, they can be reused in other applications, reducing mineral resource depletion by 76% and fossil energy consumption by 83% [

89]. Such capacity promotes more sustainable resource management, extending the life cycle of batteries and contributing to a circular economic model.

In light of these trade-offs, LFP batteries remain the preferred option for sustainable viticulture in Ica.

5.6. Environmental Impact

The sustainability analysis of the initial AgriRover concept was evaluated using the CML methodology, considering the assumptions given in

Table 5.

Table 6 shows the assumed material composition of the AgriRover and the corresponding end-of-life processing rates in Peru. These rates reflect current national trends in recycling and waste management [

90,

91].

Using the material composition and local end-of-life data, the weighted average for each waste category was calculated and is summarized in

Table 7.

These data form the basis of the sustainability analysis for the entire product life cycle. An operational energy requirement was estimated to complete the life cycle perspective. In the CML methodology adopted, the energy consumption per gram of product was considered. Assuming a four-wheel drive configuration and two daily charging cycles (each lasting 4 h), the rover would operate 8 h daily for 306 days per year. The calculation was developed as follows.

To evaluate energy use per gram, two load scenarios were considered:

Structural weight only:

Full load (565 kg + 300 kg):

The average specific energy consumption was

Table 8 shows the summary of estimates of environmental impact and energy consumption.

The results of the sustainability analyses are shown in

Figure 10, through a series of pie charts illustrating the percentage distribution of environmental impact associated with each stage of the product life cycle. For each ecological indicator considered, carbon emissions (CO

2e), acidification potential (SO

2e), and eutrophication potential (PO

4e), the specific contribution of the material production, manufacturing, transportation, use, and end-of-life phases are highlighted.

In addition,

Table 9 below shows the absolute values for each stage and indicator, accompanied by their respective percentages, to provide a comprehensive quantitative and comparative view of the system’s environmental impacts.

Table 10 shows and evaluates the AgriRover components that contribute the most to the four areas of environmental impact.

The analysis shows that the manufacturing phase is the primary contributor to the product’s overall environmental impact, followed by the production of materials. This trend is confirmed in all impact categories considered (e.g., climate change, acidification, resource consumption, etc.), highlighting how upstream life cycle activities are crucial in defining environmental performance.

In contrast, the use, transport, and end-of-life phases have a much smaller impact. In particular, the use phase has a negligible impact, an aspect that can be traced to the product’s passive nature during this phase. Although it covers a significant distance (about 9500 km), ship transport also has a limited impact, confirming that logistics-related emissions are not comparable with those generated by manufacturing processes.

However, it is essential to note that in the specific case of this project, the manufacturing phase will not be directly managed in-house, as structural components will be purchased from external suppliers. Such a choice implies that although we are not operationally involved in this phase, the environmental impact associated with manufacturing remains attributable to our product as an integral part of its life cycle. Therefore, any environmental impact mitigation strategies should focus on selecting lower-impact materials and suppliers with sustainable manufacturing practices or environmental certifications.

6. Discussion

Promoting climate-smart agriculture (CSA), improving irrigation efficiency, and integrating autonomous technologies are pivotal strategies through which to improve agricultural productivity while aligning with Peru’s environmental objectives [

2] and consumers’ preferences and willingness-to-pay for vines and wines with sustainability characteristics [

14,

92]. The Green Growth Potential Assessment (GGPA) highlights agriculture as one of the top five sectors with the most significant potential for green growth interventions, emphasizing the critical importance of CSA and advanced water management practices in driving sustainable development [

4]. Despite this potential, the Ica region faces significant challenges that disproportionately impact small-scale farmers, threatening their productivity and market competitiveness.

This article adopts a case study format to explore the interconnected challenges faced by small vineyards in developing countries. Rather than addressing these issues as a checklist of isolated technical gaps, we frame them as a systemic and interdependent problem—rooted in constrained resources, climate vulnerability, and institutional limitations—that requires a context-sensitive, locally adaptable solution. This broader framing supports the rationale behind AgriRover’s modular, affordable, and proximity-based sensing design, ensuring that the platform can be tailored to meet site-specific challenges with scalable technological components. One of the most critical barriers to sustainable viticulture practices in regions like Ica is the inability to monitor the crop effectively across all BBCH phenological stages. Each stage—from budburst to dormancy—requires precise, timely decisions (e.g., for pest control, fertilization, or irrigation). However, this is practically unfeasible for smallholders due to labour shortages and a lack of technical expertise or automation tools. Human monitoring of large or scattered vineyards with adequate frequency and granularity is time-consuming, costly, and prone to error, particularly when climate-related stresses such as drought or salinity require swift intervention. The AgriRover concept aims to address this challenge in the future with its customizable sensor platform and proximity-based mobility, enabling timely data collection at the plant level, even in rugged vineyards or those with narrow rows.

Furthermore, Peru ranks low on the Global Innovation Index, and its Technological Readiness Index remains significantly below average for middle-income countries [

4,

7]. Such positioning implies that introducing highly specialized or costly agricultural robots may be economically prohibitive and unviable in terms of local implementation capacity, maintenance infrastructure, and user skills. AgriRover would offer a practical entry point into autonomous farming using locally sourced components, open hardware–software compatibility, and gradual sensor integration depending on available resources and production needs. By lowering the entry barrier, the solution increases the chances of adoption and adaptation, especially among resource-limited smallholders.

To contextualize AgriRover’s development,

Table 11 compares AgriRover and other leading autonomous vineyard robots—VineScout, TED, Bakus, and VinBot—highlighting differences in purpose, cost, and accessibility.

As shown in

Table 11, AgriRover’s most significant advantage lies not in competing with high-end automation platforms but in providing a scalable, adaptable solution that can evolve with the user’s capacity. Its modular design will allow each vineyard to customize the sensing, navigation, and intervention features depending on available resources and phenological priorities (see

Table 3). From a sustainability perspective, AgriRover can thus act as a bridge technology, enabling smallholders to gradually adopt precision agriculture tools without depending on foreign services or unaffordable imports. Additionally, the rover’s energy-efficient electric motors and battery systems could significantly reduce greenhouse gas emissions, aligning with Peru’s commitments under the Paris Agreement (see

Section 3.2).

From an economic and scalability perspective, AgriRover will provide a cost-effective solution that supports technology adoption among smallholder farmers. Although Peru’s technological readiness remains low, initiatives like COFIDE’s rural investment programs offer a viable pathway for integrating agricultural robotics into traditional farming systems. Given that agriculture contributes significantly to Peru’s GDP, mainly through grape and blueberry exports, integrating automation in viticulture could enhance competitiveness in global markets while securing economic resilience for smallholder farmers [

94]. The cost of AgriRover was calculated by considering the value of the basic structure, which includes primary materials such as nylon for the crates, C45 steel, tyres, motors, and batteries. The initial value of the structure was estimated at approximately €8328.29. A 15% increase was applied to this amount to account for market variability and assembly costs, bringing the final price to €9577.

Although initial investment and maintenance can be challenges, scalable implementation models such as cooperative ownership, public–private partnerships, and targeted microcredit schemes should be encouraged to mitigate these obstacles. These mechanisms can support local training, skill building, and the provision of spare parts, ensuring long-term usability and reducing dependence on external resources [

95].

The development timeline (see

Figure 7) graphically outlines these phases, demonstrating a structured approach that connects real-world viticultural needs with iterative engineering development. While limitations remain, they do not detract from AgriRover’s contributions to advancing precision viticulture in low-resource settings. The platform shows that agricultural robotics can be affordable and transformative with appropriate contextualization and modular engineering.

7. Conclusions

This study presents the conceptual and agronomic foundations of AgriRover, an autonomous and affordable viticultural rover designed to address the interrelated challenges faced by smallholder vineyards in developing countries. Using a case study methodology focused on Ica, Peru, the authors framed viticultural constraints—including labour scarcity, climate variability, and salinity buildup—not as isolated technical issues but as systemic barriers requiring context-sensitive and modular solutions. AgriRover is thus conceived as a low-cost, adaptable co-pilot for the farmer, enabling proximity-based, phenology-aware sensing and mechanized assistance tailored to each vineyard’s specific needs.

The application of the BBCH phenological framework, integrated into a sensor-targeted strategy, enables AgriRover to support timely and localized decision-making. Monitoring key stages such as budburst, flowering, and berry ripening with appropriate PATs—including soil salinity sensors, multispectral cameras, and moisture probes—can enhance sustainability by reducing input overuse and increasing productivity. The rover’s articulated chassis, multibody modelling design, and independent steering system ensure terrain adaptability while minimizing soil compaction and preserving vineyard health.

This paper lays the foundation for the design and development of AgriRover through the preliminary analysis of a case study located in Peru. At this stage, the main agronomic, environmental, and operational challenges were explored in depth, translating them into the system’s design requirements and functional objectives. The analyses performed allowed for the identification of the critical issues and potentialities of the concept, providing a solid basis for the subsequent phases of optimization, validation, and engineering development. The goal is to arrive at a design solution that responds effectively and purposefully to the real needs of small-scale wine producers in low-tech contexts.

In conclusion, AgriRover offers a viable pathway through which to democratize precision viticulture in low-readiness environments. It exemplifies how integrating robotics with agronomic knowledge can support climate-resilient, economically viable, and environmentally responsible viticulture, particularly when tailored to the constraints and opportunities of smallholder agriculture in the global South.